Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Large load adjustment range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

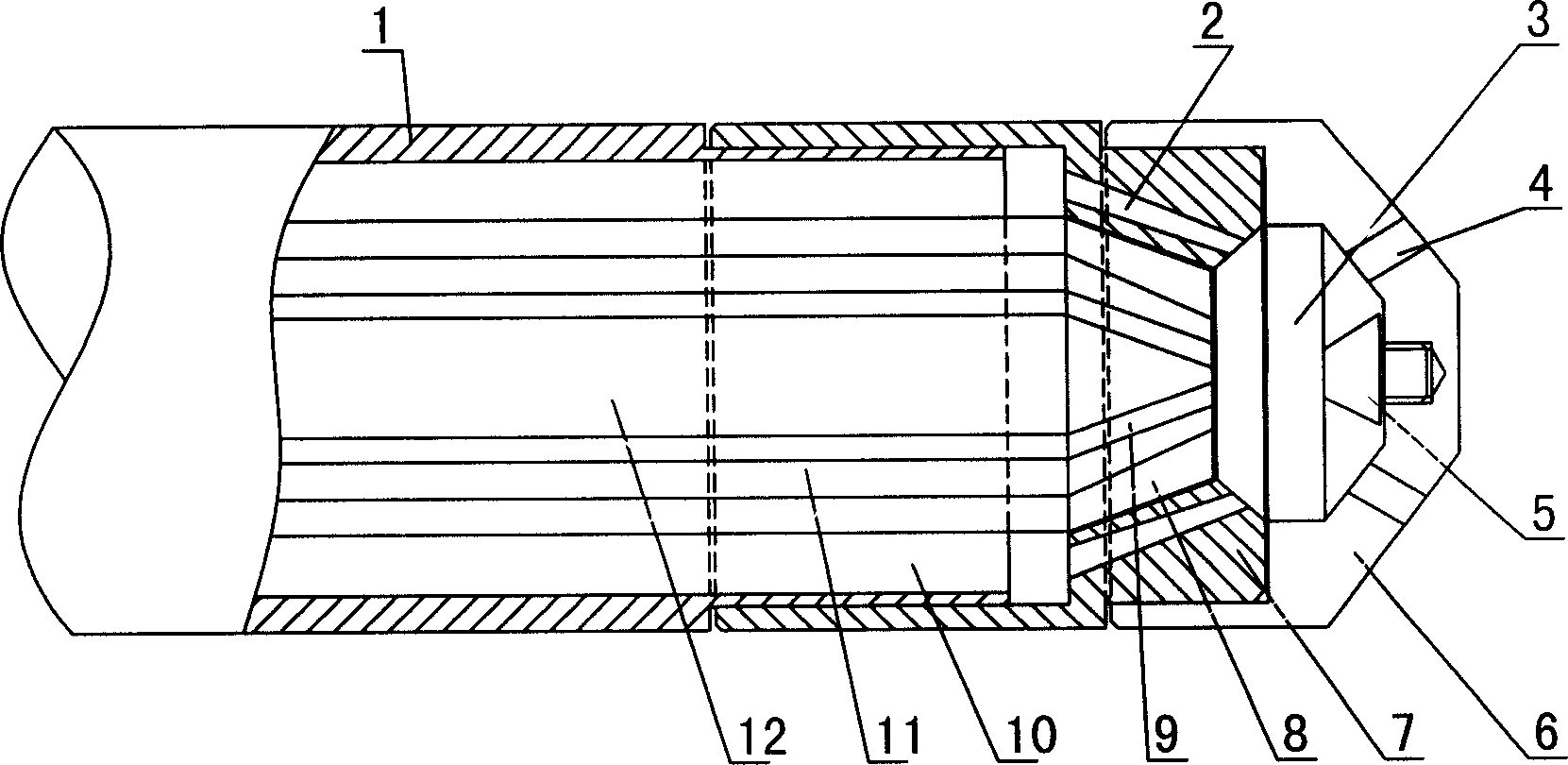

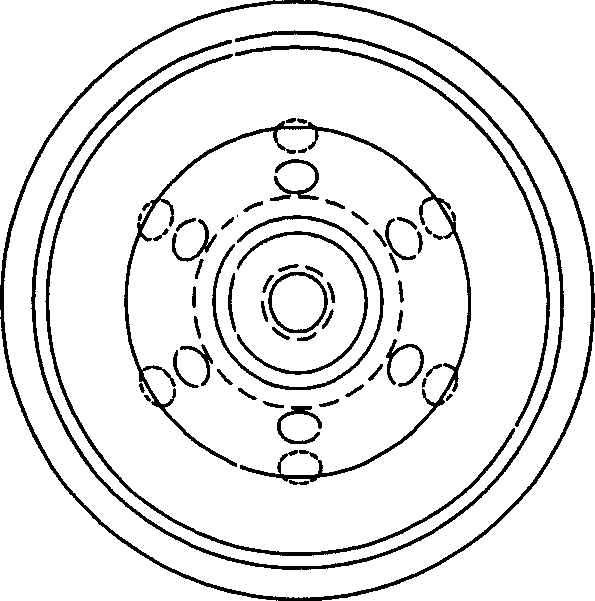

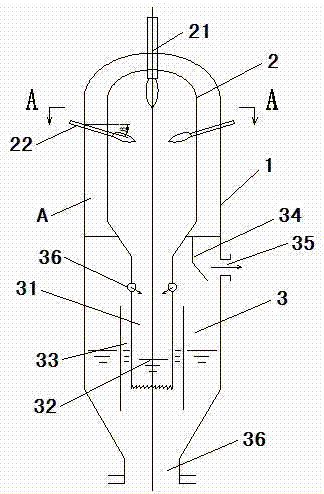

Coal-water fluid gasifying spray nozzle

InactiveCN1752521ALarge load adjustment rangeEasy to adjustLiquid fuel feeder/distributionLump/pulverulent fuel feeder/distributionInterior spaceCoal water

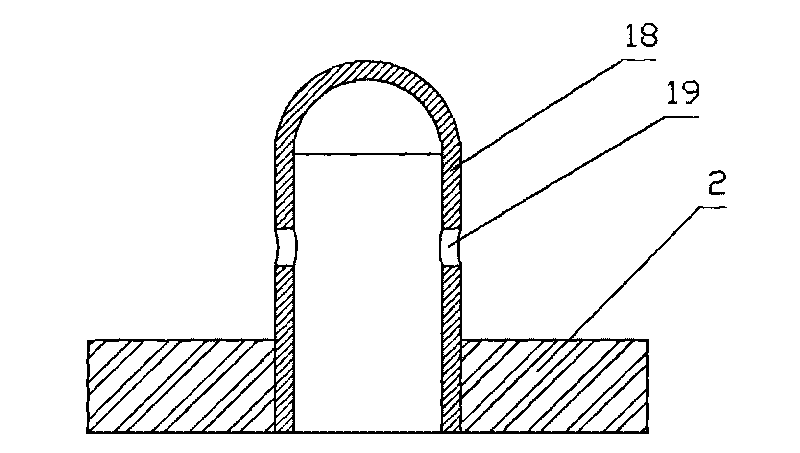

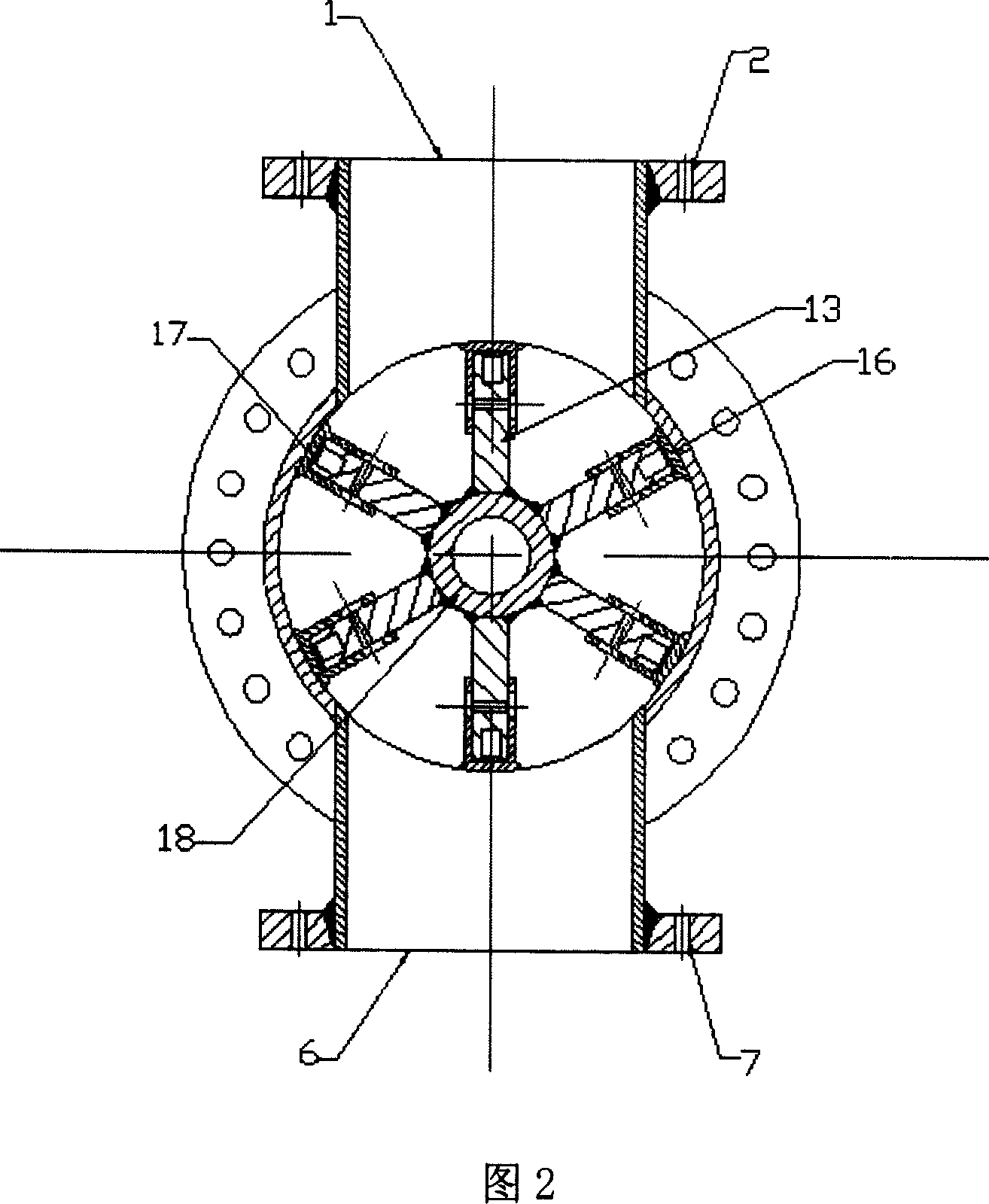

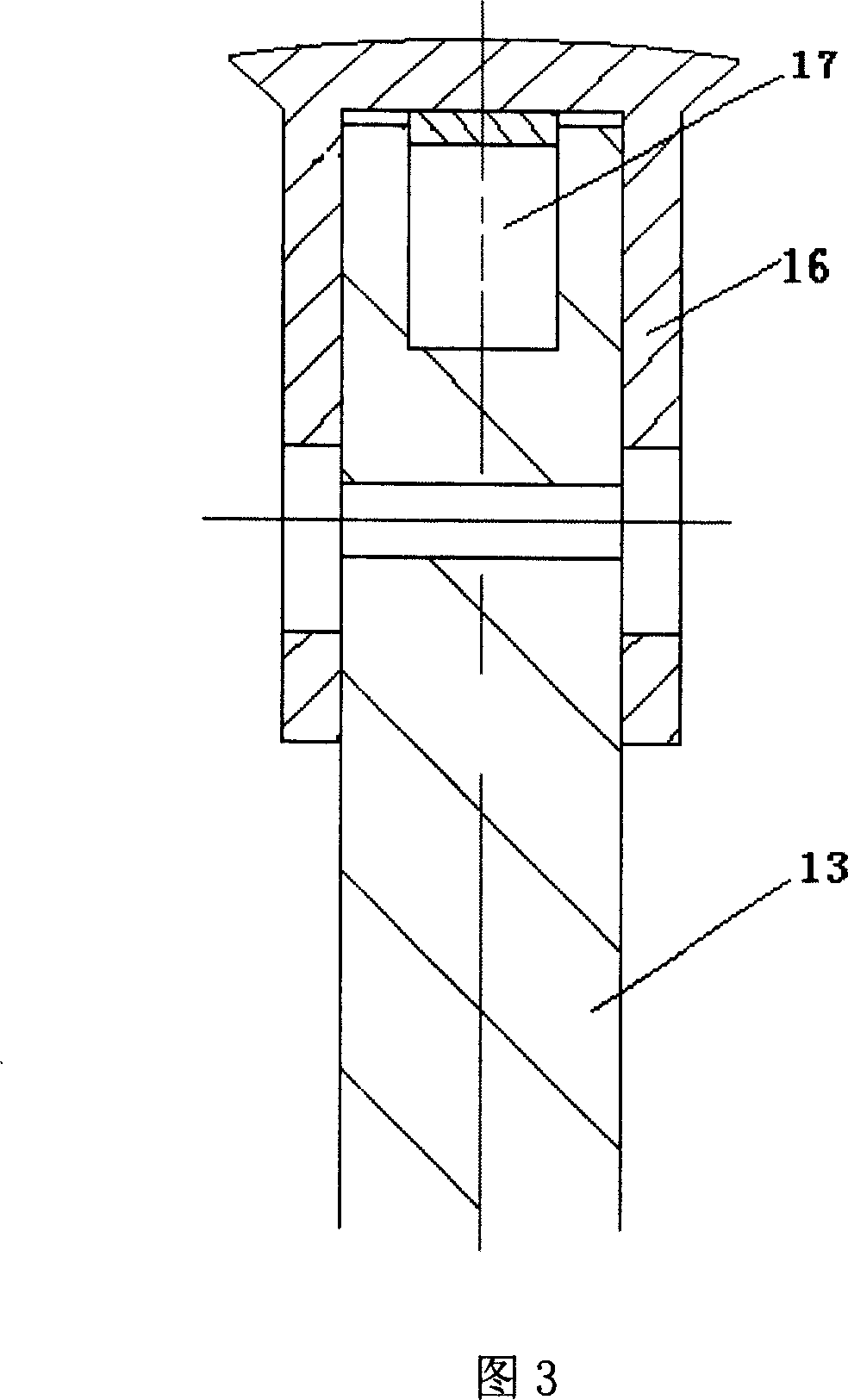

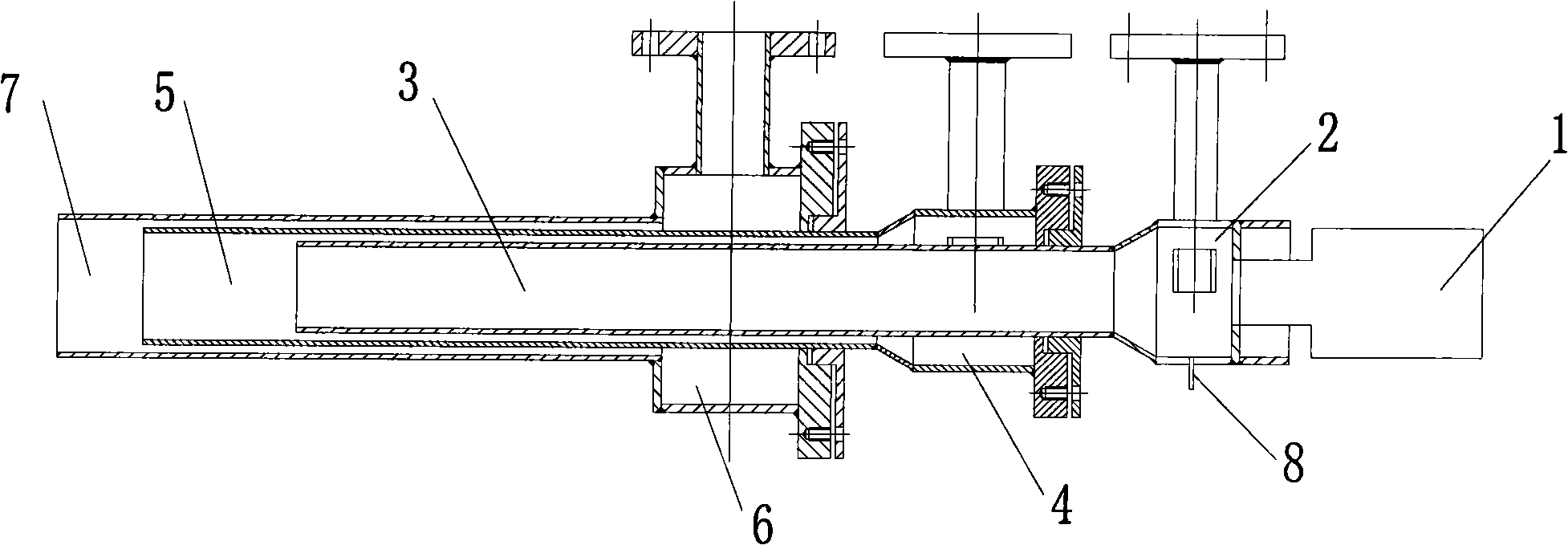

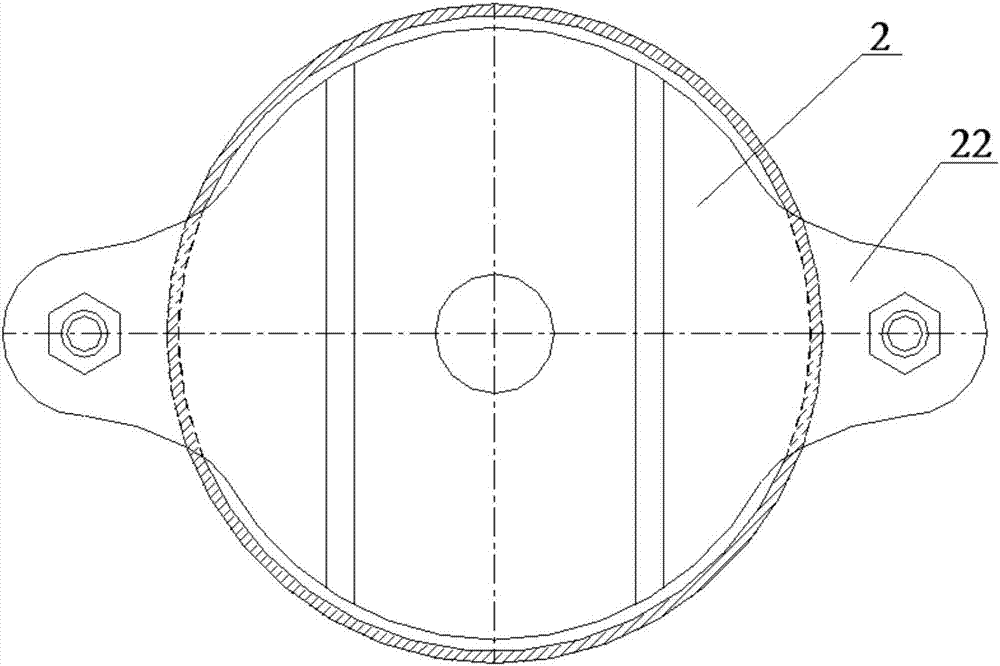

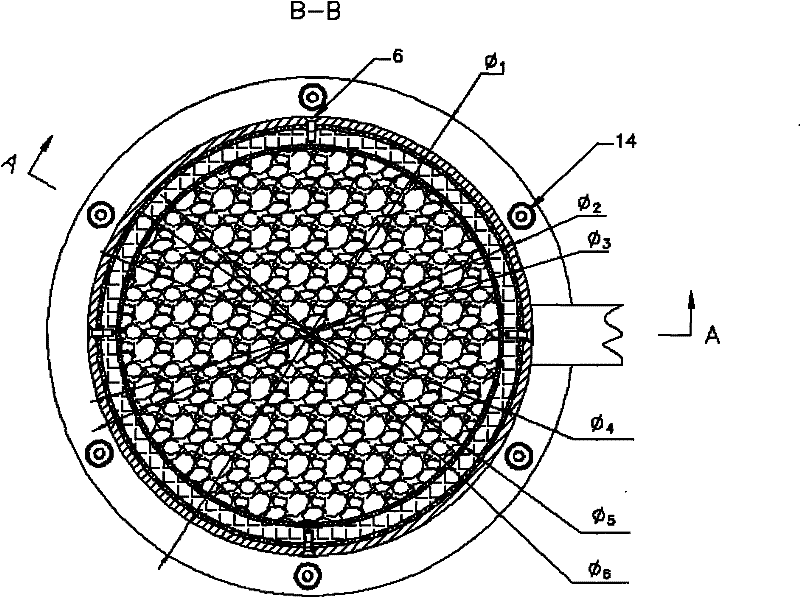

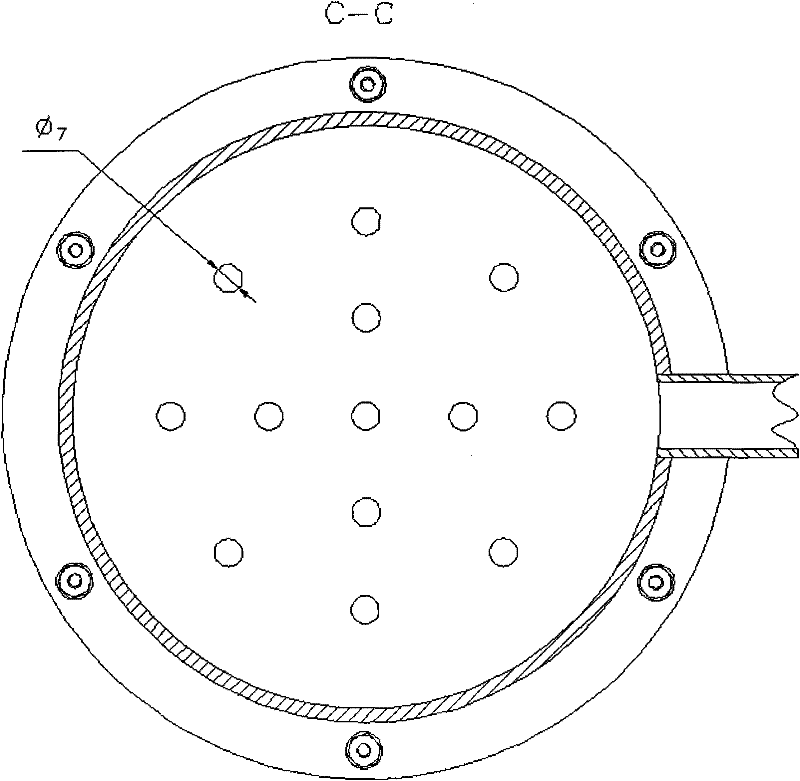

The present invention relates to a combustion device, and is aimed at providing a coal-water slurry gasification nozzle. It is characterized by forming central tube oxidant channel whose section is concentric ring-tubular structure, medium ring coal-water slurry channel and outer ring oxidant channel: the tail end of central tube oxidant channel is reducing-formed central tube nozzle, the medium ring coal-water slurry channel and outer ring oxidant channel are reducing-formed medium ring tube nozzle and outer ring tube spray head, the outer ring tube spray head is connected with atomizing head on which the jet orifices are uniformly distributed.

