Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Less washing water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

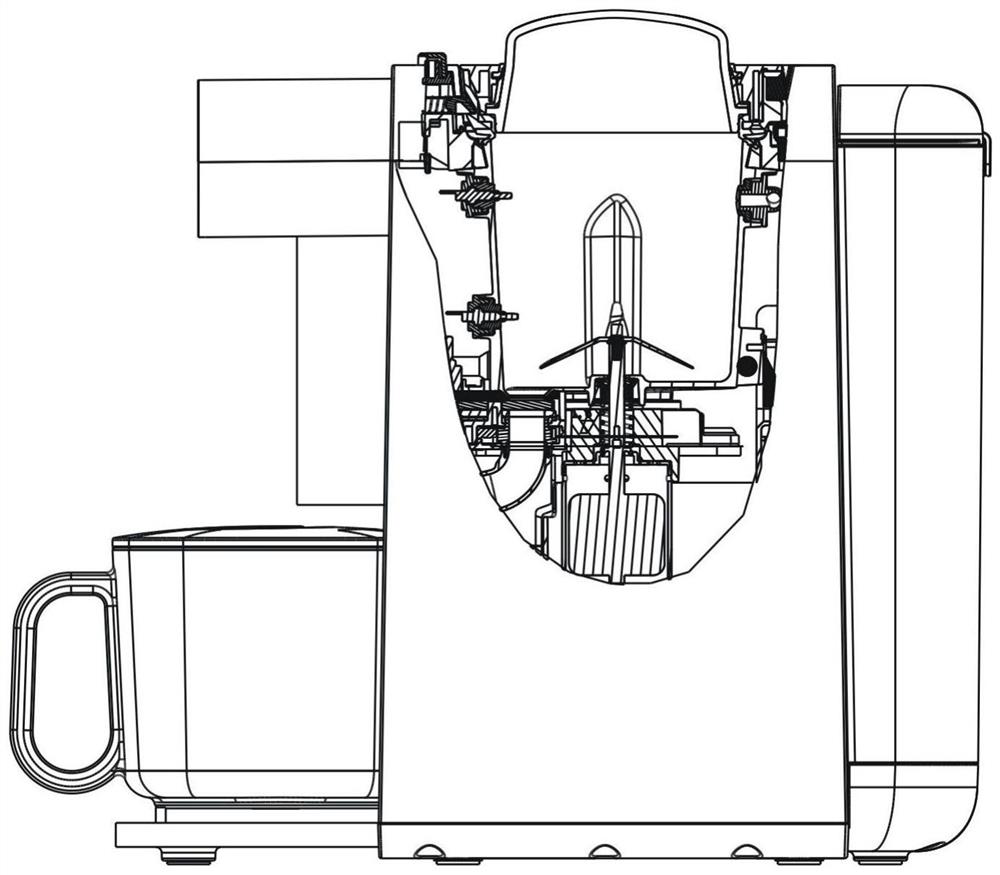

Method for cleaning capsule beverage dispenser

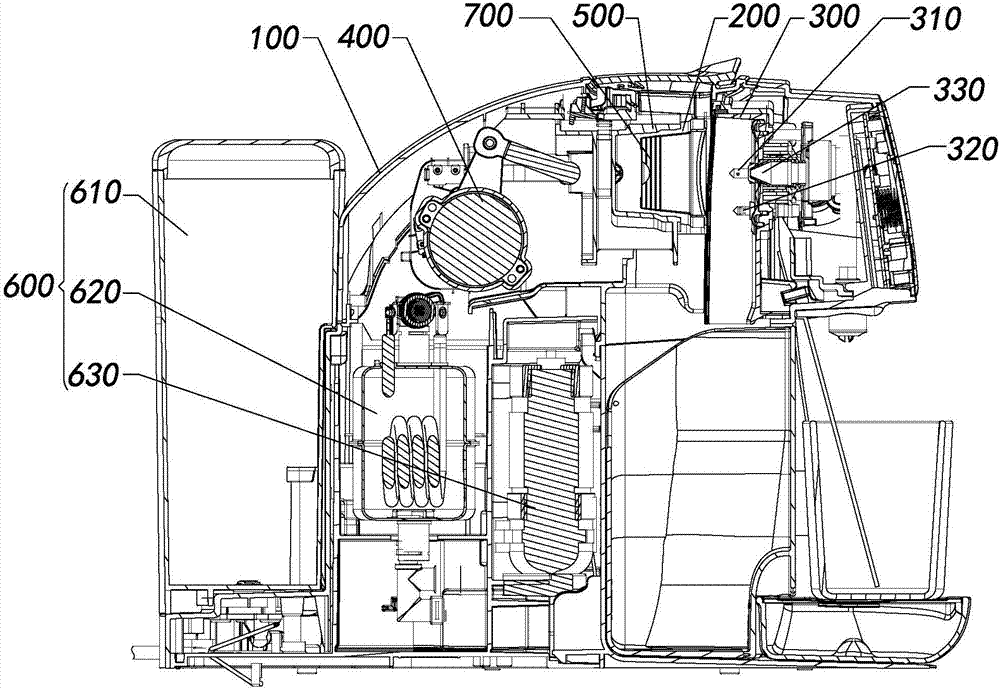

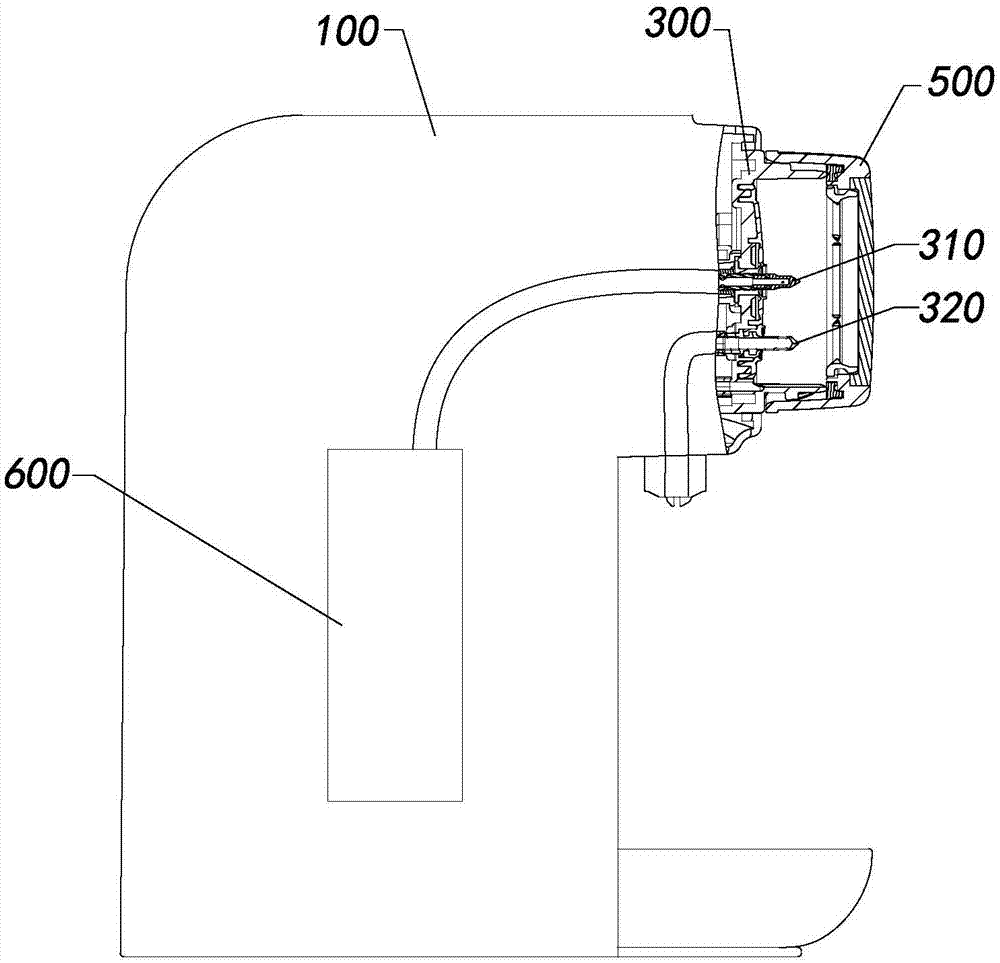

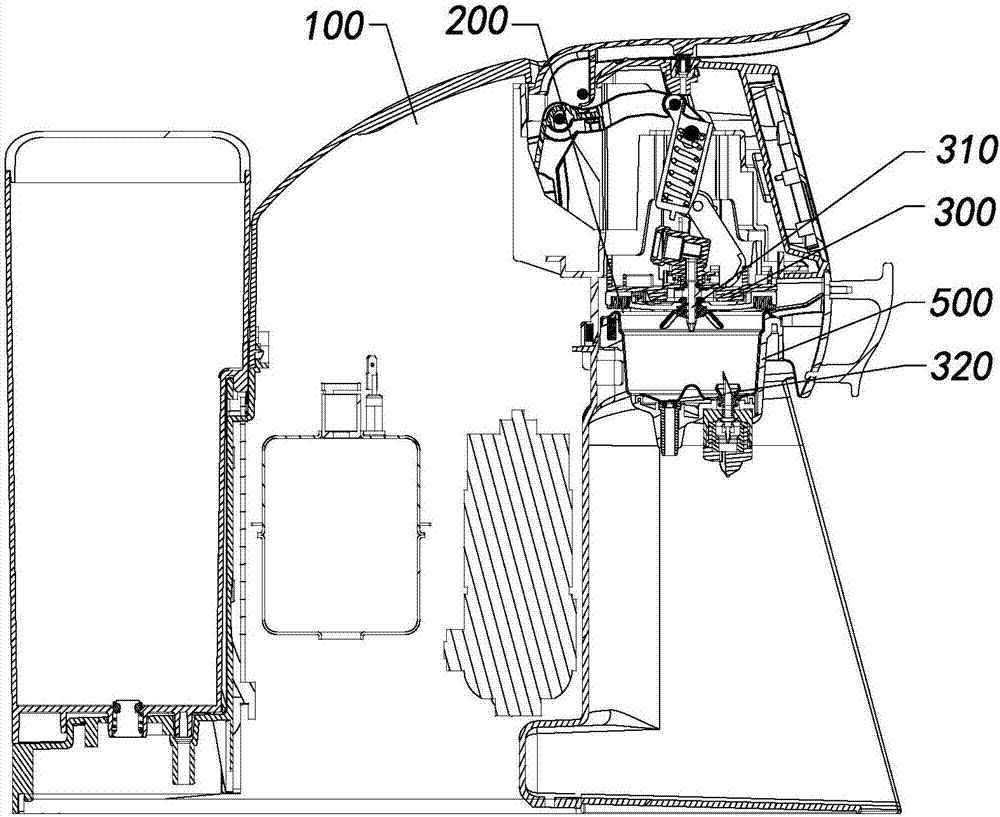

The invention discloses a method for cleaning a capsule beverage dispenser, and belongs to the technical field of beverage preparation. The problems that wasting of water is caused in the cleaning process of an existing capsule beverage dispenser and the cleaning effect is poor are solved. The capsule beverage dispenser comprises a machine base with a brewing cavity, a liquid feeding mechanism, an input module and a control module. The control module controls the capsule beverage dispenser to be cleaned according to signals of the input module. The cleaning method includes a first cleaning stage and a second cleaning stage capable of being selected to be executed. The first cleaning stage at least includes a first washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a first power P1 for cleaning. The second cleaning stage at least includes a second washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a second power P2 for cleaning. The rated power of the liquid feeding mechanism is PE1, and P1<P2<=PE1. The method disclosed by the embodiment of the invention is used for cleaning the capsule beverage dispenser. The capsule beverage dispenser can be a capsule coffee maker, a capsule soybean milk machine and the like.

Owner:杭州易杯食品科技有限公司

Water soluble anti-rust agent

InactiveCN101712817AShort film forming timeImprove quick-drying performanceAnti-corrosive paintsHazardous substanceSebacic acid

The invention relates to a water soluble anti-rust agent on the surface of ferrous metal, which comprises the following components: 2 to 10 weight percent of barium petroleum sulfonate and / or barium dinonyl decyl sulfonate, 1 to 6 weight percent of sodium molybdate and / or amine molybdate, 0 to 10 weight percent of sebacic acid, 2 to 10 weight percent of polyacrylic ester, 3 to 20 weight percent of triethanolamine oleic soap and / or 2 to 6 weight percent of polyoxyethylenesorbitan monooleate, 0 to 15 weight percent of sodium alkylsulfonate, 0 to 8 weight percent of glycerin and the balance of water or machine oil. Compared with the conventional water soluble anti-rust agent, the water soluble anti-rust agent of the invention has the advantages of short film forming time, firm film forming adsorption and good anti-rust effect; the actual anti-rust period can reach 3 to 6 months; the formed film is thin and only 3 to 5 microns; common workpieces do not need film removal and can be directly assembled and coated; the film removal is convenient, and the film is only soaked and rinsed in mild water over 50DEG C and then can be removed quickly; and the anti-rust agent has no component containing toxic and harmful substances, does not contain phosphorus, has the advantages of good environmental protection and no pollution to the environment, and is the environment-friendly water soluble anti-rust agent.

Owner:无锡市弘育化工有限公司

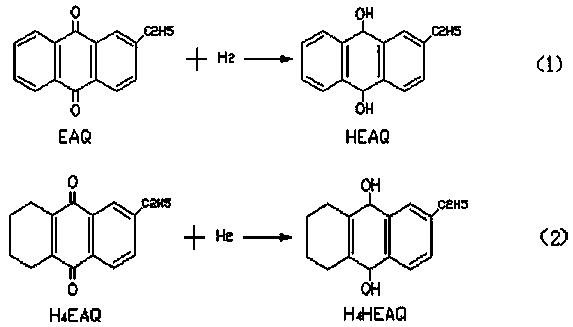

Technology for producing hydrogen peroxide by anthraquinone process

PendingCN110436418AReduce productionReduce lossesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPhosphate2-Ethylanthraquinone

The invention relates to a technology for producing hydrogen peroxide by an anthraquinone process, and relates to the technical field of industrial production of hydrogen peroxide by the anthraquinoneprocess. The technology comprises a hydrogenation reaction, an oxidation reaction, extraction, a purification process and a regeneration process; in the hydrogenation reaction, a mixed solution formed by mixing a heavy aromatic hydrocarbon, trioctyl phosphate, 2-ethylanthraquinone, tetrabutyl urea and 2-ethyltetrahydroanthracene reacts with hydrogen under the action of a palladium catalyst to obtain a hydrogenated solution; and in the oxidation reaction, the hydrogenated solution containing phosphoric acid is oxidized by oxygen in air to obtain an oxidized solution. The technology can reducethe consumption of total anthraquinone, can increase the oxidation yield of the oxidation process by using the working fluid system, and makes the amount of the generated residual liquid small.

