Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169results about How to "Adjust quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vaccine stabilizer method

InactiveUS20050186221A1Adjust qualityBacterial antigen ingredientsViral antigen ingredientsSodium thiosulfateDomestic animal

A method of treating livestock with a vaccine includes mixing a reducing agent, such as sodium thiosulfate, with water, which may include oxidizing water sanitizers, mixing the vaccine with the water after the reducing agent has neutralized the water sanitizers, and treating the livestock with the vaccine and water mixture. The method may include adding a buffer to the water along with the reducing agent to adjust the pH, and adding a coloring agent to the water to aid in identifying livestock that has been treated with the vaccine. The vaccine may be administered to the livestock in different ways, such as by including it in drinking water or by spraying the livestock with the vaccine and water mixture.

Owner:REYNOLDS BAILEY +1

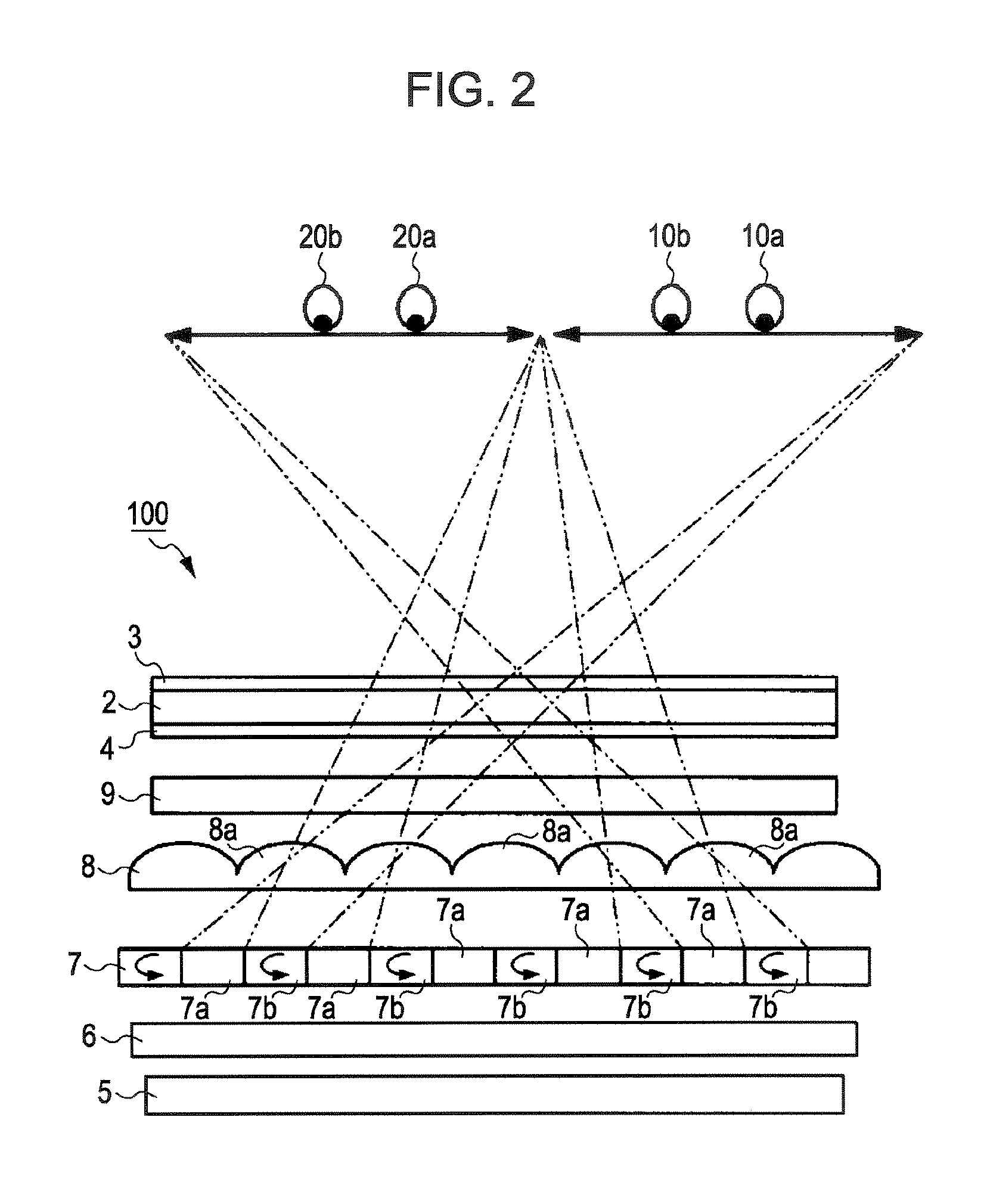

Electro-optical apparatus and electronic equipment

ActiveUS20070165145A1Improve display qualityAdjust qualitySteroscopic systemsNon-linear opticsElectronLiquid crystal

An electro-optical apparatus includes a display panel that displays an image, an illuminating device that allows light rays to pass through the display panel, a polarization axis controlling unit arranged between the illuminating device and the display panel for allowing light rays having first polarization axis out of light rays outputted from the illuminating device to pass and changing the polarization axes of part of the light rays emitted from the illuminating device to convert the light rays to light rays having second polarization axis different from the first polarization axis, and a lens having a plurality of linear lens patterns for causing the light rays having the first polarization axis and the light rays having the second polarization axis separated by the polarization axis controlling unit respectively to proceed in predetermined directions. The polarization axis controlling unit includes a liquid crystal layer and a plurality of electrodes arranged in a stripe pattern so as to oppose the liquid crystal layer. The width of the electrodes to which a voltage is applied when changing the polarization axes of the part of the light rays emitted from the illuminating device is larger than the width of the electrode to which no voltage is applied.

Owner:EPSON IMAGING DEVICES CORP +1

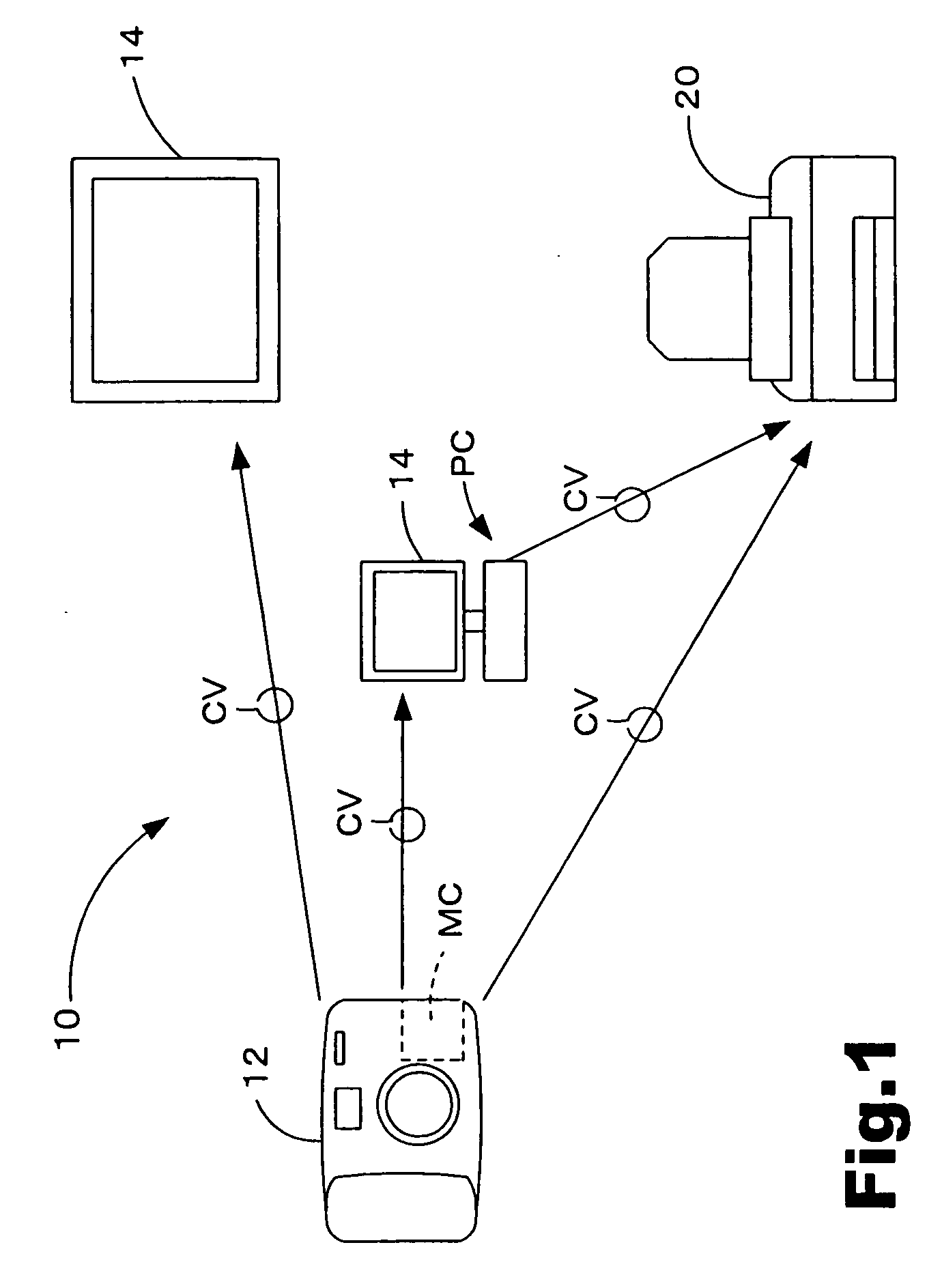

Output image adjustment method, apparatus and computer program product for graphics files

ActiveUS7375848B2Appropriate image qualityAdjust qualityImage enhancementTelevision system detailsGraphicsImaging quality

When a memory card MC is inserted into slot, a control circuit of a color printer acquires and analyzes graphics processing control information GC from the memory card MC. A CPU corrects standard values for image quality parameters indicating graphics data qualities, to reflect the graphics processing control information GC. The CPU corrects image quality parameters to bring them into approximation with the corrected standard values, and adjusts image quality of the graphics data to reflect the corrected image quality parameters.