Owner:ZHEJIANG UNIV

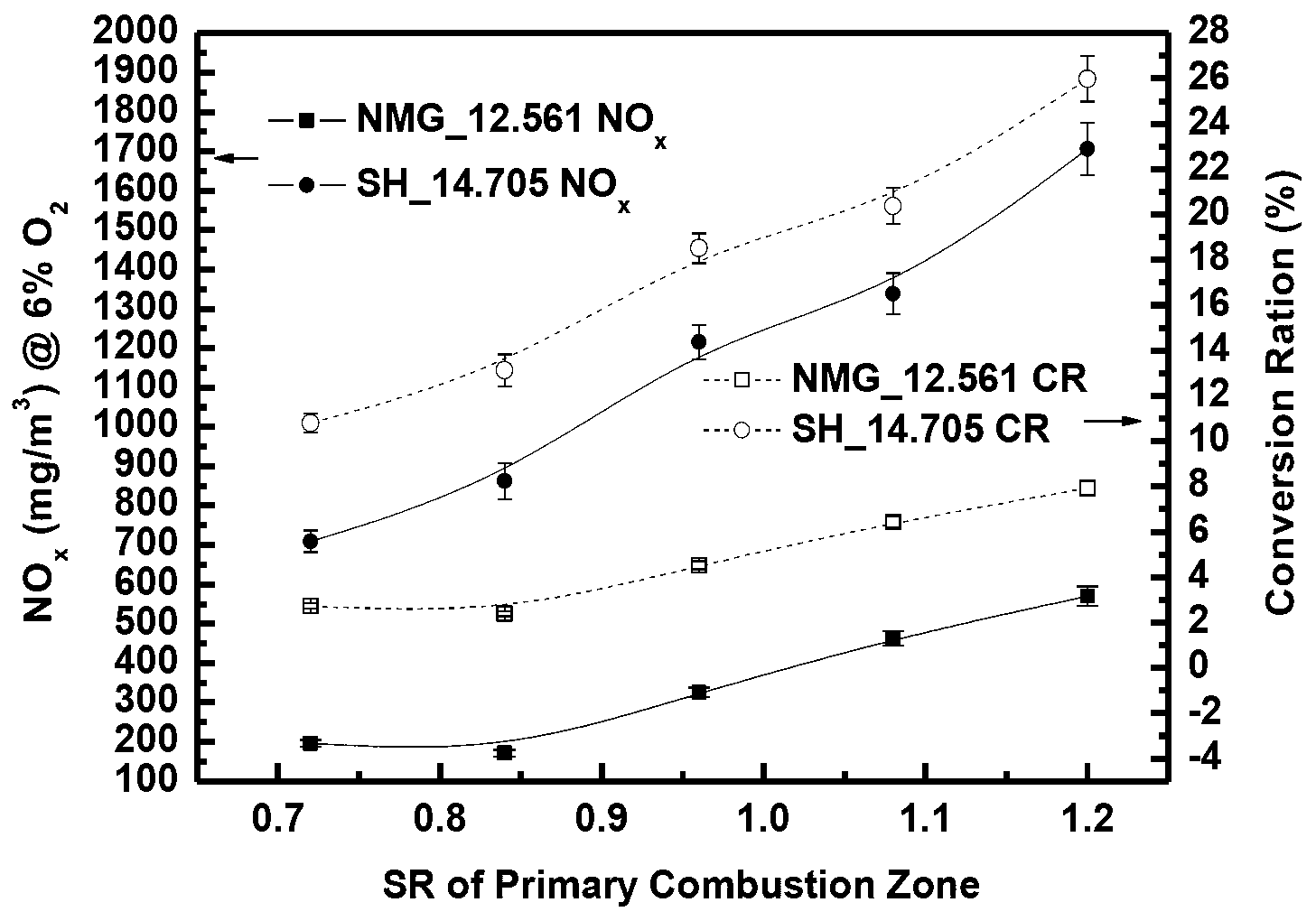

Superfine coal dust oxygen-enriched combustion technology and system

InactiveCN103234198AIncrease burnoutAlleviate the problem of slagging on the heating surfaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTrappingFlue gas

The invention discloses a superfine coal dust oxygen-enriched combustion technology and system in the technical field of energy conservation and emission reduction. The technology comprises the following steps of: preparing superfine coal dust with an average particle size of less than 20 microns, and burning in an oxygen-enriched environment with overall concentration kept at 27-35% (v / v); extracting part of the hot flue gas in a flue at the rear part of a deduster; and circularly preparing superfine coal dust by taking the extracted flue gas and oxygen as combustion-supporting mediums again. According to the technology and system disclosed by the invention, the superfine coal dust is applied to the oxygen-enriched combustion technology, and the advantages of the two are effectively combined to realize an effect of using advantages and bypassing disadvantages; and the superfine coal dust oxygen-enriched combustion technology finishes efficient trapping of CO2 and is a new coal dust combustion technology with good combustion property and better pollutant discharge performance, and surely becomes an emerging technology for pollutant cooperative removal deserving vigorous promotion.

Owner:SHANGHAI JIAO TONG UNIV

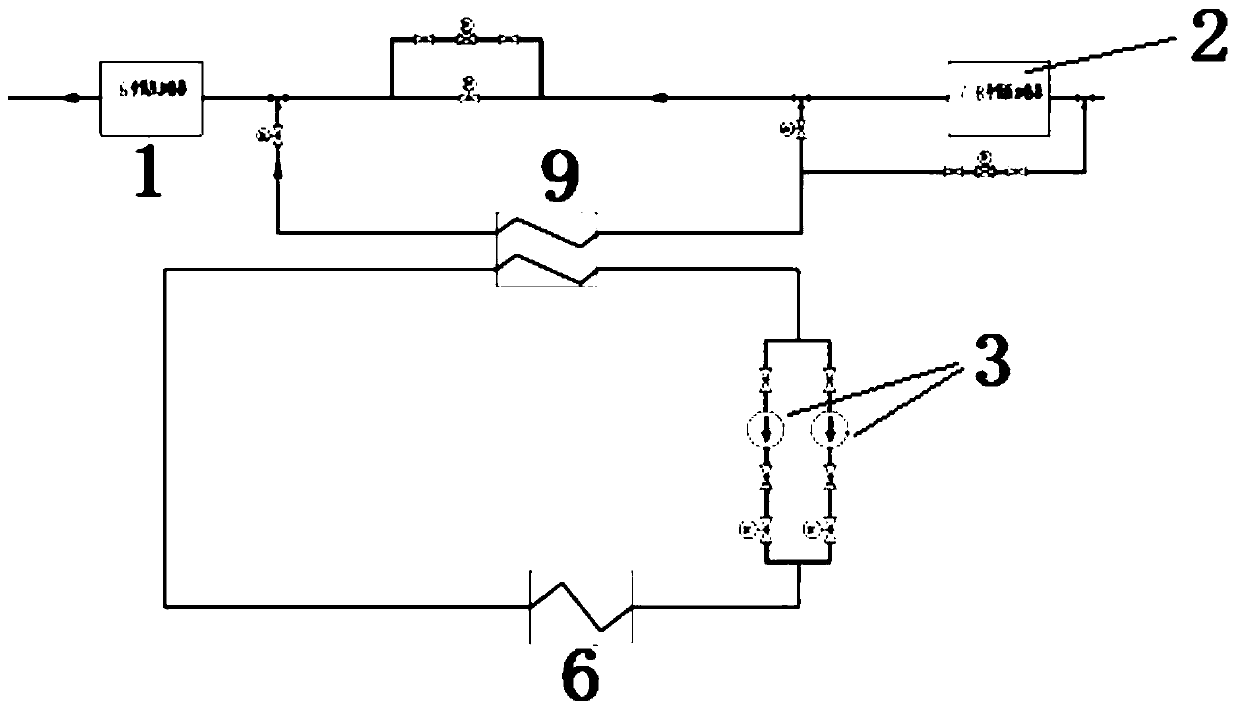

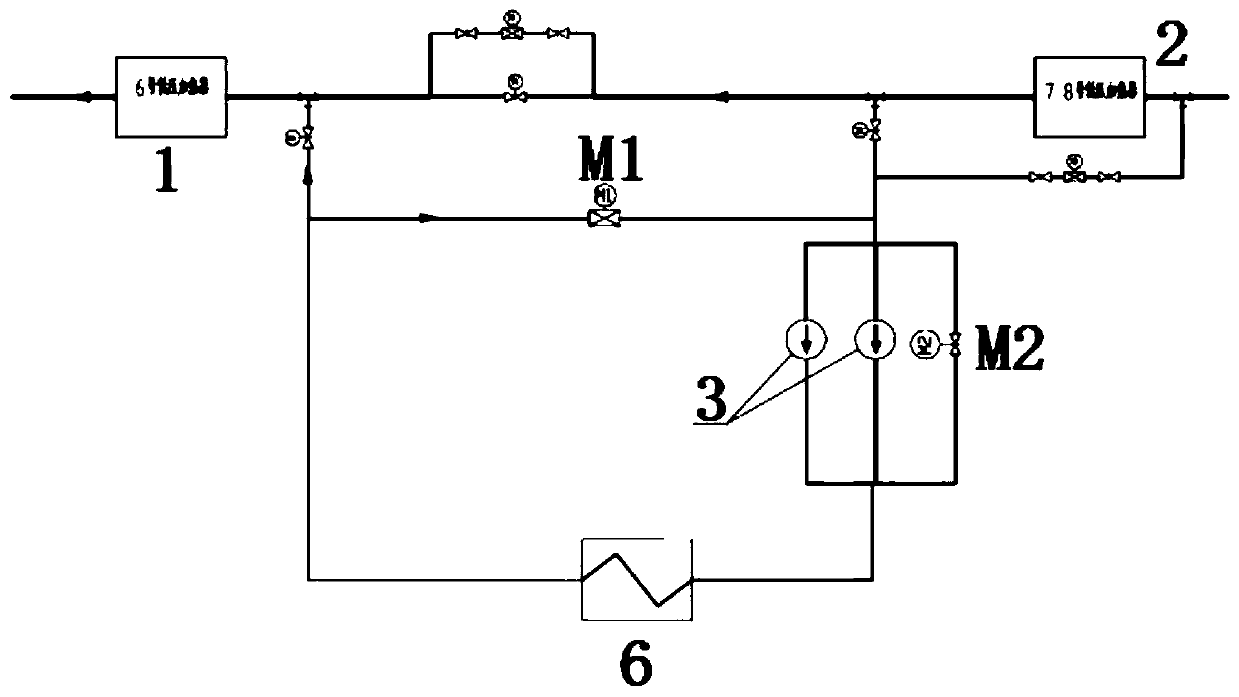

Natural gas liquefying method and device with light hydrocarbon recovery function

InactiveCN103453730AAdjust qualityHigh puritySolidificationLiquefactionPhysical chemistryRefrigerant

