Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Low atomization value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oligomer mixtures, producing process and use of oligomer mixtures, and flame-retardant polyurethanes comprising oligomer mixtures

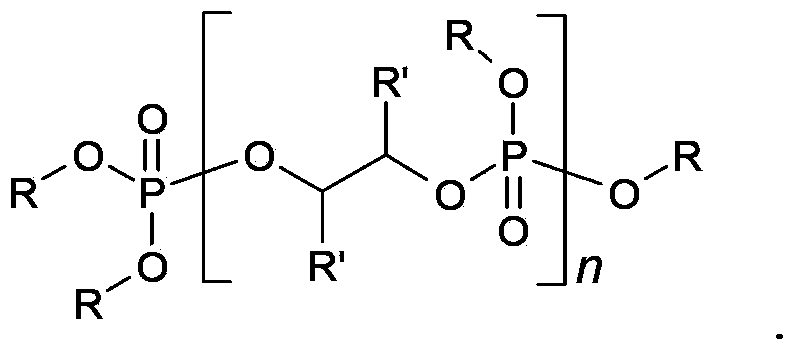

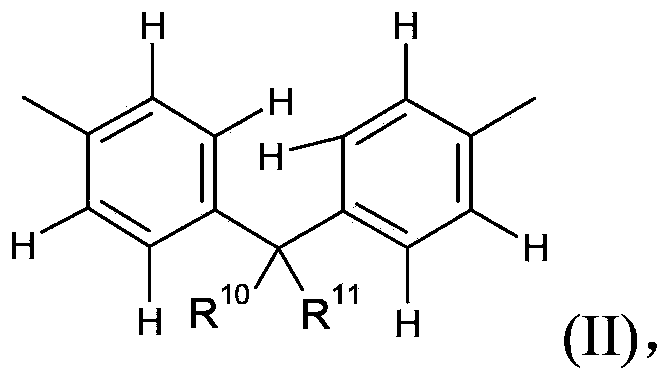

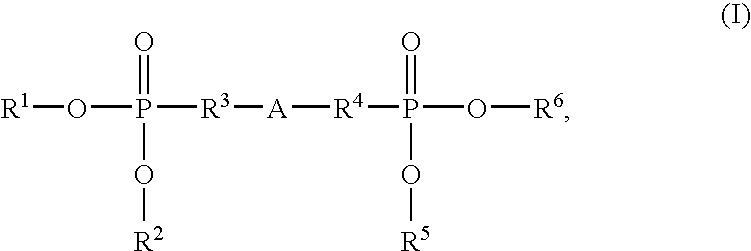

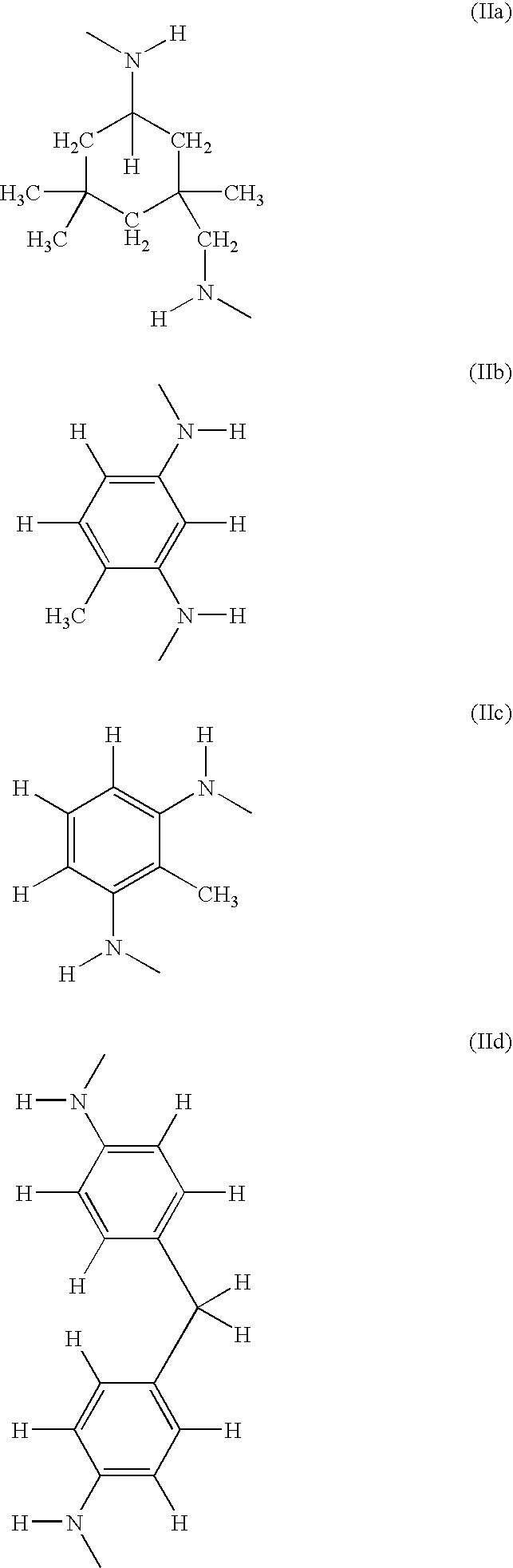

ActiveCN103570972AEasy to measureMeet the requirements of flame retardancyGroup 5/15 element organic compoundsPhosphateHalogen free

Owner:LANXESS DEUTDCHLAND GMBH

TPE (thermoplastic elastomer) material applicable to automobile interior decorations and preparation method thereof

The invention relates to a TPE (thermoplastic elastomer) material applicable to automobile interior decorations and a preparation method thereof. The material comprises the following components in parts by weight: 100-200 parts of SEBS (styrene-ethylene-butadiene-styrene), 100-200 parts of white oil, 20-80 parts of polypropylene, 30-100 parts of filler and 0.2-0.4 part of stabilizer. The method comprises the following steps: slowly mixing the SEBS and white oil in a stirrer at 50-80 DEG C for 20-30 minutes, mixing with the other raw materials and assistants for 20-30 minutes, and adding into a double screw extruder; meanwhile, adding a liquid azeotrope former into first three regions of a vacuum zone by using a melt measuring pump; and carrying out vacuum exhaust until the liquid azeotrope former is thoroughly discharged. The TPE material has the advantages of low smell, high / low-temperature resistance, low atomization value, wear resistance and excellent stretching resistance, is especially suitable for automobile interior decoration materials, has the characteristics of wide application range, high practicality and simple production technique, is more environment-friendly and durable than the existing TPE material, and is worthy of widespread popularization.

Owner:大韩道恩高分子材料(上海)有限公司

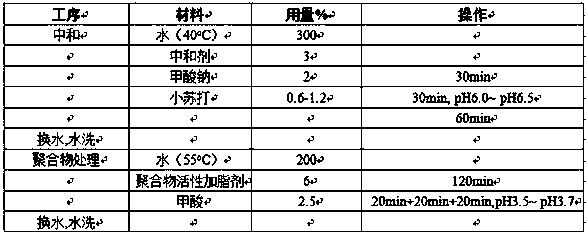

Manufacturing technology for flame-retardant, anti-yellowing and low-fogging cowhide car seat cushion leather

ActiveCN105154596AReduce ammonia nitrogen pollutionLow atomization valueTanning treatmentPre-tanning chemical treatmentCar seatManufacturing technology

The invention discloses a manufacturing technology for flame-retardant, anti-yellowing and low-fogging cowhide car seat cushion leather. The manufacturing technology comprises the production procedures that ammonium salt deliming is replaced by ammonium-salt-free deliming, the fogging value of the seat cushion leather is reduced through high-temperature washing, the flame-retardant property of the leather is improved through retanning, fat liquoring and coating step by step, and the light resistance of a coating is improved through a light-resistant material. According to the manufacturing technology, the usage quantity of leather chemicals is decreased by selecting roll coating to replace spray coating, a flame-retardant, low-fogging, light-resistant, heat-resistant, anti-yellowing and high-property car trim leather product is researched and developed, and a wide market prospect is achieved.

