Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Meet capacity needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for saving energy of network in LTE system

ActiveCN101742707AFull Coverage GuaranteedMeet capacity needsEnergy efficient ICTPower managementMobile communication systemsComputer science

The invention discloses a method for saving the energy of a network in a long term evolution mobile communication system and solving the technical problem that the network can not recover from an energy-saving state to a working state in time according to network capacity conditions under an environment of the traditional LTE ad hoc network. In the invention, a certain cell in the energy-saving state can notify a neighbour cell that the cell is in the energy-saving state through an expanded X2 interface message; and when the neighbour cell generates congestion or overload, the neighbour cell notifies the cell in the energy-saving state through an newly increased energy-saving recovery indication message or an expanded X2 interface load indication message. By adopting the method, the cell in the energy-saving state can carry out energy-saving recovery operation in time according to the congestion or overload state of the peripheral neighbour cell when the neighbour cell generates the congestion or the overload so as to ensure network coverage and meet the requirements of network capacity, and the technical effects of meeting the energy-saving requirements of operators without influencing network quality are achieved.

Owner:ZTE CORP

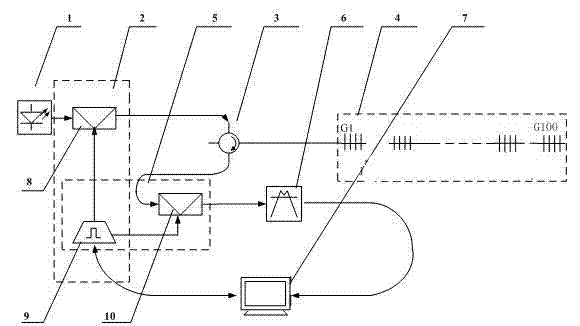

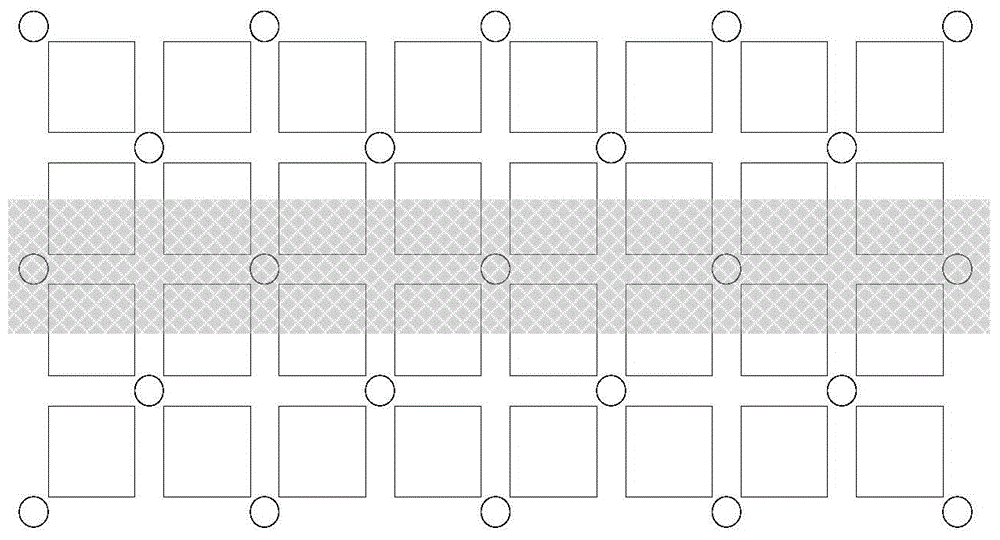

Ultra-large capacity time division and wavelength division fiber grating sensing system and query method thereof

ActiveCN102901525AMeet capacity needsPrecise positioningConverting sensor output opticallyFiberSystem capacity

The invention relates to an ultra-large capacity time division and wavelength division fiber grating sensing system and a query method of the fiber grating sensing system. The ultra-large capacity time division wavelength division fiber grating sensing system consists of a broadband light source, a modulation module, a circulator, a fiber Bragg grating sensing array, a sampling module, a wavelength demodulation instrument and a data processing computer, wherein the modulation module and the sampling module comprise a SOA high-speed photoelectric switch respectively and are driven by different channels of the same signal generator, and a phase difference exists between two drive pulses; and the fiber Bragg grating sensing array can be composed of identical fiber gratings or multi-wavelength fiber gratings. With the adoption of a technology combining a time division multiplexing with a wavelength division multiplexing, tens of thousands of gratings can be engraved on an optical fiber. The ultra-large capacity time division and wavelength division fiber grating sensing system has characteristics of large system capacity, high response speed, good expandability, high flexibility, good stability, low cost and the like, can perform dynamic measurement and static measurement at the same time, and can satisfactorily meet requirements of internet of things on information capacity.

Owner:安徽龙联智能光电有限公司

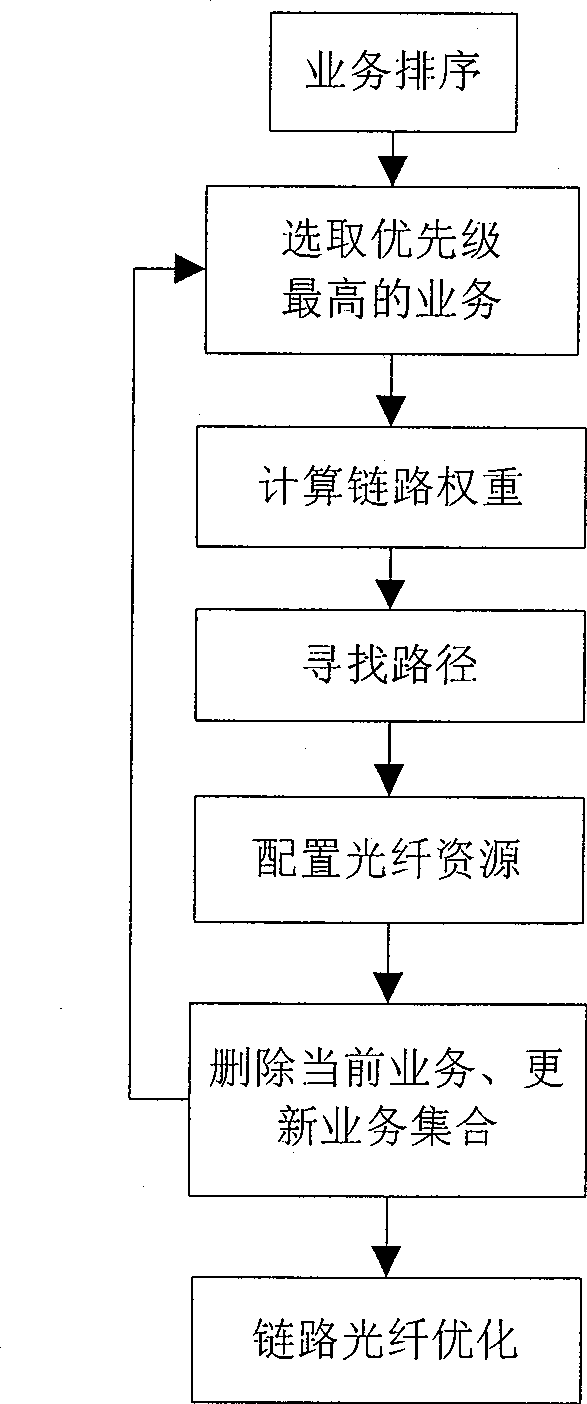

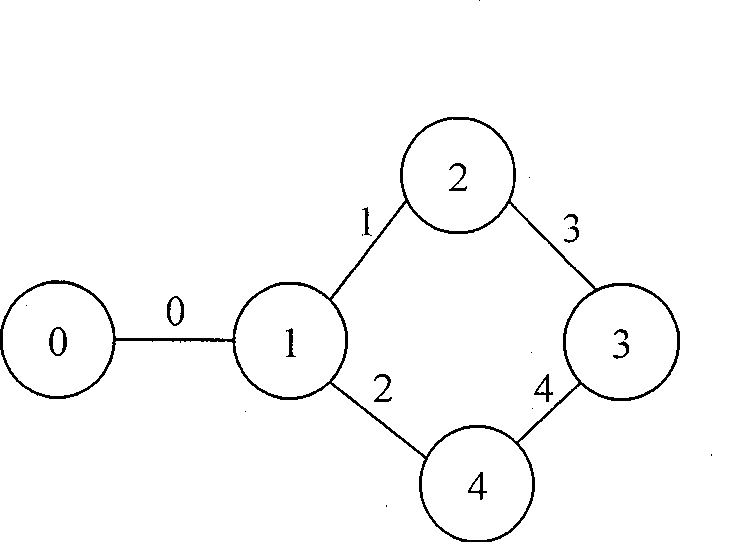

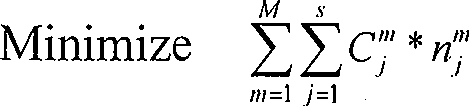

SDH network planning design method for multi-modularized optical fiber

InactiveCN101420321AIncrease profitAvoid detoursMultiplex system selection arrangementsTime-division multiplexFiberNetwork link

The present invention pertaining to the computer network communication technology field provides a SDH network planning and designing method of multi-module fibers, concretely relates to the fiber SDH network planning and designing and also relates to resource management and maintenance of the optical SDH network. According to the present invention, the cost of network fiber is made the minimum after the planning and designing under the condition that communication state between nodes, node positions and service requirements are known, and the given modularized fiber type is STM model. The method comprises the steps of service ordering, routing for each service and performing fiber resource configuration from the high service to the low service, and optimizing the fiber module cost to all the links. The present invention realizes that under the condition that the network topology and service requirements are known, whole planning of SDH mesh network with un-given upper limit of link capability is performed, and routing distribution and LSP resources are optimized through the multi-modularized weighting set, resource distribution and multi-modularized fiber cost optimization, under the condition that the network devices and the like are satisfied, finally, the configuration of the network link capability is close to the minimum.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

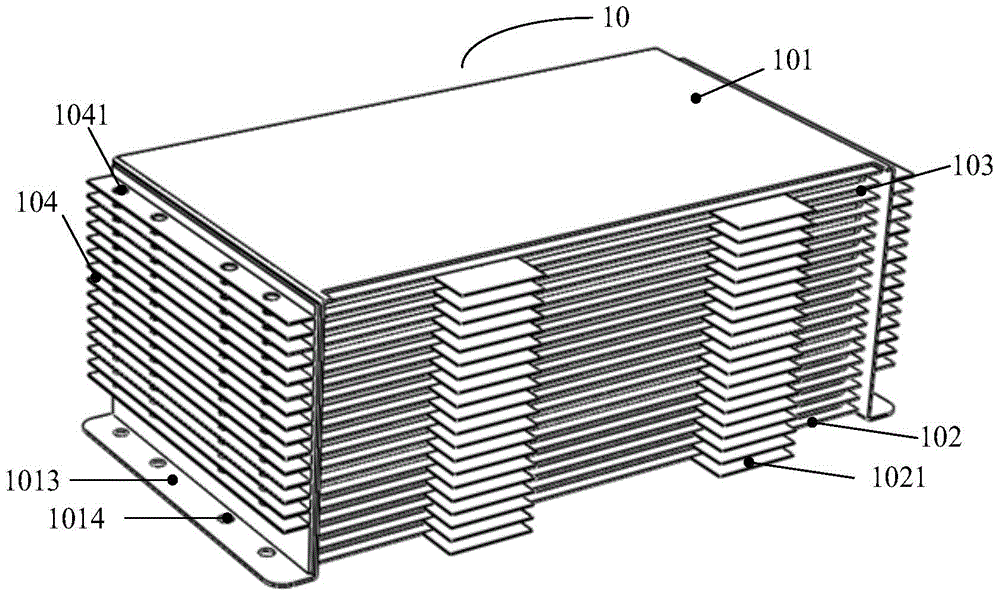

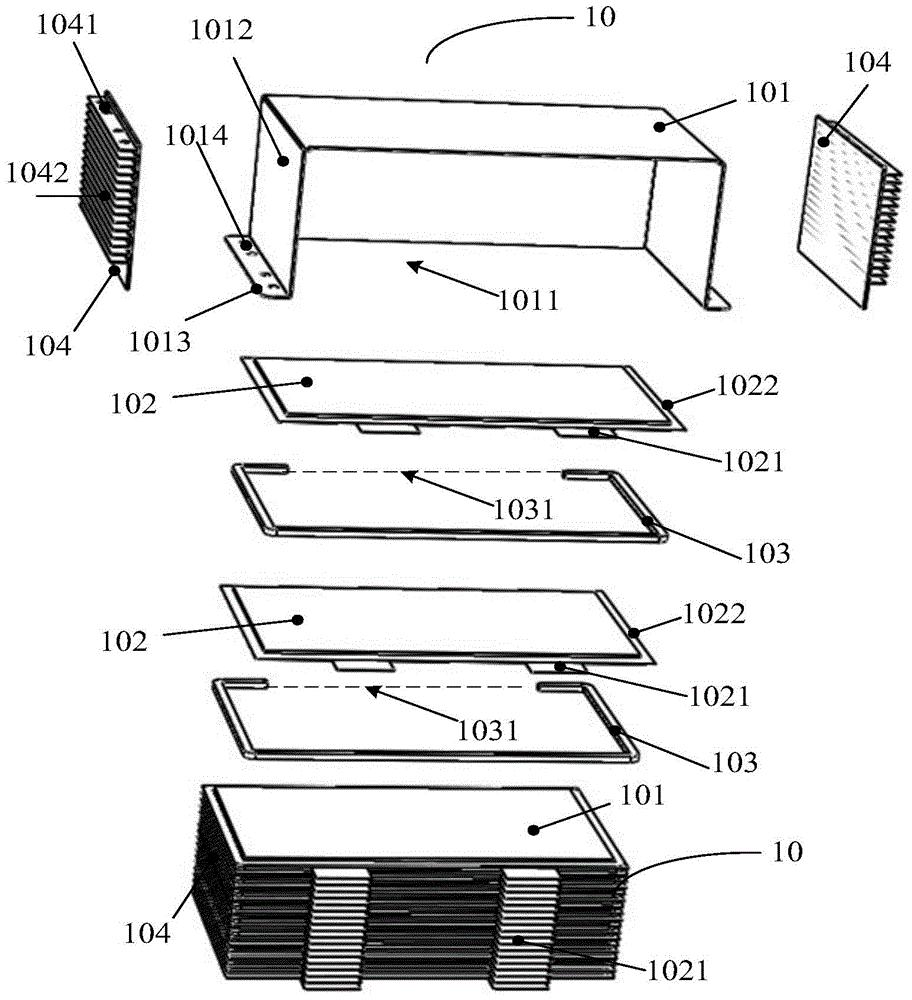

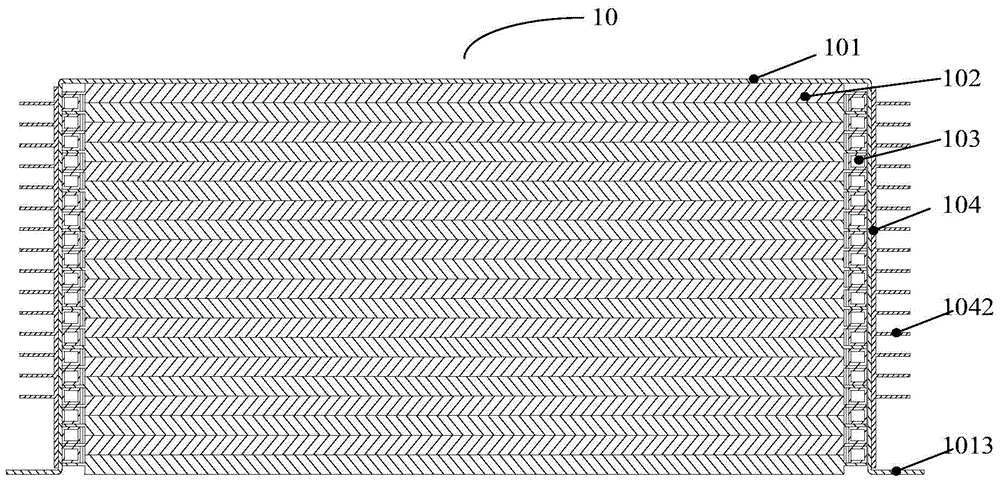

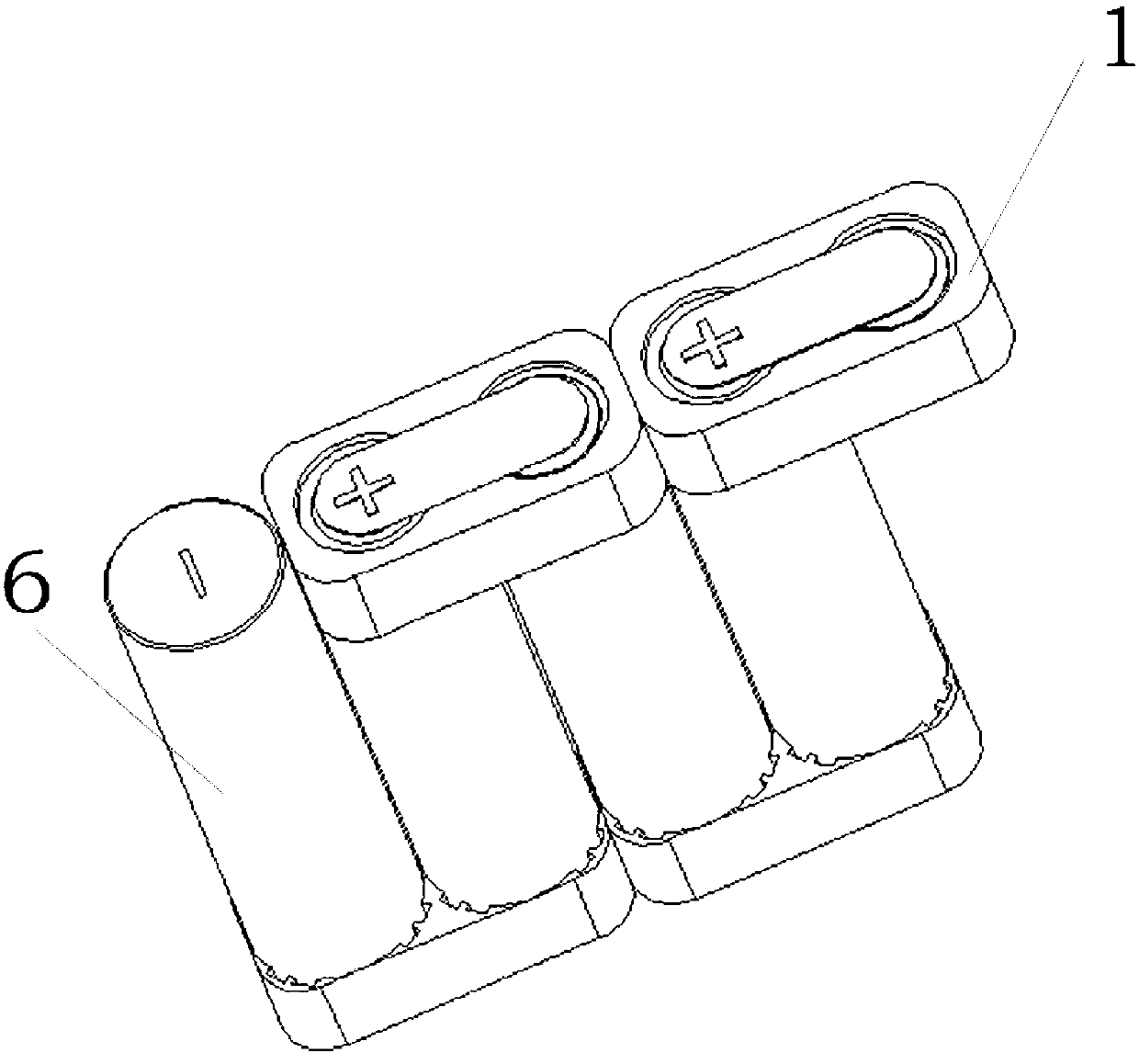

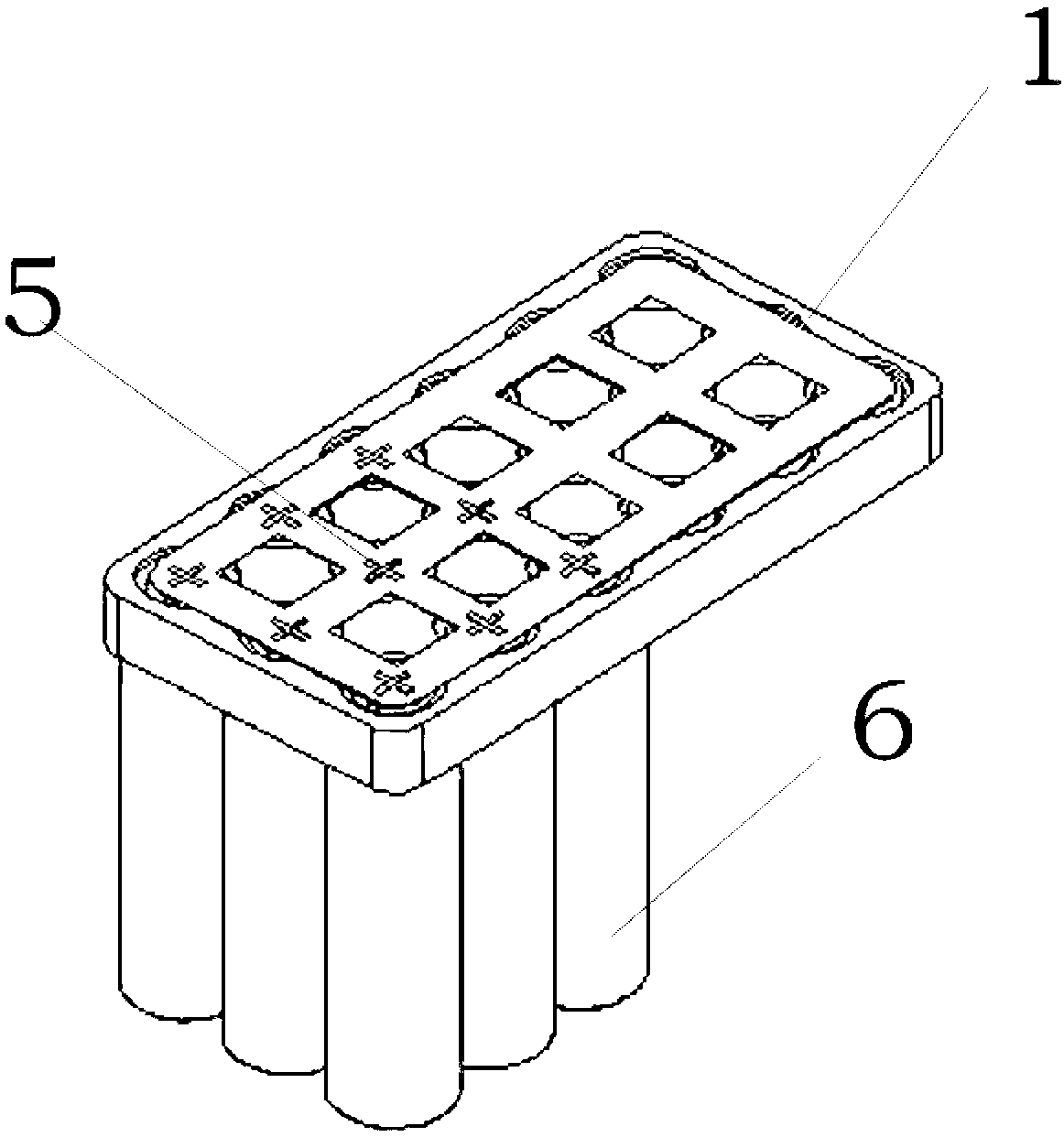

Battery module, battery module group and battery module group packaging method

InactiveCN104993183AStrong thermal uniformity and heat dissipationImprove work efficiencyFinal product manufactureElectrolyte accumulators manufactureEngineeringElectrical and Electronics engineering

The invention provides a battery module, a battery module group and a battery module group packaging method. The battery module is formed through arranging an unclosed annular heat tube with a gap between adjacent batteries, the unclosed annular heat tube encircles along the edge of the corresponding battery, and the gap of the unclosed annular heat tube is arranged at one side opposite to the electrodes of the corresponding battery, so the unclosed annular heat tube passes through the much heat electrode position of the battery, and can transmit heat generated by the electrodes to the shell of the battery module; heat dissipating plates are arranged at the side surfaces of the battery module, unclosed annular heat tubes between the batteries can be compressed, so the batteries are compact and reliable, have strong heat homogenizing and dissipating performances, have high safety, effectively improve the working efficiency of the battery module and effectively prolong the service life of the battery module; and the shell cooperates with the heat dissipating plates to simply and flexibly package the batteries in the shell, so the time and the cost of the packaging method are saved.

