Concave and convex rolling shaft pressure device of belt filter press

A technology of belt filter press and roller, which is applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve problems such as blockage, secondary pollution, and large amount of sludge residue, and achieve a large amount of sludge capture , not easy to leak, less sludge residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

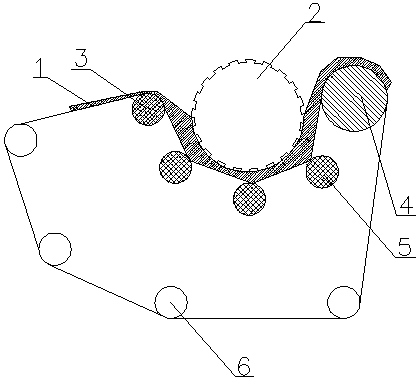

[0014] The concave-convex roller pressure device of the belt filter press includes an annular flocking filter belt 1 and a pressure roller 2. A driven roller 3 and a driving roller are respectively arranged on both sides of the arc surface of the pressure roller 2. 4. A number of extrusion rollers 5 are arranged under the pressure roller 2. The flocking filter belt 1 is set on the driven roller 3, the driving roller 4 and the extrusion roller 5, and the pressure roller 2 and the extrusion roller The shaft 5 can squeeze the flocking filter belt, and the flocking filter belt 1 is also provided with a number of tension rollers 6 to make it in a tensioned state, and the circumferential surface of the strong pressure roller 2 is a concave-convex structure of a gear.

[0015] The diameter of the pressing roller 2 described in the present invention is larger than the diameters of the driving roller 4 , the driven roller 3 and the extruding roller 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com