Device and technology for poly-generation of carbon, heat and electricity based on biomass gasification

A thermoelectric device, biomass carbon technology, applied in gasification process, petroleum industry, manufacture of combustible gas, etc., to achieve the effects of improving environmental pollution, reducing emissions, and improving carbon quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

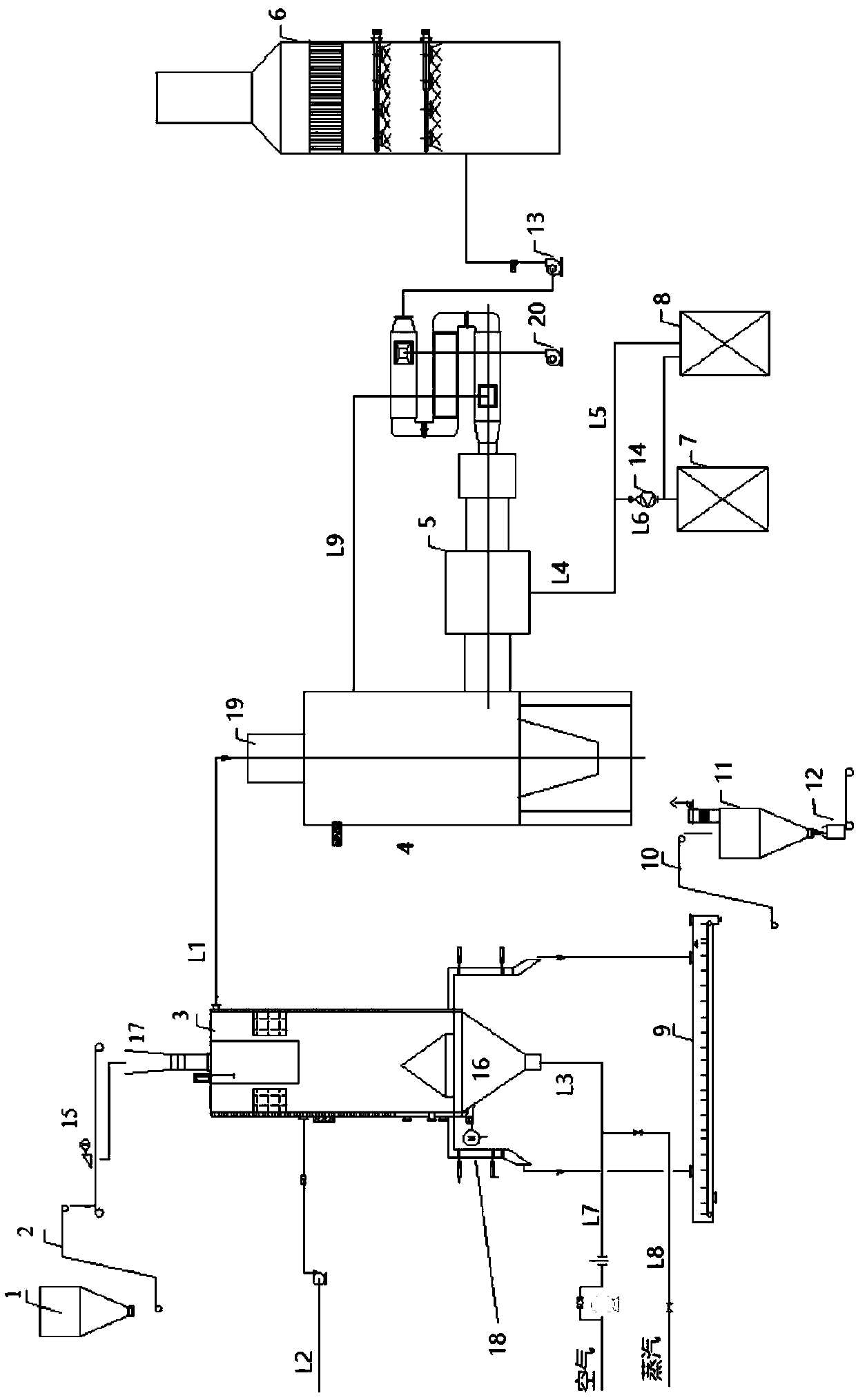

Method used

Image

Examples

Embodiment

[0057] Annual processing of shells and briquettes 40.32×10 4 t / a is an example, and the annual operating time is calculated as 8000 hours. The biomass gasification polygeneration charcoal thermoelectric process of the present invention is as follows.

[0058] (1) Biomass briquettes (wood chips, wood blocks) and fruit shells stored in the raw material warehouse are transported to the floor material warehouse 1, and then sent to the feeding belt conveyor 2 through the screw feeder in the floor material warehouse 1 . The feeding belt conveyor adopts a 52° corrugated edge belt, and the raw material is sent into the silo placed on the upper part of the gasifier 3 through the belt feeding device and the distributing device, and then opened by the slide valve at the lower part of the silo And closed to control the feeding, the raw material automatically falls into the biomass gasifier by its own gravity and the vibration of the vibration device at the lower part of the silo.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com