Owner:YANTAI UNIV

Manufacturing technology for flame-retardant, light-resistant, low-fogging and degradable cowhide car seat cushion leather

ActiveCN105154597AReduce ammonia nitrogen contentLow atomization valueTanning treatmentPre-tanning chemical treatmentCar seatPhosphonium

The invention discloses a manufacturing technology for flame-retardant, light-resistant, low-fogging and degradable cowhide car seat cushion leather. According to the manufacturing technology, ammonium salt deliming is replaced by ammonium-salt-free deliming, tetrakis hydroxymethyl phosphonium sulphate and a flame-retardant starch-type leather surfactant are selected as a leather tanning agent to replace a traditional chrome tanning agent, the fogging value of the seat cushion leather is reduced through high-temperature washing, the flame-retardant property of the leather is improved through retanning, fat liquoring and coating step by step, the light resistance of a coating is improved through a light-resistant material, and the usage quantity of leather chemicals is decreased by selecting roll coating to replace spray coating.

Owner:JILIN PROVINCE HUAYU AUTO PARTS

Halogen-free, flame-retardant polyurethane foams

The present invention relates to flame-retardant polyurethane foams which comprise, as flame retardant, halogen-free bisphosphonates free from hydroxy groups.

Owner:LANXESS DEUTDCHLAND GMBH

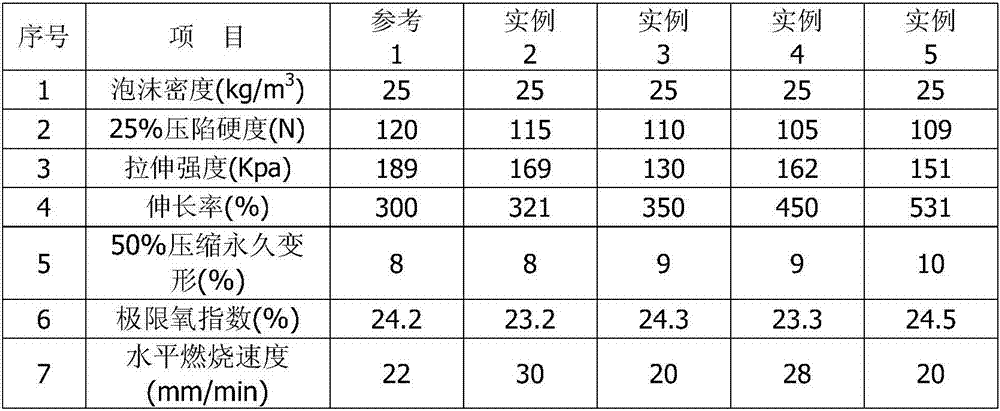

Efficient flame-retardant environment-friendly polyurethane flexible foam plastic for interior part of passenger car and preparation method of efficient flame-retardant environment-friendly polyurethane flexible foam plastic

InactiveCN107254029AImprove composite effectGood physical propertiesPolyesterEnvironmental resistance

The invention discloses an efficient flame-retardant environment-friendly polyurethane flexible foam plastic for an interior part of a passenger car and a preparation method of the efficient flame-retardant environment-friendly polyurethane flexible foam plastic. The efficient flame-retardant environment-friendly polyurethane flexible foam plastic takes polyester polyol and structural type flame-retardant polyether polyol as the main raw materials, and the main raw materials are mixed, foamed and polymerized with an isocyanate component under the actions of a reaction type or low-odor catalyst, a physical and / or chemical foaming agent and a foam stabilizer and / or a fire retardant to generate the polyurethane flexible foam plastic. The flame retardance and the environmentally friendliness of the product both meet the application requirements of a composite material, and the polyurethane flexible foam plastic is convenient to prepare.

Owner:JIANGSU LVYUAN NEW MATERIALS

Preparation method of vehicle interior decoration polypropylene composition with characteristics of low atomization value, low volatility and low odor

The invention discloses a preparation method of a vehicle interior decoration polypropylene composition with characteristics of low atomization value, low volatility and low odor. The vehicle interior decoration polypropylene composition comprises a polypropylene resin, a polyethylene resin, a toughening agent, a reinforcing agent, a heat stabilizer, a light stabilizer and a lubricant. The preparation method comprises high-speed mixing, extrusion granulation and homogenization circulation. According to the present invention, the low-VOC resin is selected and is reasonably compatible with other auxiliary agents, the two-stage water injection rinsing extraction devolatilization is used, the addition of the molecular sieve-based adsorbent is not required, and the prepared vehicle interior decoration material has advantages of low atomization value, low volatility, low odor and good molding appearance; the produced particle material is extracted into the three-component homogenization tank, and the surface of the particles is purged with hot air, so the residual volatile organic compounds in the particles can be completely devolatilized under the heating circulation action; and the preparation method has advantages of controllable process, stable quality, simple and feasible process, mature technology, wide raw material source and low production cost, and is suitable for large-scale industrial production.

Owner:SICHUAN GLARY ASIA PLASTIC TECH

Flame-retardant single-faced velvet composite fabric and preparation method and application thereof

ActiveCN108773119AImprove flame retardant performanceIncrease elasticitySynthetic resin layered productsLaminationPolyesterSurface layer

The invention discloses a flame-retardant single-faced velvet composite fabric, which comprises a flame-retardant surface layer and flame-retardant single-faced velvet. The fire-retardant surface layer is flame-retardant PVC artificial leather, phosphorus-containing flame-retardant polyurethane synthetic leather, or flame-retardant fabric prepared from a phosphorus-containing flame-retardant polyester polymer material, wherein the LOI is not less than 27%. The flame-retardant single-faced velvet is prepared from a phosphorus-containing flame-retardant polyester polymer material. Gram weight ofthe flame-retardant single-faced velvet is 150-450 g / m<2>, velvet height is 1-10 mm, and the LOI is not less than 27%. The composite fabric of the invention has good flame-retarding effect, comfortable and soft hand feeling, good resilience, wide application range and good dimensional stability. The composite fabric has characteristics of dry cloth, environmental protection, low smoke and low toxicity, low VOC, low atomization value, no odor, soft hand feeling, excellent flame retardant performance, high peeling strength, good resilience, comfortable hand feeling and good heat preservation. The composite fabric is applicable to seats, ceilings, door panels, safety seats, sofas, soft chairs and deck chairs for high-speed railway, bullet trains, suburban railway, coaches and cars.

Owner:杭州中隽科技有限公司

Preparation method and application of flame-retardant PVC leather compound for traffic interior decoration

ActiveCN111907172AComposite tightRealize heat insulation, oxygen insulation and flame retardantFireproof paintsSynthetic resin layered productsPolymer sciencePolymer chemistry

The invention discloses a flame-retardant PVC leather compound for traffic interior decoration as well as a preparation method and application thereof. The PVC leather compound comprises a PVC leatherlayer, a flame-retardant functional layer and an elastic layer, wherein the flame-retardant functional layer is prepared from 100 parts of PVC paste resin, 50-120 parts of a flame-retardant plasticizer, 5-20 parts of a phosphorus-containing liquid flame retardant, 5-20 parts of a powder flame retardant, 3-10 parts of a flame-retardant synergist, 1-10 parts of zirconium phosphate, 1-5 parts of anantioxidant, 1-5 parts of a heat stabilizer, 1-10 parts of a filler, 0-5 parts of color paste and 1-10 parts of a foaming agent; the elastic layer is polyurethane sponge. The flame-retardant functional layer is combined with the PVC leather layer to form a flame-retardant PVC leather layer, and then the flame-retardant PVC leather layer is tightly combined with the elastic layer through flame compounding, flame-retardant glue compounding or flame-retardant hot melt adhesive compounding. The flame-retardant PVC leather compound has the characteristics of excellent flame retardancy, low smoke, low toxicity, low VOC, low atomization value, no peculiar smell, soft hand feeling, high peel strength, good resilience and the like, and can be widely applied to seats, safety seats, door plates, handrails and the like of cars, passenger cars, trucks, high-speed rails, bullet trains, urban railways, low-speed trains and the like.

