High-pressure laminated hollow microporous ceramic membrane column

A microporous ceramic and laminated technology, which is applied in the field of water treatment, can solve the problems of failure, ceramic membrane scrapping, sealing, mixing, etc., and achieve the effect of less cleaning water, avoiding easy cracking, and high water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

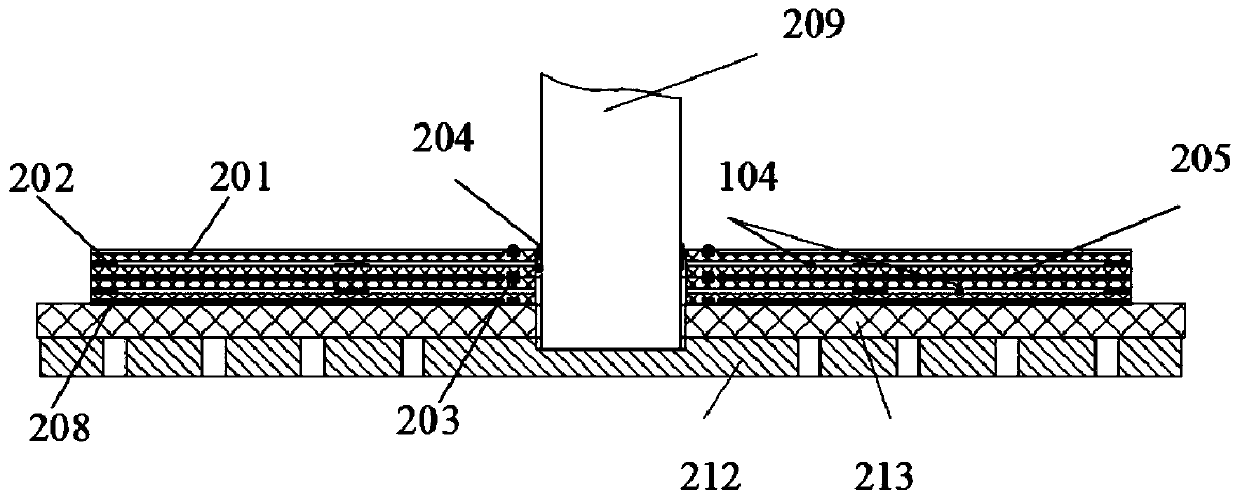

[0034]refer to Figure 1-11 , the invention provides a microporous ceramic membrane disc fired above 1300°C, and then coated with a layer of coating layer (separation membrane layer) on the upper and lower sides of the disc, which is a ceramic filter layer with a pore size of 20nm-200nm or Graphene coating with a pore size of 0.2nm-2nm, the coating layer and the microporous ceramic disk are sintered as a whole, and the graphene film is sintered in a vacuum environment.

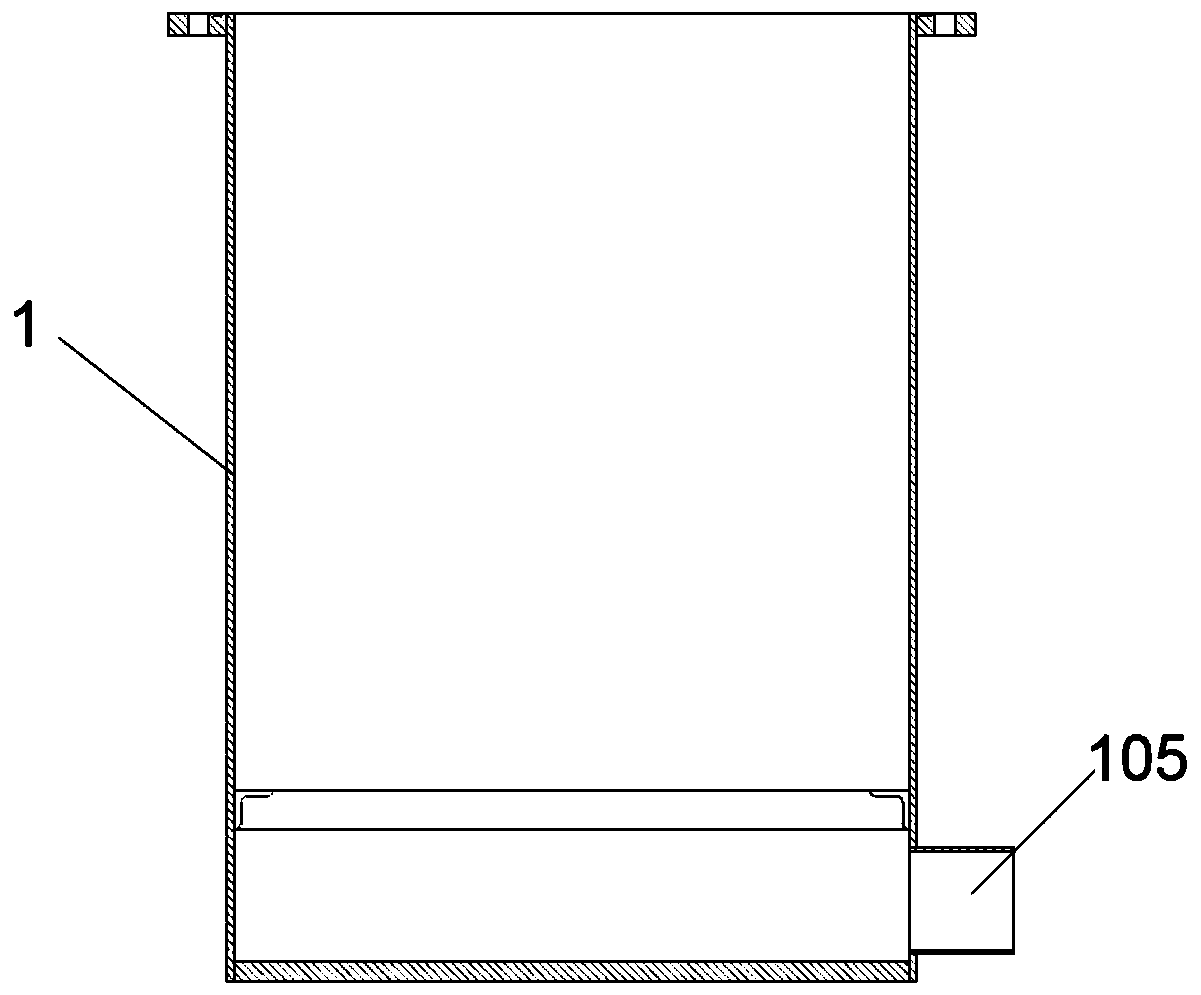

[0035] These membrane discs are connected by a central locking screw to form a high-pressure membrane column, and multiple membrane discs are assembled to form a filter column with a large surface area. Using this process, hundreds of hollow laminated ceramic membrane discs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com