Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Inhibition strength decline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

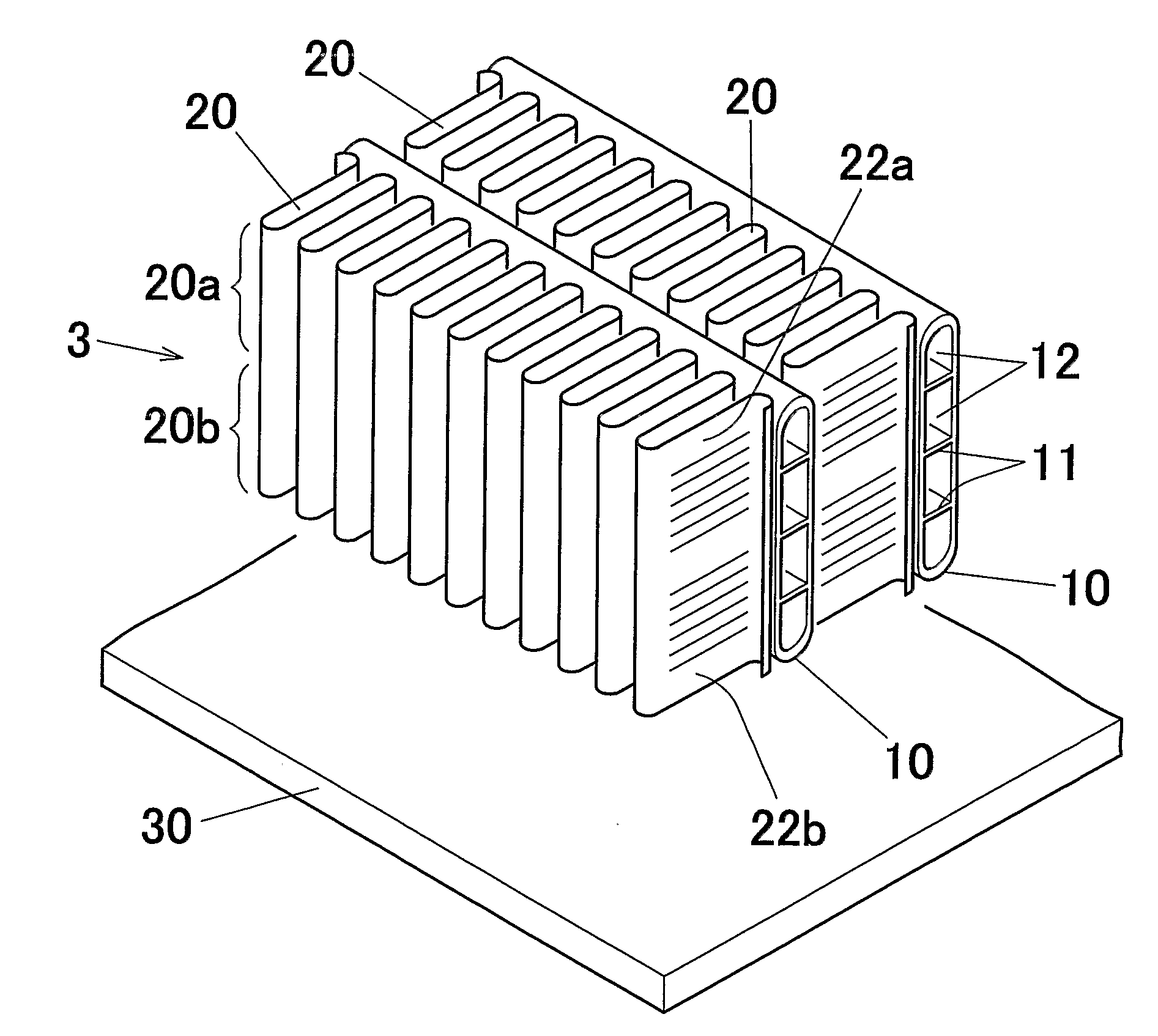

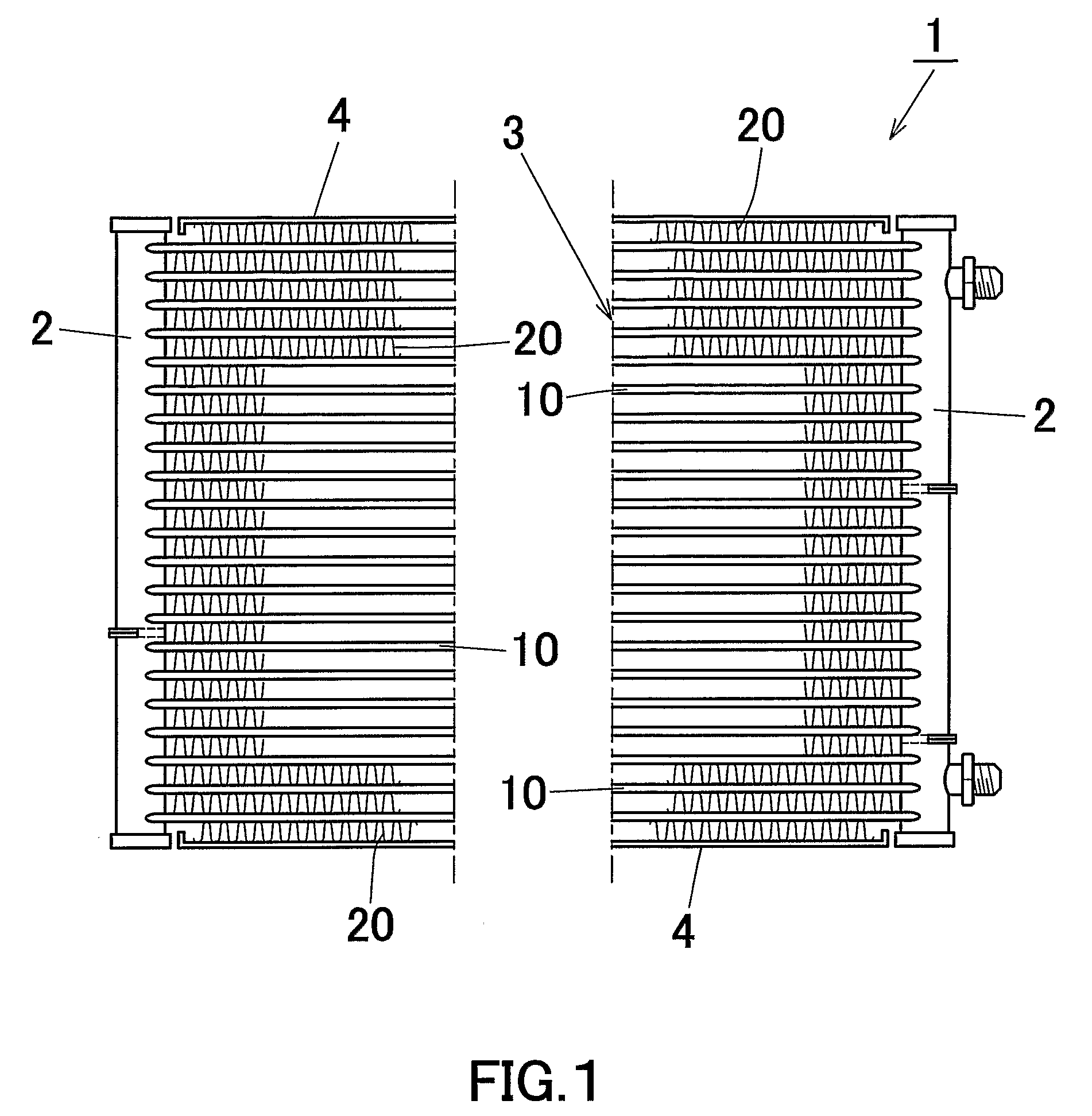

