Full-automatic binding machine for nylon cable binding belts

A fully automatic technology for cable ties, which is applied to the parts of strapping machinery, strapping materials, paper/cardboard containers, etc., and can solve problems such as inability to meet modern production and low bundling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

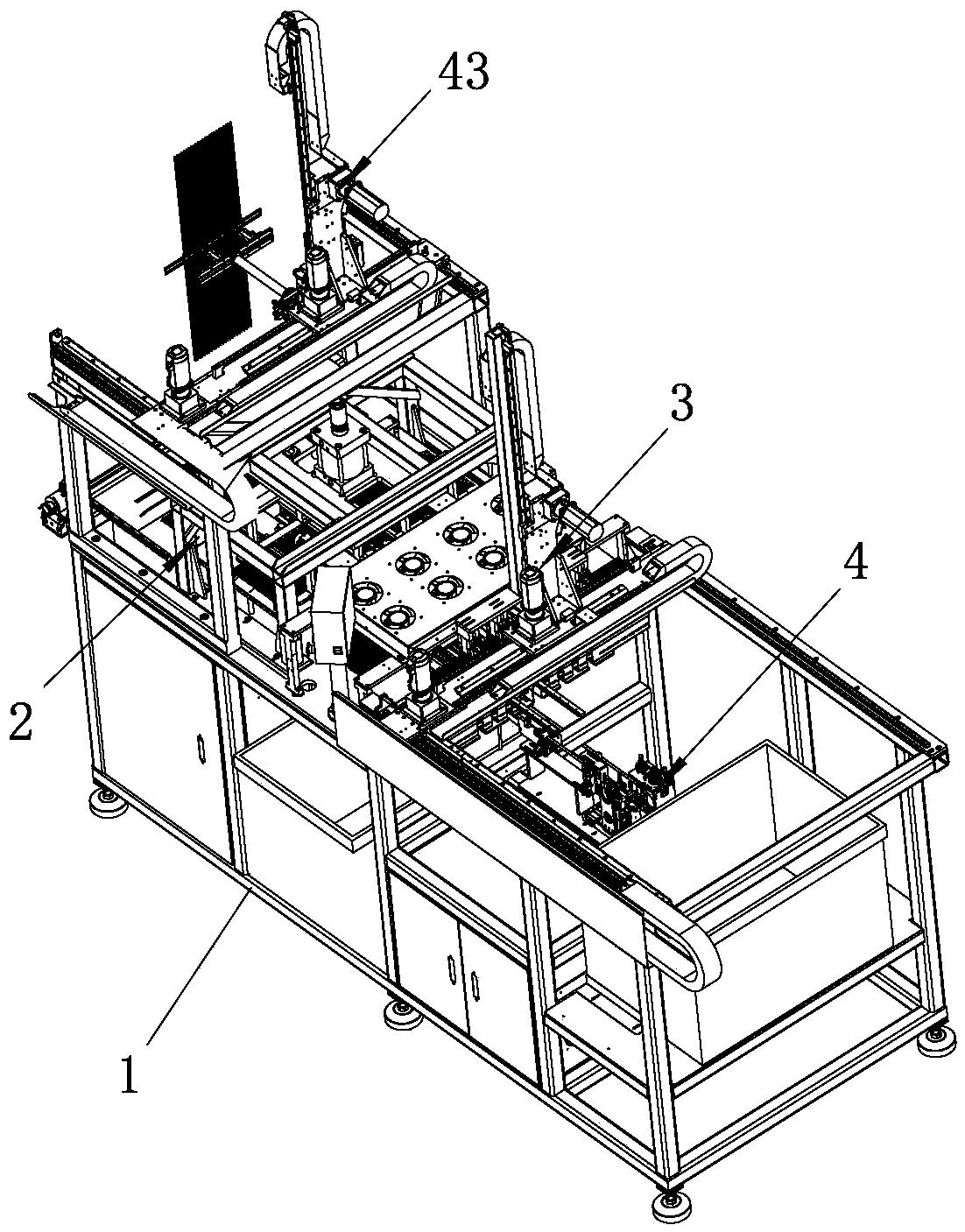

[0041] see Figure 1 to Figure 3 As shown, a kind of automatic binding machine that is used for nylon cable tie of the present invention comprises frame 1, and frame 1 adopts metal material to make, and for example, frame 1 adopts cast iron, stainless steel or aluminum alloy to make, set The finishing mechanism 2, the moving mechanism 3 and the binding mechanism 4 on the frame 1, in the present embodiment, a control box is also installed in the frame 1, and the control box is electrically connected with each mechanism, and the control box is used to regulate each Institutional operating parameters.