Owner:HANGZHOU XIANGJUN TEXTILE FLAME RETARDANT TECH

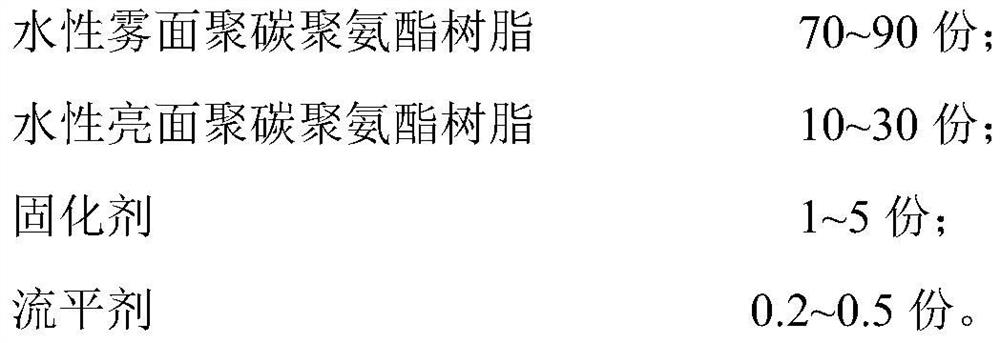

Production method of automotive interior leather with refreshing and comfortable fragrance, low emission and low atomization

ActiveCN108315508AImprove smellEliminates and prevents bad odor effects such as corruptionTanning treatmentPre-tanning chemical treatmentEngineeringRemoving hair

The invention relates to a production method of automotive interior leather with refreshing and comfortable fragrance, low emission and low atomization. The production method is characterized by comprising the following steps: liming, softening, tanning, retanning, fat liquoring, drying, bottom coating and top coating, wherein the step of liming is characterized by completing the processes of liming, saving hair and removing hair through combination of a biological ablation mode and combined action of a low quantity of liming aids and light alkali substance; the step of softening is characterized by adding 0.5% of a biological softening enzyme preparation OPORONON into a delimed leather rotary drum, reacting and rotating for 30-50 minutes; the pH value of the whole softening process is controlled to be 8-9; then the steps of washing with water and controlling water after the leather is softened to meet the requirements; the salt-added acid-leaching reaction is carried out to control the pH value to be 2.8-3.0; the temperature of bath liquid is lower than 27 DEG C. The production method of the automotive interior leather is capable of removing and preventing the influence of bad smell caused by rot of leather products because of bacterial actions, helping the leather to retain good hand feeling and elasticity, simultaneously enabling the leather body to be compact, sufficient intoughness and high in rebound resilience.

