Manufacturing process of anti-fouling, ultra-low total carbon emission, and wear-resistant cowhide car seat leather

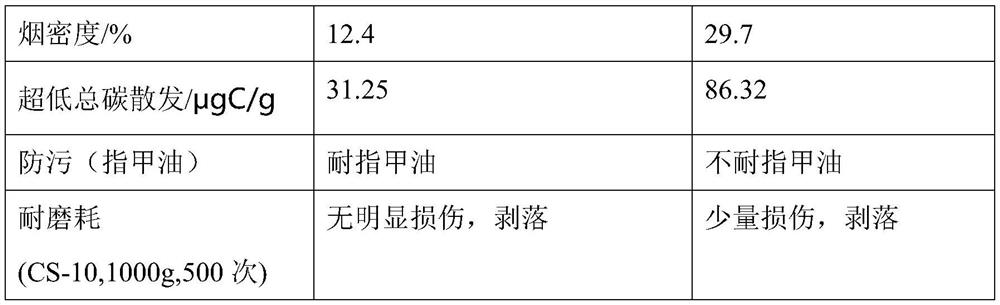

A technology of automobile seat cushion and manufacturing process, which is applied in the field of automobile seat cushion leather manufacturing process, can solve the problems affecting the aesthetic feeling and service life of automobile leather, and achieve the effect of promoting uniform penetration, delaying volatilization, and reducing the generation of free oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with example further illustrate the present invention.

[0039] The process steps of the embodiment of the present invention are as follows:

[0040] (1), pre-soaking water: raw hide is weighed as the basal number of step (1) material consumption and bath liquid liquid ratio, apply 0.10% bactericide (Badericides 72, Bright Eagle Xingye Leather Co., Ltd.), 0.15% soaking aid (Humectan RDL (Huiying Xingye Leather Co., Ltd.), 0.4% soda ash, the bath liquid ratio is controlled at 400%, the bath liquid temperature is 20-22°C, the bath liquid pH is 8.8-9.2, the Baume degree is 8, every 60min turns 5min , running for a total of 18 hours, and the next day, the fleshing, trimming, and weighing were carried out sequentially as the material consumption and bath liquid ratio base number from step (2) to step (4).

[0041] The measured water filling data: the loose part of the hide is filled with water by 55%, and the tight part is filled with water by 25% to 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com