High-building water tank

A technology for water tanks and high-rise buildings, which is used in water supply installations, water supply main pipelines, water supply pipeline systems, etc., can solve the problem of insufficient research on water tank cleaning water volume control and water saving methods, and insufficient dirt, impurities, materials and design structures inside the box. Reasonable and other issues, to achieve the effect of mature and reliable technology and methods, easy and feasible transformation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

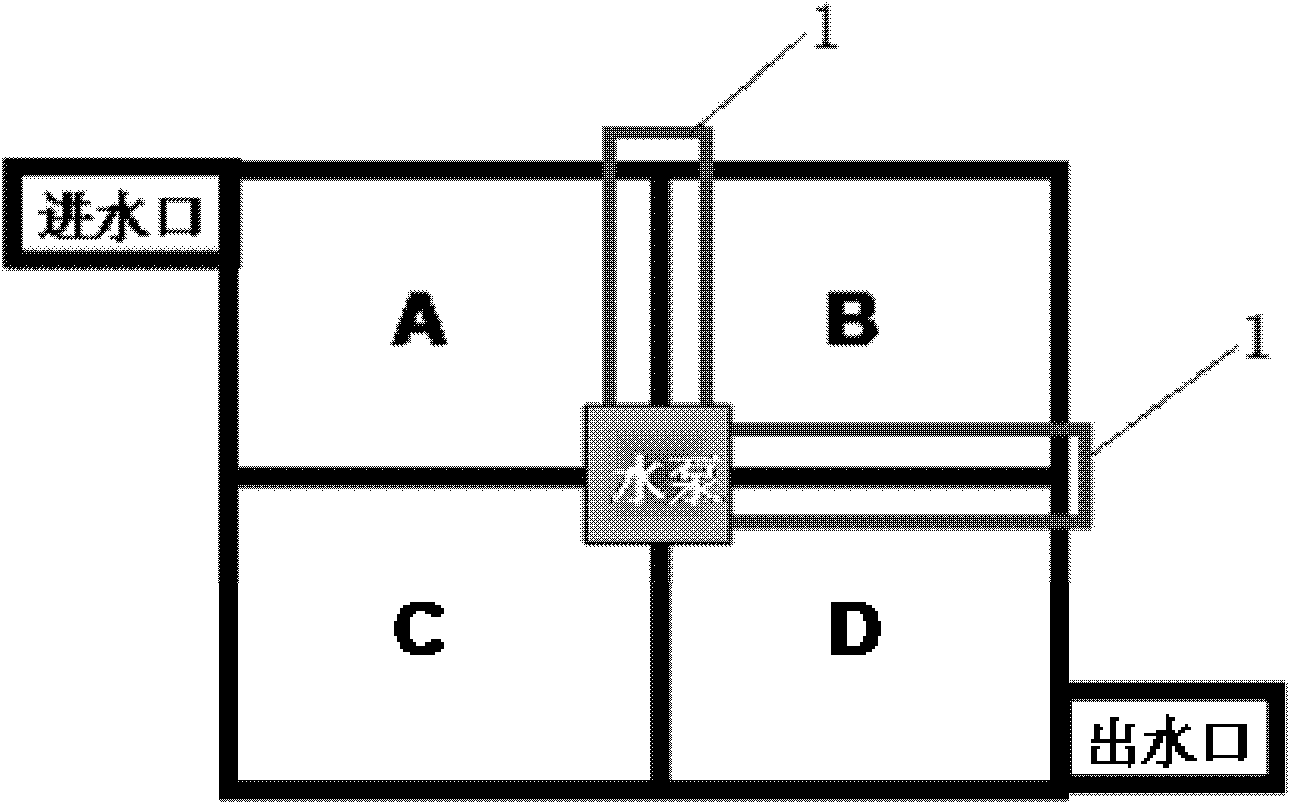

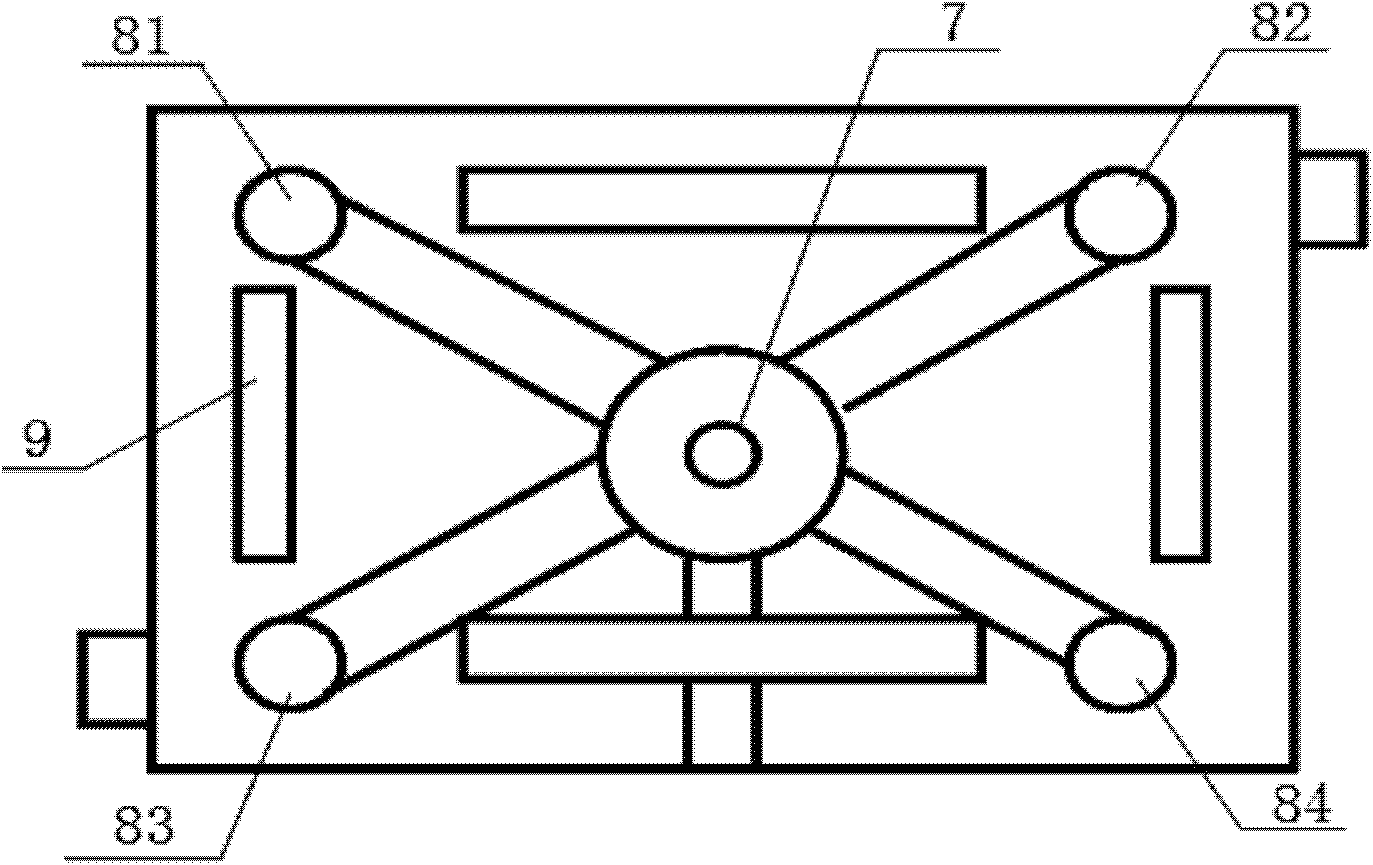

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of high-rise water tank comprises casing 6, clapboard, water pump 3, water pipe group 5, controller, total water inlet 2, total overflow outlet 7, support 9, filter screen 1; Described clapboard is located at In the box body 6, the box body 6 is divided into four containers, which are respectively the first container A, the second container B, the third container D, and the fourth container C. An overflow port is provided at the bottom of each container, respectively for the first container A, the second container B, the third container D, and the fourth container C. A container overflow port 81, a second container overflow port 82, a third container overflow port 83, and a fourth container overflow port 84, each overflow port communicates with the total overflow port 7 respectively, and the total water inlet is located in the first container In A, the water pump is connected to the controller, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com