Owner:江苏中煦科技有限公司

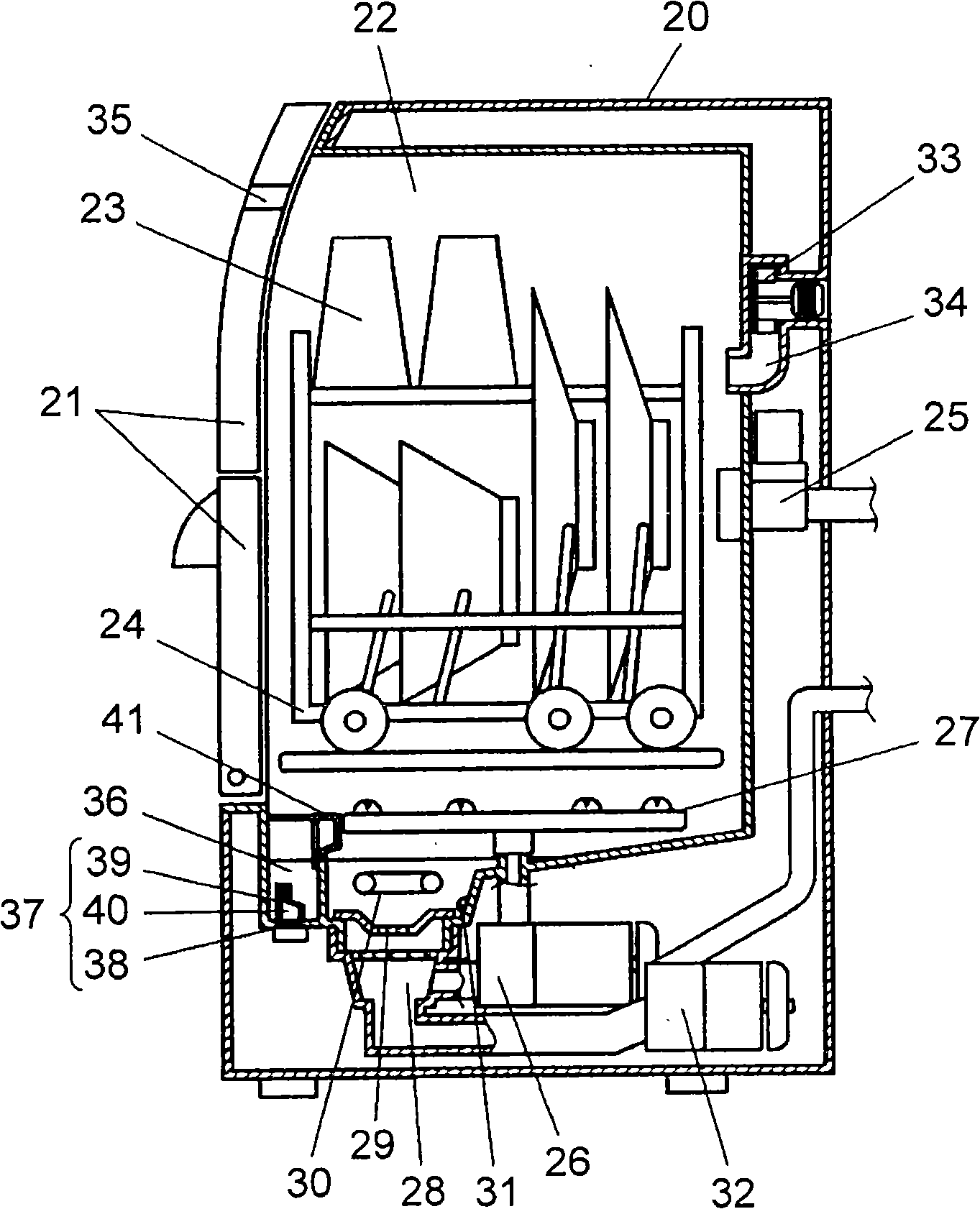

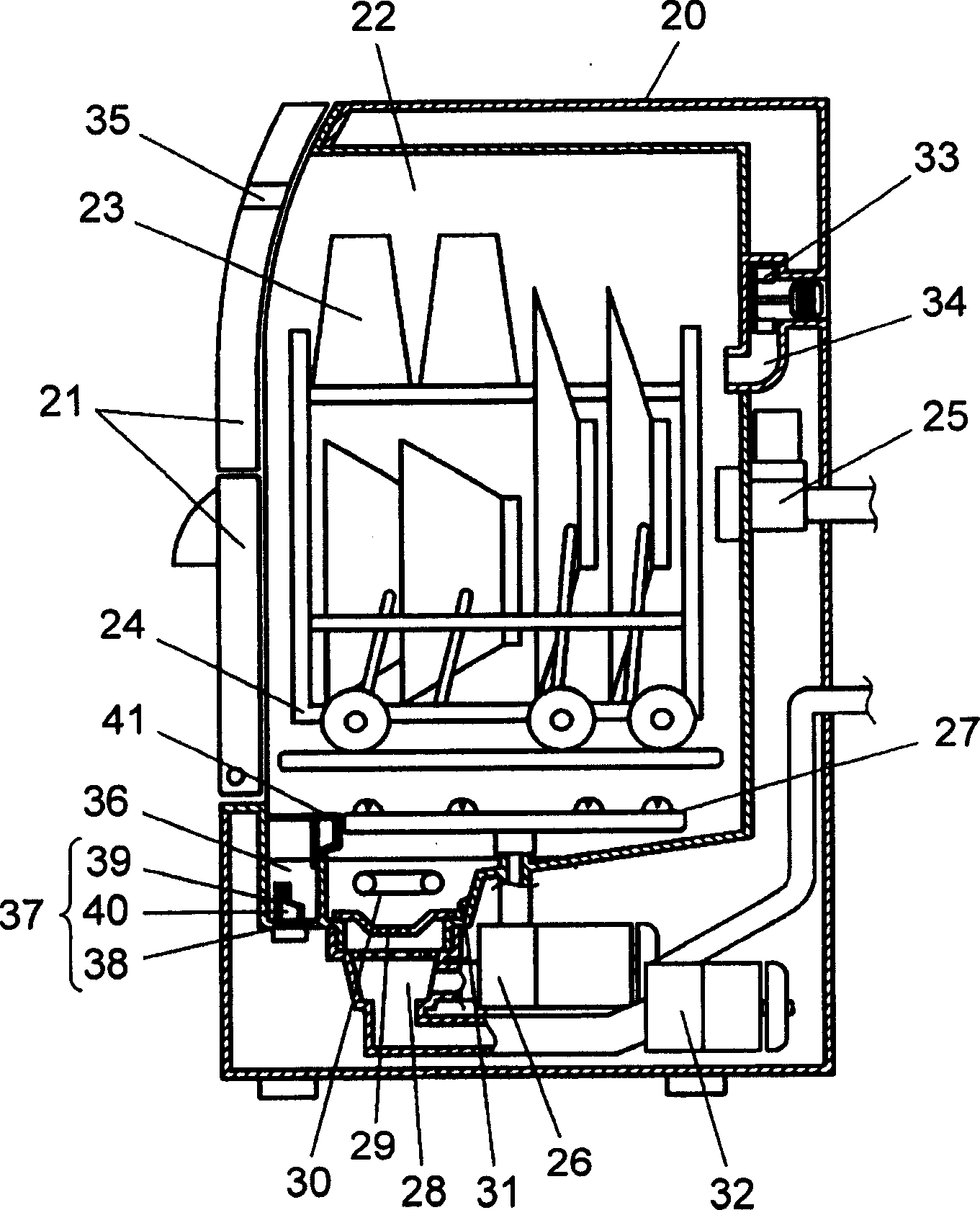

Dishwasher

ActiveCN101254085AImprove solubilityReduce workloadTableware washing/rinsing machine detailsUltrasonic vibrationEngineering

The invention relates to a dishware cleaner, including a rinse tank for filling the cleaned matter, a clean water storing part for storing the clean water; a ultrasonic vibration part for micronizing the clean water stored in the clean water storing part and flying to the rinse tank; a clean water reclaiming part for reclaiming the water raising from the water surface under the vibration of the ultrasonic vibration part in the clean water stored in the clean water storing part to the clean water storing part, wherein the clean water reclaimed by the clean water storing part is guided to the cleaning agent container of the clean water storing part.

Owner:PANASONIC CORP

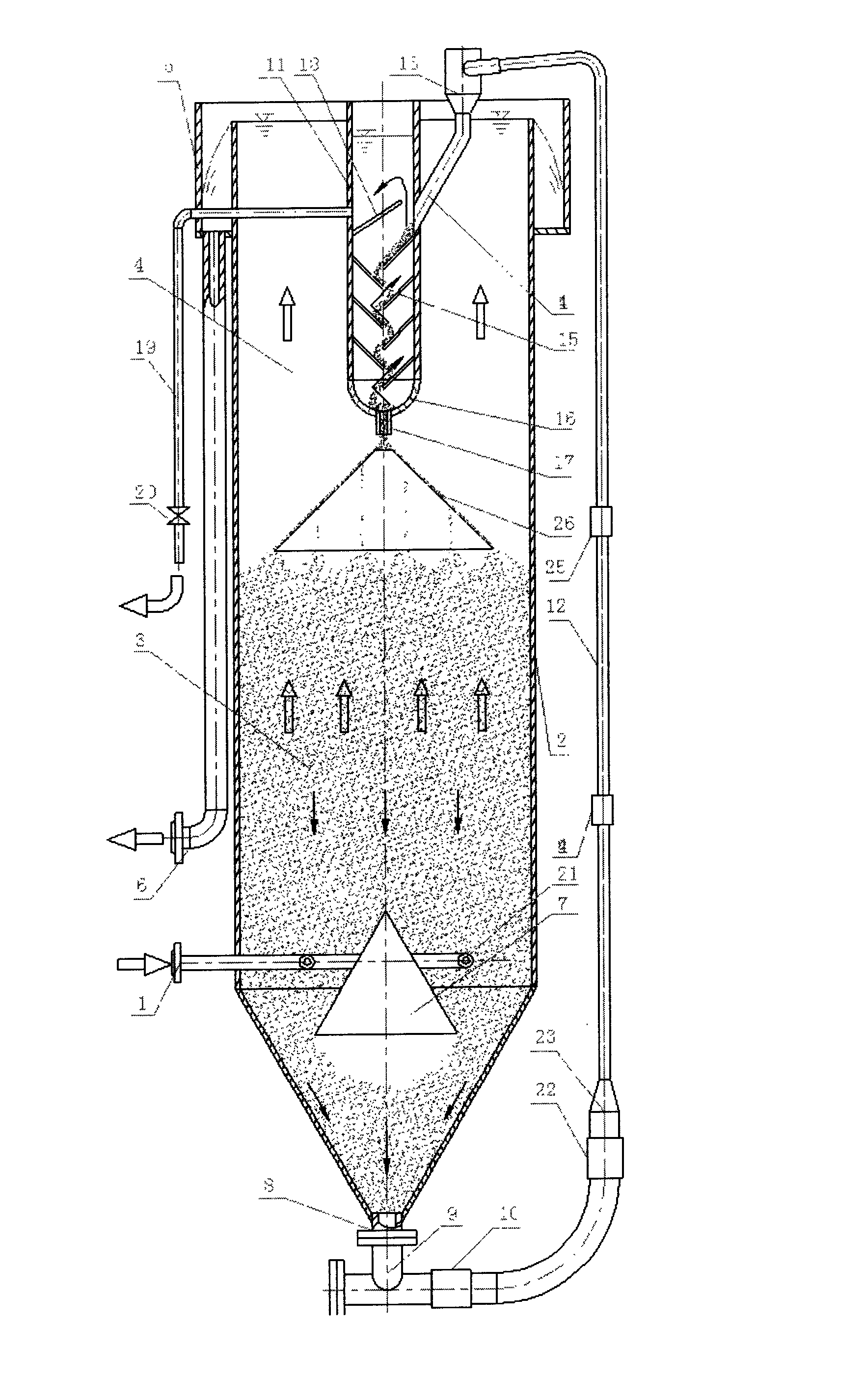

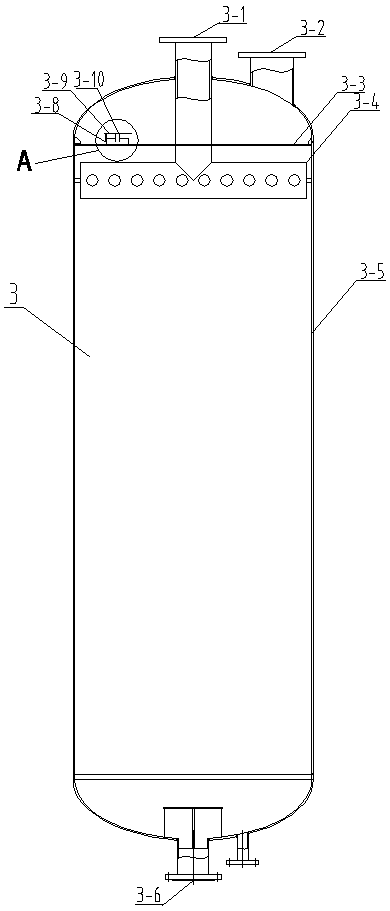

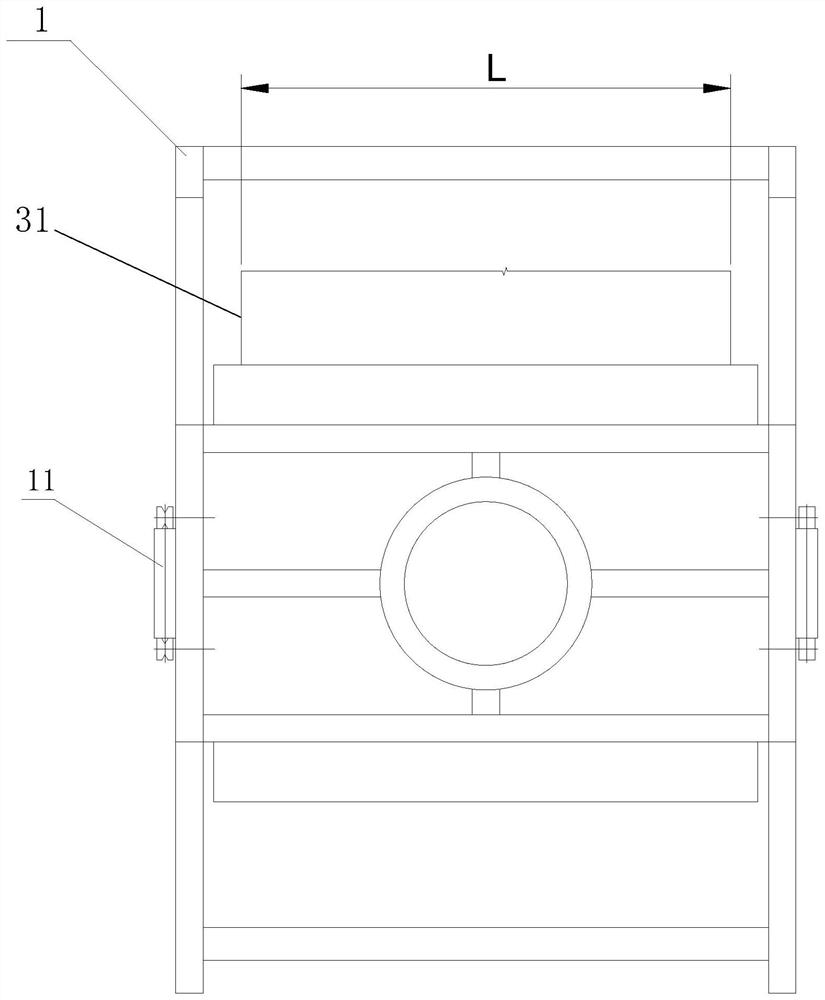

Moving bed filter

InactiveCN1597042AEasy to operateIncrease the chance of frictionLoose filtering material filtersGravity filtersWater qualityFilter material

A moving-bed filter able to continuously run for treating water is composed of cylindrical tank, water distributor, filtering bed, fairing unit, air distributor, filtering material delivering pipe, gas separator, washer, filtering material distributor and the regulating valve for the washing water.