Owner:HANGZHOU FORTUNE CRYOGENIC EQUIP CO LTD

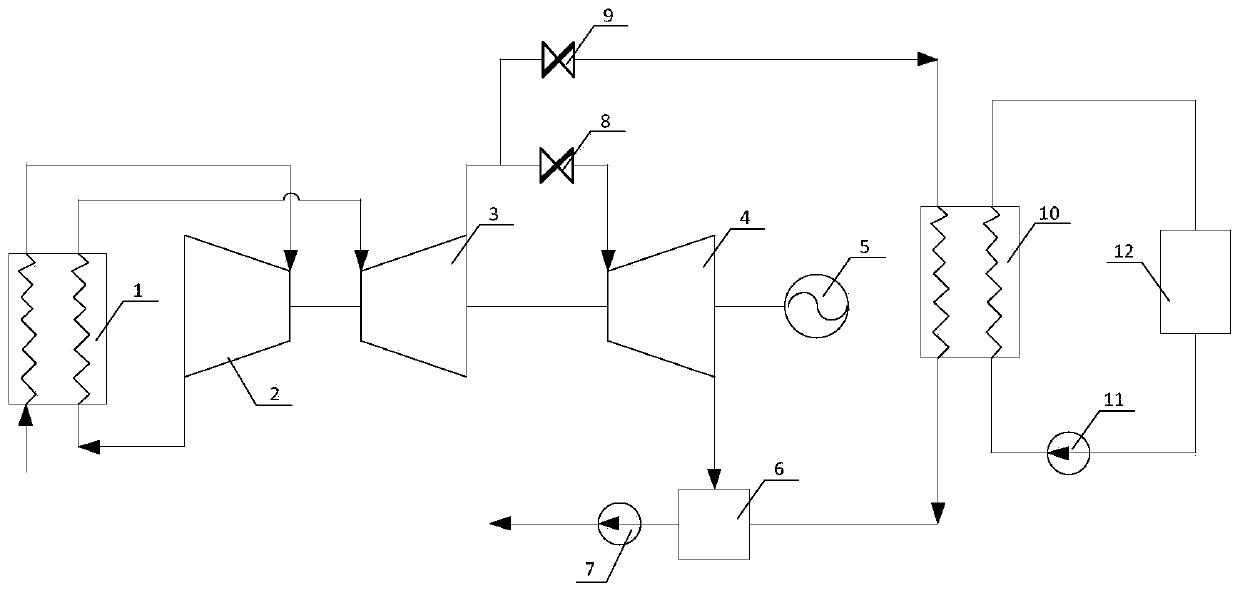

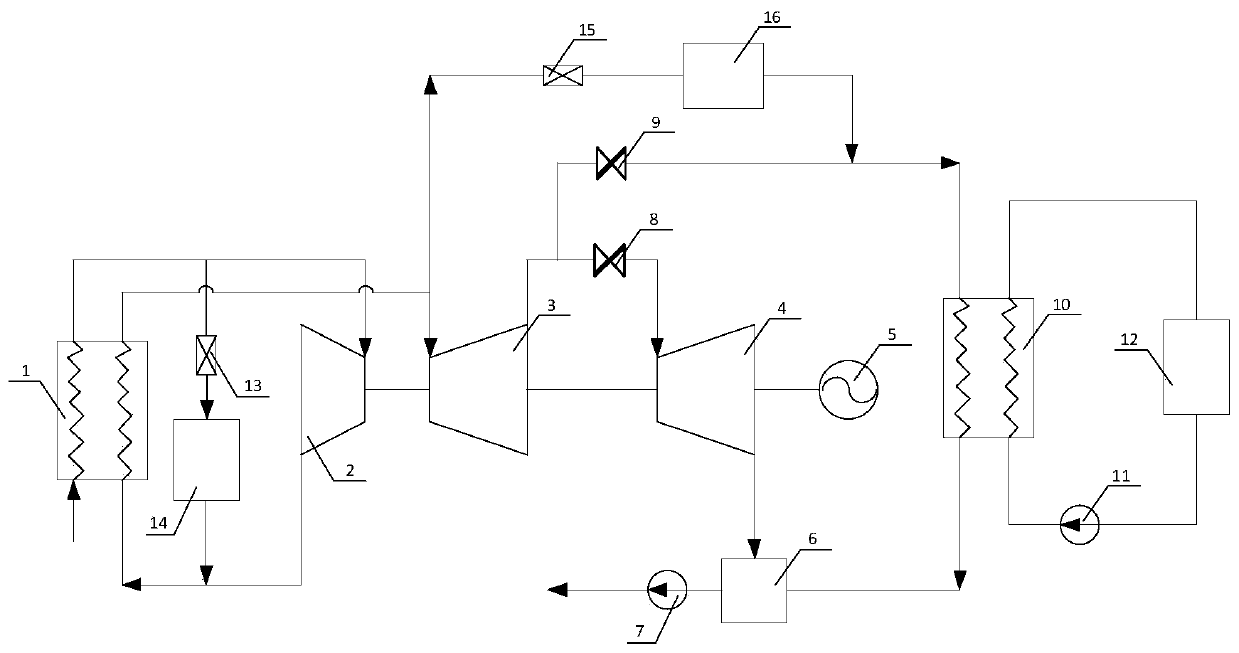

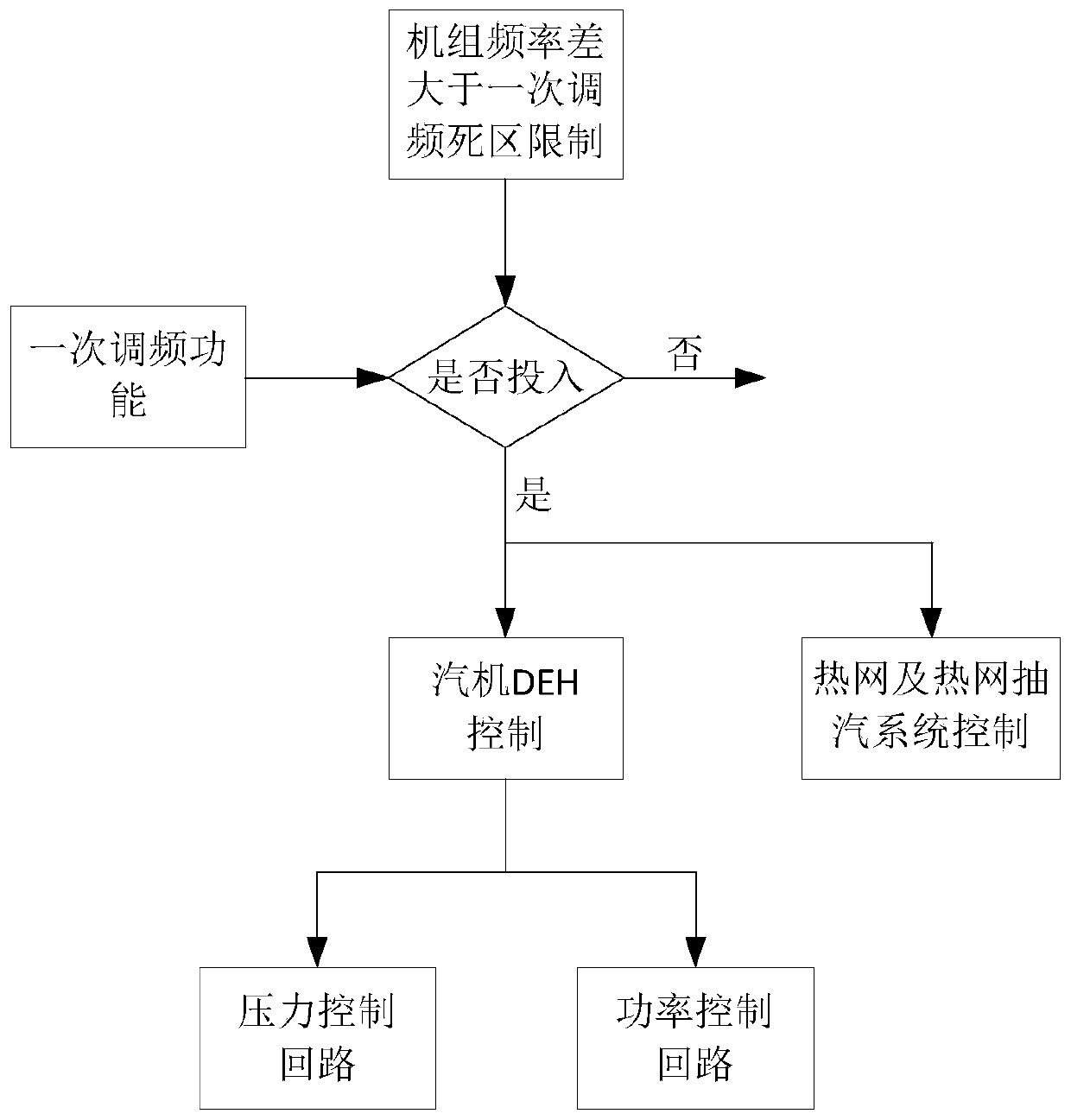

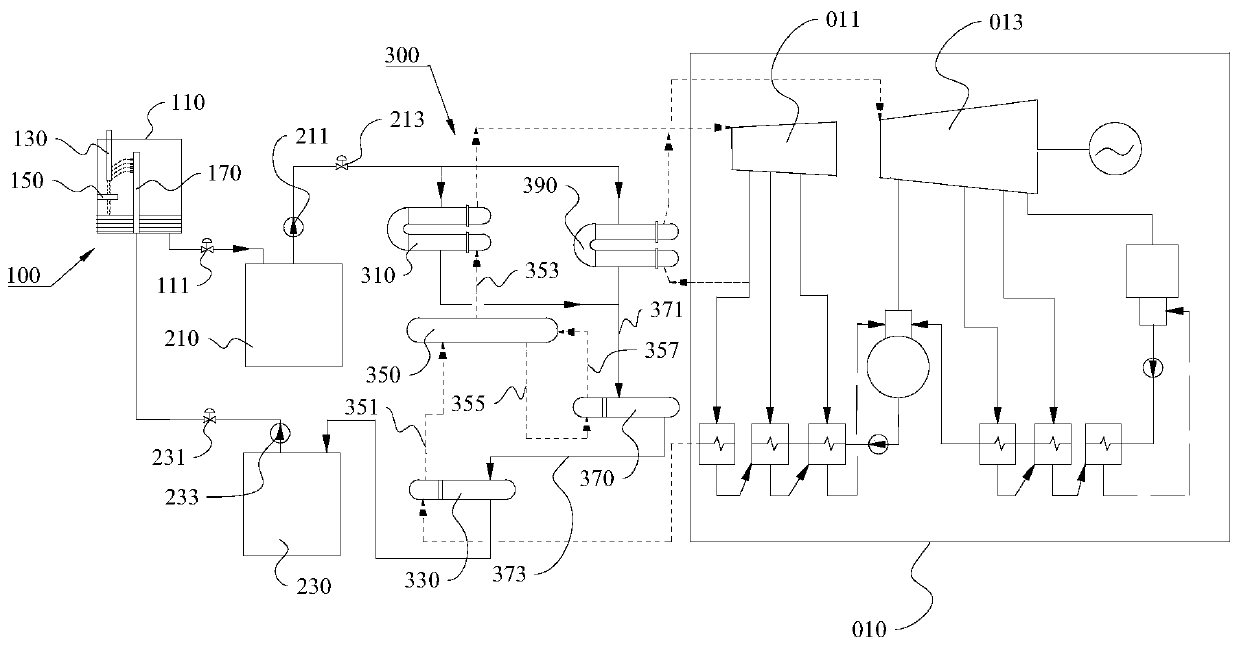

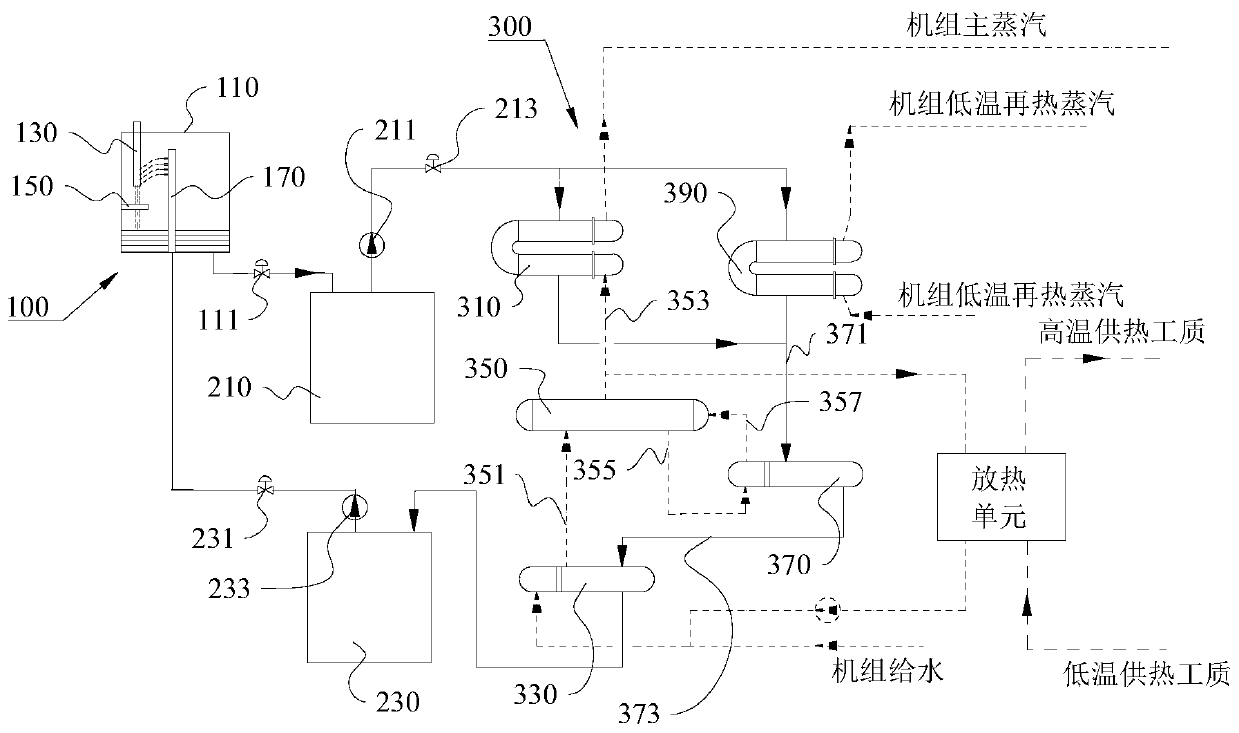

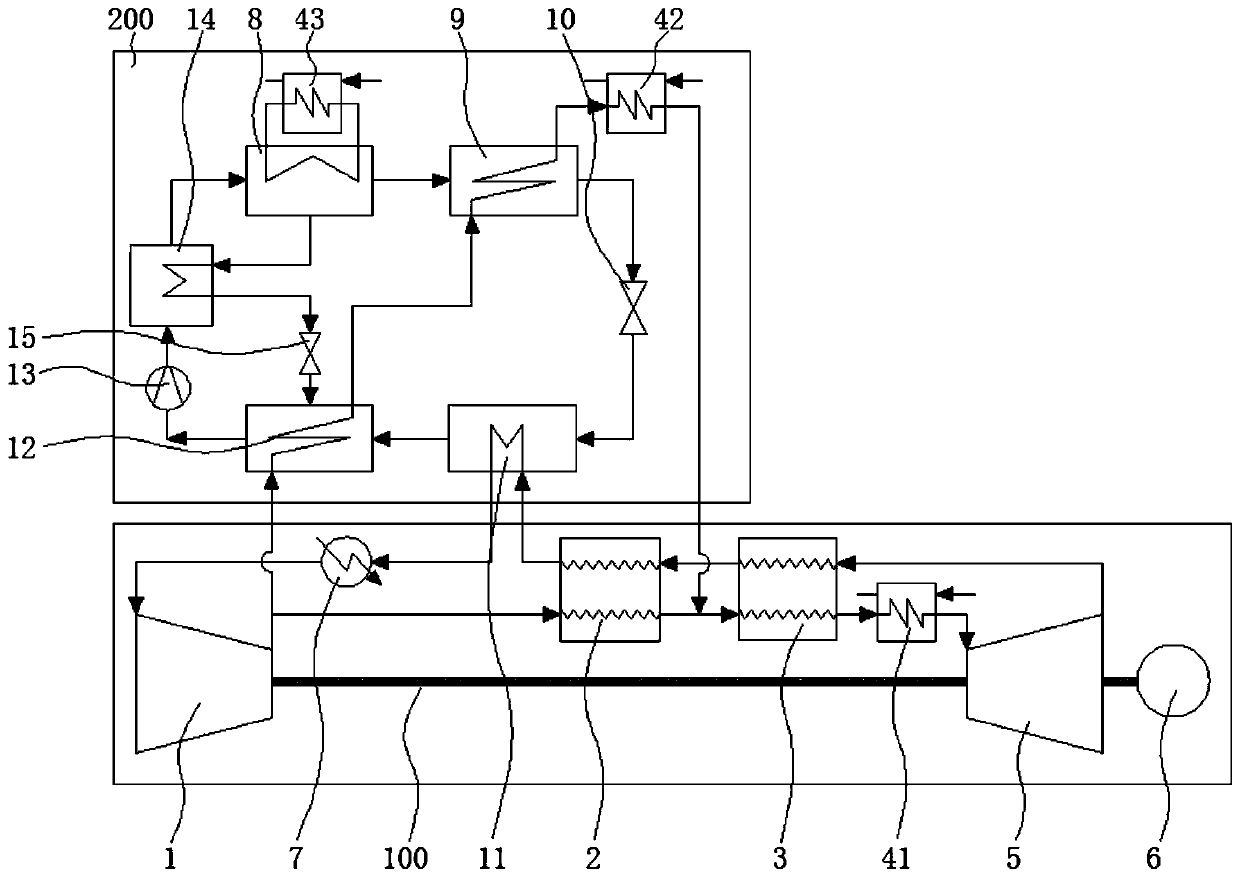

Thermodynamic system and regulation and control method for rapid load responses of heat supply unit

PendingCN110608072ASolve the technical problems of poor stability and high maintenance costsImprove the ability to quickly lift the loadLighting and heating apparatusSteam useLoad instructionEngineering

The invention discloses a thermodynamic system and a regulation and control method for rapid load responses of a heat supply unit. The technical problems that an existing thermodynamic system is poorin stability and high in cost are solved. The system is based on the heat supply unit, and the heat supply unit comprises a boiler, a high-pressure cylinder, a medium-pressure cylinder, a low-pressurecylinder and a generator which are sequentially connected. A medium-low-pressure communication butterfly valve is arranged between the medium-pressure cylinder and the low-pressure cylinder and is used for regulating the flow of steam entering the low-pressure cylinder. A heat supply steam outlet is formed between the medium-pressure cylinder and the medium-low-pressure communication butterfly valve, and a steam extraction butterfly valve is arranged on a steam extraction pipeline and is used for adjusting and controlling the flow of steam entering a heat supply network heater. The system isused for rapidly responding to AGC load instructions and primary frequency modulation instructions through the heat supply unit. The steam extraction device and a heat supply network system are adjusted through the heat supply unit, the instantaneous heat supply steam flow of the heat supply unit is quickly changed, and the instantaneous thermoelectric ratio of the whole unit is adjusted, so thatthe quick responses to power generation loads of the unit are achieved.

Owner:SPIC POWER PLANT OPERATION TECH (BEIJING) CO LTD

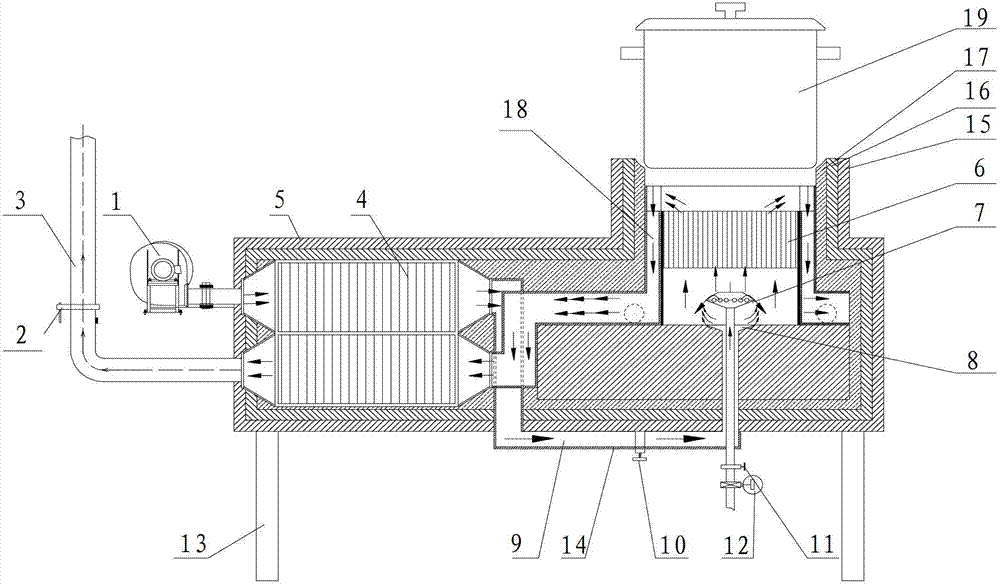

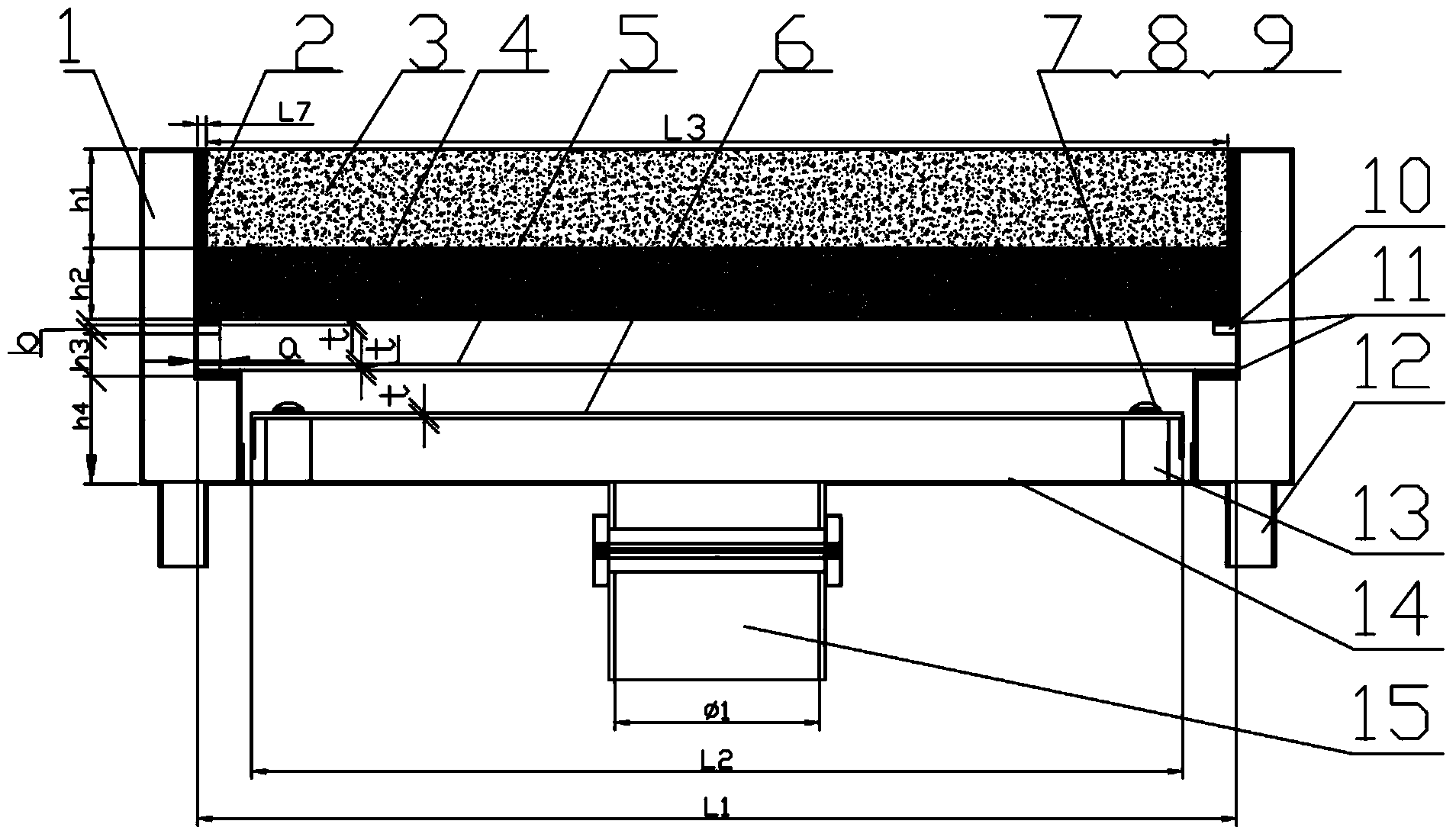

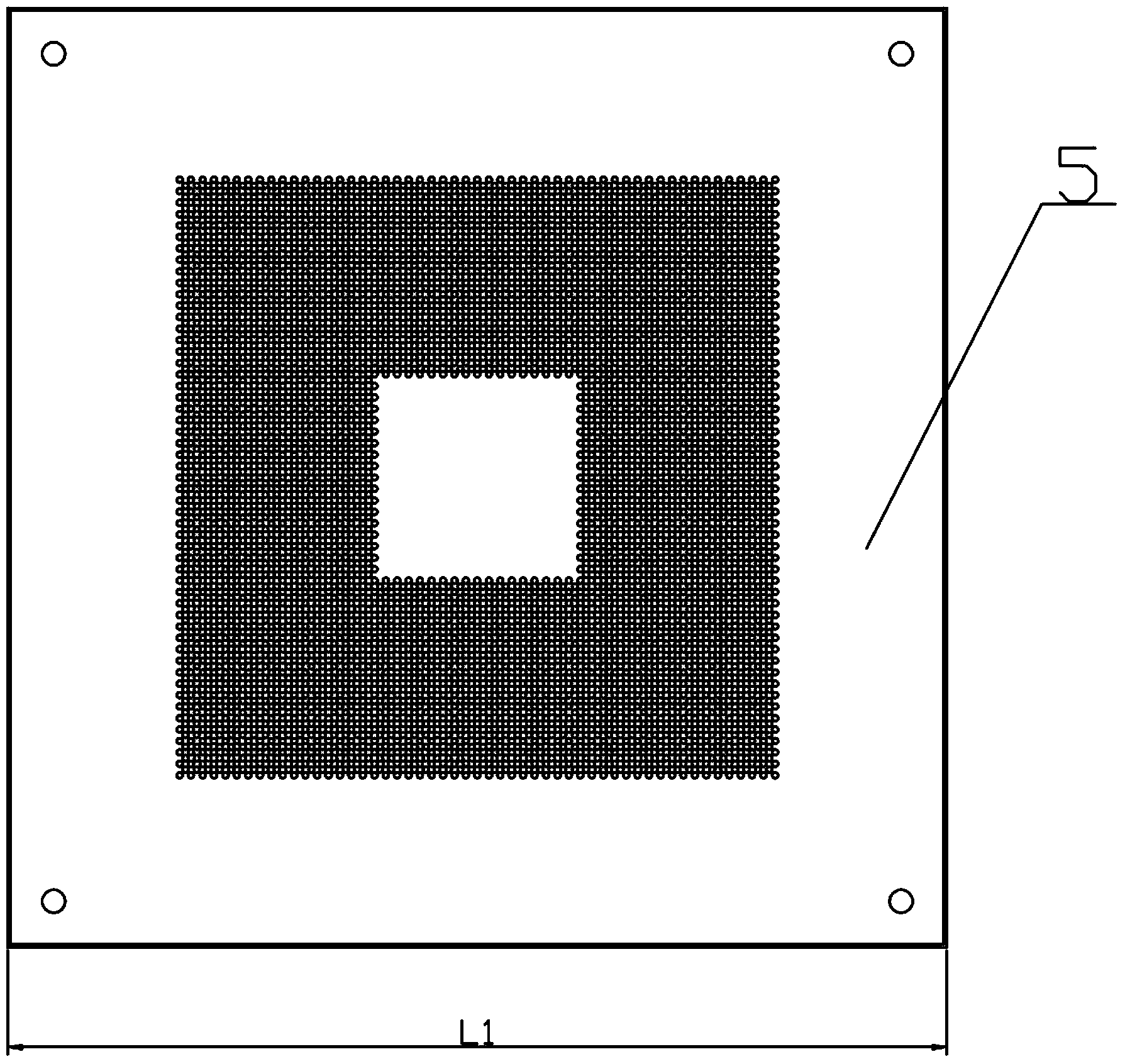

Waste heat recovering efficient gas stove

InactiveCN102759130ALower exhaust gas temperatureCompact structureDomestic stoves or rangesCombustion processCombustion chamberEngineering

The invention discloses a waste heat recovering efficient gas stove. A hot air tube (9) for supplying air and matched with a gas tube (7) is arranged on a stove body (5), a hearth of the stove body (5) is provided with a porous ceramic medium (6) covering the gas tube (7) and the hot air tube (9) to form a combustion chamber, a smoke recovering channel (18) is formed between a side wall of the porous ceramic medium (6) and a hearth side wall of the stove body (5), a cooker can seal a hearth port when placed on the hearth port, a heat exchange tube (4) is arranged in the stove body (5), an air blower (1) is connected with an air inlet of the heat exchange tube (4), an air outlet of the heat exchange tube (4) is connected with the hot air tube (9), a smoke inlet of the heat exchange tube (4) is connected with a smoke recovering channel (18), and a smoke outlet of the heat exchange tube (4) is connected with a chimney (3). The waste heat recovering efficient gas stove can effectively improve heat efficiency, reduce pollutant discharge and improve chef working environment.

Owner:HUNAN HANLON ENERGY TECH +1

Stable combustion device for pulverized coal ignition

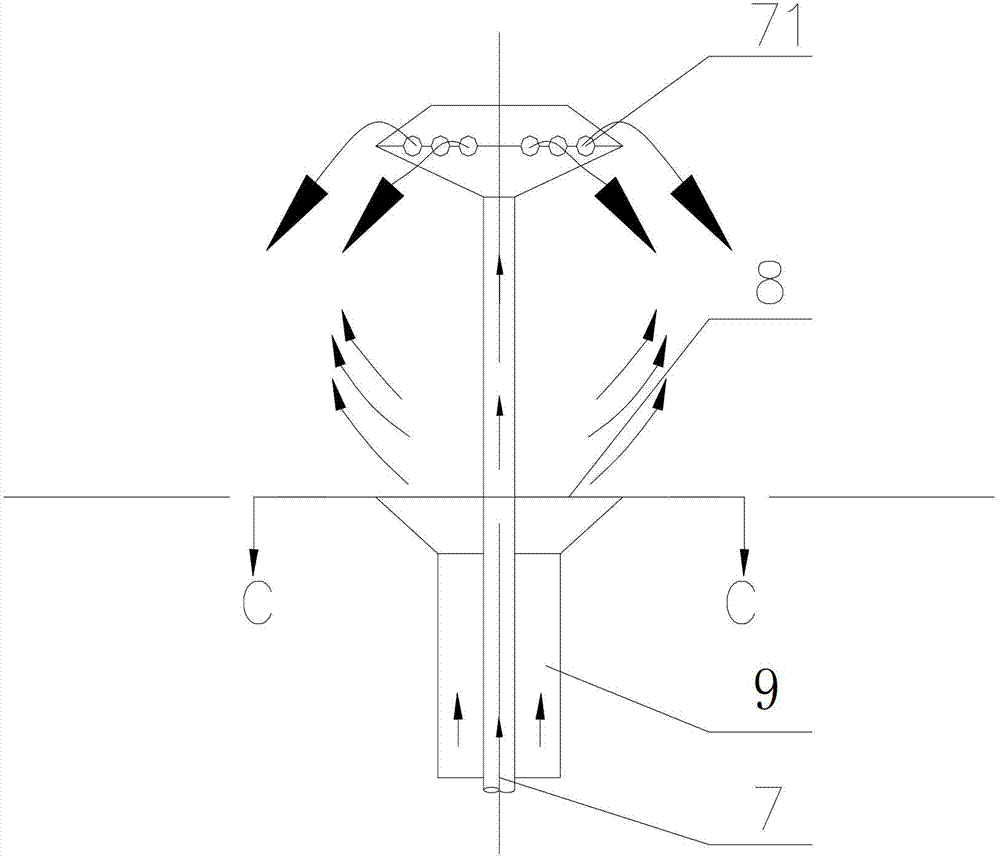

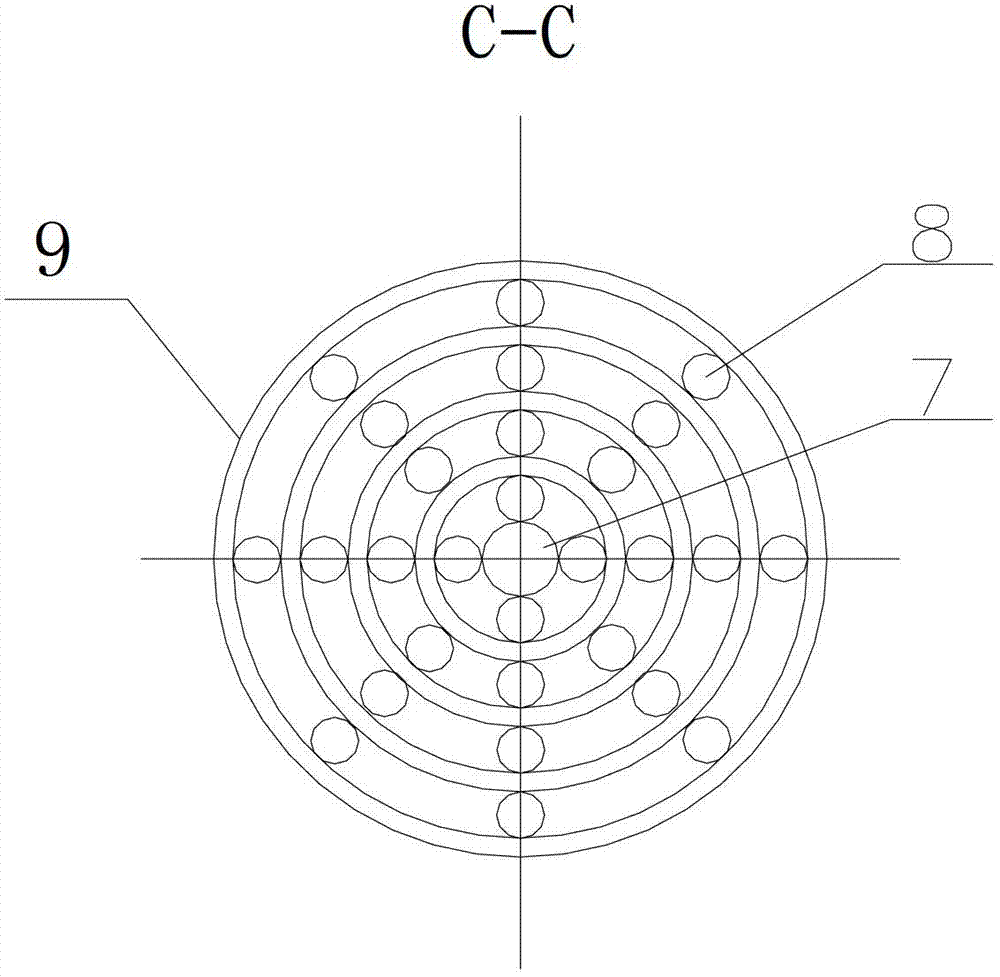

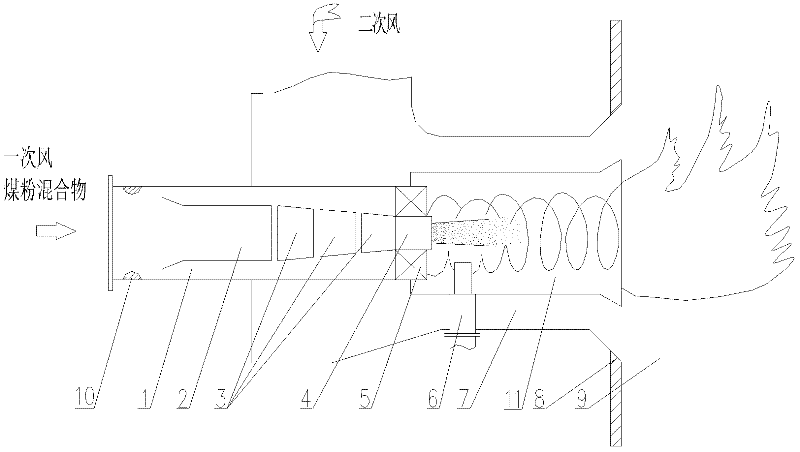

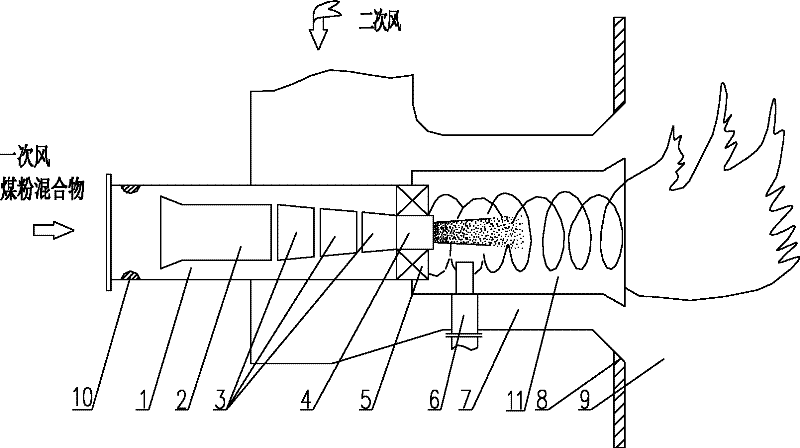

InactiveCN102353049AStrong burning abilitySave combustion oilPulverulent fuel combustion burnersLiquid jetCombustor

The invention discloses a stable combustion device for pulverized coal ignition, which comprises a primary air pipe, a flow guide sleeve, pulverized coal concentrator and a guide pipe as well as an ignitor, wherein pulverized coals pass through the primary air pipe, the flow guide sleeve, the pulverized coal concentrator and the guide pipe are arranged in the primary air pipe in sequence, and the ignitor is radially arranged at an outlet of the primary air pipe. A rotational flow blade capable of rotational liquid jet is arranged between the guide pipe and the inner wall of the primary air pipe; and a secondary air duct formed by a secondary air pipe is arranged outside the primary air pipe and an expanding primary air pipe. In the structure, a central recirculation region is formed behind the adjustable rotational blade; the ignitor is close to a low-speed central recirculation region to form a continuous and stable intensified heat source, thus the intensified heat source can be used as an ignition heat source required by the ignition of pulverized coal air flow so as to reduce the generation of NOX (nitric oxide) in the furnace effectively, and challenges caused by operation factor interferences and the substantial vibration of coal quality which occur suddenly can be dealt with. Therefore, the combustion device is suitable for pulverized boilers for burning various coals, not only can be used as a stable ignition combustion device, but also used for the operation of a main combustor.