Owner:HAINING SENDE LEATHER

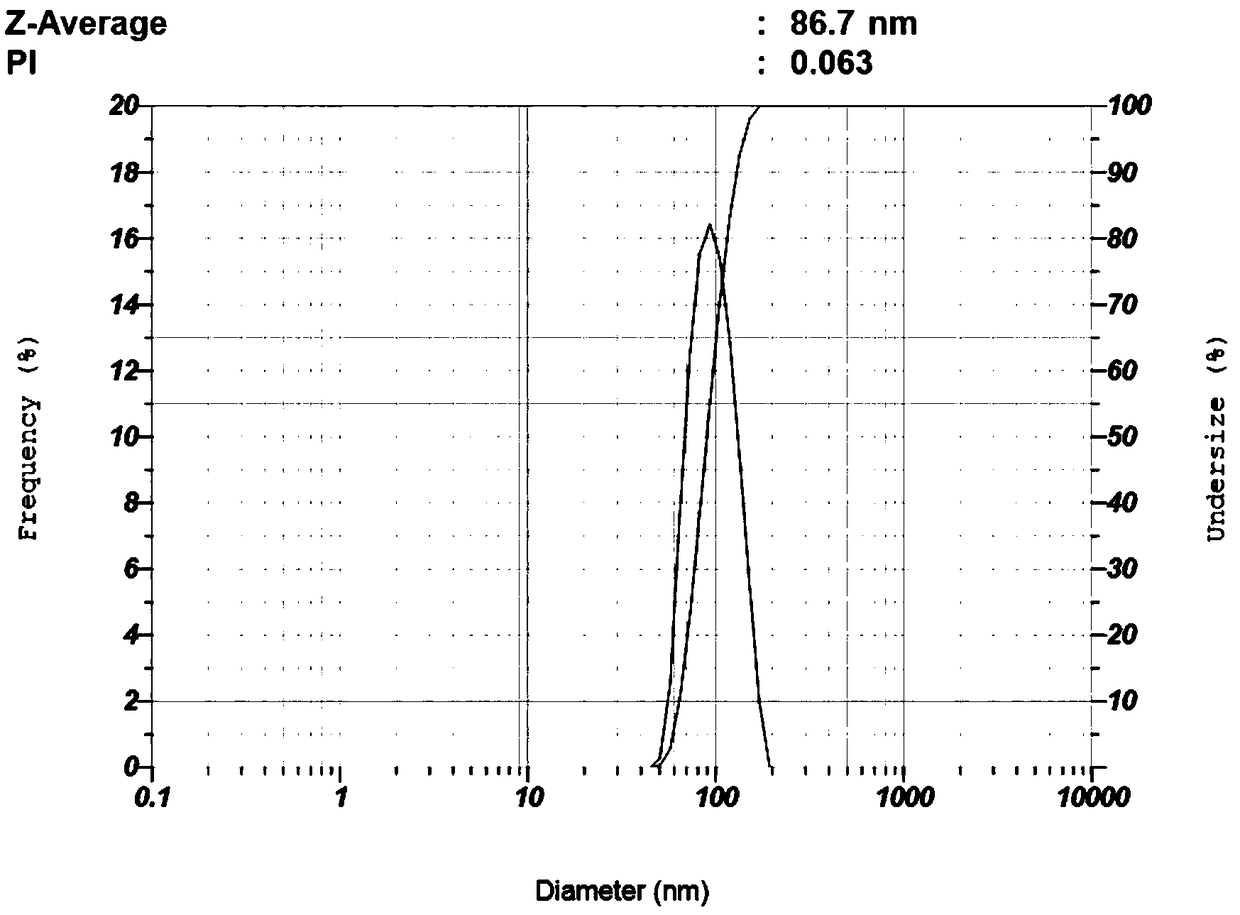

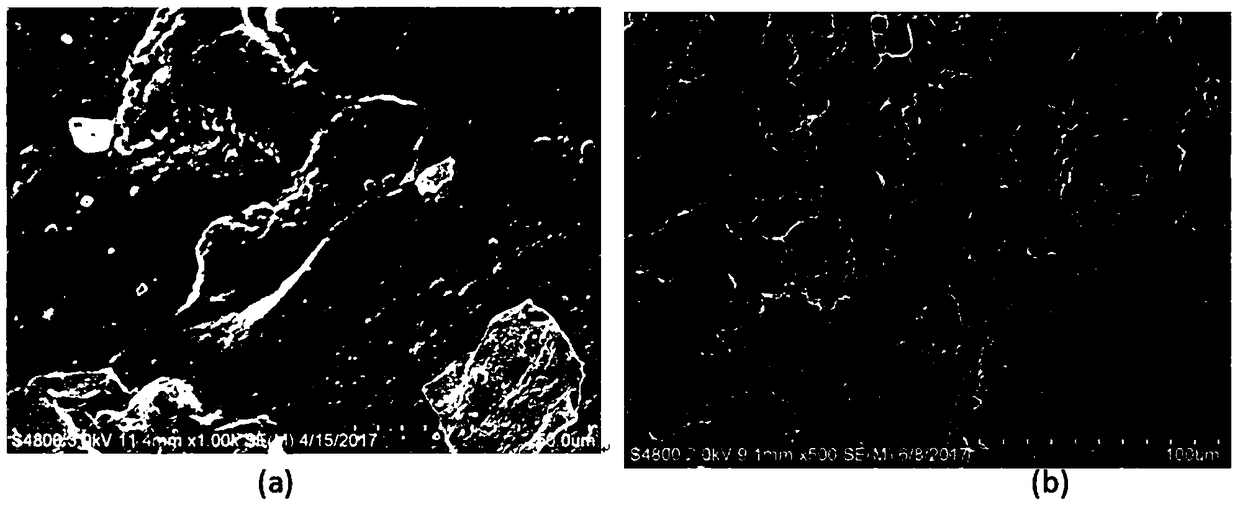

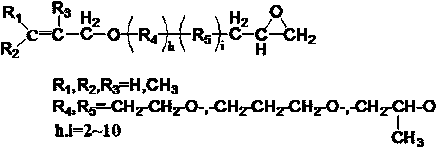

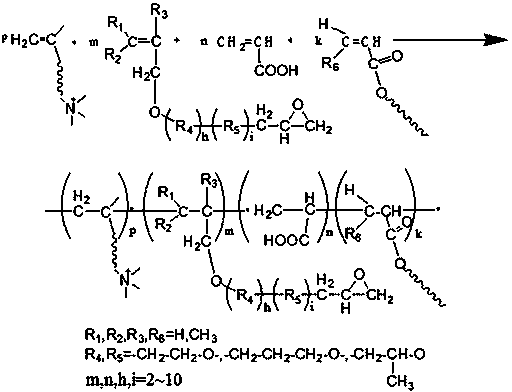

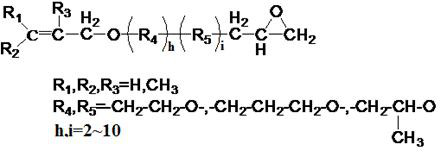

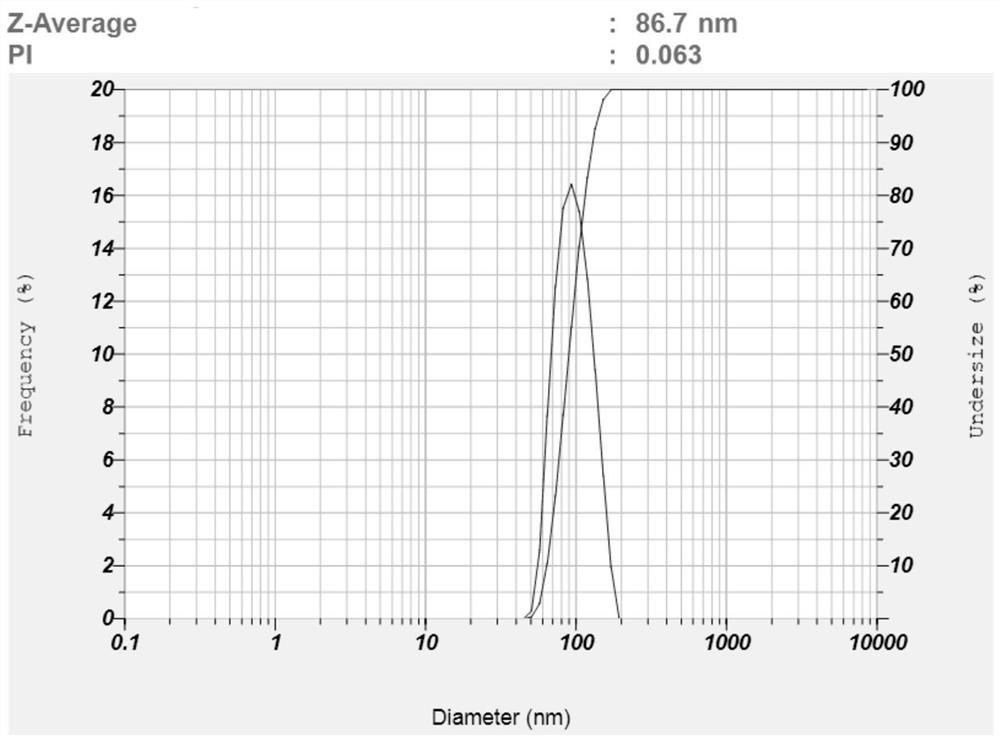

Preparation and application of polyoxyalkyl epoxy acrylate-containing polymer active fatting agent

The invention discloses a synthesis method of a reactive polymer leather fatting agent. According to the method, a vinyl monomer with a polyoxyalkyl epoxy group structure, acrylic acid long-chain ester, acrylic acid and a cationic vinyl monomer are adopted and subjected to emulsion copolymerization to obtain the multi-element amphiphilic copolymer fatting agent. Epoxy groups in the molecular structure of the fatting agent have high reaction activity and can be covalently combined with skin collagen fibers; the polyoxyalkyl structure endows the copolymer with hydrophilicity and is beneficial toimproving the stability of an emulsion system; the long-chain alkyl structure plays a role in lubricating the leather fibers; and the cationic monomer can improve the bonding and fixing performance of the cationic monomer and the leather fiber. A solvent-free emulsion polymerization method is adopted for preparing the fatting agent, the requirement of the ecological fatting agent can be met, andthe fatting agent is particularly suitable for fatting non-chrome tanned leather. Because of the saturability of the molecular structure of the polymer and a reactive group contained in the molecularstructure, the defects that a traditional natural fatting agent is prone to oxidation and yellowing, poor in migration resistance and the like can be overcome.

Owner:SICHUAN UNIV

A kind of TPE material that can be used for automobile interior decoration and preparation method

The invention relates to a TPE (thermoplastic elastomer) material applicable to automobile interior decorations and a preparation method thereof. The material comprises the following components in parts by weight: 100-200 parts of SEBS (styrene-ethylene-butadiene-styrene), 100-200 parts of white oil, 20-80 parts of polypropylene, 30-100 parts of filler and 0.2-0.4 part of stabilizer. The method comprises the following steps: slowly mixing the SEBS and white oil in a stirrer at 50-80 DEG C for 20-30 minutes, mixing with the other raw materials and assistants for 20-30 minutes, and adding into a double screw extruder; meanwhile, adding a liquid azeotrope former into first three regions of a vacuum zone by using a melt measuring pump; and carrying out vacuum exhaust until the liquid azeotrope former is thoroughly discharged. The TPE material has the advantages of low smell, high / low-temperature resistance, low atomization value, wear resistance and excellent stretching resistance, is especially suitable for automobile interior decoration materials, has the characteristics of wide application range, high practicality and simple production technique, is more environment-friendly and durable than the existing TPE material, and is worthy of widespread popularization.

Owner:大韩道恩高分子材料(上海)有限公司

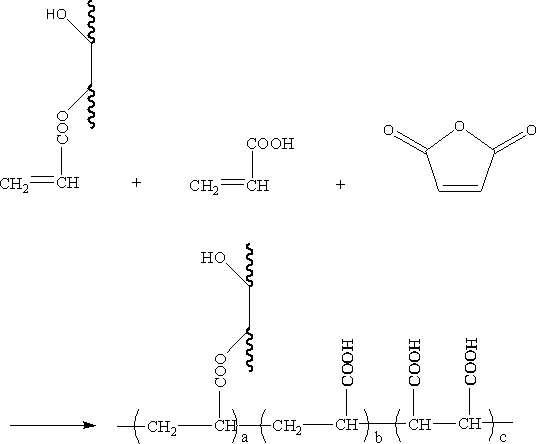

Low-atomization leather synthetic fatting agent as well as preparation method and application thereof

ActiveCN112626292AReduce volatilityHigh saturationLeather impregnationMaleic anhydrideAutomobile seat cushion

The invention provides a low-atomization leather synthetic fatting agent as well as a preparation method and application thereof, and relates to the technical field of leather chemical engineering. The invention provides a low-atomization synthetic leather fatting agent. The low-atomization synthetic leather fatting agent is prepared from the following raw materials in parts by weight: 20-40 parts of N-oleoyl sarcosine; 50-100 parts of palm oil; 10-20 parts of maleic anhydride; 10-50 parts of mineral oil with a high boiling point; 10-50 parts of synthetic grease; 5-50 parts of a neutralizer; 10-30 parts of an emulsifier; 100-200 parts of water. Unsaturated grease and volatile components in the adopted raw material components are few, the high saturation degree of palm oil is utilized, volatile matter formation is further reduced through chemical modification, and high-boiling-point mineral oil is matched, so that the atomization value and VOC are reduced; when the low-atomization synthetic leather fatting agent provided by the invention is used for automobile base cushion leather, good low-atomization performance can be obtained.