Owner:JIANGSU UNIV OF SCI & TECH

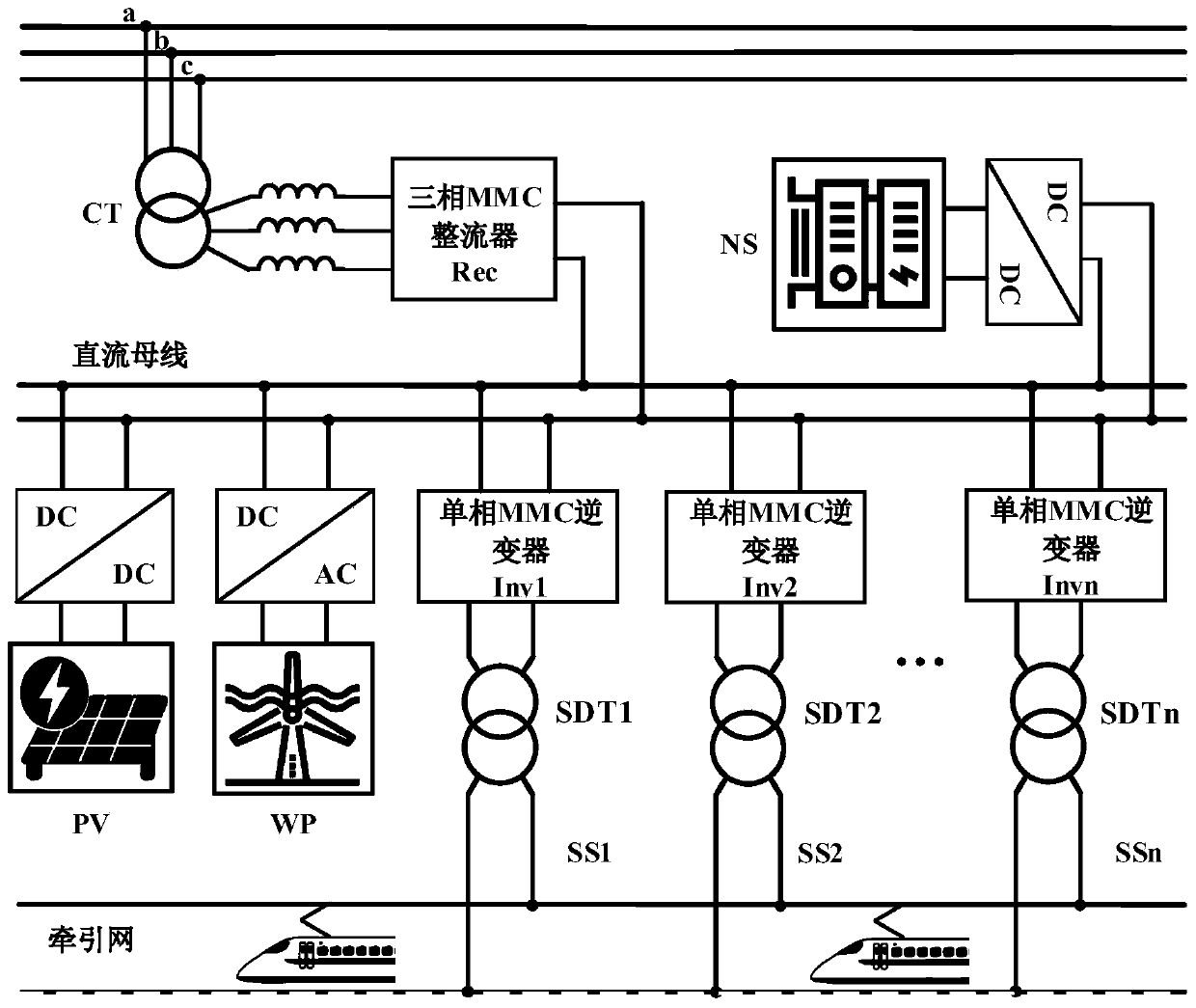

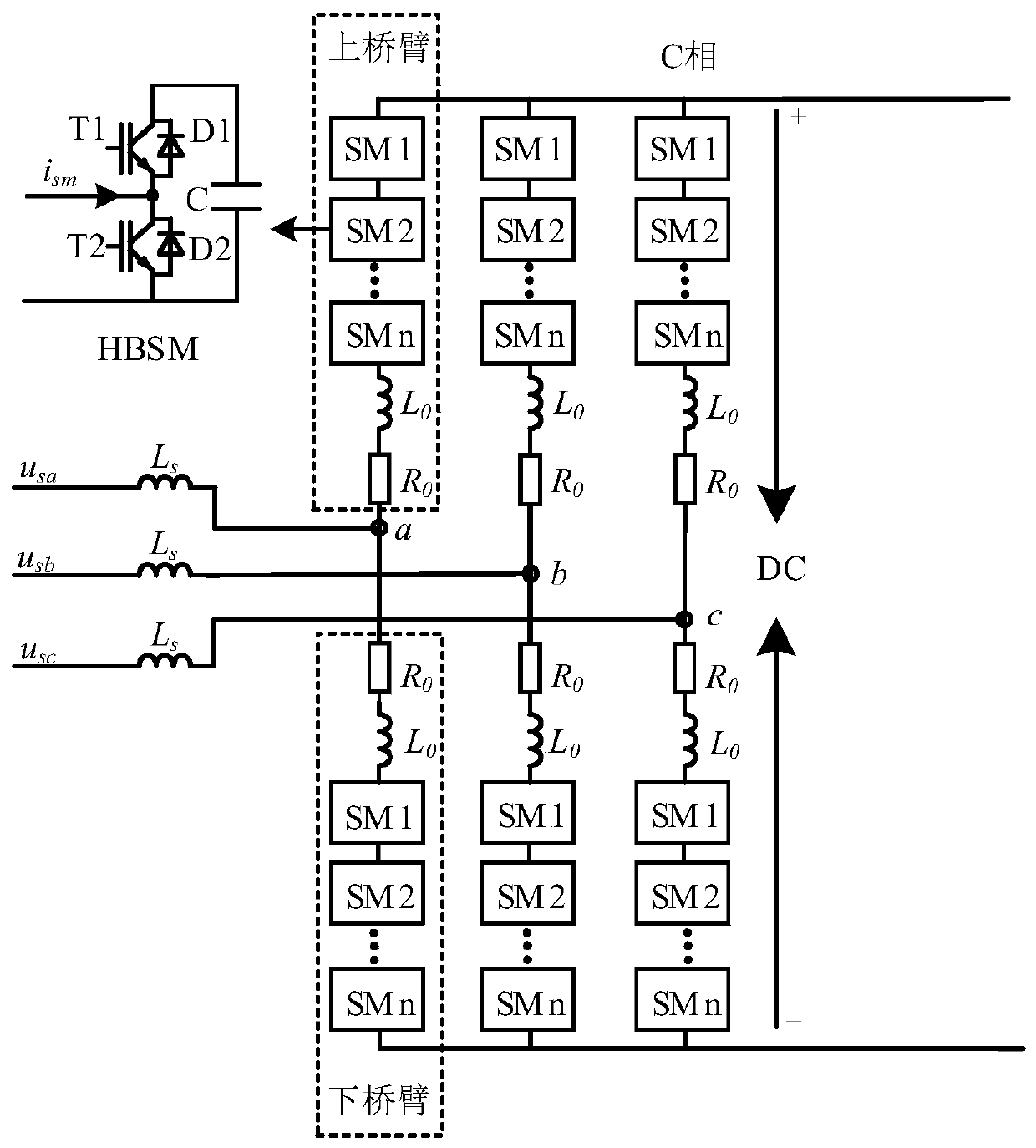

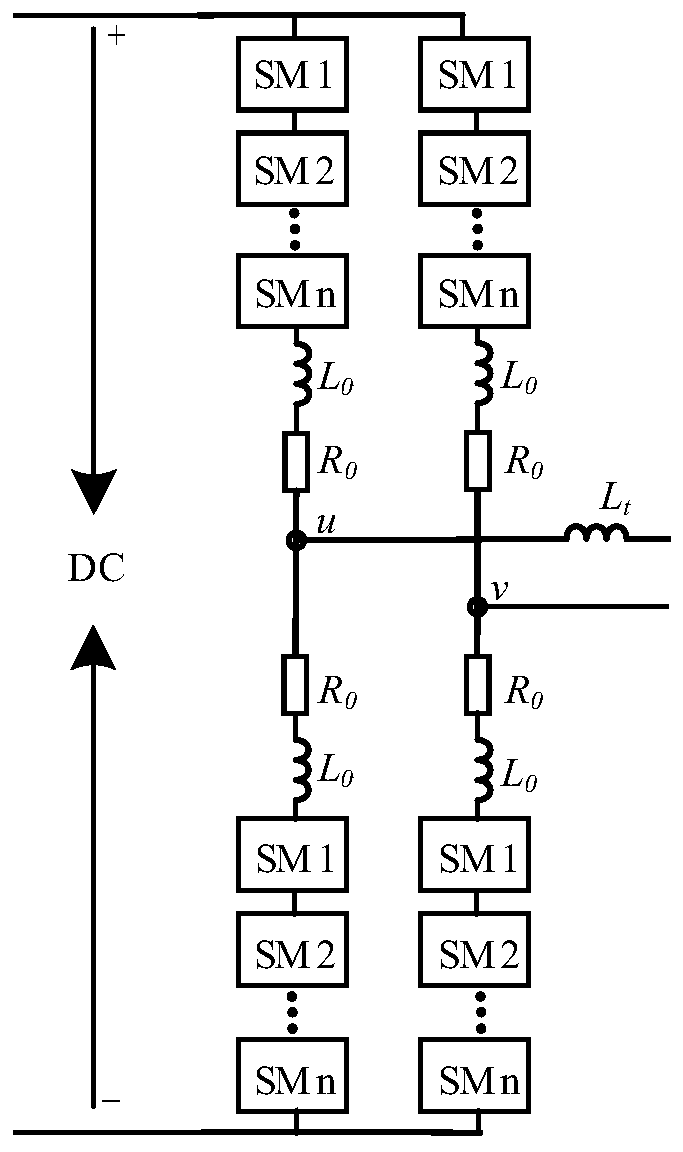

Electrified railway through-type traction power supply system

PendingCN110341728ASubstitutableEasy system maintenanceElectrodynamic brake systemsAc-dc conversionWind forceSingle phase

The invention provides an electrified railway through-type traction power supply system, and belongs to the technical field of railway traction power supply systems. The traction power supply system is characterized in that the output end of a connection transformer CT is connected with an alternating current side of a three-phase MMC rectifier through a filter inductance Ls, and a direct currentside DC is connected with a direct current bus; the input end of a single-phase MMC inverter is connected with the direct current bus, the output side is connected with a single-phase step-down transformer SDT primary winding, and single-phase alternating current, with output voltage of 27.5 kV, of the secondary side of the single-phase step-down transformer is connected into a railway traction network to supply power to trains. The alternating current side of a AC-DC transformer of wind power generation WP is connected with the output of a fan, the direct current output side is connected thedirect current bus, one side of a DC-DC converter of photovoltaic power generation PV is connected with the output of a photovoltaic panel, the other side of the DC-DC converter of the photovoltaic power generation PV is connected with the direct current bus; and one side of a DC-DC converter of an energy storage system NS is connected with a hybrid energy storage system formed by a storage battery and a super capacitor, and the other side of the DC-DC converter of the energy storage system NS is connected with the direct current bus.

Owner:SOUTHWEST JIAOTONG UNIV

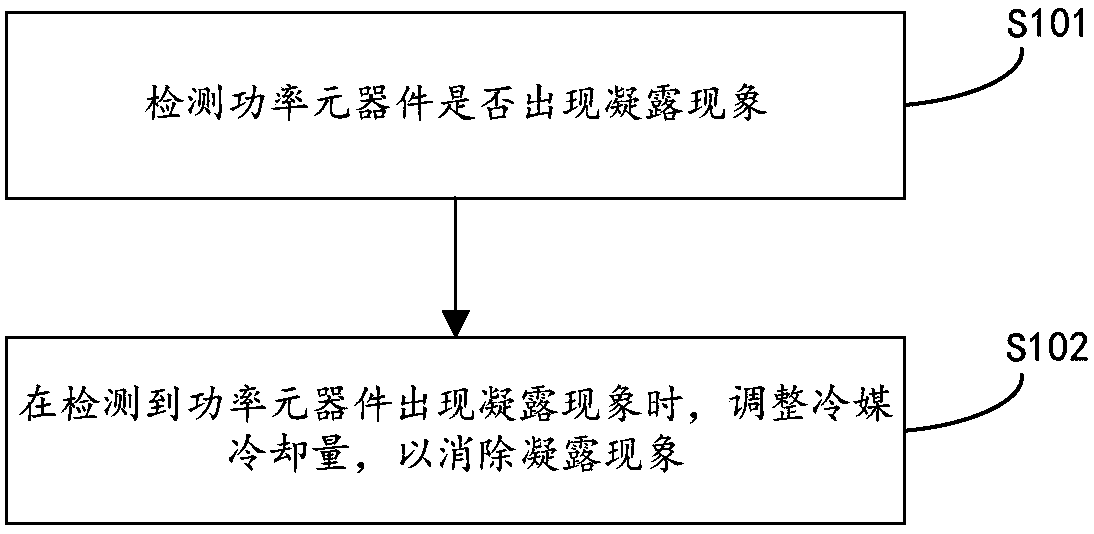

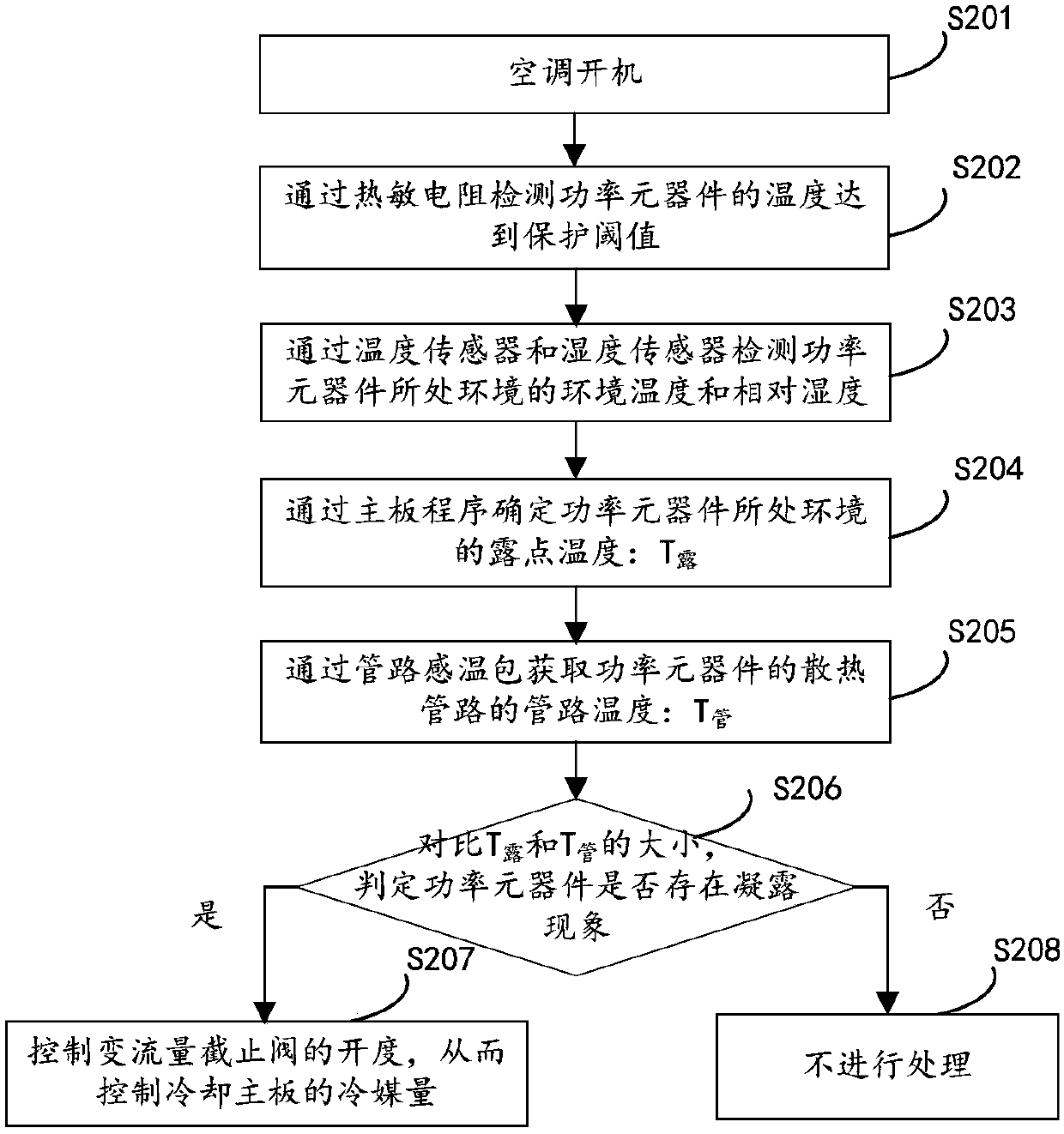

Method, device and system for preventing condensation of power component

InactiveCN106196425AControl coolingPrevent problems such as premature agingMechanical apparatusSpace heating and ventilation safety systemsEngineeringPower component

The invention discloses a method, device and system for preventing condensation of a power component. The method comprises the steps of detecting whether the power component is condensed or not, and adjusting the cooling amount of a refrigerant when it is detected that the power component is condensed so that condensation can be eliminated. By the application of the technical scheme, by detecting whether the power component is condensed or not, the cooling amount of the refrigerant is controlled, cooling for the power component can be achieved synchronously, and the problem that a mainboard is aged in advance due to overhigh stress strain of the power component and alternate cooling and heating is solved; the purpose that the power component is free of condensation can be achieved, and reliability of a unit is ensured; and the capacity demand of the unit can also be met, and condensation prevention in a frequency reducing mode or frequency limiting mode or other modes is not needed.

Owner:GREE ELECTRIC APPLIANCES INC

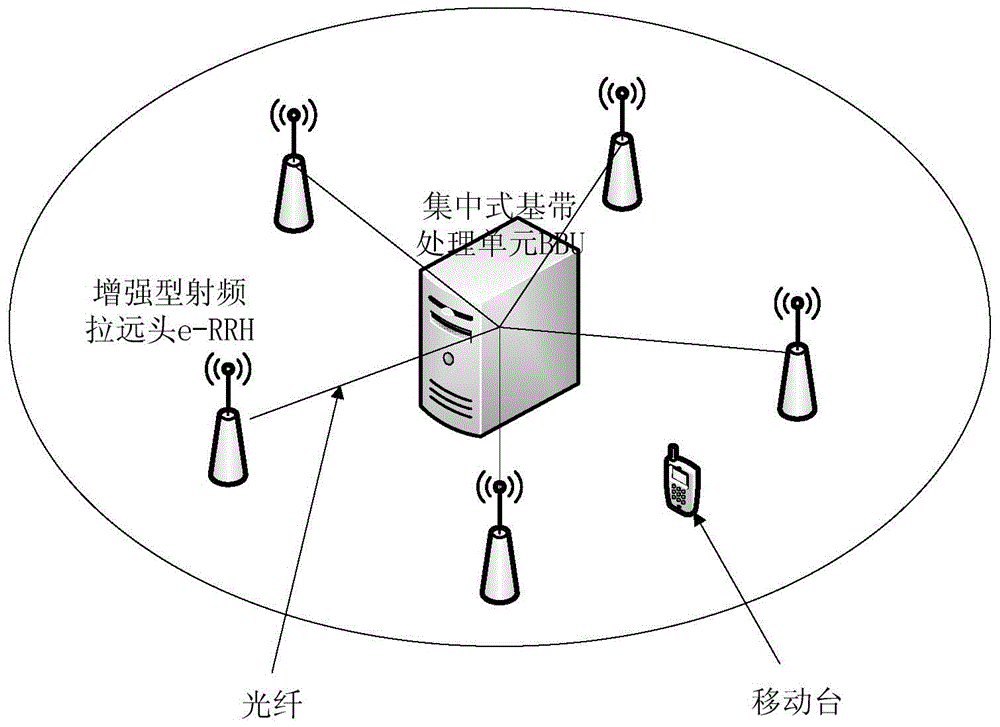

Dynamic distributed antenna deployment method for enhancing network capacity and coverage

ActiveCN105120467AImprove received signal strengthMeet capacity needsRadio transmission for post communicationNetwork planningFailure rateNetwork deployment

The invention relates to a dynamic distributed antenna deployment method for enhancing the network capacity and coverage. The method comprises the following steps: deploying distributed antenna nodes on crossroads in a city network, wherein remote radio head nodes of distributed antennas can be clustered into distributed antenna cells of different forms in different ways; and when loads in the clustered cells are light, executing a radio frequency receiving-transmitting functional module of a remote radio head to transmit the same data under the configuration of a central processing server module in a center cluster head station of the clustered cells through network nodes in the same distributed antenna cell in order to enhance signal receiving intensity of users within a service range. Compared with a method for separately deploying hot-spot base stations, the dynamic distributed antenna deployment method has the advantages that the influence of interference between adjacent base stations under dense network deployment can be lowered, and the mobility problems of excessive switching times, high switching failure rate and the like due to dense deployment under the situation of a narrowed cell range are solved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

