Spherical high temperature and high pressure continuous feeding airlock system

A high-temperature, high-pressure, spherical technology, applied in the direction of using atmospheric pressure to chemically change substances, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low efficiency, and achieve high work efficiency and large load adjustment range , The effect of less leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

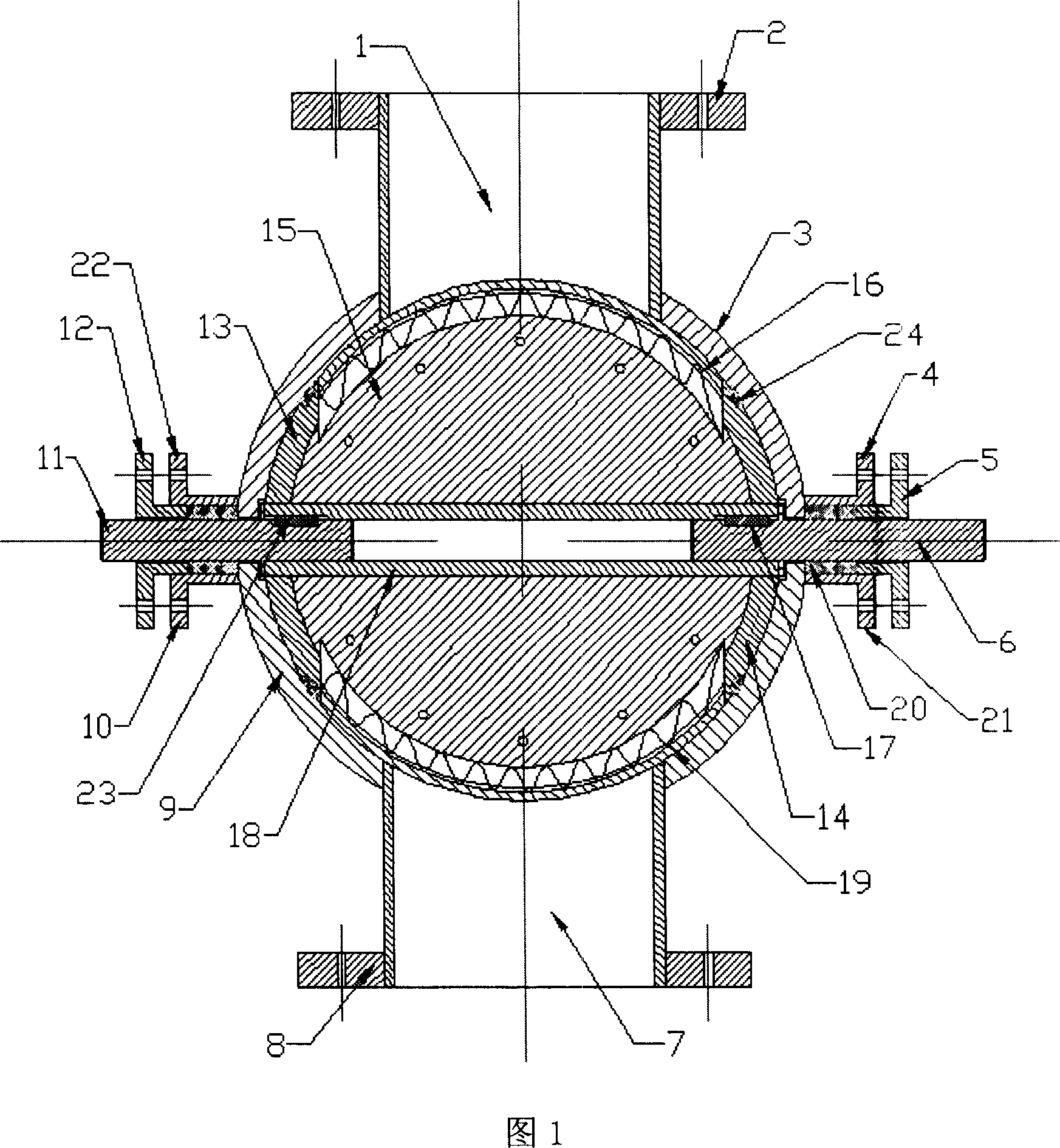

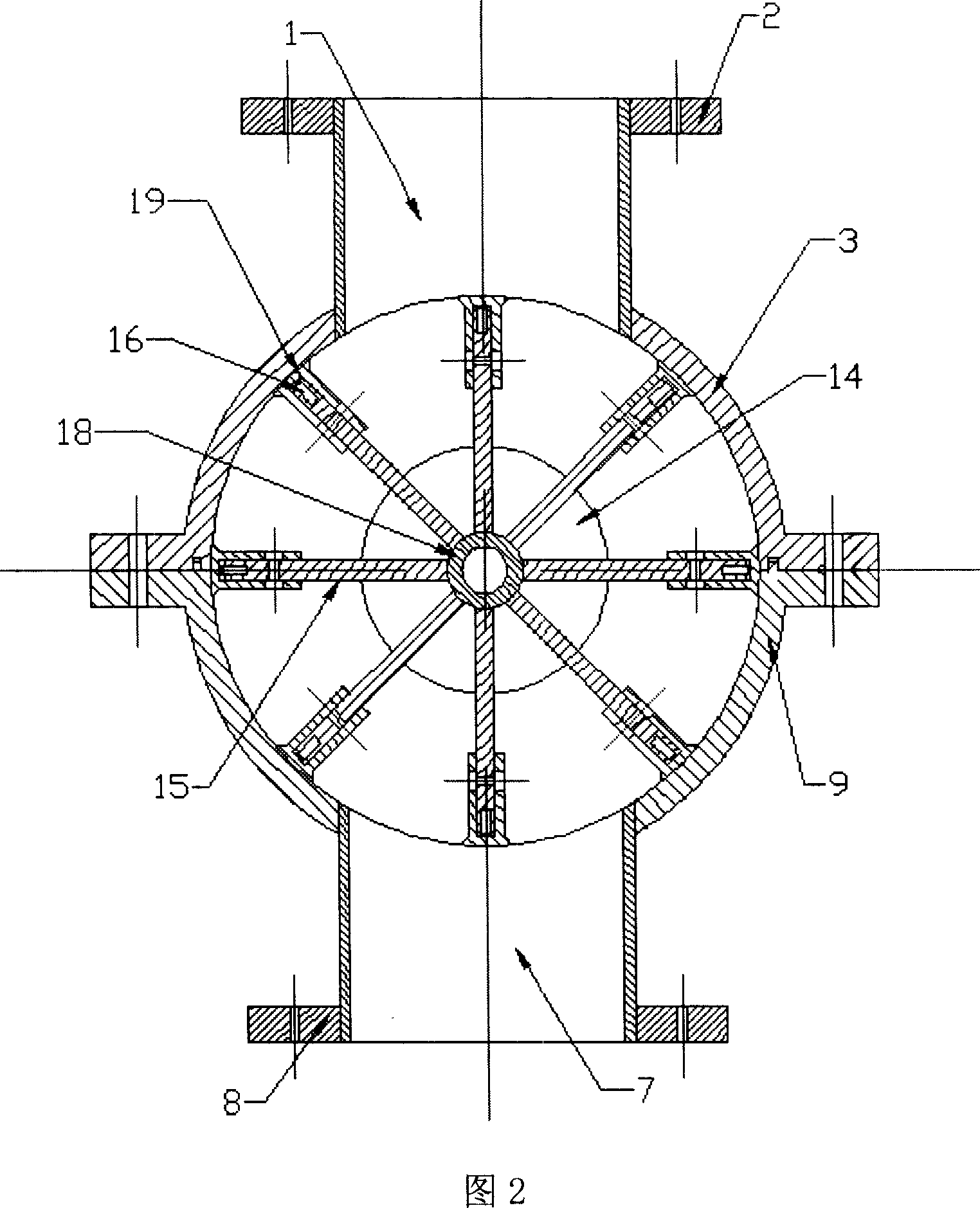