Owner:EASTERN BOILER CONTROL CO LTD

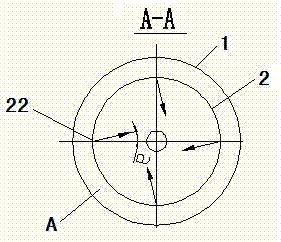

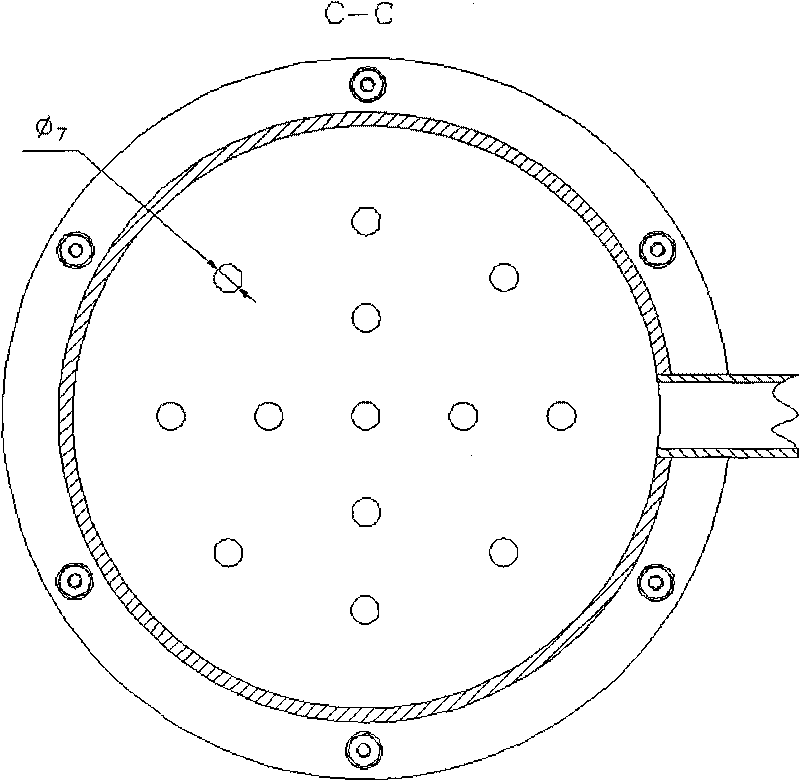

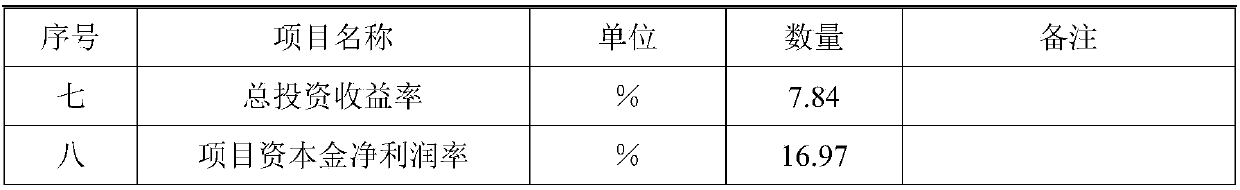

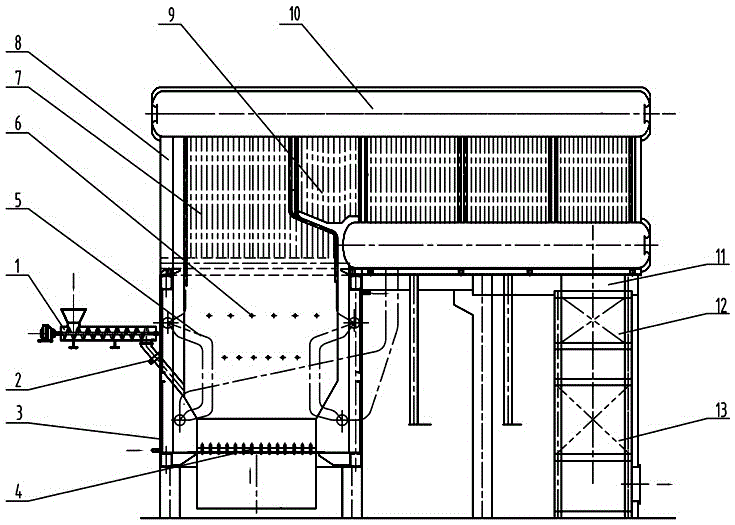

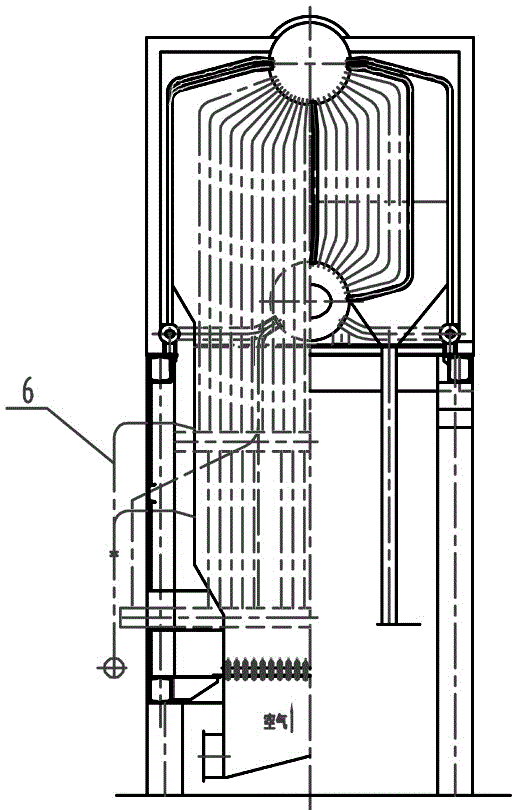

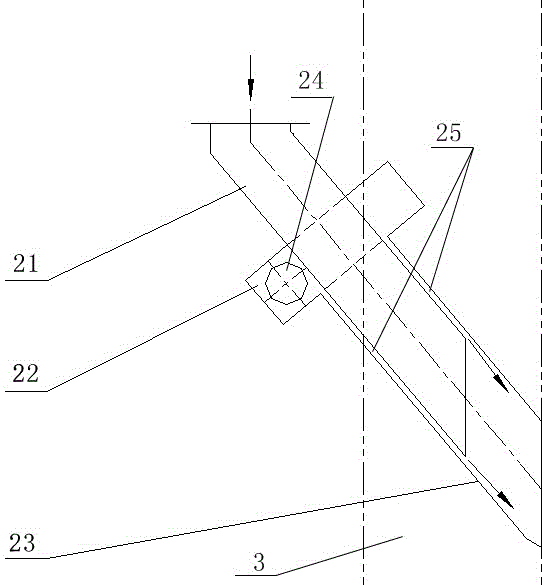

Load-adjustable step feeding type entrained flow bed gasifier

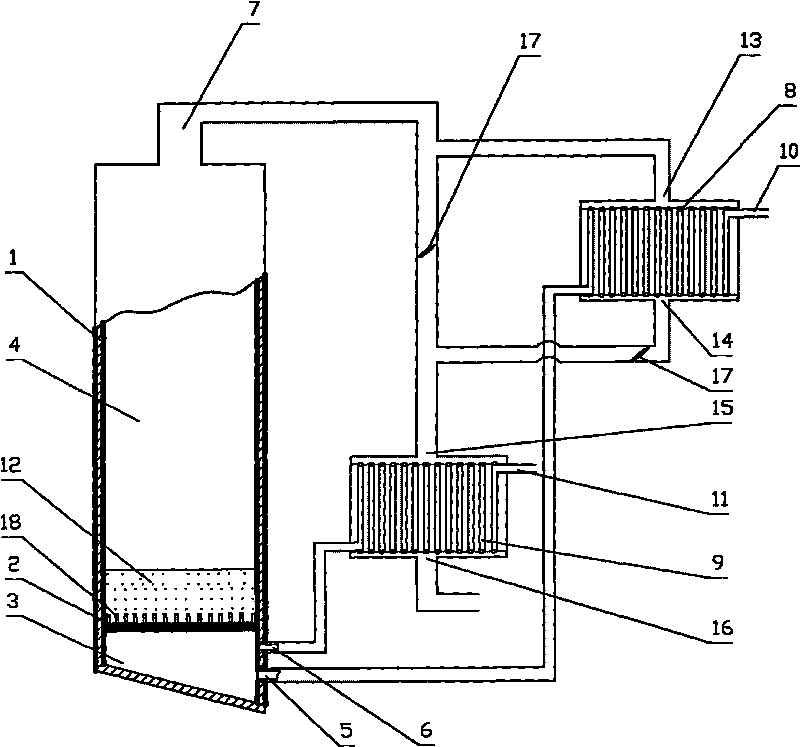

ActiveCN102827642AIncrease productionExtended stayGranular/pulverulent flues gasificationSyngasWater baths

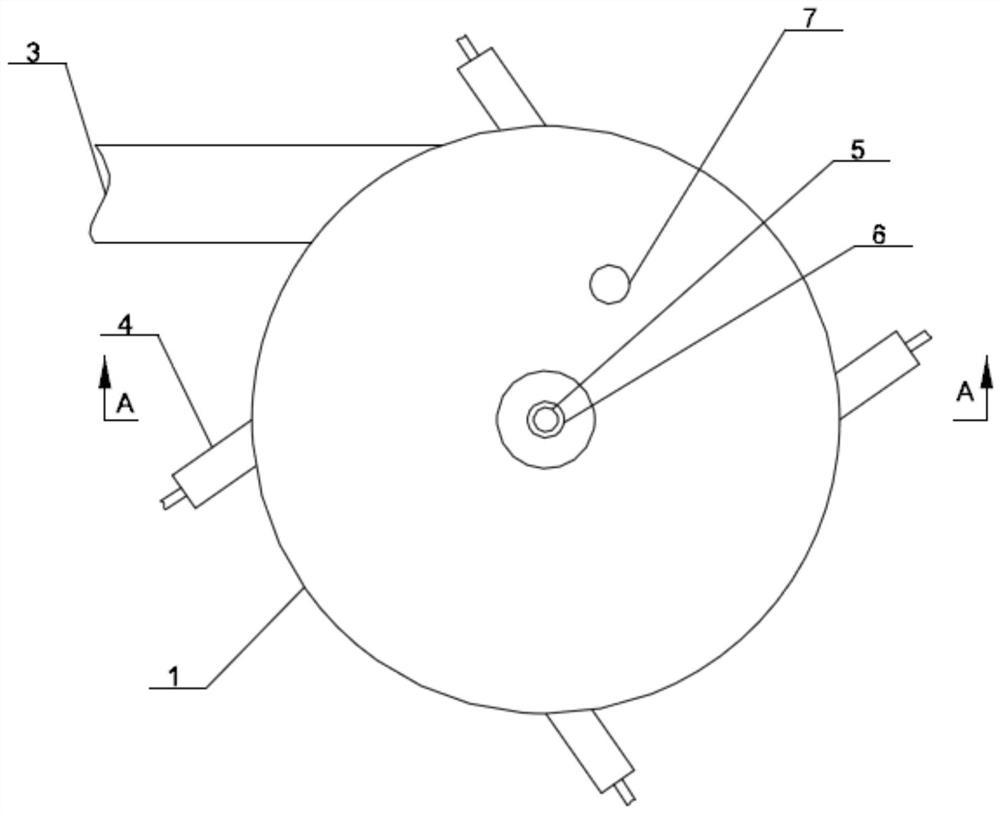

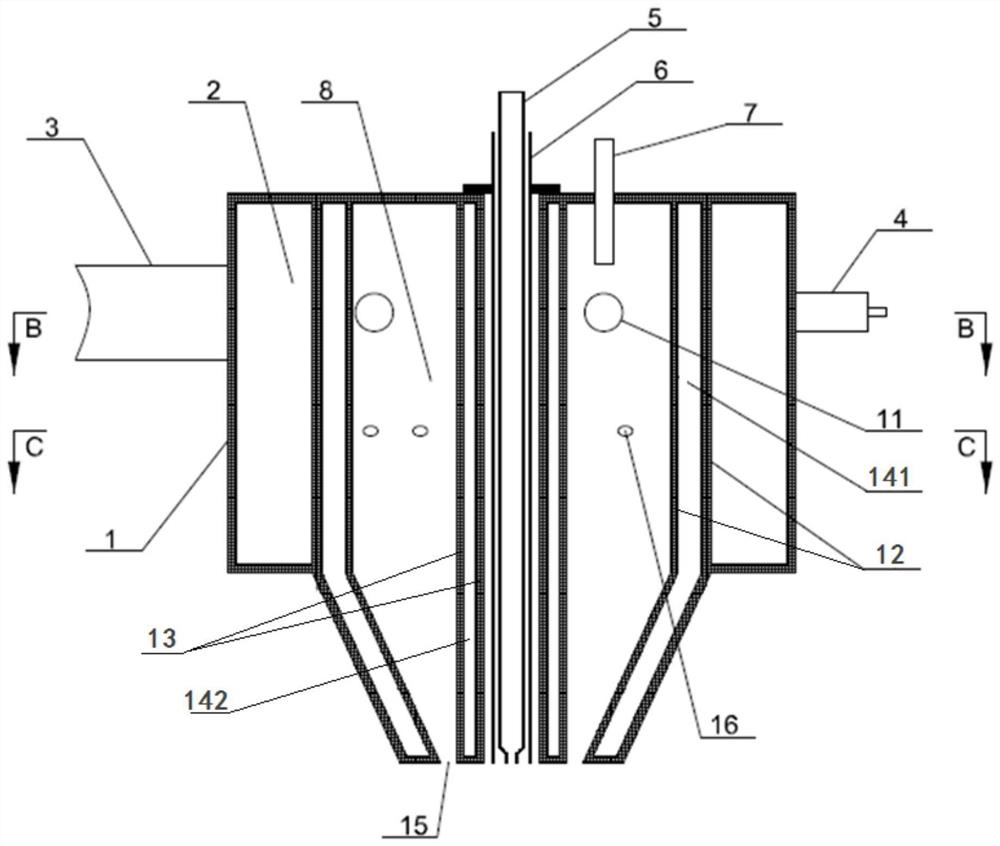

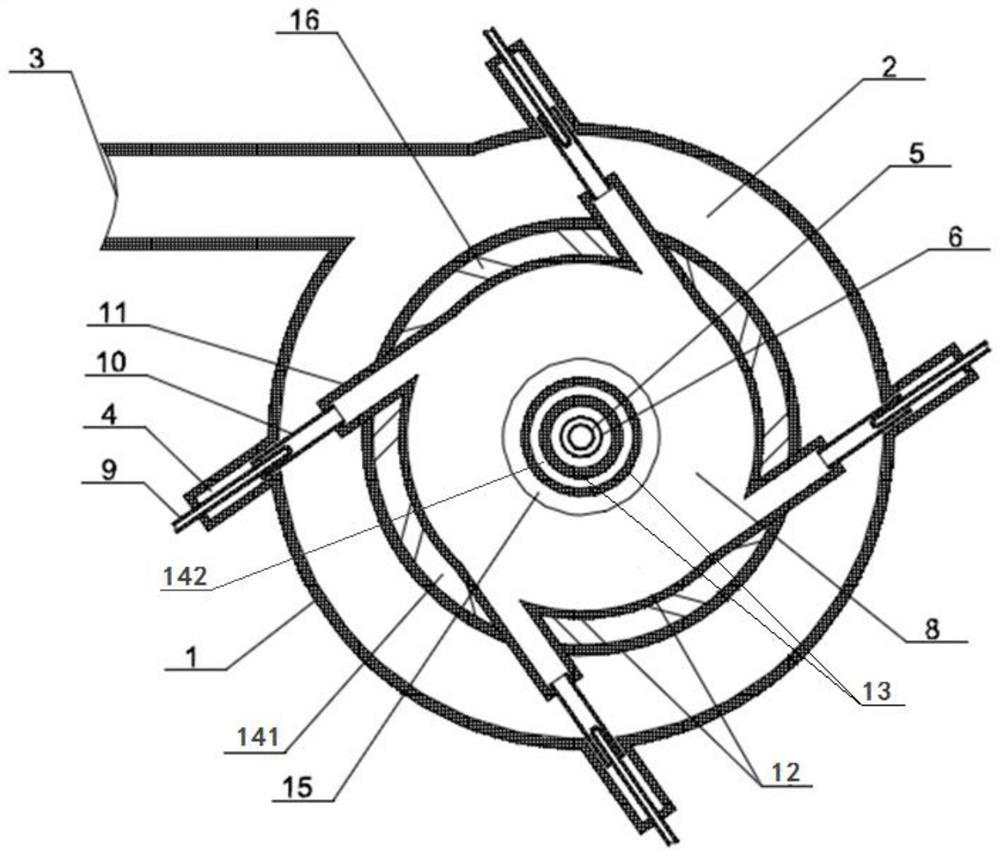

The invention discloses a load-adjustable step feeding type entrained flow bed gasifier. The load-adjustable step feeding type entrained flow bed gasifier is characterized by comprising a pressure shell body, and a reaction chamber and a cooling / dust removal / water bath chilling chamber which are supported and hung in the pressure shell body, wherein the cooling / dust removal / water bath chilling chamber is coaxially arranged at the lower part of the reaction chamber; an annular gap space is arranged between the reaction chamber and the pressure shell body; and the reaction chamber is provided with a main nozzle and a plurality of load adjustment nozzles. The cooling / dust removal / water bath chilling chamber is coaxially arranged at the lower part of the reaction chamber, the main nozzle is arranged at the top part of the gasifier, the load adjustment nozzles are symmetrically arranged in the space at the upper part of the reaction chamber, and water is used to chill high-temperature synthetic gas and clinker discharged below the reaction chamber, so that the single-gasifier yield is effectively increased, the single-gasifier production load adjustment capability is realized, and the hearth reaction region is reasonably arranged, thereby ensuring that the synthetic gas in the hearth can produce a rotational flow, the retention time is long, the reaction is thorough and the load adjustment range is wide.

Owner:中国船舶集团有限公司第七一一研究所

Diffusion type porous medium gas fuel combustor

InactiveCN101737778AUniform density distributionPrevent flashbackGaseous fuel burnerCombustorPorous medium

A diffusion type porous medium gas fuel combustor comprises a shell, an air duct and a fire-resistant casing pipe, the air duct is connected with the shell, the bottom end of the shell is connected with the top plate of a gas flow dividing tank, the shell is internally provided with the fire-resistant casing pipe, a tray and a gas flow dividing tube from top to bottom, the bottom end of the fire-resistant casing pipe is contacted with the tray, the tray is fixed on the shell or the gas flow dividing tube, the bottom end of the gas flow dividing tube is fixed on the top plate of the gas flow dividing tank, and the gas flow dividing tube and the gas flow dividing tank are communicated internally; the fire-resistant casing pipe is provided with macro porous medium, micro porous medium and lower layer metal fiber from top to bottom, and the lower layer metal fiber is connected with the tray and the gas flow dividing tube simultaneously. The inventive diffusion type porous medium gas fuel combustor can be used for efficiently avoiding tempering when combustion intensity is stronger, thus achieving the effects of protecting micro porous medium and saving energy.

Owner:NORTHEASTERN UNIV

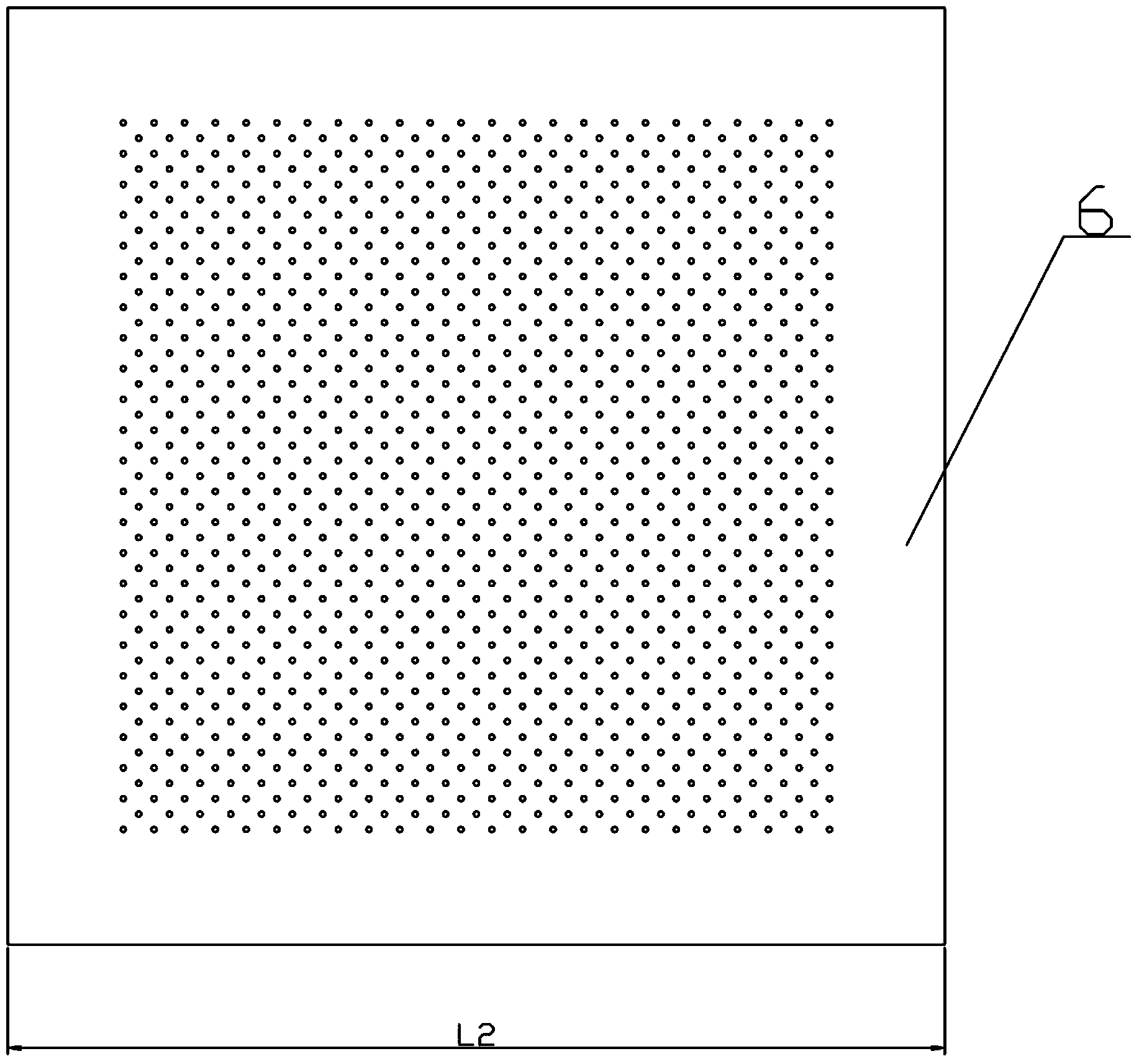

Partially premixed gas fuel burner of bi-layer porous foamed ceramic plate

The invention discloses a partially premixed gas fuel burner of a bi-layer porous foamed ceramic plate. The partially premixed gas fuel burner comprises a shell, a macroporous foamed ceramic plate, a microporous foamed ceramic plate, a top air distributor and a bottom air distributor, wherein the shell comprises a cooling cavity in an annular structure and a shell base-plate arranged on the cooling cavity, the cooling cavity is provided with a cooling cavity used for providing secondary air to pass through, and the bottom of the cooling cavity is provided with a secondary air inlet communicated with the cooling cavity; the inner side wall of the cooling cavity is provided with a secondary air outlet communicated with the cooling cavity, an annular frame formed by the cooling cavity is sequentially provided with the macroporous foamed ceramic plate, the microporous foamed ceramic plate and the top air distributor from top to bottom; the bottom air distributor and a shell base-plate, the secondary air outlet is located between the microporous foamed ceramic plate and the top air distributor, and the shell base-plate is provided with a mixed gas inlet for providing mixed gas of fuel and air to enter. According to the burner provided by the invention, the heating efficiency can be improved, and the heating uniformity can be improved.