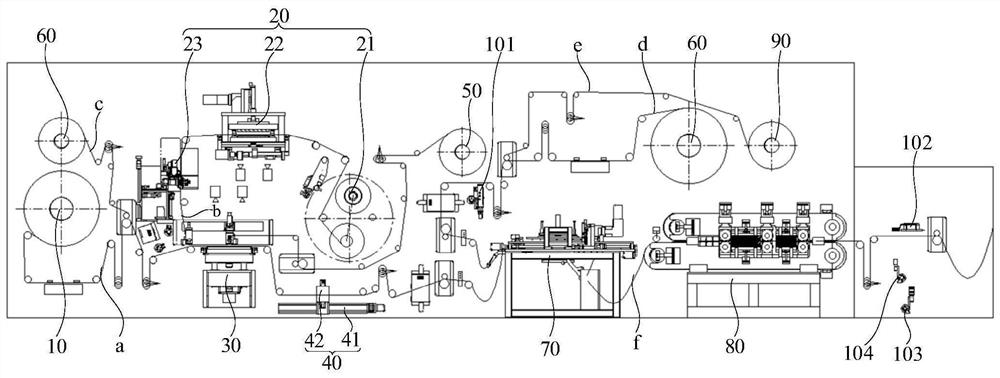

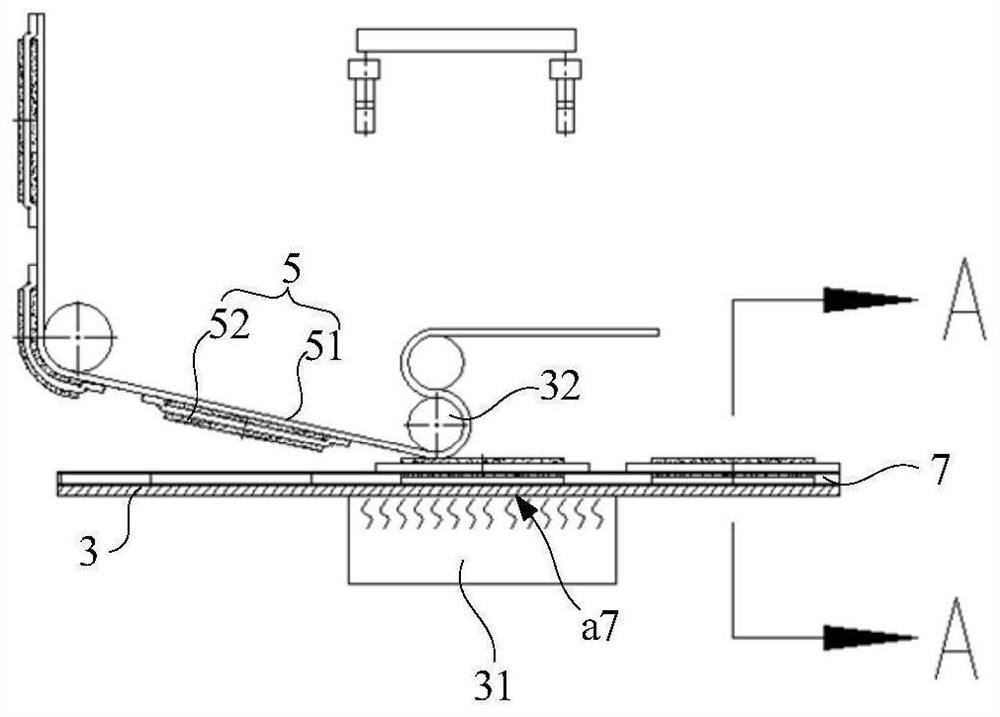

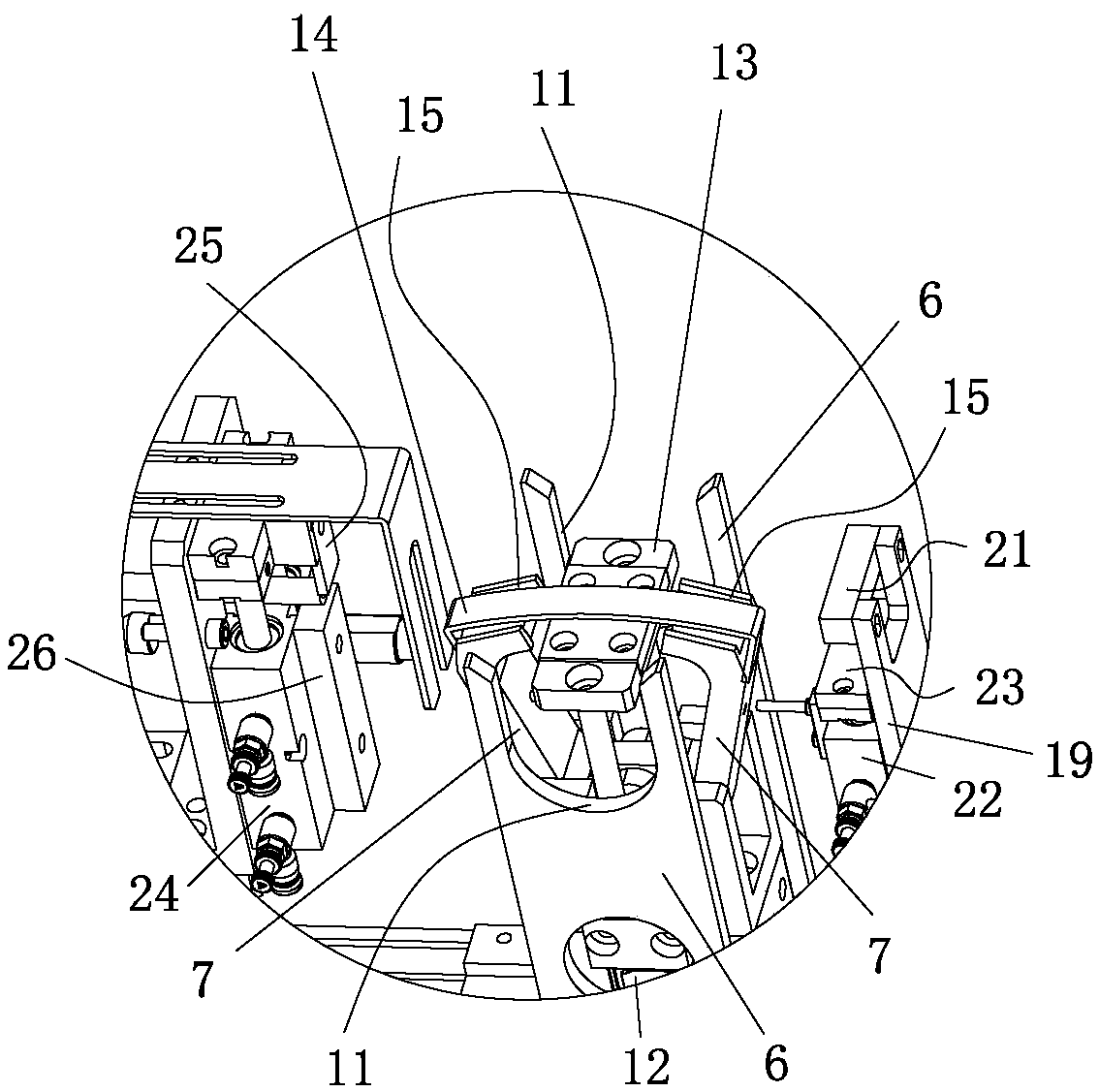

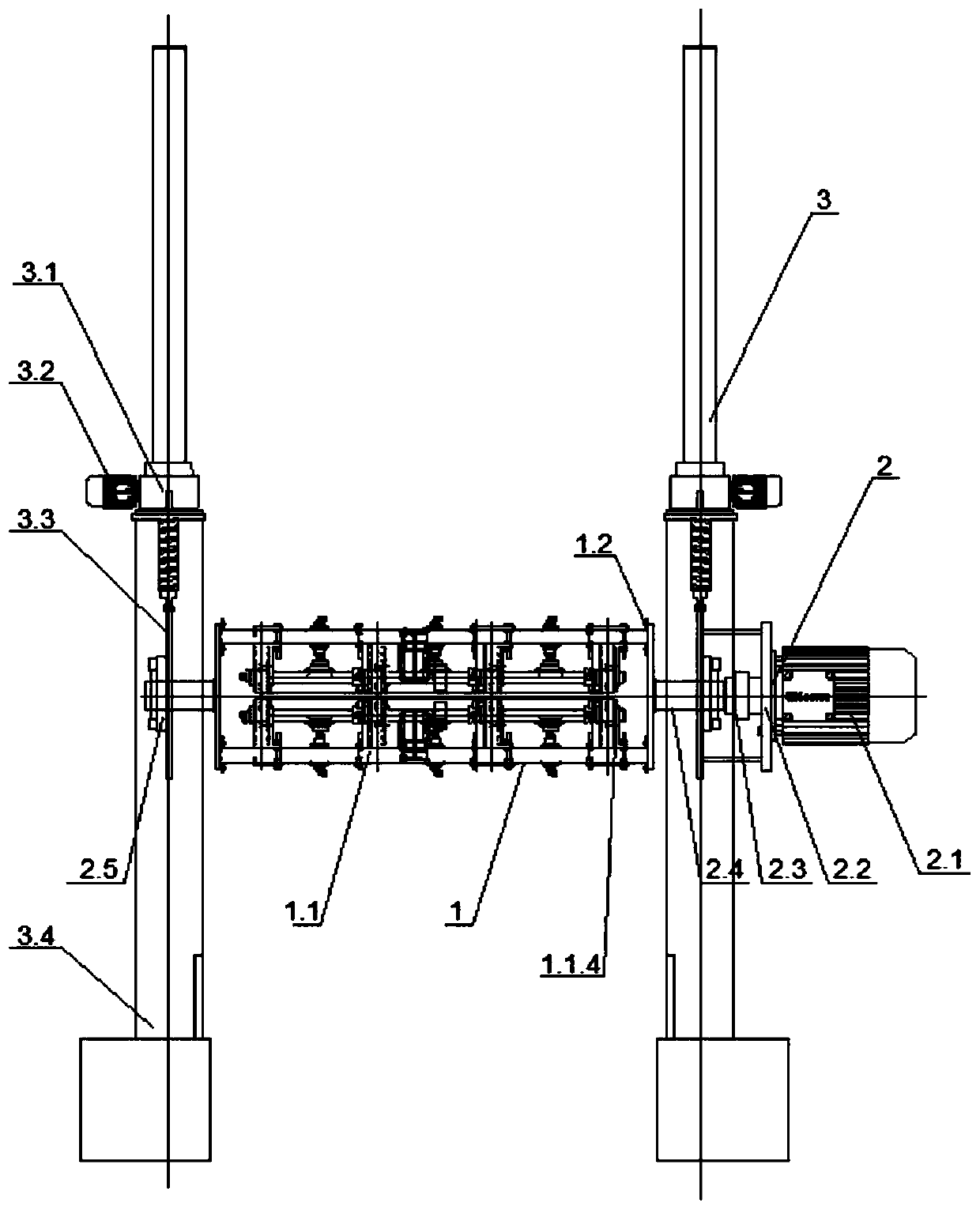

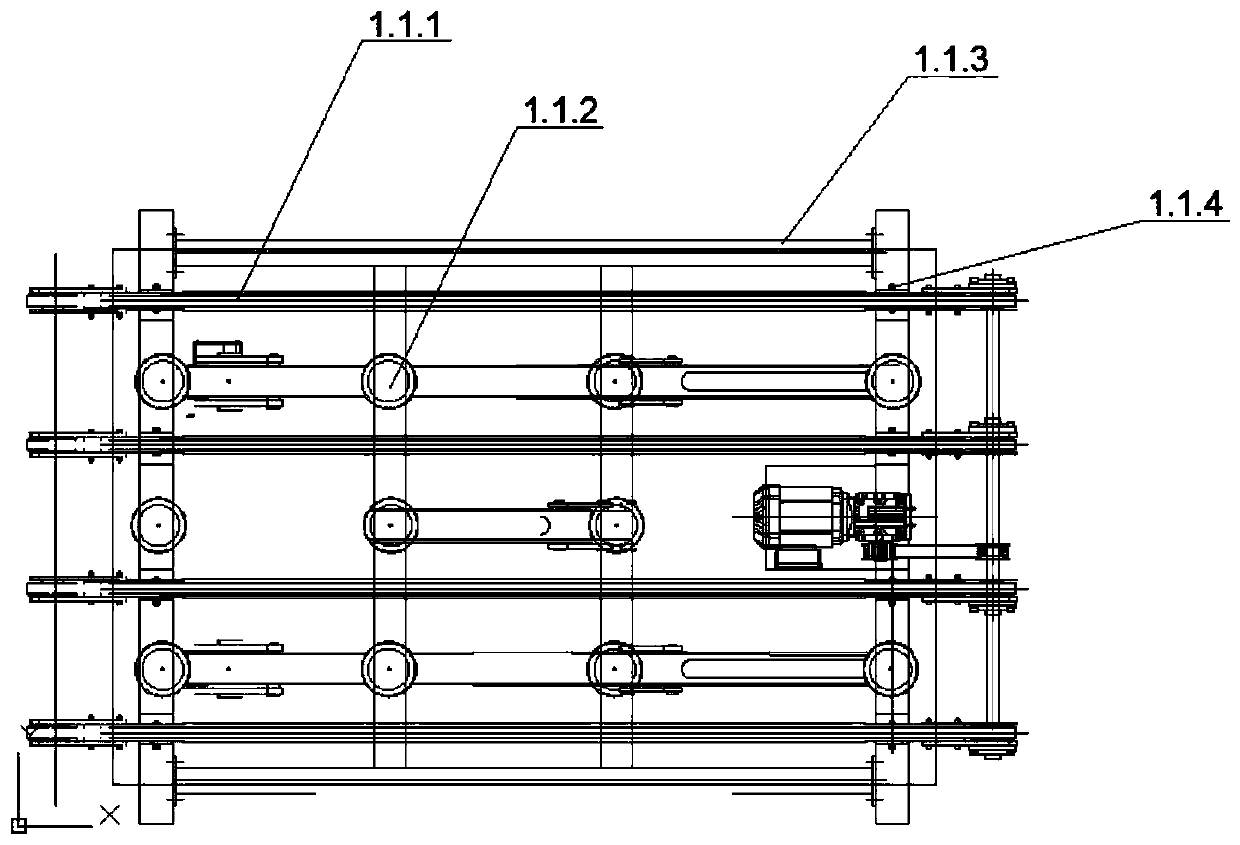

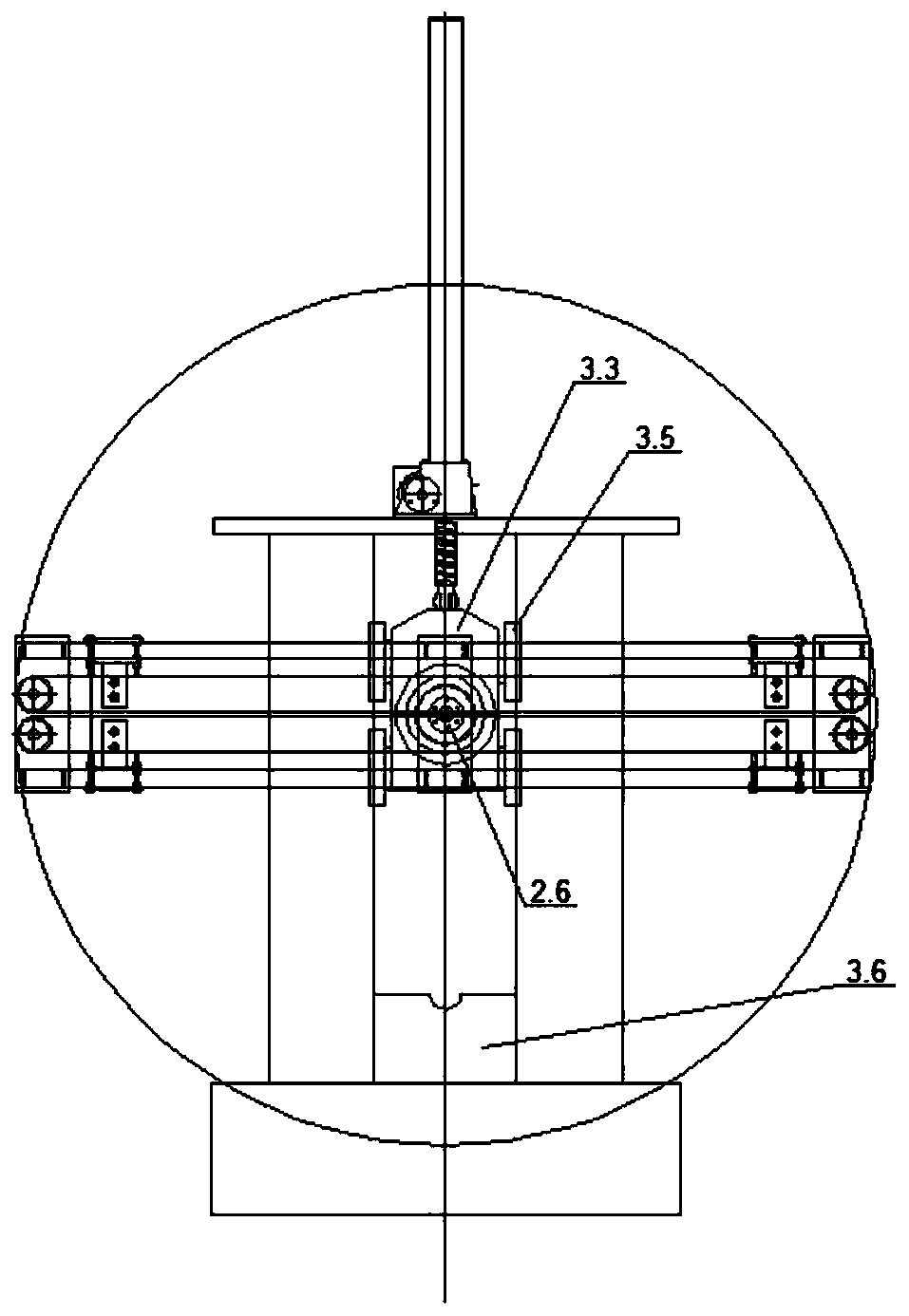

Manufacturing device of membrane electrode

ActiveCN112582655AReduce loading waiting timeIncrease productivityFinal product manufactureFuel cell detailsAdhesiveMechanical engineering

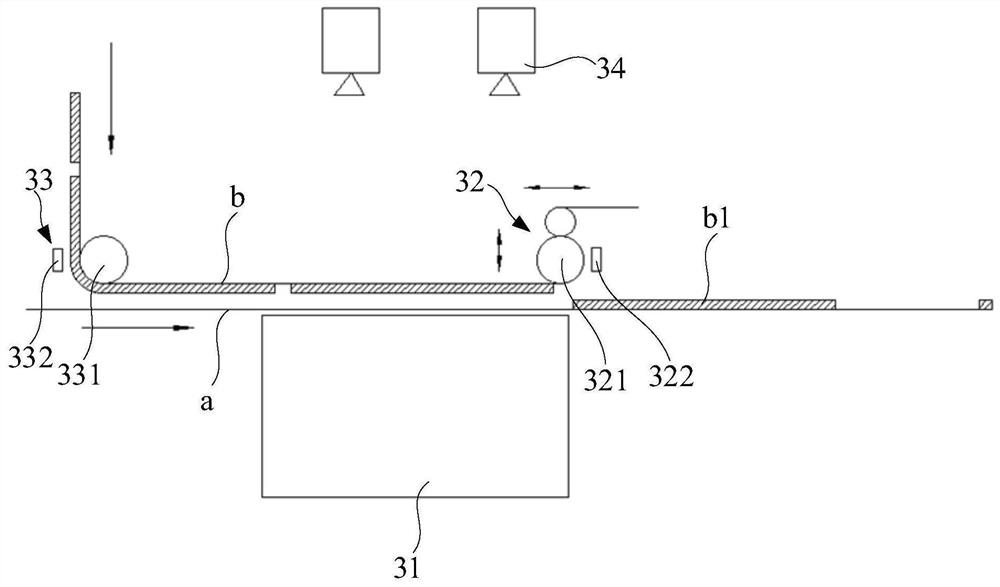

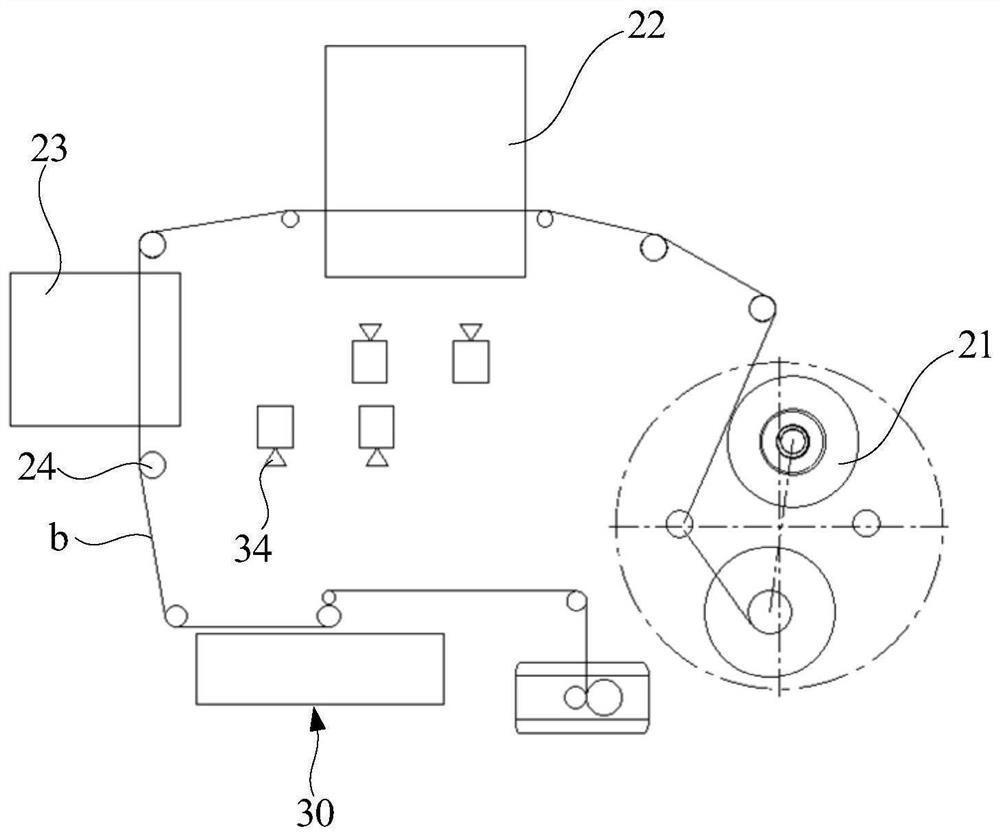

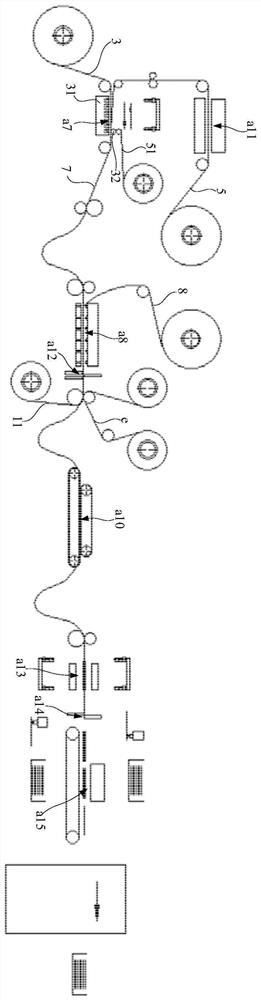

The invention relates to a manufacturing device of a membrane electrode. The manufacturing device of the membrane electrode comprises a first frame unwinding device used for unwinding and outputting afirst frame material belt; a CCM unwinding device used for unwinding and outputting a CCM material belt; and a laminating device which comprises a heating platform and a clamping roller assembly which are oppositely arranged along a first direction, wherein the heating platform is used for heating the first frame material belt, and the clamping roller assembly is used for winding the CCM materialbelt. The clamping roller assembly can move relative to the heating platform along the first direction and a second direction, the first frame material belt and the CCM material belt can be pressed on the heating platform in the moving process of the clamping roller assembly in the first direction, and the first frame material belt and the CCM material belt which are pressed on the heating platform can be rolled in the moving process of the clamping roller assembly in the second direction, so that the CCM unit is adhered to the first frame material belt through the first adhesive and is separated from the CCM material belt.

Owner:JIANGSU HYDROGEN GUIDE INTELLIGENT EQUIP CO LTD

Method for producing membrane electrode

ActiveCN112582654AIncrease productivityMeet capacity needsFinal product manufactureFuel cell detailsStructural engineeringManufacturing engineering

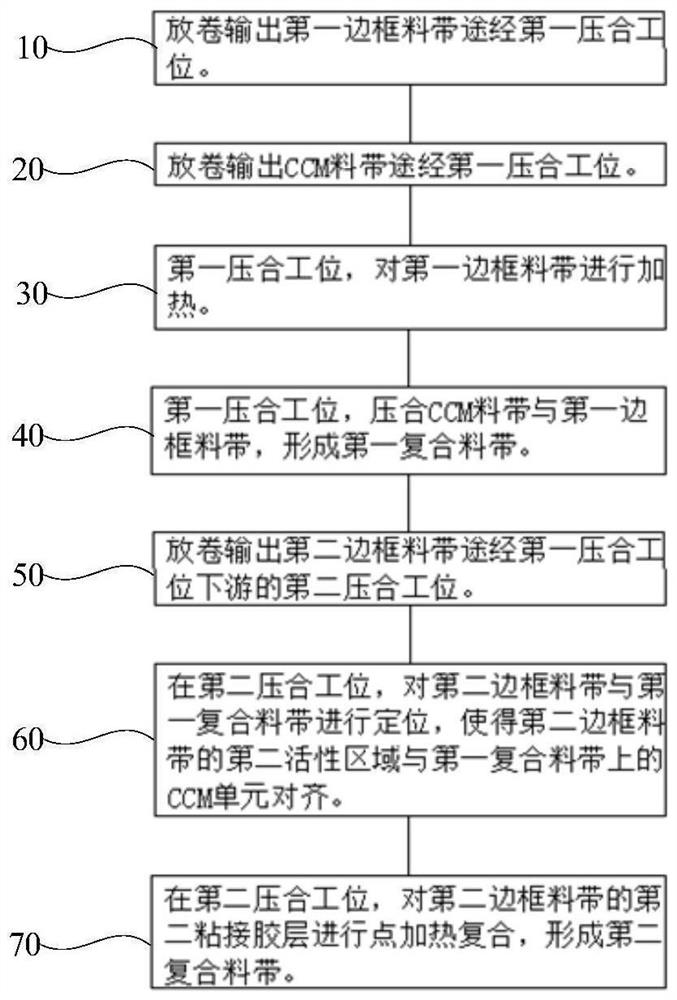

The present invention relates to a method for manufacturing a membrane electrode. The method for manufacturing the membrane electrode comprises the following steps of unwinding and outputting a firstframe material belt to pass through a first pressing station; unwinding and outputting a CCM material belt to pass through the first pressing station; and at the first pressing station, pressing the CCM material belt and the first frame material belt to form a first composite material belt, and bonding the CCM units to a first active area of a first frame layer one by one through a first bonding glue layer, and separating from a back film. Compared with the prior art that the CCM material belt and the frame material belt are manufactured into the sheet materials and are flatly pressed to be compounded, the CCM units are transferred to the first active area of the first frame layer in a roll-to-roll manner, so that the production efficiency is improved, and the capacity requirement is better met.

