A method for reducing TOC content in lithium battery multi-element materials

A lithium battery, multi-component technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of reducing, affecting the performance of lithium batteries, and high impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

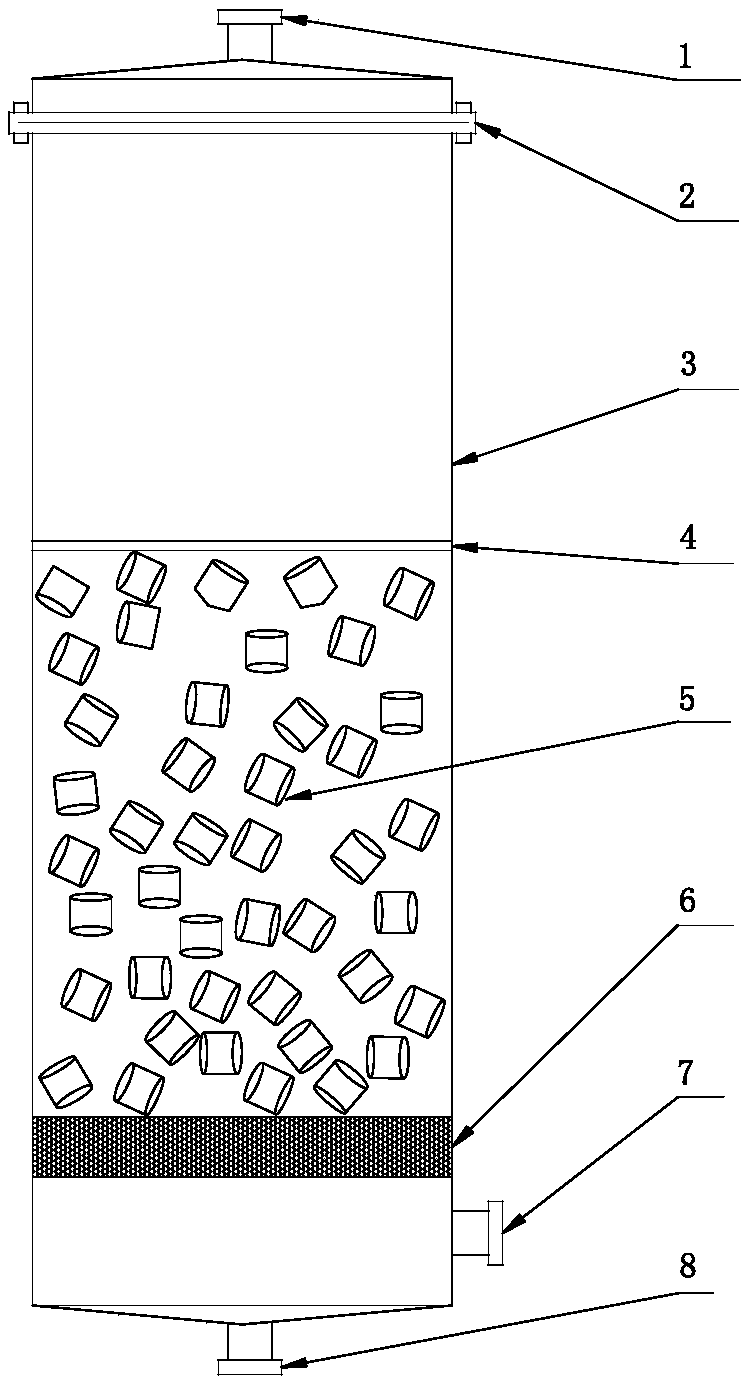

Image

Examples

Embodiment 1

[0084] A method for reducing TOC content in lithium battery multi-component materials. The lithium battery multi-component solution is firstly treated by a microcrystalline filtration system as an example, and then sequentially processed by an activated carbon filtration system, a primary ultrafiltration system and a secondary ultrafiltration system.

[0085] Among them, the effective use volume of the microcrystalline filtration system is 5m 3 , the flow rate of the lithium battery multi-component solution through the microcrystalline filtration system is 20m 3 / h, the use temperature is 30°C, and polyvinyl chloride is used, the particle size is 50μm; the effective use volume of the activated carbon filter system is 10m 3 , the flow rate of the lithium battery multi-component solution through the activated carbon filter system is 20m 3 / h, the operating temperature is 30°C, and its average pore size is 20μm; the effective use area of the primary ultrafiltration system is 2...

Embodiment 2

[0090] A method for reducing TOC content in lithium battery multi-component materials. The lithium battery multi-component solution is firstly treated by a microcrystalline filtration system as an example, and then sequentially processed by an activated carbon filtration system, a primary ultrafiltration system and a secondary ultrafiltration system.

[0091] Among them, the effective use volume of the microcrystalline filtration system is 10m 3 , the flow rate of the lithium battery multi-component solution through the microcrystalline filtration system is 30m 3 / h, the use temperature is 30°C, and polyvinyl chloride is used, the particle size is 50μm; the effective use volume of the activated carbon filter system is 20m 3 , the flow rate of the lithium battery multi-component solution through the microcrystalline filtration system is 30m 3 / h, the operating temperature is 30°C, and its average pore size is 20μm; the effective use area of the primary ultrafiltration system...

Embodiment 3

[0096] A method for reducing TOC content in lithium battery multi-component materials. The lithium battery multi-component solution is firstly treated by a microcrystalline filtration system as an example, and then sequentially processed by an activated carbon filtration system, a primary ultrafiltration system and a secondary ultrafiltration system.

[0097] Among them, the effective use volume of the microcrystalline filtration system is 10m 3 , the flow rate of the lithium battery multi-component solution through the microcrystalline filtration system is 30m 3 / h, the operating temperature is 35°C, and polyvinyl chloride is used, the particle size is 50μm; the effective use volume of the activated carbon filter system is 20m 3 , the flow rate of the lithium battery multi-component solution through the microcrystalline filtration system is 30m 3 / h, the operating temperature is 35°C, and its average pore size is 20μm; the effective use area of the primary ultrafiltration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com