Owner:138 EAST LCD ADVANCEMENTS LTD

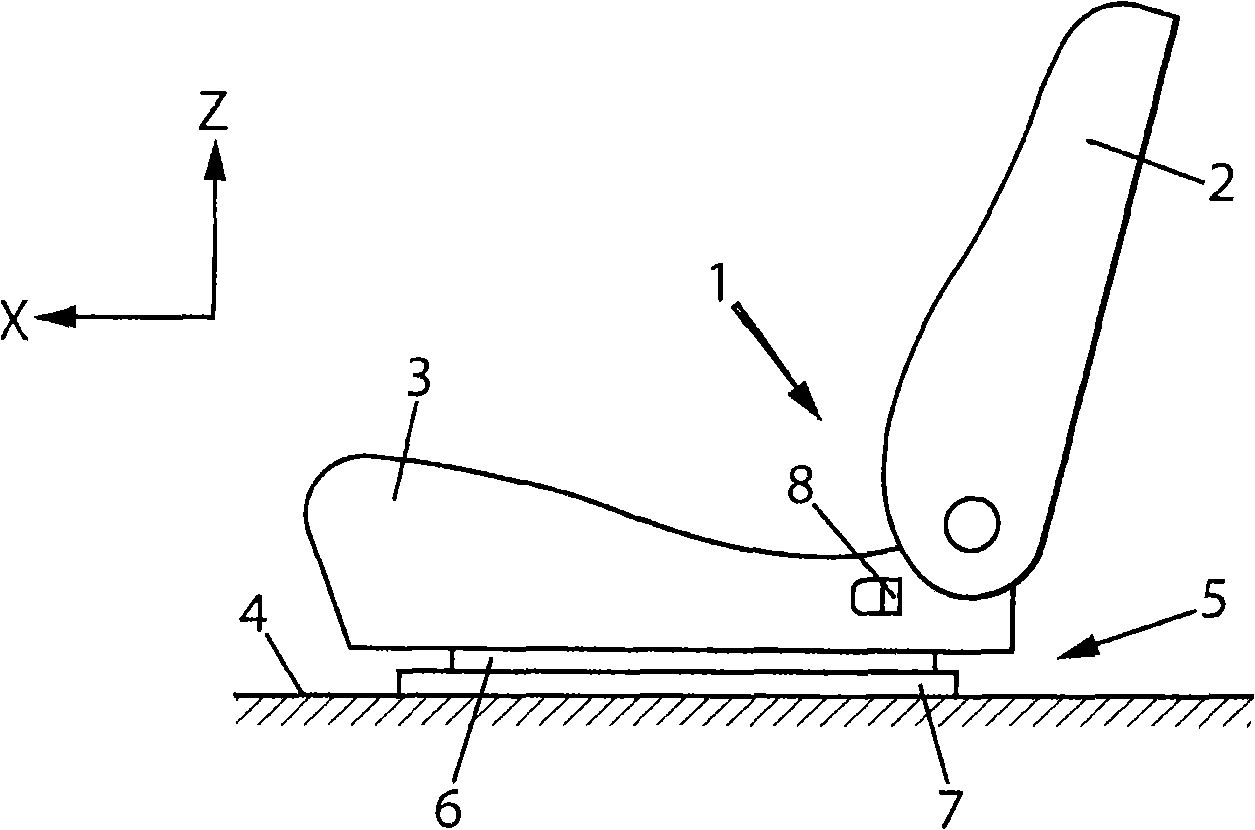

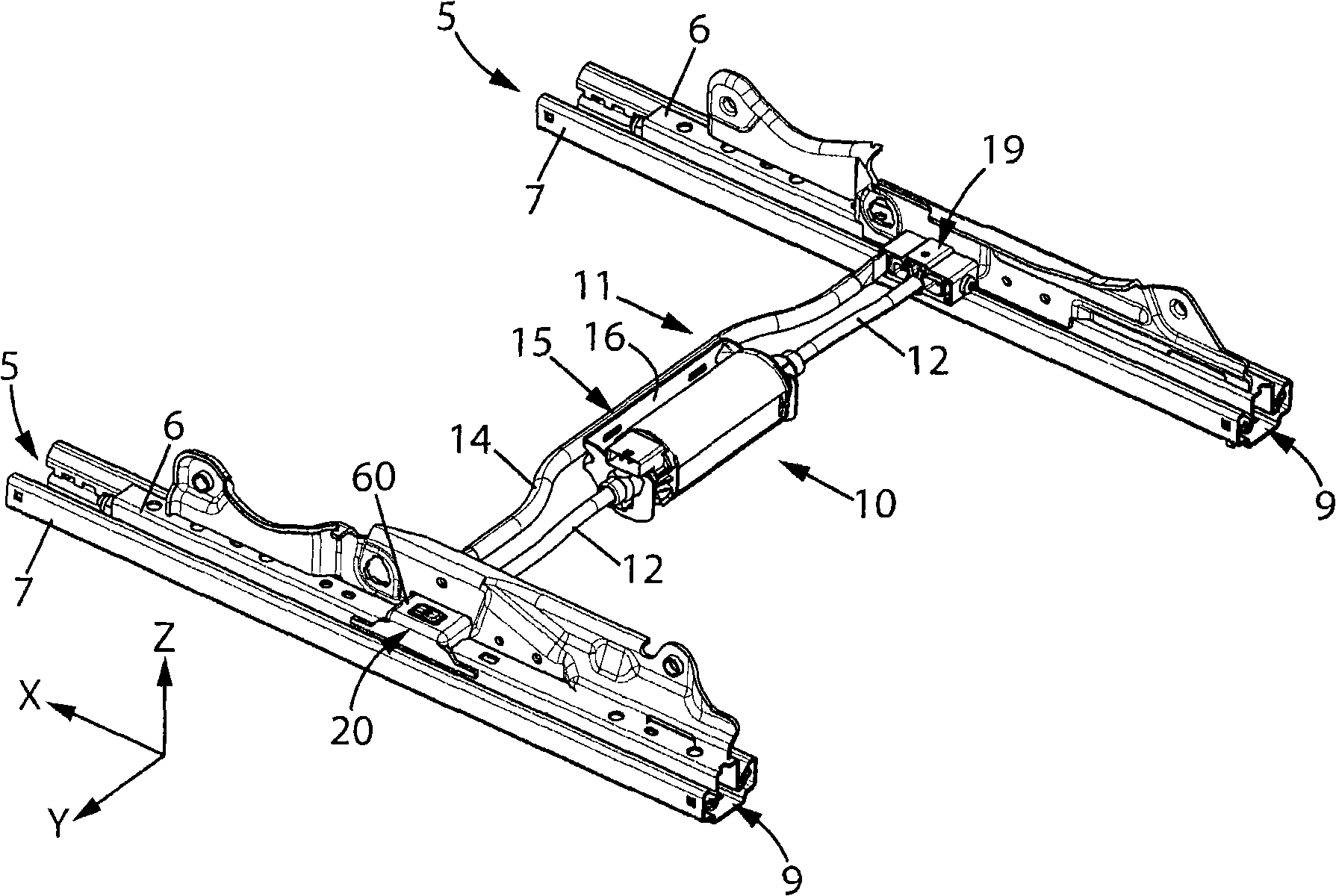

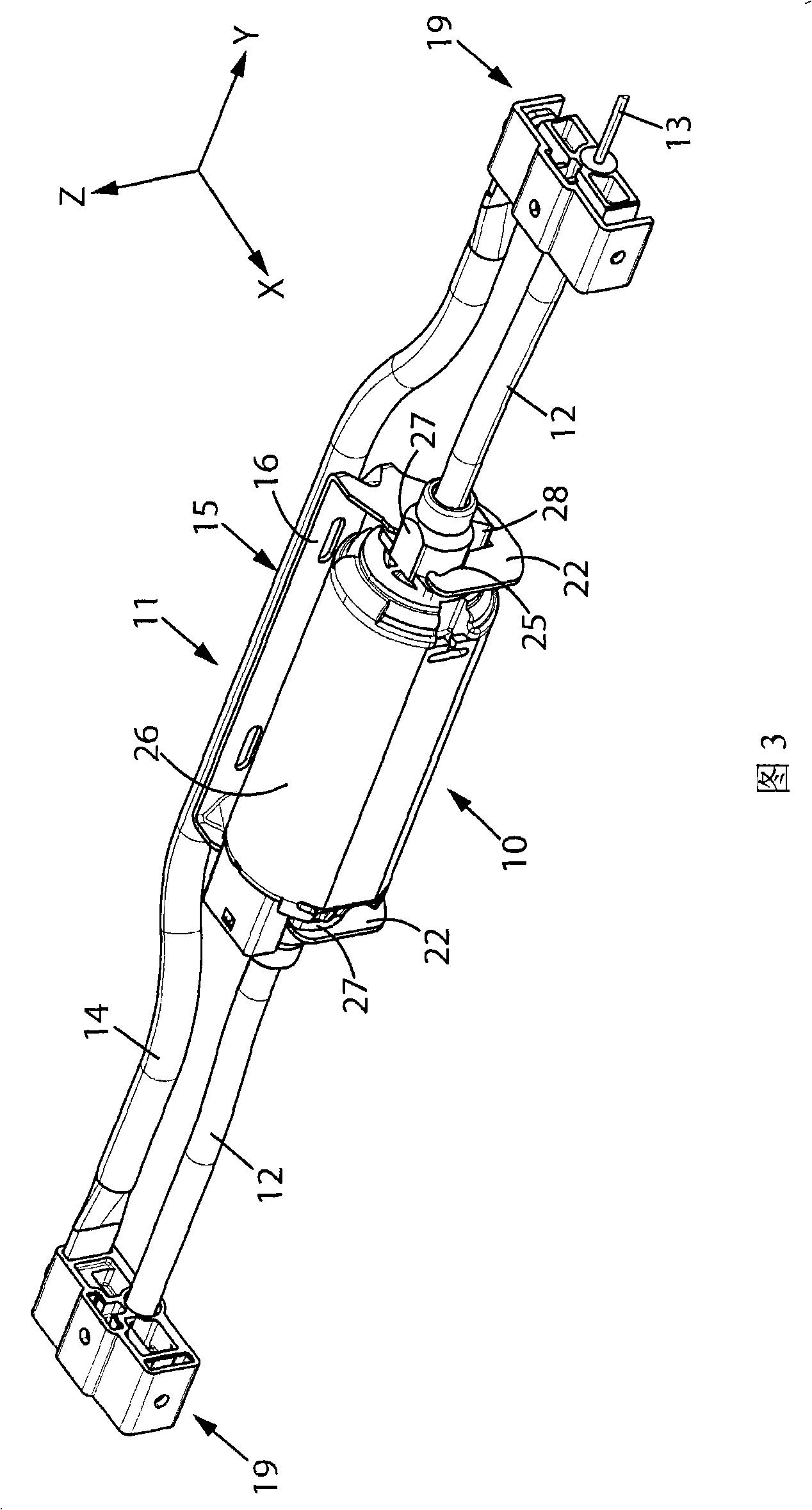

Slider for seat, motor vehicle seat comprising the seat slider or apparatus thereof

ActiveCN101244701AEasy to modularizeImprove adaptabilityMovable seatsInterior spaceMotor vehicle part

The slider (5) has an adjusting device (20) adjusting a sliding element (6) with respect to another sliding element. The device has a screw extending along a longitudinal direction (X) in an internal space (9) formed between the elements, and is mounted on the latter sliding element. The device has a rigid retaining device (60) provided with an upper part (60b) that is projected with respect to a side opening (70) and a base part (60a) that is inserted in the internal space through the side opening. A nut (32) is engaged on the screw. An independent claim is also included for a sliding system for a motor vehicle seat.

