Preparation method of water-insoluble phosphate

A phosphate and phosphoric acid technology, applied in the direction of phosphate, phosphorus oxyacids, chemical instruments and methods, etc., can solve the problems of difficult washing and difficult treatment of chemical wastewater, etc., reduce the number of washing times, reduce chemical wastewater, and reduce nitrate The effect of the presence of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

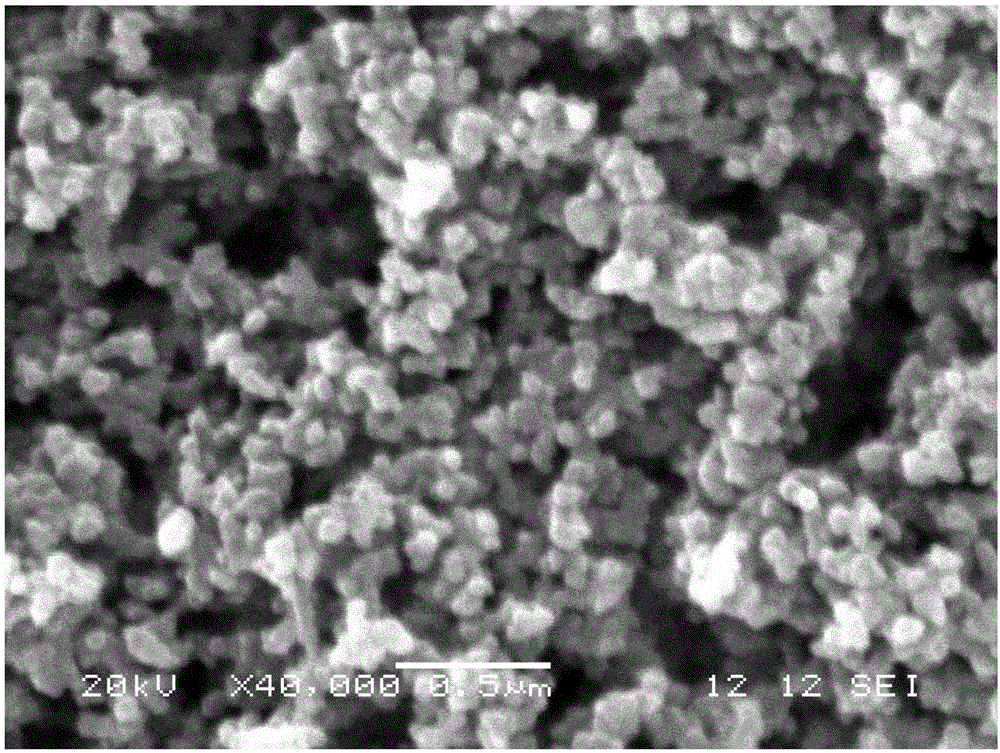

Image

Examples

preparation example Construction

[0025] The preparation method of the water-insoluble phosphate of the embodiment of the present invention, described method comprises the steps:

[0026] 1) The raw material capable of acid-eluting metal ions is dissolved with a mixed acid, and a clear solution is obtained after separation; the raw material capable of acid-eluting metal ions is selected from metals, metal oxides, metal hydroxides, metal carbonates and metal alkalis One or more mixtures of formula carbonates, said mixed acids include nitric acid and phosphoric acid;

[0027] 2) adding an organic reducing agent to the clarified solution to form a reaction system, the reaction generates water-insoluble phosphate, solid-liquid separation to obtain a phosphate solid, washing to remove impurities in the phosphate solid; the organic reducing The agent is selected from one or a mixture of aldehydes, phenols, alcohols and ketones.

[0028] Such metals include, but are not limited to, magnesium, iron, calcium, aluminum...

Embodiment 1

[0031] The preparation method of the water-insoluble phosphate of embodiment 1 of the present invention, at first dissolving the metal with the mixed acid of nitric acid and phosphoric acid, filtering to remove solid impurities to obtain a clear solution, then adding an organic reducing agent to the solution, and reacting at a certain temperature , when the yield of water-insoluble phosphate in the reaction system reaches an appropriate level, then filter and wash to obtain water-insoluble phosphate.

[0032] The metal is aluminum, and the water-insoluble phosphate is aluminum phosphate.

[0033] In the mixed acid, the molar ratio of nitric acid and phosphoric acid is 0.5:1.

[0034] The reaction temperature under the certain temperature condition is 70°C.

[0035] The yield of water-insoluble phosphate in the reaction system reaches an appropriate level of 60%.

[0036] The molar ratio of aluminum element to phosphoric acid in the raw material is 3 / n:1, n is the valence of ...

Embodiment 2

[0041] The preparation method of the water-insoluble phosphate of embodiment 2 of the present invention, at first the metal hydroxide raw material is dissolved with the mixed acid of nitric acid and phosphoric acid, and the solid impurity is removed by filtration to obtain a clarified solution, then an organic reducing agent is added in the solution, at a certain Reaction under temperature conditions, when the yield of water-insoluble phosphate in the reaction system reaches an appropriate level, then filter and wash to obtain water-insoluble phosphate.

[0042] The metal hydroxide raw material is magnesium hydroxide. The phosphate that is insoluble in water is magnesium phosphate.

[0043] In the mixed acid, the molar ratio of nitric acid and phosphoric acid is 10:1.

[0044] The reaction temperature under the certain temperature condition is 150°C.

[0045] The yield of water-insoluble phosphate in the reaction system reaches an appropriate level of 0.1%.

[0046] The mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com