Flame-retardant single-faced velvet composite fabric and preparation method and application thereof

A composite fabric, flame retardant composite technology, applied in the field of flame retardant materials, can solve the problems of environmental protection, flame retardant, cost is not easy to take into account, flame retardant is difficult to achieve LOI, etc. The effect of good performance and low fogging value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Weigh 266.8 grams of isophorone diisocyanate (Bayer, Germany), 191.2 grams of phosphorus-containing polyester diol DM1304 (product of Beijing Demei Kechuang Technology Co., Ltd., molecular weight 478, hydroxyl value 233mgKOH / g, phosphorus content 19.7 % (wt, %)), 200 gram polyether polyols N210 (Nanjing Zhongshan Chemical Co., Ltd.), 33.5 gram dimethylol propionic acid (0.25 moles) (Jiangxi Tianlan Industrial Co., Ltd.) carry out polycondensation reaction, control reaction temperature At 80°C, react under stirring and heating for 2.5 hours, then add 13.4 grams of trimethylolpropane (Jilin Petrochemical Company) (0.1 mol) and 13.4 grams of butanone, and react at 80°C for 1 hour;

[0074] Add 80 grams of butanone to reduce the viscosity. After the temperature of the reaction system drops below 40°C, neutralize with 26.91 grams of triethylamine. The molar ratio of triethylamine to dimethylol propionic acid is 1:1, and the degree of neutralization is controlled. at 100%;

...

Embodiment 2

[0077] Take by weighing 218.4 grams of hexamethylene diisocyanate (Bayer Corporation of Germany), 102.1 grams of N, N-bis(2-hydroxyethyl) aminomethylene phosphonic acid diethyl ester, 300 grams of polyether polyol N220 (Nanjing Zhong Mountain Chemical Co., Ltd.), 44.7 grams (0.334 moles) of dimethylol propionic acid (Jiangxi Tianlan Industrial Co., Ltd.) for polycondensation reaction, control the reaction temperature at 80 ° C, react under stirring and heating for 2.5 hours, then add 16.1 grams (0.12 mol) trimethylolpropane (Jilin Petrochemical Company) and 16.1 gram butanone, reacted 1 hour at 82 ℃;

[0078] Add 70 grams of butanone to reduce the viscosity. After the temperature of the reaction system drops below 40°C, neutralize with 33.69 grams of triethylamine. The molar ratio of triethylamine to dimethylolpropionic acid is 1:1, and the degree of neutralization is controlled. at 100%;

[0079] Add 664.0 grams of ionized water, under the speed of 1300RPM, high-speed emulsi...

Embodiment 3

[0081] Weigh 956 grams of phosphorus-containing polyester diol DM1304 (Beijing Demei Kechuang Technology Co., Ltd. DM1304, molecular weight 478, hydroxyl value 233mgKOH / g, phosphorus content (wt, %) 19.7%), 134 grams of dimethylol propane Acid and 400 grams of polyether polyol N210 (Nanjing Zhongshan Chemical Co., Ltd.), drop 870 grams of toluene diisocyanate (Yantai Wanhua Chemical Group Co., Ltd.) to carry out polycondensation reaction, control the molar ratio NCO / OH in the material at 1.5 : 1, add 100 gram butanone, react 2.0 hours at 78 ℃;

[0082] Use 298.3 grams of methyl ethyl ketone oxime (Zhejiang Quzhou New Future Chemical Co., Ltd.) to cap the remaining NCO at the end group, and react at 70°C for 1.0 hour;

[0083] Neutralize with 101 grams of triethylamine, the molar ratio of triethylamine to dimethylolpropionic acid is 1:1, and the neutralization degree is controlled at 100%;

[0084] Add 2448.4 grams of deionized water, emulsify at a high speed at 1400RPM, emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

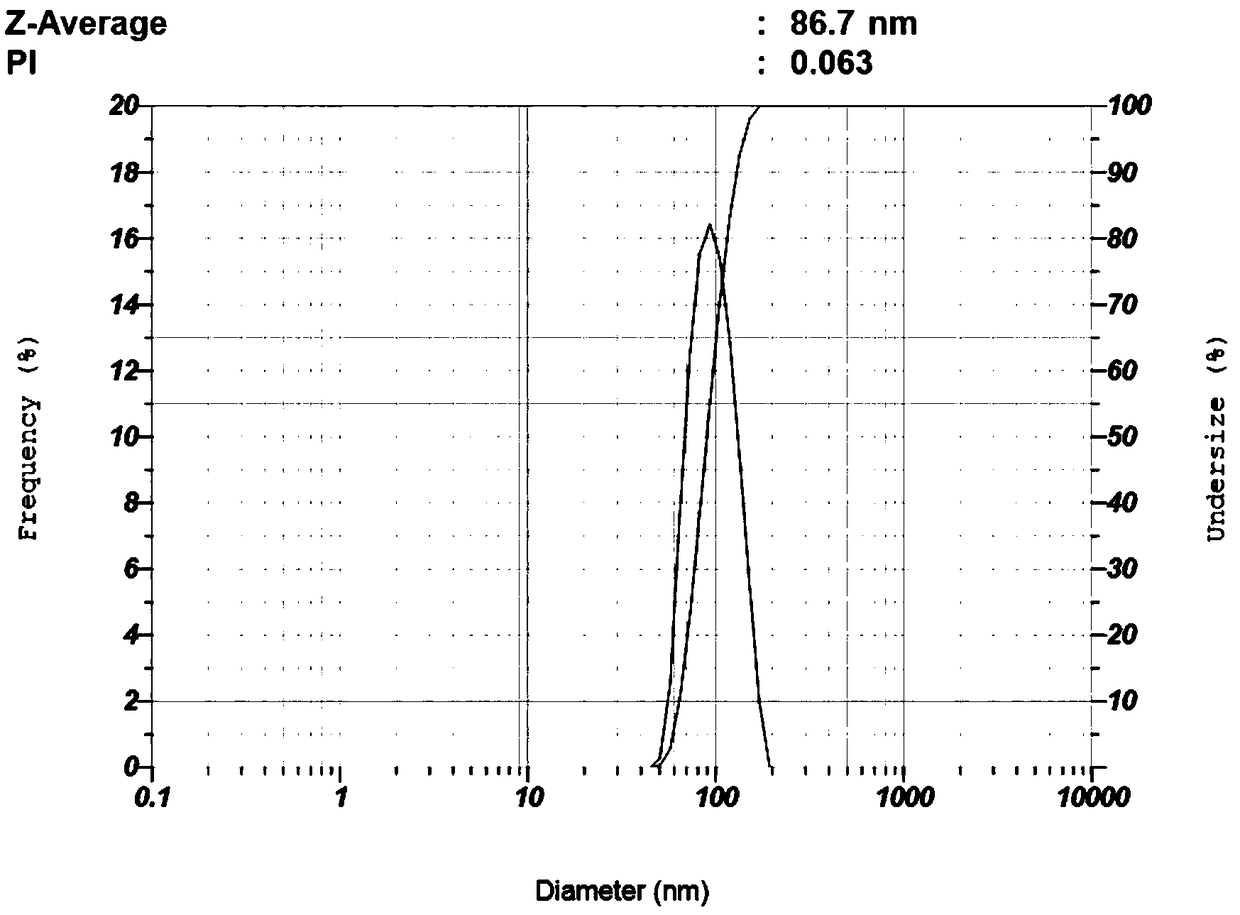

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com