Full-automatic multifunctional bander

A multi-functional, baler technology, applied in packaging, agricultural machinery and implements, applications, etc., can solve the problems of time-consuming and laborious results, waste of manpower and material resources, etc., to achieve strong applicability, easy transportation and loading and unloading, and achieve high-precision straight lines the effect of exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

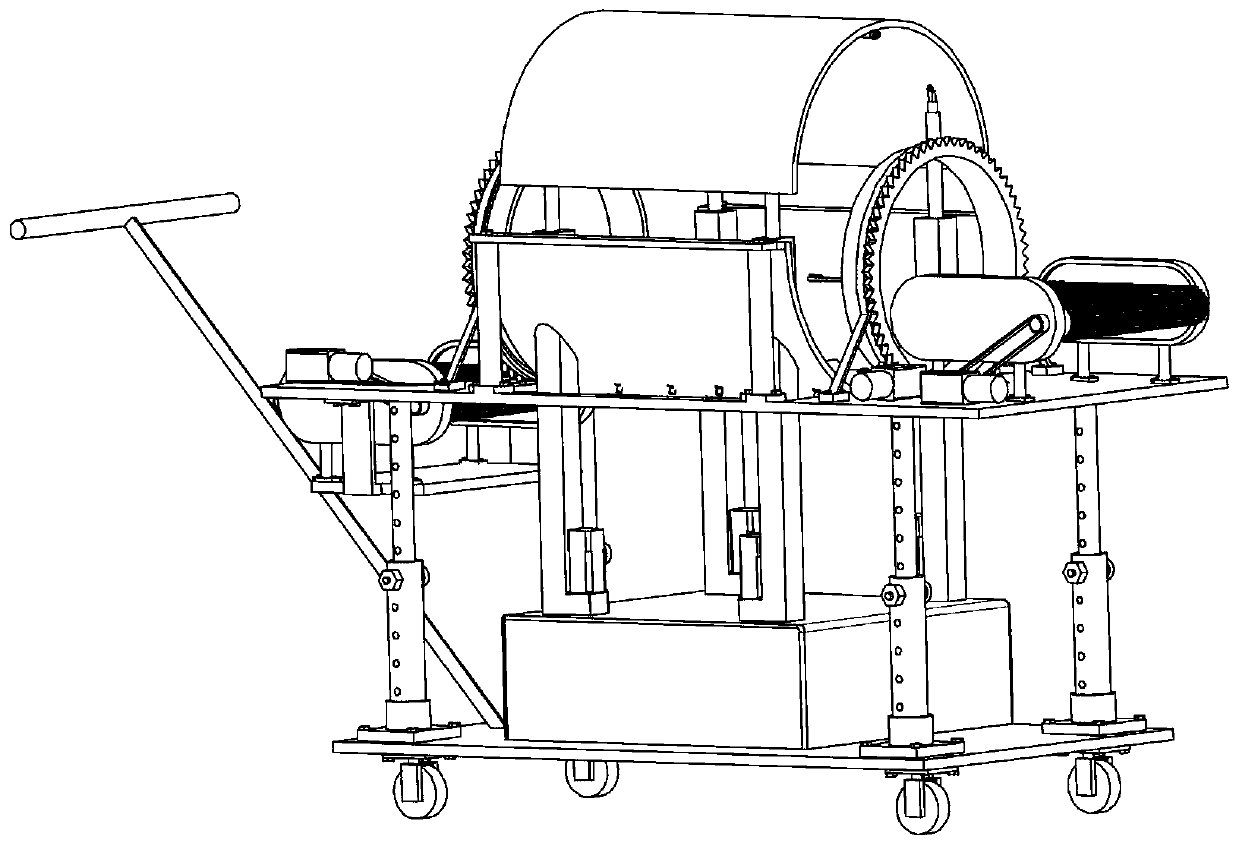

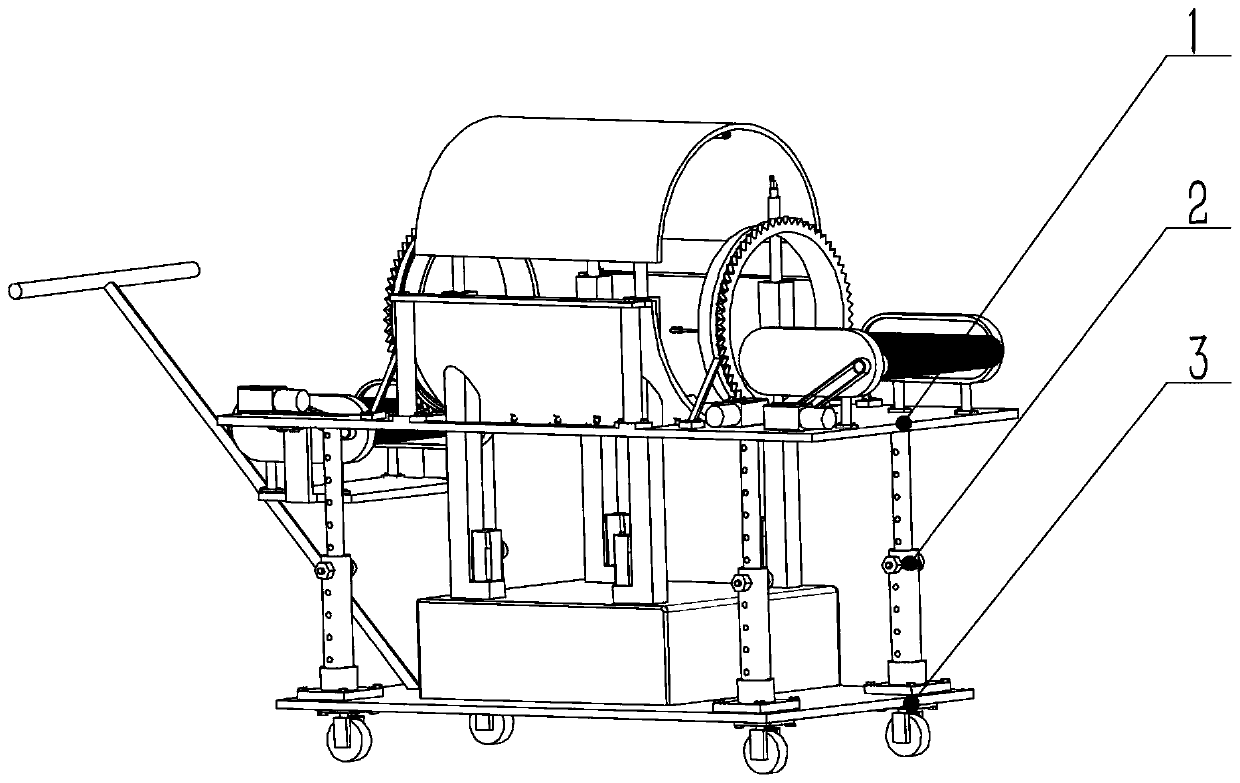

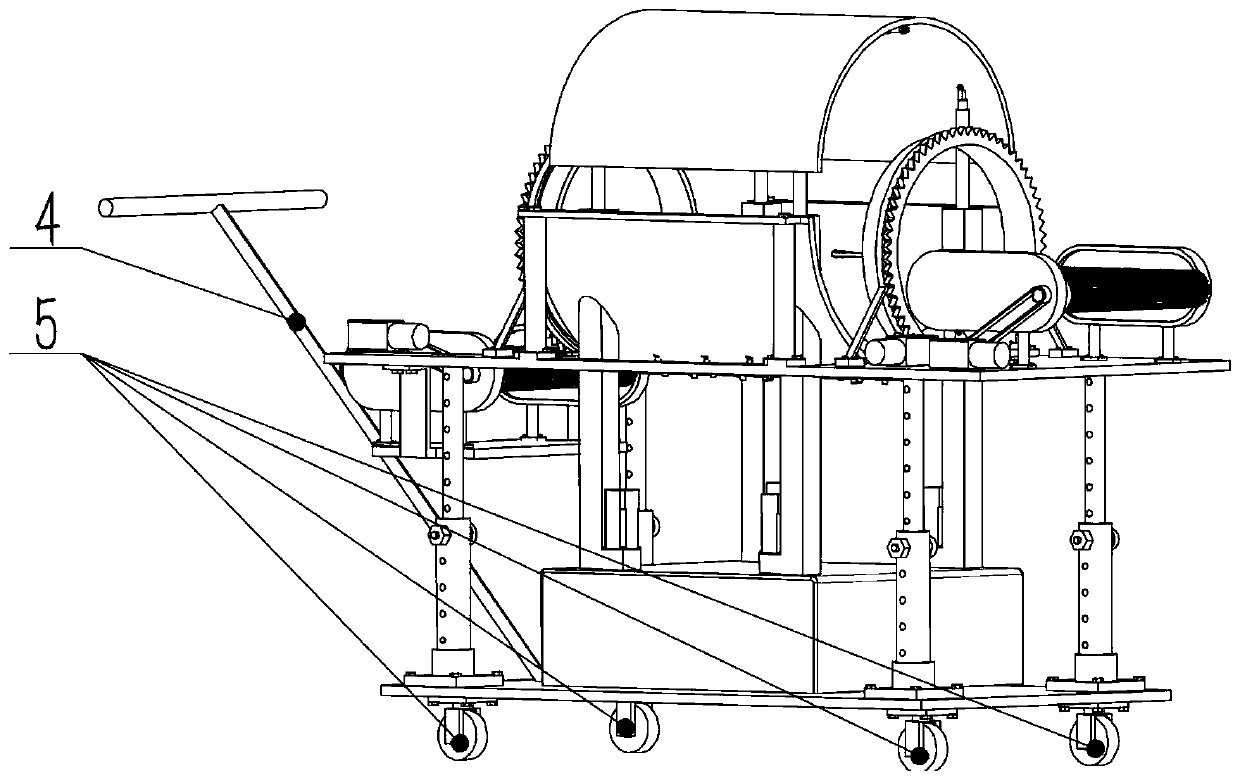

[0026] A fully automatic multi-functional bundling machine, including a carrying mechanism, a moving mechanism, a transmission mechanism, a forming mechanism and a rope winding mechanism, the carrying mechanism includes a carrying plate 1, a telescopic rod group 2 and a frame supporting plate 3, the described The telescopic rod group 2 is installed on the frame support plate 3, the moving mechanism includes a control rod 4 and a universal wheel set 5, the control rod 4 is installed on the frame support plate 3, and the universal The wheel group 5 is installed on the bottom of the vehicle frame support plate 3, and the transmission mechanism includes a motor one 6, a belt one 7, a motor two 8, a belt two 9, a conveyor belt shaft group one 10, a conveyor belt one 11, a honeycomb transmission group 12, Conveyor belt shaft group two 13, conveyor belt two 14, prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com