Ceramic hand mold production equipment and technology thereof

A technology of production equipment and hand molds, which is applied in the field of ceramic hand mold production equipment and its technology, can solve the problems of low degree of automation, poor surface treatment effect, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

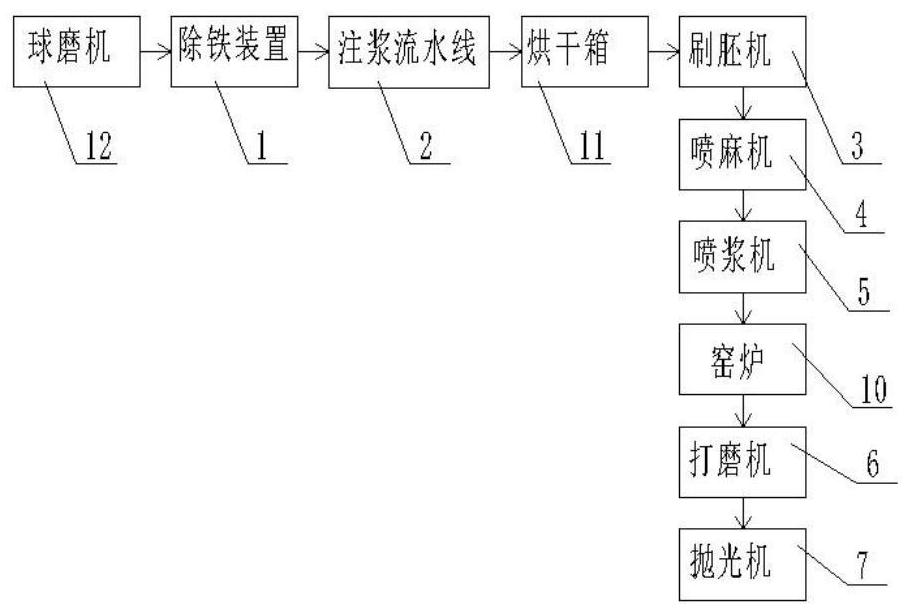

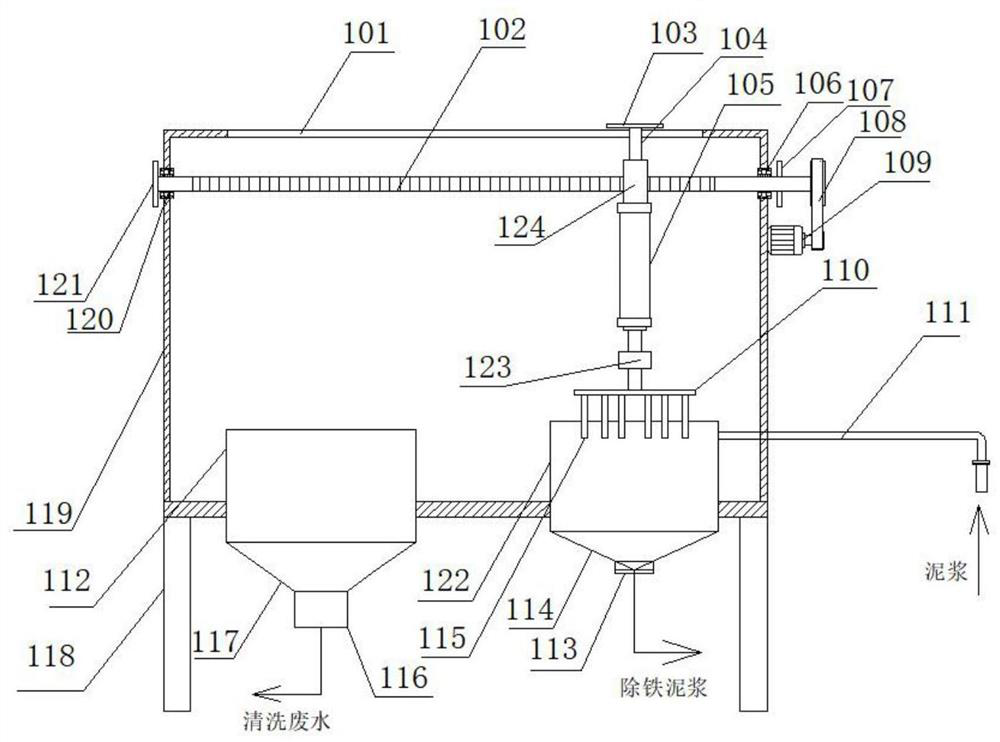

[0077]Example 1, such asFigure 2 to 32As shown, the present invention is a ceramic hand mold production apparatus, including an automatic grouting pipeline 2, a ball mill 12, an iron apparatus 1, a drying box 11, a brush, a blasting, a mass, a slurry machine 5, a kiln 10, the grinding machine 6 and the polishing machine 7, the outlet of the ball mill 12 is connected to the inlet of the iron machine by the diaphragm pump, and the exit of the iron apparatus 1 is connected to the bolus tank through the diaphragm pump, and the laminate is connected by the diaphragm pump. Inlet, the grout pipe 2 includes a first conveyor line 201 and a second conveying line 202, and one end of the first conveyor line 201 is provided with a circular wheel motor 203, and the first conveying line 201 is fixedly provided with a circle. Wiring wheel 204, the circular rotary wheel motor 203 is driven by the chain with the circular wheel 204, and one end of the second conveying line 202 is provided with a squar...

Embodiment 2

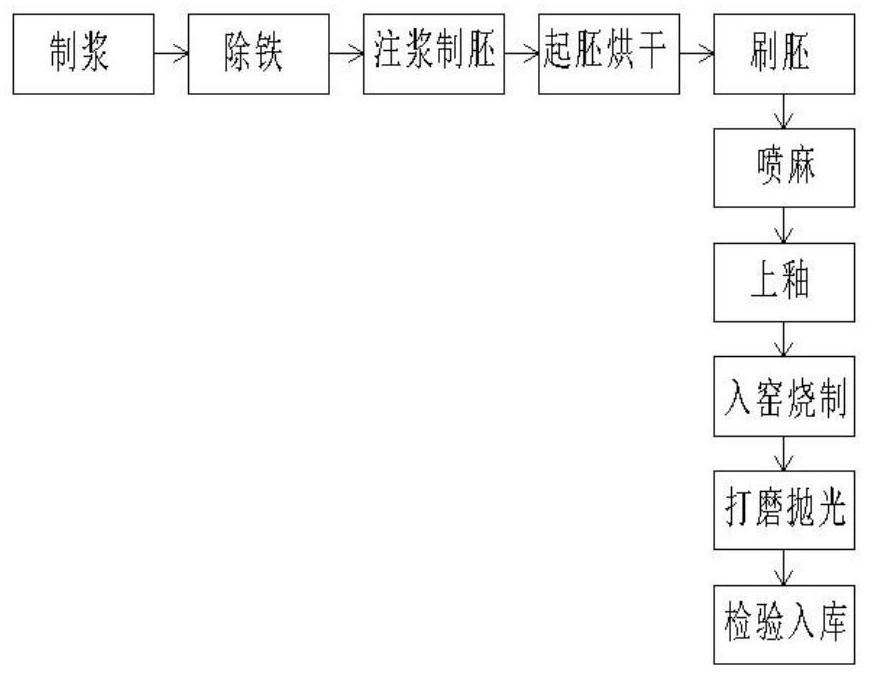

