Diffusion type porous medium gas fuel combustor

A technology of porous media and gas fuel, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as tempering, small lean burn limit combustion rate and stability, load adjustment range, and difficulty in manufacturing, etc., to achieve Uniform density distribution, avoid tempering phenomenon, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

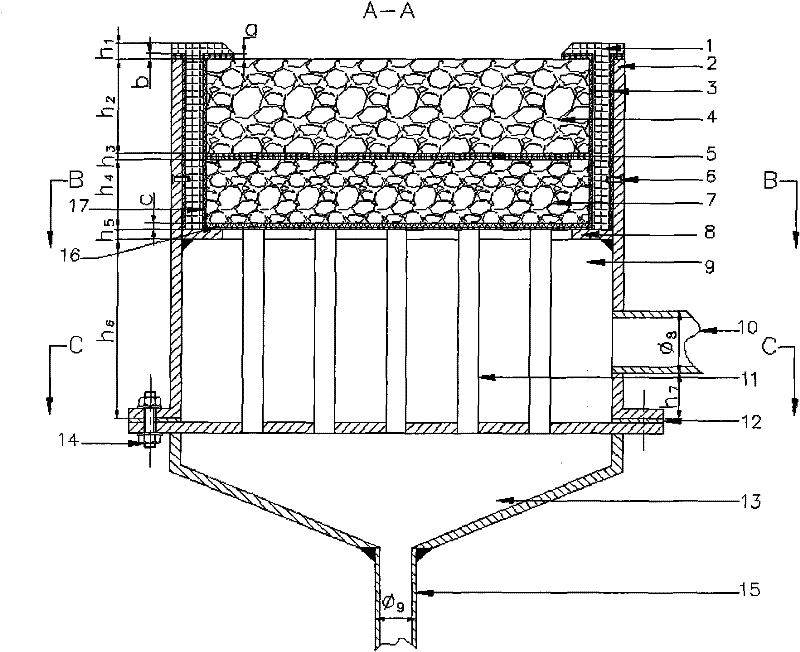

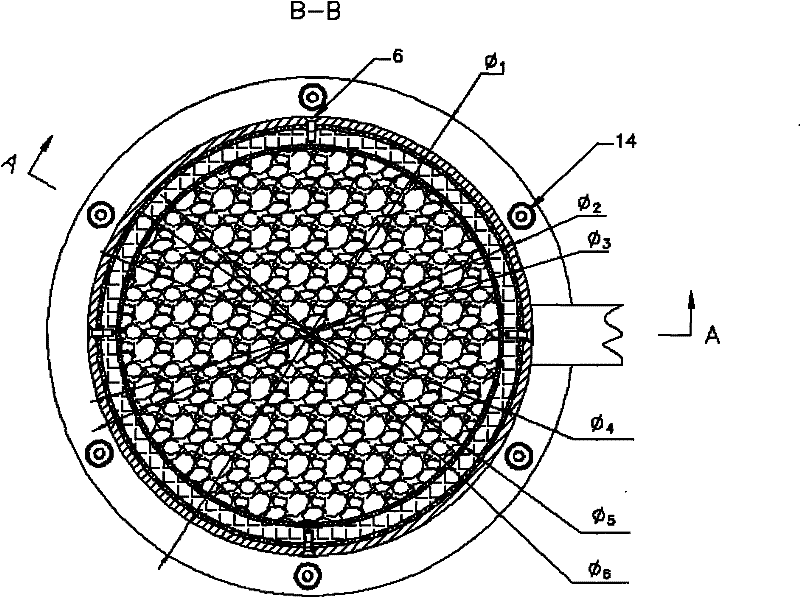

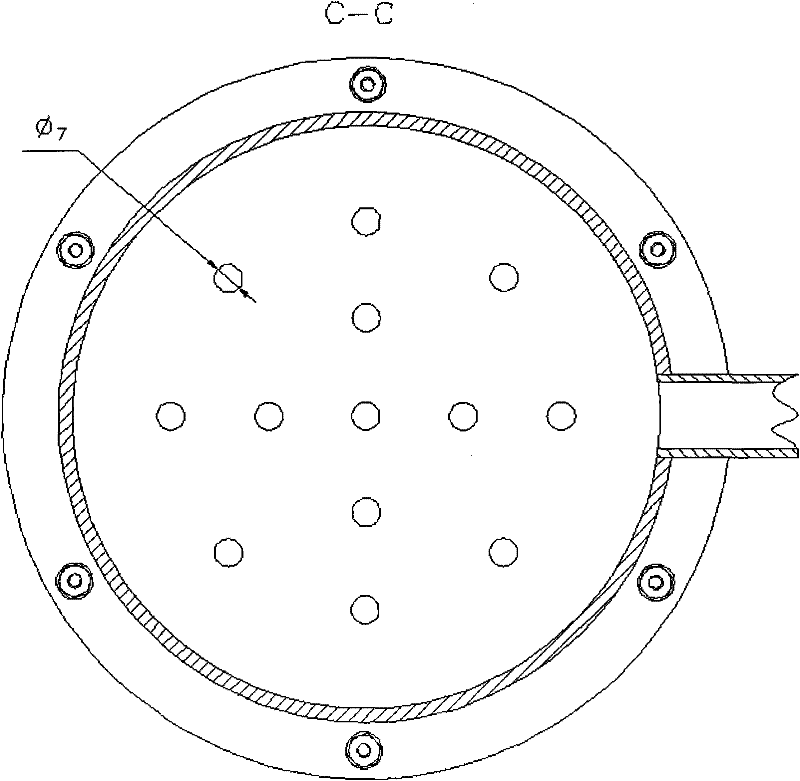

[0044] Diffusion porous media gas fuel burner structure such as figure 1 As shown, the A-A section view is as follows figure 2 As shown, the B-B section view structure is as follows image 3 As shown, the burner is mainly composed of a refractory casing 1, a casing 2, a tray 8, a gas distribution pipe 11 and a gas distribution tank 13, and the structure of the tray 8 is as follows Figure 4 As shown, the tray hole in the tray 8 connects the upper and lower end faces of the tray, the bottom end of the casing 2 is connected with the top plate of the gas distribution tank 13, and the interior of the casing 2 is sequentially provided with a refractory sleeve 1, a tray 8 and a gas Distributor pipe 11, the bottom end of refractory casing 1 is in contact with tray 8, and the outer edge of tray 8 is welded and fixed with shell 2; Internal communication; the refractory casing 1 is provided with large-pore porous media 4, small-pore porous media 7 and lower metal fibers 16 from top t...

Embodiment 2

[0068] The structure of the diffused porous medium gas fuel burner is the same as that in Embodiment 1; the material of the large-pore porous medium is calcium oxide-based zirconia, and the material of the small-pore porous medium is yttrium oxide-based zirconia.