Owner:WISDRI WUHAN WIS IND FURNACE

Modularized coal fines cleaning combustion apparatus

InactiveCN101290115AEasy to igniteEconomical co-firingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberButt joint

The invention discloses a modularized pulverized coal clean combustion device, relating to a combustion device for a boiler. The modularized pulverized coal clean combustion device comprises a cylindrical burning chamber arranged in the foreside of the boiler; the central part of the upper head face of the burning chamber is provided with a cyclone burner; the middle of the burning chamber is provided with a shrinking waist which divides the burning chamber into an upper burning chamber and a lower burning chamber, wherein the upper burning chamber is connected with a primary wind pulverized coal inlet with direct current incision; the upper and the lower burning chambers are connected with a secondary wind spout with direct current incision; the central part of the bottom of the lower burning chamber is provided with a mouth; a detritus tank is arranged on the corresponding position of the mouth; the tail of the lower burning chamber is connected with the boiler through a burnout chamber. The modularized pulverized coal clean combustion device can be directly in modularized butt joint with a pressed body of the prior boiler, is suitable for burning various pulverized coals, improves thermal efficiency, replaces the prior coal blocks or fuel gas as fuel and has good environment-friendly effect.

Owner:赵凯

Molten salt electrode boiler heat storage and power generation system

InactiveCN111288428AAchieve large-scale storageImplement schedulingHeat storage plantsEnergy storageElectric powerBoiler (power generation)

The invention provides a molten salt electrode boiler heat storage and power generation system, and belongs to the field of energy storage. The system involves a heating part, a high-temperature molten salt storage tank and a heat utilization part; the heating part comprises a boiler body, a high-voltage electrode, a neutral electrode and a low-temperature molten salt supply head, wherein the high-voltage electrode, the neutral electrode and the low-temperature molten salt supply head are arranged in the boiler body, the high-voltage electrode is used for being connected with a power generation system, and the low-temperature molten salt supply head is used for filling the boiler body with low-temperature molten salt; one end of the high-temperature molten salt storage tank is connected with the bottom of the boiler body, and the other end of the high-temperature molten salt storage tank is connected with the heat utilization part; and the heat utilization part is used for carrying outheat exchange on the molten salt sent out by the high-temperature molten salt storage tank and a water working medium for pushing the steam turbine to act, and sending the cooled molten salt back tothe boiler body. Wind power photovoltaic curtailed electricity is used for heating the molten salt and storing heat in the off-peak period of electricity utilization, and high-temperature molten saltis used for heating feed water to generate high-temperature and high-pressure steam in the peak period of electricity utilization, so that the steam turbine is pushed to act, he stored heat is converted into electric energy to be output, and the curtailed wind and light can be effectively consumed to realize large-scale storage and scheduling of non-water renewable energy power.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

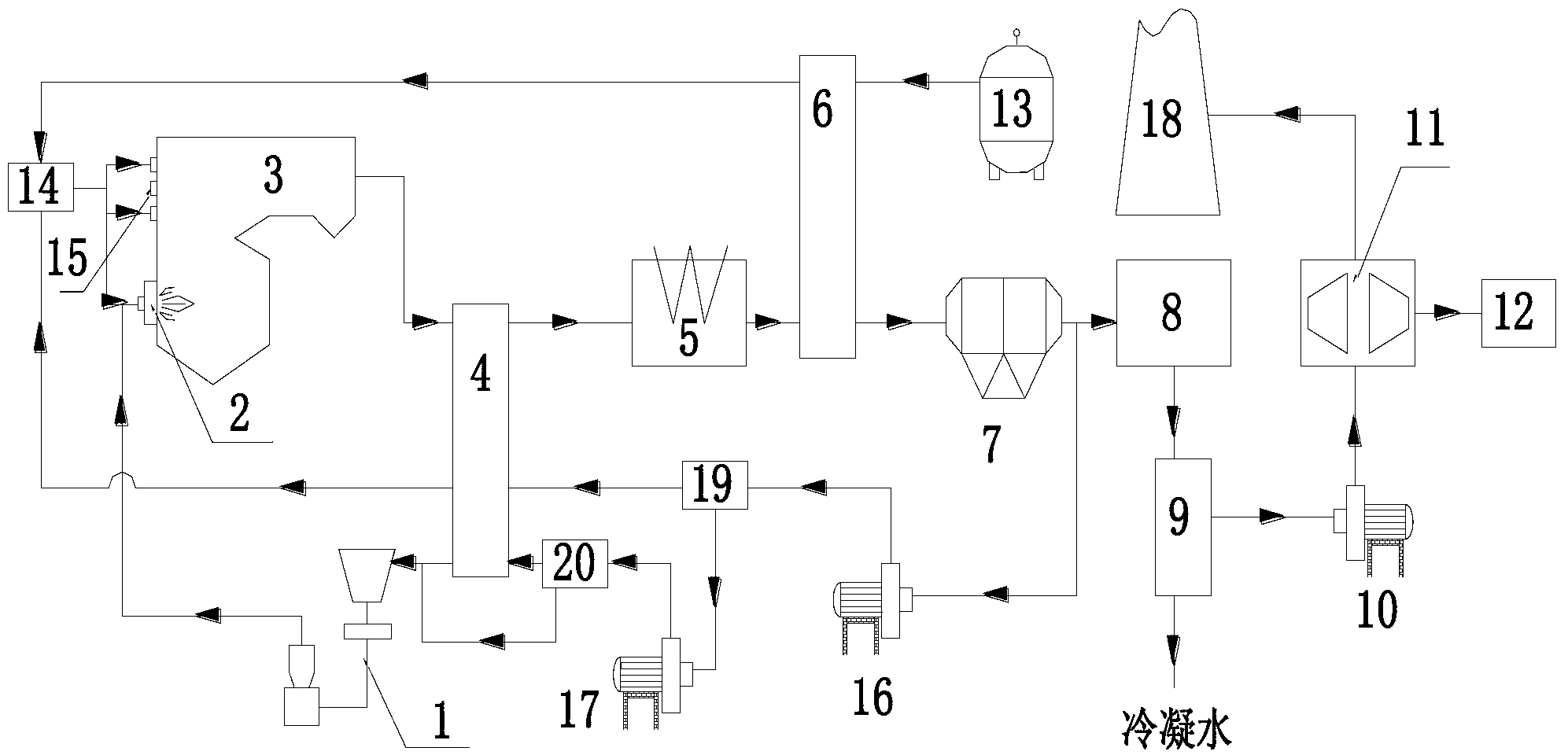

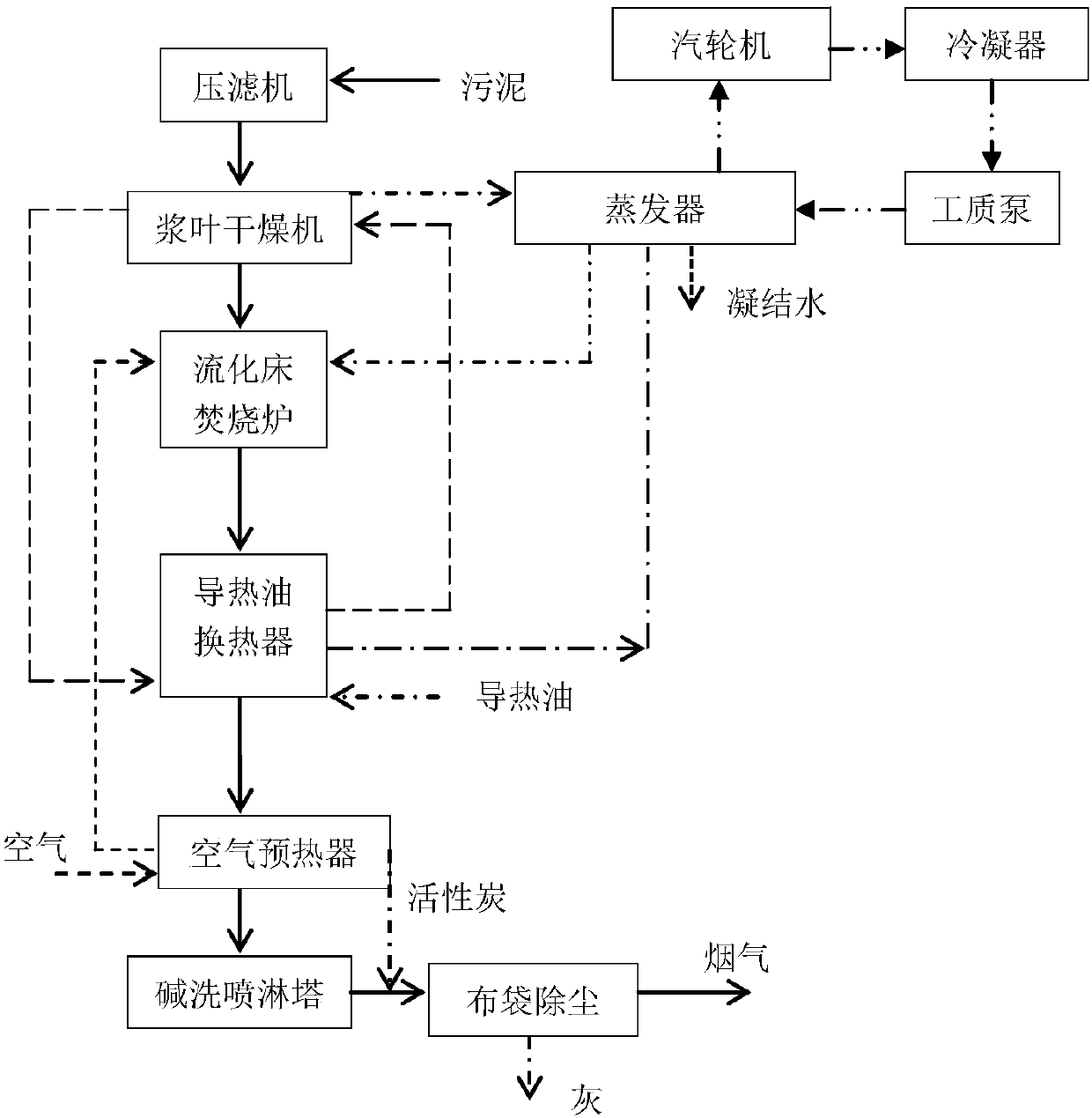

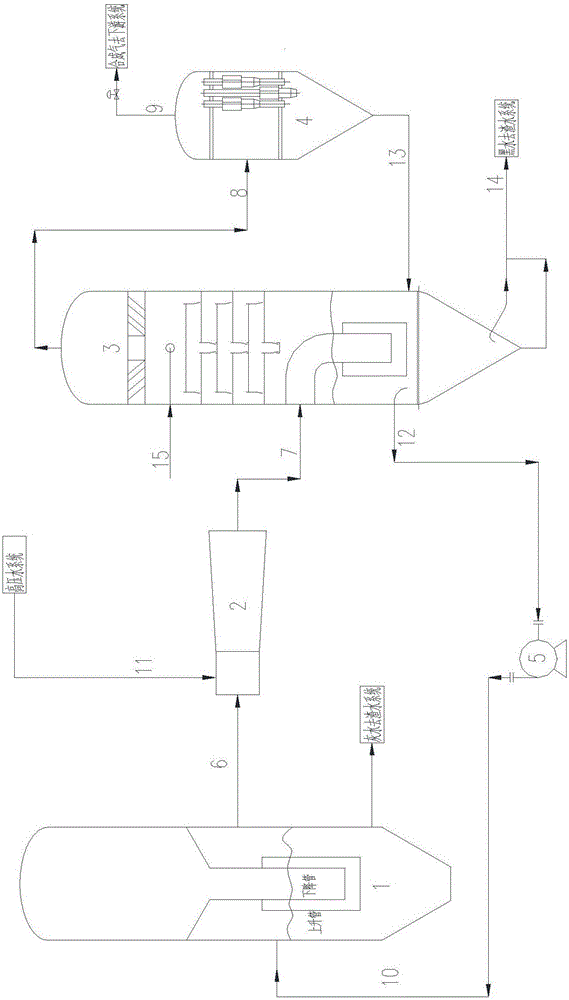

Energy recovery type sludge drying and incineration system

PendingCN107640875AGuaranteed captureLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAir preheaterEnergy recovery

The invention belongs to the technical field of sludge incineration treatment, and particularly relates to an energy recovery type sludge drying and incineration system. A filter press is connected with a paddle drier, the paddle drier is connected with an evaporator, the evaporator is connected with a fluidized bed incinerator, the evaporator is connected with a steam turbine, the steam turbine is connected with a condenser, the condenser is connected with a working medium pump, the working medium pump is connected with the evaporator, the fluidized bed incinerator is connected with a heat-conduction-oil heat exchanger, the heat-conduction-oil heat exchanger is connected with an air preheater, the heat-conduction-oil heat exchanger is connected with the paddle drier, the air preheater isconnected with the fluidized bed incinerator, the air preheater is connected with a spraying tower, the spraying tower is connected with an activated carbon ejector, and the spraying tower is connected with a bag-type dust collector. The system provided by the invention can be used to solve the problems in a current sludge incineration process that the energy consumption is high, the operation cost is high, and the secondary pollution of heavy metals exists, and the like.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

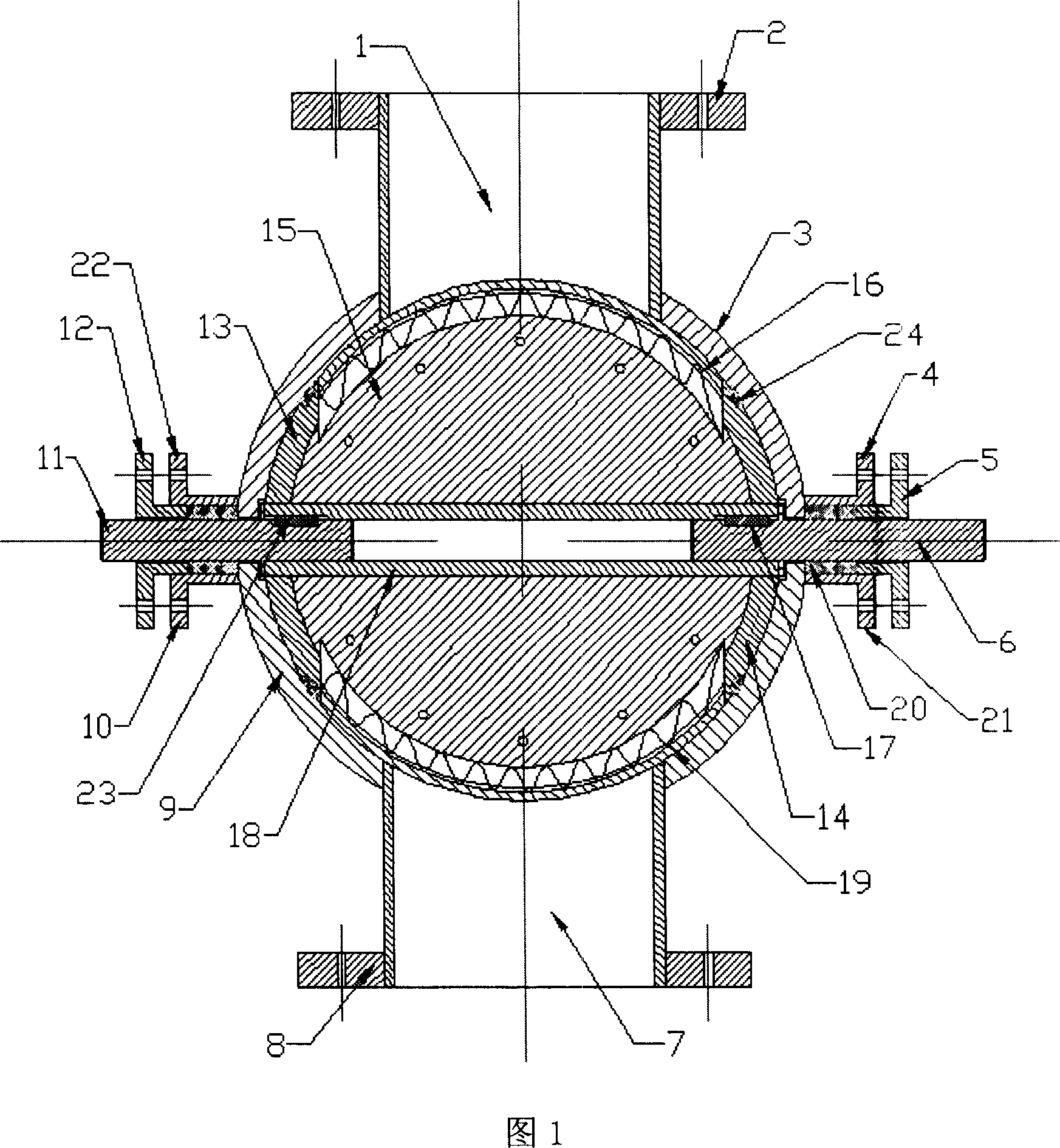

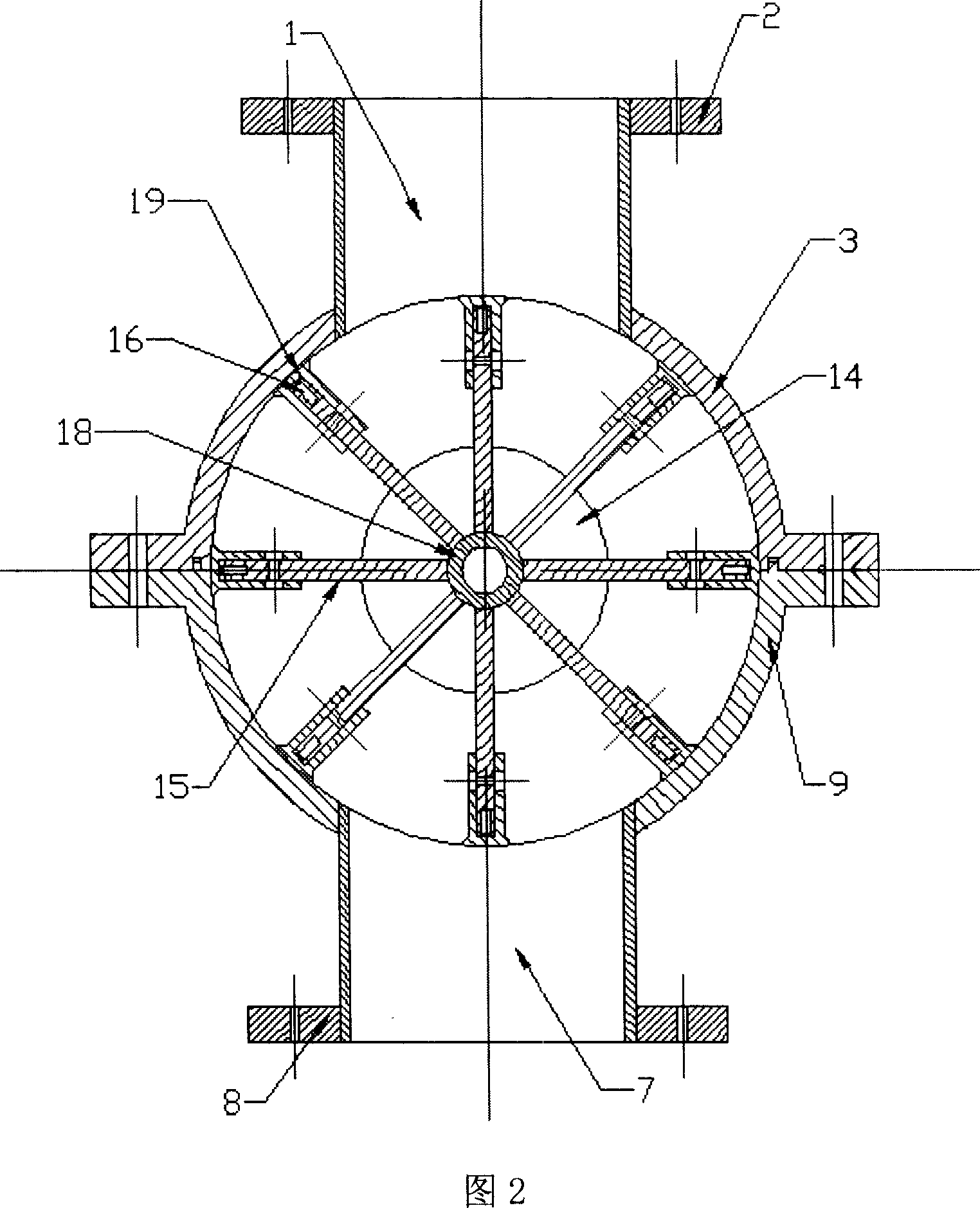

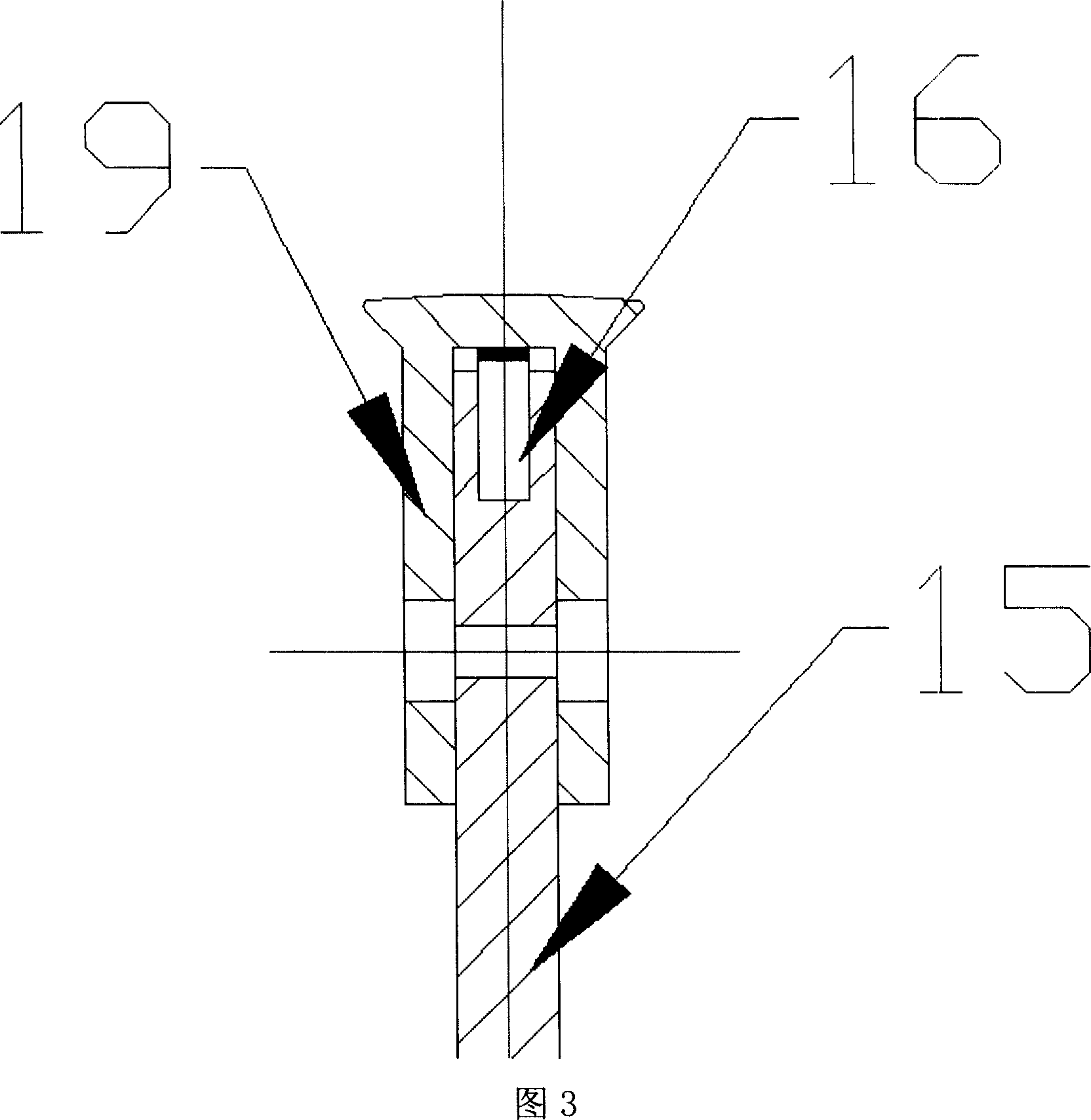

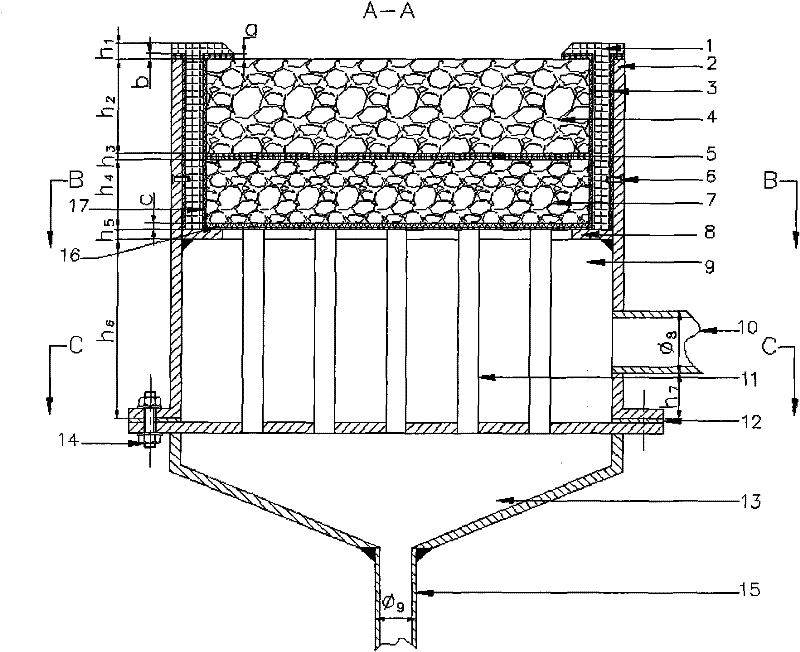

Spherical high temperature and high pressure continuous feeding airlock system

InactiveCN101053805AStop the leakImprove work efficiencyPressurized chemical processEngineeringHigh pressure

