Stable combustion device for pulverized coal ignition

A stable combustion device and pulverized coal technology, which is applied in the direction of the burner, burner, and combustion type of burning powder fuel, and can solve the problems of ignoring the important role of flame propagation speed and not completely solving it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

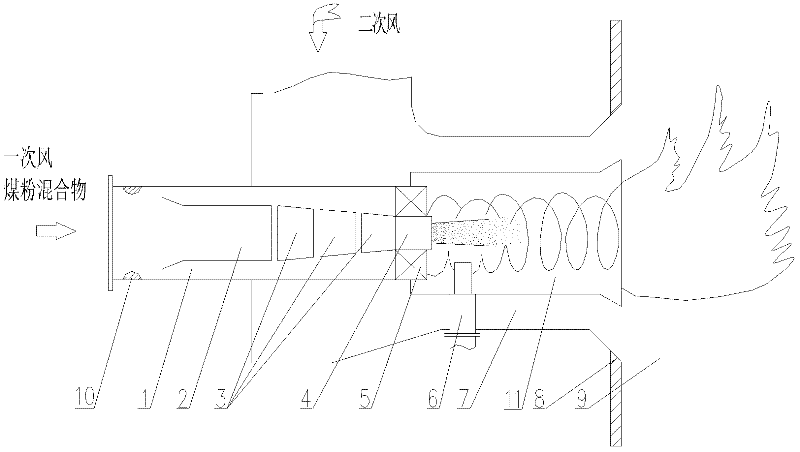

Embodiment 1

[0017] Example 1, such as figure 1 As shown, a pulverized coal ignition and stable combustion device includes a primary air duct 1 passing through pulverized coal and a diversion sleeve 2, a pulverized coal concentrator 3, and a conduit 4 arranged in sequence in the duct, which are radially arranged in the primary air duct 1 outlet of the igniter 6. Swirling vanes 5 forming swirling jets are arranged between the duct 4 and the inner wall of the primary air duct 1 .

Embodiment 2

[0018] Embodiment 2, a pulverized coal ignition and stable combustion device, on the basis of Embodiment 1, in order to initially concentrate the pulverized coal, the inner wall of the inlet of the primary air duct 1 and the front end of the diversion sleeve 2 are provided with concentrated coal Powder stopper10.

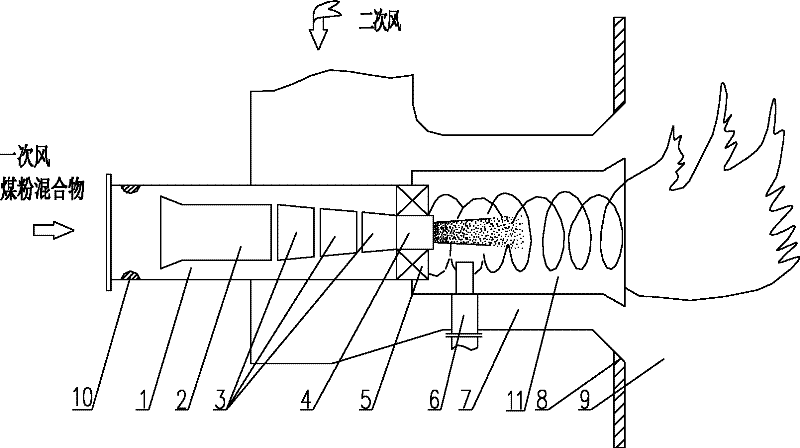

Embodiment 3

[0019] Embodiment 3, a pulverized coal ignition and stable combustion device, on the basis of Embodiment 1 or 2, in order to further build a stable combustion zone, an enlarged diameter primary air duct 11 is also set at the outlet of the primary air duct 1, the described The diameter-expanding primary air duct 11 outlet is a flared mouth with a cone angle of 0-40°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com