Regeneration system for raffinate in process for producing hydrogen peroxide by anthraquinone method

A regeneration system, raffinate technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, water pollutants, multi-stage water treatment, etc., can solve problems that are not conducive to saving production , the loss of activated alumina, the large amount of working fluid, etc., to avoid the alternating operation of acid and alkali, prolong the service life, and reduce the initial investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

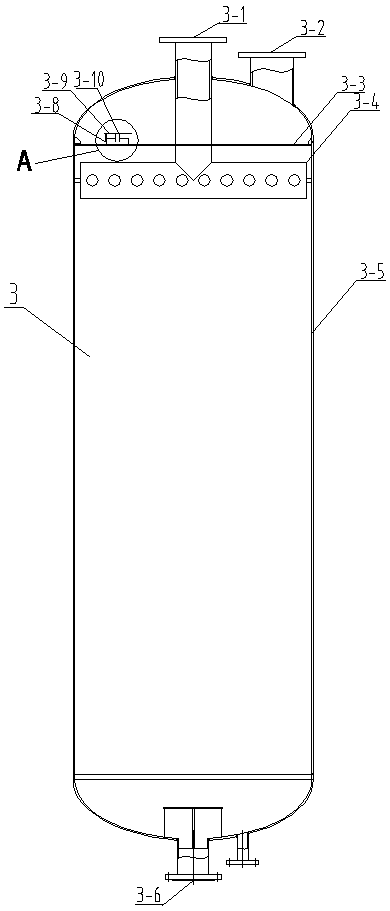

[0038] Such as figure 1 As shown, the regeneration system of the raffinate in the process of producing hydrogen peroxide by anthraquinone method includes the raffinate pipeline 1 connected to the outlet of the extraction tower. The port is connected to the coalescer 2, the primary flash evaporator 3, the secondary flash evaporator 7, and the clay bed feed pump 14 in turn, and the liquid outlet of the clay bed feed pump 14 is connected to the tube-side liquid inlet of the heat exchanger 13, and the heat The tube-side liquid outlet of the exchanger 13 is connected to the heater 11, the liquid outlet of the heater 11 is connected to the liquid inlet of the clay bed 12, and the liquid outlet of the clay bed 12 is connected to the shell-side liquid inlet of the heat exchanger 13 , the shell side liquid outlet of the heat exchanger 13 is connected to the primary filter 8 , the liquid outlet of the primary filter 8 is connected to the secondary filter 9 , and the liquid outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com