TFT touch screen grinding rod and preparation method thereof

A grinding rod, touch screen technology, applied in other manufacturing equipment/tools, engine components, turbines, etc., can solve problems such as screen edge grinding and light leakage, and achieve high quality, cost-effective, strong holding power, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

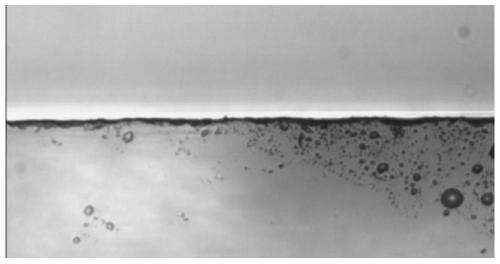

Image

Examples

preparation example Construction

[0026] The preparation method of the TFT touch screen grinding rod disclosed by the present invention is as follows:

[0027] (1) Mix the metal powders and then ball mill to obtain the metal matrix; the metal powders are composed of copper powder, tin powder, cobalt powder, silver powder and cerium powder;

[0028] (2) Mix the metal matrix and diamond to obtain the material;

[0029] (3) Cold pressing the material to obtain the green body;

[0030] (4) The green body is hot-pressed and sintered to obtain a TFT touch screen grinding rod.

Embodiment

[0032] Mixing: According to the formula requirements of the mass percentage ratio in Table 1, add the metal powder into the ball mill, add alcohol with a total mass of 30% of the metal powder, and then put in zirconium balls, the ball-to-material ratio is 2:1 (wt%), and the speed is 400 rpm Minutes, mixed and ball milled for 20 minutes, the material was taken out and dried, then put into a V-type mixer, added acetone with 10% of the total mass of metal powder, and then added diamond with 20% of the total mass of metal powder, mixed for 120 minutes, baked After drying, pass through a 120# sieve (120 microns) to obtain a uniformly mixed material;

[0033] Pressing: the above materials are added to the existing mold and placed on a hydraulic press, and a pressure of 3 tons / cm is applied 2 , keep the pressure for 10 seconds; then reverse the mold up and down, and apply a pressure of 3 tons / cm 2 , hold the pressure for 10 seconds, thereby making a cold-pressed green body with unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com