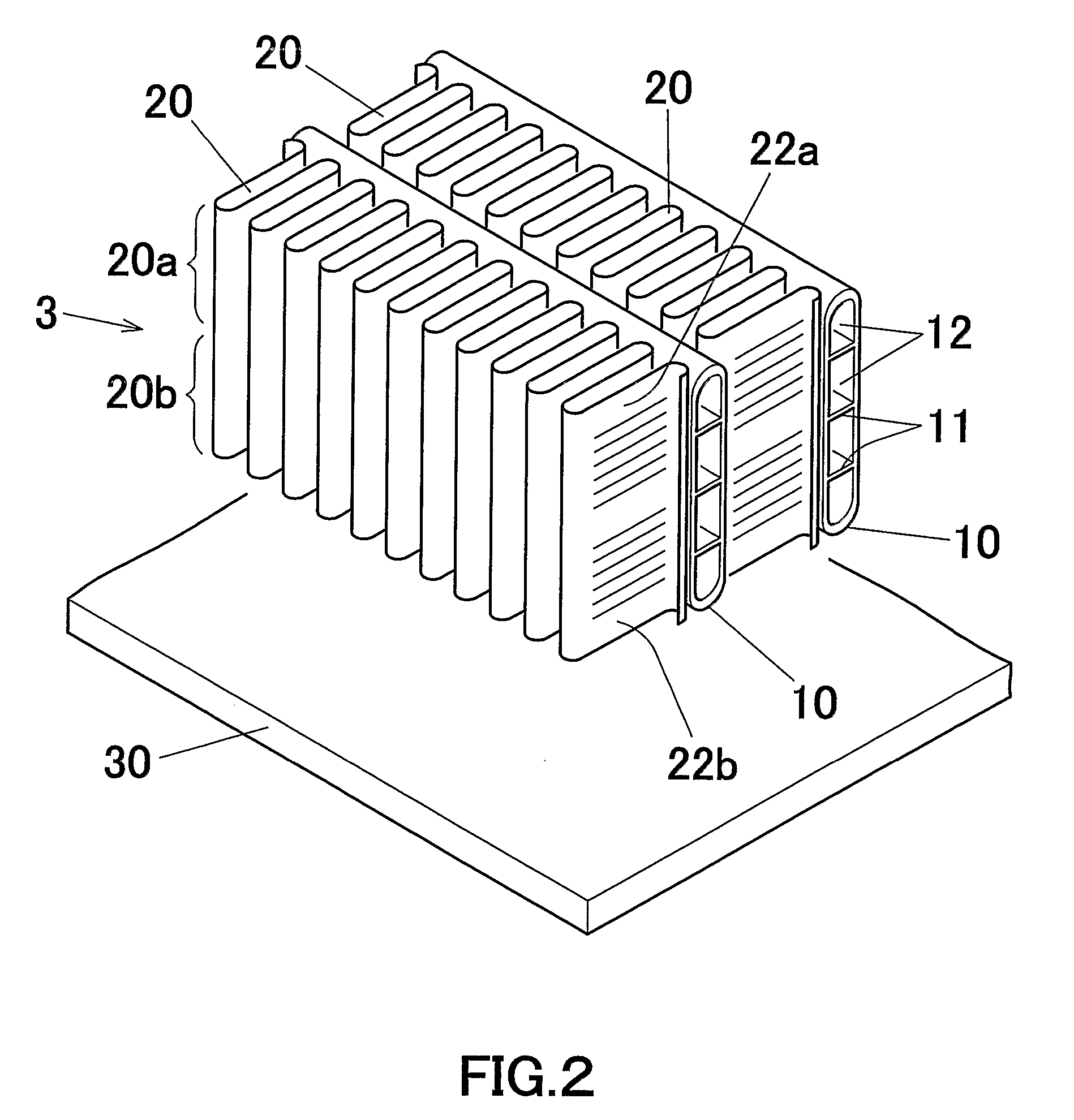

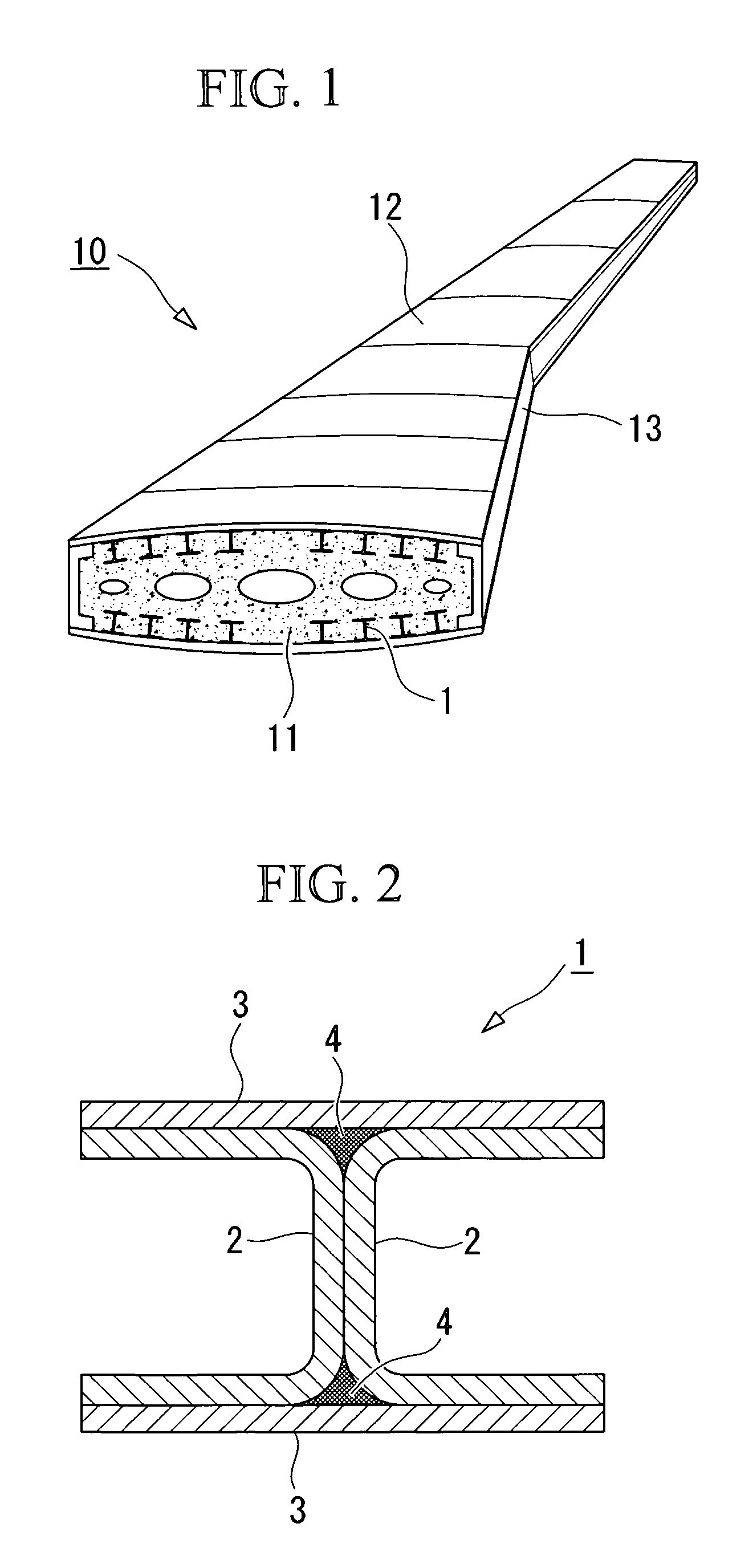

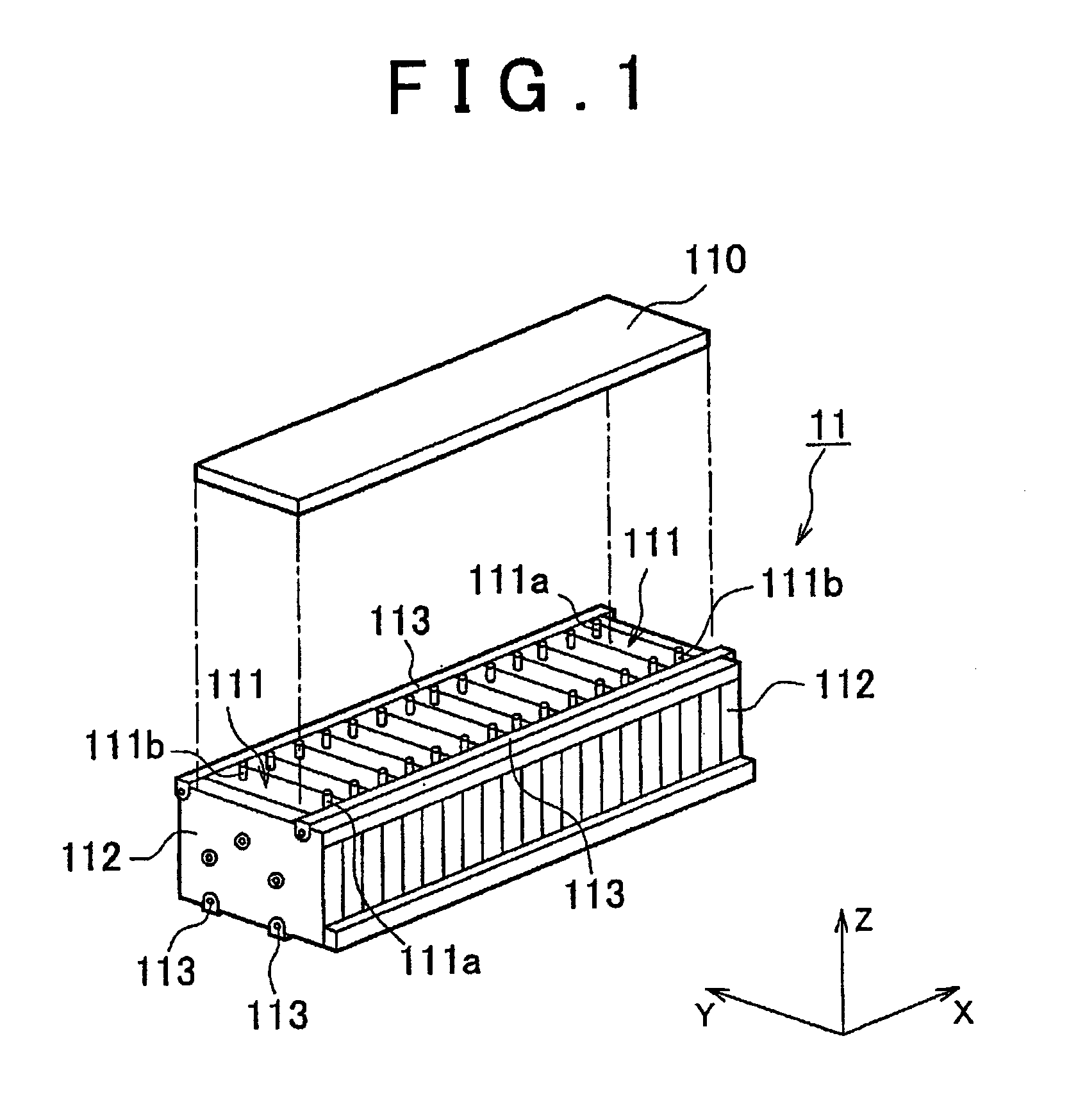

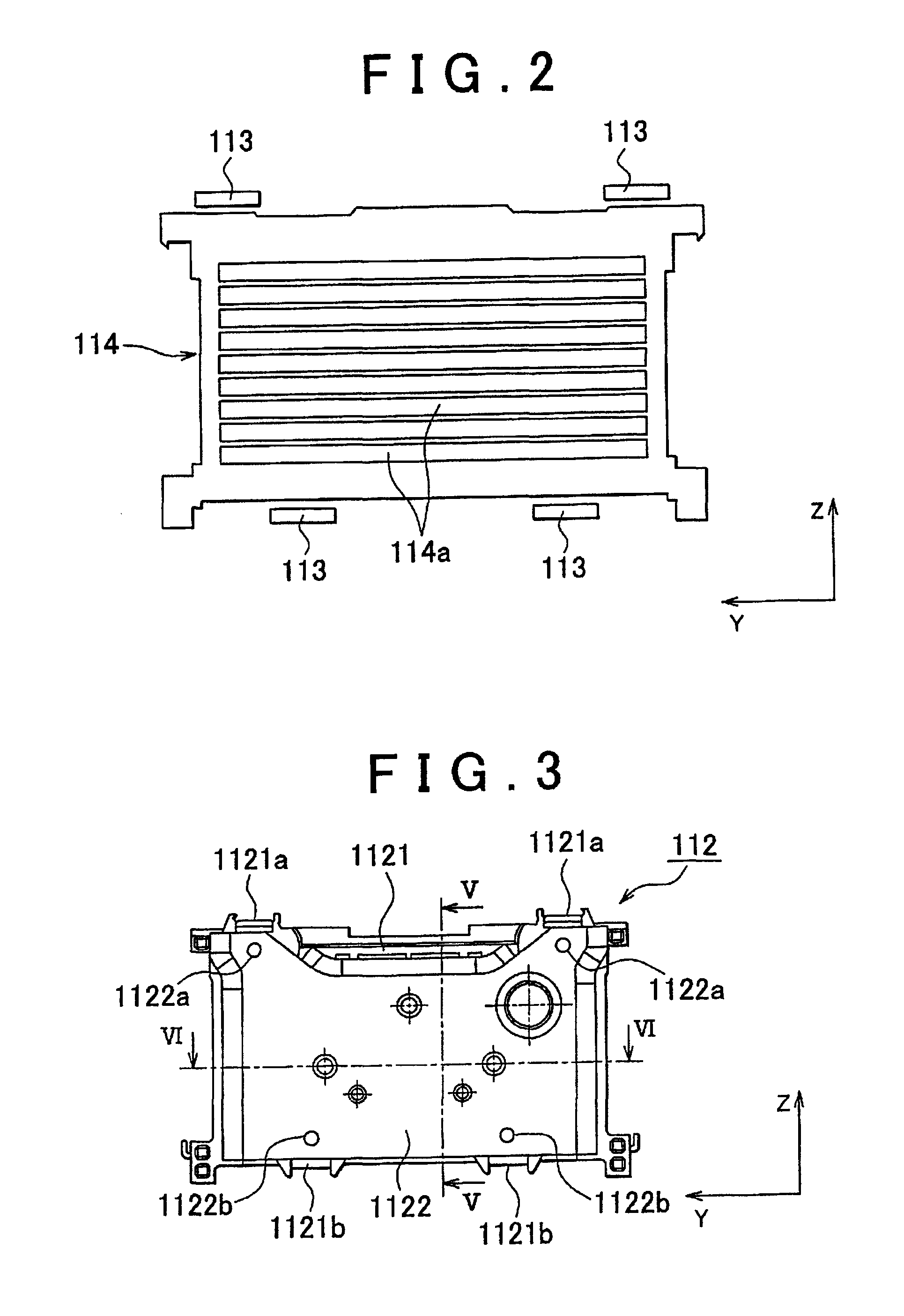

Heat Exchange and Method of Manufacturing the Same

InactiveUS20080041571A1Certain fin strengthReduced strengthSoldering apparatusCorrosion preventionPotential differenceEngineering

In a heat exchanger having a core portion in which aluminum flat tubes and aluminum fins are disposed alternatively and brazed with each other, each fin has one side portion located at one side of the tube and the other side portion located at the other side of the tube. The one side portion of the fin is higher in pitting potential than the other side portion of the fin, and the pitting potential difference between the one side portion of the fin and the other side portion of the fin is 40 to 200 mV. The pitting potential difference can be formed by the Zn concentration difference in the aluminum alloy constituting the fin.

