Combined ordered multi-pass internal-classification screening vertical type ball mill

A multi-pass and internal grading technology, applied in grain processing and other directions, can solve the problems of low work efficiency, time-consuming and laborious work, etc., and achieve the effect of increasing production capacity, avoiding overall disassembly and assembly, and improving the efficiency of grinding work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

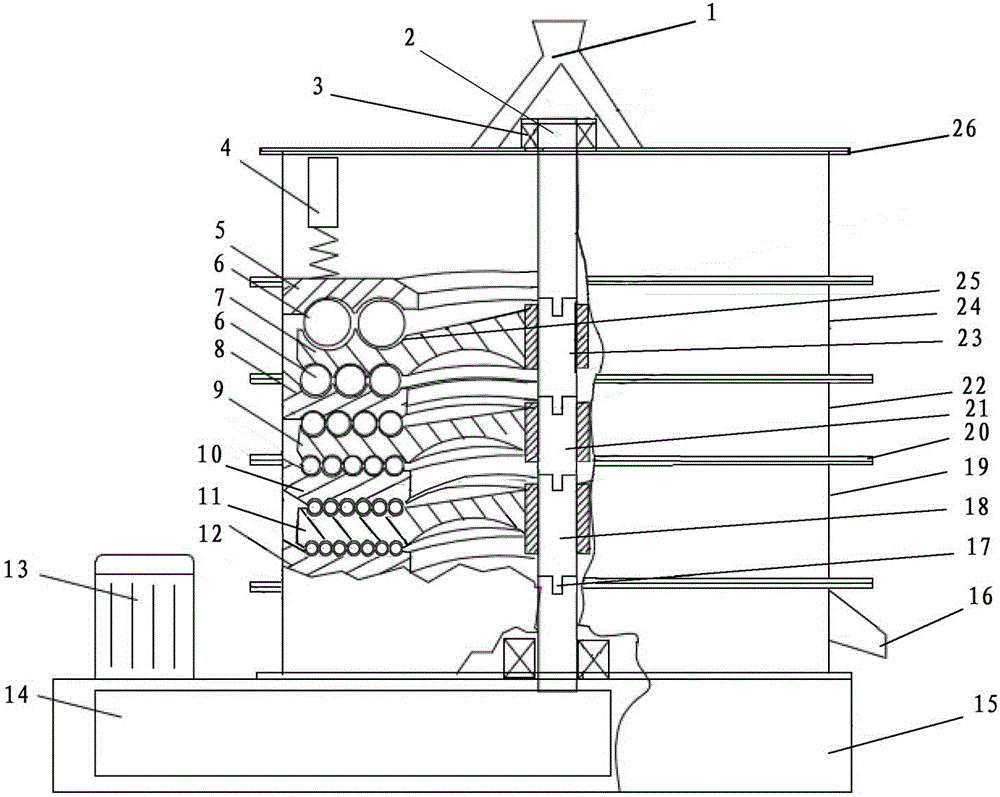

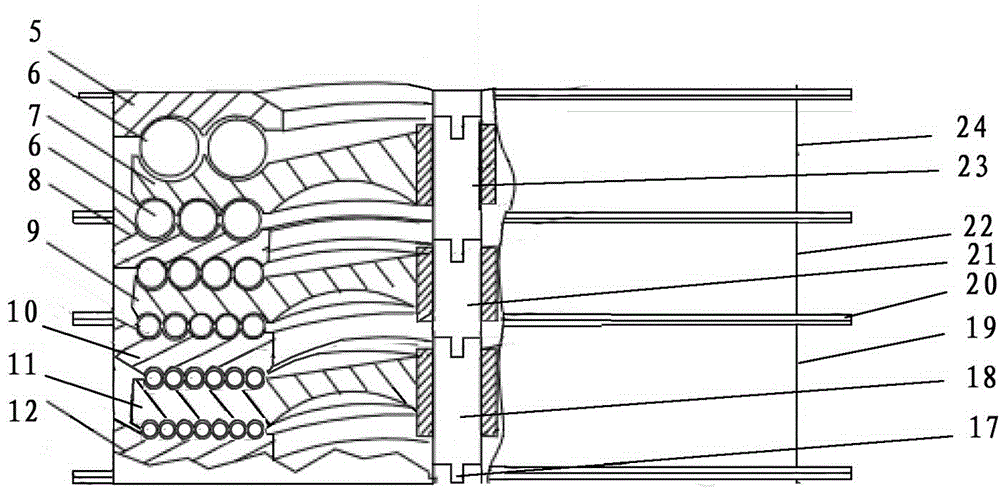

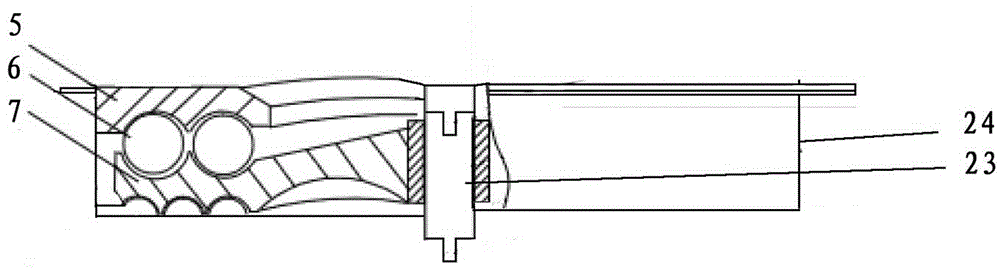

[0018] according to Figure 1~5 Detailed description of the specific structure of the present invention, such as figure 1 As shown, a combined orderly multi-pass internal grading and screening vertical ball mill includes a grinding mechanism driven by a motor 13. The grinding mechanism is assembled on a base 15 through a bearing assembly 3 and a main shaft 2, and is connected by the motor 13 to reduce speed The device 14 drives the spindle 2 to drive the grinding mechanism. The upper cover 26 communicates with the feed port 1 above the grinding mechanism. The upper cover 26 is also provided with a spring pressure device 4 and the discharge port 16 is provided below the grinding mechanism.

[0019] Such as Figure 1 to 3 As shown, the grinding mechanism is composed of multiple layers of grinding units connected, which can be composed of three layers of grinding units, and each fixed grinding disc and rotating grinding disc constituting the grinding mechanism are arranged alternatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com