Owner:FAURECIA SIEGES DAUTOMOBILE (FR)

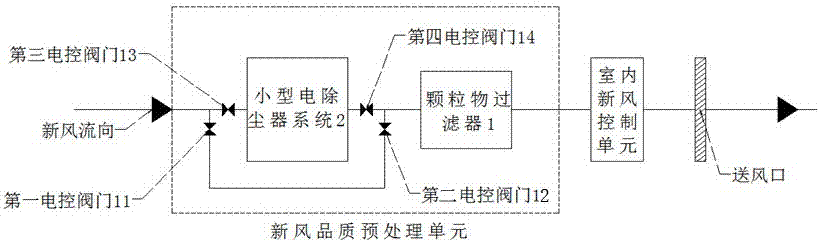

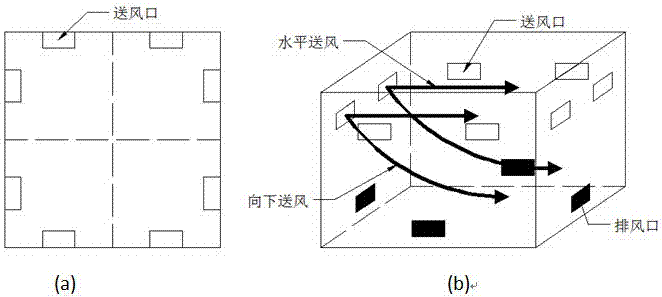

Intelligent regulating system for air quality and temperature in closed room and use method of intelligent regulating system

InactiveCN106895551AGuaranteed qualityGuaranteed temperatureMechanical apparatusSpace heating and ventilation safety systemsParticulatesIndoor air quality

The invention relates to an intelligent regulating system for the air quality and temperature in a closed room and a use method of the intelligent regulating system. The system comprises a fresh air quality pretreatment unit, an indoor detection unit, an indoor fresh air control unit and an intelligent control unit. The fresh air quality pretreatment unit comprises a particulate filter and a small electric dust removal system. The indoor detection unit comprises a CO2, formaldehyde, temperature and infrared intensity detector. The indoor fresh air control unit comprises a fresh air flow and temperature controller. The intelligent control unit comprises a data processor and an intelligent control terminal. Indoor personnel inputs various parameters of the room into the intelligent control terminal, the data processor works out the required fresh air flow and temperature meeting the requirements of the indoor air quality and temperature through a preset model algorithm according to the input parameters and the detection result of the detector, and the fresh air flow and the temperature are fed back to the control unit for execution. The system has three working states and can be switched among the three working states according to different operating time lengths so as to achieve the purposes of adjusting and keeping the indoor air quality and temperature.

Owner:TONGJI UNIV

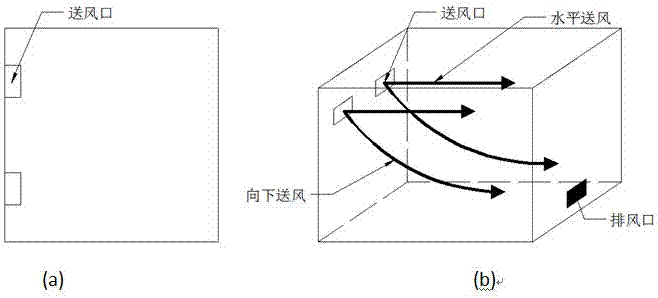

Printing machines having at least one machine element that can be adjusted by a setting element

InactiveUS7464645B2Minimize the differenceAdjust qualityAddressographsPlaten pressesPrinting pressIndustrial engineering

Owner:KOENIG & BAUER AG

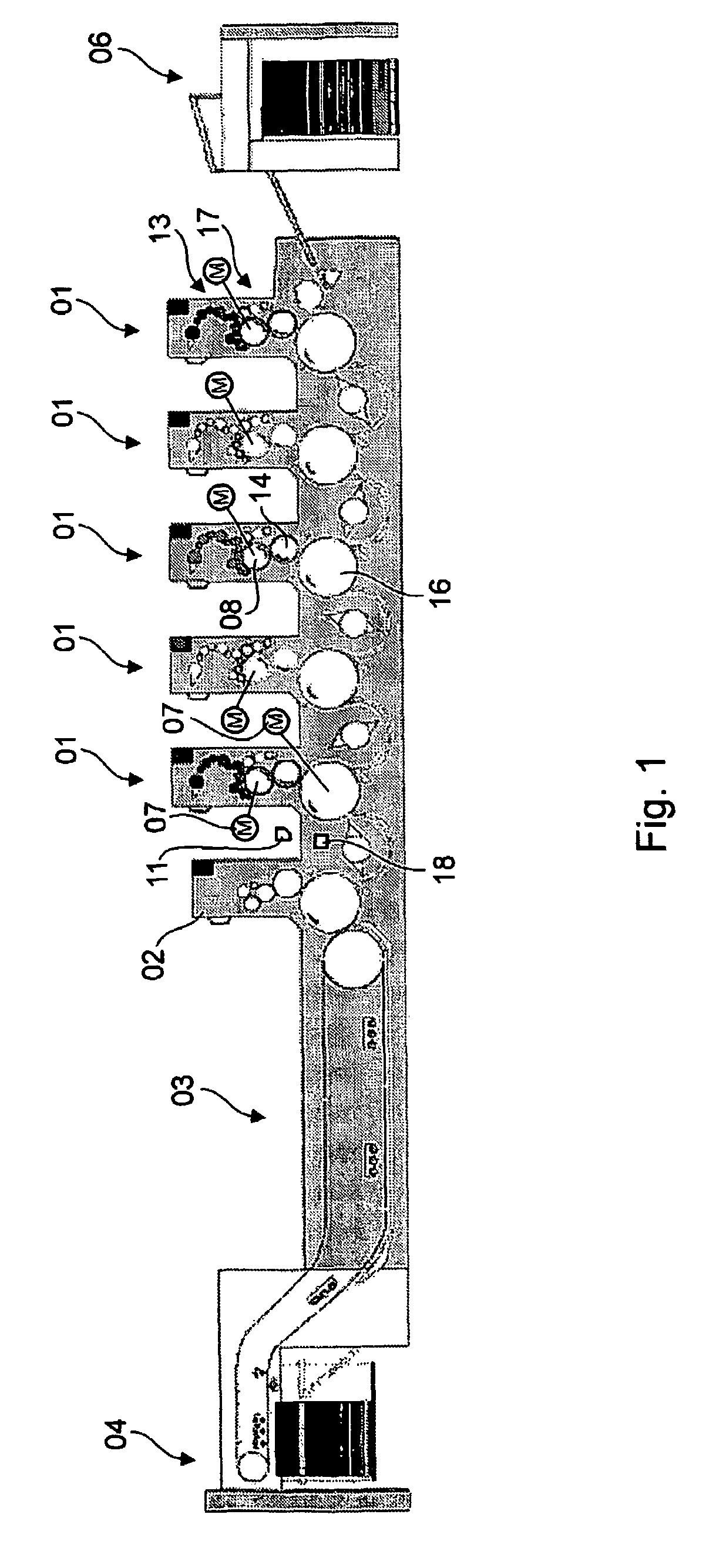

Apparatus and method for adjusting image

InactiveUS20070206121A1Adjust image qualityEasy to adjustTelevision system detailsCathode-ray tube indicatorsComputer graphics (images)Imaging quality

An apparatus and method for adjusting an image are provided, which enable to adjust an image quality easily so as to attain a desired image for a user when the image quality of the image displayed on a television and so on is to be adjusted. An adjustment image suited to an image quality to be adjusted is stored in a memory in advance, and upon the adjustment, a plurality of adjustment display images having different image quality parameter values from each other are formed with regard to the adjustment image and displayed on a monitor, and one image having a desired image quality is selected from a plurality of the adjustment display images in an operating section, so that an image quality parameter value to be adjusted in an image quality adjusting section is determined.

