Combustion method of low-concentration combustible gas and fluidized reactor

A combustion method and low-concentration technology, which is applied in the combustion method, the fuel burned in the molten state, and the combustion type, etc., can solve the problems of stable combustion, low calorific value of low-concentration combustible gas, and large variation in the concentration of combustible components. The effect of improving stable combustion efficiency, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

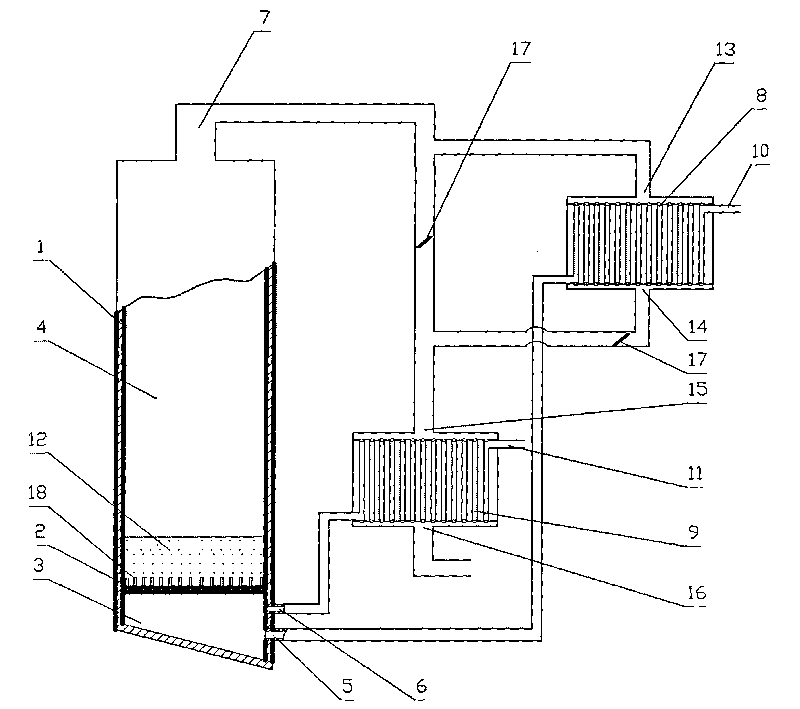

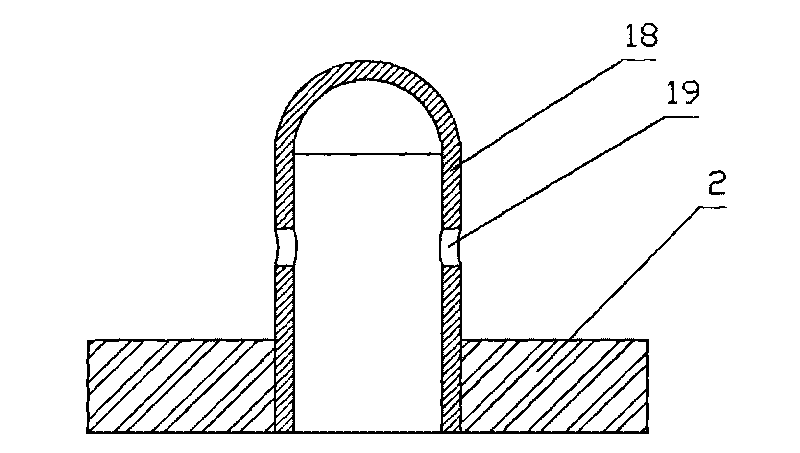

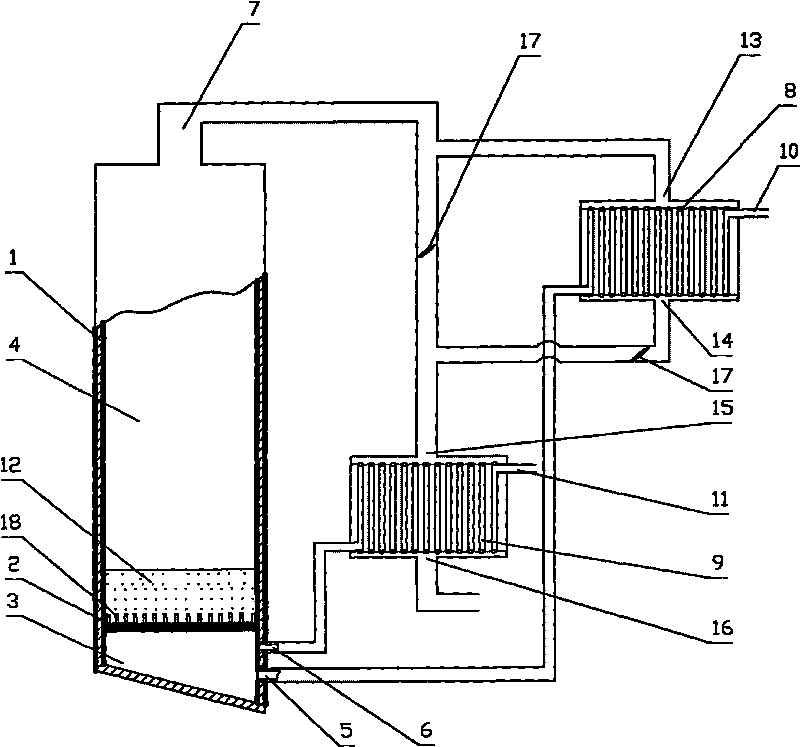

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The combustion method of low-concentration combustible gas adopts a fluidized reactor as a burner, and sand particles are placed on the air distribution plate of the burner; the specific steps of the method include: firstly, passing low-concentration combustible gas and combustion-supporting air into the heat exchange Then, pass the heat-exchanged low-concentration combustible gas and combustion-supporting air into the mixing chamber of the fluidized reactor for mixing; then the mixed gas enters the burner through the air distribution plate Combustion in the combustion chamber; the gas after combustion is used as the heat source of the heat exchanger.

[0025] In this embodiment, the sand grains are quartz sand grains, and the quartz sand grains are inert grains with a diameter of 0.1-10 mm, which are pre-stacked on the air dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com