Owner:CHINA PETROLEUM & CHEM CORP +1

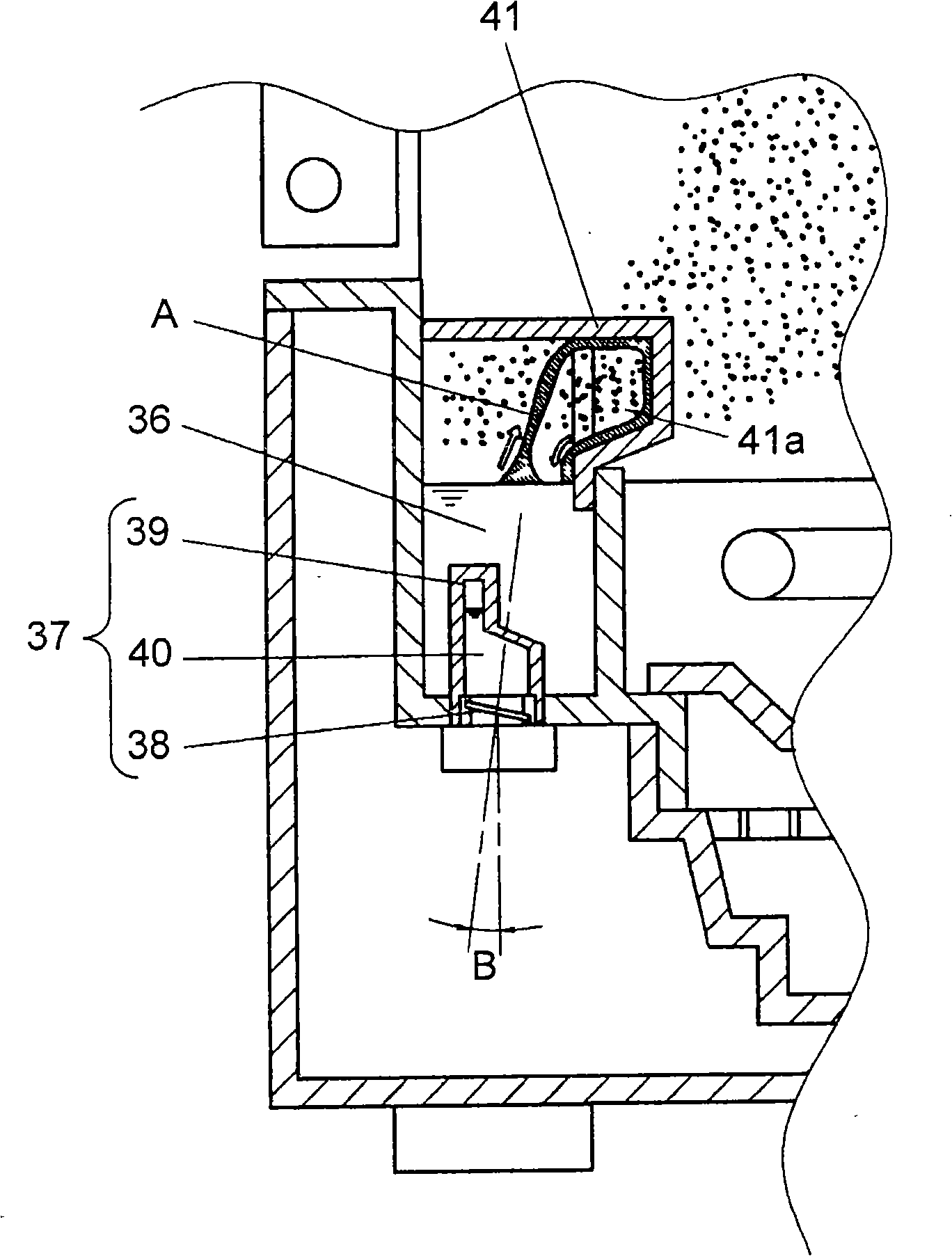

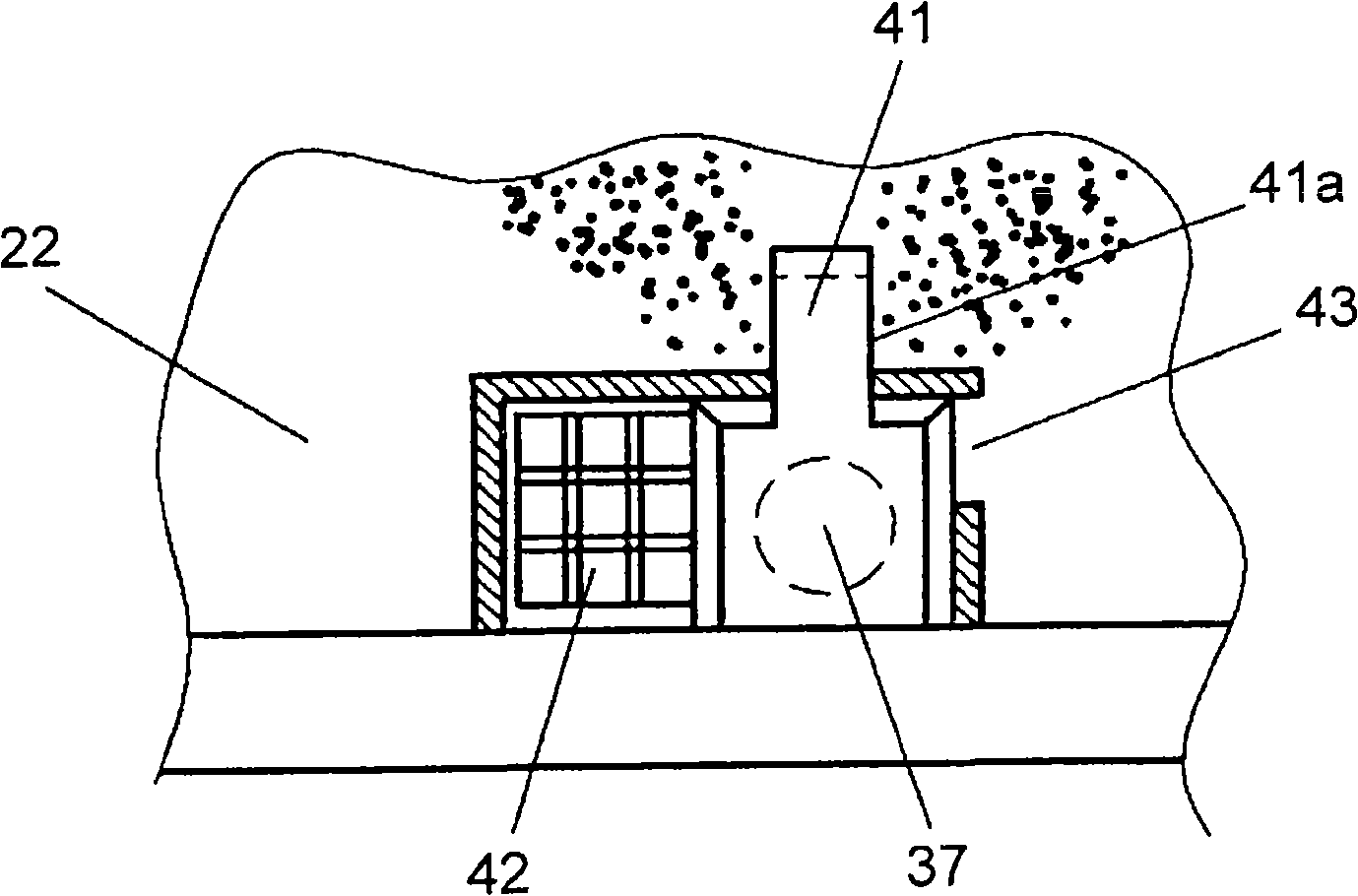

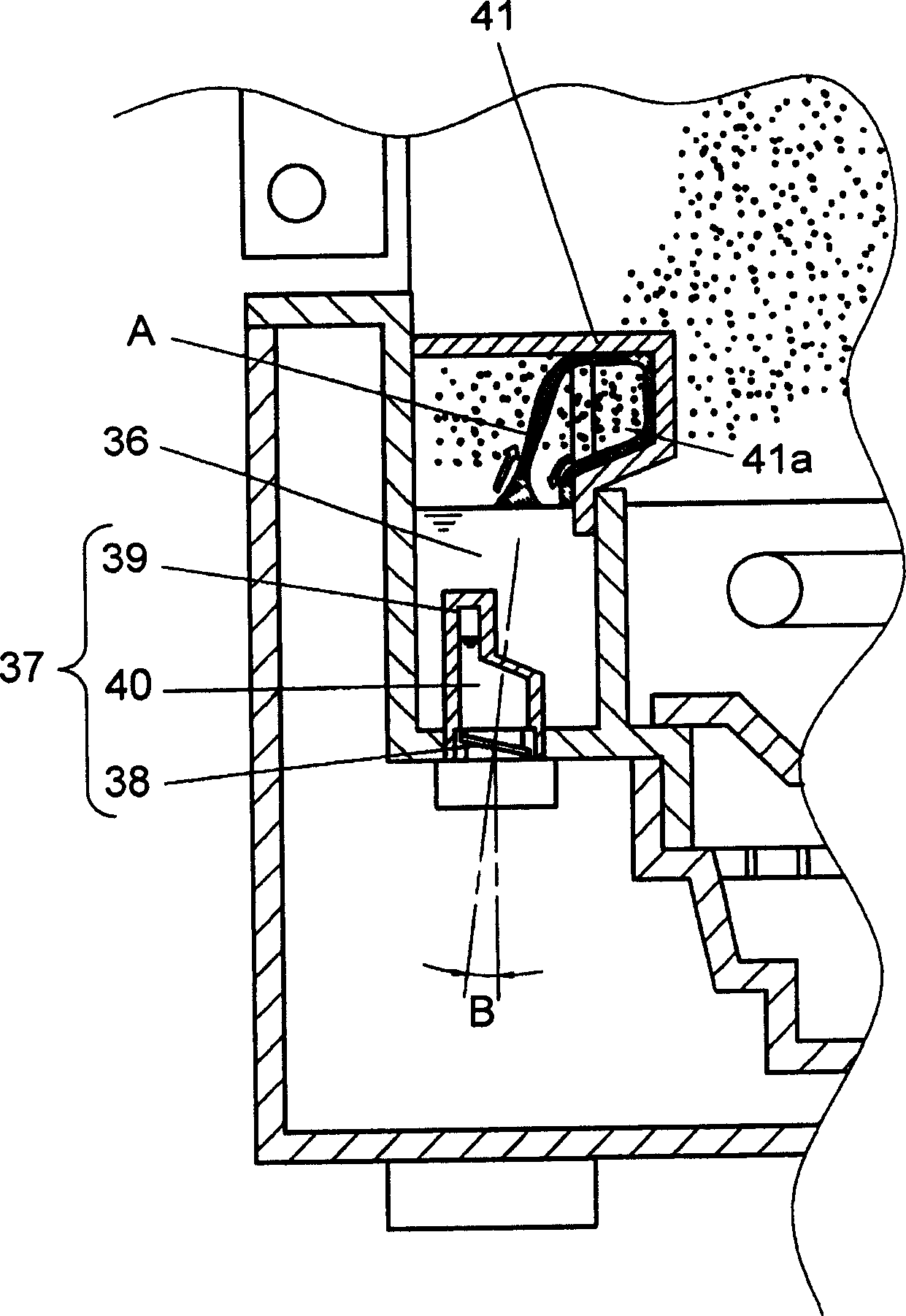

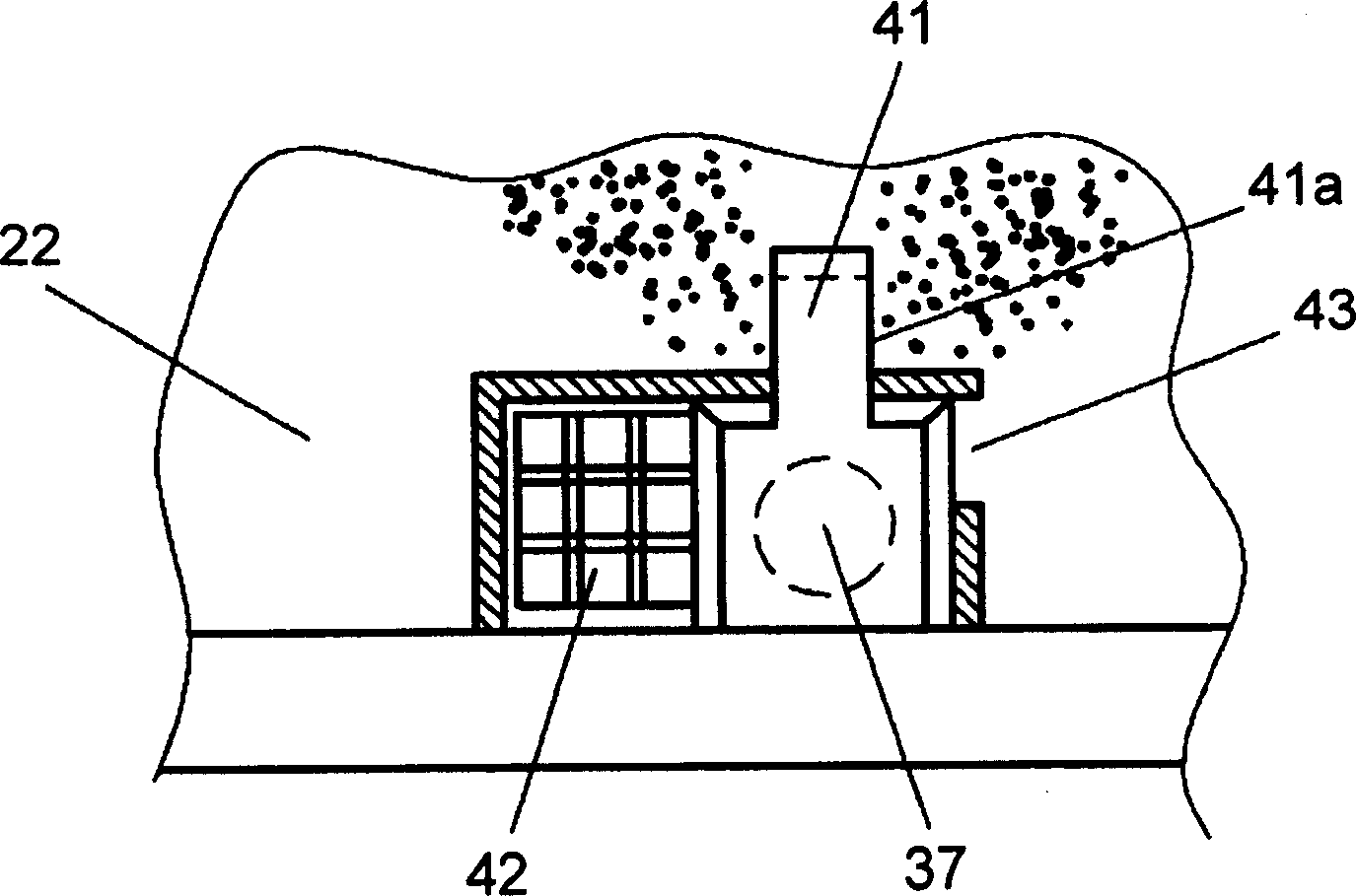

Cleaning unit and tableware washing machine therewith

ActiveCN1679440AImprove solubilityReduce workloadTableware washing/rinsing machine detailsCleaning equipmentUltrasonic vibrationProcess engineering

To improve the washing effects of a dishwasher by washing dishes with highly concentrated washing solution without increasing the quantity of a detergent to be used. The dishwasher comprises a washing solution storage part 36 in which the washing solution is stored, and an ultrasonic vibration part 37 for scattering the washing solution inside a washing tub 22. The washing solution raised from the water surface by the vibration of the ultrasonic vibration part 37 is collected in the washing solution storage part 36. The washing solution with high detergent concentration is micronized using an ultrasonic vibrator 38 and scattered with only a very small quantity of washing solution. With the action of highly concentrated components of the detergent such as alkali, a surfactant and a bleaching agent on the stain, the stain can be powerfully removed.

Owner:PANASONIC CORP

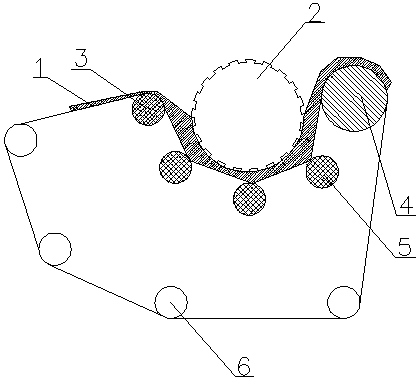

Concave and convex rolling shaft pressure device of belt filter press

InactiveCN104069671ADifferent degrees of squeezingImprove dehydration effectMoving filtering element filtersConvex structureSludge

The invention relates to a concave and convex rolling shaft pressure device of a belt filter press. The concave and convex rolling shaft pressure device of the belt filter press comprises a ring-shaped flocking filter belt and a pressure rolling shaft, wherein a driven rolling shaft and a driving rolling