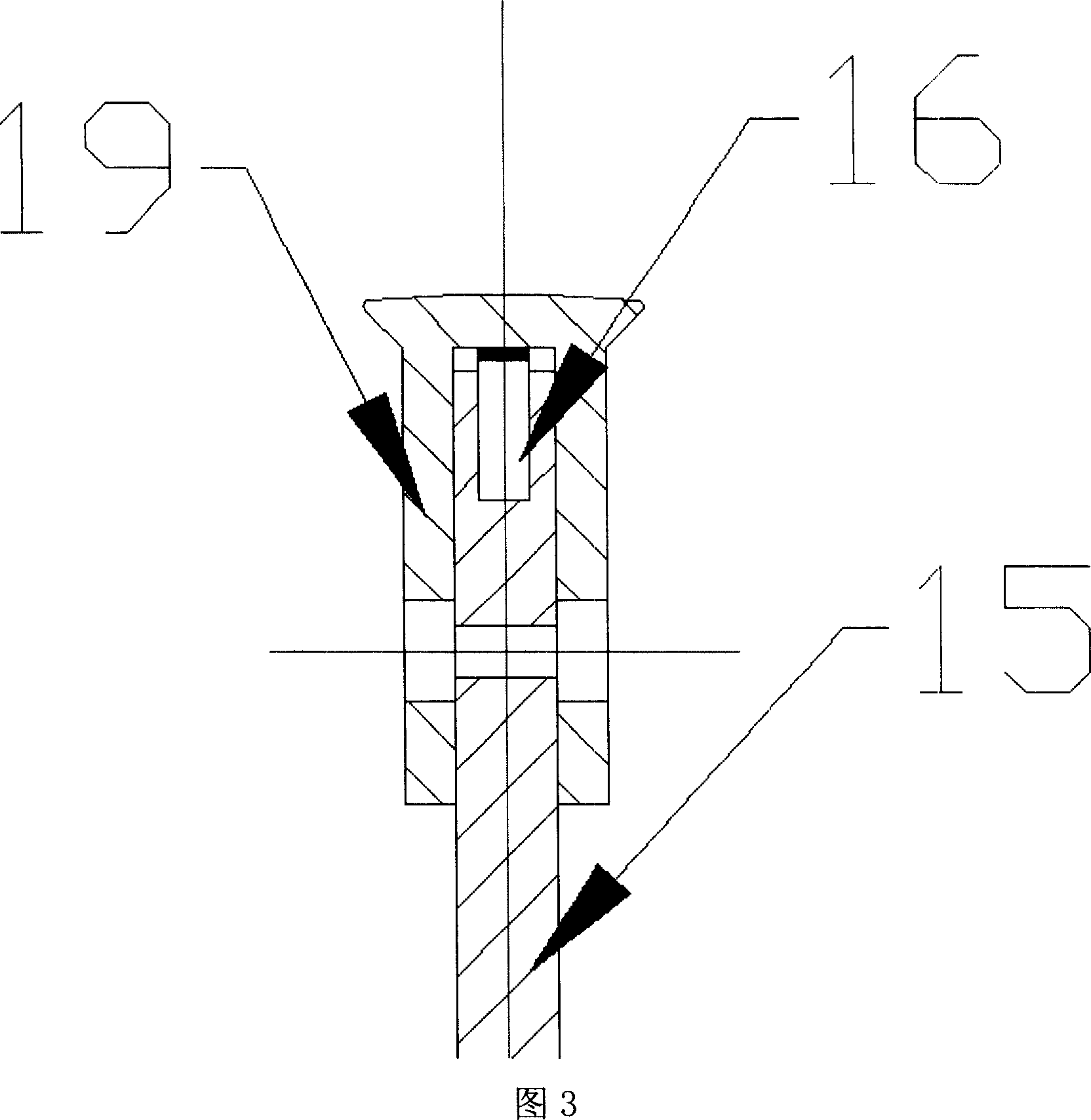

[0018] Referring to the accompanying drawings, the spherical high-temperature and high-pressure continuous feeding airlock system of the present invention includes a spherical casing, the spherical casing is opposed by two hemispherical cylinders 3, 9 concave surfaces, connected by bolt flanges, and composed of two The glands 5 and 12 are formed by connecting flanges with bolts. The upper part of the cylinder body 3 is provided with a material inlet 1, and the lower part of the cylinder body 9 is provided with a material outlet 7, and the material inlet flange 2 and the material outlet flange 8 are respectively welded. Spherical casings can withstand greater operating pressures than other styles of casings. A runner is installed inside the casing, and the runner is welded on the rotating shaft 18 by the uniformly distributed semicircular runner piece 15 and the spherical segment-shaped baffle ring pieces 13 and 14 on both sides, and the top of the runner piece 15 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com