Owner:QI HE LI HOU CHEM CO LTD

Hot melt adhesive for automobile trunk mats and preparation method of hot melt adhesive

InactiveCN109666423ALow VOCSmall smellMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesHigh resistanceElastomer

The invention discloses a hot melt adhesive for automobile trunk mats and a preparation method of the hot melt adhesive. The hot melt adhesive is prepared from, by weight, 10-30 parts of propylene-rich polyolefin elastomer, 30-50 parts of ethylene and propylene copolymerized polyolefin elastomer, 25-50 parts of tackifying resin and 0.3-1 part of an antioxidant. The hot melt adhesive for the automobile trunk mats and the preparation method have advantages that the preparation method is simple, harmful substance discharge in a production process is avoided, solvent consumption is avoided, and the hot melt adhesive is environmentally friendly; in use, operating process simplicity and low equipment investment are realized, and the hot melt adhesive has advantages of low VOC, low odor, low atomization value, excellent adhesiveness, high resistance to high and low temperatures and aging resistance.

Owner:FUJIAN CHANGDE PLASTIC IND

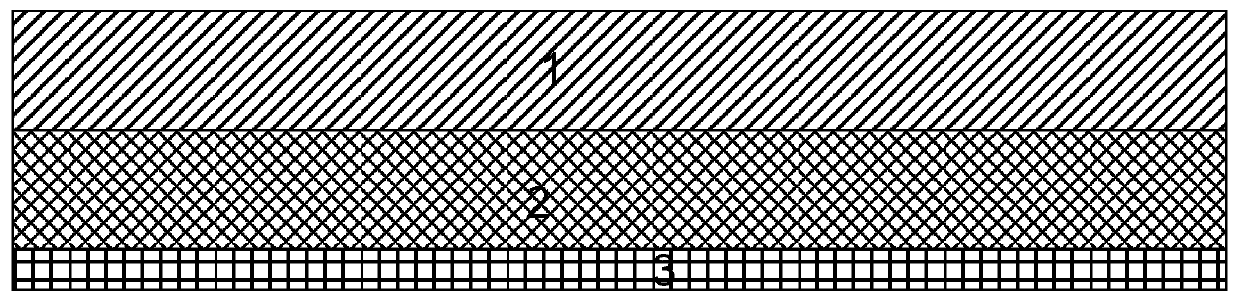

Low-atomization PU synthetic leather and preparation method thereof

ActiveCN113502664ANo precipitationLow atomization valueTextile/flexible product manufactureTextiles and paperPolymer scienceSynthetic resin

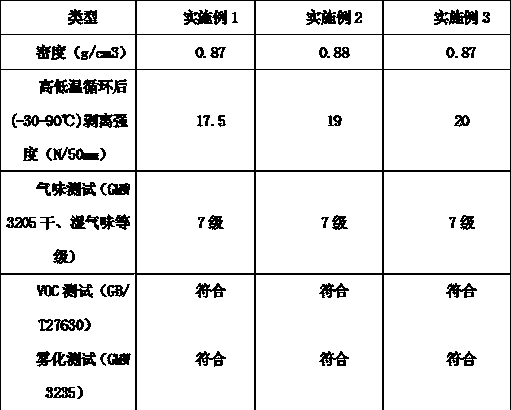

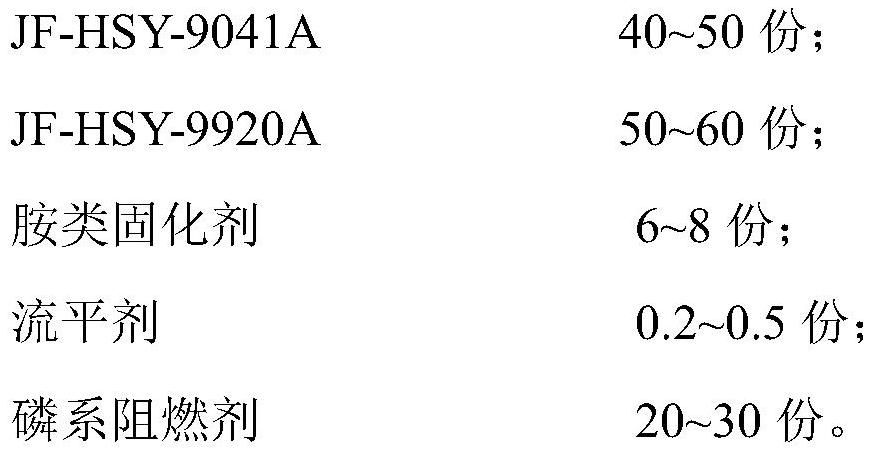

The invention relates to low-atomization PU synthetic leather and a preparation method thereof. The low-atomization PU synthetic leather comprises a base cloth layer, a bonding layer, a middle layer and a surface layer which are sequentially stacked; a raw material formula of the middle layer comprises middle layer PU resin; the middle layer PU resin comprises JF-HSY-9041A and JF-HSY-9920A; the mass ratio of the JF-HSY-9041A to the JF-HSY-9920A is 1: (0.8-1.5); and the JF-HSY-9041A and the JF-HSY-9920A are from Zhejiang Huafeng synthetic resin Ltd. According to the invention, the middle layer of the synthetic leather is improved, the formula of the middle layer is optimized, the two kinds of high-solid-content resin JF-HSY-9041A and JF-HSY-9920A of Huafeng are compounded according to a certain mass ratio, and the prepared synthetic leather is free of precipitation and low in atomization value.