shaft are respectively arranged at the two sides of the circular arc surface of the pressure rolling shaft; a plurality of extrusion rolling shafts are arranged under the pressure rolling shaft; the flocking filter belt is sheathed on the driven rolling shaft, the driving rolling shaft and the extrusion rolling shafts, and is extruded by the pressure rolling shaft and the extrusion rolling shafts; the flocking filter belt is also internally provided with a plurality of tension rolling shafts used for enabling the flocking filter belt to be in a tensioning state; the circumferential surface of the pressure rolling shaft has a concave-convex structure of a gear. The concave and convex rolling shaft pressure device is simple in structure, good in dehydration effect, good in mud cake stripping effect, little in sludge residue, not easy to block and small in cleaning water quantity, and thus reducing secondary pollution.

Owner:YANGZHOU TIANLONG ENVIRONMENTAL PROTECTION EQUIP

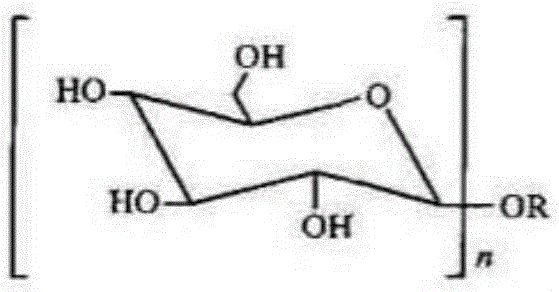

Cleaning agent composition

InactiveCN105670830ALess washing waterSave waterInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistrySodium dodecylbenzenesulfonate

The invention relates to a cleaning agent composition which comprises the following components in parts by weight: 1-9 parts of sodium dodecyl benzene sulfonate, 1-5 parts of sodium hydroxide or potassium hydroxide, 0.5-3 parts of coconutt diethanol amide, 1-9 parts of C12-C13 fatty alcohol-polyoxyethylene ether, 1-8 parts of alkyl polyglucoside, 2-10 parts of sodium metasilicate, 0.1-2 parts of citric acid, 0.1-1.7 parts of sodium ethylenediaminetetraacetate and the balance of water based on 100 parts in total. By adopting the cleaning agent composition provided by the invention, oil stains on a surface can be removed perfectly.