Owner:PIONEER CORP

Natural gas liquefying method and device with light hydrocarbon recovery function

InactiveCN103453730AAdjust qualityHigh puritySolidificationLiquefactionPhysical chemistryRefrigerant

Owner:HANGZHOU FORTUNE CRYOGENIC EQUIP CO LTD

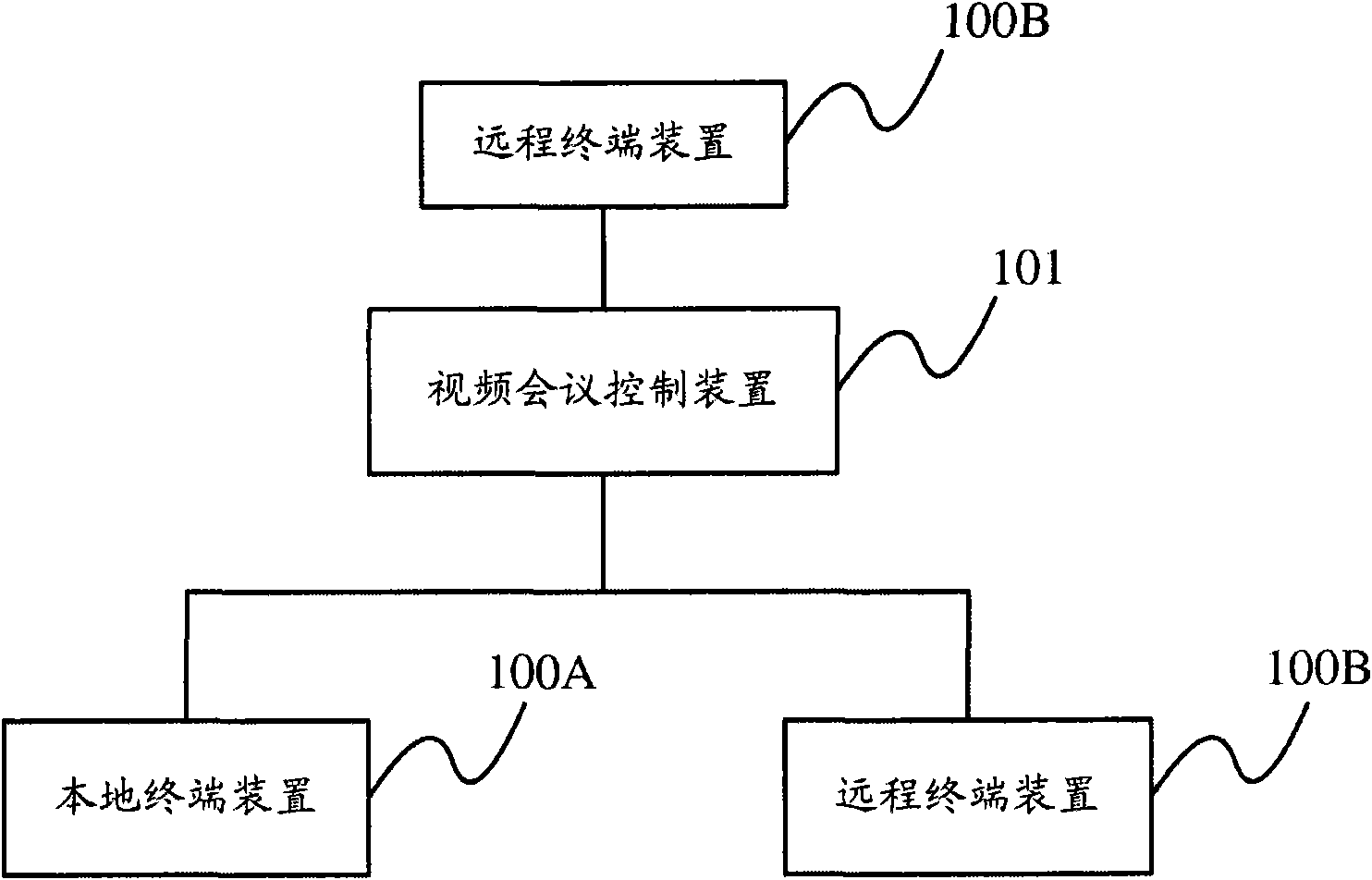

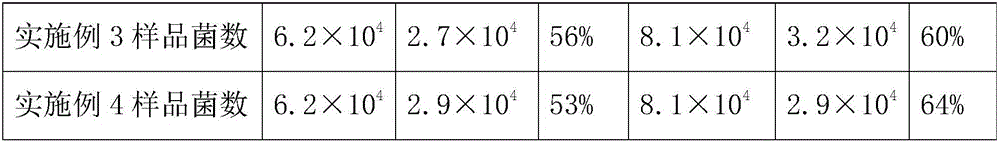

Video conference system and processing method used therein

InactiveCN102170552AQuality improvementImprove performanceTelevision conference systemsTwo-way working systemsComputer graphics (images)Terminal equipment

Owner:RICOH KK

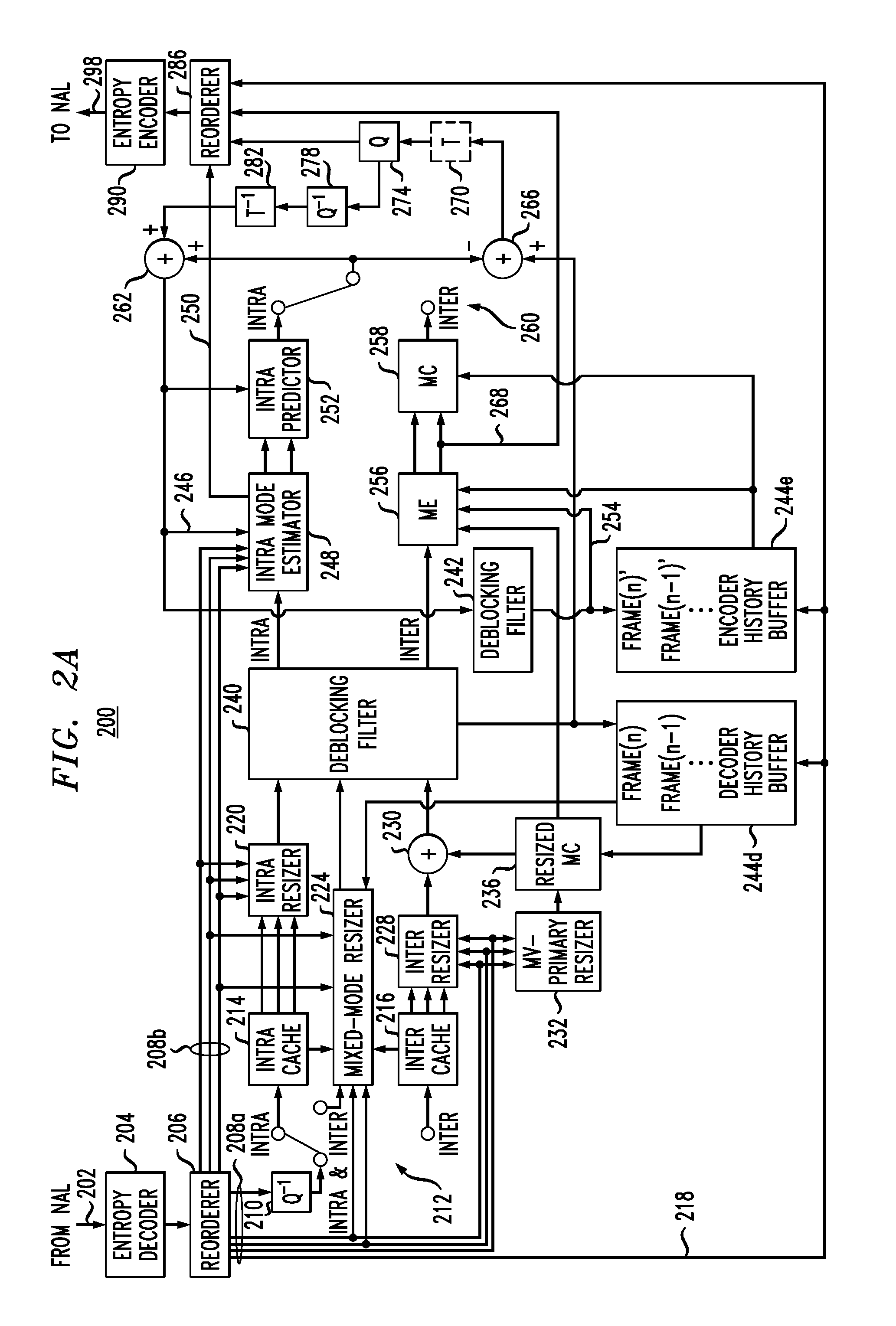

Video transcoder with flexible quality and complexity management

ActiveUS20120051440A1Adjust complexity and picture qualityAdjust complexityColor television with pulse code modulationColor television with bandwidth reductionImage resolutionComputational resource

A video transcoder for converting a compressed input video bit-stream having one spatial resolution into a compressed output video bit-stream having a different spatial resolution in a manner that enables the transcoder to dynamically change the amount of computational resources allocated to the conversion process. In one embodiment, the video transcoder has a plurality of configurable processing paths whose configuration determines the amount of allocated computational resources. Exemplary processing-path configuration changes may include, but are not limited to engaging or disengaging a processing path, redirecting a data flow from flowing through one processing path to flowing through another processing path, and attaching or detaching one or more processing modules to an engaged processing path. The capability to make these and other configuration changes enables the video transcoder to adjust the computational complexity and picture quality on the fly, without interrupting the video sequence in the output video bit-stream.

Owner:EQUSR CHEM LP +1

Heat-insulation and heat-preservation water-based coating material with air purifying function

InactiveCN103450761ALow thermal conductivityQuality improvementFireproof paintsLignin material coatingsWater basedHazardous substance

The invention provides a heat-insulation and heat-preservation water-based coating material with an air purifying function. The water-based coating material is prepared through compounding raw materials, such as diatomite, hollow glass beads, lignocellulose, zirconium phosphate loaded sliver powder, nano zinc oxide, tourmaline powder, aluminum oxide, hydroxypropyl methylcellulose, a pure acrylic emulsion, a dispersing agent 5040, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 1,2-propanediol, Kathon, a silicone defoamer, deionized water and the like. The water-based coating material provided by the invention further has the functions of improving air quality, regulating air humidity, preventing mildew and the like through adsorbing harmful substances in air and releasing negative ions, besides an excellent heat insulation function.