Owner:SUZHOU BEST DECORATION NEW MATERIALS

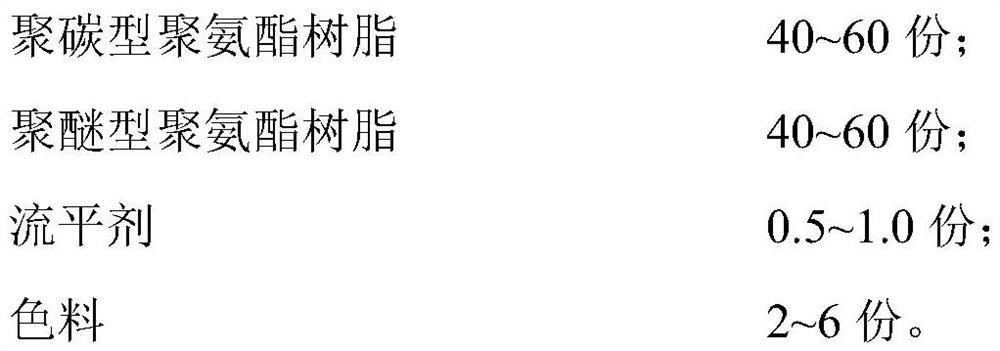

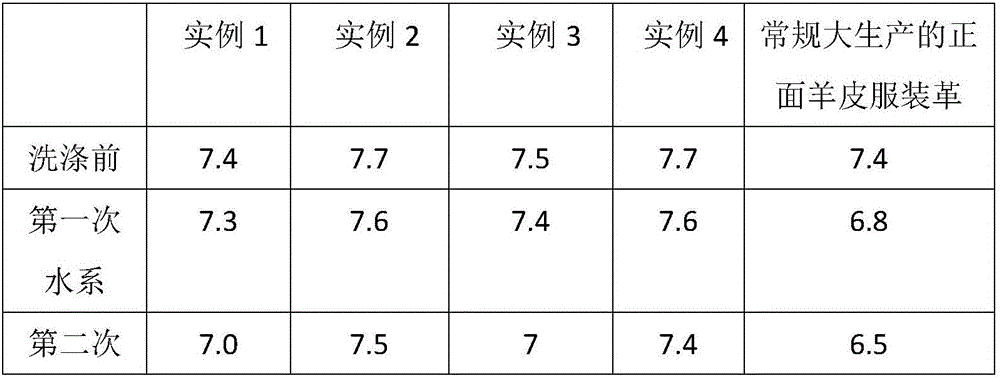

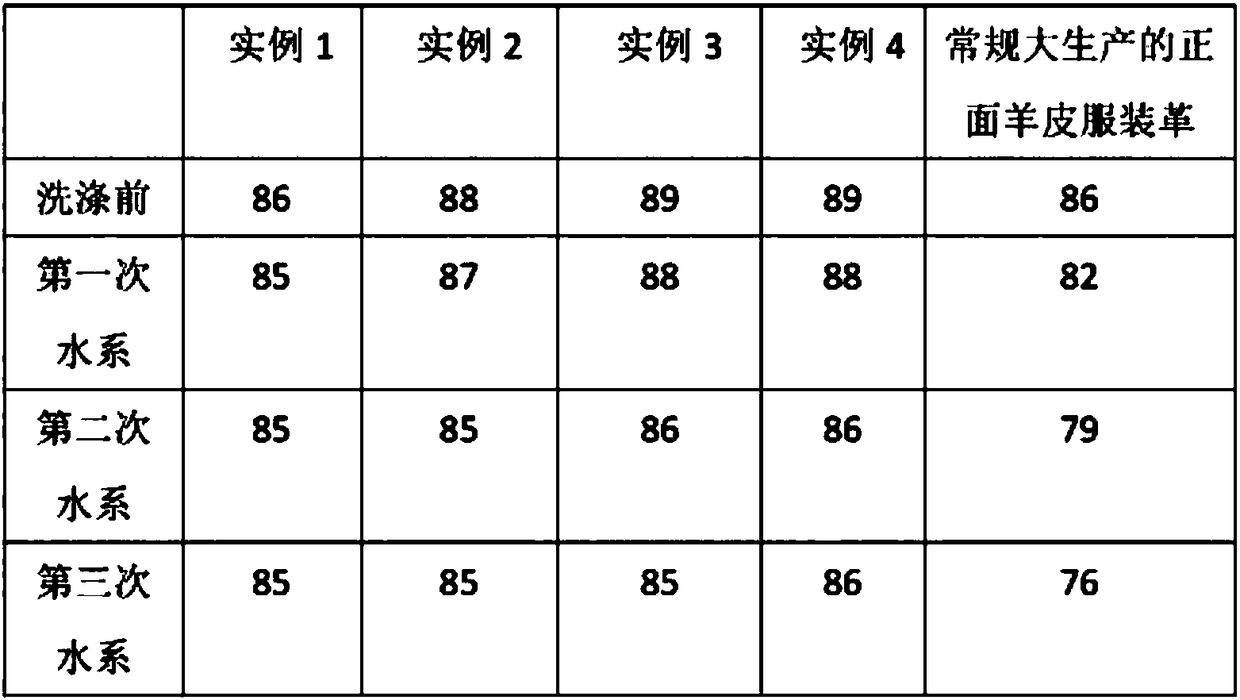

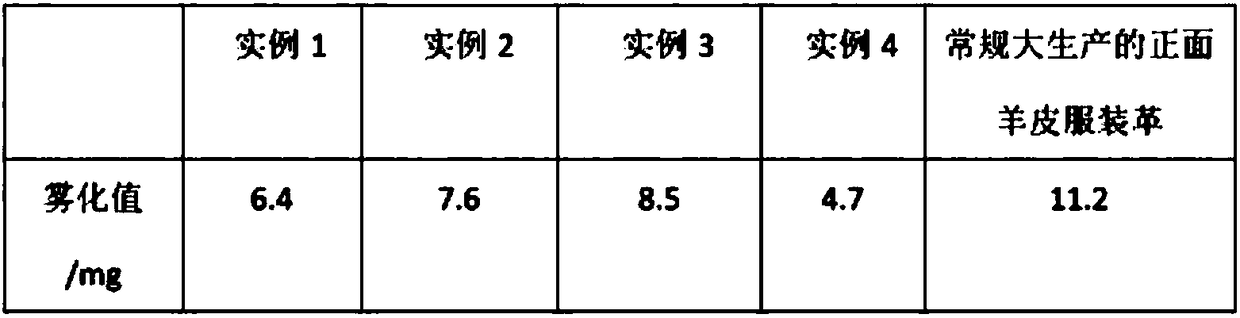

Environmental-friendly processing technology for sheepskin clothing leather

ActiveCN106222329AImprove mechanical propertiesPromote absorptionTanning treatmentLeather surface finishingNaringinAcrylic resin

The invention discloses an environmental-friendly processing technology for sheepskin clothing leather. In order to overcome the flaws that clothing leather generates smell, is bad in washing resistance, is not environmentally friendly in chrome tanning and generates oil cream, according to the processing technology, naringin, N-naphthalene-1-yl-3-hydroxynaphthoic acid-2-formamide and glycine are adopted to improve the mechanical property of the clothing leather; sorbitol, 2-bromine-2-nitro-1,3-propyl alcohol, pyridoxine, D-panthenol, oleamide, polyacrylamide and 2,3-dihydrobutanedioic acid are adopted to improve the absorption of small molecule acrylic resin for the leather; sorbitol, mannite, THPC and an aluminate coupling agent are adopted to fix grease and small molecule compounds; and 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride, polymine, alum, titanium dioxide and talcum powder are adopted to avoid the oil cream and absorb the small molecule compounds.

Owner:绅邦服饰有限公司

Suede type styrene-butadiene segmented copolymer-based superfine fiber synthetic leather and production method thereof

PendingCN112593407AClean and environmentally friendly productionSolve compound puzzlesGrip property fibresCar seatPolymer science

The invention discloses suede type styrene-butadiene segmented copolymer-based superfine fiber synthetic leather and a production method thereof, and relates to the technical field of superfine fibersynthetic leather. The preparation method comprises the following steps of infiltrating and compounding a styrene-butadiene segmented copolymer material and a sea-island fiber non-woven fabric base material in a curtain coating and extruding manner to obtain a composite material; treating the obtained composite material through a steam alkali deweighting technology to obtain a styrene-butadiene segmented copolymer / superfine fiber composite material; and carrying out an after-finishing process on the obtained styrene-butadiene segmented copolymer / superfine fiber composite material to obtain thesuede-type styrene-butadiene segmented copolymer-based superfine fiber synthetic leather. The production process is clean and environmentally friendly, the obtained product is soft and full in hand feeling, the atomization value is smaller than 4 mg, the smell is smaller than the third level, the product can be used as a vamp material and has good bonding strength with an SBS injection molding sole, and the product can be used for producing high-performance anti-skid sneakers and can also be used as an environment-friendly skin material of automobile seats.

Owner:JIANGSU KEMEI NEW MATERIALS

Preparation and application of a kind of reactive fatliquoring agent containing polyoxyalkylene epoxy group acrylate polymer

The invention discloses a method for synthesizing a reactive polymer leather fatliquoring agent. The method adopts vinyl monomer with polyoxyalkylene epoxy structure, long-chain acrylate, acrylic acid and cationic vinyl monomer to obtain multiple amphiphilic copolymer fatliquor through emulsion copolymerization. The epoxy group in the molecular structure of this type of fatliquoring agent has high reactivity and can covalently bond with skin collagen fibers; the polyoxyalkylene structure endows the copolymer with hydrophilicity and is beneficial to improve the stability of the emulsion system properties; the long-chain hydrocarbon structure plays a role in lubricating the skin fibers; the cationic monomer can improve its binding and fixing properties with the skin fibers. The preparation of the fatliquoring agent described in the invention adopts a solvent-free emulsion polymerization method, which can meet the requirements of an ecological fatliquoring agent, and is especially suitable for fatliquoring non-chrome tanned leather; the saturation of the molecular structure of the polymer and the presence of reactive groups The structural characteristics can solve the shortcomings of traditional natural fatliquor such as easy oxidation, yellowing and poor migration resistance.

