Anion health-care viscose fabric

A health care viscose fiber and negative ion technology, applied in the field of clothing fabrics, can solve the problems of low quality and high price, and achieve good physical properties, good compatibility and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A negative ion health-care viscose fabric, which is formed by weaving after blending negative ion health-care viscose fibers and cotton fibers into yarn;

[0028]Wherein, the preparation process of the negative ion health-care viscose fiber includes: dissolving sodium alginate in a sodium hydroxide solution with a concentration of 5 wt%, stirring at 90°C for 1 hour to obtain sodium alginate colloid; Purpose negative ion powder is added in described sodium alginate colloid under stirring condition, after stirring evenly, obtain the sodium alginate colloid containing negative ion powder; Soak in sodium hydroxide solution for 1 h at 40°C to obtain a cellulose alkalized product; add 37% CS based on the total fiber weight to the cellulose alkalized product 2 , stirring and reacting at -10°C for 2h to obtain a viscose solution; adding 0.2% of the sodium alginate colloid containing negative ion powder based on the total weight of the fiber to the viscose solution and stirring ...

Embodiment 2

[0030] A negative ion health-care viscose fabric, which is formed by weaving after blending negative ion health-care viscose fibers and cotton fibers into yarn;

[0031] Wherein, the preparation process of the negative ion health-care viscose fiber includes: dissolving sodium alginate in a sodium hydroxide solution with a concentration of 8 wt%, stirring at 70°C for 3 hours to obtain sodium alginate colloid; Purpose negative ion powder is added in described sodium alginate colloid under stirring condition, after stirring evenly, obtain the sodium alginate colloid containing negative ion powder; Soak in sodium hydroxide solution for 1.5h at 30°C to obtain a cellulose alkalized product; add 35% CS based on the total fiber weight to the cellulose alkalized product 2 , stirred and reacted at 20°C for 1 hour to obtain a viscose solution; 3% of the sodium alginate colloid containing negative ion powder based on the total weight of the fiber was added to the viscose solution and stir...

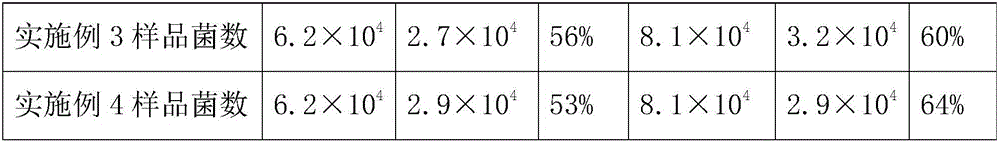

Embodiment 3

[0037] A negative ion health-care viscose fabric, which is formed by weaving after blending negative ion health-care viscose fibers and cotton fibers into yarn;

[0038] Wherein, the preparation process of the negative ion health-care viscose fiber includes: dissolving sodium alginate in a sodium hydroxide solution with a concentration of 6 wt%, stirring at 80°C for 2 hours to obtain sodium alginate colloid; Purpose negative ion powder is added in described sodium alginate colloid under stirring condition, after stirring evenly, obtain the sodium alginate colloid containing negative ion powder; Soak in sodium hydroxide solution for 1.2h at 35°C to obtain a cellulose alkalized product; add 36% CS based on the total fiber weight to the cellulose alkalized product 2 , stirring and reacting at 5°C for 1.5h to obtain a viscose solution; adding 1.6% of the sodium alginate colloid containing anion powder based on the total weight of the fiber to the viscose solution and stirring even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com