Sequencing batch type deep dehydration belt machine

A deep dehydration and belt machine technology, applied in water/sludge/sewage treatment, chemical instruments and methods, sludge treatment, etc., can solve problems such as large amount of flushing water, blocked water channels, and short service life of filter cloths. To achieve long life, save replacement costs, the effect of small amount of cleaning water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

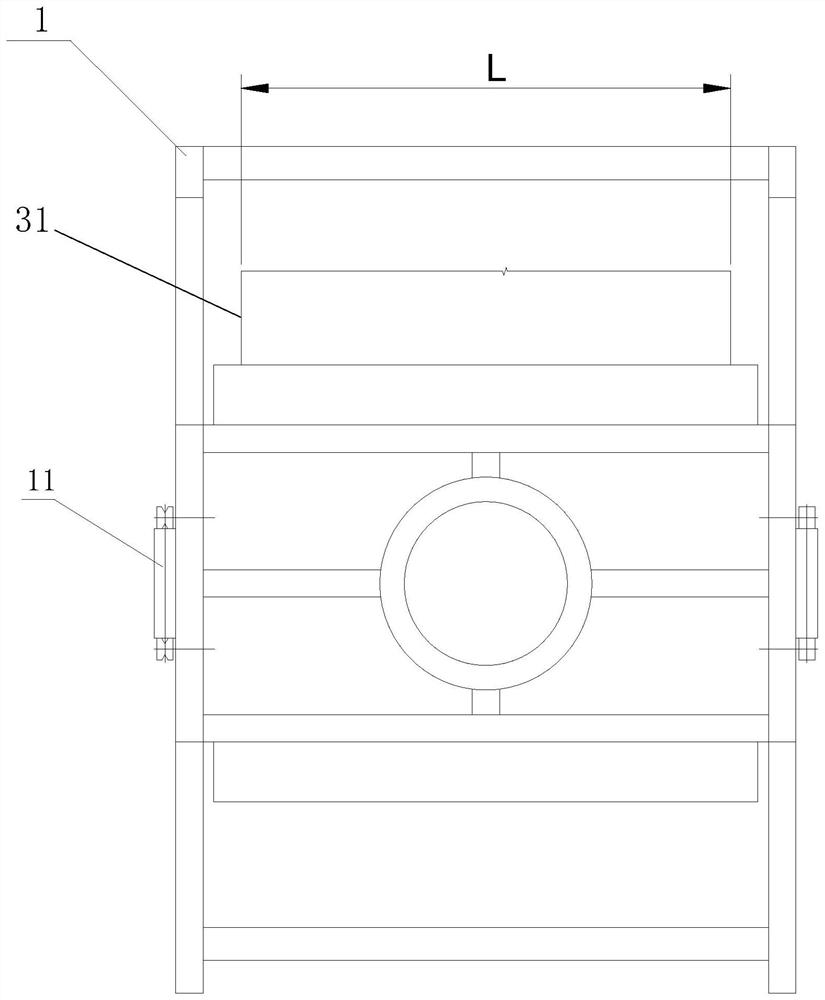

[0058] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a sequential batch type deep dehydration belt machine, including:

[0059] Frame, cutting strip distributor, filter cloth transmission mechanism, hydraulic pressure filter mechanism, filter cloth cleaning assembly and discharge mud scraping assembly; among them,

[0060] The filter cloth transmission mechanism includes: a filter cloth traveling driving device, a filter cloth deviation correcting device and a steering roller arranged in a ring on the frame, and the filter cloth traveling driving device, a filter cloth deviation correcting device and a steering roller A filter cloth is set, and the running path of the filter cloth on the frame is circular;

[0061] The cut strip distributor is arranged on the frame, at the front end feeding port of the filter cloth transmission mechanism;

[0062] The hydraulic filter press mechanism is arranged on the frame, and each filter plate e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com