Owner:SHANGHAI SIMAIER DAILY CHEM CO LTD

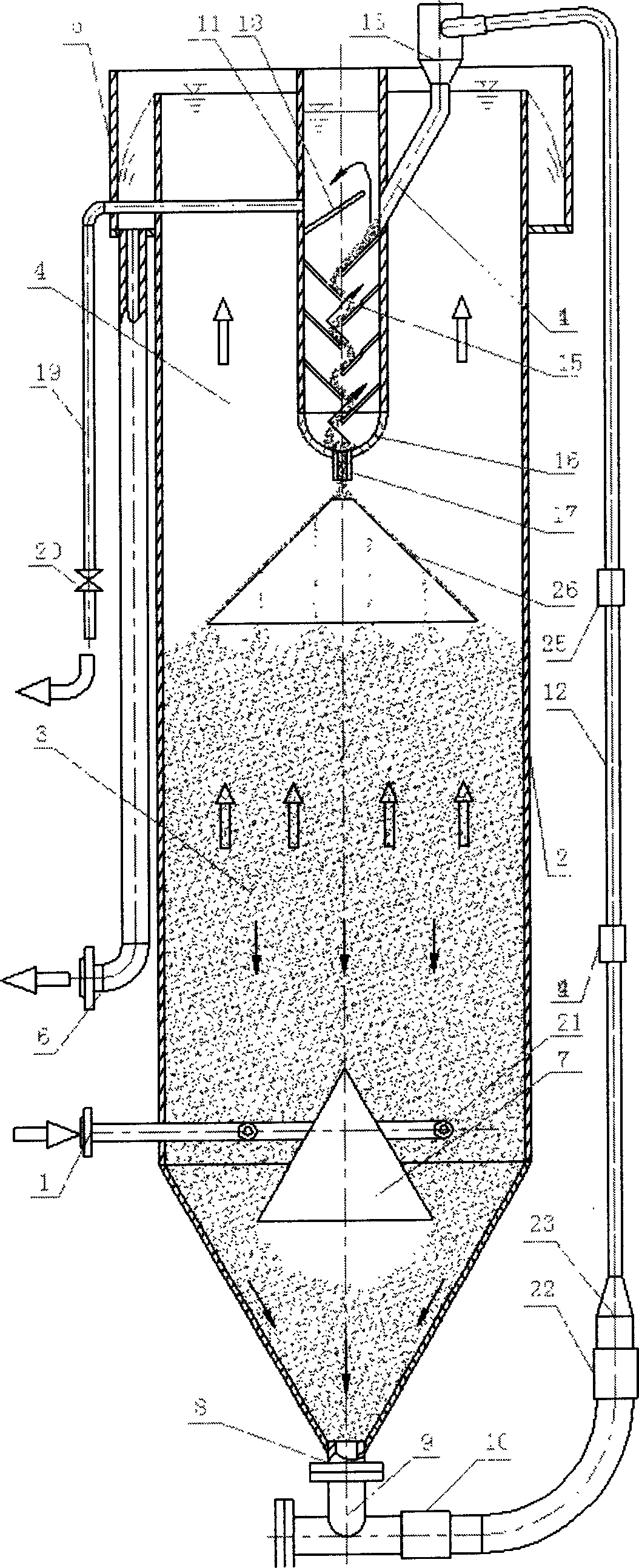

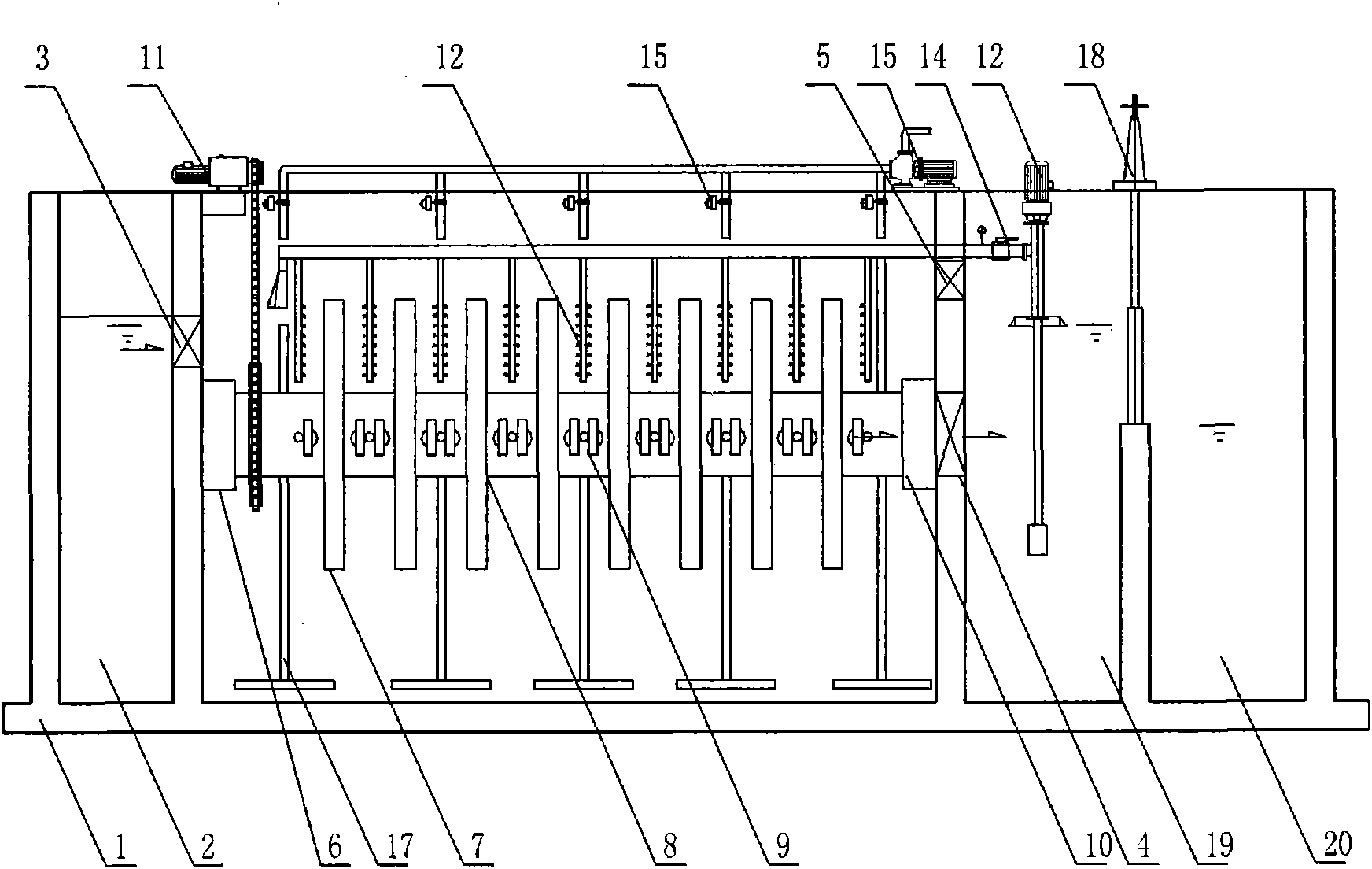

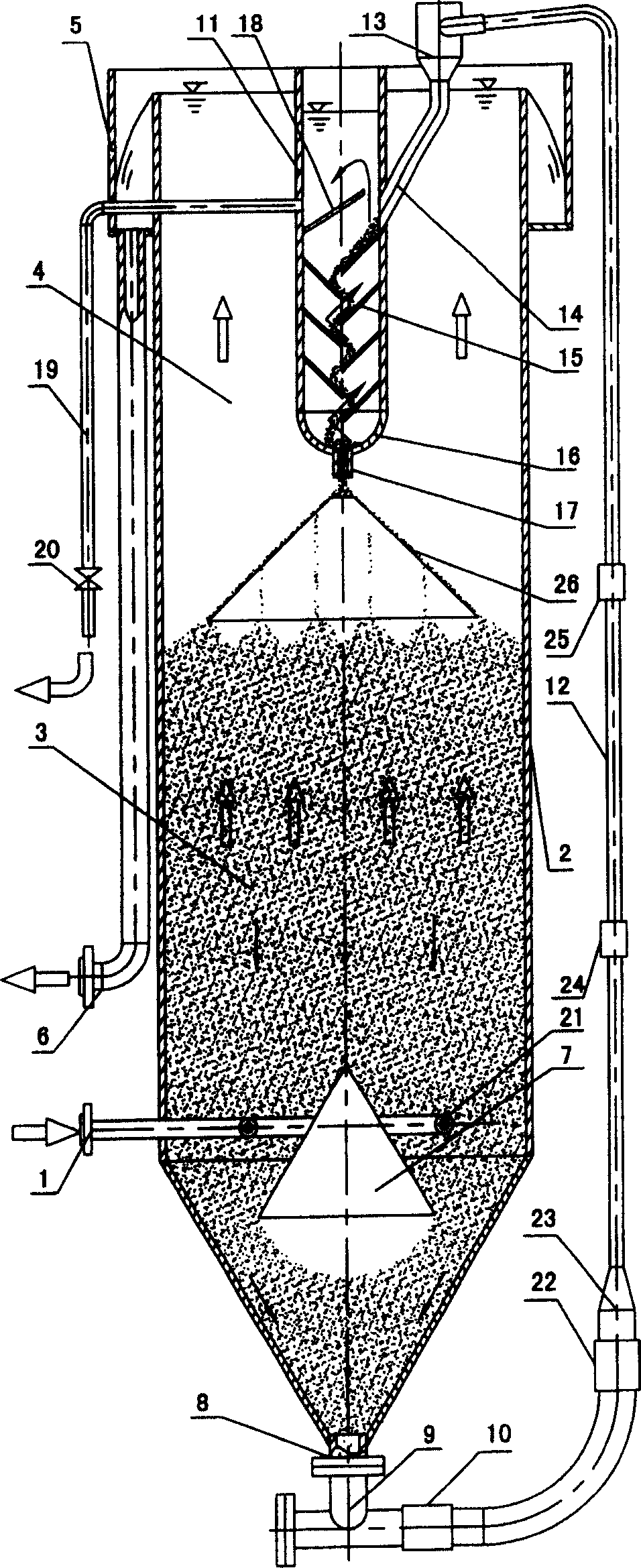

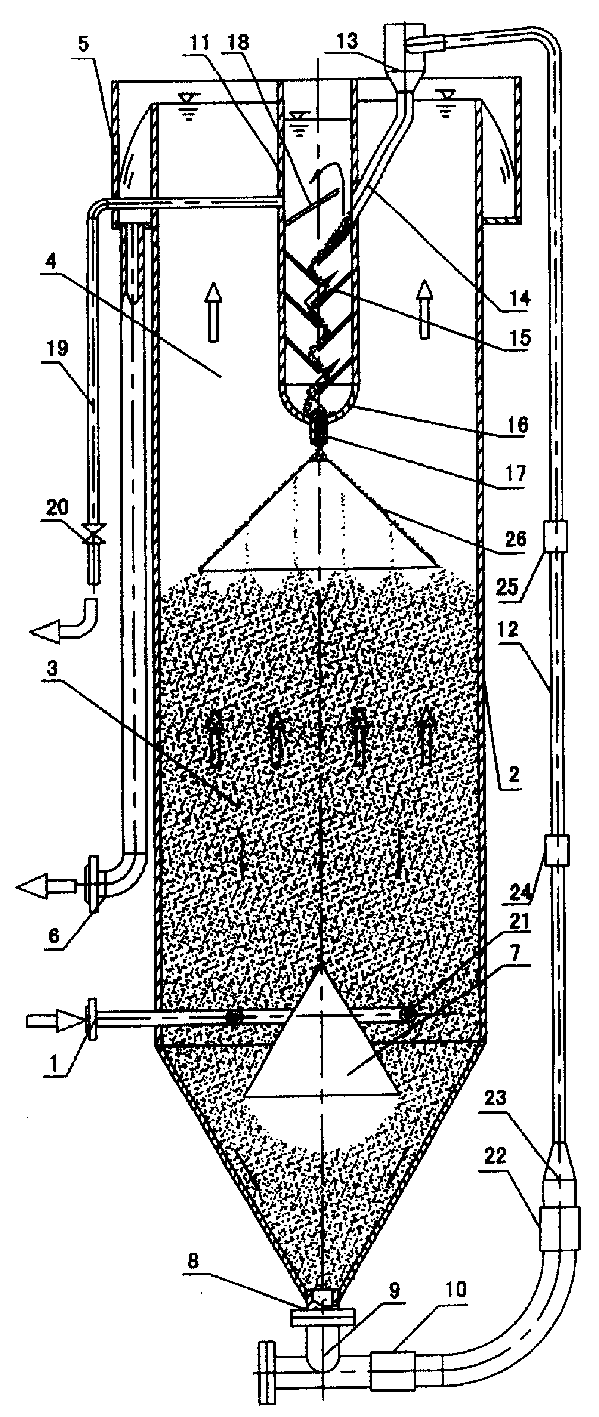

Efficient active flowing bed purifier

InactiveCN104984572AShorten the construction periodImprove efficiencyLoose filtering material filtersGravity filtersArchitectural engineering

An efficient active flowing bed purifier comprises a cylinder body, wherein the center of the upper part of the cylinder body is provided with a washer and a sand distributing device; the washer comprises the cylinder body, the upper end of the cylinder body is sealed, the lower end of the cylinder body is open, the inner wall, close to the lower end, of the cylinder body is provided with a plurality of circles of guide plates inclined downwards, the top end of the cylinder body is vertically downwards provided with a sand blocking column, the tail end of the sand blocking column is provided with a reflective plate for a water surface, and a drain outlet hose connecting pipe is arranged on the cylinder body at one side of the reflective plate, and extends out of the cylinder body of the purifier; the sand distributing device comprises a center pipe and a sand lifting pipe arranged in the center pipe, the upper end of the center pipe extends into the cylinder body of the washer, the outer surface of the extending-in end is provided with a plurality of circles of guide plates inclined downwards, the guide plates are staggered with the guide plates on the inner wall of the cylinder body, a circle of guide plates inclined downwards is arranged on the center pipe wall below the cylinder body of the washer, the diameters of the guide plates are larger than those of the guide plates arranged on the outer surface of the extending-in end, and the tail end of the center pipe extends into a pedestal.

Owner:JIANGSU DELI ENVIRONMENTAL PROTECTION ENGLIMITED BY SHARE

Continuous activated carbon filter device and operation method thereof

PendingCN109173363AImprove filtering effectImprove flushing effectLoose filtering material filtersGravity filtersActivated carbon filtrationFilter effect

The invention relates to the technical field of sewage treatment and particularly relates to a continuous activated carbon filter device and an operation method thereof. The continuous activated carbon filter device comprises a device casing, a water distribution system installed inside the device casing and a filter material cleaning system. Raw water passes through an activated carbon filler sothat the suspended solids in the raw water are retained by the activated carbon filler and the clean filtered water is obtained. The activated carbon filler can adsorb and filter the pollutants in theraw water and further improve the raw water filtering effects. When the sewage and contaminated activated carbon filler are lifted in an air riser, the contaminated activated carbon filler is initially cleaned, the amount of washing water is small, water resources are saved, the water quantity is continuously stable and the impact on the front treatment unit is reduced. A compressor blows the compressed gas into an anti-blocking spray pipe and the compressed gas instantaneously enters the activated carbon filler through a first blowing hole and a second blowing hole of the anti-blocking spraypipe so that caking of the activated carbon filler is prevented.

Owner:XINJIANG LVFENG ENVIRONMENT PROTECTION ENG CO LTD

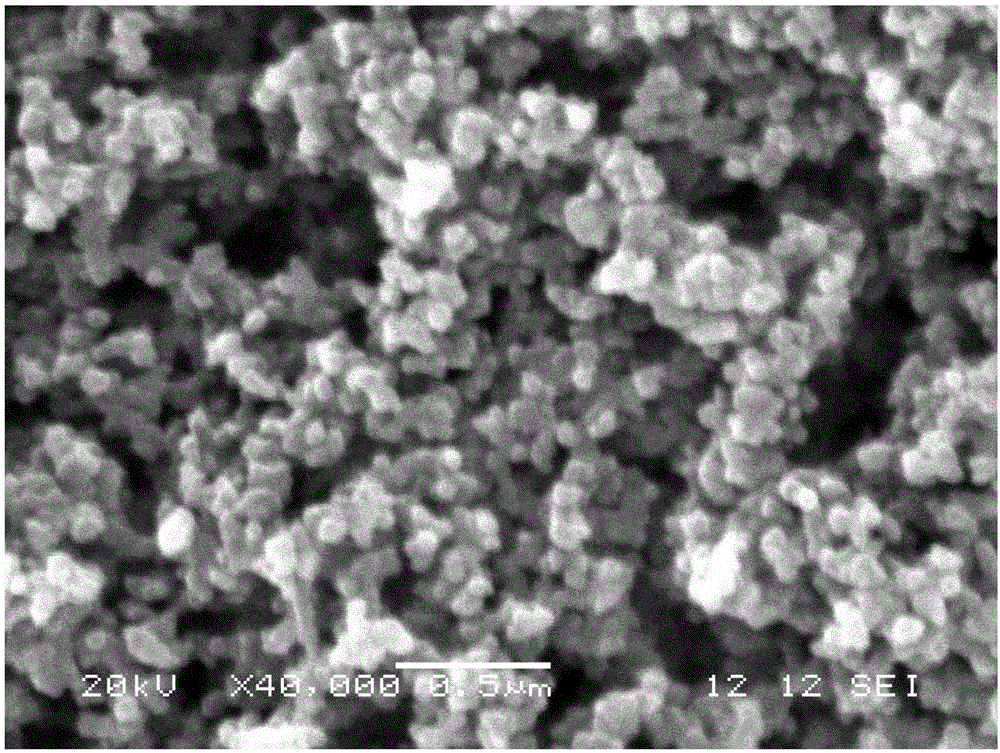

Preparation method of water-insoluble phosphate

ActiveCN106829901AReduce the number of washesReduce generationPhosphatesNanotechnologyWater insolublePhosphate

The invention provides a preparation method of a water-insoluble phosphate. The method comprises the following steps: 1) dissolving raw materials capable of being acid soluble to form metal ions by using mixed acid, and separating to obtain a settled solution, wherein the raw materials capable of being acid soluble to form metal ions are selected from one or a mixture of more of metal, metallic oxide, meta hydroxide, carbonate and metal subcarbonate, and the mixed acid comprises nitric acid and phosphoric acid; 2) forming a reaction system after adding an organic reducing agent in the settled solution, conducting reaction to generate the water-insoluble phosphate, obtaining a phosphate solid, and washing to remove impurities in the phosphate solid, wherein the organic reducing agent is selected from one or a mixture of more of aldehydes, phenols, alcohols and ketone organic matters. Few involatile impurities are introduced in the system in the method, few washing times are required, and the prepared product is high in purity and small in granularity, so that an effective and feasible method is provided for the preparation of the water-insoluble phosphate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

