Hot melt adhesive for automobile trunk mats and preparation method of hot melt adhesive

A hot-melt adhesive and back-up technology, used in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc. Solvent glue has problems such as high volatility, and achieves the effects of low atomization value, simple preparation method and less equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

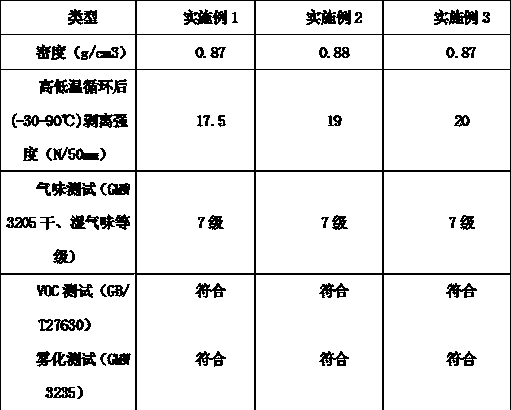

Embodiment 1

[0022] A kind of hot-melt adhesive for automobile trunk mat, comprising the following components by weight: 15 parts by weight of polyolefin elastomer rich in propylene, 47 parts by weight of polyolefin elastomer of ethylene and propylene copolymerization, and 37.7 parts by weight of tackifying resin part, 0.3 part by weight of antioxidant.

[0023] Specifically, the tackifying resin is one or both of hydrogenated petroleum resin and non-hydrogenated petroleum resin.

[0024] Specifically, the antioxidants are tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol, 2,6-di-tert-butyl-4-methylphenol and tris[2.4 - one or two kinds of di-tert-butylphenyl] phosphite.

[0025] A kind of hot-melt adhesive for automobile trunk cushion and preparation method thereof, comprises the following steps:

[0026] 1) Put 15 parts by weight of propylene-rich polyolefin elastomer, 47 parts by weight of ethylene, propylene copolymerized polyolefin elastomer and 0.3 parts by w...

Embodiment 2

[0033] A kind of hot-melt adhesive for automobile trunk cushion as described in embodiment 1 and preparation method thereof, can also adopt following technology:

[0034] 1) Put 20 parts by weight of propylene-rich polyolefin elastomer, 42 parts by weight of ethylene, propylene copolymerized polyolefin elastomer and 0.5 part by weight of antioxidant into the reactor, start heating and stir evenly, the reactor The temperature of the inner material is controlled at 160-170°C, and heated for 50-70 minutes until the material is completely melted.

[0035] 2) Put 37.5 parts by weight of tackifying resin into the reaction kettle of step 1) and stir evenly. The stirring speed is controlled at 60-100r / min. After stirring for 5-10min, stop heating, close the reaction kettle, and pump out the inside of the reaction kettle. Vacuum until the pressure is less than -0.09Mpa, control the vacuuming time at 40-60 minutes, and release the vacuum after the vacuuming time is over, to obtain hot-m...

Embodiment 3

[0039] A kind of hot-melt adhesive for automobile trunk cushion as described in embodiment 1 and preparation method thereof, can also adopt following technology:

[0040] 1) Put 30 parts by weight of propylene-rich polyolefin elastomer, 32 parts by weight of ethylene, propylene copolymerized polyolefin elastomer and 1 part by weight of antioxidant into the reactor, start heating and stir evenly, the reactor The temperature of the inner material is controlled at 160-170°C, and heated for 50-70 minutes until the material is completely melted.

[0041] 2) Put 37 parts by weight of tackifying resin into the reaction kettle of step 1) and stir evenly. The stirring speed is controlled at 60-100r / min. After stirring for 5-10min, stop heating, seal the reaction kettle, and pump out the inside of the reaction kettle. Vacuum until the pressure is less than -0.09Mpa, control the vacuuming time at 40-60 minutes, and release the vacuum after the vacuuming time is over, to obtain hot-melt p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com