Machining process method of large-size single degree face wedge-shaped workpiece

A processing technology and single-dimensional surface technology, applied in the field of wedge-shaped workpiece processing technology, can solve the problems of low workpiece processing accuracy, complex processing technology, and low processing efficiency, and achieve the goals of increasing workload, simplifying processing technology, and improving processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

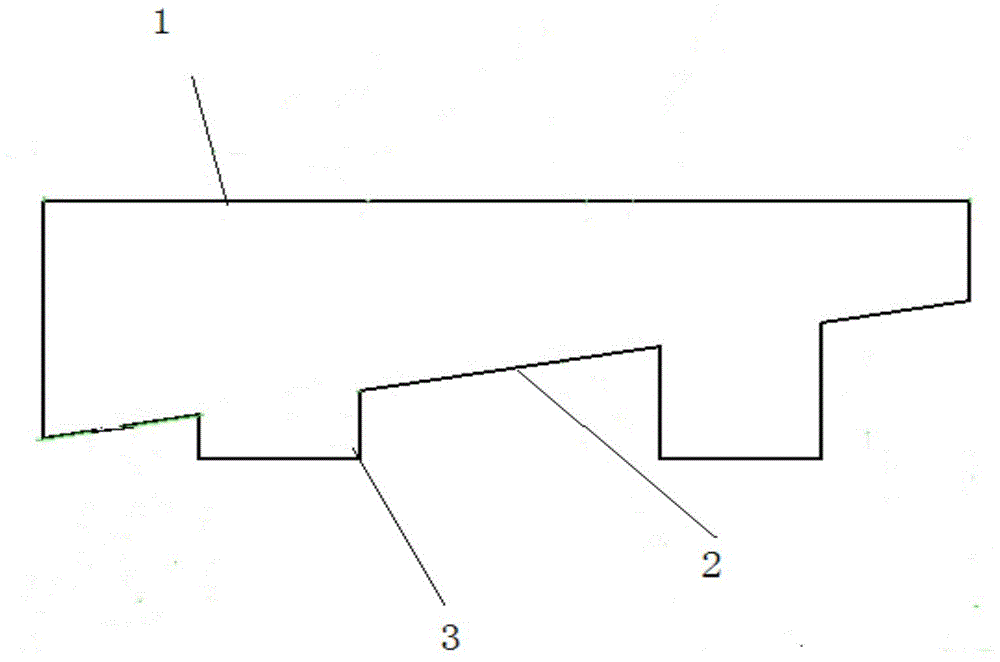

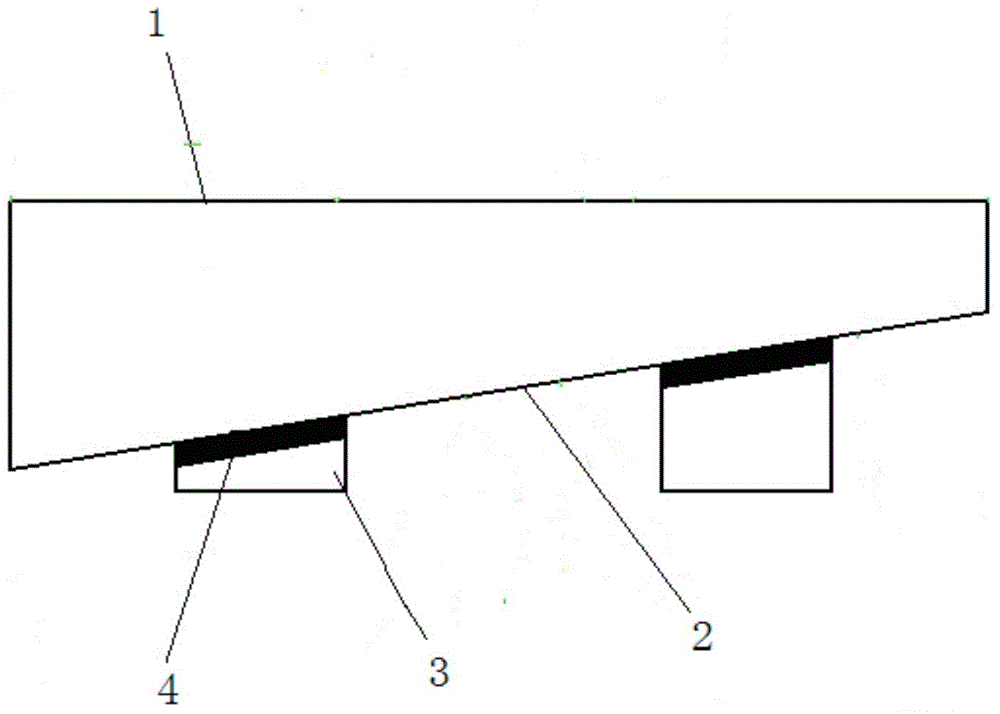

[0031] The single-dimensional wedge-shaped workpiece processed in this embodiment is a component in a locking mechanism, with a length of 1500 mm and a width of 400 mm. As the inclined plane of the working surface, the inclination is 15 degrees, and the processing smoothness of the reference plane and the inclined plane is ▽ 0.8. The machining process of this single-degree surface wedge-shaped workpiece is as follows:

[0032] (1) The reference plane of the milling workpiece;

[0033] (2) Taking the datum plane after milling as the machining datum for machining the inclined plane of the workpiece, milling and grinding the inclined plane of the workpiece;

[0034] (3) 5 process bosses with a width of 100 mm, a lower end surface as a plane, and an upper end surface as an inclined plane consistent with the inclination of the inclined plane of the workpiece are bonded equidistantly on the inclined plane of the workpiece with an epoxy metal adhesive;

[0035] (4) Take the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com