Owner:JIANGSU HYDROGEN GUIDE INTELLIGENT EQUIP CO LTD

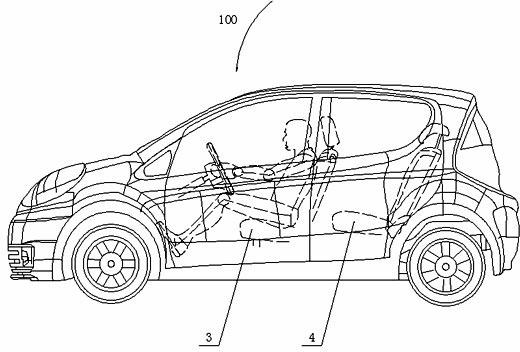

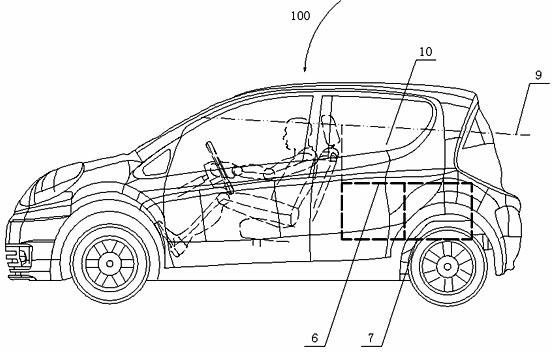

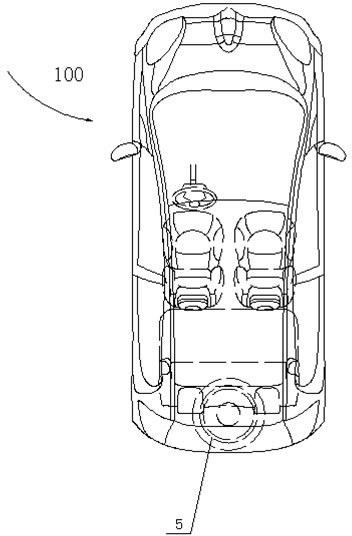

Arrangement structure for power battery assembly of electric automobile with two seats

InactiveCN102139623AEfficient use ofIncrease capacityElectric propulsion mountingPower batteryElectrical battery

The invention discloses an arrangement structure for a power battery assembly of an electric automobile with two seats; the power battery assembly is arranged at a rear seat place of a passenger cabin and a spare tire place below a trunk and is arranged between a left longitudinal beam and a right longitudinal beam; the shape of a battery is designed according to the left longitudinal beam, the right longitudinal beam, a transverse beam, an internal structure of an automobile body and a floor of the automobile body. The arrangement structure ensures enough back view and space of the trunk while ensuring key technologies such as the axle load distribution of the whole automobile, safe collision and the like. The arrangement structure for the power battery assembly can simultaneously meet the maximization of capacity and volume of the battery and achieve the goal of the minimization of the automobile body modification; and the arrangement structure has advantages of convenient installation and disassembling, attractive arrangement, convenient management and the like.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

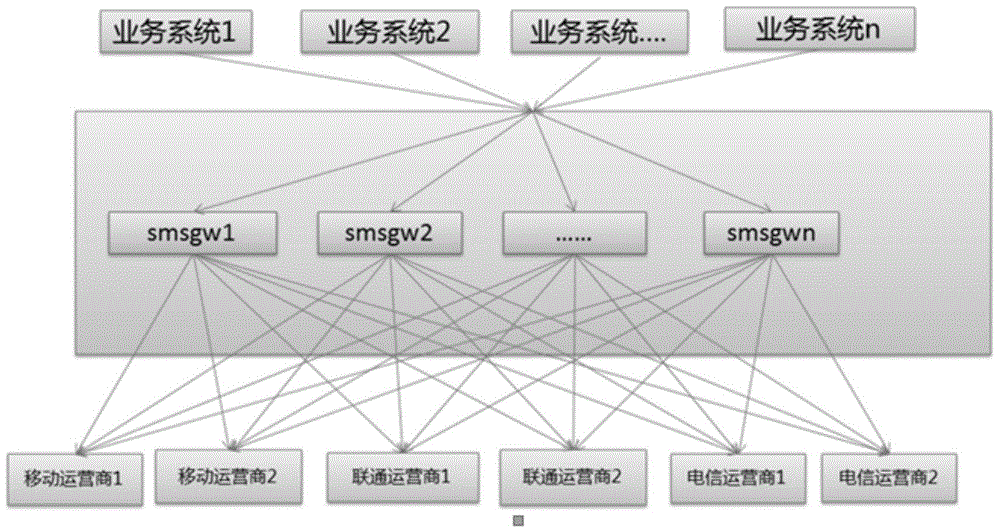

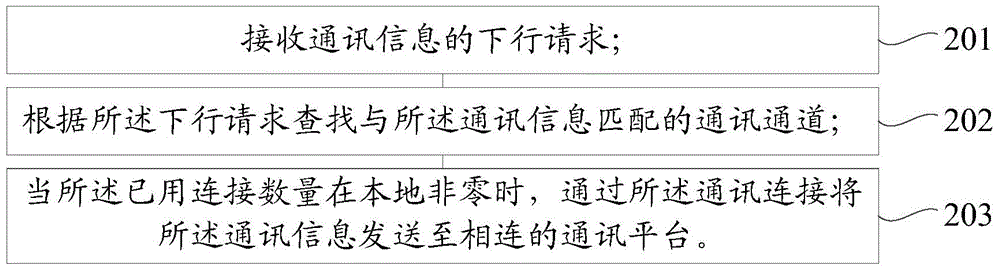

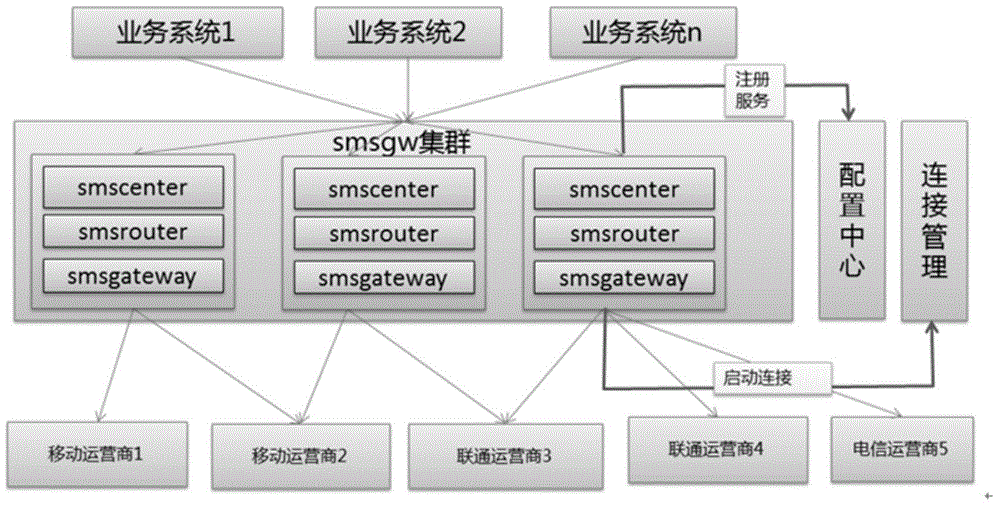

Communication information transmitting method and communication information transmitting device

ActiveCN105578426AImplement Differentiated DeploymentIncrease profitMessaging/mailboxes/announcementsConnection numberUtilization rate

The invention provides a communication information transmitting method and a communication information transmitting device. The communication information transmitting method is characterized in that a downlink request of communication information can be received; a communication channel matched with the communication information can be searched according to the downlink request; the communication channel is provided with the related communication connections and the used connection number; when the local used connection number is not zero, the communication connections can be used to transmit the communication information to the connected communication platform, which is used to transmit the communication information to the corresponding communication object. The differentiation deployment of the communication channels of the servers can be realized, and the number of the servers is not required to be equal to the number of the communication connections, and under the condition of the unequal and limited communication connections provided by the communication platform, the communication connections can be fully used, and therefore the utilization rate of the communication connections can be improved, the idle states of the resources can be prevented, the strong dependence on the connection resources of the communication platform is not required, the convenience of the dilatation can be improved, and the requirement of increasing the capacity constantly can be satisfied.

Owner:ADVANCED NEW TECH CO LTD

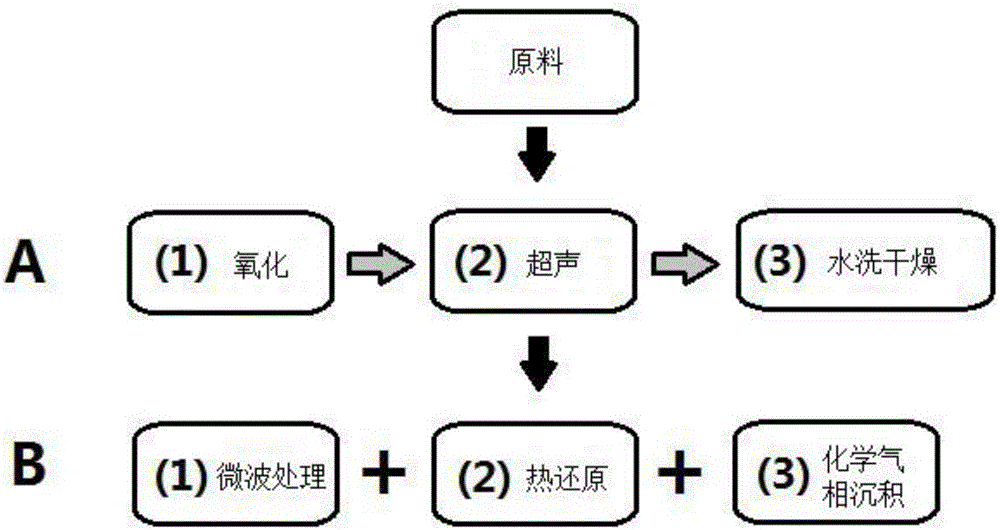

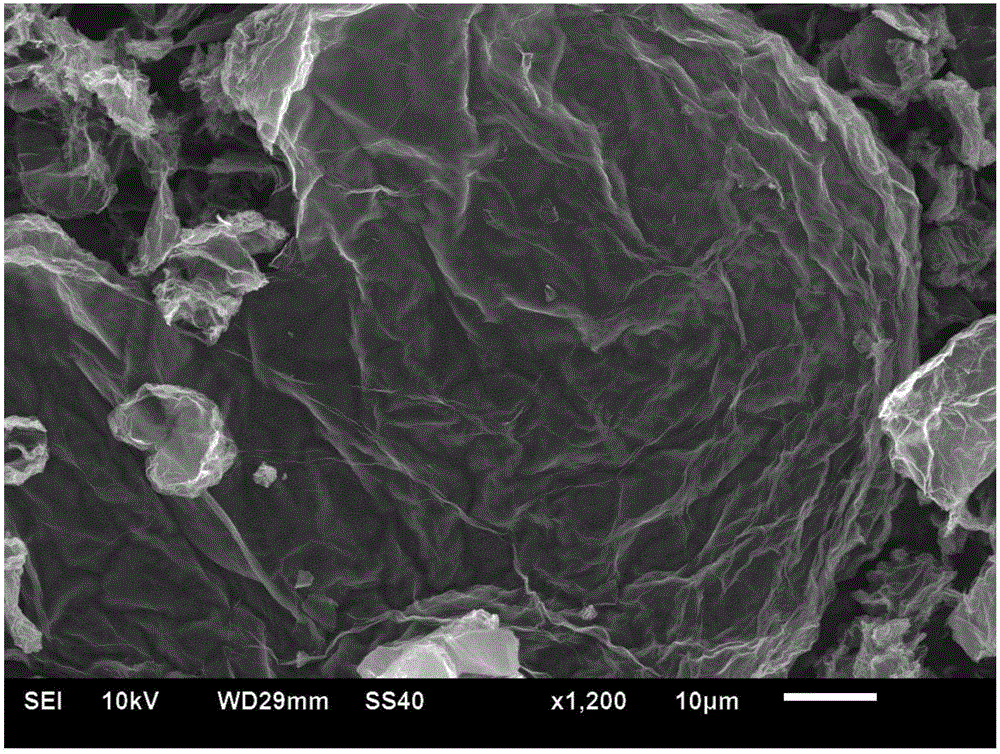

High-specific-surface-area nitrogen doped grapheme and preparation method thereof

ActiveCN106145101ALarge specific surface areaMeet capacity needsHybrid capacitor electrodesCell electrodesDoped grapheneMicrowave

The invention provides a preparation method of high-specific-surface-area nitrogen doped grapheme by adopting a microwave vacuum high-temperature heating furnace. The preparation method includes the steps of 1), preparing grapheme oxide (2) by a Hummers method and performing in-situ microwave treatment, thermal reduction and chemical vapor deposition (CVD) doping of the grapheme oxide. In-situ operations of microwave prestripping and thermal reduction before thermal reduction and chemical vapor deposition doping after thermal reduction of the grapheme oxide are realized on the premise of self-improvement of equipment, synthetic efficiency is increased, energy consumption of synthesis is lowered, and the preparation method is suitable for industrial mass production. The doped grapheme obtained in synthesis can be used in fields of electrochemical catalysis, supercapacitor and the like.

Owner:BEIJING GUANGKEBOYE SCI & TECH

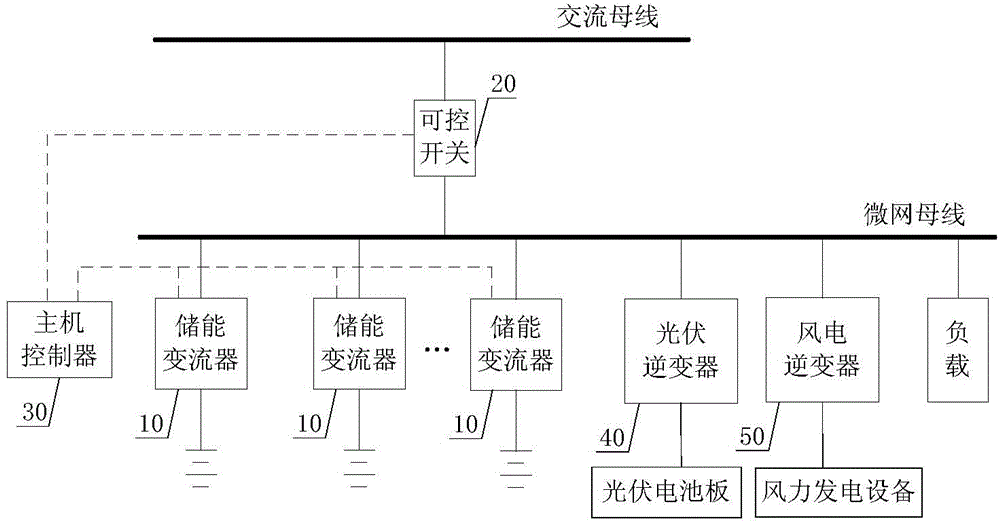

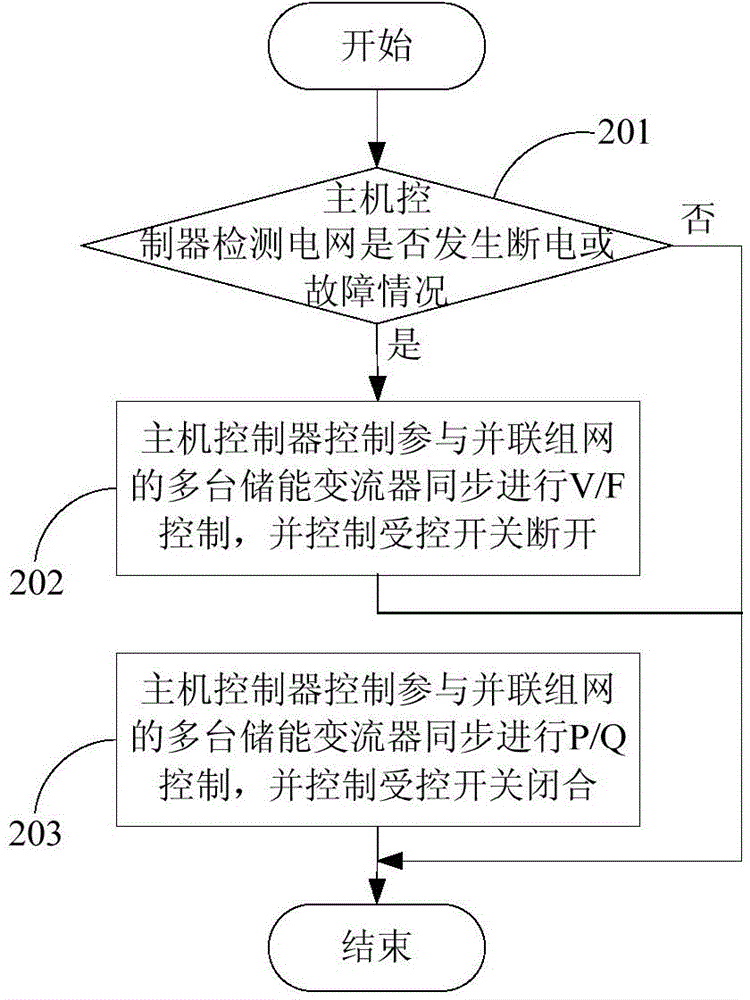

Micro-grid system and seamless grid connection/disconnection switching method for energy storage converters

The invention discloses a micro-grid system and a seamless grid connection / disconnection switching method for energy storage converters. The micro-grid system comprises a plurality of energy storage converters participating in parallel connection networking, a controlled switch for connecting a micro-grid bus with an alternating-current bus, and a host controller in communication connection with the controlled switch and the energy storage converters participating in parallel connection networking. The host controller is used for controlling the energy storage converters participating in parallel connection networking to perform V / F control synchronously and controlling the controlled switch to be disconnected when detecting grid outages or faults, and controlling the energy storage converters participating in parallel connection networking to perform P / Q control synchronously and controlling the controlled switch to be connected when detecting grid power restoration, so that seamless grid connection / disconnection switching of the energy storage converters is achieved on the premise of meeting micro-grid system capacity requirements.

Owner:SUNGROW POWER SUPPLY CO LTD

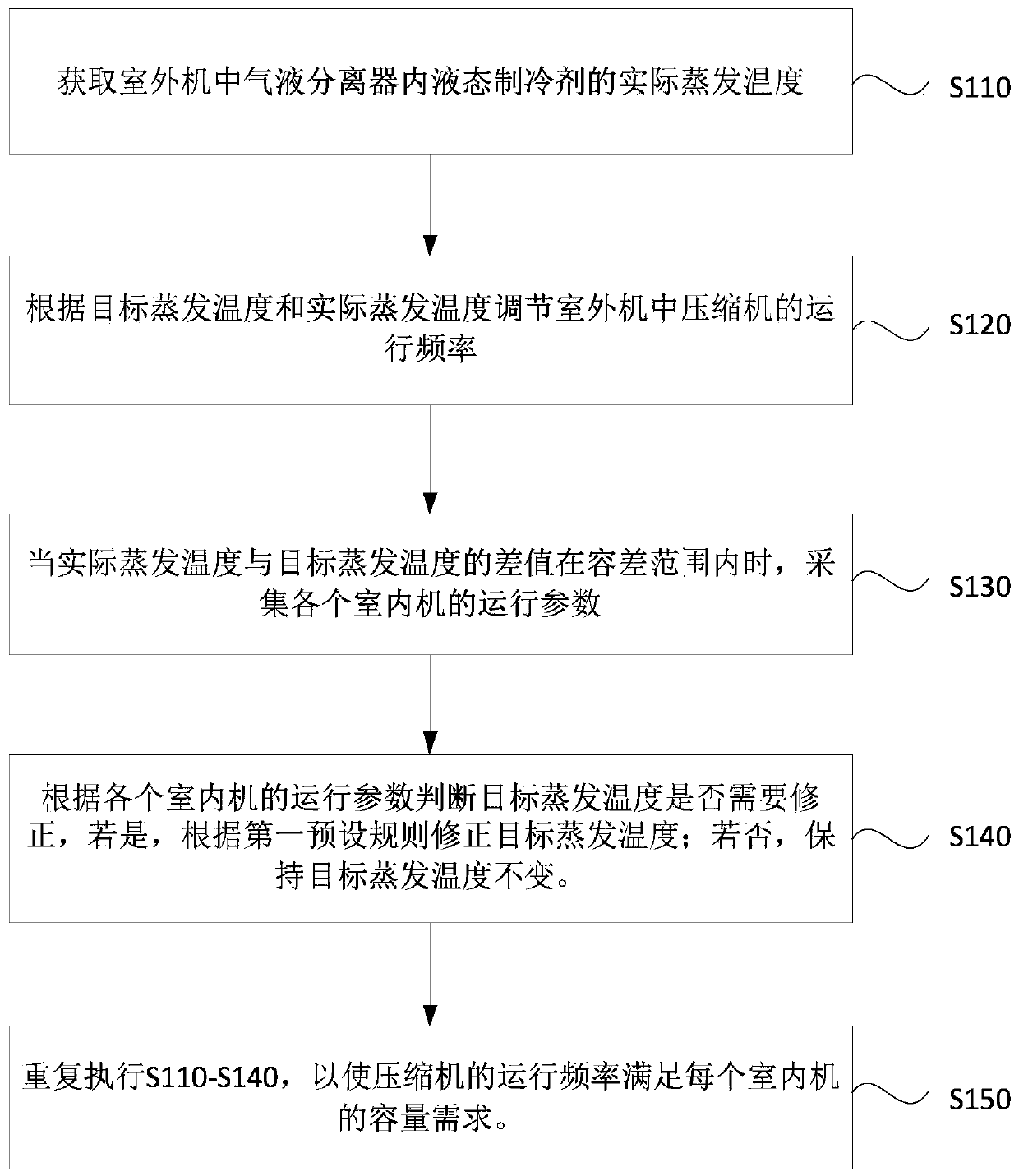

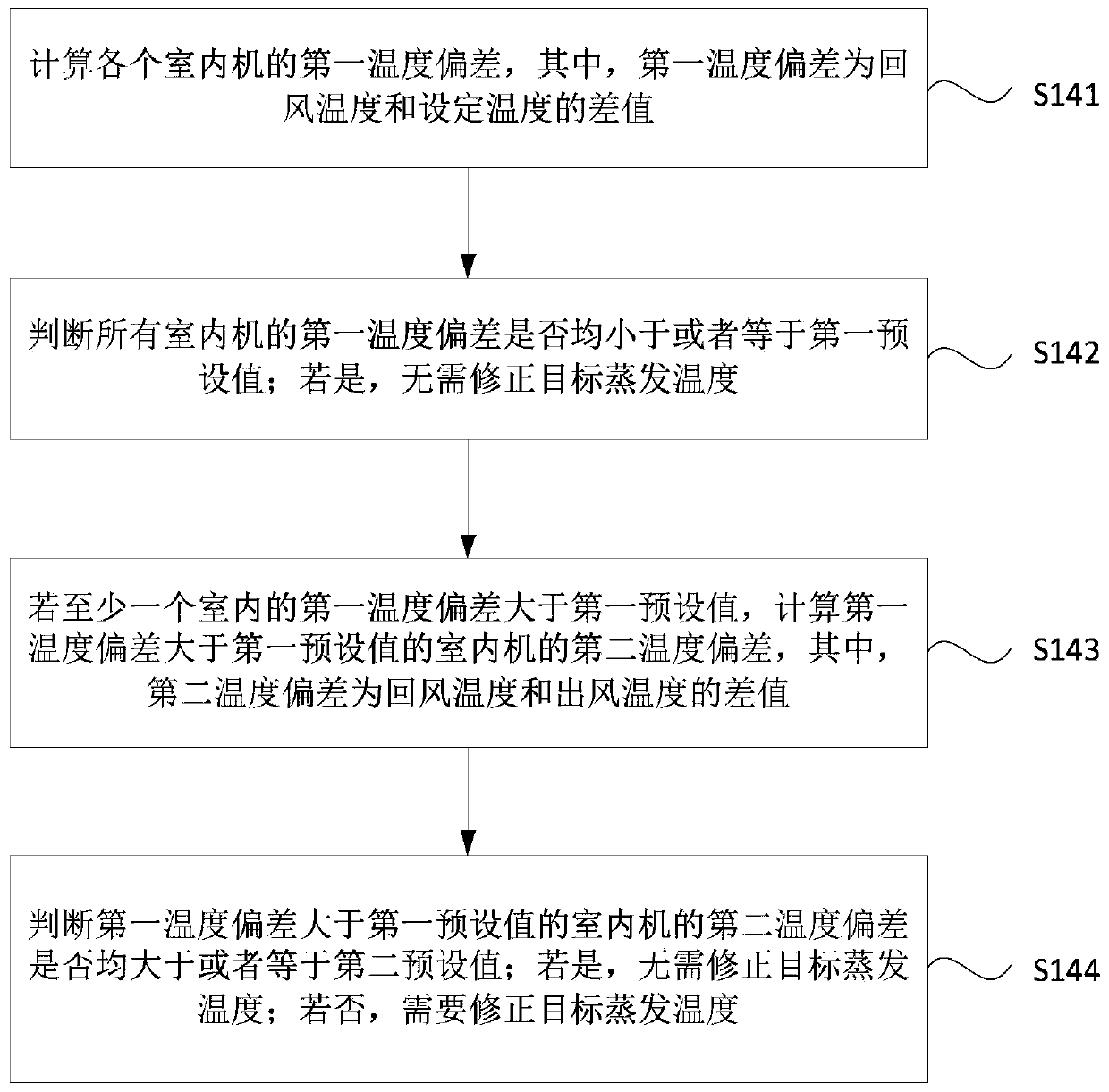

Air conditioning system evaporation temperature control method and device and air conditioning system

ActiveCN109855256AMeet capacity needsMechanical apparatusSpace heating and ventilation safety systemsRefrigerantEngineering

The invention discloses an air conditioning system evaporation temperature control method and device and an air conditioning system. The method comprises the following steps that the actual evaporation temperature of a liquid refrigerant in a gas-liquid separator in an outdoor unit is acquired, the operation frequency of a compressor in the outdoor unit is adjusted according to the target evaporation temperature and the actual evaporation temperature, and when the actual evaporation temperature reaches the target evaporation temperature, operation parameters of each indoor unit are collected,and whether the target evaporation temperature needs to be corrected or not is judged according to the operation parameters of each the indoor unit, and if the target evaporation temperature needs tobe corrected, whether the target evaporation temperature needs to be corrected or not is judged according to the operation parameters of all the indoor units, and the target evaporation temperature iscorrected according to a first preset rule; and if not, the target evaporation temperature is kept to be unchanged, and the steps are repeated, so that the operating frequency of the compressor meetsthe capacity requirement of each indoor unit. According to the technical scheme, the operation frequency of the compressor can meet the capacity requirement of each indoor unit in the air conditioning system.

