Special grinding machine for pipeline inner hole

A grinding machine and pipe technology, applied in machine tools, grinding machines, grinding/polishing equipment designed for grinding the rotating surface of workpieces, etc. requirements, improve work efficiency, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

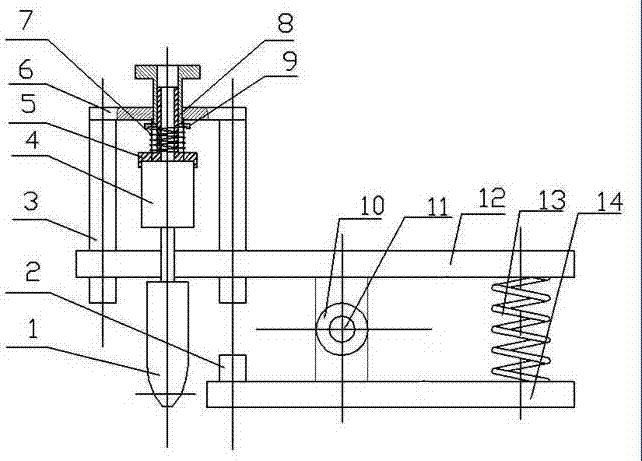

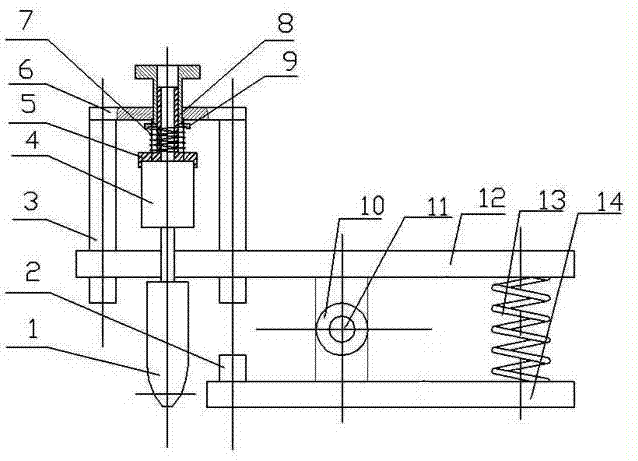

[0008] Such as figure 1 As shown, the present invention provides a special grinding machine for the inner opening of a pipeline, which includes a spring clamp, a limiting plate 6, a manual grinding machine 4, and a grinding head 1, and the limiting plate 6 is fixed on the spring clamp through an upper bayonet pin 3 ; The manual grinding machine 4 is located in the limiting plate 6, a compression spring 7 is arranged between the manual grinding machine 4 and the limiting plate 6, and the manual grinding machine 4 is elastically connected to the limiting plate 6; the grinding head 1 After passing through the spring clip, it is connected with the manual grinder 4. The compression spring 7 is provided with an adjusting bolt 8, through which the tightness of the compression spring 7 can be adjusted. Also be provided with guide cylinder 5, and pad 9 in limiting plate 6, described guide cylinder 5 is positioned at manual grinding machine 4 afterbody, and manual grinder 4 links to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com