Owner:深圳市宜丽环保科技有限公司

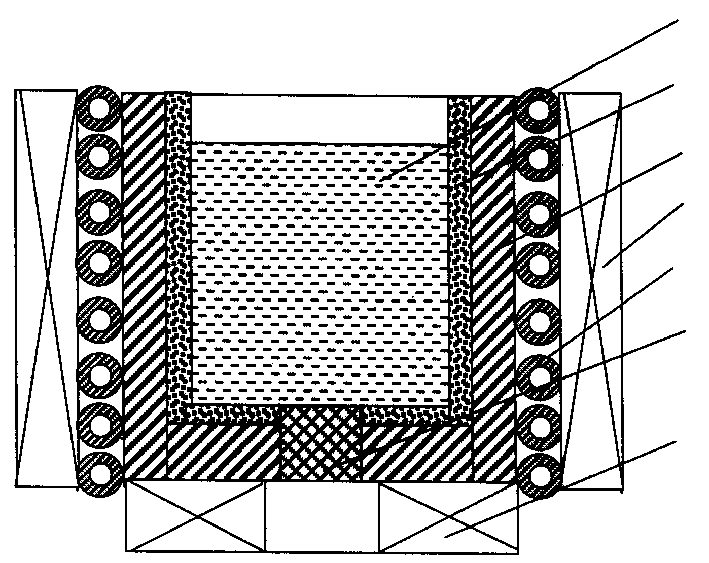

Method and equipment for preparing semisolid fused mass of ferrous material

An apparatus for preparing the semi-solid molten body of iron and steel is composed of a special container for molten iron or steel, temp regulator, stirrer and bottom vibrator. The linear layer of said special container contains nucleation promoter. Its method includes pouring the molten iron or steel at the temp which is 5-10 deg.C, higher than the temp of liquid-phase line into said special container, and stirring or vibrating for 1-10 min.

Owner:BEIJING JIAOTONG UNIV

Data transmission method and apparatus

ActiveCN101335590AImprove versatilityTune up quality and system performanceError preventionMultiple carrier systemsData transmissionDistributed computing

The embodiment of the invention discloses a method and a device for data transmission, wherein, the method comprises the steps that: the link performances of different modulation code combinations are compared; according to the results of the comparison, a modulation code combination with the best link performance is selected from the modulation code combinations so as to carry out data transmission. The device comprises a comparing unit used for comparing the link performances of different modulation code combinations; a selecting and transmitting unit used for selecting a modulation code combination with the best link performance from the modulation code combinations according to the results of the comparison so as to carry out the data transmission. During the data transmission, the technical proposal adopted by the embodiment of the invention selects a modulation code combination which is most suitable for the channel transmission by comparing the link performances of different modulation code combinations so as to carry out data transmission and can effectively increase the quality of data transmission and the performance of the system.

Owner:SHANGHAI HUAWEI TECH CO LTD

Flue gas desulphuration gypsum-alkaline residue soil stabilizer

InactiveCN102899048AAlleviate the pressure of resource shortageReduce waste burdenBuilding constructionsOrganic fertilisersEcological environmentSlag

The invention discloses a FGD (flue gas desulphuration) gypsum-alkaline residue soil stabilizer, comprising the following ingredients: 12-30wt% of FGD gypsum, 20-50wt% of alkaline residue, 0-30wt% of slag, 0-5wt% of additive, and 0-20wt% of fly ash; wherein the summation in weight percentage of the ingredients is 100%. The soil stabilizer disclosed herein has the advantages of alleviating the environmental protection pressure of alkaline and power enterprises and resource shortage pressure of building material enterprises, reducing waste discharge burden of enterprises, increasing income, and improving ecological environment.

Owner:中诚正丰环保科技有限公司

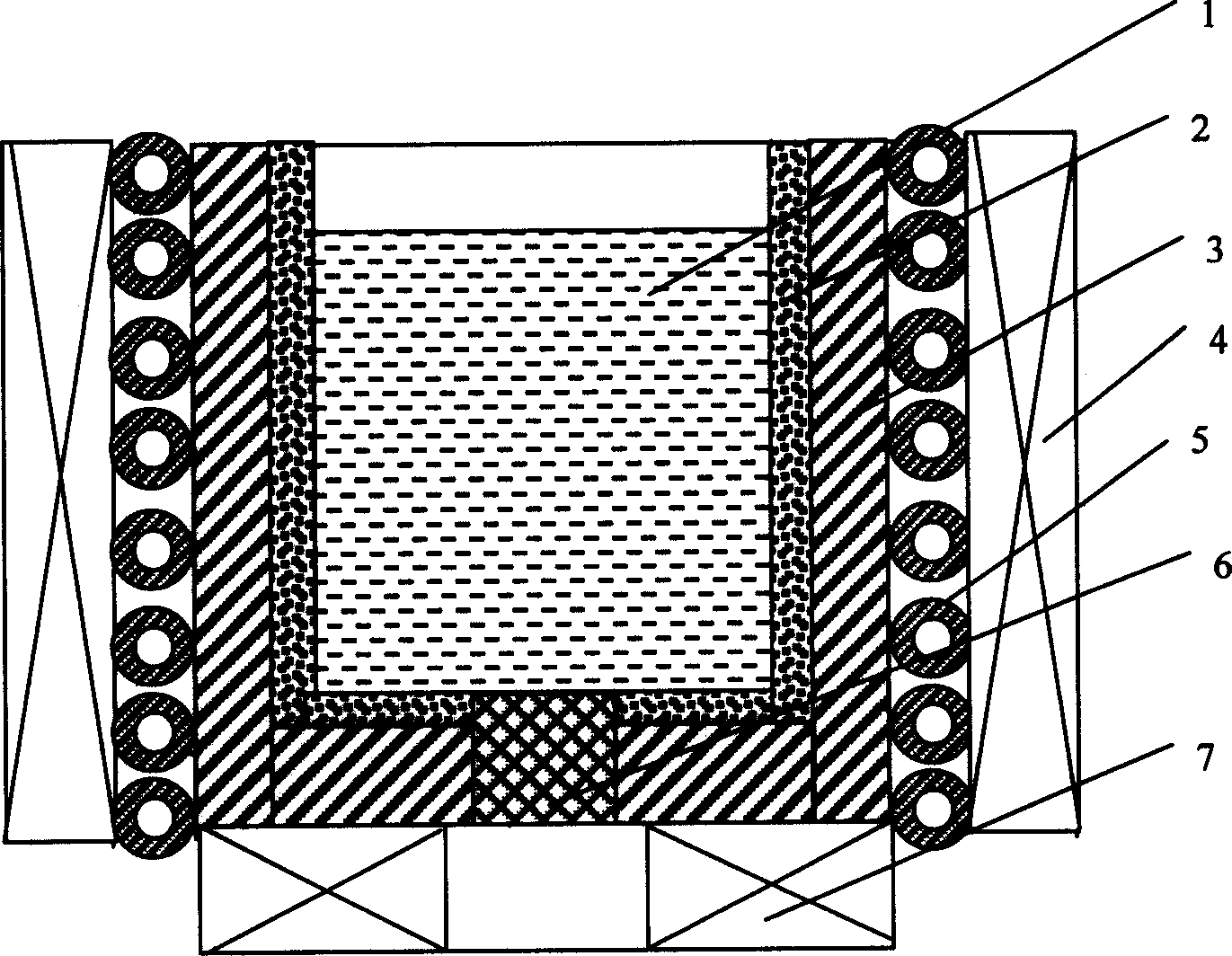

Ecological environment protection type pavement tile and producing process thereof

InactiveCN101413241AFast water seepageMaintain the water tableSolid waste managementMixing operation control apparatusAluminium saltsAcid water

The invention belongs to the field of environment-friendly energy-saving building materials, and in particular relates to an ecological environment-friendly footway brick and a production process thereof. The brick comprises a brick body (1), and is characterized in that the upper surface of the brick body (1) is provided with a groove (3); the position of the groove (3) of the brick body (1) is provided with a through hole (2) in the longitudinal direction; the brick body adopts materials (1) comprising a cementitious material, aggregate and activator; the cementitious material contains slag micro-powder, red mud, C-type fly ash and kieselguhr; the aggregate adopts waste residue particles; and the activator contains polycarboxylic acid water reducing agent, power plant desulphurization gypsum, aluminum sulfate slag and fly ash. The production process comprises two parts of: 1) preparing raw materials according to the requirements, and 2) physically molding, which is to install a column-type body on a brick press mold, have the through hole (2) when the brick is physically molded and extrude the groove (3) on the surface of the brick body. The footway brick has the advantages of simple structure and high water seepage efficiency, and can effectively reduce urban heat island effect.

Owner:王振山

Preparation method of strong gelatin fibrillin

InactiveCN108617848AChange internal structureAdjust qualityProtein composition from fishProteins working-up by texturisingProtein solutionMyofibril

The invention discloses a preparation method of strong gelatin fibrillin. The method comprises the following steps of (1) preparing fibrillin; (2) dissolving the fibrillin; performing concentration toobtain concentration liquid; (3) adding the concentration liquid into pyrogallic acid; performing uniform mixing; thus obtaining a mixed protein solution after the placement at the normal temperature; (4) performing vacuum packaging on the mixed protein solution; performing treatment at ultrahigh pressure; (5) performing program temperature rise on materials obtained in the step (4); performing sharp cooling to obtain the strong gelatin fibrillin. The system oxidization degree of the fibrillin is weakened by using the oxidization resistance of pyrogallic acid; ultrahigh pressure treatment iscombined, so that the inside structure of the fibrillin is changed; the uniform three-dimensional network gel structure is formed. The method is applicable to the field of food processing auxiliary materials; the quality of fish meat products is regulated.

Owner:XIAMEN UNIV

Output image adjustment method, apparatus and computer program product for graphics files

InactiveUS20080198396A1Adjust qualityImage enhancementTelevision system detailsGraphicsImaging quality

When a memory card MC is inserted into slot, a control circuit of a color printer acquires and analyzes graphics processing control information GC from the memory card MC. A CPU corrects standard values for image quality parameters indicating graphics data qualities, to reflect the graphics processing control information GC. The CPU corrects image quality parameters to bring them into approximation with the corrected standard values, and adjusts image quality of the graphics data to reflect the corrected image quality parameters.