Owner:天津欧科环境设备有限公司

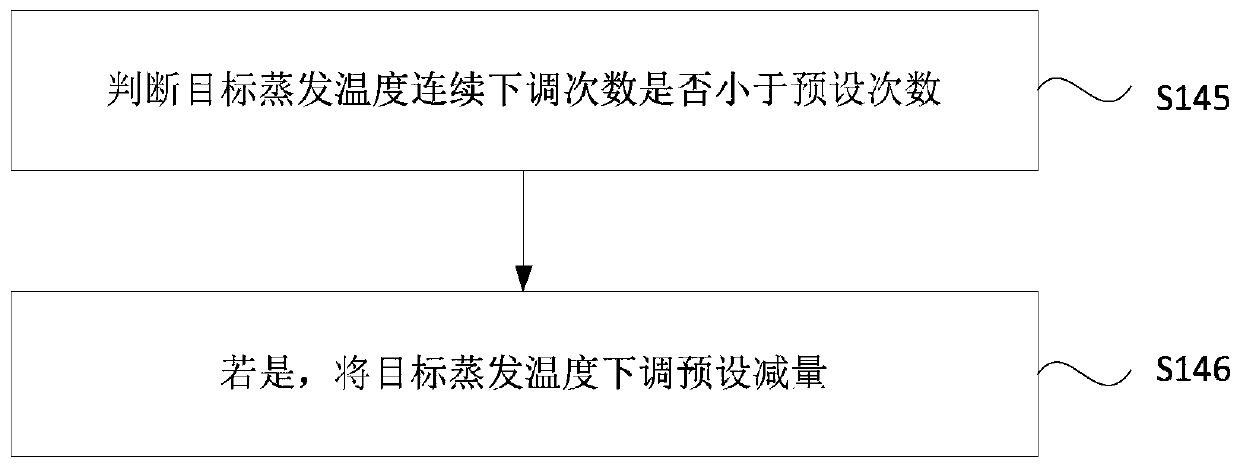

High and low frequency band spectrum resource allocation method applicable to 5G network

InactiveCN106792718AEasy to moveImprove wireless broadband data access servicesNetwork planningSystem capacityFrequency spectrum

The invention discloses a high and low frequency band spectrum resource allocation method applicable to a 5G network and relates to the field of spectrum resource allocation of network frequency bands. The method comprises steps as follows: S1: a physical frequency band at 3-6 GHz is allocated into a 3.3-3.4 GHz frequency band, a 4.4-4.5 GHz frequency band and a 4.8-4.99 GHz frequency band; S2: a physical frequency band at 6-100 GHz is allocated into a 28 GHz frequency band area at a 27.5-28.35 GHz frequency band, a 37 GHz frequency band area at a 37-38.6 GHz frequency band, a 39 GHz frequency band area at a 38.6-40 GHz frequency band and a 70 GHz frequency band area at a 64-71 GHz frequency band. By means of the method, spectrum resources can be reasonably allocated for high and low frequency bands, the network coverage problem at the high and low frequency bands can be solved, and the system capacity demands at the high and low frequency bands are met.

Owner:WUHAN POST & TELECOMM RES INST CO LTD

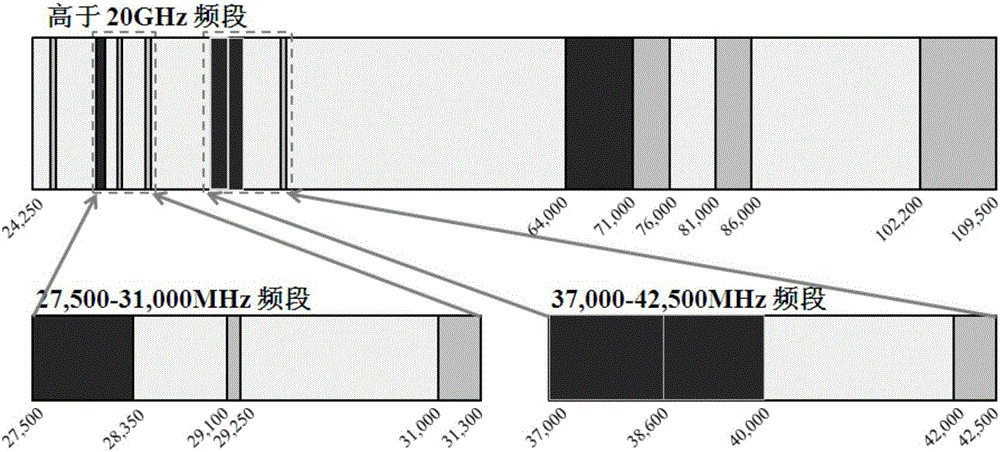

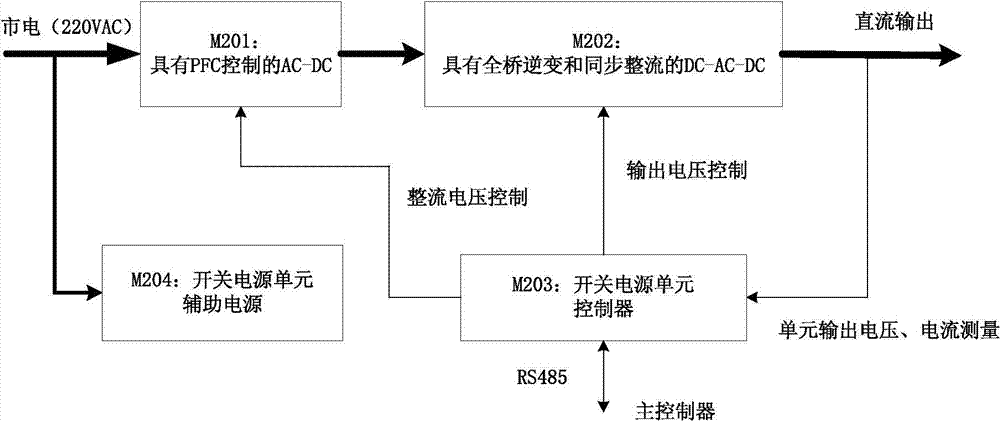

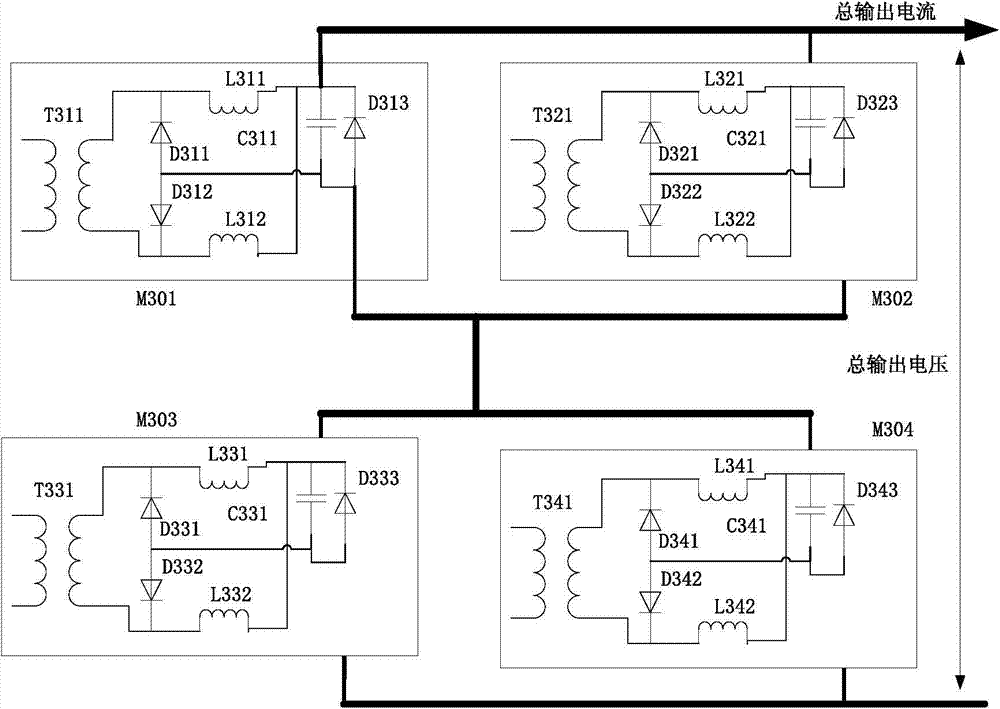

Electric automobile modularized vehicle-mounted battery charger and charging method thereof

InactiveCN103490490AMeet different voltage levelsMeet capacity needsBatteries circuit arrangementsElectric powerPower factorElectrical battery

The invention discloses an electric automobile modularized vehicle-mounted battery charger and a charging method thereof. The vehicle-mounted battery charger comprises an auxiliary charging power source, a switching power package, a linear power collecting module and a main controller. The auxiliary charging power source outputs direct current power used for supplying power for the linear power collecting module and the main controller by being connected with ground charging equipment, the linear power collecting module is respectively connected with the switching power package and the main controller, the switching power package is formed by a plurality of switching power units through series connection and parallel connection, and each switching power unit is connected with the main controller through an RS-485 bus. The main controller is connected with the ground charging equipment through a control guiding circuit, and the main controller is respectively connected with a rechargeable battery module and an instrument panel through CAN buses. The vehicle-mounted battery charger is assembled in a modularized mode, the PFC technology, the ZVS technology, the current double technology and the synchronous rectification technology are applied comprehensively, power factors are improved, and switching losses and electromagnetic interference are reduced.

Owner:SOUTH CHINA UNIV OF TECH

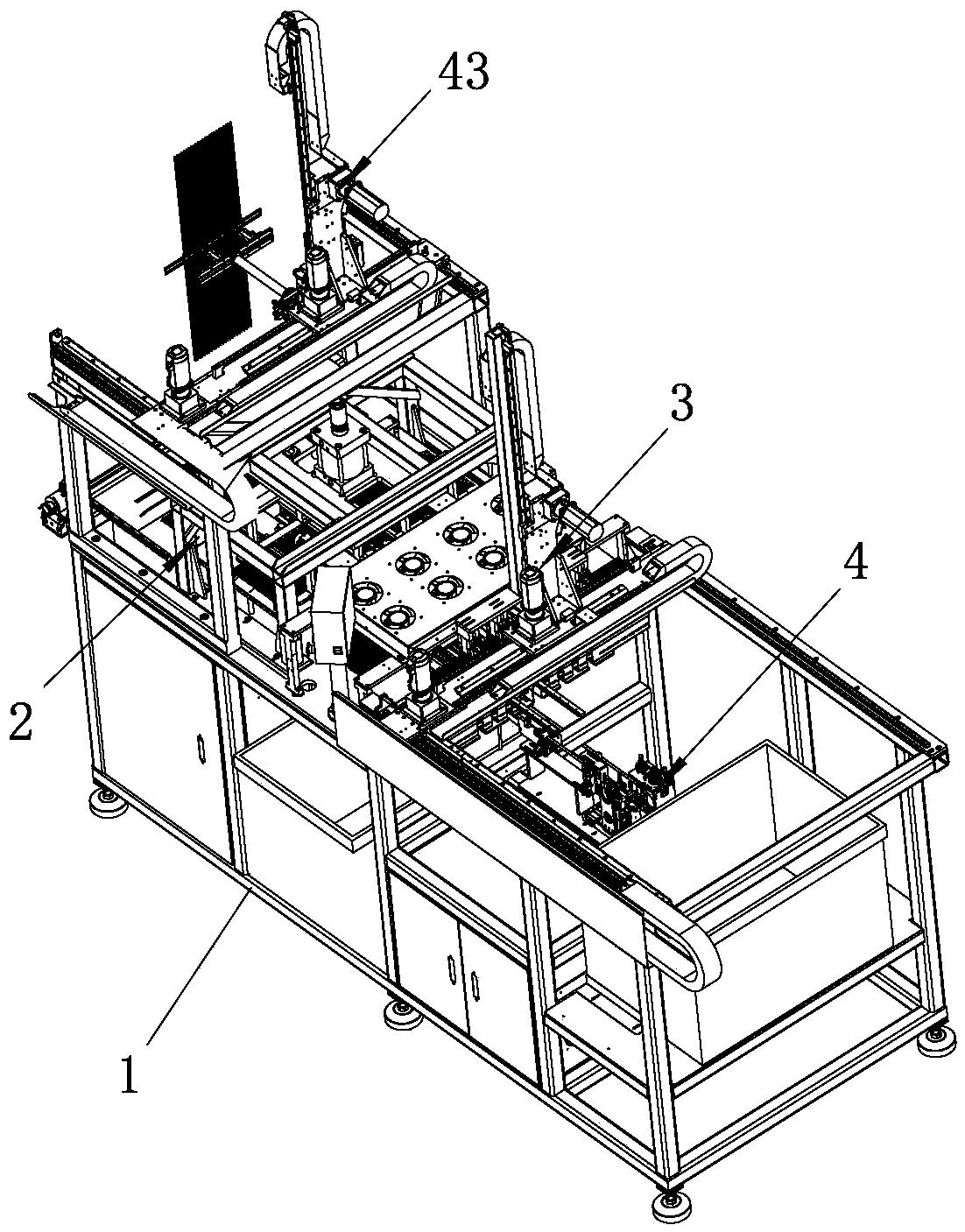

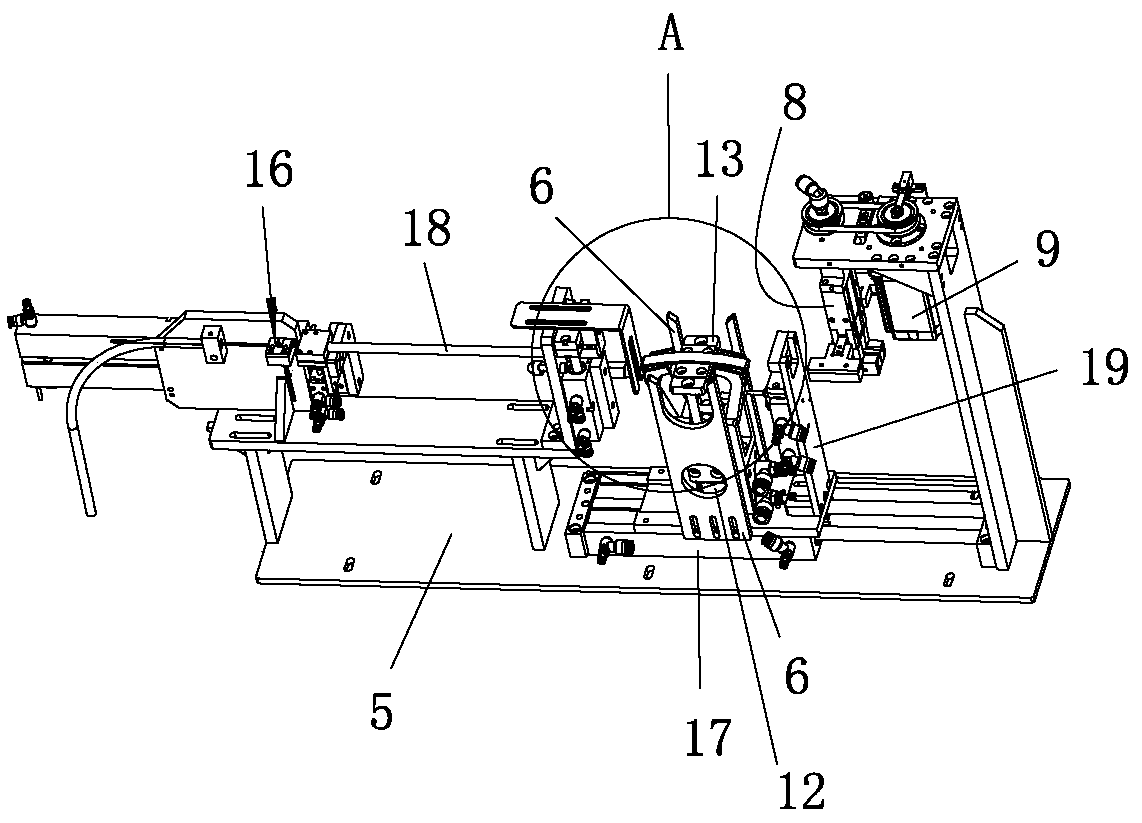

Full-automatic binding machine for nylon cable binding belts

PendingCN110002026AAutomate bundling operationsImprove bundling efficiencyBinding material applicationBundling machine detailsMechanical engineeringBinding efficiency

The invention relates to the technical field of binding belt binding, in particular to a full-automatic binding machine for nylon cable binding belts. The full-automatic binding machine comprises a machine frame, a sorting mechanism, a moving mechanism and a binding mechanism, wherein the sorting mechanism, the moving mechanism and the binding mechanism are arranged on the machine frame, the sorting mechanism is used for integrating the multiple nylon cable binding belts scattered outside into a pile shape, the moving mechanism is used for transferring the stacked nylon cable binding belts which are integrated by the sorting mechanism to the binding mechanism, the binding mechanism is used for binding the stacked nylon wire binding belts conveyed by the moving mechanism together through the binding belts outside, and the moving mechanism is used for moving the bundle-shaped nylon wire binding belts which are bundled together by the moving mechanism. The automatic binding operation of the scattered nylon cable binding belts is realized, a worker does not need to manually bind the scattered nylon cable binding belts together, the binding efficiency of the nylon wire binding belts isimproved, and the capacity requirement of modern production is met.

Owner:DONGGUAN TONGYI MACHINE

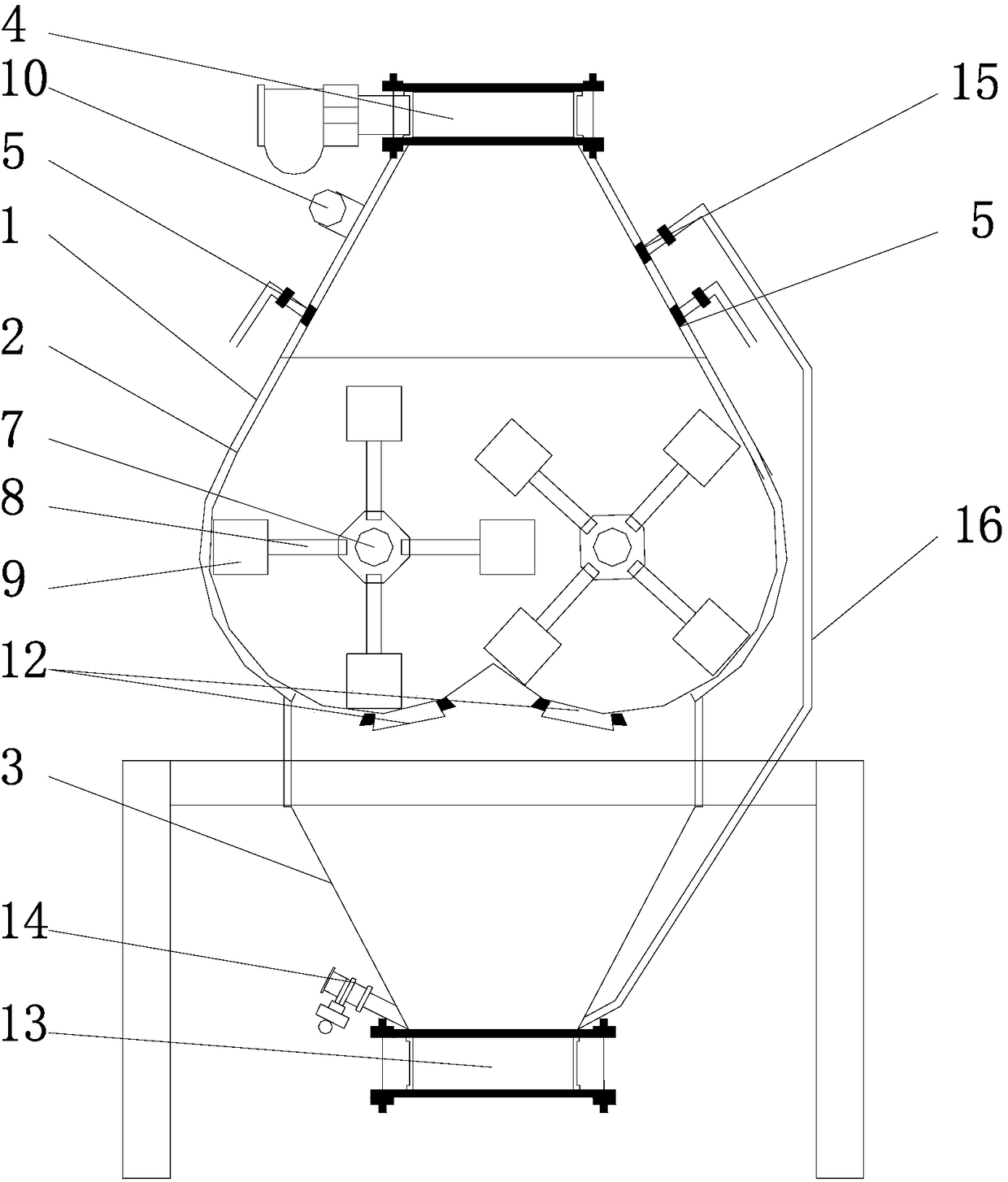

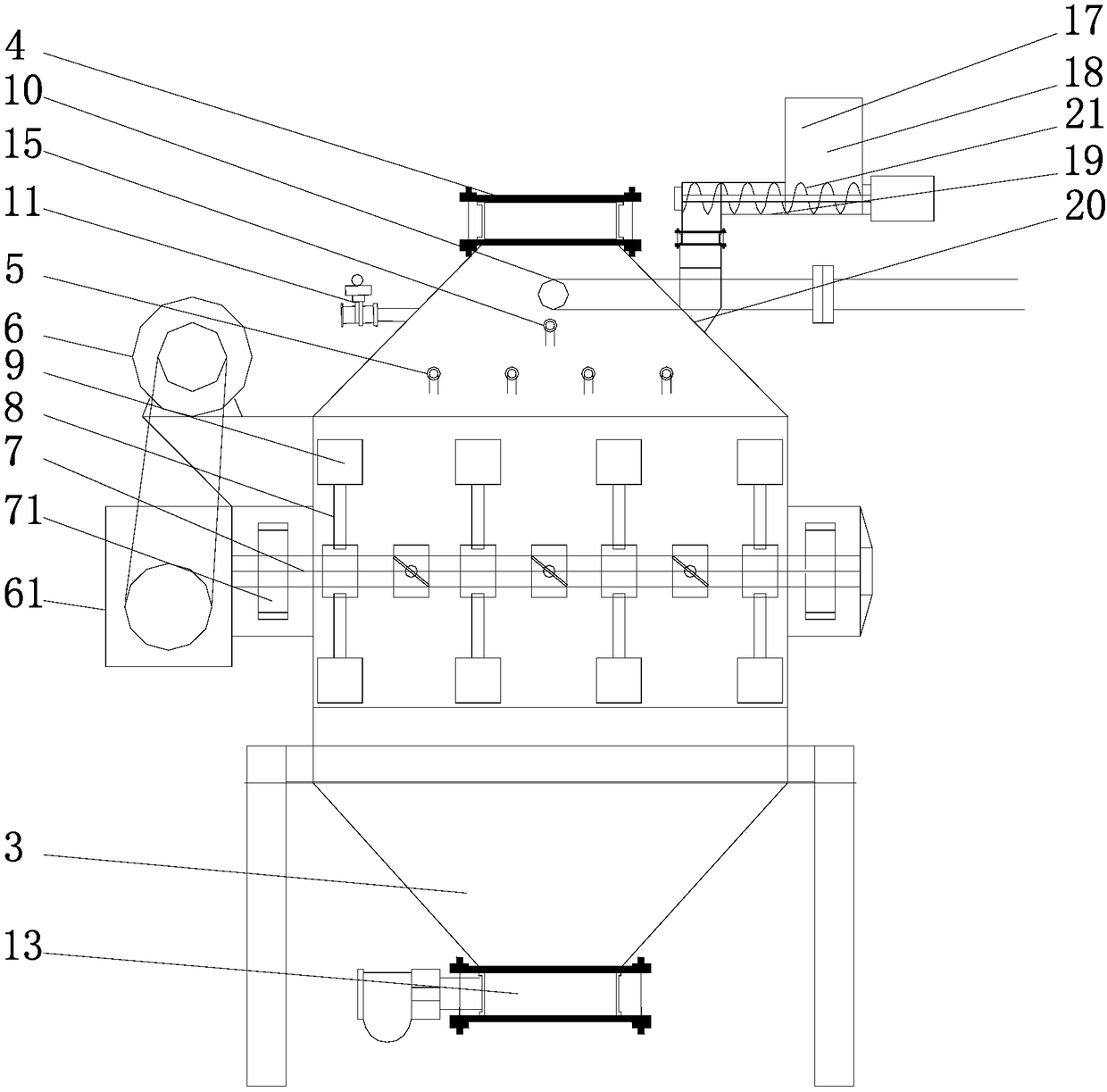

Horizontal vacuum spraying machine

InactiveCN108465397AMeet capacity needsIncrease production capacityRotary stirring mixersTransportation and packagingSpray nozzlePulp and paper industry

The invention relates to a horizontal vacuum spraying machine. A horizontal structure is adopted, and compared with a spraying machine of a vertical structure, the production capacity is improved greatly, so that the production capacity requirement of an existing large-sized extruder is met, wherein the stirring and mixing effect is good so as to ensure the product quality; compared with an existing horizontal machine, the horizontal vacuum spraying machine adopts arrangement of two-shaft stirring so as to further improve the mixing effect; furthermore, since two stages of gates, a recovery nozzle and an oil recovery pipe are arranged, the pressure difference between a stirring chamber and a recovery chamber is utilized to send leaked oil to the stirring chamber through the oil recovery pipe for recovery so as to conduct spraying, so that the problem of oil leakage is solved.