[0069] Geometric dimensions are with embodiment 1.

[0070] Using 3# burner (φ 4 =170mm), the combustion intensity is 900~2000kw / m respectively under the condition of no air preheating 2 The combustion test, the test data are shown in Table 4.

[0071] Table 4

[0072]

[0073]

[0074] Using 3# burner (φ 4 =170mm), the combustion intensity is 900~2000kw / m respectively under the condition of air preheating to 300℃ 2 The combustion test, the test data are shown in Table 5.

[0075] table 5

[0076]

[0077]

Embodiment 3

[0079] Diffusion porous media gas fuel burner structure such as Figure 5 As shown, the A-A section view is as follows Figure 6 As shown, the B-B section view structure is as follows Figure 7 As shown, the structure of the diffused porous media gas fuel burner is as follows figure 1 As shown, the A-A section view is as follows figure 2 As shown, the B-B section view structure is as follows image 3 As shown, the burner is mainly composed of a refractory casing 1, a casing 2, a tray 8, a gas distribution pipe 11 and a gas distribution tank 13, and the structure of the tray 8 is as follows Figure 8 As shown, the tray hole in the tray 8 connects the upper and lower end faces of the tray, the bottom end of the casing 2 is connected with the top plate of the gas distribution tank 13, and the interior of the casing 2 is sequentially provided with a refractory sleeve 1, a tray 8 and a gas The distribution pipe 11 and the bottom end of the refractory sleeve 1 are in contact wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com