Owner:SICHUAN UNIV

Novel polypropylene compositions with low fogging

Polypropylene composition comprising (A) 60 to 95 wt % of a heterophasic polypropylene (HECO) comprising 10 to 30 wt % of dispersed phase with the dispersed phase having a comonomer content of 30 to 45 wt % and the HECO having a melt flow rate MFRPP in the range of 12 to 200 g / 10 min and being prepared in the presence of a Ziegler Natta catalyst (ZN-C), (B) 0 to 15 wt % of one or more elastomers, (C) 5 to 20 wt % of at least one filler wherein the polypropylene composition fulfils inequation (1) fogging≤0.02 MFRComp+0.3. The composition allows for a well-balanced combination of a good impact / stiffness balance, a good scratch resistance, low VOC and FOG emissions and remarkable good fogging values.

Owner:BOREALIS AG

Polypropylene compositions with low fogging

Owner:BOREALIS AG

Manufacturing process of flame-retardant, light-resistant, low-fog degradable cowhide car seat leather

ActiveCN105154597BReduce ammonia nitrogen contentLow atomization valueTanning treatmentPre-tanning chemical treatmentPhosphoniumManufacturing technology

Owner:JILIN PROVINCE HUAYU AUTO PARTS

Low VOC content tread rubber material and manufacturing method and application thereof

The invention relates to the technical field of tires, and in particular relates to a low VOC content tread rubber material. The low VOC content tread rubber material comprises the following components in parts by weight: 100 parts of rubber main material including 1-60 parts of cis-1,4-polyisoprene rubber, 1-80 parts of cis-butadiene-trans-butadiene copolymer synthetic rubber, and 1-50 parts of styrene-butadiene copolymer synthetic rubber; and in 100 parts by weight of rubber main material, the compounding agent comprises 1-10 parts of cyclic oligosaccharide. The tread rubber material has the beneficial effect that the use of the cyclic oligosaccharide can obviously reduce the VOC value and atomization value of the rubber material.

Owner:SHANDONG LINGLONG TIRE

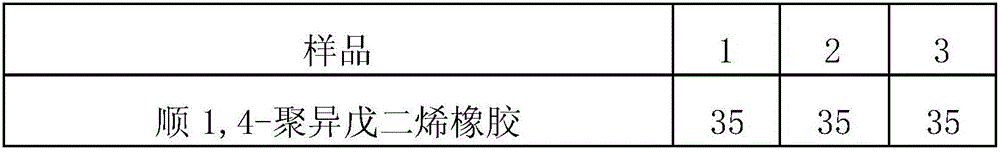

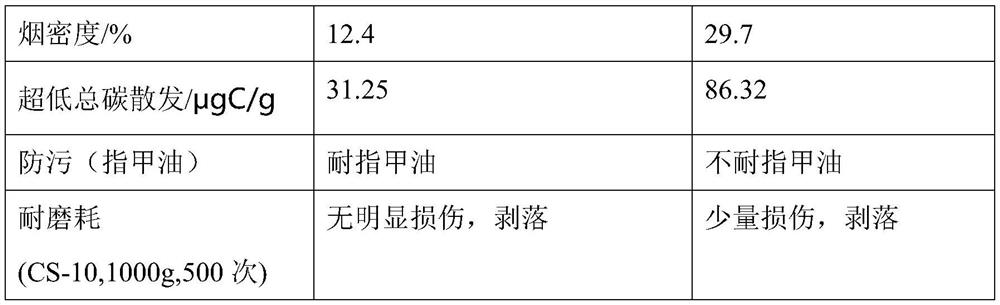

Manufacturing process of anti-fouling, ultra-low total carbon emission, and wear-resistant cowhide car seat leather

ActiveCN110055358BReduce TOCLow atomization valueTanning treatmentPre-tanning chemical treatmentCar seatPolymer science

The invention relates to an antifouling, ultra-low total carbon emission, and wear-resistant cowhide automobile seat leather manufacturing process. The primer coating includes water-based pigment paste, light-resistant coating, light-resistant acrylic resin coating, light-resistant water-based polyurethane, flame-retardant Coatings and cationic oils; intermediate coatings include matting polyurethane, bright polyurethane, crosslinking agents, materials, wear-resistant polyurethanes, carbodiimides, PTFE emulsions, and smog-suppressing materials; top coatings include hand feel agents and cationic oils. The prepared cowhide car seat leather has improved anti-fouling, ultra-low total carbon emission and wear resistance of the car leather on the basis of maintaining flame retardancy, light resistance and low fogging.

Owner:YANTAI UNIV +2

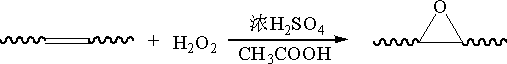

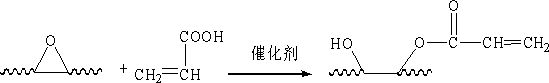

A kind of jatropha oil-based polymer fatliquoring agent and preparation method thereof

ActiveCN107778420BHigh polymerization activityGood self-emulsifying performanceTanning treatmentLeather impregnationPolymer scienceVegetable oil

The invention relates to a preparation method of a jatropha carcass oil base polymer fatting agent. The preparation method comprises the following steps: a, performing epoxidation on jatropha carcassoil by using hydrogen peroxide, glacial acetic acid and concentrated sulfuric acid so as to obtain epoxy jatropha carcass oil; b, by taking sodium p-toluenesulfonate as a catalyst, hydroquinone as a polymerization inhibitor, and acrylic acid as a nucleophilic reagent, performing a ring-opening reaction on the epoxy jatropha carcass oil so as to obtain acrylic acid esterified jatropha carcass oil,and introducing an active vinyl part to a plant oil molecular chain; and c, by taking 2,2'-azobis(2-methylpropionitrile) as a catalyst, and acetanilide as an anti-gel agent, adding maleic anhydride, acrylic acid and acrylic acid esterified jatropha carcass oil, and performing copolymerization, thereby obtaining the jatropha carcass oil base polymer fatting agent. Based on natural plant oil which is cheap and easily available as a raw material, the prepared polymer fatting agent is relatively good in cold water emulsification property and good in hydrophilcity, and is an environment-friendly and degradable fatting material.

