A kind of flame-retardant automotive interior composite fabric and preparation method thereof

A technology for automotive interior and composite fabrics, applied in the field of flame-retardant automotive interior composite fabrics and its preparation, can solve problems that do not meet the development requirements of the times, and achieve low atomization value, wide range of material selection, and good antistatic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

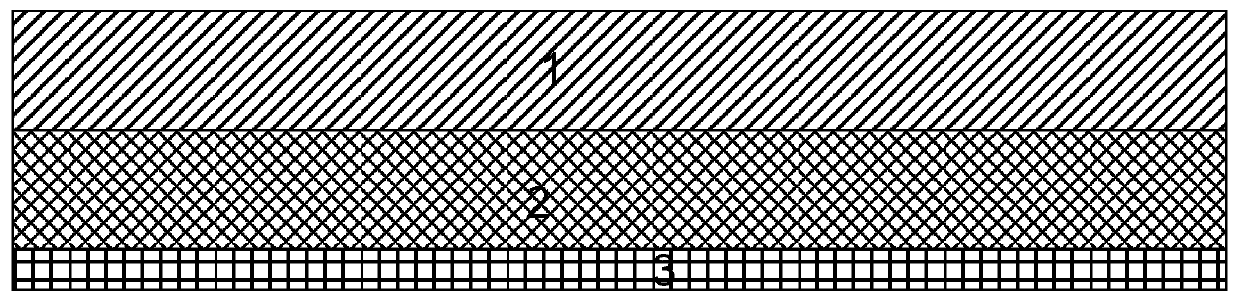

Image

Examples

Embodiment 1

[0046] Weigh 478 grams of phosphorus-containing polyester diol DM1304 (Beijing Demei Kechuang Technology Co., Ltd. DM1304, molecular weight 478, hydroxyl value 233mgKOH / g, phosphorus content (wt, %) 19.7%), 262 grams of dibromoneopentyl diol Alcohol (Yixing City Zhongzheng Chemical Co., Ltd.), 134 grams of dimethylol propionic acid and 400 grams of polyether polyol N210 (Nanjing Zhongshan Chemical Co., Ltd.), drop 870 grams of toluene diisocyanate (Yantai Wanhua Chemical Group Co., Ltd. Co., Ltd.) to carry out polycondensation reaction, control the molar ratio NCO / OH in the material at 1.5:1, add 100 grams of butanone, and react at 78 ° C for 2.0 hours;

[0047] Use 298.3 grams of methyl ethyl ketoxime (Zhejiang Quzhou New Future Chemicals Co., Ltd.) to cap the remaining NCO at the end group, and react at 70°C for 1.0 hour;

[0048] Neutralize with 101 grams of triethylamine, the molar ratio of triethylamine to dimethylolpropionic acid is 1:1, and the neutralization degree is ...

Embodiment 2

[0051] Weigh 478 grams of phosphorus-containing polyester diol DM1304 (Beijing Demei Kechuang Technology Co., Ltd. DM1304, molecular weight 478, hydroxyl value 233mgKOH / g, phosphorus content (wt, %) 19.7%), 340 grams of brominated polyether polyol Alcohol IXOL B251 (Solvay Chemical (Shanghai) Co., Ltd., product molecular weight 340, hydroxyl value 330mgKOH / g, bromine content (wt, %) 31.5%, chlorine content (wt, %) 6.9%, acid value 3mgKOH / g), 134 grams of dimethylol propionic acid and 400 grams of polyether polyol N210 (Nanjing Zhongshan Chemical Co., Ltd.), drop 946.7 grams of toluene diisocyanate (Yantai Wanhua Chemical Group Co., Ltd.) to carry out polycondensation reaction 1. Control the molar ratio NCO / OH in the material at 1.6:1, add 120 grams of butanone, and react at 78 ° C for 2.0 hours;

[0052] Use 355.5 grams of methyl ethyl ketone oxime (Zhejiang Quzhou New Future Chemical Co., Ltd.) to cap the remaining NCO at the end group, and react at 68 ° C for 1.8 hours;

...

Embodiment 3

[0056] Take by weighing 125 grams of emulsion containing 50 grams of water-based phosphorus-containing polyurethane (Zhejiang Chuanhua Co., Ltd. TF-686, with a solid content of 40%), dilute with water, add 225 grams of water, and the emulsion quality of water and water-based phosphorus-containing polyurethane is total 350 grams;

[0057] Add 2 grams of wetting agent W-18 (Hemmings Deqian (Shanghai) Chemical Co., Ltd.), 3 grams of dispersant TC-34 (Lin'an Keda Coating Chemical Research Institute), 2 grams of aliphatic nonionic emulsifier AEO -9 (Jiangsu Haian Petrochemical Plant);

[0058] In the case of stirring and dispersing, add 22 grams of organosilicon flame retardant crosslinking agent (Silicone-9312), 20 grams of reactive phosphorus-containing flame retardant 2-carboxyethylphenylphosphinic acid (CEPPA) containing active groups ( Shandong Xingqiang Flame Retardant Technology Co., Ltd.), 40 grams of Example 1 product (water-based blocked isocyanate containing flame retar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com