The invention discloses a spherical high temperature and high pressure continuous feed gas lock system, comprising a spherical casing, which has two semisphere tunnel body with the concave opposite, and connected by bolt flange, forming form two capping connected by bolt flange. The semisphere tunnel body is mounted with feed port and discharge port, and is welded with feed port flange and discharge port flange. A runner is mounted in the casing, and the runner is composed of uniformly distributed hemicycle runner vanes and ball-jap baffle circle fins at both sides welded on the shaft, which are welded together. The arc wide friction plate is mounted at the top of the runner vane, and the regular thread seal is replaced by face rubbing seal. The system can tolerate high temperature and hundreds of atmospheric pressure, especially for the industry and agriculture use and scientific research, at the condition that the temperature reaches to 600 degree C, continuously conveying solid material from the condition of low temperature and low pressure to that of high temperature and high pressure.

Owner:XI AN JIAOTONG UNIV

Pure pre-mixed gas fuel burner of bi-layer porous foamed ceramic plate

The invention discloses a pure pre-mixed gas fuel burner of a bi-layer porous foamed ceramic plate. The pure pre-mixed gas fuel burner comprises a shell, a macroporous foamed ceramic plate, a microporous foamed ceramic plate, a top air distributor and a bottom air distributor, wherein the shell comprises a cooling cavity in an annular structure and a shell base-plate arranged on the cooling cavity, the cooling cavity is provided with a cooling cavity used for providing cooled air to cool the cooling cavity, and the bottom of the cooling cavity is provided with a cooled air inlet communicated with the cooling cavity; the top of the cooling cavity is provided with a cooled air outlet communicated with the cooling cavity, an annular frame formed by the cooling cavity is sequentially provided with the macroporous foamed ceramic plate, the microporous foamed ceramic plate, the top air distributor, the bottom air distributor and the shell base-plate from top to bottom, and the shell base-plate is provided with a mixed gas inlet for providing mixed gas of fuel and air to enter. According to the burner provided by the invention, the heating efficiency can be improved, and the heating uniformity can be improved.

Owner:WISDRI WUHAN WIS IND FURNACE

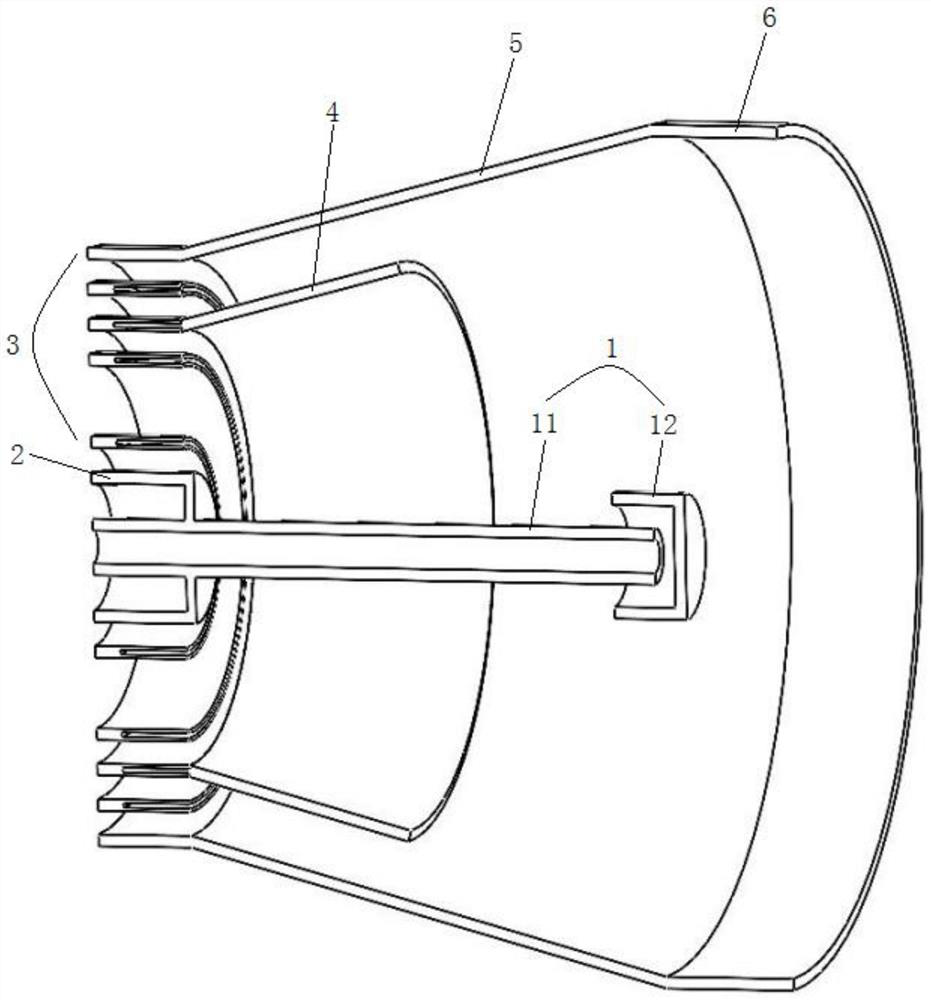

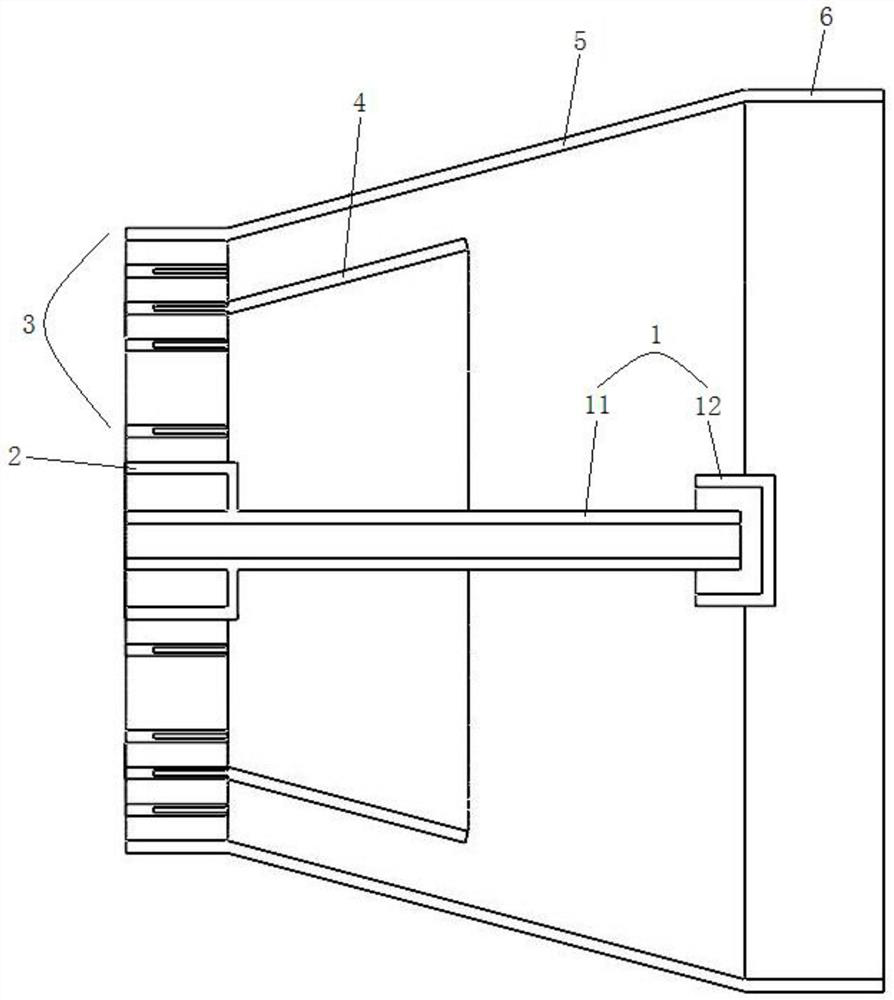

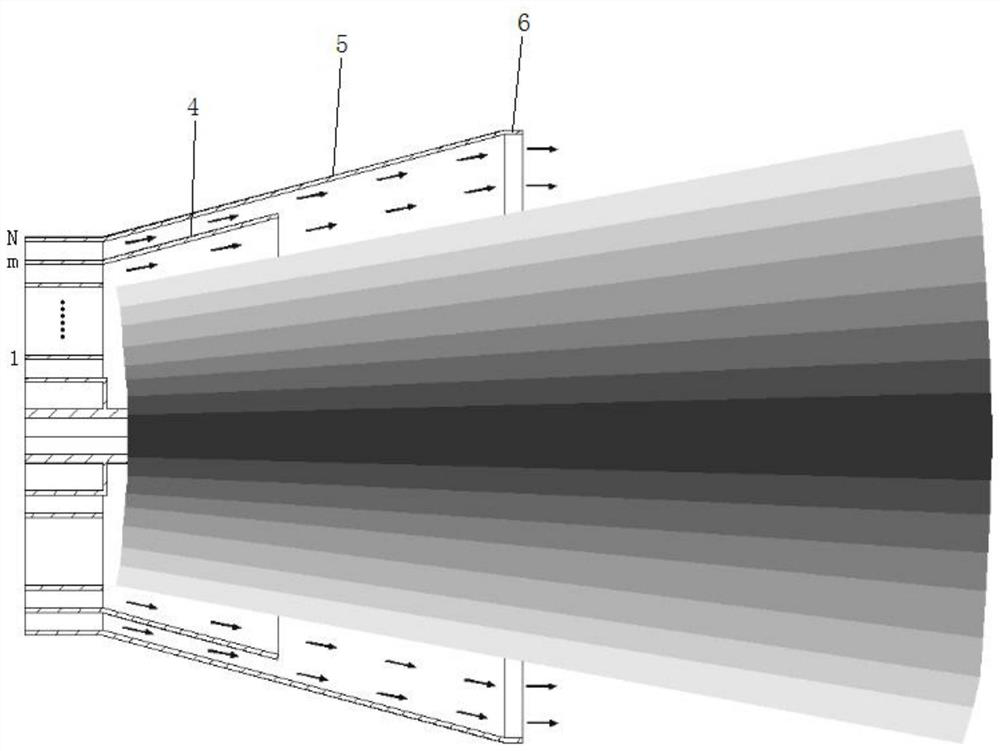

Multi-channel reverse injection type swirl single cone combustor and use method thereof

PendingCN111895400AIncrease mixing rateFire stablePulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to a multi-channel reverse injection type swirl single cone combustor and a use method thereof. The combustor comprises a pulverized coal supply mechanism, a transition channel,a multi-stage air distribution assembly, diversion plates, a stable combustion cavity and a rectifying cavity; the multi-stage air distribution assembly comprises N air ducts, the N air duct is connected with the stable combustion cavity and the rectifying cavity in sequence to form a combustor body, the pulverized coal supply mechanism penetrates through the inner part of the combustor body,and the transition channel sleeves the pulverized coal supply mechanism; except for the N air duct, the other air ducts are of double-layer hollow structures, and one end of at least one diversionplate is inserted into the corresponding air duct; at least one direct current channel is formed between each diversion plate and the stable combustion cavity, flaring is formed in the other end of each diversion plate, and the angle of the flaring is the same as the angle of the stable combustion cavity. The combustor adopts the design of the multi-stage air distribution assembly, air is dividedinto N strands to enter the combustor body, and the turbulence intensity at the airflow boundary is strong, so that the air and powder mixing rate is strengthened, pulverized coal ignites stably, andhigh-efficiency and low-nitrogen combustion of the pulverized coal can also be guaranteed.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

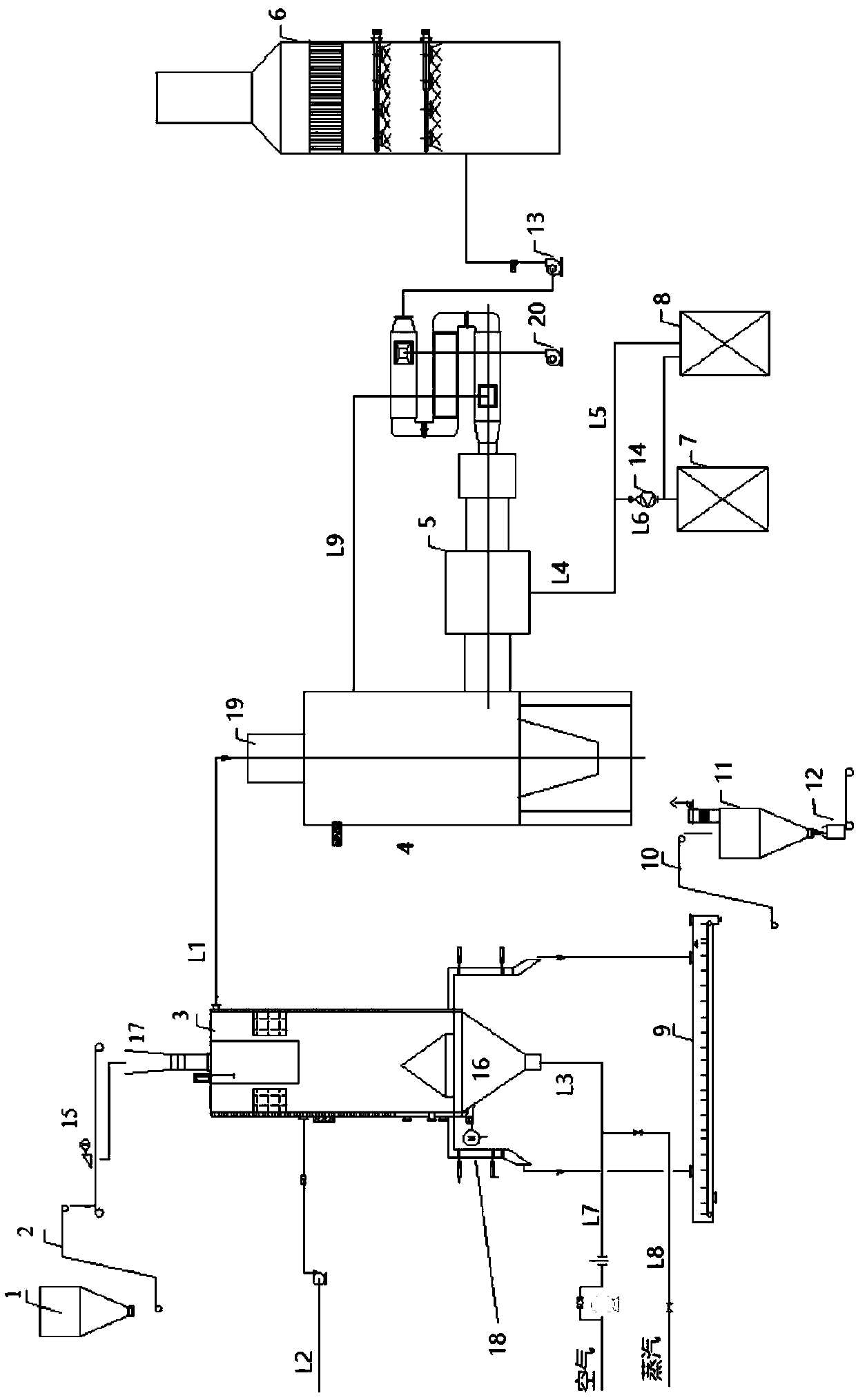

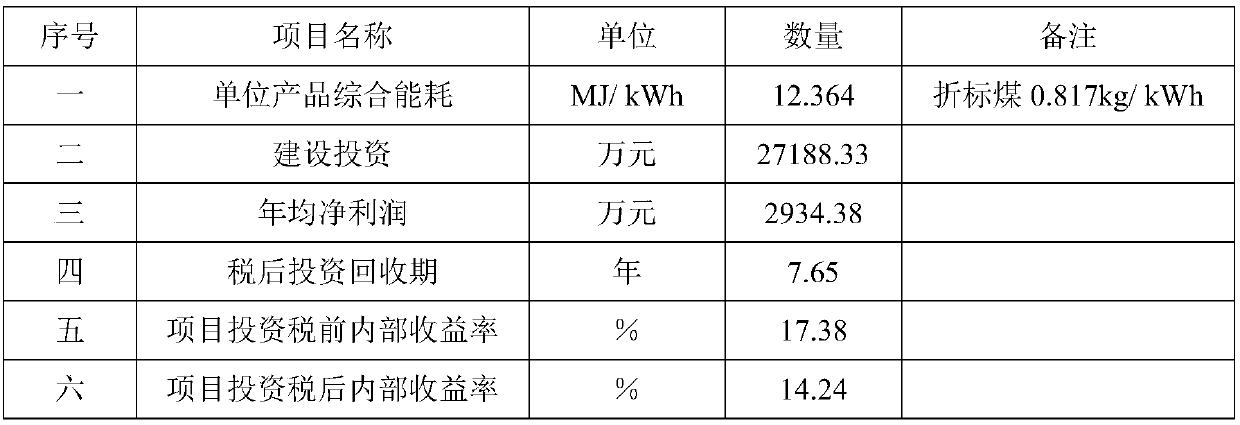

Device and technology for poly-generation of carbon, heat and electricity based on biomass gasification

PendingCN109679695ADevelop circular economyReduce dosageEnergy inputGasification processes detailsElectricityFixed bed

The invention discloses a device and a technology for poly-generation of carbon, heat and electricity based on biomass gasification. The technology comprises steps of biomass transport, biomass gasification, boiler processing, electricity generation, desulphurization and dust removal. A large-dip-angle belt is adopted to perform continuous automatic feeding for biomass transport; a composite gasification fixed bed gasification technology with combination of upper and lower suction is adopted for biomass gasification, and a byproduct is a carbonized material; steam produced by a boiler after burning of gasified gas enters a steam turbine for generating electricity and then passes through a heat exchange station for providing a heat source for heating; a scattering tower based desulphurization and dust removal integration technology is adopted for desulphurization and dust removal. The device and the technology have the advantages of being environmentally friendly and safe and realizingpoly-generation of carbon, heat and electricity.

