Thermodynamic system and regulation and control method for rapid load responses of heat supply unit

A heating unit, load response technology, applied in heating systems, household heating, hot water central heating systems, etc., can solve the problems of poor stability and high maintenance costs, and achieve rapid load reduction capabilities, small impact, and increased The effect of power generation load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

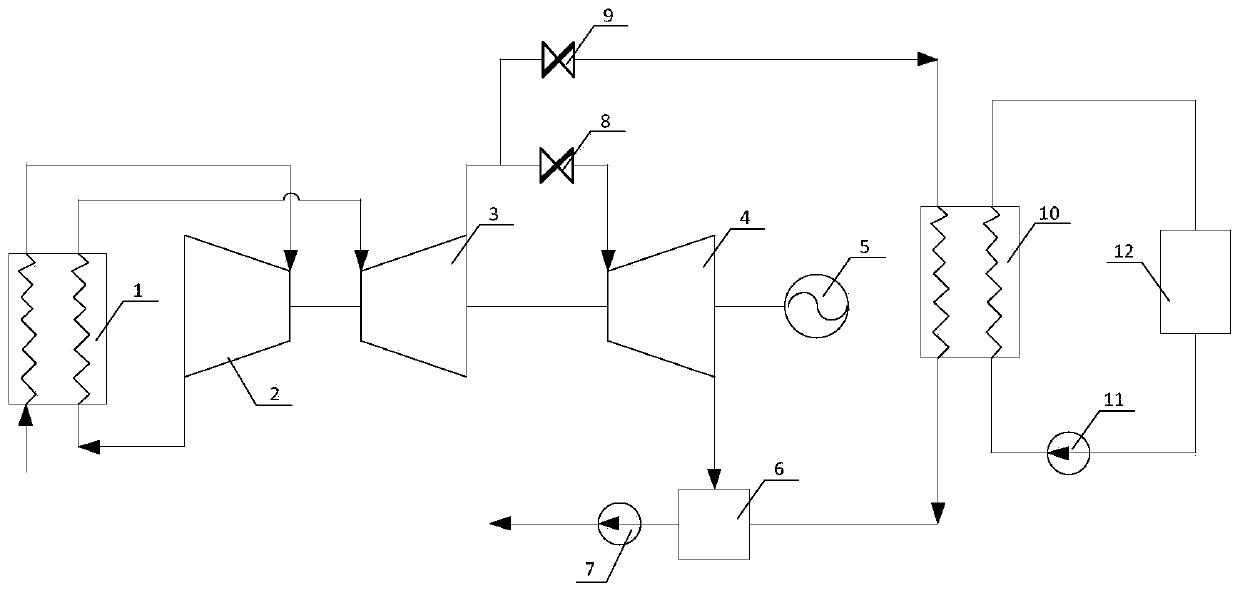

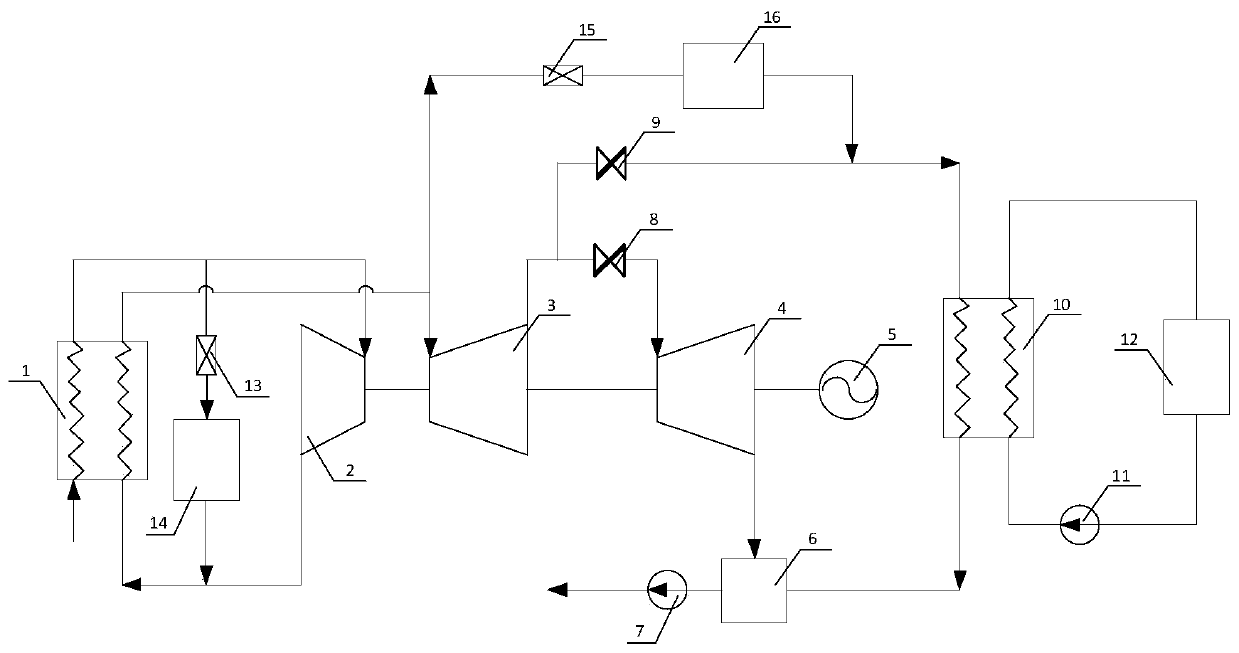

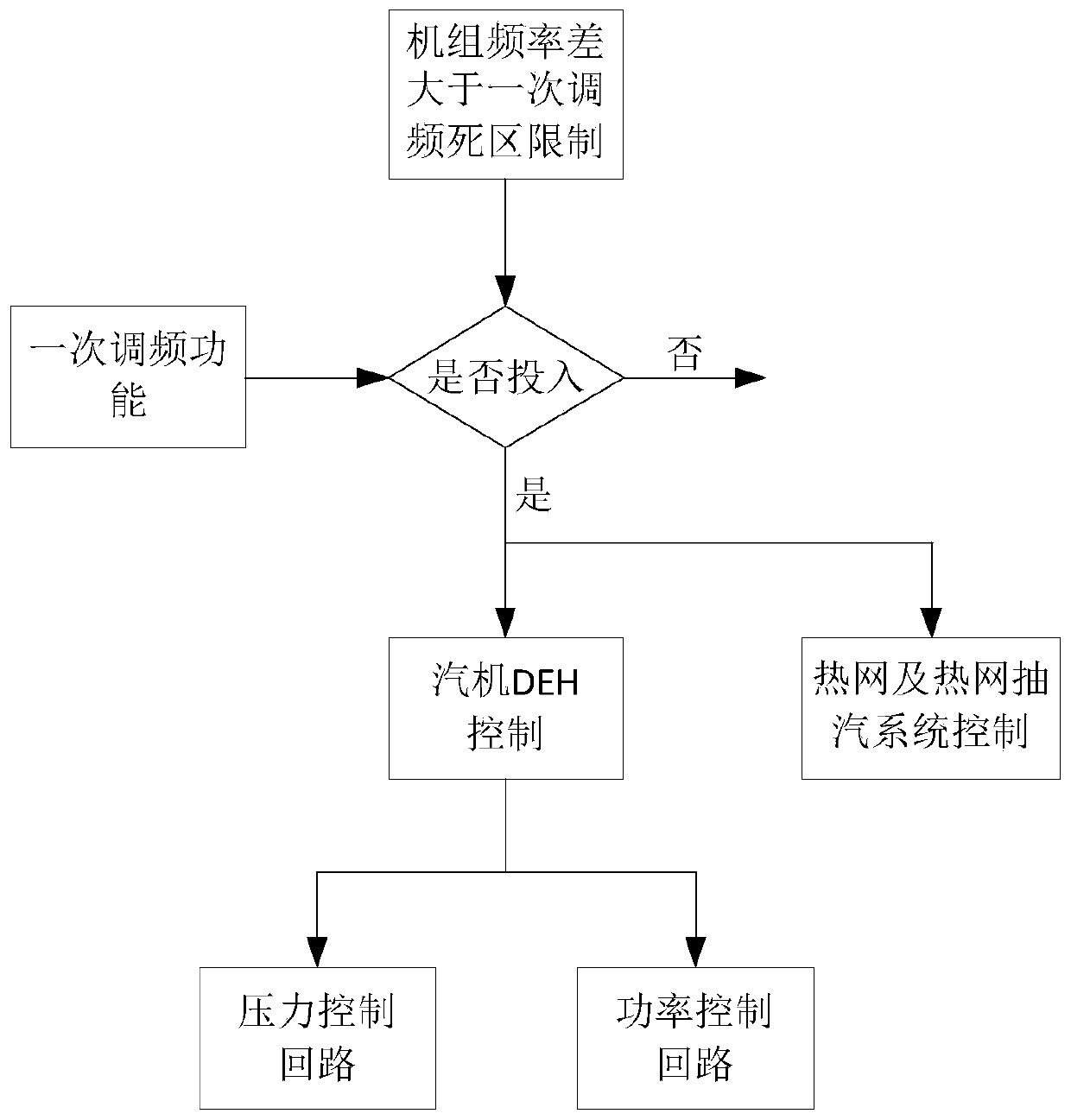

[0036] like figure 1 and figure 2 As shown, the thermal system and control method for the rapid load response of the heating unit described in this embodiment are based on the heating unit, and the heating unit includes boiler 1, high-pressure cylinder 2, medium-pressure cylinder 3, and low-pressure cylinder connected in sequence 4 and the generator 5, a medium-low pressure communication butterfly valve 8 is set between the medium-pressure cylinder 3 and the low-pressure cylinder 4, and is used to adjust the flow of steam entering the low-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com