[0090]Example 2, such asfigure 1 As shown, the present invention is to produce a ceramic hand mold production process using the equipment in Example 1, including the following steps:

[0091]First, pulping, the pulping raw material is polished from the ball mill 12, making a mud;

[0092]Second, remove iron, extract the made mud to the automatic detachment machine using the diaphragm pump, and then the detachment pump is stored in the storing pool in the reservoir;

[0093]Third, grouting embryo, using diaphragm pumps into automatic grouting pipeline 2 to make ceramic hand molded embryos;

[0094]Fourth, the sucked has been dried, and the mud embryo in the hand model model is then sent to the semi-finished dry box;

[0095]V. Brush embryo, put the dried mud embryo to the brush machine, then use artificially refined, remove the joints, pores, impurities of the surface of the embryo, and then naturally dry;

[0096]Six, shiroma, put the dried pehed-filled in sandblasting and mawas;

[0097]Seven, glazed, ...

Embodiment 3

[0114]Example 3, Different from Example 2, the step one in the steps of ball mud fineness detection standards are below 10 microns, accounting for 70%, and the mud density requires 1.65g / cm3, step eight in the kiln kiln The temperature is controlled at a high temperature 1250 ° C, and the half-finished product drying box temperature control ranges from 20 to 30 ° C, and the porcelain ball diameter is 1 mm in step six.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com