Owner:XINDI ENERGY ENG TECH

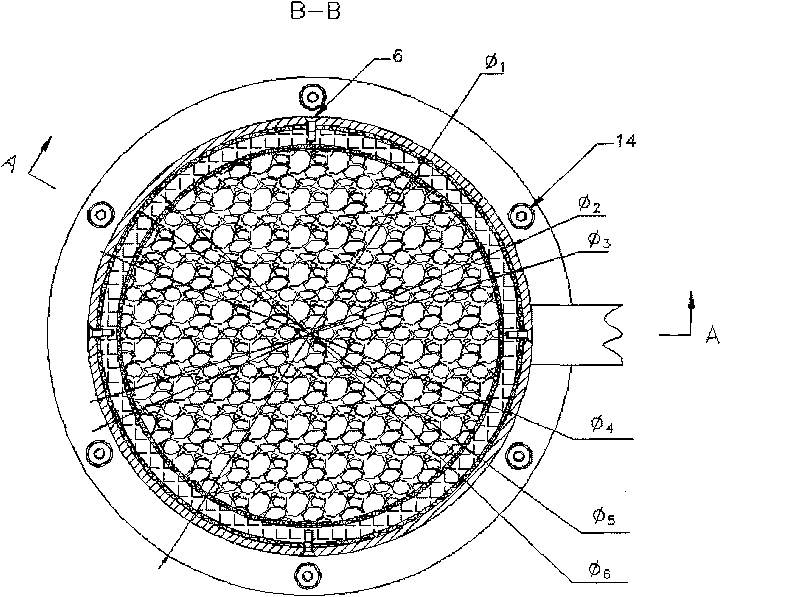

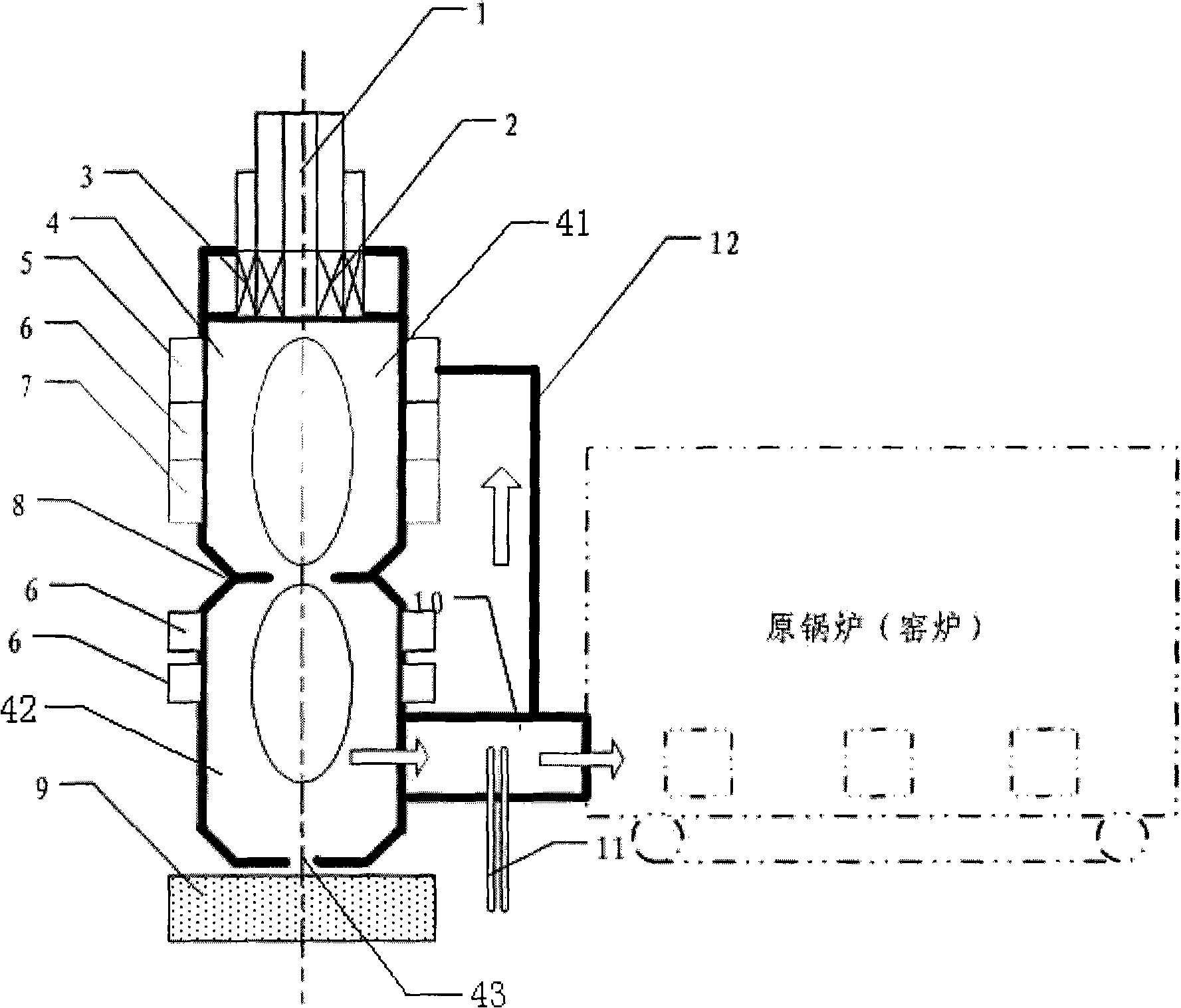

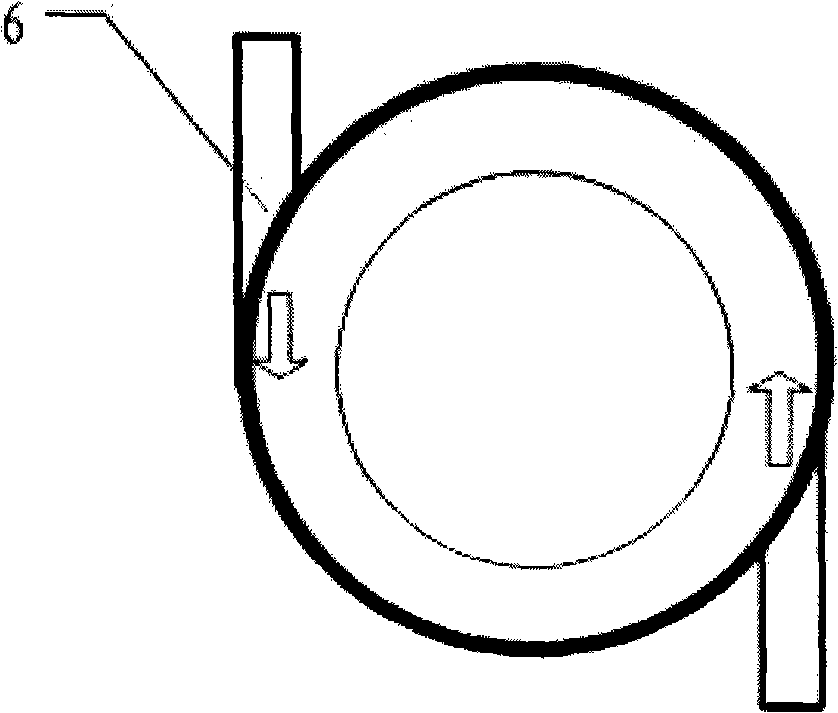

Combustion method of low-concentration combustible gas and fluidized reactor

InactiveCN101713534ASmall temperature fluctuationsIncreased chance of fireFluidized bed combustionApparatus for fluidised bed combustionProcess engineeringProduct gas

The invention discloses a combustion method of low-concentration combustible gas, which comprises the following steps of: firstly, introducing the low-concentration combustible gas and combustion-supporting air respectively into a heat exchanger for heat exchange; then introducing the low-concentration combustible gas and the combustion-supporting air after the heat exchange into a mixing cavity of a fluidized reactor for mixing; then introducing the mixed gas into a combustion cavity of a combustor through an air distributor for combustion; and taking the combusted gas as a heat source of the heat exchanger. The invention also provides the fluidized reactor to realize the method. The invention can not only enable the low-concentration combustible gas to be ignited reliably and combusted stably, but also ensure small temperature fluctuation inside the fluidized reactor; the combustion cavity can be used as both a reactor and a heat accumulator; the fluidized reactor has a wider loading adjusting range when working under ordinary pressure, and the mixed gas can keep combusting when the concentration of combustible components is higher than 2 percent; therefore, the invention is suitable for the combustion of the low-concentration combustible gas.

Owner:CHONGQING UNIV

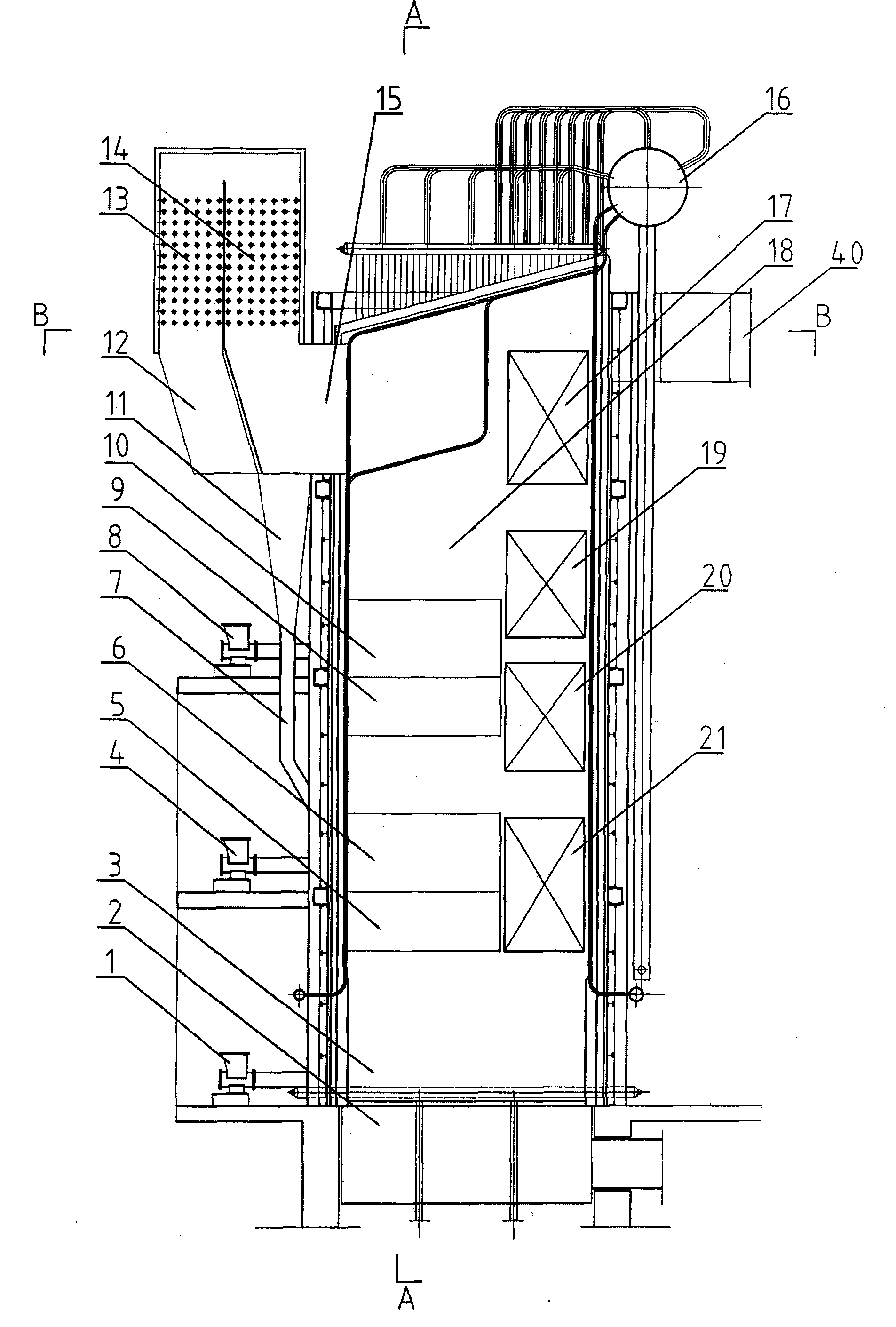

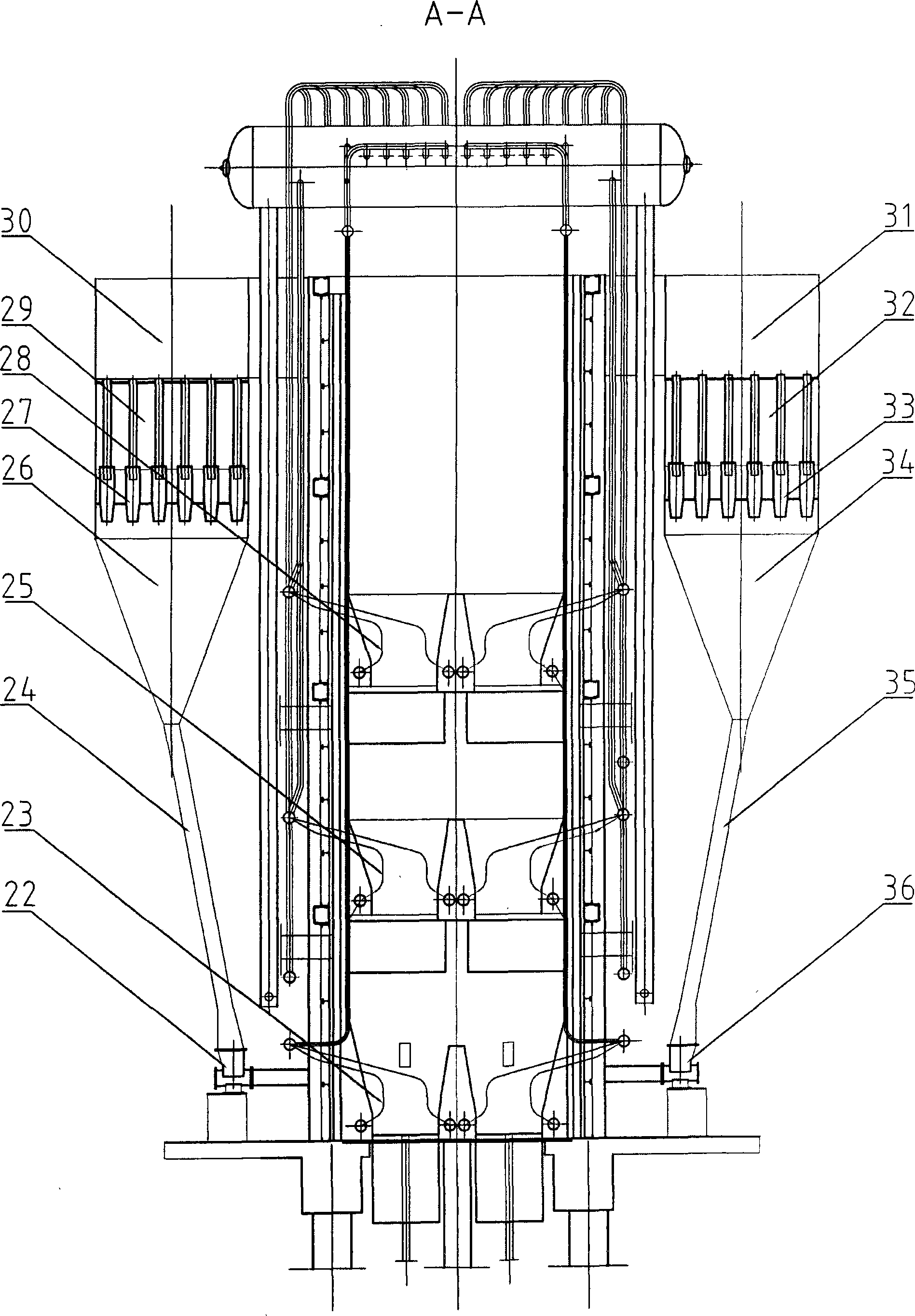

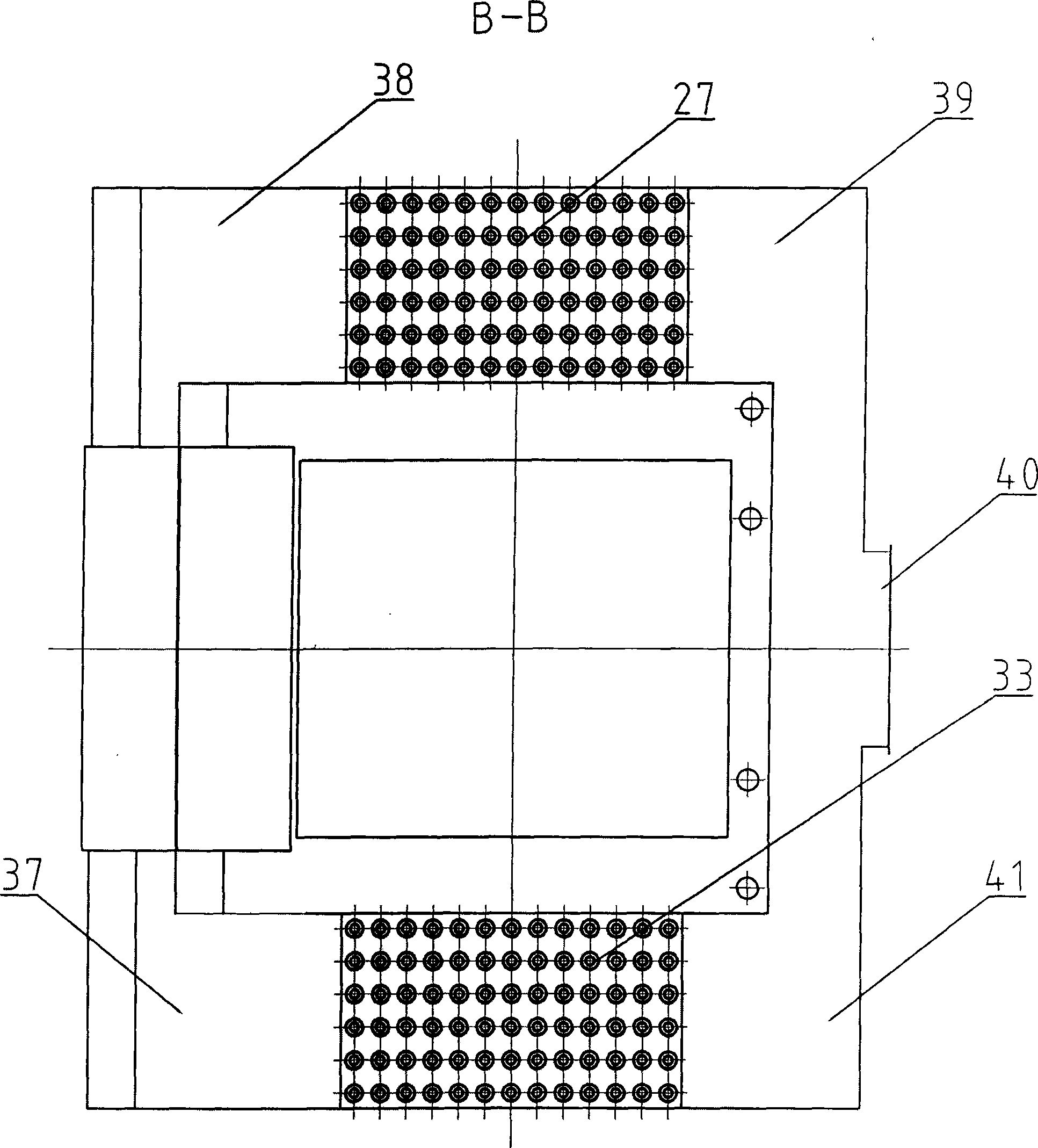

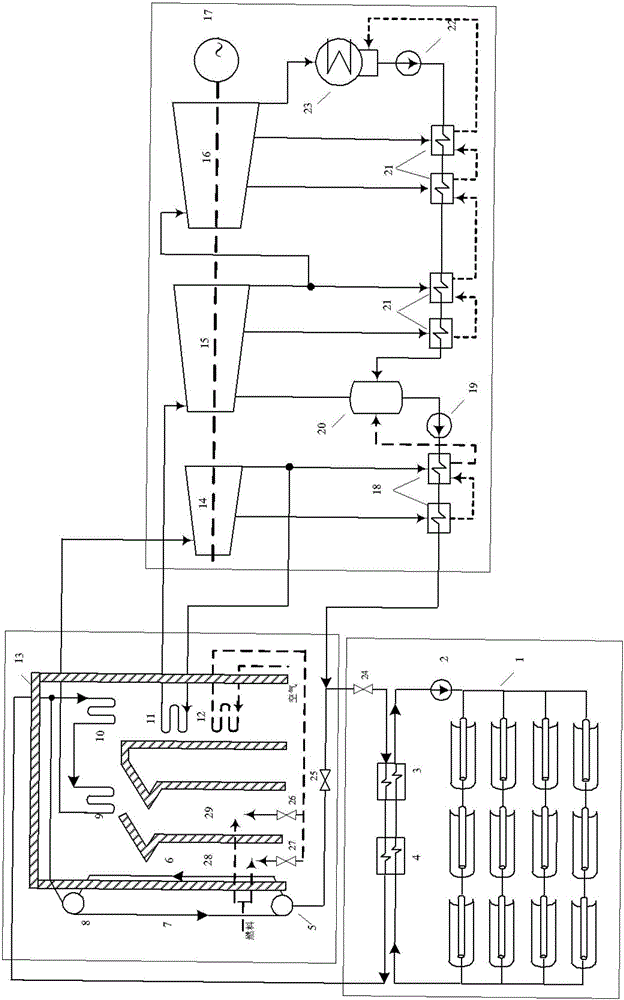

Temperature-adjusting type waste heat boiler

InactiveCN105805715ALarge load adjustment rangeSteam generation using hot heat carriersFlue gasSuperheater

The invention discloses a temperature-adjusting type waste heat boiler. The temperature-adjusting type waste heat boiler comprises a boiler barrel, a superheater, a high-temperature evaporator, a temperature-adjusting water heater, a low-temperature evaporator, a coal economizer, a water heater, an inlet flue, a body flue, an outlet flue, a pollutant assisting-removal device and a tail flue. The temperature-adjusting type waste heat boiler has the beneficial effects that a denitration device in a transition flue and the tail pollutant assisting-removal device are adopted for the temperature-adjusting type waste heat boiler, pollutants in flue gas can be effectively lowered, ultra-low emission is achieved, meanwhile, the temperature-adjusting type waste heat boiler can adapt to a complicated flue gas work condition, and the load adjusting range is wide.

Owner:南通万达能源动力科技有限公司

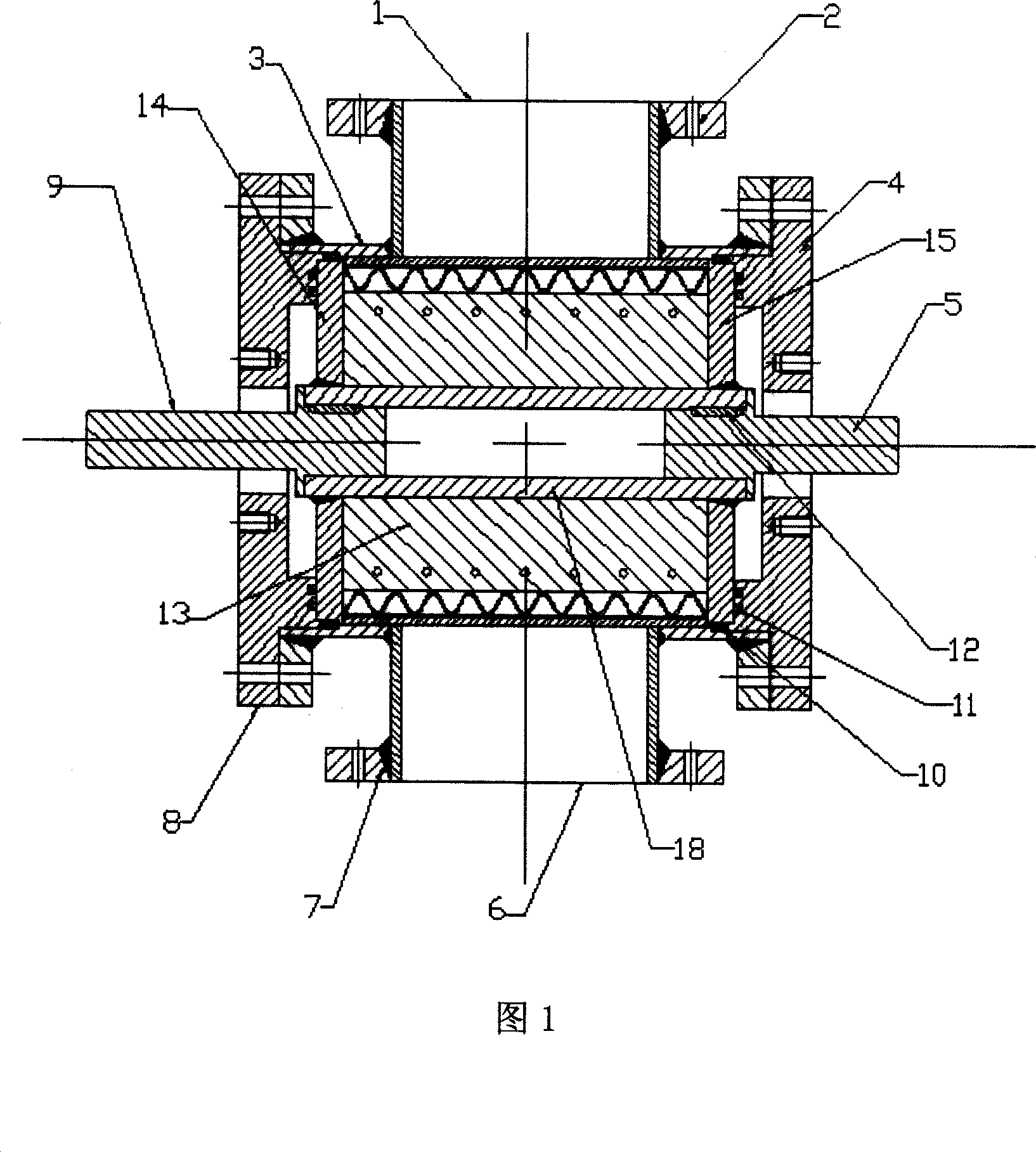

High-temperature and high-pressure wheeled continuous feeding airlock system

InactiveCN101028890AImprove work efficiencyImprove sealingEngine sealsTobacco treatmentHigh pressureHigh heat

A rotor-type air lock system for continuously conveying solid material from low-temp and -pressure environment into high-temp and -pressure one is composed of a casing consisting of a cylindrical body with top feeding inlet and bottom discharging outlet and two end covers, and a rotor in said casing and consisting of a rotary axle, several blades and two baffle rings, which are welded onto said rotary axle, and several wide friction plates installed to the top of said blades for using surface friction sealing to replace line sealing.