Owner:SHAANXI UNIV OF SCI & TECH

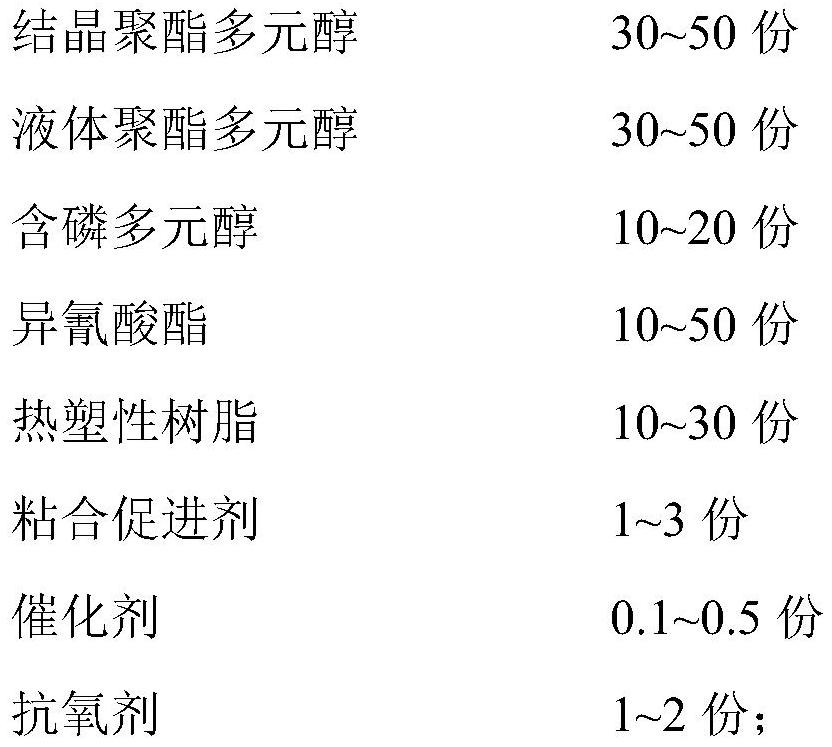

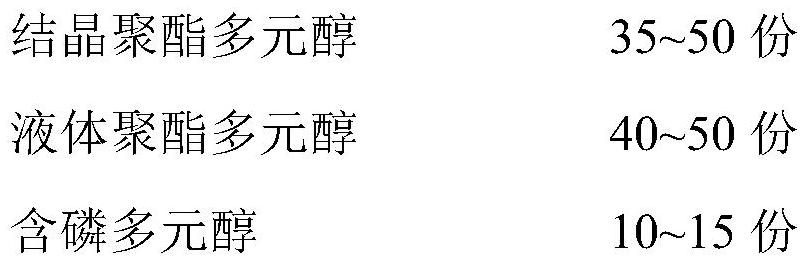

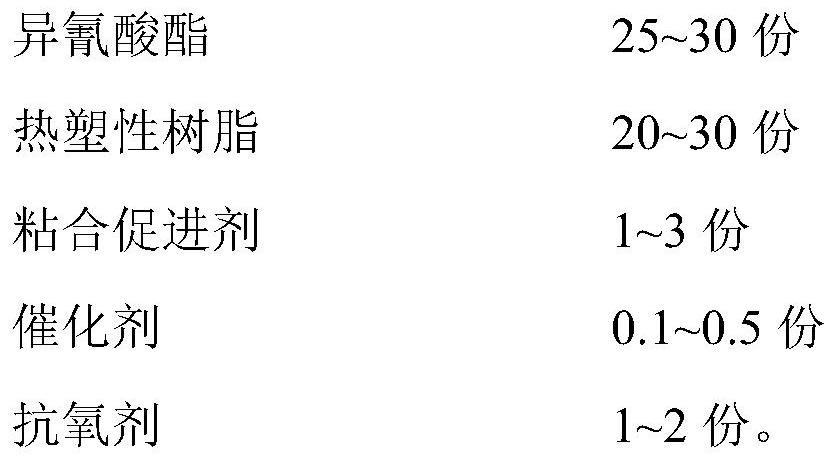

Reactive polyurethane hot melt adhesive and preparation method thereof

ActiveCN108559437BImprove adhesionImprove the immunityPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterPolymer science

The invention relates to a reactive polyurethane hot melt adhesive and a preparation method thereof. The reactive polyurethane hot melt adhesive comprises the following raw materials in parts by weight: 30 to 50 parts of crystalline polyester polyol, 30 to 50 parts of liquid polyester polyol, 10 to 20 parts of phosphorus-containing polyol, 10 to 50 parts of isocyanate, 10 to 30 parts of thermoplastic resin, 1 to 3 parts of adhesion promoter, 0.1 to 0.5 part of catalyst and 1 to 2 parts of antioxidant. The reactive polyurethane hot melt adhesive has the advantages of excellent flame retardancyand adhesion, and has the advantages of fast curing speed, high final bonding strength, good environmental resistance, low atomization value and the like, and is particularly suitable for the field ofhigh flame-retardant requirements, thereby having good market prospect. Besides, the reactive polyurethane hot melt adhesive is an one-component moisture-curing polyurethane adhesive, belongs to thesolvent-free environment-friendly adhesive agent industry, and can be used for bonding substrates such as plastic, glass, metal, textile and the like.

Owner:GUANGZHOU BAIYUN CHEM IND

Process for Preparing a Flame-retardant, Lightfast, Low Fogging and Degradable Car Seat Leather

InactiveUS20170114424A1Reduce ammonia contentGood dispersionTanning treatmentPre-tanning chemical treatmentSpray coatingAmmonia

The present invention discloses a process for preparing a flame-retardant, lightfast, low fogging and degradable car seat leather wherein ammonia salt deliming is replaced with an ammonia free one, tetrakis hydroxymethyl phosphonium sulfate and the flame-retardant starchy leather surfactant are used as the tanning agents to replace the conventional chrome tanning agent, hot water washing is used to reduce the fogging value of the seat leather, the flame-retardant performance is enhanced by combination of retanning, greasing and coating, the lightfast material is applied to enhance the lightfastness of the coating and the spray coating is replace with the roller coating to lower the consumption of the paints.

Owner:YANTAI UNIV

A kind of synthetic fatliquoring agent of low atomization leather and its preparation method and application

The invention provides a low-atomization leather synthetic fatliquoring agent as well as its preparation method and application, and relates to the technical field of leather chemical industry. The synthetic fatliquoring agent for low atomization leather provided by the present invention, the preparation raw material comprises the following components by weight: 20-40 parts of N-oleoyl sarcosine; 50-100 parts of palm oil; 10-20 parts of maleic anhydride 10-50 parts of high boiling point mineral oil; 10-50 parts of synthetic oil; 5-50 parts of neutralizer; 10-30 parts of emulsifier; 100-200 parts of water. In the raw material components used in the present invention, there are less unsaturated oils and volatile components, and the higher saturation of palm oil is used to further reduce the formation of volatiles through chemical modification, and then matched with high-boiling point mineral oil, thereby reducing fog value and VOC; the low fogging leather synthetic fatliquoring agent provided by the invention is used for automobile upholstery leather, and good low fogging performance can be obtained.

Owner:QI HE LI HOU CHEM CO LTD

A kind of flame-retardant single-face cashmere composite fabric and its preparation method and application

ActiveCN108773119BImprove flame retardant performanceIncrease elasticitySynthetic resin layered productsLaminationPolyesterEngineering

Owner:杭州中隽科技有限公司

A kind of environment-friendly sheepskin garment leather processing technology

ActiveCN106222329BImprove mechanical propertiesPromote absorptionTanning treatmentLeather surface finishingMeth-Pyridoxine

The invention discloses an environmental-friendly processing technology for sheepskin clothing leather. In order to overcome the flaws that clothing leather generates smell, is bad in washing resistance, is not environmentally friendly in chrome tanning and generates oil cream, according to the processing technology, naringin, N-naphthalene-1-yl-3-hydroxynaphthoic acid-2-formamide and glycine are adopted to improve the mechanical property of the clothing leather; sorbitol, 2-bromine-2-nitro-1,3-propyl alcohol, pyridoxine, D-panthenol, oleamide, polyacrylamide and 2,3-dihydrobutanedioic acid are adopted to improve the absorption of small molecule acrylic resin for the leather; sorbitol, mannite, THPC and an aluminate coupling agent are adopted to fix grease and small molecule compounds; and 3-chlorine-2-hydroxypropyl trimethyl ammonium chloride, polymine, alum, titanium dioxide and talcum powder are adopted to avoid the oil cream and absorb the small molecule compounds.

Owner:绅邦服饰有限公司

A kind of flame-retardant automotive interior composite fabric and preparation method thereof

ActiveCN107116876BLow atomization valueNo smellFireproof paintsSynthetic resin layered productsEnvironmental resistanceEngineering

The invention discloses flame-retardant automotive interior composite fabric and a preparation method thereof. The flame-retardant automotive interior composite fabric comprises flame-retardant automotive interior fabric and flame-retardant soft polyurethane foam sponge which are compounded through flame compounding, wherein the back surface of the flame-retardant automotive interior fabric contains a flame-retardant coating adhesive functional material. The flame-retardant automotive interior composite fabric has the characteristics of environment friendliness, low smoke, low toxicity, low VOC, a low fogging value, no peculiar smell, a soft hand feel, excellent flame resistance, high peel strength, good resilience, good antistatic performance and the like, and can be widely applied to seats, safety seats, roofs, door panels and handrails of cars or buses.

Owner:杭州中隽科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com