Low-atomization PU synthetic leather and preparation method thereof

A technology of synthetic leather and PU resin, which is applied in the field of synthetic leather, can solve the problems of complex preparation process of artificial leather, and achieve the effect of low atomization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The PU synthetic leather provided in this embodiment comprises a base cloth layer, an adhesive layer, an intermediate layer, a surface layer and a surface treatment layer formed on the surface layer which are stacked in sequence, wherein,

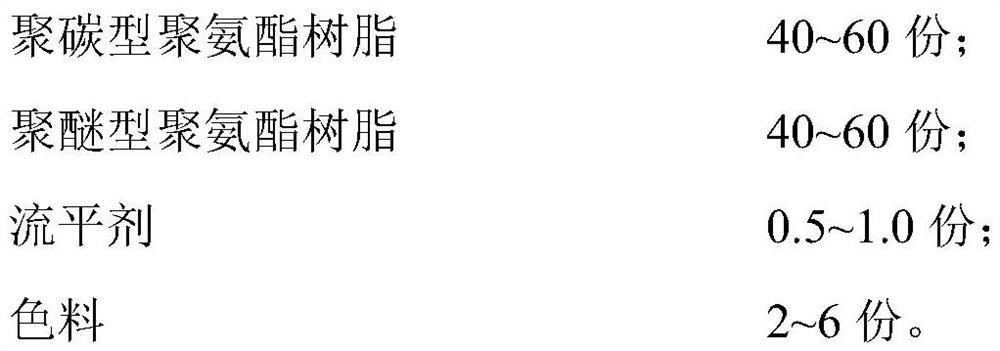

[0034] The raw material formula of the surface layer is 50 parts of water-based polycarbonate polyurethane resin, 50 parts of water-based polyether polyurethane resin, 0.8 part of leveling agent and 5 parts of colorant.

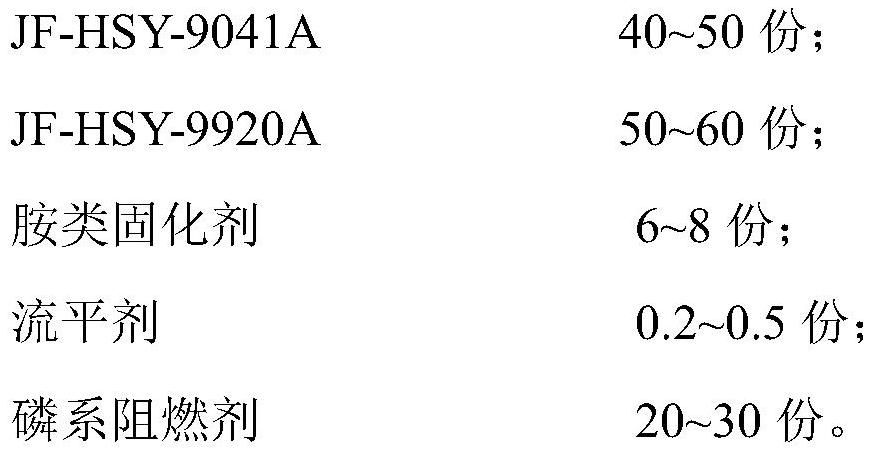

[0035] The raw material formula of the middle layer is 40 parts of JF-HSY-9041A, 60 parts of JF-HSY-9920A, 7 parts of amine curing agent JF-BY-1007, 0.4 parts of leveling agent and 25 parts of phosphorus flame retardant.

[0036] The raw material formula of the adhesive layer is 100 parts of adhesive and 0.4 parts of phosphorus flame retardant.

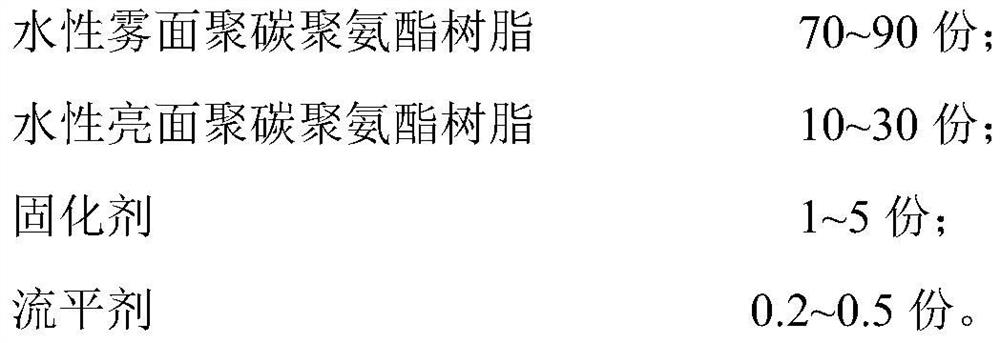

[0037] The raw material formula of the finishing agent used in the surface treatment layer is 80 parts of water-based matte polycarbonate polyurethane resin, 20 parts of wa...

Embodiment 2

[0044] The PU synthetic leather provided in this embodiment comprises a base cloth layer, an adhesive layer, an intermediate layer, a surface layer and a surface treatment layer formed on the surface layer which are stacked in sequence, except that the formula of the intermediate layer is different from that of Example 1 , all the other are with embodiment 1.

[0045] In this example, the raw material formula of the middle layer is 50 parts of JF-HSY-9041A, 50 parts of JF-HSY-9920A, 1006 parts of amine curing agent, 0.4 parts of leveling agent and 20 parts of phosphorus-based flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com