Test system for extension of multi-axis and salt-spray corrosion fatigue crack

A technology of fatigue crack growth and salt spray corrosion, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., it can solve the problem that the actual needs of fatigue crack growth rate cannot be met, and achieve continuous, stable and reliable supply, accurate Test results, the effect of uniform distribution of salt spray concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The working process of the present invention will be further described below in conjunction with the accompanying drawings.

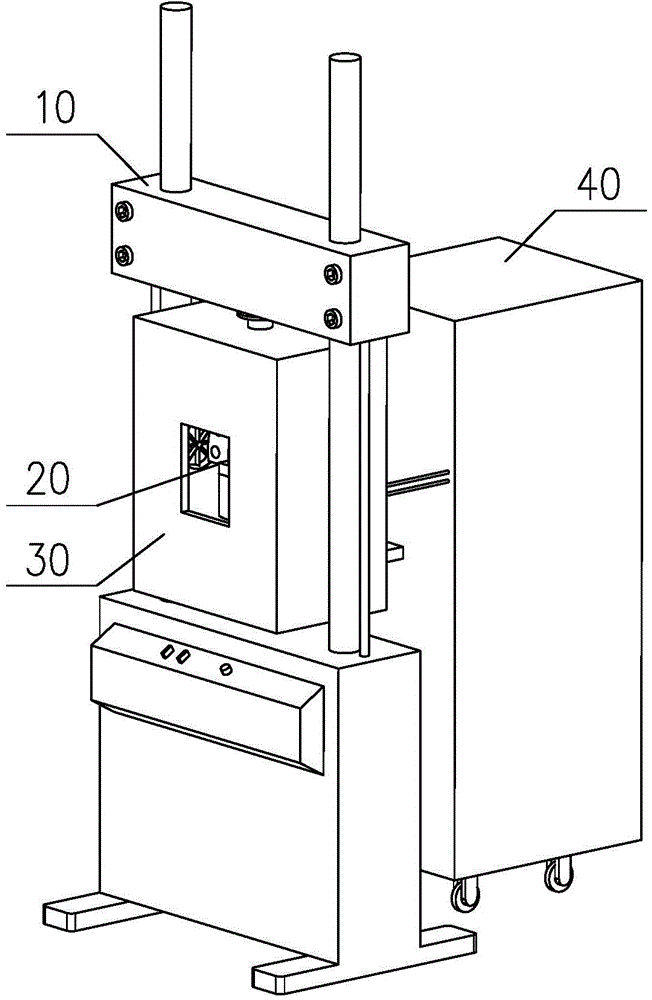

[0044] The multi-axis salt spray corrosion fatigue crack growth test system includes the following components: fatigue testing machine 10, tension-shear-torsion multi-axis loading fixture 20, fatigue crack growth sample 21, salt spray corrosion box 30, salt spray pre-generation case 40, such as Figure 1-8 shown.

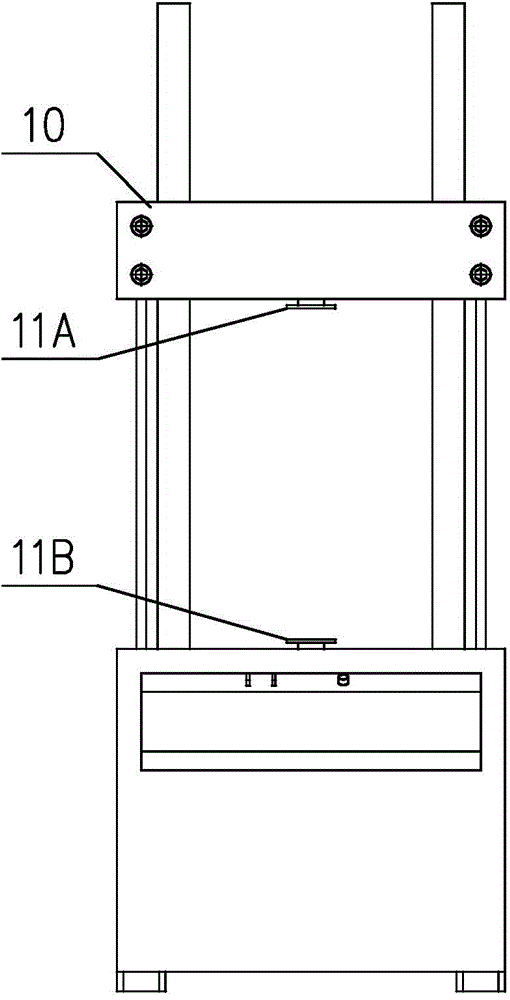

[0045] The fatigue testing machine 10 is provided with an upper flange 11A and a lower flange 11B, which are respectively connected and sealed with the upper bellows 31A and the lower bellows 31B of the salt spray corrosion box 30 , as shown in the following figure: figure 2 shown.

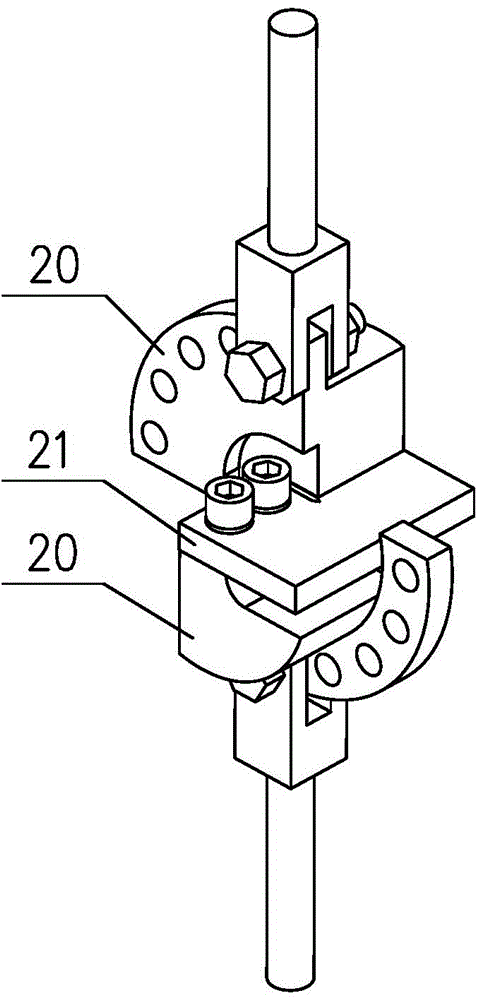

[0046] The tensile-shear-torsion multiaxial loading fixture 20 converts the uniaxial fatigue load provided by the fatigue testing machine 10 into the I-type, II-type, III-type and compound-type fatigue loads required for the test and applies it to the fat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com