Owner:XI AN JIAOTONG UNIV

Plasma non-oil ignition system for low volatile component coal

The invention belongs to the thermal boiler field, and discloses a plasma oil-free ignition system for low volatile coal. The plasma oil-free ignition system comprises a plasma generator and a burner, and is characterized in that the burner comprises a reaction chamber, a water injector, a reaction cylinder, a wind coal chamber, a wind coal cylinder, a wind chamber and a wind cylinder, wherein the water injector is arranged in the reaction chamber, the reaction cylinder is communicated with the outlet of the reaction chamber, the wind coal cylinder is communicated with the outlet of the wind coal chamber, the wind cylinder is communicated with the outlet of the wind chamber, the wind coal chamber and the wind coal cylinder are sleeved on the periphery of the reaction cylinder, the wind coal cylinder extends out of the outer end of the reaction cylinder, the wind chamber and the wind cylinder are sleeved on the periphery of the wind coal cylinder, the wind cylinder extends out of the outer end of the wind coal cylinder, and the outlet of the plasma generator is communicated with the reaction chamber.

Owner:XI AN JIAOTONG UNIV

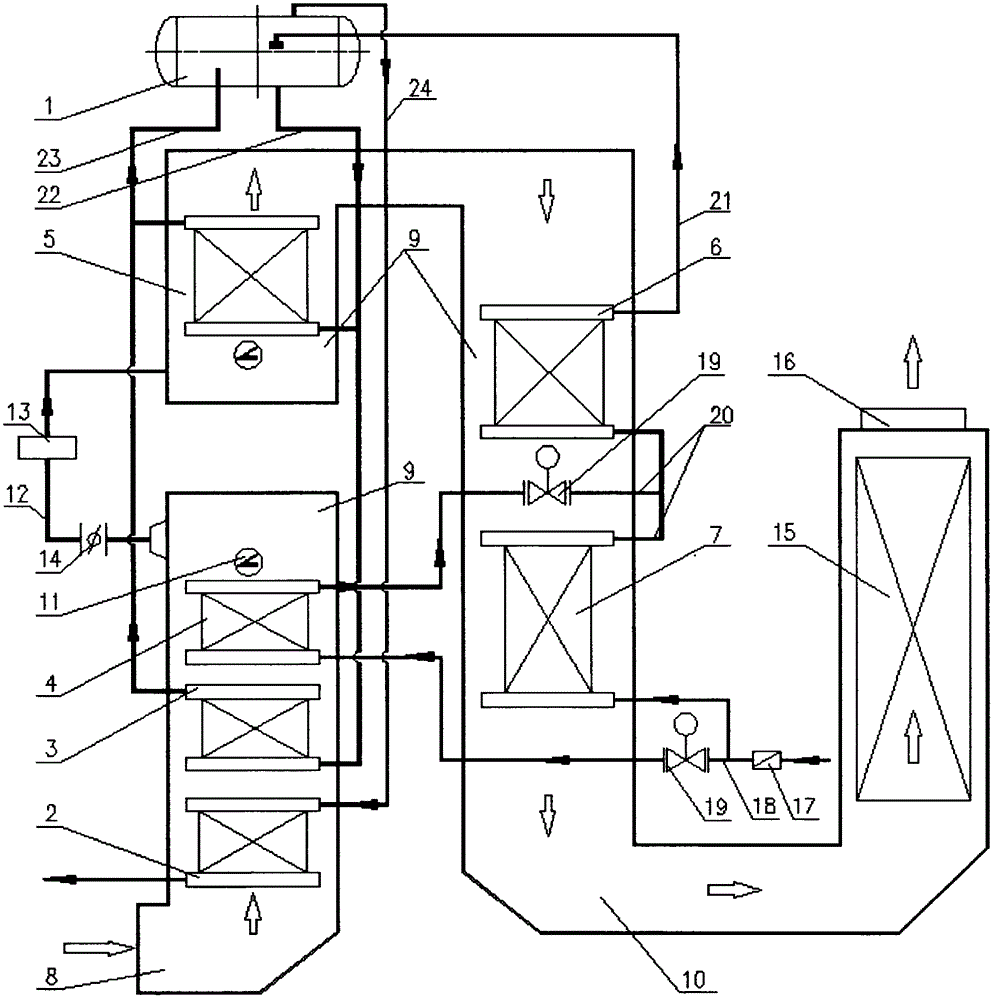

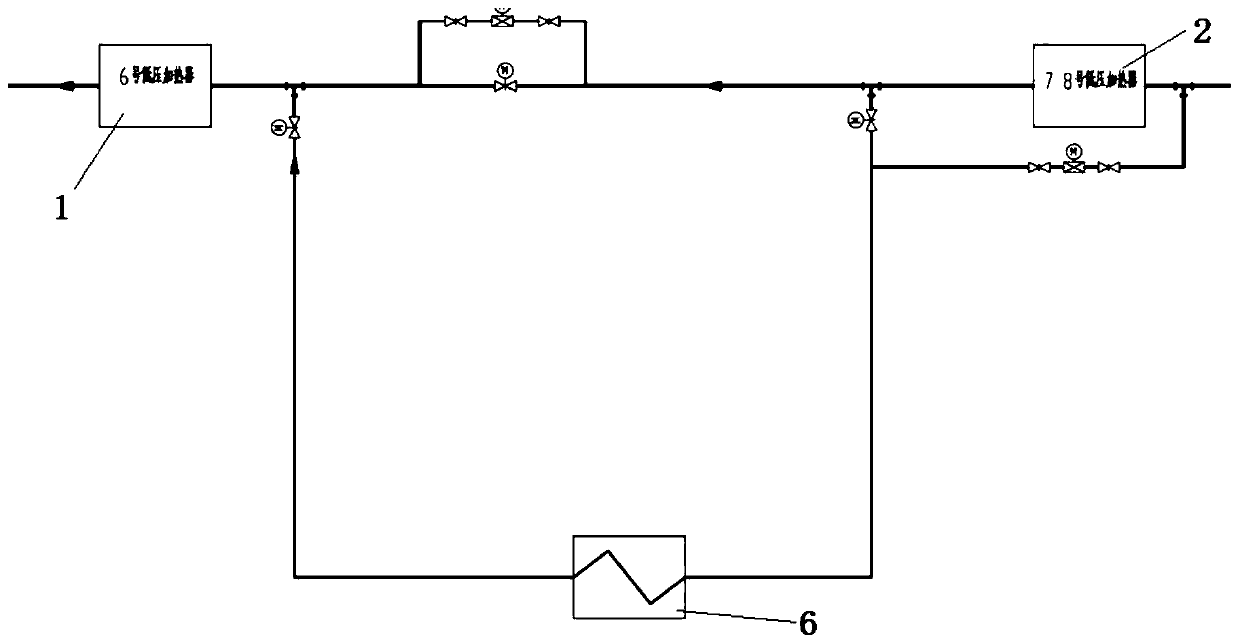

Hot water recirculation system for waste heat recovery of flue gas

PendingCN110864274ACondensate flow is stableReduce power consumptionRecuperative heat exchangersFeed water supplyEnergy conservationAir heater

The invention provides a hot water recirculation system for waste heat recovery of flue gas, and belongs to the technical field of thermal power energy conservation. The hot water recirculation systemis characterized in that heaters and a flue gas waste heat recovery heat exchanger are connected in parallel to access an adjusting valve; a gate valve and a booster water pump are additionally arranged, and the adjusting valve ensures that condensed water flow entering the flue gas waste heat recovery heat exchanger when an extracting and condensing steam turbine is operated under the steam extraction working condition is stable; a bypass valve is arranged at the booster water pump, the booster water pump does not operate when the steam turbine is in a pure condensing condition, the bypass valve is opened, the system relies on the unit condensation water pump margin to form an open cycle, the power consumption of the system can be reduced, and the power supply coal consumption is reduced; and after the flue gas waste heat recovery heat exchanger is added, an air heater is additionally arranged, so that the flue gas waste heat recovery system realizes multiple modes of operation, theload regulation range is large, and the unit adaptability is good. According to the hot water recirculation system, the waste heat recovery rate of the smoke exhaust is improved, the initial investment of the equipment is reduced, the adjustment is flexible, the energy-saving effect is remarkable, and the engineering implementation difficulty is reduced.

Owner:石家庄良村热电有限公司 +1

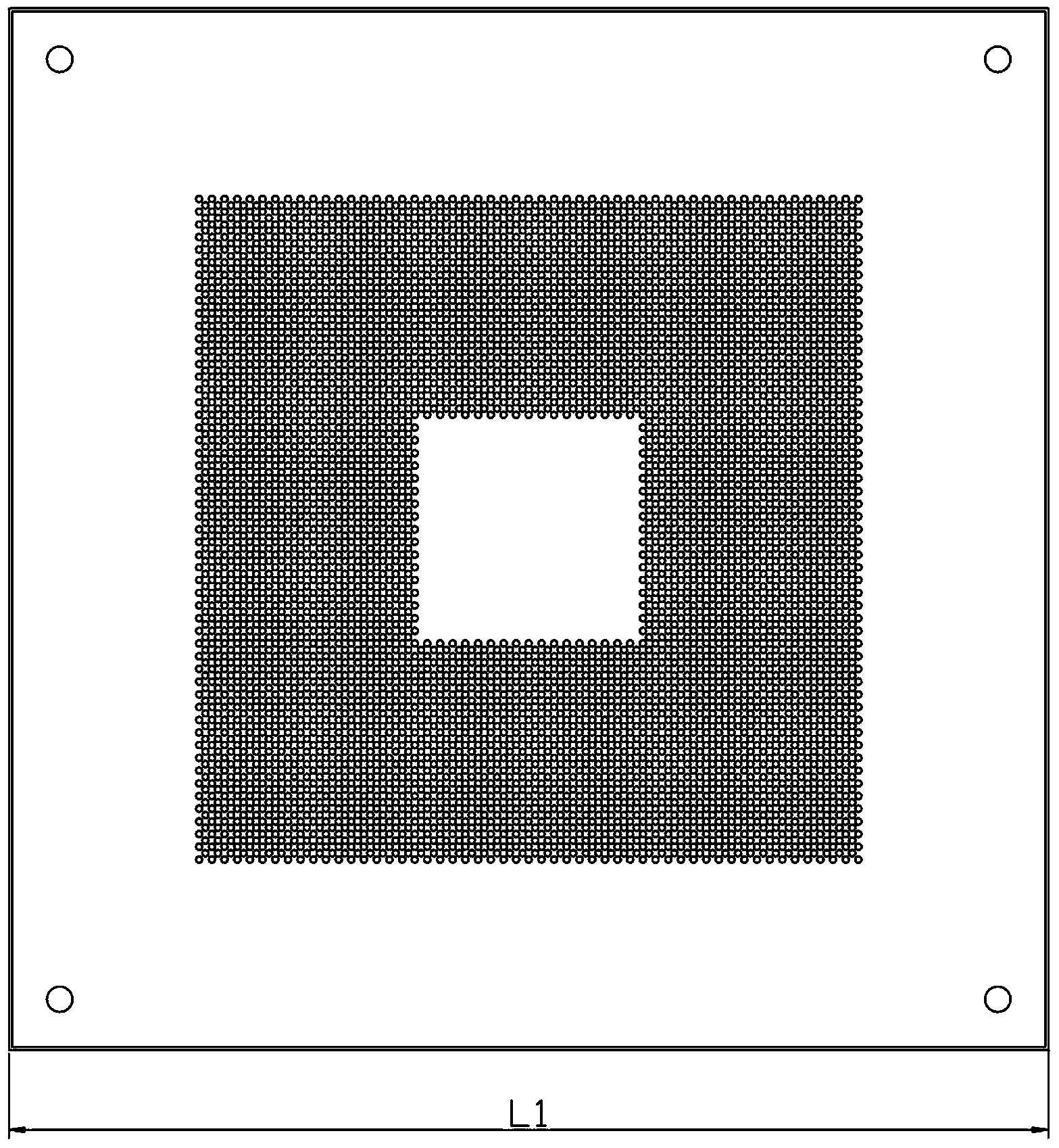

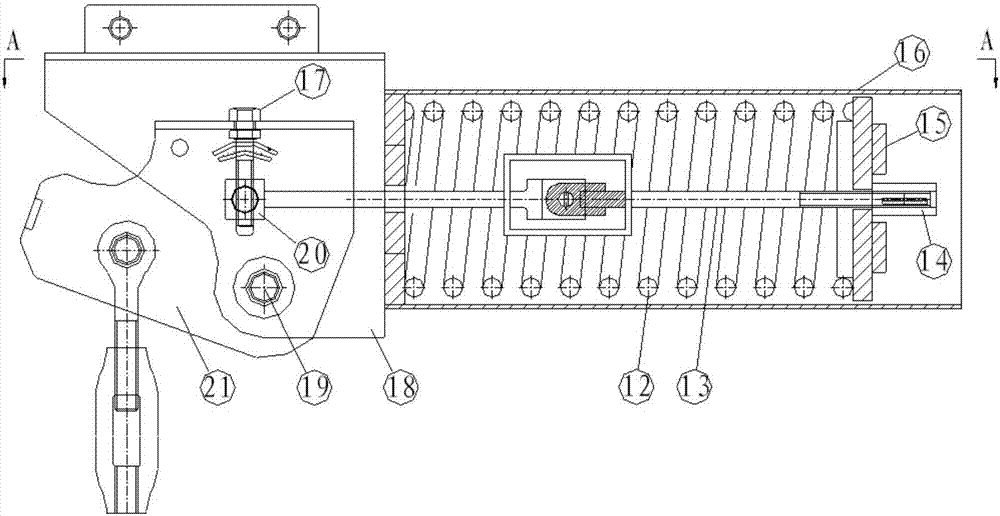

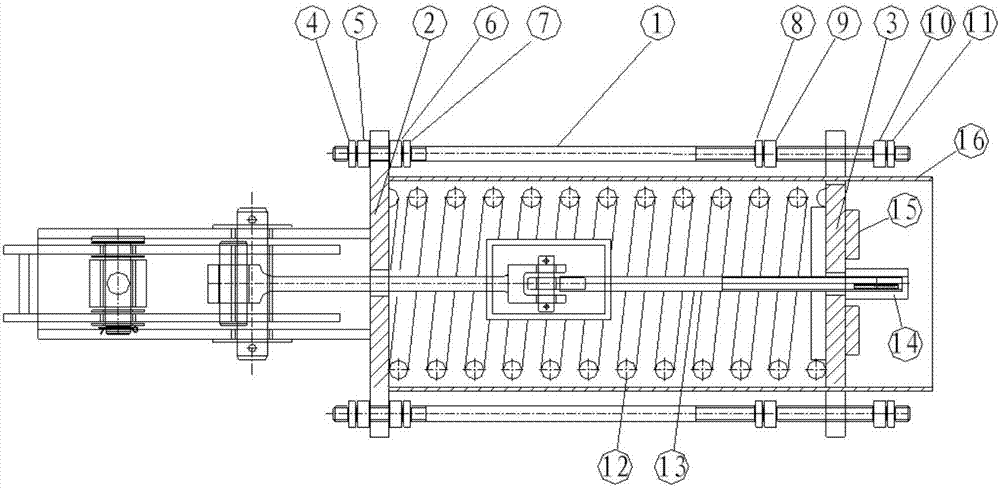

Load locking and adjusting improved constant force spring support hanging bracket

The invention discloses a load locking and adjusting improved constant force spring support hanging bracket. The load locking and adjusting improved constant force spring support hanging bracket comprises a front end plate, a spring cover barrel, an outer frame, a rotation frame, a pull rod, a spindle, a tail end plate, a spring pull rod, a guiding sleeve and a load adjusting nut. One side face of the front end plate is fixed to the end face of one end of the spring cover barrel, and the outer frame is fixed to the other side face of the front end plate. The end portion of the rotation frame is located in the outer frame. The spindle penetrates the outer frame and the rotation frame to connect the outer frame with the rotation frame. The tail end plate is located in the other end of the spring cover barrel. A spring is arranged in the spring cover barrel, one end of the spring pull rod is connected with the guiding sleeve, and the other end of the spring pull rod penetrates the outer frame and then penetrates the front end plate, the spring and the tail end plate to be connected with the load adjusting nut. The guiding sleeve and the rotation frame are connected through a load bolt. The support hanging bracket is convenient to lock, the load adjusting range is wide, and load adjustment is convenient.

Owner:XIAN THERMAL POWER RES INST CO LTD

Flame denitration combustor device and flame denitration system

PendingCN113339793AGuaranteed atomization effectStable combustionDispersed particle separationGaseous fuel burnerCombustorUranyl

The invention discloses a flame denitration combustor device. The device comprises a flame cavity, a combustion head and a material nozzle, wherein the combustion head communicates with the flame cavity and used for introducing mixed gas of fuel gas and air into the flame cavity, the mixed gas is ignited and combusted in the flame cavity and generates high-temperature gas, the flame cavity is provided with a combustion gas outlet, the combustion gas outlet is formed in the end, away from the combustion head, of the flame cavity, a penetrating inner hole is formed in the center of the flame cavity, the material nozzle is arranged in the penetrating inner hole of the flame cavity, penetrates through the flame cavity and is used for circulating uranyl nitrate, and a position of an outlet of the material nozzle and a position of the combustion gas outlet are at the same end of the flame cavity, so that the uranyl nitrate sprayed by the material nozzle can make contact with the high-temperature gas discharged from the combustion gas outlet to perform a denitration reaction. The invention further discloses a flame denitration system comprising the flame denitration combustor device. According to the device, stable operation of the uranyl nitrate denitration reaction can be ensured.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Composite-bed low circulation fluidized bed boiler

ActiveCN101482264AReduce running power consumptionReduce wearFluidized bed combustionSteam superheatersAir preheaterCyclone

The invention is a composite bed type low range circulating fluid bed boiler. A tower structure is used; multiple layers of fluid bed combustion chambers are installed along the height of a furnace chamber; the combustion chambers are internally provided with embedded pipe heating surfaces; each layer of combustion chambers can independently run; and low fluid wind speed is used for reducing abrasion of flame retardant coating and heating surface and reducing the operation power consumption of the boiler. A reheater, a superheater and a coal economizer are respectively installed inside the furnace chamber. The upper part of the outlet of the boiler furnace chamber is provided with a horizontal air preheater, and a low-temperature gas-solid cyclone separator is installed at the rear of the horizontal air preheater; fly ash matters separated are fed in a return conveyor of fly ash matters through a ash bucket and feed legs thereof, and are then fed in the fluid bed combustion chambers so as to form circulating combustion of fly ash. The fly ash matters separated from the low-temperature cyclone separator is very low, and the problems of reburning scorification and blockage of feeding material cannot occur, thereby greatly improving the reliability of fly ash circulating system.

Owner:哈尔滨工大格瑞环保能源科技有限公司

Solar thermal power generation system of integrated double-hearth biomass boiler

ActiveCN106123040AIncrease flexibilityExtended service lifeSolar heating energySteam generation heating methodsGeneration processElectronic systems

The invention provides a solar thermal power generation system of an integrated double-hearth biomass boiler. The solar thermal power generation system comprises a solar heat collection subsystem, a double-hearth biomass combustion subsystem and a power generation subsystem. The double-hearth biomass boiler is adopted, so that the system reliability and safety are improved. Solar energy and biomass energy supplement each other to achieve power generation, the power generation efficiency is improved, zero emission of carbon is achieved in the whole cycle period, and high efficiency and cleanliness are achieved in the power generation process.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Combined fluidized bed biomass boiler

InactiveCN105066119AEasy to separateExtended burn timeFluidized bed combustionApparatus for fluidised bed combustionFluidized bedEmission standard

The invention discloses a combined fluidized bed biomass boiler which comprises a hearth, a secondary air pipe, a water cooling pipe, a fluidized bed and a tempering preventing feeding device. The tempering preventing feeding device comprises a feeding pipe and a jacket, and an air supply interlayer is formed between the jacket and the feeding pipe. The combined fluidized bed biomass boiler is low in tempering accident rate, and multiple kinds of fuel can be combusted at the same time. The load adjusting range is wide, the environmental protection performance is excellent, emissions of NOx and SO2 are effectively controlled, and the national emission standard is met. Heat conduction in the boiler is even, high heat accumulation performance is achieved, the heat recovery efficiency is high, and a recovery heat source is stable. The recyclability of ash residues is high.

Owner:XIANGTAN BOILER

Diffusion type porous medium gas fuel combustor

InactiveCN101737778BUniform density distributionPrevent flashbackGaseous fuel burnerCombustorPorous medium

A diffusion type porous medium gas fuel combustor comprises a shell, an air duct and a fire-resistant casing pipe, the air duct is connected with the shell, the bottom end of the shell is connected with the top plate of a gas flow dividing tank, the shell is internally provided with the fire-resistant casing pipe, a tray and a gas flow dividing tube from top to bottom, the bottom end of the fire-resistant casing pipe is contacted with the tray, the tray is fixed on the shell or the gas flow dividing tube, the bottom end of the gas flow dividing tube is fixed on the top plate of the gas flow dividing tank, and the gas flow dividing tube and the gas flow dividing tank are communicated internally; the fire-resistant casing pipe is provided with macro porous medium, micro porous medium and lower layer metal fiber from top to bottom, and the lower layer metal fiber is connected with the tray and the gas flow dividing tube simultaneously. The inventive diffusion type porous medium gas fuel combustor can be used for efficiently avoiding tempering when combustion intensity is stronger, thus achieving the effects of protecting micro porous medium and saving energy.

Owner:NORTHEASTERN UNIV LIAONING

Coal slime treatment method

InactiveCN109000221AImprove thermal efficiencyStable oxidation temperatureFluidized bed combustionApparatus for fluidised bed combustionResource utilizationFlue gas

The invention discloses a coal slime treatment method. The treatment method comprises the following steps: enabling coal slime to enter a reactor and be in contact with temperature-regulating medium particles in the reactor, carrying out a reaction under the effect of fluidizing air, performing separating treatment on the reacted flue gas, separating the large-size temperature-regulating medium particles taken out by the flue gas, returning to the reactor, and performing subsequent treatment on ground fine powder of small-particle coal slime and temperature-regulating medium particles in a flyash form along with the flue gas. According to the coal slime treatment method disclosed by the invention, due to use of the temperature-regulating medium particles in the reactor, a stable coal slime temperature is provided, coal slime reduction, innocent treatment and high-efficiency resource utilization can be realized, oxidation burning can be performed by taking pure coal slime as the raw material for recovering the heat, and the coal slime oxidation efficiency and thermal efficiency of the device are high.

Owner:DALIAN EAST REFRIGERATION EQUIP +1

Closed type circulation power generation system of integrated absorption heat pump

PendingCN110080842ASimple structureEasy to controlHeat pumpsSteam engine plantsLower gradeLow graded

The invention discloses a closed type circulation power generation system of an integrated absorption heat pump, and relates to the technical field of power circulation, in particular to the closed-type circulation power generation system of the integrated absorption heat pump. The closed-type circulation power generation system comprises a supercritical carbon dioxide circulation and absorption heat pump, the supercritical carbon dioxide circulation comprises a compressor, an outlet of the compressor is connected with a high-pressure side inlet of a low-temperature heat regenerator and a low-temperature side inlet of an absorber of the absorption heat pump, and a low-temperature side outlet of the absorber of the absorption heat pump is connected with a low-temperature side inlet of the condenser of the absorption heat pump. According to the closed type circulation power generation system of the integrated absorption heat pump, waste heat released by supercritical carbon dioxide circulation is converted into high-grade heat through the absorption heat pump, and the high-grade heat is supplied to the supercritical carbon dioxide circulation to be recycled, so that the power generation efficiency of the system is improved; and in addition, a simple heating mode is adopted, the structure of the system is simpler, the control is simpler, and a high-low-grade heat source can be cooperatively used, so that the cost of the heat source can be reduced, and the heat and power supply can be facilitated.

Owner:SHANGHAI POWER EQUIP RES INST

Synthesis gas washing, dedusting and dewatering system

PendingCN106398779AAvoid affecting long-term operationAvoid problems such as affecting long-term operationGas dust removalSyngasProcess engineering

The invention discloses a synthesis gas washing, dedusting and dewatering system. The system comprises a water cooling chamber, a venturi mixer, a washing tower and a pipe bundle centrifugal separator. The synthesis gas washing, dedusting and dewatering system has advantages that solids and liquid in synthesis gas can be efficiently removed, and problems of poor effects in micron dust removal, high quantity of required equipment, large gas pressure drop and high water consumption of an existing washing system, high water content of synthesis gas discharging from the washing tower and the like are solved.

Owner:CHANGZHENG ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com