Owner:SEIKO EPSON CORP

Air treatment module and air conditioner

ActiveCN107525134AAdjust qualityRegulate humidityMechanical apparatusLighting and heating apparatusAir treatmentComputer engineering

The invention discloses an air treatment module and an air conditioner adopting the air treatment module. The air treatment module is utilized in the air conditioner. The air conditioner comprises a heat exchange air duct. The air treatment module comprises a shell, a purification filter screen, a humidification assembly and a fan, wherein the shell is provided with an air treatment air duct, and air inlets and air outlets which communicate with the air treatment air duct; the heat exchange air duct and the air treatment air duct are independently arranged; the purification filter screen is arranged in the air treatment air duct; the air treatment air duct is divided into a humidification cavity and an air inlet cavity up and down; the air inlet cavity communicates with the air inlets; the humidification cavity communicates with the air outlets; at least a part of the humidification assembly is accommodated in the humidification cavity; and the fan is accommodated in the humidification cavity. According to the air treatment module, the technical problem that in the prior art, the heat exchange function of the air conditioner is affected due to the fact that the air treatment module is added in the air conditioner is solved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

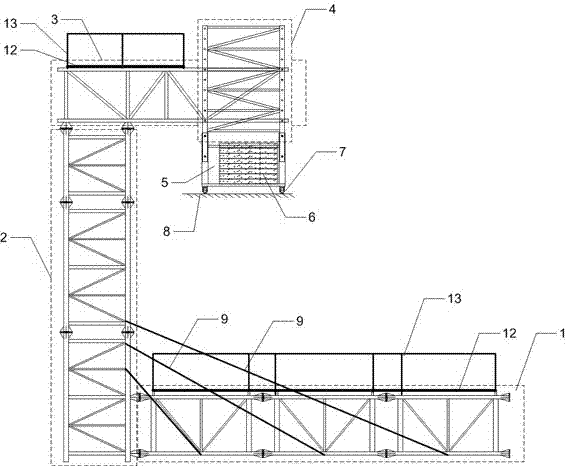

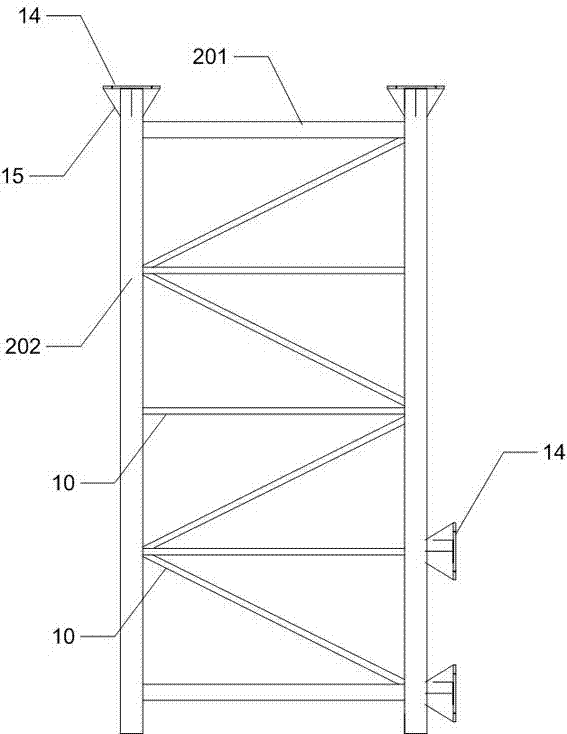

Superlong prestress strand combing, binding and strand pulling integrated device

InactiveCN103669214APlay a protective effectGuaranteed integrityBridge erection/assemblyCable stayedPre stress

The invention discloses a superlong prestress strand combing, binding and pulling integrated device, relates to the field of tools for combing, binding and pulling of steel strands in highway bridges, and aims to provide a superlong prestress strand combing, binding and pulling integrated device which is easy and convenient to operate, saves cost and can greatly improve strand pulling efficiency and quality. The superlong prestress strand combing, binding and pulling integrated device comprises a winch load cable (1), a traction bar (3), a clamping ring (2), a strand pulling sleeve (4), a strand combing plate, a base, a fixing hoop (8) and a sealing plate (13), wherein the load cable and the traction bar are connected through the clamping ring (2), one end of the traction bar is sleeved with the strand pulling sleeve (4), the base (7) is located at the bottom of the strand combing plate, the fixing hoop (8) is fixed to the outer side of the top end of the strand combing plate, and the sealing plate (13) is located in the middle of the strand combing plate. The superlong prestress strand combing, binding and pulling integrated device can be widely applied to all prestress strand pulling construction through a post-tensioning method, and particularly superlong prestress strand combing, binding and pulling of suspension casting segmental box girders of prestressed concrete large-span cable-stayed bridges, suspension bridges and continuous girder bridges. Strand pulling, combing and binding are integrated, so that the strand pulling efficiency and quality can be greatly improved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Control method and device for fresh air machine

InactiveCN106123207AAdjust qualityIncrease usageMechanical apparatusSpace heating and ventilation safety systemsFresh airEngineering

The invention discloses a control method and device for a fresh air machine. The control method includes the following steps of obtaining current outdoor air quality, regulating the working gear of the fresh air machine according to the current outdoor air quality so as to achieve the regulated working gear, and controlling the fresh air machine to operate according to the regulated working gear. According to the control method, the outdoor air quality is detected, the operating gear of the fresh air machine is controlled according to the outdoor air quality, and the situation that a large amount of outdoor air is still introduced when the outdoor air quality is poor is avoided. In combination with the outdoor air quality, the operating gear of the fresh air machine is intelligently regulated and controlled, and therefore the quality of indoor air can be regulated more effectively, regulation efficiency is high, and energy loss is low.

Owner:GREE ELECTRIC APPLIANCES INC

Electro-optical apparatus and electronic equipment

ActiveUS8248694B2Improve display qualityAdjust qualitySteroscopic systemsNon-linear opticsElectronLiquid crystal

An electro-optical apparatus includes a display panel that displays an image, an illuminating device that allows light rays to pass through the display panel, a polarization axis controlling unit arranged between the illuminating device and the display panel for allowing light rays having first polarization axis out of light rays outputted from the illuminating device to pass and changing the polarization axes of part of the light rays emitted from the illuminating device to convert the light rays to light rays having second polarization axis different from the first polarization axis, and a lens having a plurality of linear lens patterns for causing the light rays having the first polarization axis and the light rays having the second polarization axis separated by the polarization axis controlling unit respectively to proceed in predetermined directions. The polarization axis controlling unit includes a liquid crystal layer and a plurality of electrodes arranged in a stripe pattern so as to oppose the liquid crystal layer. The width of the electrodes to which a voltage is applied when changing the polarization axes of the part of the light rays emitted from the illuminating device is larger than the width of the electrode to which no voltage is applied.

Owner:EPSON IMAGING DEVICES CORP +1

Active regeneration artificial cornea graft and preparation method thereof

InactiveCN101380486AUnsuitable for transplantationSolve the strength problemEye implantsPolyvinyl alcoholBiocompatibility Testing

The invention belongs to the technical field of artificial cornea production and more particularly provides an active regenerating artificial cornea implant and a preparation method thereof. The artificial cornea implant comprises 5-30 shares of chitosan, 5-30 shares of collagen, 0.1-0.5 share of chondroitin-sulfuric acid, 5-10 shares of polyethylene glycol, 5-25 shares of polyvinyl alcohol and 15-80 shares of triple-distilled water; preferably the artificial cornea implant also comprises appropriate amount of cornea cell growing factor, fibronectin and laminin. The preparation method of the active regenerating artificial cornea implant is as below: dissolving the chitosan, the collagen and the chondroitin-sulfuric acid in hydrochloric acid, acetic acid and water respectively, and then infusing the mixture of the components which are agitated uniformly at the room temperature into a mould for drying, and then obtaining the product after water immersion, cleaning and drying. The artificial cornea implant has good biocompatibility, high substance rigidity and good transparency; the preparation method is easy to be operated, the raw materials are easy to be obtained and are cheap, and large-scale industrialized production can be performed.

Owner:JINAN UNIVERSITY

Hanging basket for detecting and maintaining anchor mooring heads of boom and stay cable of bridge

ActiveCN105442446AIncrease flexibilityHigh degree of standardizationBridge structural detailsCable stayedEngineering

The invention discloses a hanging basket for detecting and maintaining anchor mooring heads of a boom and a stay cable of a bridge. The hanging basket mainly comprises a detecting platform, a suspension structure (comprising suspension belts, a suspension frame and a suspension arm), a supporting structure (comprising a supporting frame, a counterweight platform seat and a counterweight arranged on the counterweight platform seat) and a walking structure (comprising walking wheels and a track), wherein the detecting platform, the suspension structure, the supporting structure and the walking structure are sequentially connected; the detecting platform, the suspension frame, the suspension arm and the supporting frame are all of cube structures; the suspension belts are high-strength steel wire ropes; the value of a tension force of the suspension belts can be regulated through a chain block. According to the hanging basket disclosed by the invention, an assembling mode is adopted, components are light and convenient, transportation is convenient, disassembling and assembling are convenient and quick, and a dedicated hoisting device is not needed during disassembling and assembling; the hanging basket is mainly applied to the fields of detecting and maintaining construction of an anchor mooring head of the stay cable of a cable-stayed bridge and an anchor mooring head of the boom of a boom arch bridge, and the like. When the traffic flow on the bridge is larger, the detecting and maintaining construction time is longer, or the adoption of a bridge detecting operation vehicle is difficult, the hanging basket disclosed by the invention has the advantages of quickness in disassembling and assembling, good controllability, high safety and low cost.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

Method and equipment for producing high-quality sponge iron for reduced iron powder

InactiveCN102994679AGuaranteed smooth productionInhibition of segregationShaft furnaceProcess efficiency improvementIron powderShaft furnace

The invention relates to a method and equipment for producing high-quality sponge iron for reduced iron powder. The method comprises the steps of: preparing composite solidified pellets by iron ore concentrate powder; mixing the composite solidified pellets or iron stones with a solid reducing agent, adding the mixture into a shaft furnace reaction chamber of a combined reaction tank; heating furnace burdens at a preheating section in the reaction chamber to 800-900 DEG C, and then at a reducing section to 1100-1200 DEG C to carry out reduction reaction for 12-18h; cooling the reacted materials through a cooling section, and then enabling the materials to enter a rolling screening system through a frequency control discharging system for online screening; after screening, conveying the waste reducing agent to a storage bin through a vacuum negative-pressure suction system; and carrying out different normal aftertreatments on the sponge iron obtained by screening according to used different raw materials to obtain the reduced iron powder or a sponge iron briquette. According to the method and the equipment for producing the high-quality sponge iron for the reduced iron powder, the production process is automatically controlled, the mechanization degree is high, the labor intensity of workers is reduced, the production environment is improved, the sponge iron pellets and the reducing agent are separated by the automatic screening and vacuum negative-pressure suction systems, a part of reducing agent is recycled, and thus the energy consumption is reduced.