Owner:佛山市金柏机械制造有限公司

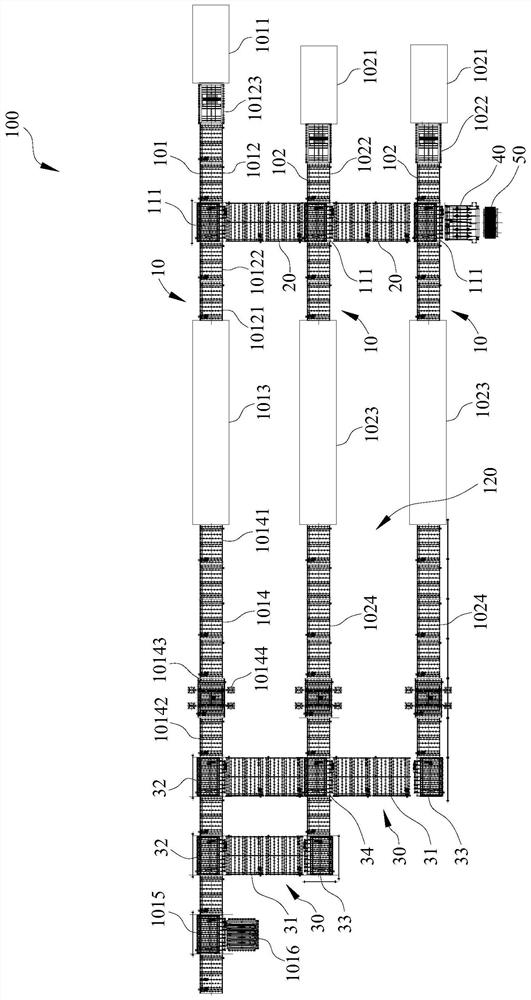

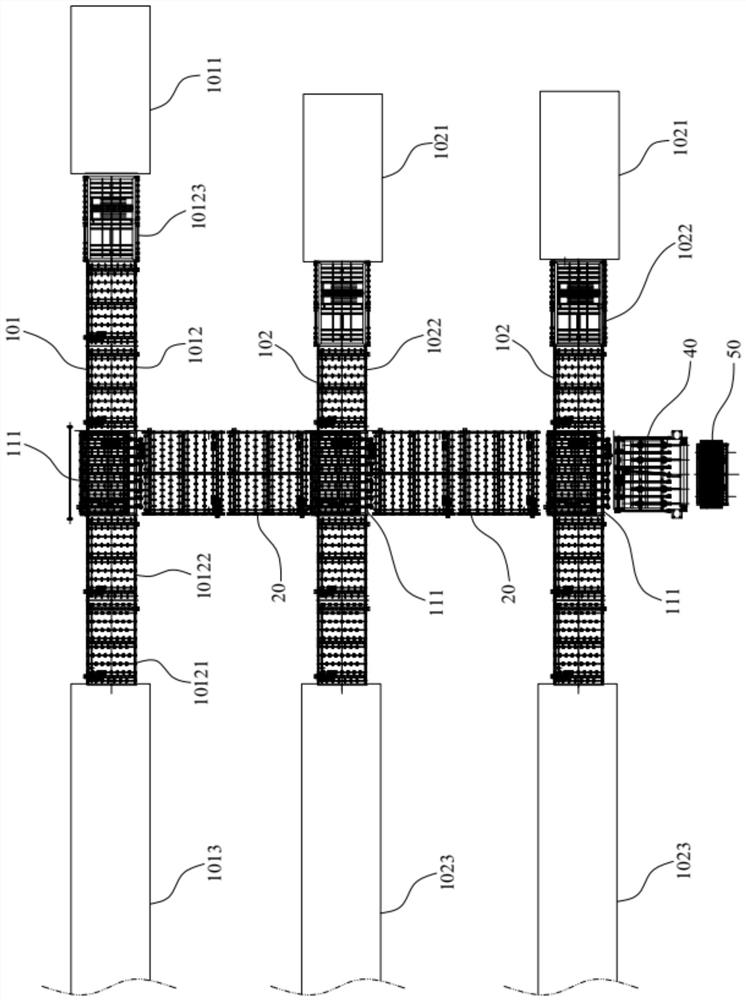

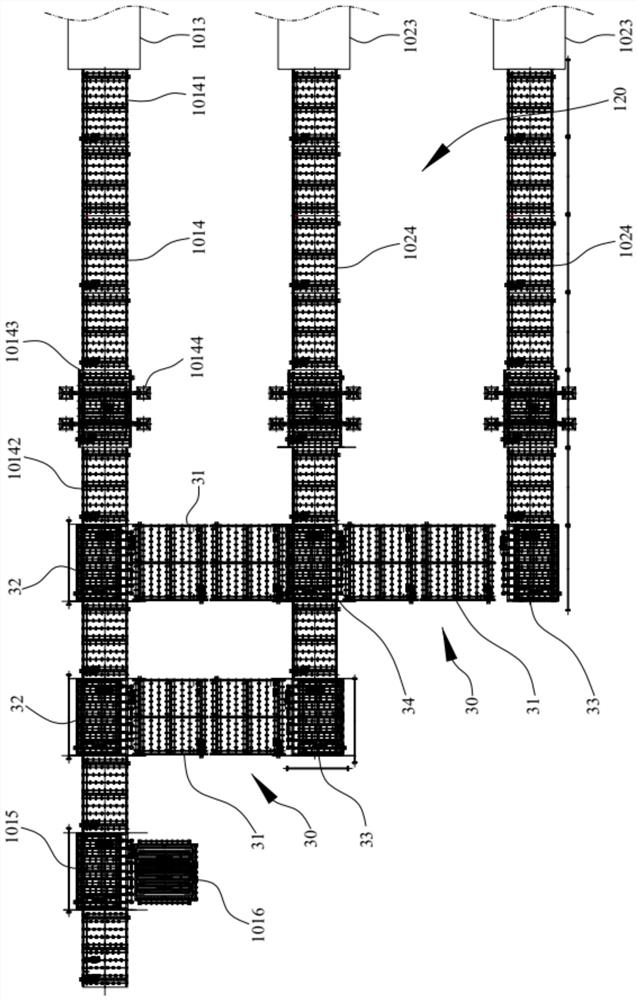

Glass machining transfer line, glass production line and glass machining transfer method

PendingCN112374155AGuaranteed processing efficiencyGuarantee production efficiencyCharge manipulationConveyor partsProduction lineTransfer mechanism

The invention relates to the technical field of glass machining, and provides a glass machining transfer line, a glass production line and a glass machining transfer method. The glass machining transfer line comprises at least two machining lines and a transition transfer mechanism, both machining lines are used for machining glass and transferring the glass to a toughening process, each machiningline is provided with at least two machining sections used for machining glass and a conveying section used for connecting the two adjacent machining sections and conveying the glass between the twomachining sections, the transition transfer mechanism is connected to the transfer sections of the at least two machining lines, so that the glass on the transfer section of one machining line can betransferred to the other transfer section of the other machining line through the transition transfer mechanism. By adoption of the technical scheme, interconnection and intercommunication between themachining sections of the machining lines are achieved, even if the machining section of a certain machining line breaks down or is overhauled, only local shutdown is needed, other machining sectionscan still work normally, and therefore the machining efficiency of glass is guaranteed, full-load operation of follow-up toughening procedure is facilitated, and the production efficiency of a toughening furnace is guaranteed.

Owner:刘伟

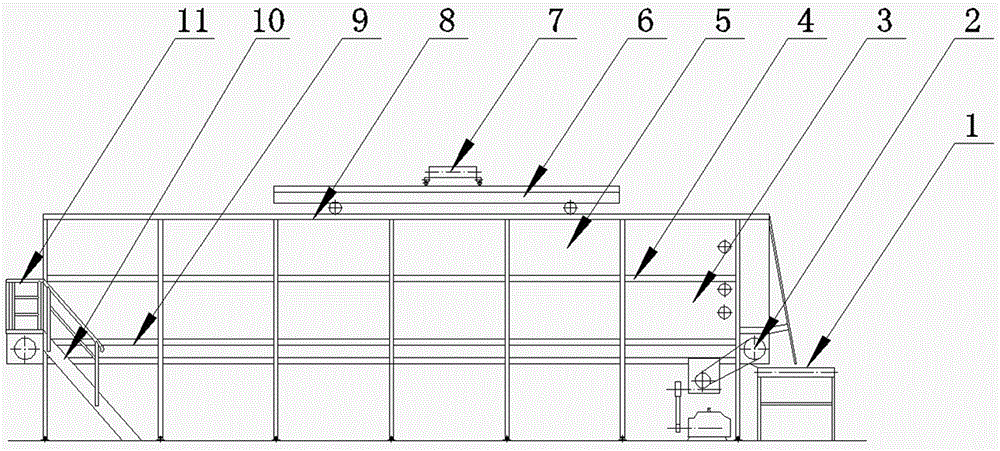

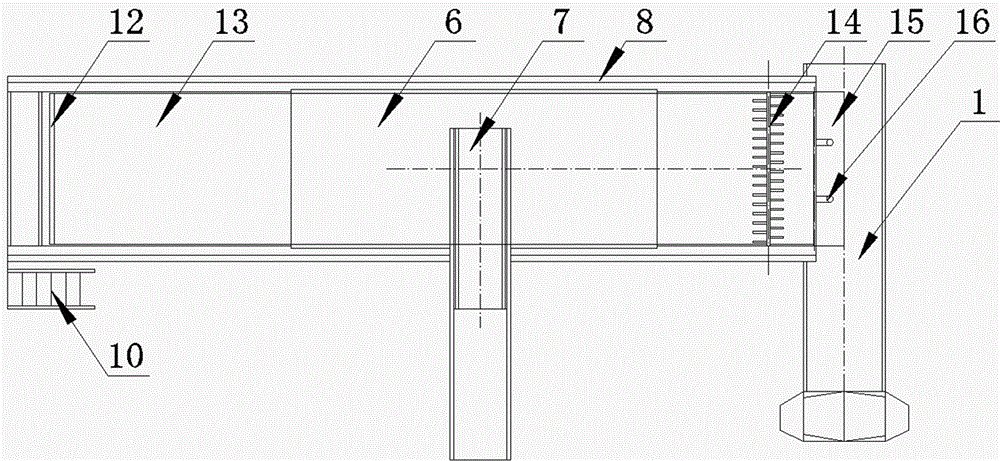

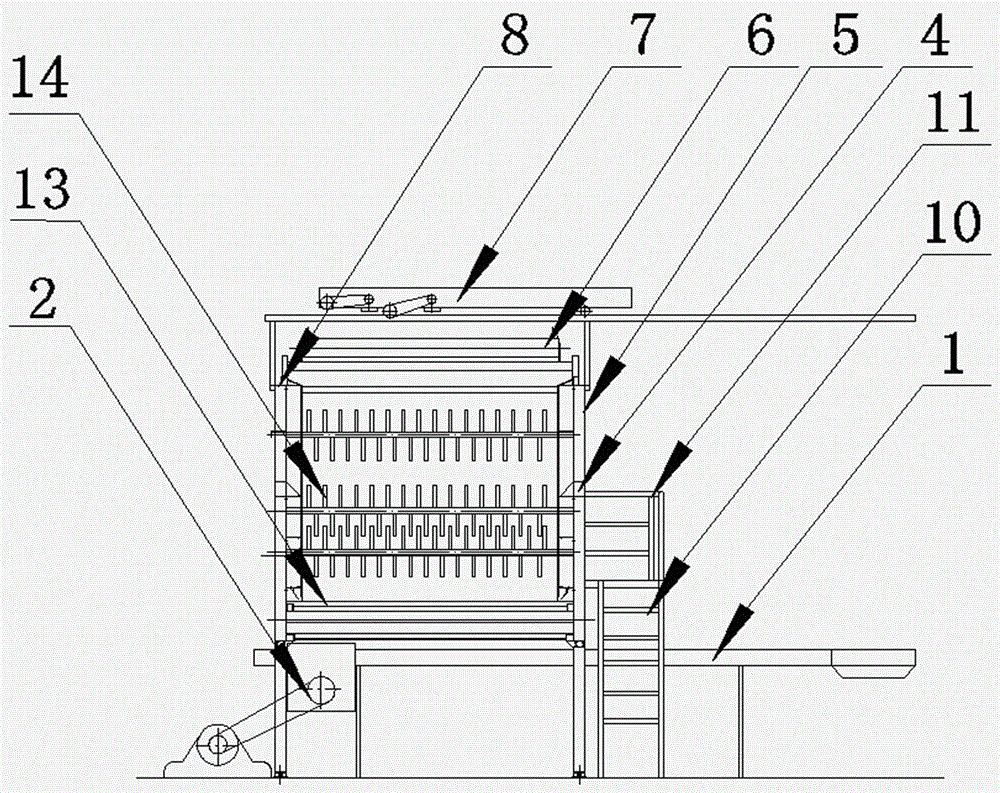

Tea blending and egualizing machine

InactiveCN106070768ASimple structureEasy to operatePre-extraction tea treatmentAgricultural engineeringLarge size

The invention discloses a tea blending and egualizing machine. The tea blending and egualizing machine is provided with a discharging conveyor, a speed reduction motor traction device, a box, a material distributing crane, a feeding crane, crane guide rails, a pile opening conveyor, an overhaul stair, a polling platform, a pile opening baffle, a pile opening conveying belt, a tea raking device and a discharging bin door. The tea blending and egualizing machine is high in mechanization and automation degree, easy to operate, easy to maintain and repair and high in production efficiency, in the refining processing process of tea, the tea in different batches can be blended, egulaized and mixed uniformly, the uniform egualizing effect is good, and practical devices from a small size to a large size can be manufactured to meet various productivity requirements.

Owner:福建茶叶进出口有限责任公司

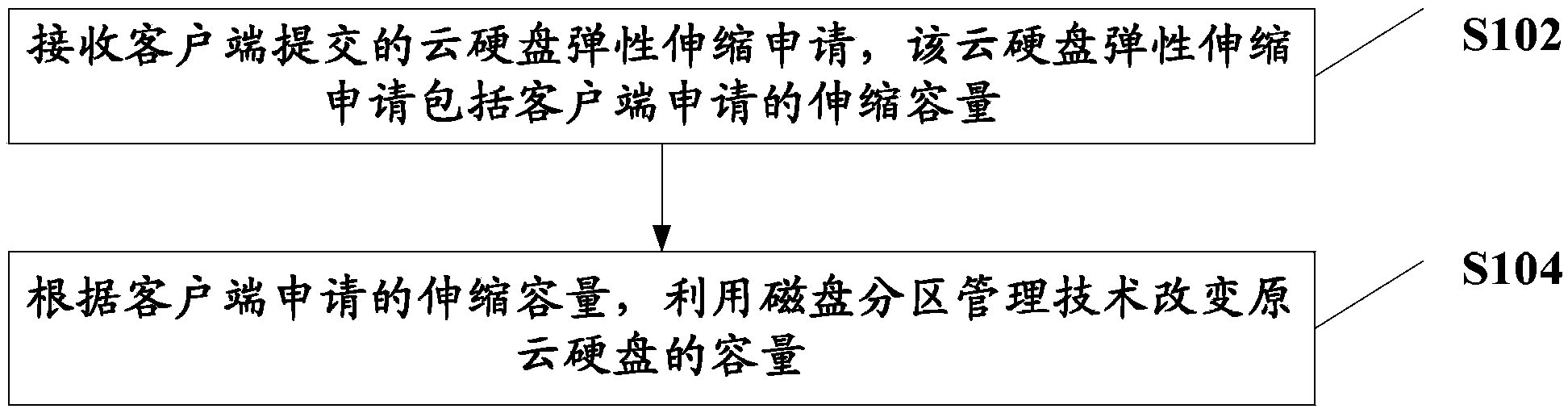

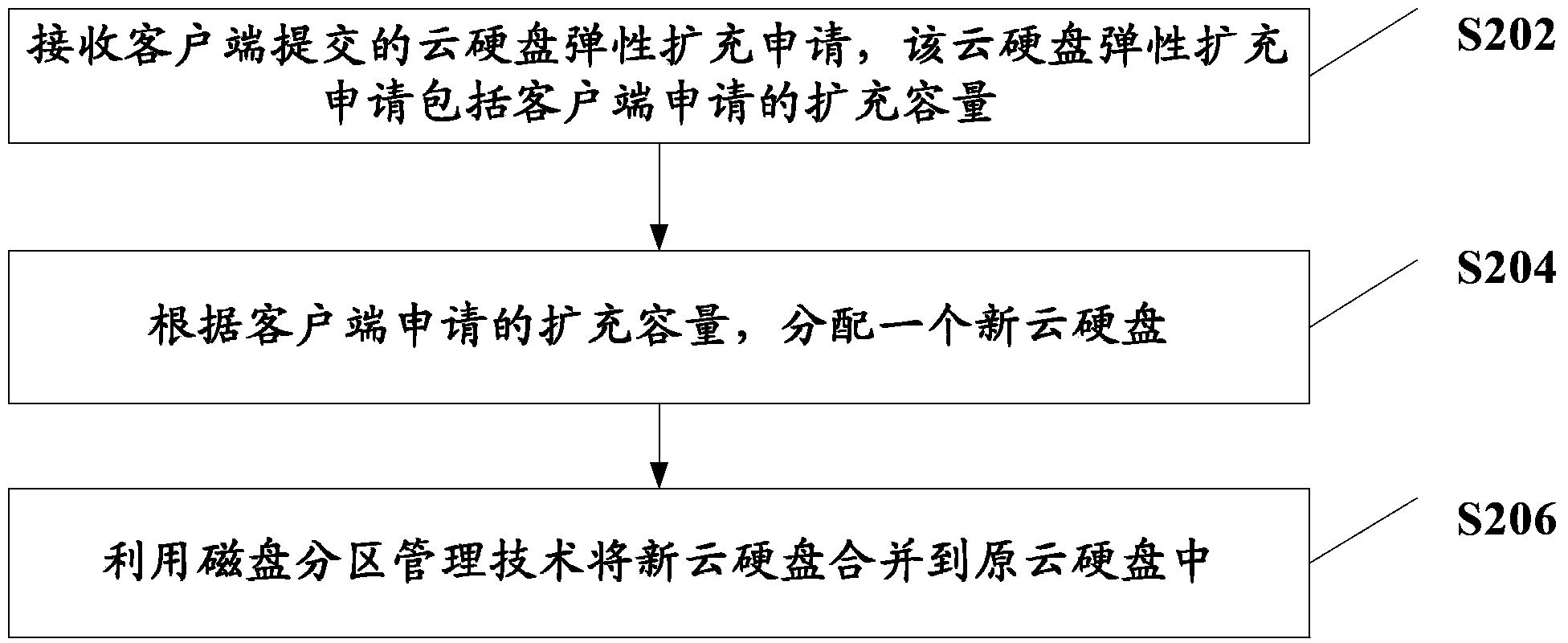

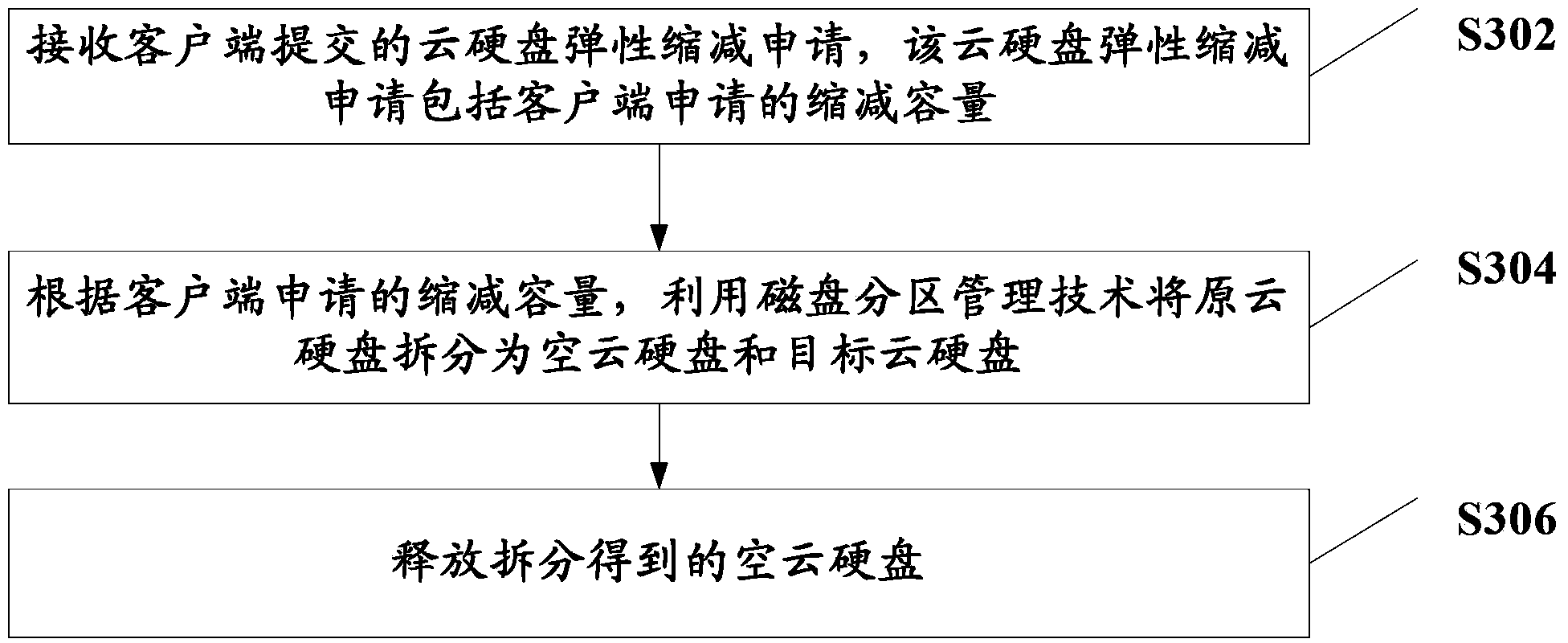

Cloud drive capacity expansion method and cloud drive capacity expansion device

The invention discloses a cloud drive capacity expansion method and a cloud drive capacity expansion device and relates to the technical field of cloud computing. The method comprises the following steps: a cloud drive flexibility expansion application submitted by a client is received, wherein the cloud drive flexibility expansion application includes expansion capacity applied by the client; and the capacity of an original cloud drive is changed with the use of a disk partition management technology according to the expansion capacity applied by the client. Through the scheme, the capacity of the original cloud drive is changed with the use of the disk partition management technology according to the expansion capacity applied by the client so that one cloud drive can meet capacity requirements of customers and convenience is provided for customers in disk management and using.

