Rotary filtering pond for sewage treatment

A sewage treatment, turntable technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The equipment is simple and compact, the quality of the effluent is good, and the cleaning interval is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

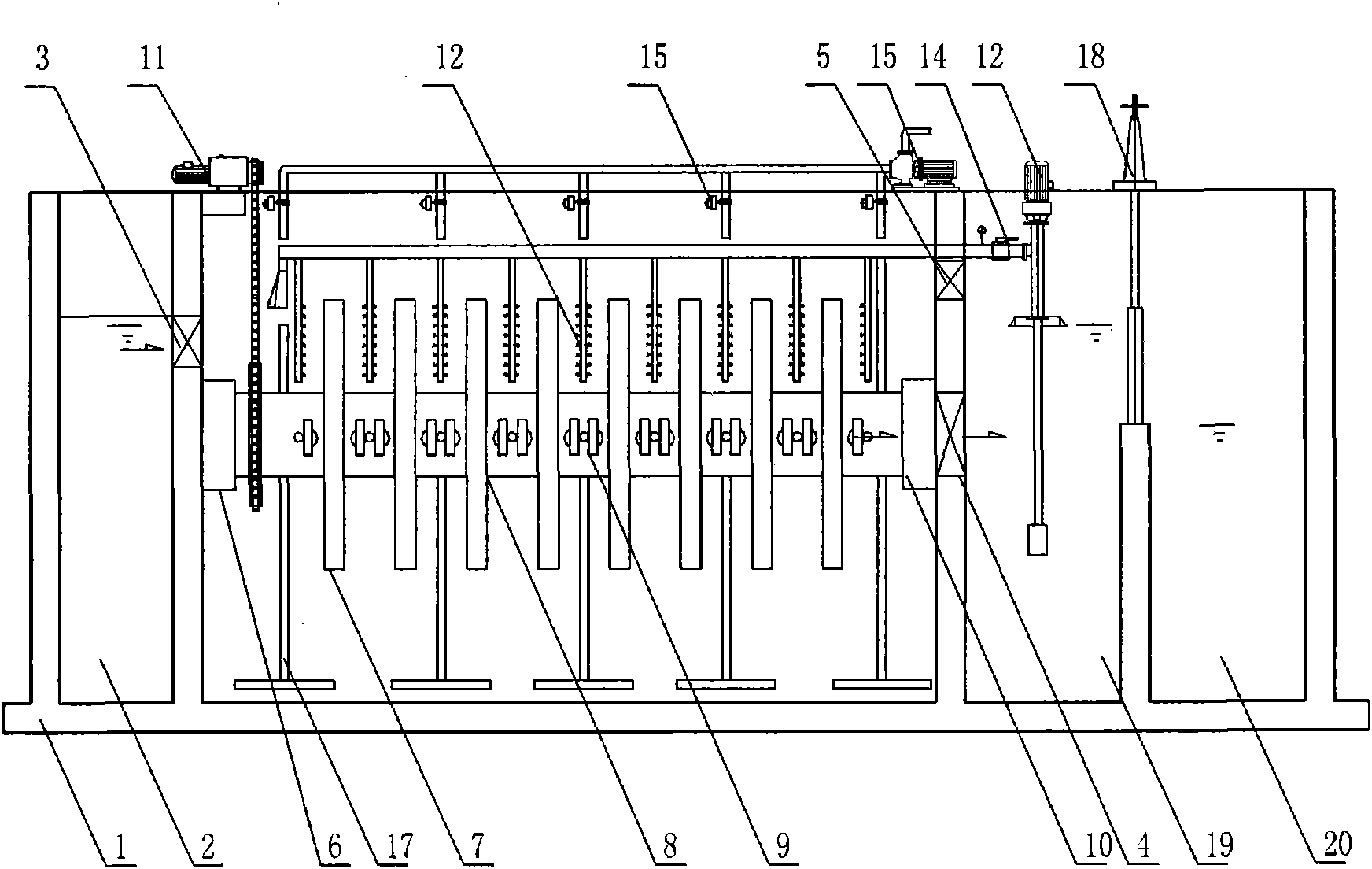

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The invention relates to a turntable filter tank for sewage treatment, which is characterized in that the main body comprises: a tank body (1), a water inlet and distribution well (2), a water inlet (3), a water outlet (4), and an overflow port (5) , Turntable front support (6), turntable and filter cloth (7), center drum (8), turntable suction device (9), turntable rear support (10), reducer and transmission device (11), backwash nozzle (12), backwash water pump (13), pulse pressure regulator (14), sludge suction pump (15), electric valve (16), mud suction pipe (17), water level regulating weir gate (18), clear water Pond (19), drainage pond (20), water inlet distribution weir (21), sludge bucket (22), rotary table suction pump (23) etc.

[0032] The water intake of the rotary disc filter tank has a water distribution well (2) to rectify the water flow,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com