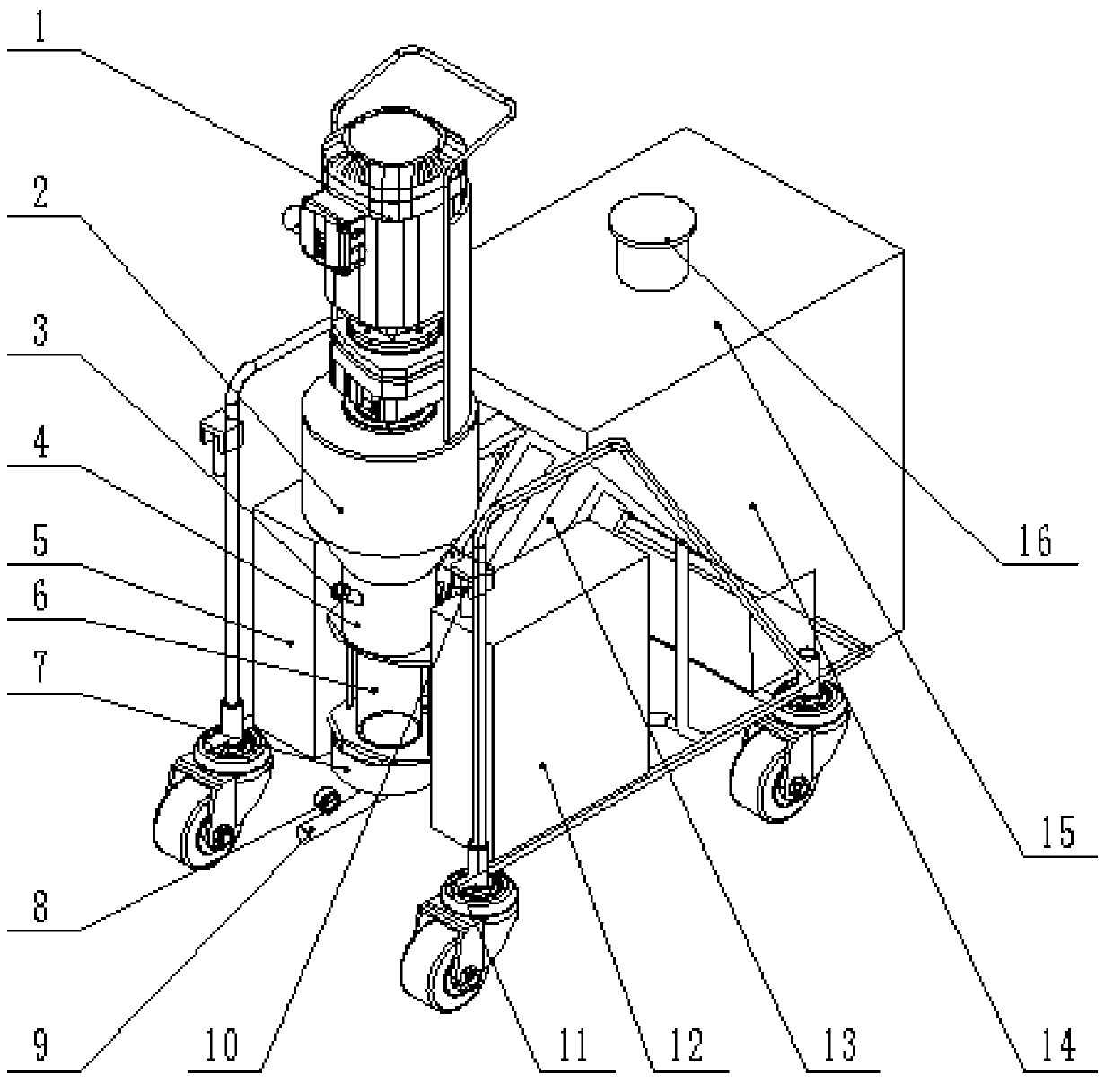

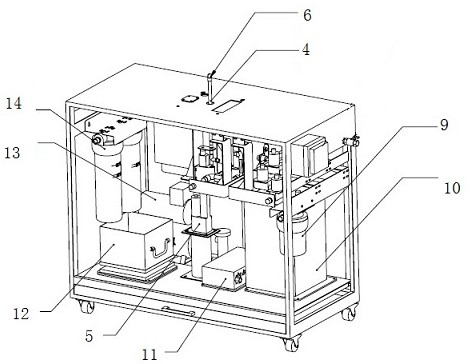

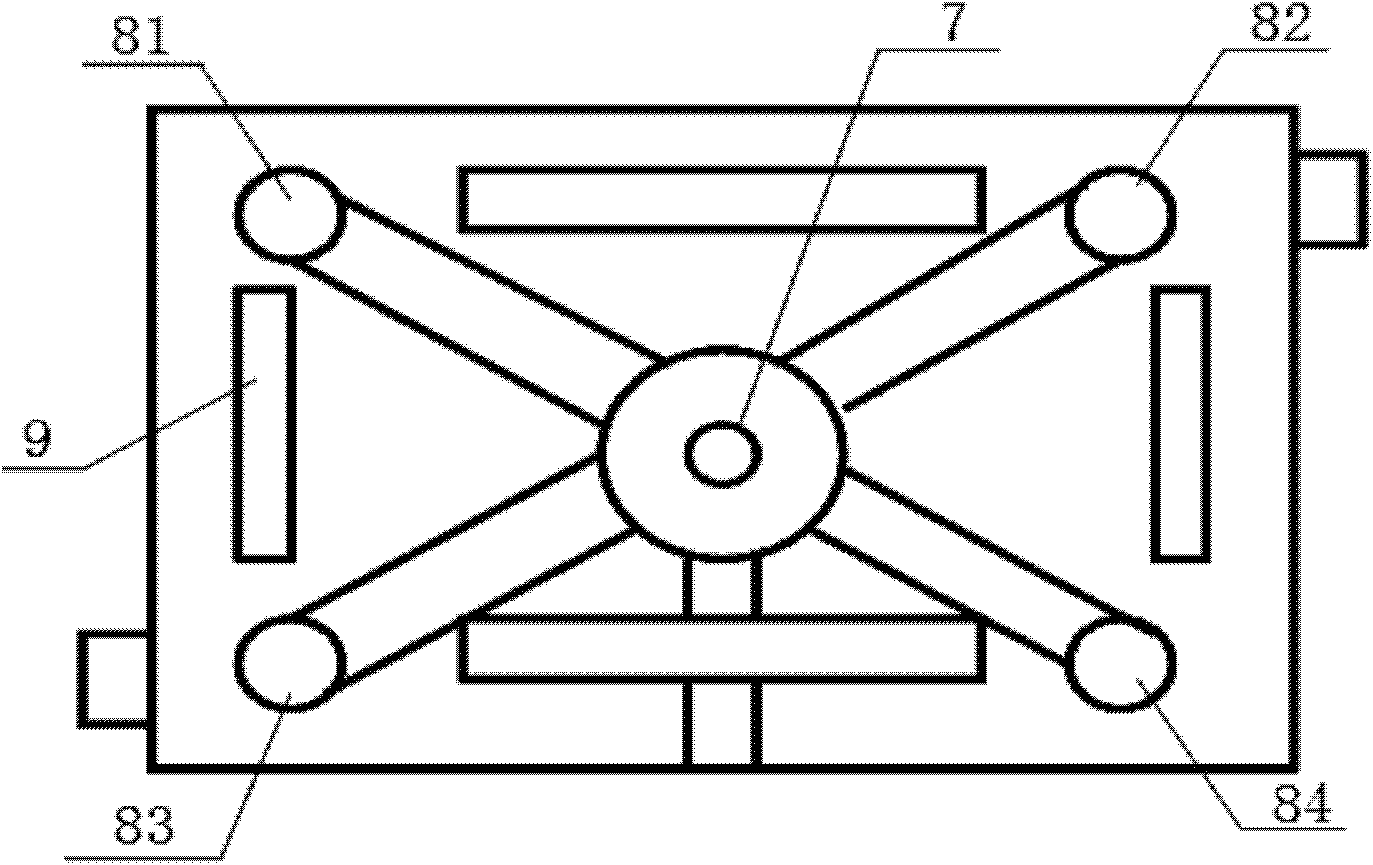

Mobile grouting device for fixing radioactive waste

InactiveCN111497012AImprove uniformityImprove performanceMixing operation control apparatusHollow article cleaningControl cellRadioactive waste

The invention relates to the technical field of treatment of medium-and-low-level radioactive waste in the nuclear industry, in particular to a mobile grouting device for fixing radioactive waste. Themobile grouting device comprises a control unit, a metering device and a stirring grouting device, the stirring grouting device comprises a stirrer, a screw pump and a post-mixer, the stirrer comprises a stirring rod and a stirring motor, and the stirring motor simultaneously drives the stirring rod, the screw pump and the post-mixer to operate. According to the mobile grouting device for fixingthe radioactive waste, mixing, outputting and grinding are achieved at the same time through the stirring motor, the size is small, movement is achieved, continuous feeding and continuous stirring ofwater, additives and cement and continuous discharging of cement paste can be achieved, and the grouting efficiency is greatly improved; dry powder agglomerates are secondarily crushed by using the post-mixer, so that the uniformity and performance of wet mixed materials are improved; and the equipment is not provided with an independent cleaning pipeline any more, and the mixer can be thoroughlycleaned by replacing the stirring rod with a cleaning rod.

Owner:武汉海王新能源工程技术有限公司

Regeneration system for raffinate in process for producing hydrogen peroxide by anthraquinone method

PendingCN110482764AGuaranteed service lifeExtended service lifePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesWater contaminantsLiquid storage tankRaffinate

The invention discloses a regeneration system for the raffinate in a process for producing hydrogen peroxide by an anthraquinone method and relates to the technical field of industrial production of hydrogen peroxide by an anthraquinone method. The regeneration system comprises a raffinate pipeline, a carclazyte bed and a regenerated liquid storage tank; according to the direction from the liquidinlet to the liquid outlet, a liquid outlet of the raffinate pipeline is sequentially connected with a coalescer, a primary flash evaporator, a secondary flash evaporator and a carclazyte bed feedingpump; a liquid outlet of the carclazyte bed feeding pump is connected with a tube pass liquid inlet of the heat exchanger, a tube pass liquid outlet of the heat exchanger is connected with the heater,a liquid outlet of the heater is connected with a liquid inlet of the carclazyte bed, a liquid outlet of the carclazyte bed is connected with a shell pass liquid inlet of the heat exchanger, and a shell pass liquid outlet of the heat exchanger is connected with the regenerated liquid storage tank; the first-stage flash evaporator is further connected with a first-stage condenser, and the first-stage condenser is connected with a first vacuum unit; the second-stage flash evaporator is further connected with a second-stage condenser, and the second-stage condenser is connected with a second vacuum unit; and the liquid outlet of the primary flash evaporator is connected with the regenerated liquid storage tank. The production cost can be saved, and the green production requirement can be guaranteed.

Owner:江苏中煦科技有限公司

A kind of synthetic and refining method of sodium methacrylate

ActiveCN112851555BIncrease concentrationIncrease productivityOrganic compound preparationOrganic chemistry methodsSulfite saltSodium sulfate

Owner:ZHEJIANG HUANGMA TECH +3

Sequencing batch type deep dehydration belt machine

PendingCN113754225ASolution to short lifeLower replacement costsSludge treatmentRinse waterProcess engineering

The invention discloses a sequencing batch type deep dehydration belt machine. The sequencing batch type deep dehydration belt machine comprises: a filter cloth transmission mechanism which is annularly arranged on a rack; a slitting and distributing device which is arranged on the rack and is positioned at a feeding hole in the front end of the filter cloth transmission mechanism; a hydraulic filter pressing mechanism which is arranged on the rack, wherein the end part of each filter plate of the hydraulic filter pressing mechanism is provided with a roll shaft; a filter cloth of the filter cloth transmission mechanism, wherein the filter cloth is wound by each roll shaft at the end part of each filter plate and clings to the surface of each filter plate of the hydraulic filter pressing mechanism; a filter cloth cleaning assembly which is arranged on the rack, corresponds to the filter cloth of the filter cloth transmission mechanism in position and can clean the filter cloth; and a discharge mud scraping assembly which is arranged at a discharge port at the rear end of the filter cloth transmission mechanism. The dehydration belt machine is good in dehydration effect, long in service life of the filter cloth, small in flushing water amount and high in treatment efficiency.

Owner:北京首创污泥处置技术有限公司 +1

Cleaning technology for silica scales of reverse osmosis membrane

InactiveCN109019773AEasy to cleanEasy to operateReverse osmosisWater/sewage treatment bu osmosis/dialysisReverse osmosisChemical cleaning

The invention relates to a cleaning technology for silica scales of a reverse osmosis membrane. The technology comprises the following steps: (a) cleaning oil and microbe contaminations on a contaminated reverse osmosis membrane by using a high-pH cleaning solution; (b) cleaning inorganic scale or metal oxide contaminations on the contaminated reverse osmosis membrane by using a low pH cleaning solution; and (c) preparing a silica scale cleaning solution from a specific chemical agent, and cleaning the silica scales on the reverse osmosis membrane to make the reverse osmosis membrane recover the original performances. The specific chemical agent is used to change the composition or properties of contaminants to achieve chemical cleaning of the reverse osmosis membrane system with special silica scales, so the original performances of the membrane element are recovered. The cleaning technology has the advantages of simplicity in operation, safety in running, wideness in promotion, stable cleaning effect, and prolongation of the service life of the reverse osmosis membrane.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

Preparation method of phosphate

The invention provides a preparation method of phosphate. The preparation method comprises the following steps of (1) using acid to dissolve the raw material which can dissolve out metal ions by acid,and separating, so as to obtain a clear solution, wherein the acid comprises nitric acid, and the raw material which can dissolve out metal ions by acid is a mixture of one or multiple of metal, metal oxide, metal hydroxide, metal carbonate and metal base carbonate; (2) adding a phosphor-containing reducing agent into the clear solution to form a reaction system, and reacting to generate the phosphate and oxynitride gas; when the yield rate of phosphate in the reaction system reaches the proper degree, separating solid and liquid, so as to obtain phosphate solid and mother liquid; washing toremove the impurities out of the phosphate solid, wherein the phosphor-containing reducing agent is a phosphor-containing matter with valence state lower than positive five valence. The preparation method has the advantages that the amount of impurities introduced into the system is small, the washing frequency is low, and the cost is low; the prepared product has high purity and small granularity, and a feasible method is provided for the preparation of the phosphate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Rotary filtering pond for sewage treatment

The invention relates to a rotary filtering pond for sewage treatment, which is applied in sewage depth filtration treatment, belonging to the technical field of sewage treatment, wherein the main body comprises: a water inflow distribution well, a water inflow distribution dam, a turnplate support, a turnplate and a filter cloth thereof, a central rotary drum, a speed reducer and a transmission device thereof, a back-washing water pump, a back-washing sprayer, a pulse pressure regulating device, a sludge suction pump, a water level regulating checkgate, a clean-water reservoir, a sludge bucket, a turnplate suction pump and so on. The pond employs the outer inflow type and is provided with the distribution dam for water inflow, and is also provided with the sludge suction device and the washing device for the filter cloth. The inflow water enters the filter pond from the water distribution dam on the two ends by rectifying the water flow through the water distribution well. Because of the differences between the inner and outer pressures of the turnplate, water passes through the micrometre-scale filter cloth while suspended matters are held back in the filtering pond and precipitated in the sludge bucket on the lower part, and sucked out of the filtering pond by the sludge suction pump, wherein the permeated water enters the clean-water reservoir through the hollow central rotary drum to finish the filtering on the sewage. The suspended matters held back on the surface of the filter cloth of the turnplate are washed away by a high pressure sprayer and a suction device.

Owner:SICHUAN STONG EURO & AMERICA ENVIRONMENT ENG

Control method of food processor

PendingCN113455937AGood cleaning and disinfection effectSimple planSteam cooking vesselsHeatHand washingProcess engineering

The invention relates to a control technology of kitchen household appliances, in particular to a control method of a food processor, the food processor comprises a pulping chamber, a liquid discharge assembly for controlling the pulping chamber to be opened and closed, and a steam generating device for introducing steam into the pulping chamber, the control method is characterized by comprising the steps that when the liquid discharging assembly is in an open state, the steam generating device introduces steam into the pulping cavity, and the steam is discharged out of the pulping cavity through the liquid discharging assembly. According to the food processing machine adopting the control method, in the cleaning process, impurities (stains, residues or pulp residues) in the pulping chamber can be discharged through steam without cleaning water or with little cleaning water, and moreover, the method can realize automatic sterilization, disinfection, automatic pulp discharging and residue discharging of the food processing machine, hand washing is not needed, and even the soybean milk is automatically heated.

Owner:JOYOUNG CO LTD

Cosmetic bottle cleaning device

PendingCN114101251AEasy to cleanLess washing waterDomestic cooling apparatusHollow article cleaningReciprocating motionDrive motor

The invention discloses a cosmetic bottle cleaning device which comprises a main table, a cleaning table, a fixing support and a cleaning mechanism, the cleaning table is connected to the upper side of the main table, a space for containing the fixing support is formed in the cleaning table, a space for containing the cleaning mechanism is formed in the main table, and the cleaning mechanism comprises a moving rod, a driving motor and a rotating nozzle. Along with the up-down reciprocating motion of the driving motor, one end of the moving rod is provided with a rotating nozzle, a cleaning channel is formed in the moving rod to be connected with the rotating nozzle, the other end of the moving rod is communicated with a cleaning source, and the cleaning source enters the rotating nozzle through pressure driving (driving the nozzle to rotate to work). And the spray head on the moving rod extends into the bottle body. The cosmetic bottle cleaning device is ingenious in structure, small in occupied area and capable of being conveniently arranged in a corresponding cosmetic store, customers can conveniently clean cosmetic bottles, cold and hot water cleaning and cold and hot air drying are provided, the cleaning degree is high, and the user satisfaction degree is improved.

