Organic sulfur compound containing water discharge apparatus

A treatment device and compound technology, applied in biological water/sewage treatment, water treatment parameter control, sustainable biological treatment, etc., can solve problems such as low decomposition speed, organic matter decomposition, poor decomposition speed, DMS treatment outflow, etc., to achieve Effect of reducing TOC and preventing short flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

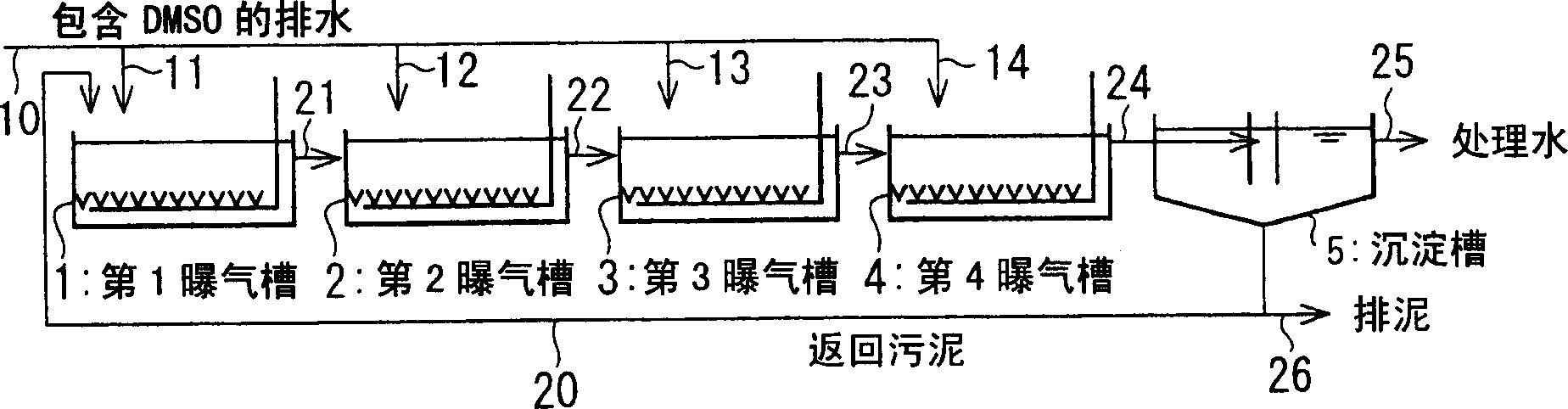

[0084] exist figure 1 In the shown device, untreated water is injected into each aeration tank of the first to fourth aeration tanks 1 to 4 at a flow rate of 15 L / h each time to treat it. In addition, nitrogen and phosphorus were added to untreated water, and water was passed so that BOD:BOD:N:P=100:5:1 (weight ratio) was assumed to be 3 times TOC.

[0085] The water quality of the obtained treated water and the DMS concentration in the exhaust gas of each aeration tank were investigated, and the results are listed in Table 1.