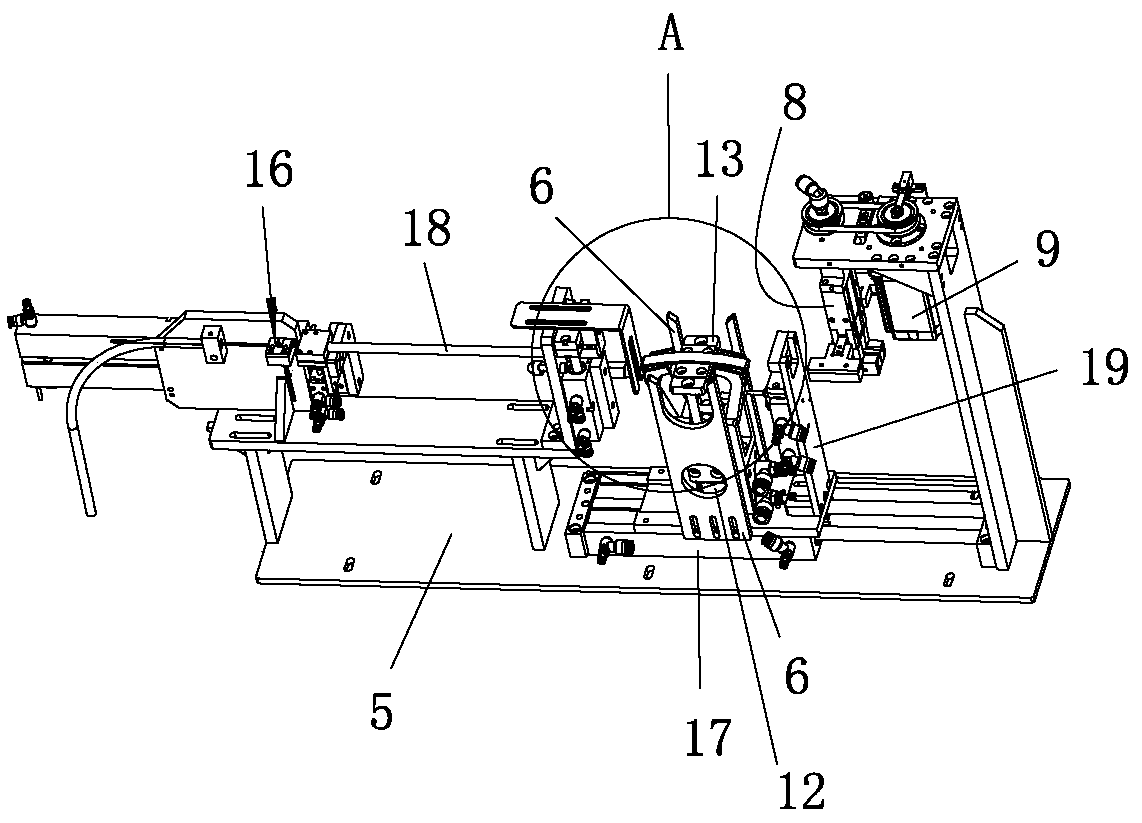

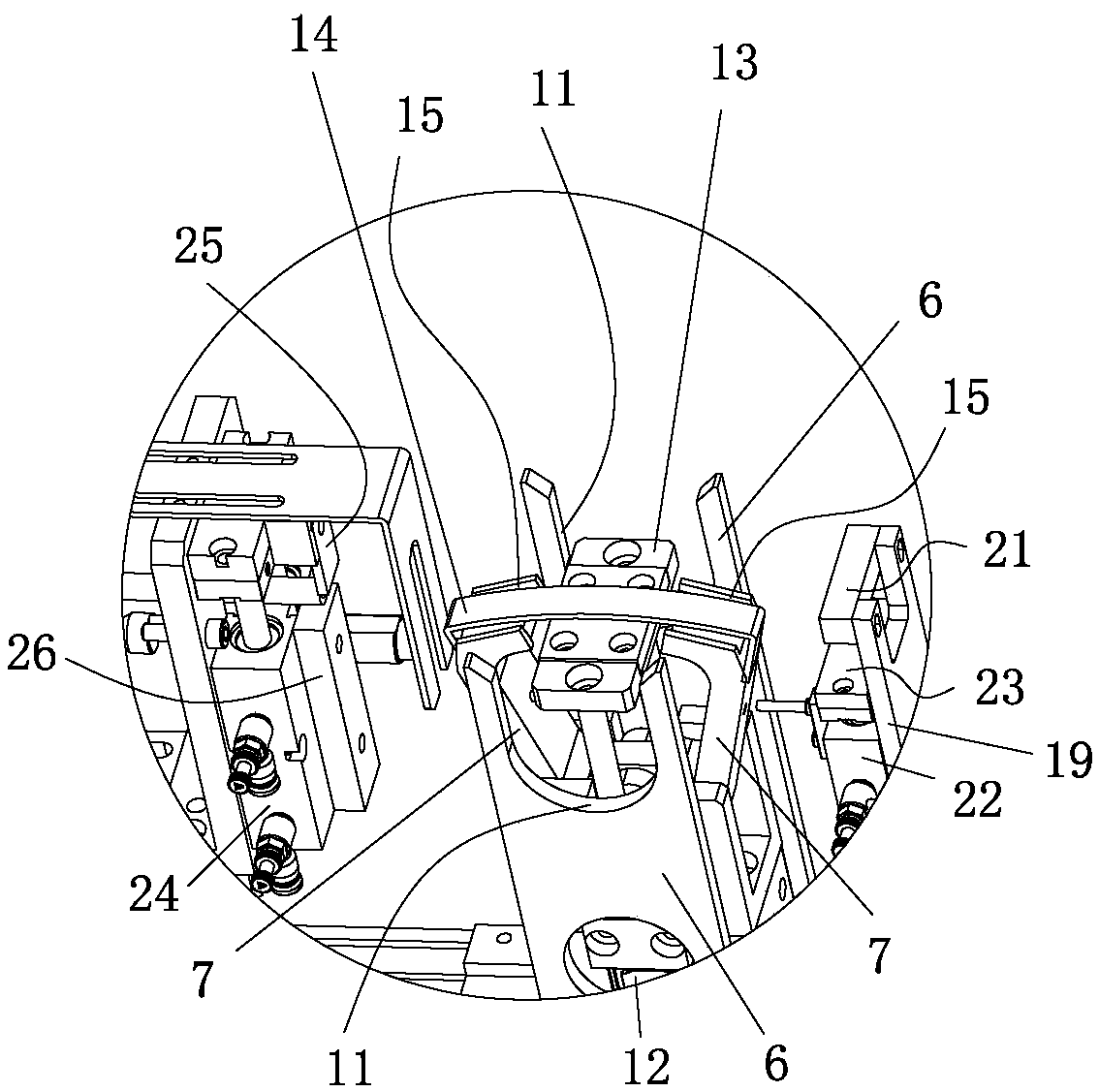

[0042] The binding mechanism 4 includes a first support 5 installed on the frame 1, two binding support plates 6 arranged on the first support 5, the two binding support plates 6 are spaced from each other and arranged in parallel, and are located between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com