Owner:CHINA TELECOM CORP LTD

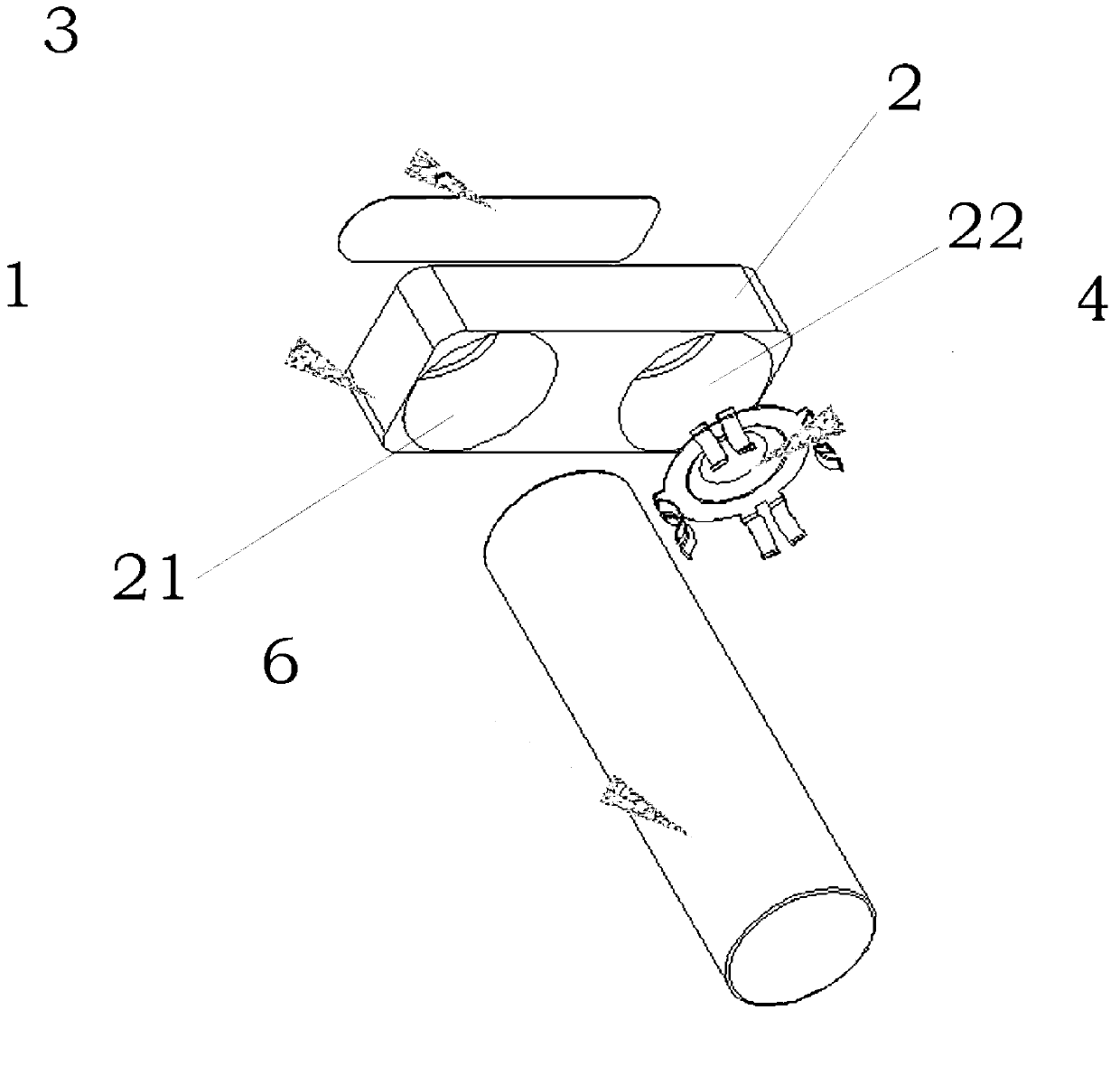

Battery connecting device and battery component using battery connecting device

InactiveCN103280548AEasy to assembleMeet the voltageCell component detailsElectrical connectionElectrical bonding

The invention provides a battery connecting device, which is used for connection of many battery monomers, and the apparatus comprises a connecting block prepared by insulating material and installed on the terminal of the battery monomer and a conducting strip for electric connection. The invention has the advantages of compact structure and convenient connection, thereby each monomer battery is connected in series or in parallel connection on the same plane with series-parallel flexibility and free degrees of space arrangement, and the welding connection between electrodes and the assembly fixation between batteries of the assembled battery composed by connection are not needed. The invention not only can be operated conveniently, safely and reliably, but also can be combined at will for realizing circumferential serial connection and series-parallel and parallel electrical connection structures, and satisfying voltage and capacity demands of various storage batteries and batteries.

Owner:SUZHOU ANKAO ENERGY

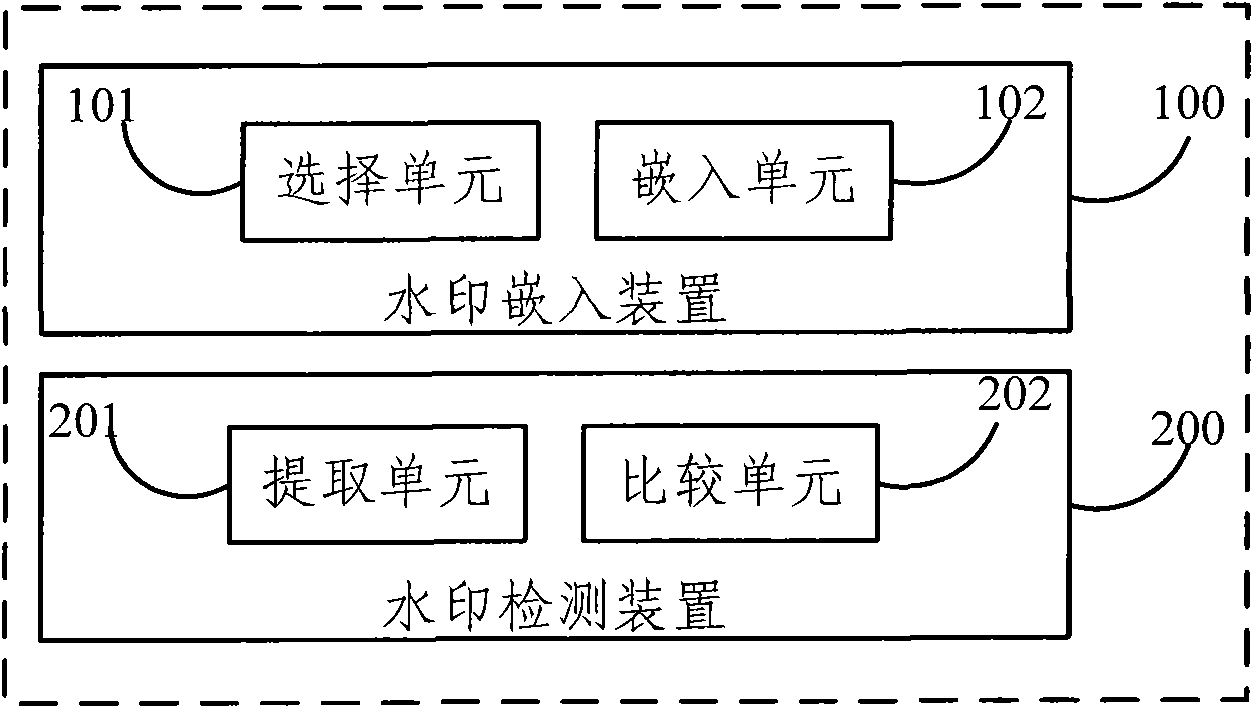

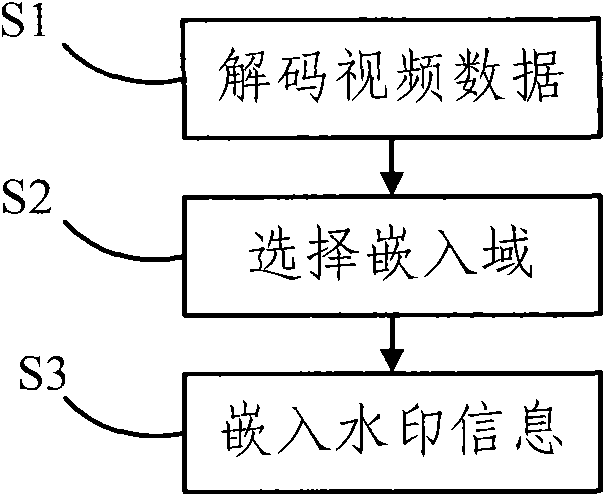

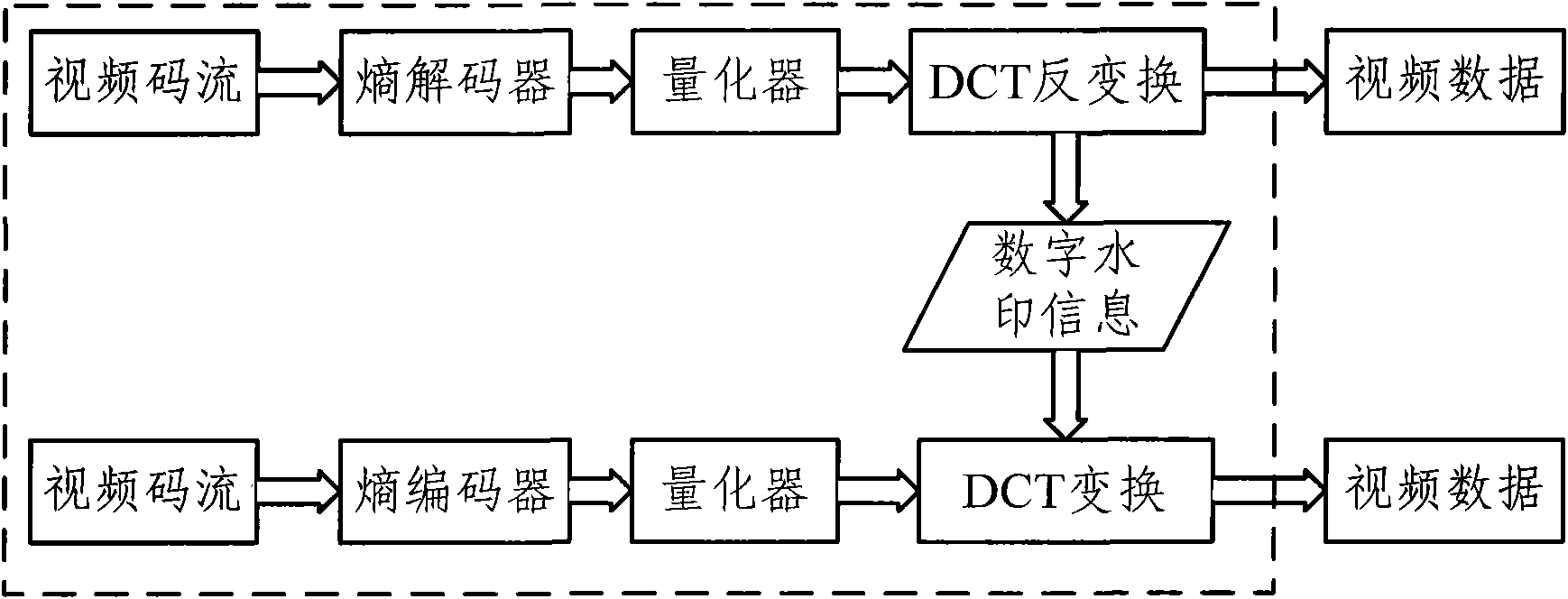

Video digital watermark embedding and detecting system based on DCT (Discrete Cosine Transformation) domain and method thereof

InactiveCN101808241ACannot be easily crackedDoes not affect playback rateTelevision system detailsColor television detailsDigital videoDiscrete cosine transform

The invention relates to a video digital watermark embedding and detecting system based on a DCT (Discrete Cosine Transformation) domain and a method thereof. The system comprises a watermark embedding device and a watermark detecting device, wherein the watermark embedding device comprises a selecting unit for selecting an embedding domain and an embedding unit for embedding legal watermark information in the embedding domain; and the watermark detecting device comprises an extracting unit for detecting and extracting the watermark information of video data to be detected and a comparing unit for identifying copyright information. By embedding the imperceptible watermark information in the digital video, the invention can detect and trace the copyright information contained in the digital video, ensures that the protected digital media content is not randomly reproduced and spread, protects digital media content suppliers and the whole industry chain, and overcomes the existing defects in the prior art.

Owner:北京金石威视科技发展有限公司

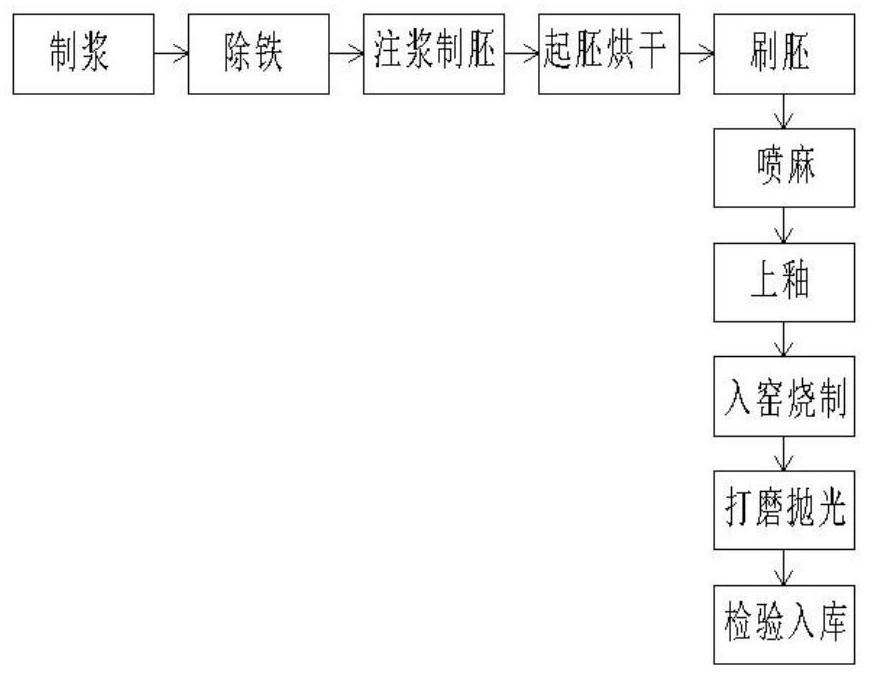

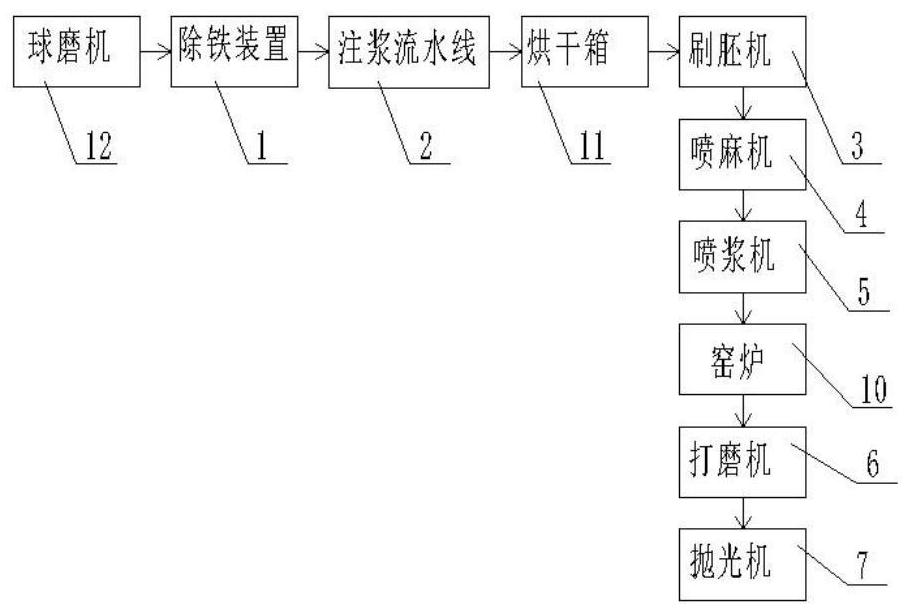

Ceramic hand mold production equipment and technology thereof

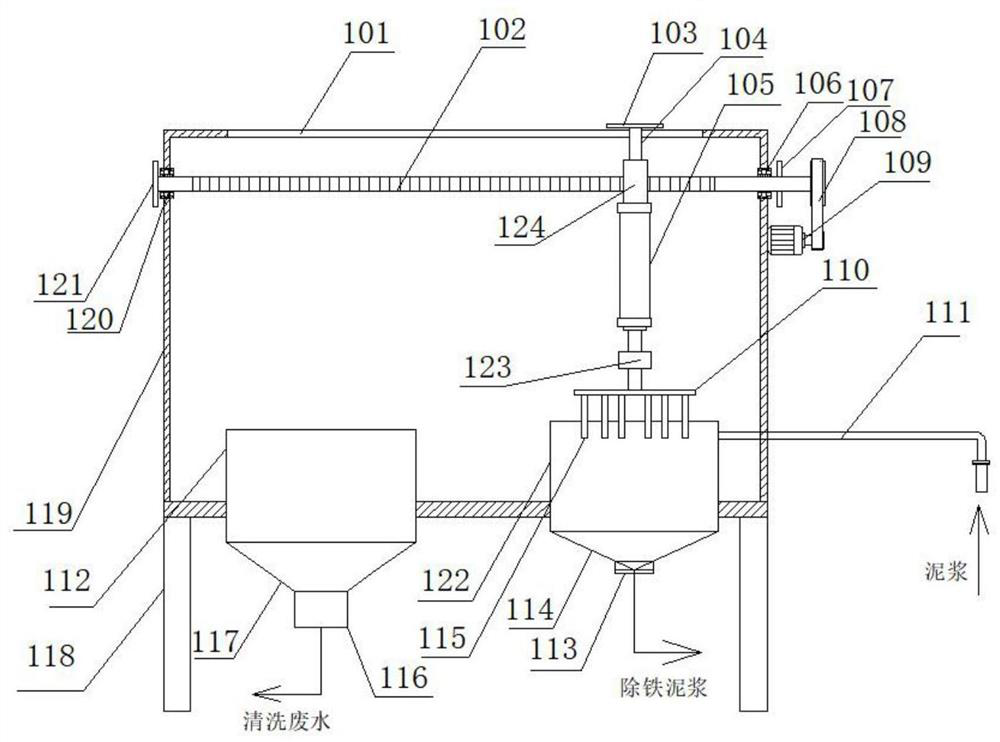

ActiveCN112454641AShorten drying timeImprove brushing efficiencyEdge grinding machinesPolishing machinesIron removalAssembly line

The invention relates to ceramic hand mold production equipment and a technology thereof, and belongs to the technical field of ceramic hand mold production. The equipment comprises an automatic grouting assembly line, a ball mill, an iron removal device, a drying box, a blank brushing machine, a hemp spraying machine, a pulp spraying machine, a kiln, a grinding machine and a polishing machine. The technology comprises the following steps of pulping, iron removal, blank forming and drying, blank brushing, hemp spraying, glazing, firing in the kiln, grinding and polishing. According to the technology, drying is conducted through a dryer after slip casting, the drying time is shortened, the blank brushing procedure is conducted after drying, mechanical rough brushing and manual fine brushingare conducted during blank brushing, the defects such as joint closing, pores, impurities and the like on the surface of a semi-finished blank hand mold are brushed away through a sponge, and the effect that the whole surface is smooth, tidy and flawless is achieved; in addition, the hemp beating procedure and the pulp spraying procedure are added, the technology is applicable to production of pitted surface hand molds, the fired hand molds are subjected to surface micro-grinding treatment through a porcelain ball mill hand machine, and then surface overall polishing is conducted through a cloth wheel polishing machine, so that the product quality is better.