Owner:DIAM DISPLAY CHINA CO LTD

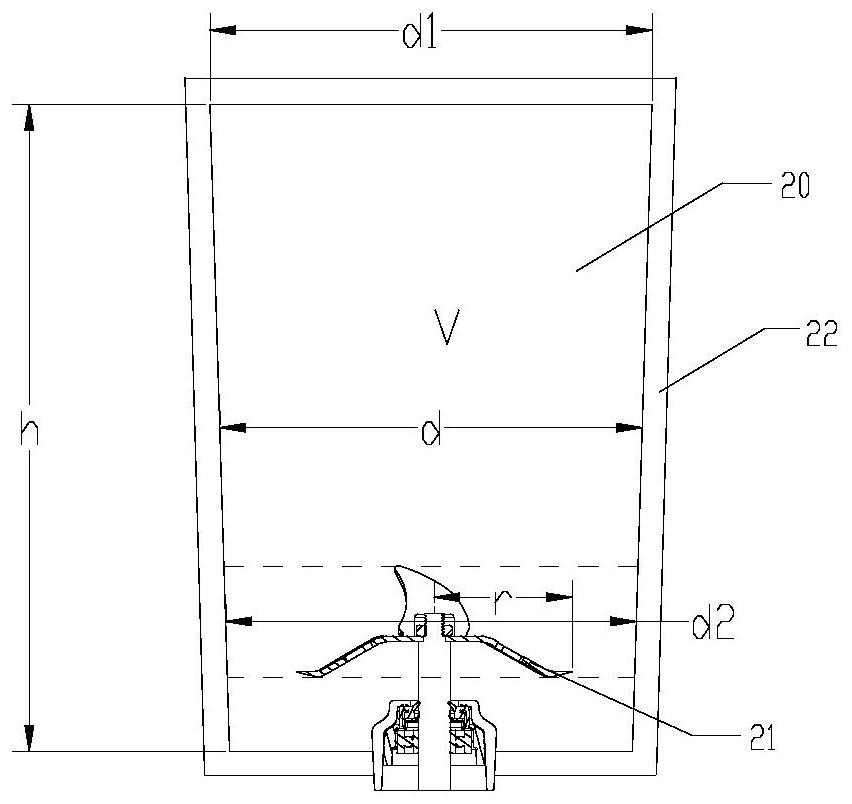

A food processor with good cleaning effect

ActiveCN111728505BEasy to cleanImprove the perturbation effectKitchen equipmentWater flowElectric machinery

The invention relates to a food processing machine with good cleaning effect, which includes a main machine and a crushing chamber installed on the main machine. A cleaning knife driven by a motor is arranged in the crushing chamber, and the cleaning knife rotates to drive the water flow in the crushing chamber to clean the crushing chamber. Cleaning, the center of the equivalent space formed when the cleaning knife rotates is located below the center of the equivalent space of the crushing chamber, the volume of the crushing chamber is V1, and the maximum orthographic distance between the tip of the cleaning knife and the knife axis on the horizontal plane is r, the maximum orthographic height of the cleaning knife in the axial direction of the crushing chamber is h, and the rotation speed of the cleaning knife is w, among them, 0.6wr 2 h≤V1≤6wr 2 h. By controlling the relationship between the size and rotational speed of the cleaning knife and the volume of the crushing chamber, the kinetic energy matching the volume of the crushing chamber is provided to drive the water flow to clean the crushing chamber, thereby improving the cleaning effect of crushing chambers with different volumes.

Owner:JOYOUNG CO LTD

Water soluble anti-rust agent

InactiveCN101712817BShort film forming timeImprove quick-drying performanceAnti-corrosive paintsHazardous substanceSebacic acid

The invention relates to a water soluble anti-rust agent on the surface of ferrous metal, which comprises the following components: 2 to 10 weight percent of barium petroleum sulfonate and / or barium dinonyl decyl sulfonate, 1 to 6 weight percent of sodium molybdate and / or amine molybdate, 0 to 10 weight percent of sebacic acid, 2 to 10 weight percent of polyacrylic ester, 3 to 20 weight percent of triethanolamine oleic soap and / or 2 to 6 weight percent of polyoxyethylenesorbitan monooleate, 0 to 15 weight percent of sodium alkylsulfonate, 0 to 8 weight percent of glycerin and the balance of water or machine oil. Compared with the conventional water soluble anti-rust agent, the water soluble anti-rust agent of the invention has the advantages of short film forming time, firm film forming adsorption and good anti-rust effect; the actual anti-rust period can reach 3 to 6 months; the formed film is thin and only 3 to 5 microns; common workpieces do not need film removal and can be directly assembled and coated; the film removal is convenient, and the film is only soaked and rinsed in mild water over 50DEG C and then can be removed quickly; and the anti-rust agent has no component containing toxic and harmful substances, does not contain phosphorus, has the advantages of good environmental protection and no pollution to the environment, and is the environment-friendly water solubleanti-rust agent.

Owner:无锡市弘育化工有限公司

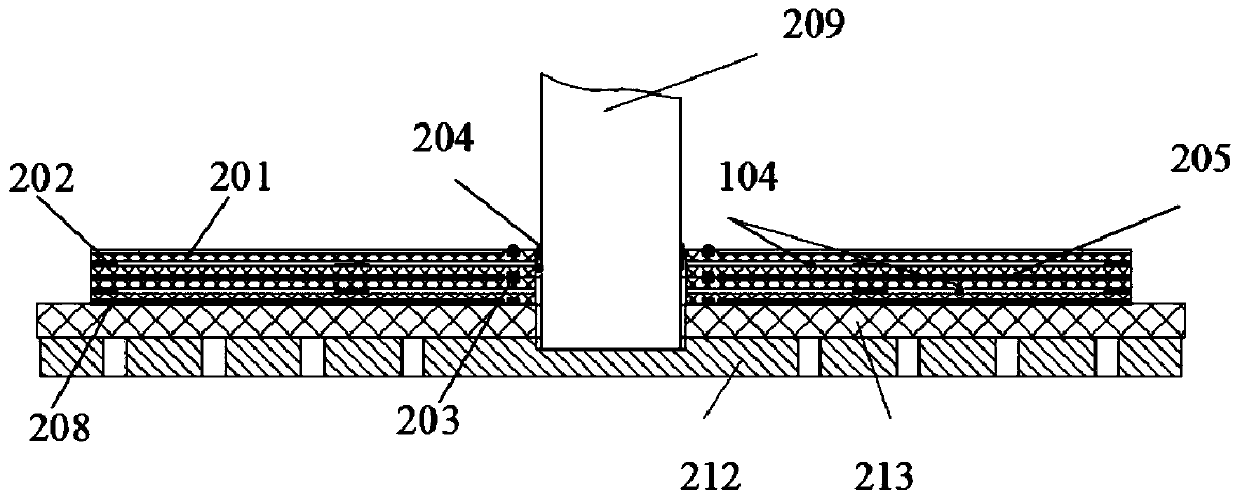

A kind of boiling and filling process of highland barley and its filling device

ActiveCN109566992BLow viscosityIncrease dietary fiberClimate change adaptationLiquid bottlingBiotechnologySUGAR/WATER

The invention discloses a highland barley boiling and filling process and a filling device thereof, comprising the following steps in sequence: (1) boiling the raw highland barley with normal temperature water to 90°C; (2) boiling the highland barley in step (1) in Keep warm at 90-96°C for 15-25 minutes to get the ripe barley; (3) Take out the cooked barley and drain; (4) Mix the drained barley with sugar water, add baking soda to adjust the pH to 7.2-7.5 to obtain the mixed solution; (5) post-fill the mixed solution, and sterilize it at 115-125°C for 15-25 minutes in the filling container to obtain the matured highland barley mixture; (6) put the matured highland barley mixture in Heat preservation at 70-80°C for 0.5-1.5h to obtain the finished product. The process of the invention has the characteristics of stable filling and no regeneration, and at the same time, the device of the invention does not splash liquid when filling, the equipment is highly clean, and can also save resources.

Owner:XIANGPIAOPIAO FOOD

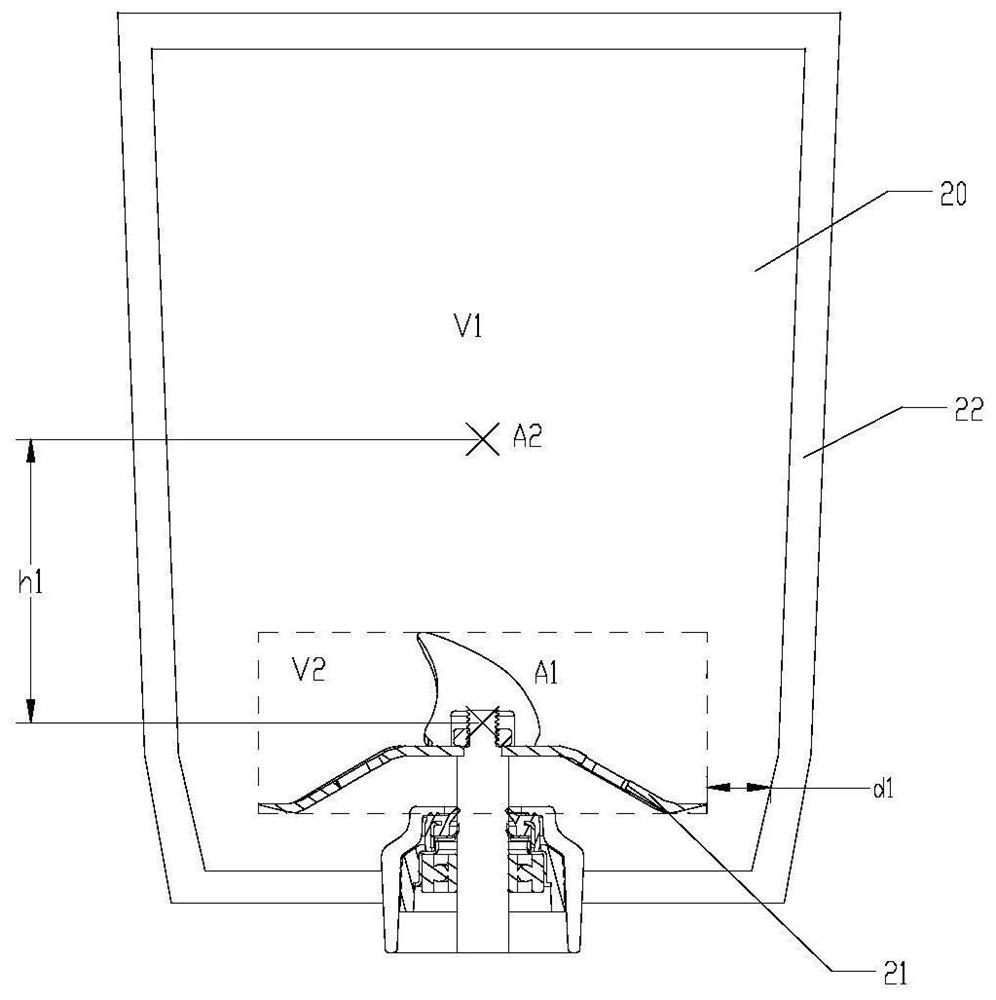

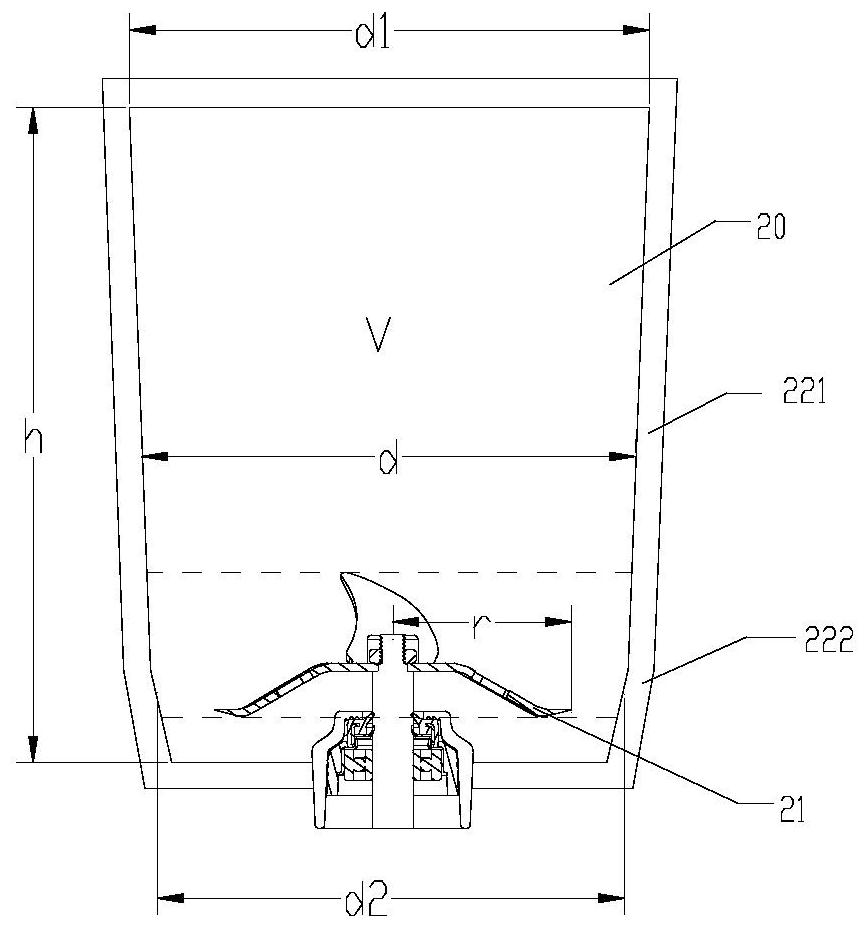

A food processor that enhances the cleaning effect

ActiveCN111713999BEasy to cleanImprove upward guidanceHollow article cleaningKitchen equipmentWater flowElectric machinery

The invention relates to a food processing machine for improving the cleaning effect, which includes a main machine and a crushing chamber installed on the main machine. A cleaning knife driven by a motor is arranged in the crushing chamber, and the cleaning knife rotates to drive the water flow in the crushing chamber to clean the crushing chamber. Cleaning, the volume of the crushing chamber is V, the maximum inner diameter of the crushing chamber is d1, the cleaning knife is located below the maximum inner diameter of the crushing chamber, and the average inner diameter of the crushing chamber outside the cleaning knife is d2, wherein, 0.1≤(d1‑d2) 2 / V≤0.9, the side wall of the crushing chamber between the maximum inner diameter of the crushing chamber and the top of the cleaning knife forms a guide surface, the inner diameter of the upper crushing chamber in the guide surface is not smaller than the inner diameter of the lower crushing chamber, by controlling the crushing chamber The relationship between the maximum inner diameter and the average inner diameter of the crushing chamber located outside the cleaning knife and the volume of the crushing chamber, so as to guide the upward projection of the water flow in the crushing chambers of different volumes to the maximum extent, so as to improve the cleaning effect of the crushing chambers of different volumes.