Owner:武汉桂坤科技有限公司

Anion health-care viscose fabric

ActiveCN106087104AImprove spinnabilitySolve defects such as low strength and easy to generate static electricityConjugated cellulose/protein artificial filamentsHeating/cooling textile fabricsYarnMoisture absorption

The invention discloses an anion health-care viscose fabric. The anion health-care viscose fabric is formed by weaving yarns which are formed by blending anion health-care viscose and cotton fibers; a preparation technology of the anion health-care viscose fabric comprises the steps that sodium alginate colloid is prepared; anion powder is added into the sodium alginate colloid, and uniform stirring is conducted, colloid containing the anion powder is obtained; bamboo fibers, taxus chinensis fibers and microporous lignocellulose are added into sodium hydroxide for soaking, CS2 is added, a stirring reaction is conducted, and a viscose solution is obtained; the colloid containing the anion powder is added into the viscose solution to be stirred to be uniform, grinding is conducted, and a viscose mixed solution before spinning is obtained; filtering, defoaming, curing, spinning, desulfurization, water washing, oiling and drying are conducted, and the anion health-care viscose fabric is obtained. The anion health-care viscose fabric has the advantages of being good in skin adaptability, moisture absorption and liberation and air permeability, resistant to bacteria, healthy, green, environmentally friendly and the like.