Owner:淄博昊祥模具科技有限公司

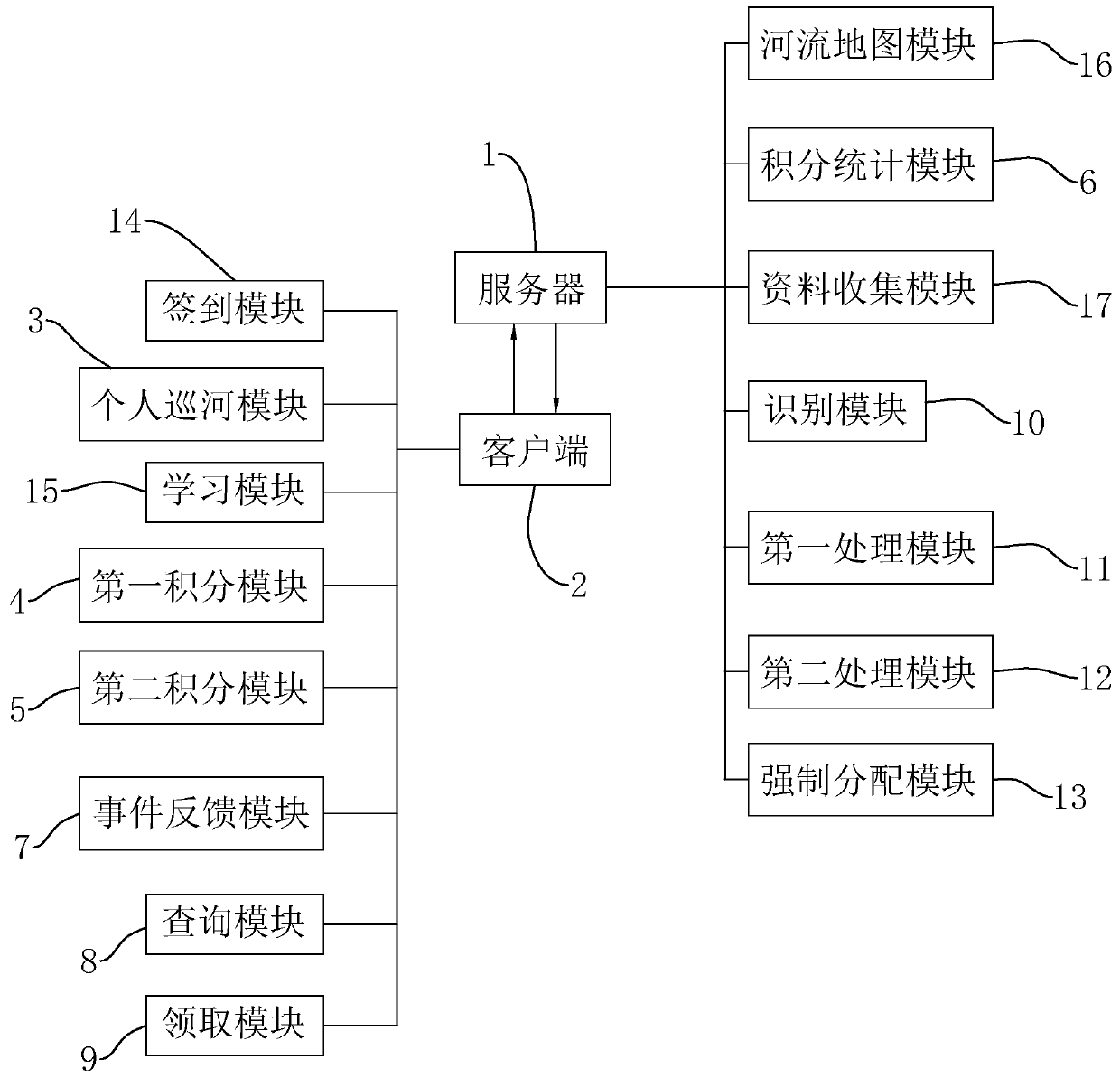

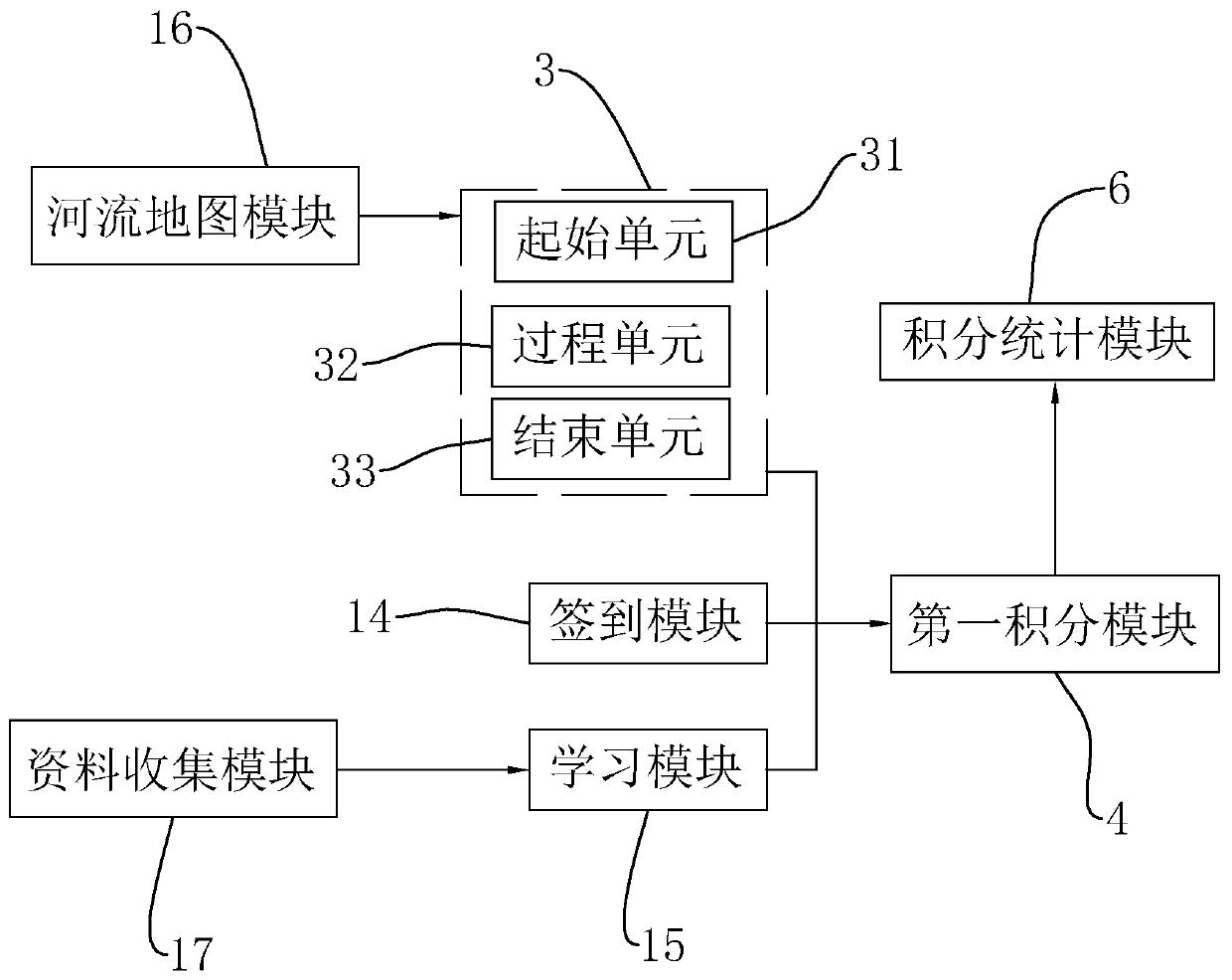

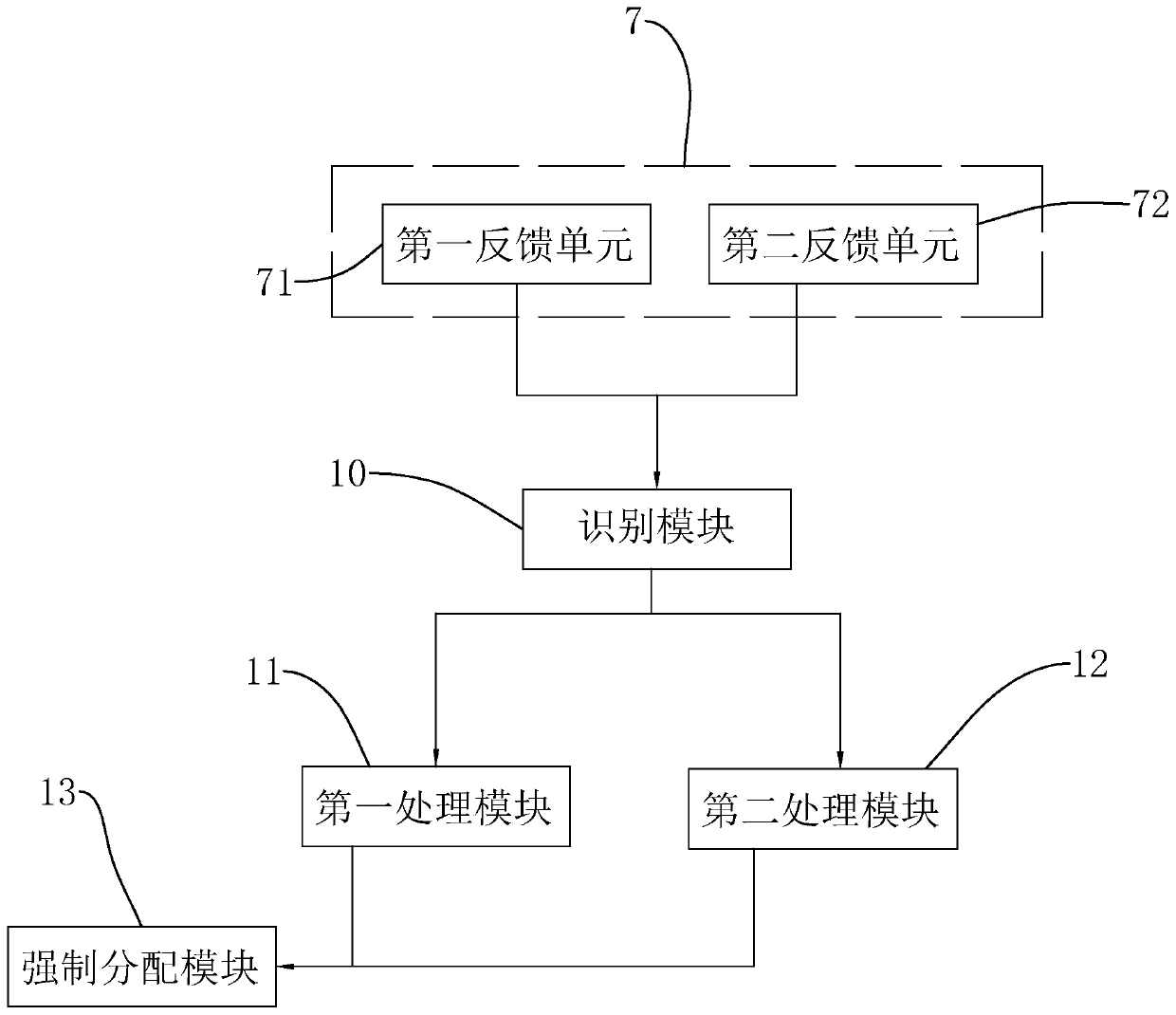

River leader system integral statistical assessment system

PendingCN111598463AReduce participationReduce workloadOffice automationResourcesAgricultural scienceAgricultural engineering

The invention relates to a river leader system integral statistical assessment system. The river leader system integral statistical assessment system comprises a client, wherein the client comprises astarting unit, a process unit and an ending unit; the starting unit is used for comparing the current geographic position information of the client with the starting point in response to the touch operation of the client, and if the current geographic position information of the client is located in the starting point, the current river patrol starting time is recorded and the process unit is triggered to be started; the process unit is used for recording the current geographic position and time of the client at set intervals; and the ending unit is used for comparing the current geographic position information of the client with an ending point in response to the touch operation of the client, and recording the current river patrol ending time and closing the process unit if the currentgeographic position information is located in the ending point. Through interaction between the river patrol personnel and the client, a personal river patrol module is used for identifying whether the river patrol personnel carry out river patrol work in a specified place or not, so that the workload of management personnel is greatly reduced, and the management mode of daily work of the river patrol personnel is optimized.

Owner:浙江职信通信科技有限公司

Pretreatment production process of large-specification steel wire for copper-clad steel cladding

InactiveCN109396200AEven by forceUniform and fine roughnessExtrusion cleaning devicesEnvironmental resistanceDecomposition

The invention discloses a pretreatment production process of a large-specification steel wire for copper-clad steel cladding. The pretreatment production process sequentially comprises the following steps: mechanical shucking, abrasive belt grinding, horizontal wiredrawing, paying off, tubular ammonia decomposition tempering degreasing, cooling, fully-closed acid pickling, four-stage back flushing, drying and winding up. The problems that as for treatment by a traditional process, binding force between copper and steel is poor, the thicknesses of the exposed steel and a copper layer are uneven, and acid mist pollution exists are solved, and according to the pretreatment process of the large-specification steel wire, the production process is environmentally friendly, the surface of the steel wire is bright, clean and rounding, in the subsequent cladding process, continuous production is achieved, and thus the steel wire and a copper strip are metallurgically bonded.

Owner:ZHEJIANG PUJIANG BAICHUAN IND

Glass turnover device

PendingCN111377220ASolve flipIncrease productivityCharge manipulationConveyor partsPhysicsElectric machinery

The invention provides a glass turnover device. The glass turnover device comprises a conveying system, a turnover system and a lifting system, wherein the conveying system comprises a servo conveyingmotor, an upper conveying device and a lower conveying device, the upper conveying device and the lower conveying device are connected in parallel up and down through an adjustable connecting plate,the upper conveying device and the lower conveying device are provided with conveying belts and suction cup assemblies, each conveying belt is provided with multiple suction cup assemblies used for sucking or releasing glass, and the servo conveying motor conveys the glass by controlling the conveying belts; the turnover system comprises a servo gear motor and a turnover assembly, the turnover assembly is in shaft connection with the conveying system, and the servo gear motor turns over the conveying system by controlling the turnover assembly; and the lifting system comprises a servo liftingmotor, lifting tables and a lifting transmission assembly, the lifting tables are arranged on the two sides of the conveying system, and the servo lifting motor adjusts the distance between the initial position of the conveying system and the working position of the conveying system through the lifting transmission assembly. The glass turnover device has the beneficial effects that the capacity requirement is met, and the glass production efficiency is improved.

Owner:CHINA TRIUMPH INT ENG

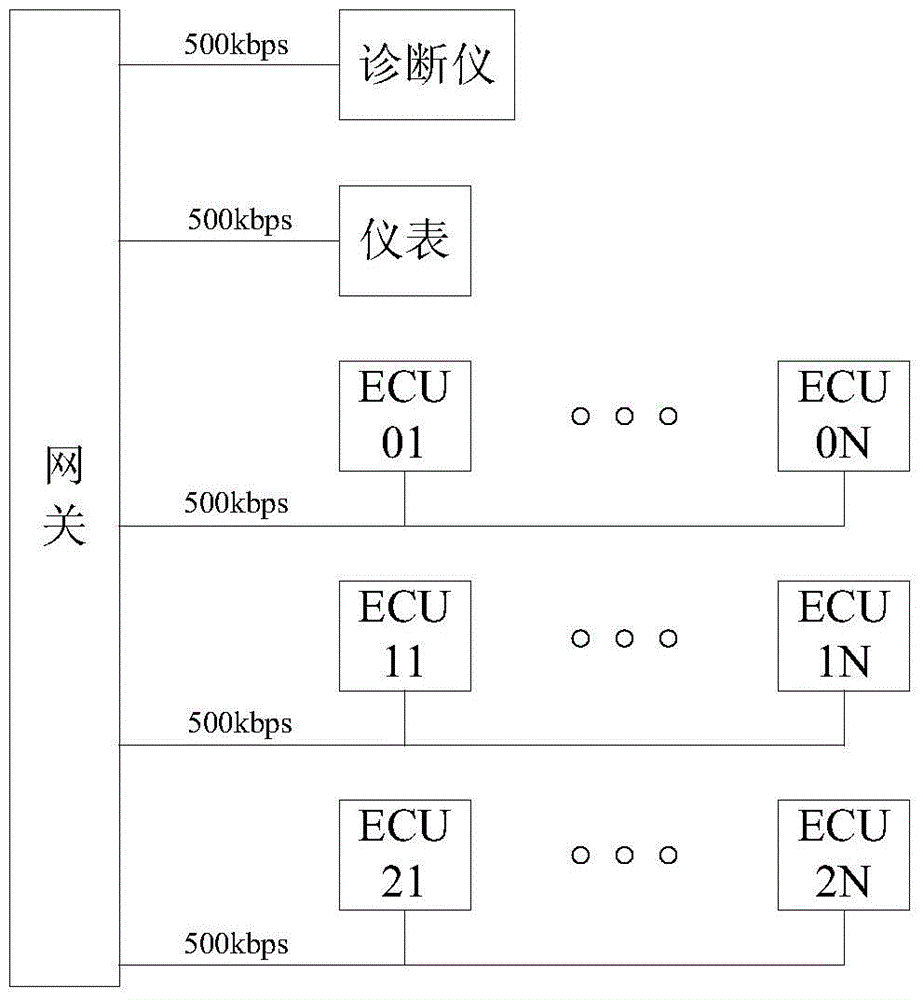

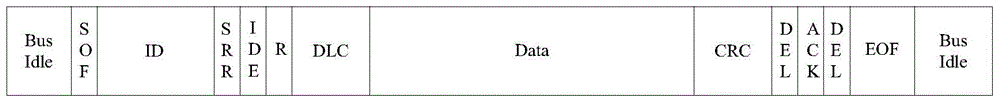

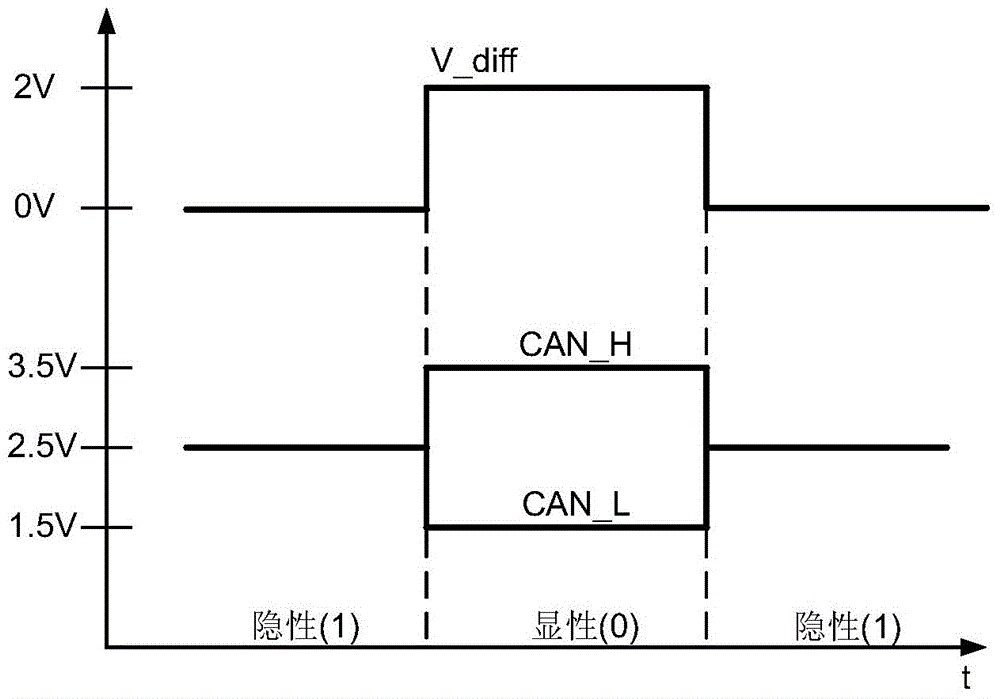

Method of improving transmission rate of CAN network in automobile and system

ActiveCN104869146AIncrease transfer rateAnd increased bandwidthTransmissionTransmission delayTransmission rate

The embodiment of the invention provides a method of improving a transmission rate of a CAN network in an automobile and a system. The method mainly comprises steps: level corresponding to a data field of standard frames of the CAN network is expanded through a CAN network driving circuit in the automobile to enable each one in the data frame of standard frames of the CAN network to express at least two-bit data; and the data are transmitted through the expanded CAN network standard frame. According to the embodiment of the invention, through expanding the level of the data field of the standard frames of the CAN network in the automobile, each one in the data frame of standard frames of the CAN network transmits two-bit data, capacity of effective data can be effectively expanded on the basis of not influencing the prior bus structure, the transmission rate and the bandwidth of the standard frames of the CAN network are doubled, and requirements of the prior functions on the network capacity can be met.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

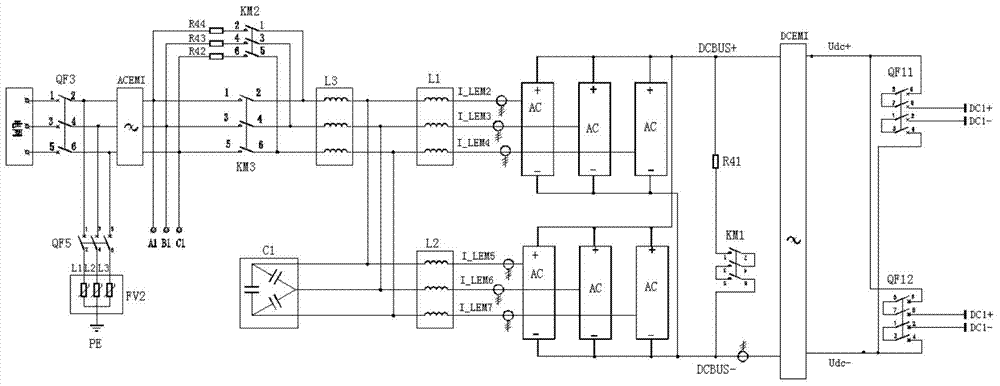

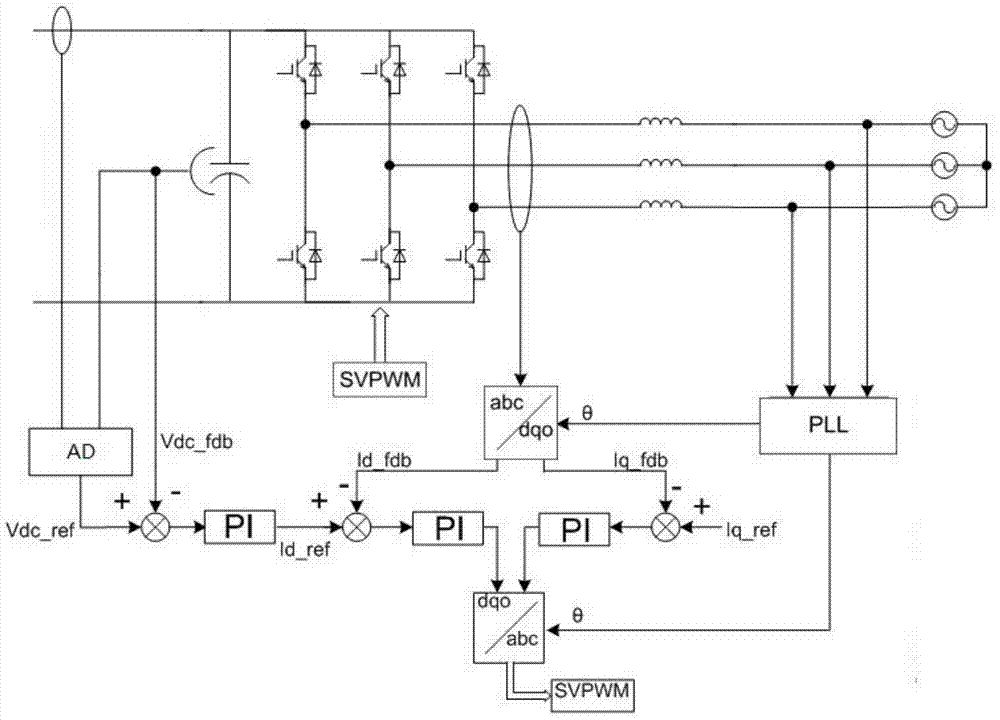

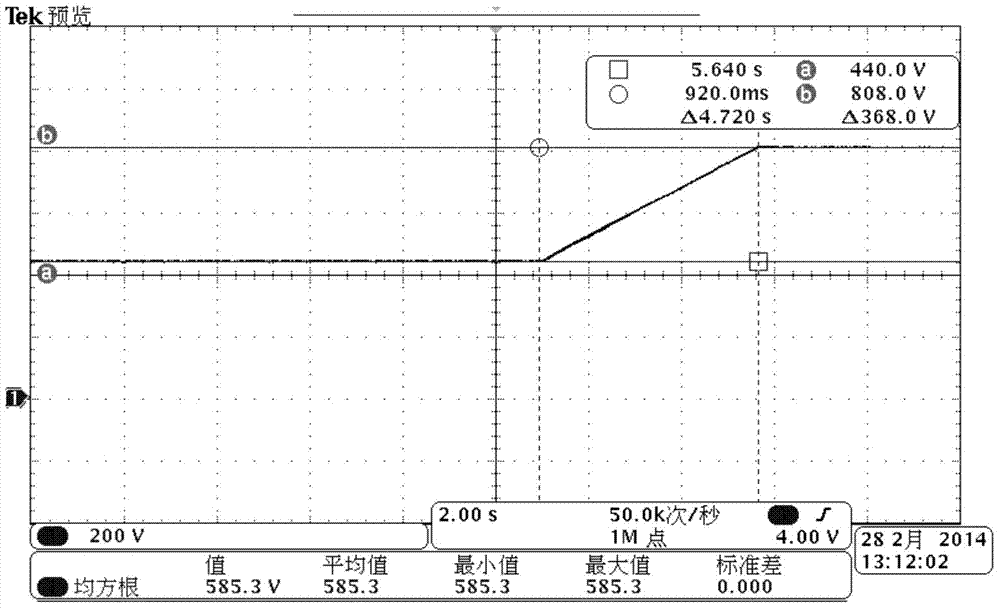

High-power DC source used for testing of photovoltaic grid-connected inverter

InactiveCN104333242AMeet testing needsWaveform is smooth and stableAc-dc conversionAc-ac conversionVoltage overshootGrid connected inverter

The invention discloses a high-power DC source used for testing of a photovoltaic grid-connected inverter. Two sets of parallel-connected three-phase full-bridge controllable rectification circuits are adopted so that input voltage range is wider, adaptability is higher, high-power DC can be outputted, level of the outputted DC voltage can be adjusted according to test requirements, and output power can meet the capacity requirement of domestic inverters. The outputted DC voltage is smooth and stable in waveform and common mode voltage to the ground is low. DC voltage response time is short, voltage build-up rate is 80V / s, impact to equipment is low and voltage overshoot amount is 0V so that the tested equipment is ensured to be safe and reliable. DC output adopts parallel-connected output of two paths of DC800A circuit breakers so that DC allowance is high, and a tripping phenomenon does not occur when the tested inverter is overloaded for 1.1 times.

Owner:XJ ELECTRIC

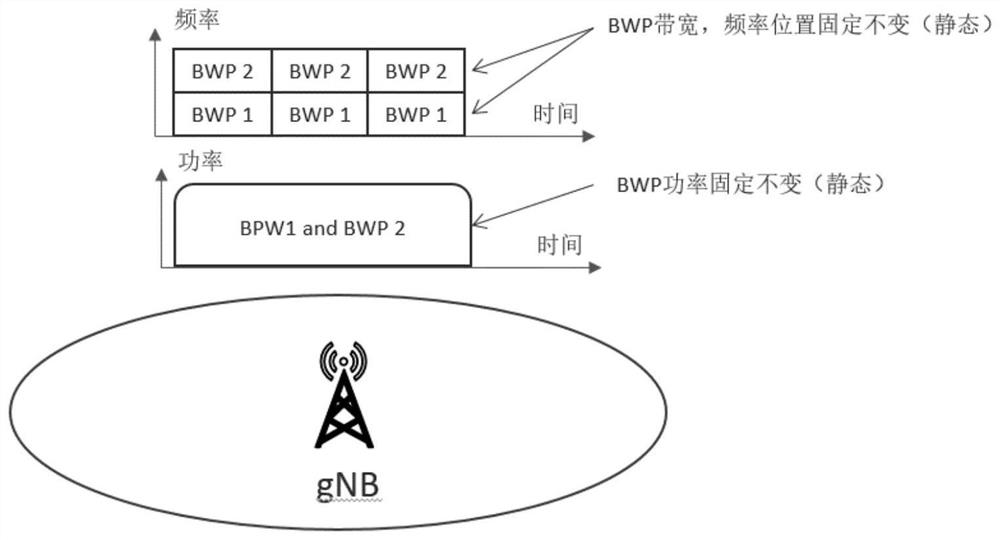

BWP distribution method and device, electronic equipment and computer readable storage medium

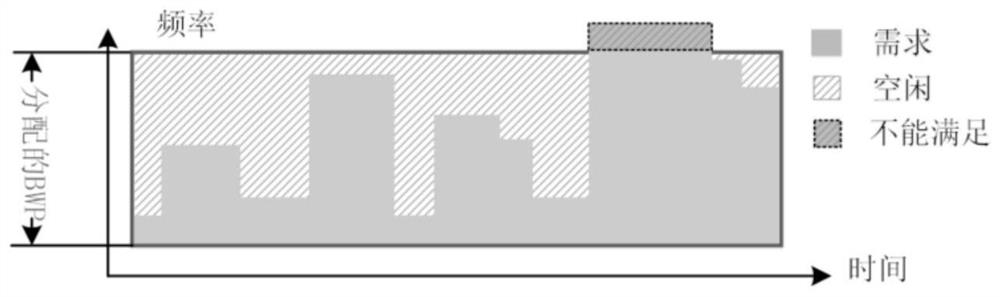

PendingCN114007225AMeet capacity needsImprove throughputPower managementNetwork planningDistribution methodEnergy consumption

The embodiment of the invention provides a BWP distribution method and device, electronic equipment and a computer readable storage medium, and relates to the technical field of communication. The method comprises the following steps: acquiring service related information of at least one base station; determining configuration information of the BWP of the at least one base station based on the service related information of the at least one base station; and configuring the BWP of the at least one base station according to the configuration information. According to the BWP allocation method, the requirements of different services and different user capabilities can be met, the throughput of the network is improved, and the energy consumption is reduced.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com