Owner:JOYOUNG CO LTD

Moving bed filter

InactiveCN1242827CEasy to operateIncrease the chance of frictionLoose filtering material filtersGravity filtersMoving bedWasher

A moving-bed filter able to continuously run for treating water is composed of cylindrical tank, water distributor, filtering bed, fairing unit, air distributor, filtering material delivering pipe, gas separator, washer, filtering material distributor and the regulating valve for the washing water.

Owner:CHINA PETROLEUM & CHEM CORP +1

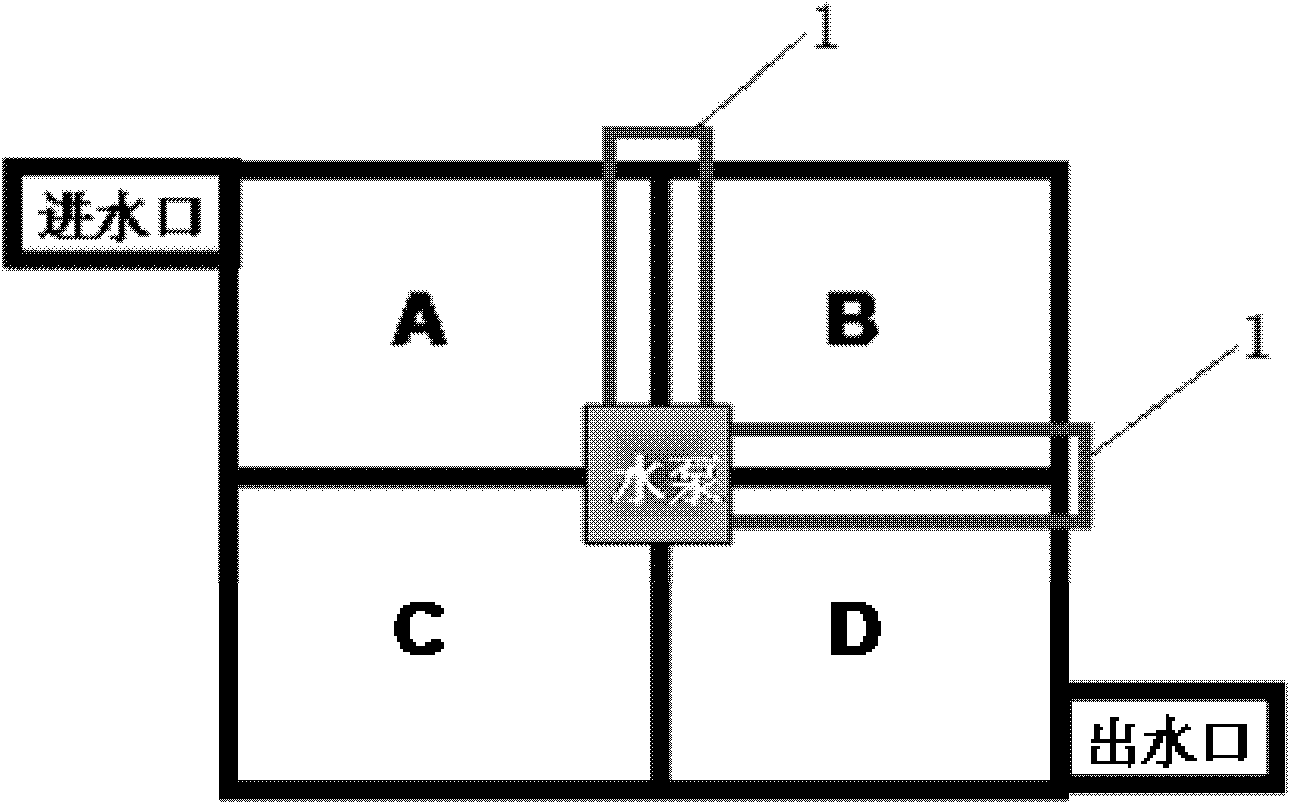

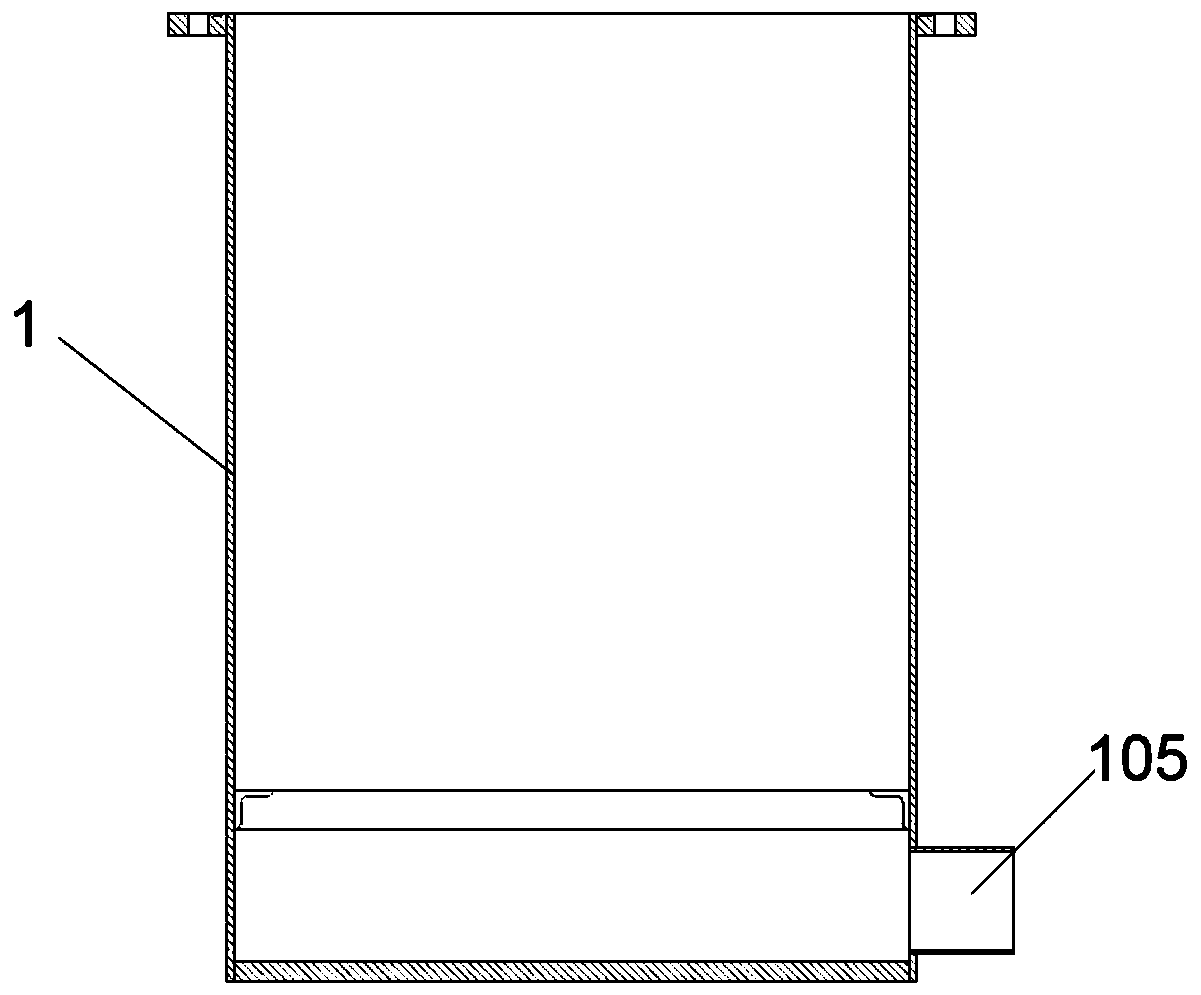

High-building water tank

InactiveCN102758466BLess washing waterReduce the totalOperating means/releasing devices for valvesService pipe systemsAgricultural engineeringPollution

The invention relates to a high-building water tank which is characterized by comprising a tank body, a partition plate, a water pump, a water pipe group, a controller, a main water inlet, a main overflow port and a filter net, wherein the partition plate is arranged in the tank body and divides the tank body into four containers, namely a first container, a second container, a third container and a fourth container; an overflow port is arranged at the bottom of each container; each overflow port is communicated with the main overflow port; the filter net is arranged on the partition plate; the main water inlet is arranged on the first container; the water pump is connected with the controller; the water pump and the controller are arranged at the upper part of the tank body respectively; and the water pump is connected with the four containers through the water pump group respectively. Compared with the prior art, the high-building water tank provided by the invention greatly saves the cleaning water, avoids the secondary pollution, is easy to reconstruct and feasible, and has the advantages of high automation degree, simple structure, safe and reliable performance and the like.

Owner:SHANGHAI UNIV OF ENG SCI

Automatic cleaning food processor

ActiveCN112043179AClean upHigh impact energyHollow article cleaningKitchen equipmentElectric machineryKnife blades

The invention relates to kitchen cooking electric appliances, in particular to an automatic cleaning food processor. The processor comprises a machine body, a crushing cavity, a crushing blade, a motor and a water supply device, wherein the crushing cavity is of a barrel-shaped structure with a depth larger than an inner diameter, the crushing cavity is obliquely installed in the machine body, andafter inclination, the top wall and the peripheral wall of the crushing cavity are connected at the highest point through a corner part; the crushing blade is mounted at the bottom of the crushing cavity, a rotating shaft driven by the motor penetrates the cavity wall of the crushing cavity and extends into the crushing cavity, and the crushing blade is fixed to the tail end of the rotating shaft; and the water supply device can automatically supply cleaning water to the crushing cavity, a liquid level height of the cleaning water is H1, a vertical height from the bottommost portion of the inclined crushing cavity to the corner part is H2, H1 / H2 is larger than or equal to 0.181, and during automatic cleaning, the cleaning water can rush to the corner part along the cavity wall of the crushing cavity to clean the cavity wall of the crushing cavity. According to the food processor, automatic cleaning can be achieved, during cleaning, the highest point of the crushing cavity can be cleaned, cleaning is cleaner, and water consumption during cleaning is less.

Owner:JOYOUNG CO LTD

High-pressure laminated hollow microporous ceramic membrane column

PendingCN110548405AAchieve separationAvoid crackingSemi-permeable membranesGeneral water supply conservationMetallurgyWater flow

The invention discloses a high-pressure laminated hollow microporous ceramic membrane column comprising a column shell and a high-pressure membrane column; the high-pressure membrane column is formedby laminating a plurality of inorganic ceramic plates; the inorganic ceramic plates are formed by splicing, sintering or bonding two same concave-convex inorganic ceramic membranes; the inner surfacesof cavities of the ceramic plates are purified water surfaces, and the outer surfaces of the ceramic plates are raw water surfaces; and only purified water flows in a cavity formed by the two purified water surfaces, but raw water does not flow in the cavity. The ceramic plates of the high-pressure laminated hollow microporous ceramic membrane column can be used in an environment of high pressureless than or equal to 2 MPa; compared with an existing 0.04 MPa ceramic plate filtering and permeating technology, the high-pressure laminated hollow microporous ceramic membrane column has the advantages that the water production efficiency is increased by 30 times or above, the water production cost is reduced by 30 times, the high-pressure laminated hollow microporous ceramic membrane column has the same service life reaching up to 10 years and is small in floor area, low in water production and management costs and easy to wash so as to be a substitute product of an organic membrane in the future water treatment industry and be capable of gradually substituting the organic membrane product market monopolized by European and American countries for 20 years.

Owner:廖忠烈 +1

Food processor capable of improving cleaning effect

ActiveCN111713999AEasy to cleanImprove upward guidanceHollow article cleaningKitchen equipmentWater flowElectric machinery

The invention relates to a food processor capable of improving the cleaning effect. The food processor comprises a main machine and a pulverizing cavity formed in the main machine. A cleaning knife driven by a motor is arranged in the pulverizing cavity; the cleaning knife rotates to drive water flow in the pulverizing cavity to clean the pulverizing cavity; the volume of the pulverizing cavity isV; the maximum inner diameter of the pulverizing cavity is d1; the cleaning knife is positioned below the maximum inner diameter of the pulverizing cavity; the average inner diameter of the pulverizing cavity positioned on the outer side of the cleaning knife is d2, wherein (d1-d2) 2 / V is greater than or equal to 0.1 and less than or equal to 0.9; a guide surface is formed on the side wall of thepulverizing cavity between the maximum inner diameter of the pulverizing cavity and the top of the cleaning knife; the inner diameter of the upper pulverizing cavity in the guide surface is not smaller than that of the lower pulverizing cavity; by controlling the relation between the maximum inner diameter of the pulverizing cavity and the volume of the pulverizing cavity and the relation betweenthe average inner diameter of the pulverizing cavity located on the outer side of the cleaning knife and the volume of the pulverizing cavity, water flow is guided to be thrown upwards in the pulverizing cavities of different volumes to the maximum extent, and the cleaning effect of the pulverizing cavities of different volumes is improved.

Owner:JOYOUNG CO LTD

Regeneration equipment for adsorbing heavy metals in water by using complex resin and process thereof

PendingCN113461098ALess washing waterReduce acid consumptionSpecific water treatment objectivesWater contaminantsEnvironmental chemistryPolymeric adsorbent

The invention provides regeneration equipment for adsorbing heavy metals in water by complexing resin, which comprises a resin tank, an upper water distributor arranged at the upper end of the resin tank, a lower water distributor arranged at the lower end of the resin tank, a resin layer filled above the lower water distributor, and a first acid barrel and a second acid barrel respectively connected to the top of the resin tank through pipelines, and the bottom of the resin tank is respectively connected with a regeneration water-returning barrel, an alkali barrel and a heavy metal recycling barrel through pipelines. According to the regeneration process for adsorbing the heavy metals in the water by the complex resin, the cleaning water amount is saved, and compared with the traditional acid absorption and cleaning steps, the consumption of the cleaning water can be saved by 30-66%, the consumption of regenerated acid is saved, and the heavy metal concentration of the recovered liquid is greatly improved.

Owner:钱中明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com