Battery module, battery module group and battery module group packaging method

A battery module and battery module technology, applied in the field of power supply, can solve the problems of reduced battery consistency, low battery compaction, and high cost, improve work efficiency and service life, save packaging process time and cost, and achieve heat soaking. The effect of strong heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose and features of the present invention more comprehensible, the specific embodiments of the present invention will be further described below with reference to the accompanying drawings. However, the present invention can be implemented in different forms and should not be limited to the described embodiments.

[0037] Hereinafter, a battery module and a battery module composed of the battery module provided by the embodiments of the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

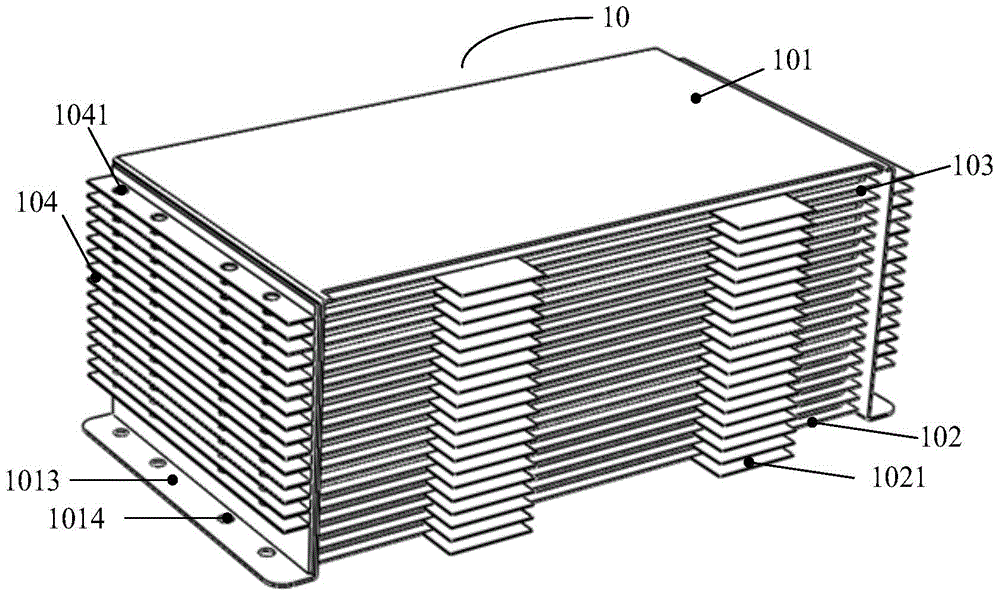

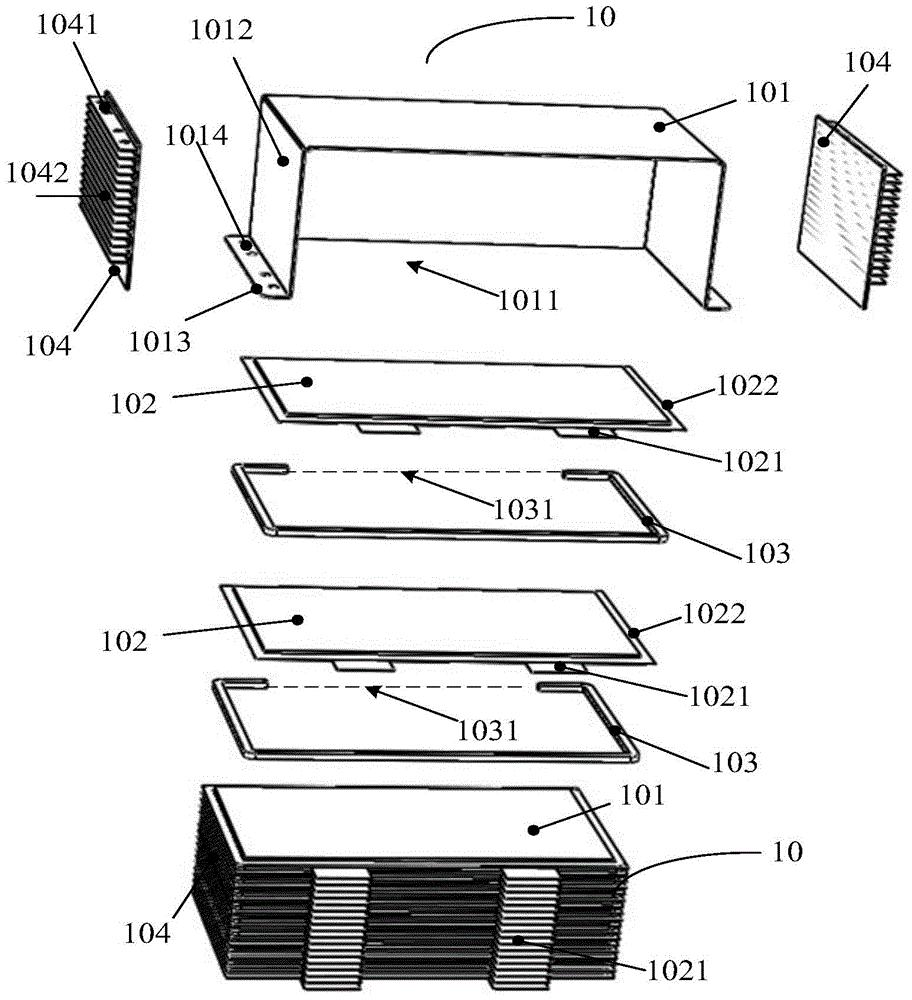

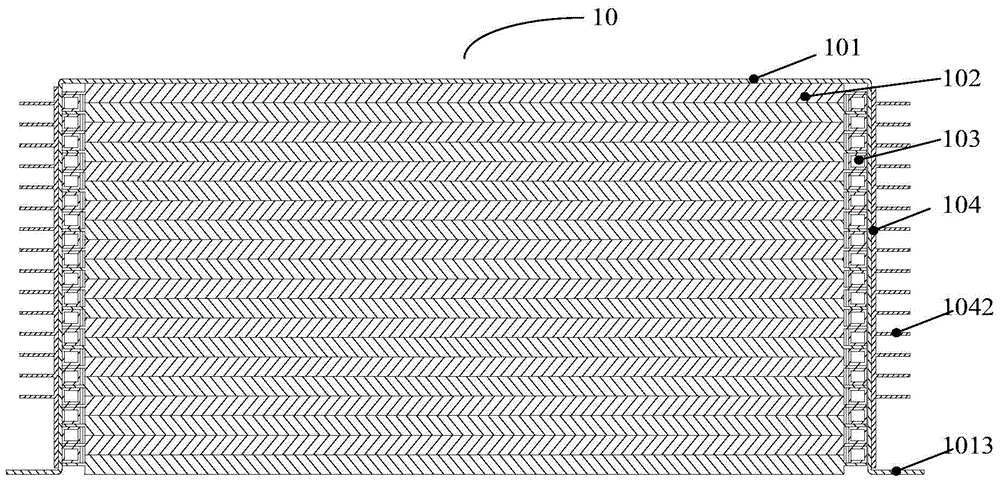

[0038] Please refer to Figure 1 to Figure 3 , The present invention provides a battery module 10, including: a housing 101 with a accommodating cavity, a heat dissipation plate 104 fixed on the outside of the accommodating cavity, and a plurality of battery cells placed in the accommodating cavity 102 and a plurality of non-closed annular heat pipes 10 (heat pipes) 3 with gaps 1031; the plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com