Embodiment 2

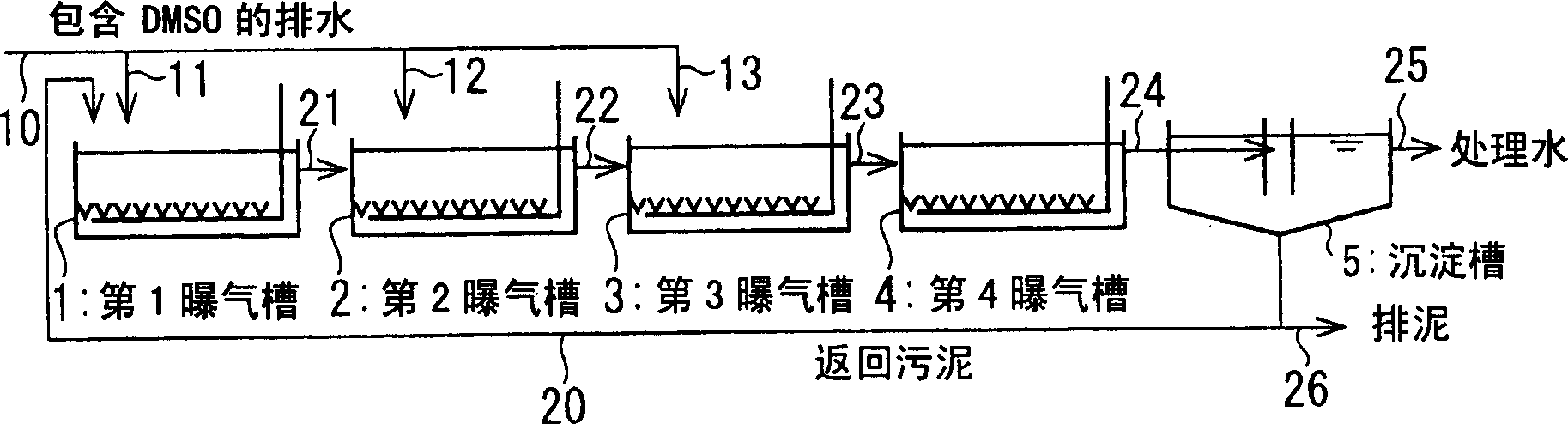

[0087] use figure 2 In the shown device, untreated water is injected into the first to third aeration tanks 1 to 3 at a flow rate of 20 L / h each time, and it is treated in the same manner as in Example 1 except that, The water quality of the obtained treated water and the DMS concentration in the exhaust gas of each aeration tank are listed in Table 1.

Embodiment 3

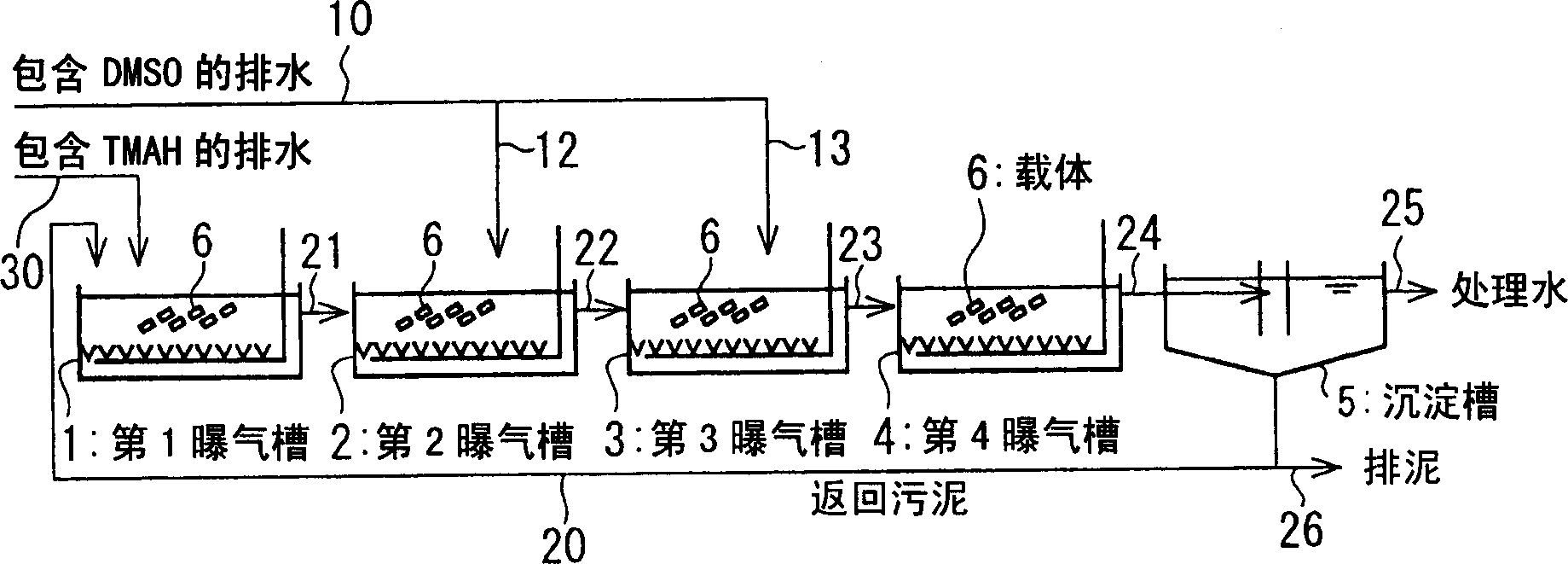

[0089] picture image 3 As shown, in each of the aeration tanks 1 to 4, the apparent capacity is used to add a square sponge with a side length of 3mm according to 30% of the tank capacity, and each time the untreated Water is injected into the second to third aeration tanks 2 and 3, respectively, and the following water quality containing TMAH is supplied to the first aeration tank. In the untreated water, three times the TOC is assumed as BOD, Add phosphorus in the ratio of BOD: P=100: 1 (weight ratio), in addition, according to the mode identical with embodiment 1, it is processed, the water quality of the treated water that has obtained and each aeration tank exhaust DMS concentrations are listed in Table 1.

[0090] (Drainage including TMAH)

[0091] Soluble TOC: 32.8mg / L

[0092] TMAH: 53.8mg / L

[0093] Nitrogen by Keidel method: 12.3mg / L

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com