Owner:江苏华拓纺织科技有限公司

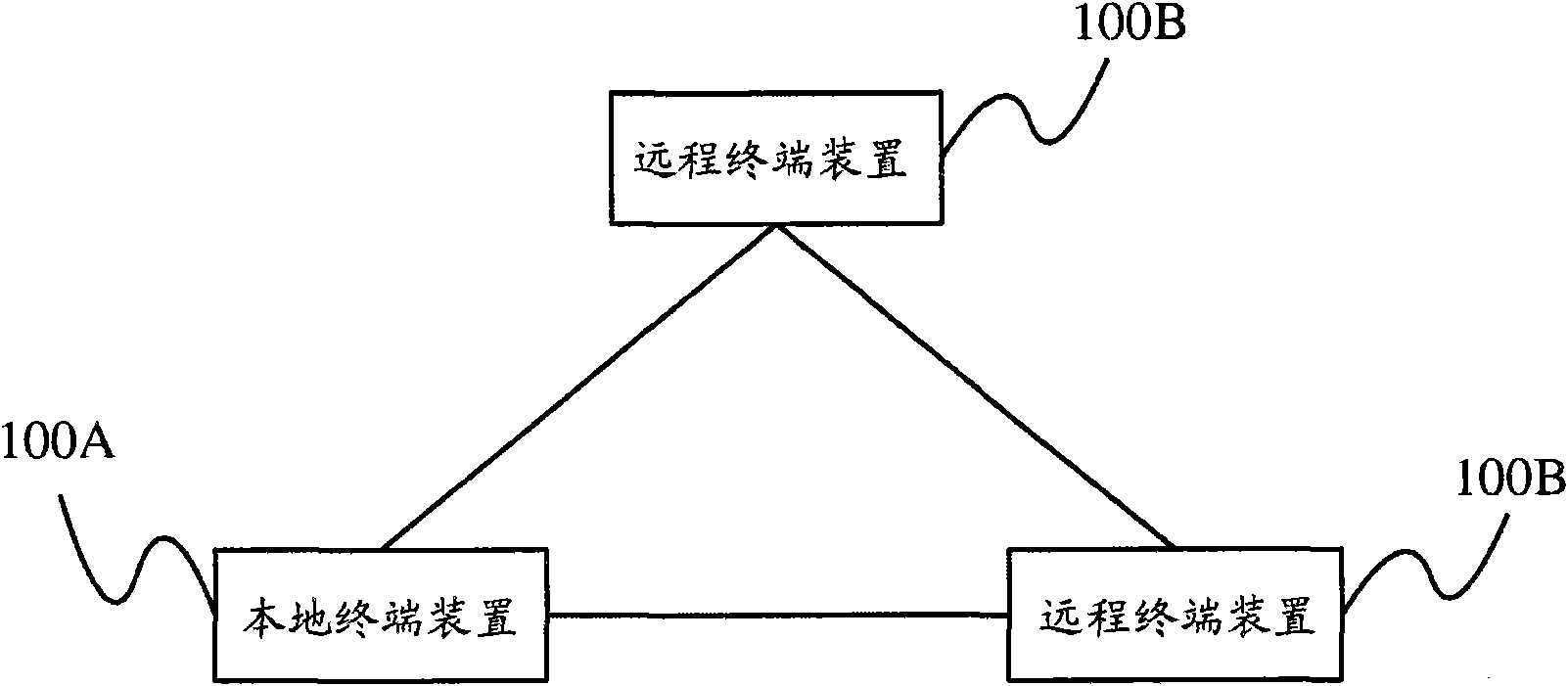

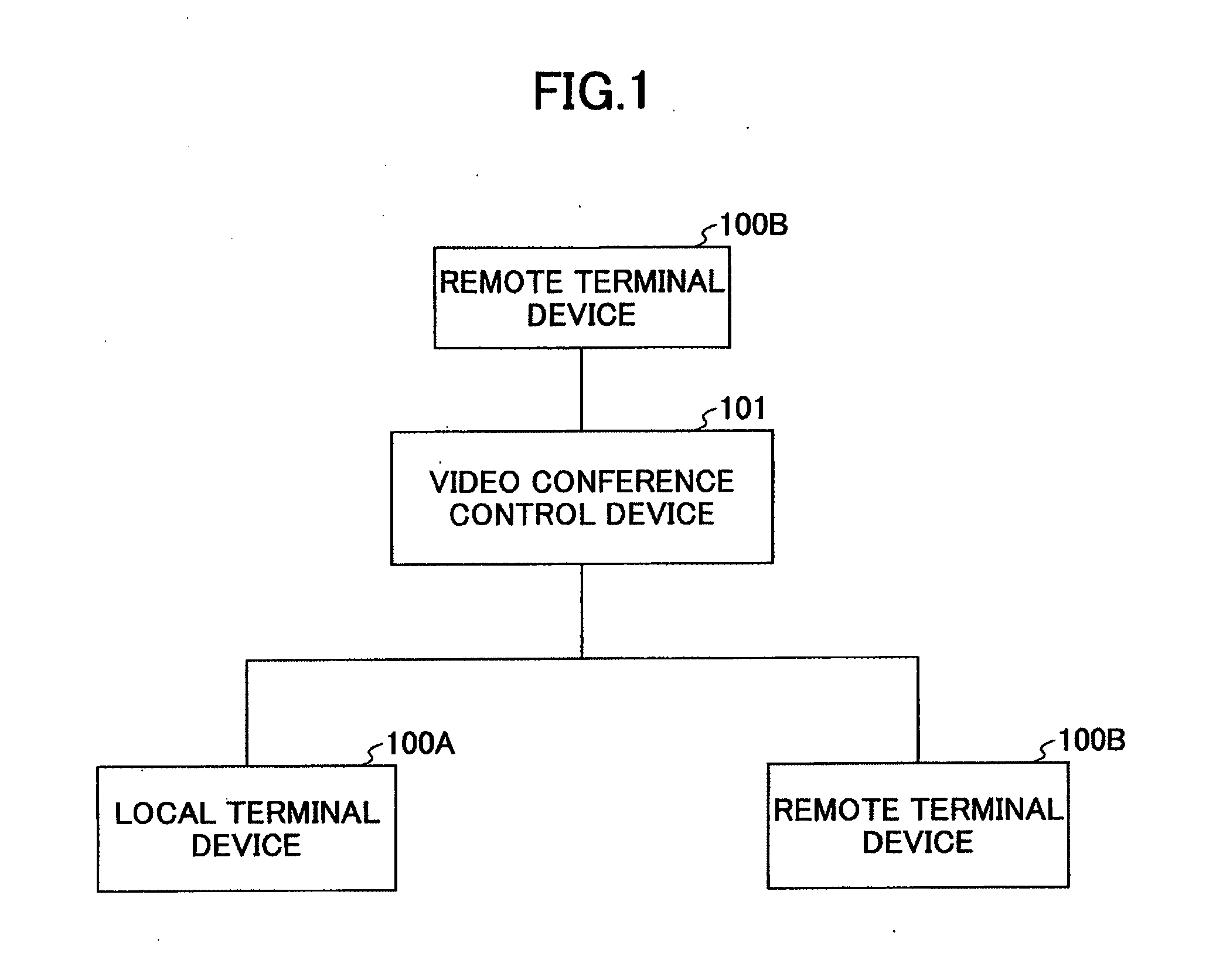

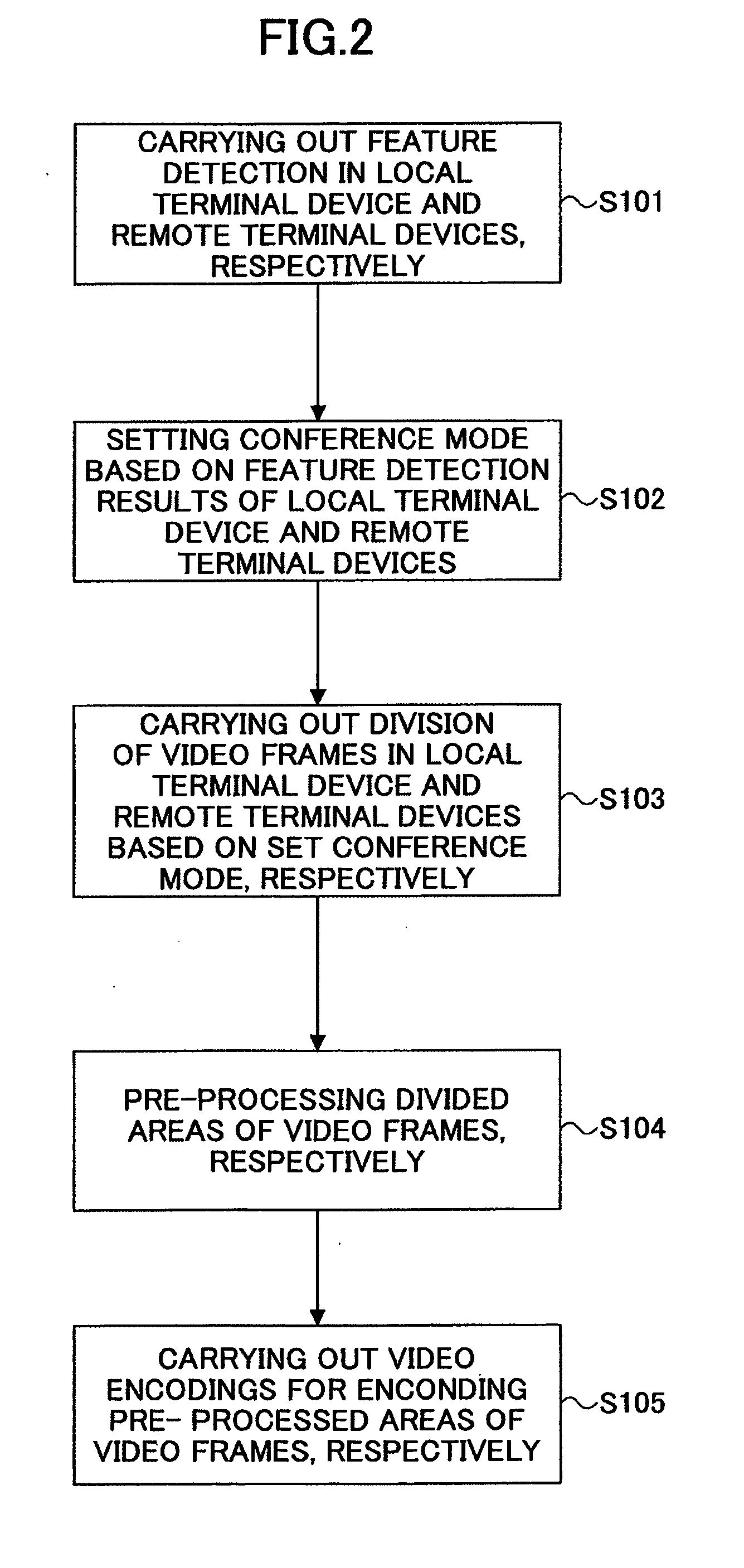

Video conference system, processing method used in the same, and machine-readable medium

ActiveUS20110205330A1Clear and accurate focusImprove video qualityTelevision conference systemsTwo-way working systemsVideo encodingTerminal equipment

Disclosed is a processing method used in a video conference system having a local terminal device and at least one remote terminal device, comprising a feature detection step of carrying out a feature detection in the local terminal device and the remote terminal device, respectively; a conference mode setting step of setting a conference mode for the local terminal device and the remote terminal device, respectively; and a video encoding step of dividing a video frame in the local terminal device and the remote terminal device, and then pre-processing the divided areas so as to encode the pre-processed areas, respectively.

Owner:RICOH KK

Air treatment module and air conditioner

PendingCN107366971AAvoid failureFailure issues do not affectDucting arrangementsMechanical apparatusAir treatmentComputer engineering

The invention discloses an air treatment module and an air conditioner applying the air treatment module, wherein the air treatment module is used for the air conditioner; the air conditioner is provided with a heat exchange duct; the air treatment module comprises a shell, a purification filter net, a humidifying net and a fan; the shell is provided with an air treatment duct as well as an air inlet and an air outlet which communicate with the air treatment duct, and the heat exchange duct and the air treatment duct are arranged in a way of being independent from each other; the purification filter net is arranged in the air treatment duct and is used for partitioning two sides of the air treatment duct into an air inlet cavity and a humidifying cavity, the air inlet cavity communicates with the air inlet, and the humidifying cavity communicates with the air outlet; the humidifying net is arranged at the bottom of the humidifying cavity; and the fan is accommodated in the humidifying cavity and is located at the upper end of the humidifying net. By using the air treatment module disclosed by the invention, the technical problem that the air conditioner is internally additionally provided with the air treatment module to affect the heat exchange function of the air conditioner in the prior art is solved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Fresh air air-conditioning system and control method

InactiveCN111578378AQuickly adjust temperatureQuickly adjust humidityMechanical apparatusLighting and heating apparatusFresh airProcess engineering

The invention discloses a fresh air air-conditioning system and a control method, and belongs to the fresh air air-conditioning technical field. The control method comprises the following steps that work modes are selected according to indoor air temperature and indoor air humidity and comprise a fresh air work mode, an air-conditioning work mode and a manual mode; in the air-conditioning work mode, the fresh air air-conditioning system is configured to only suck indoor air, and the indoor air temperature and humidity are independently adjusted and controlled; and in the fresh air work mode, the fresh air air-conditioning system is configured to only suck outdoor air and filter the sucked outdoor air, and different fresh air work sub-modes are selected to be executed. The fresh air air-conditioning system comprises a fresh air module and an air-conditioning module, and the fresh air module and the air-conditioning module are in sealed communication. By means of the fresh air air-conditioning system and the control method, the temperature and humidity of indoor air can be rapidly adjusted, the advantages of low noise and the large fresh air inflow quantity are achieved, and the advantages of the high indoor air replacement rate and low energy consumption and economic cost are also achieved.

Owner:全厚志

Versatile music distribution

InactiveUS20160005411A1Adjust qualityKey distribution for secure communicationSpeech analysisControl mannerControl signal

Methods and devices are described whereby a representation of an original PCM signal may be reversibly degraded in a controlled manner and information losslessly embedded to produce a streamable PCM signal, which provides a controlled audio quality when played on standard players and conditional access to a lossless presentation of the original PCM signal. Using such techniques allows control over the level of degradation of the signal and also flexibility in the type information of information embedded. Some methods require a song key, which is employed in one or both of the degrading and embedding steps and for creating a token. These methods may further require a user key, which is used to encrypt the song key before creating the token.

Owner:MERIDIAN AUDIO

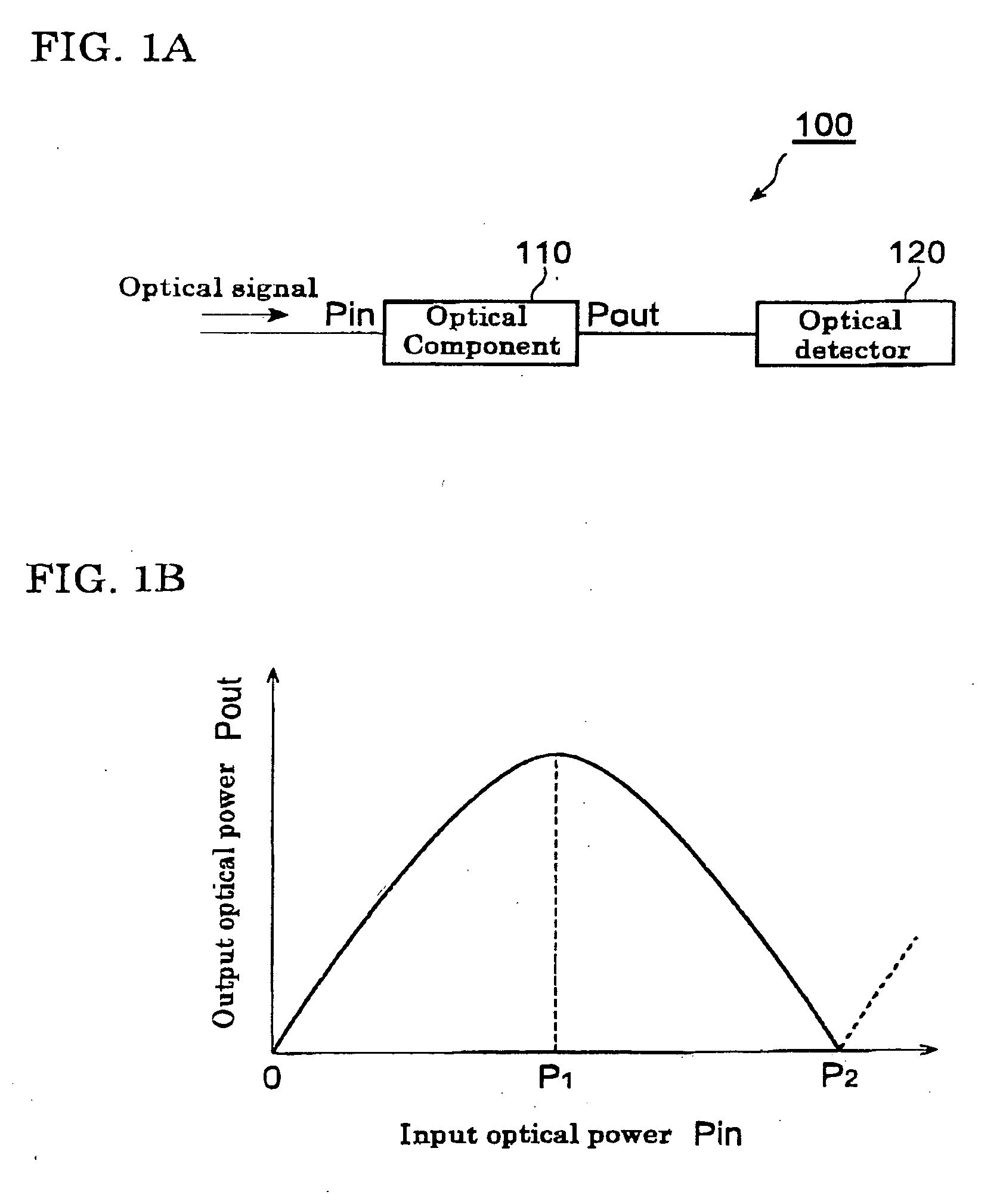

Signal-quality evaluation device, signal adjustment method, optical-signal evaluation system, and optical transmission system

InactiveUS20060159451A1Shorten timeSuperior applicabilityWavelength-division multiplex systemsDc level restoring means or bias distort correctionOptical powerTransmission system

Provided are a signal-quality evaluation device and a signal adjustment method which require shorter evaluation time and which have high flexibility of application. A signal quality evaluation device 100 includes an optical component 110 and an optical output detector 120. In the optical component 110, an output optical power Pout is a function of an input optical power Pin, and this function Pout(Pin) has at least one maximum point. The optical output detector 120 detects the time-average power of light output from the optical component 110.

Owner:SUMITOMO ELECTRIC IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com