Owner:SHOWA DENKO KK

Oil cooler

InactiveUS20120325446A1Reduced strengthDeterioration of anti-corrosion propertyMountingLaminated elementsEngineeringMechanical engineering

Owner:MAHLE FILTER SYST JAPAN CORP

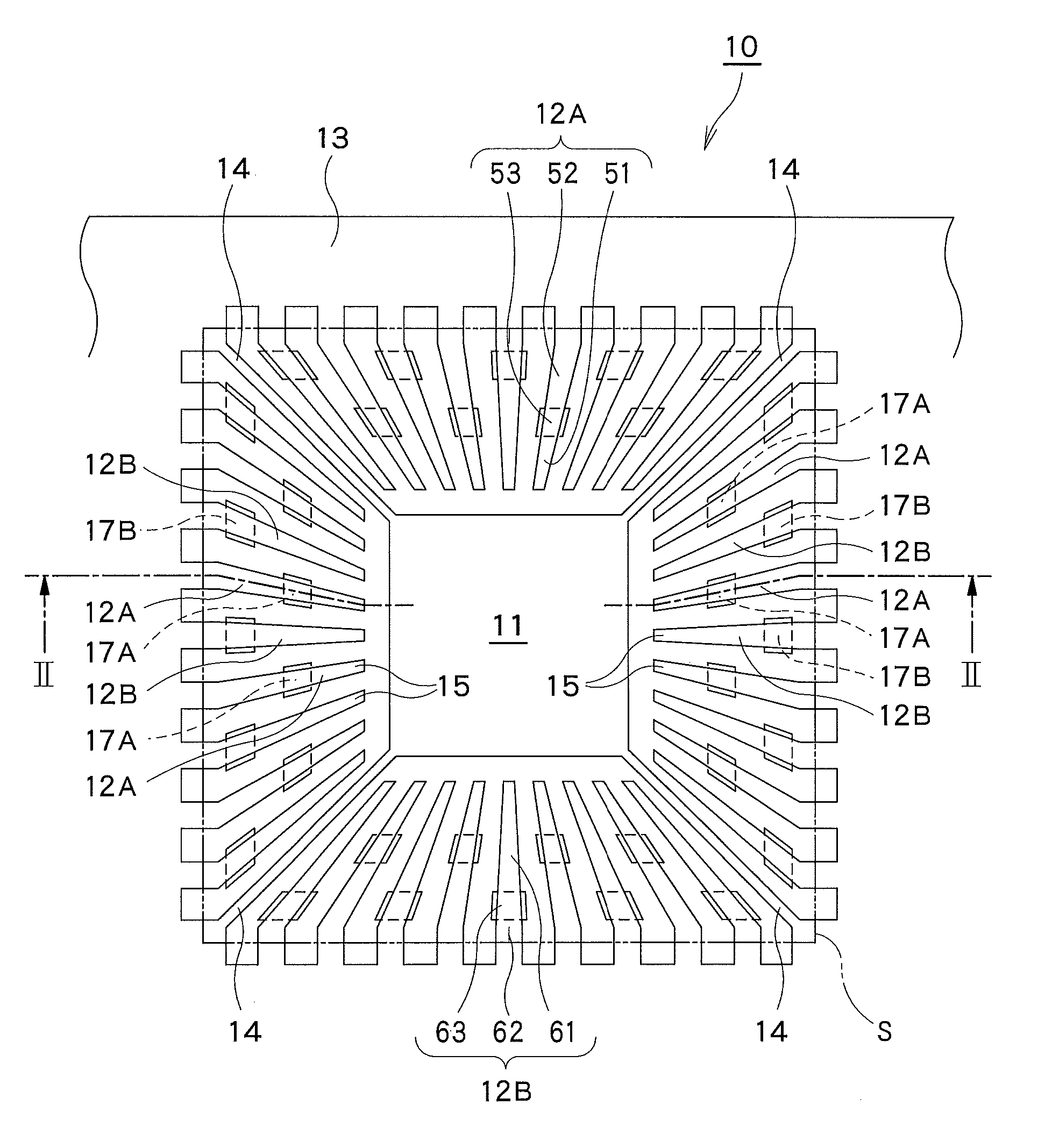

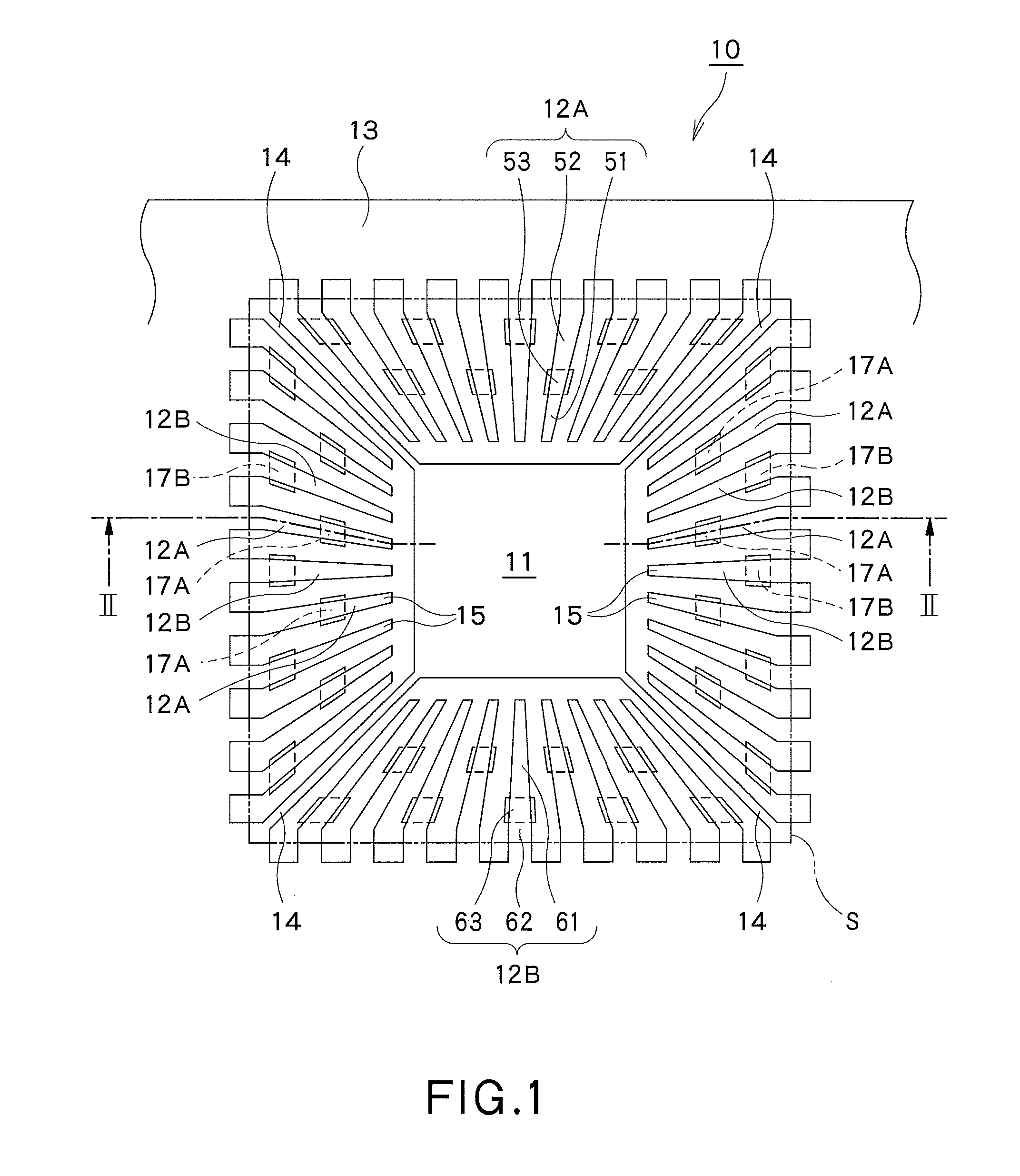

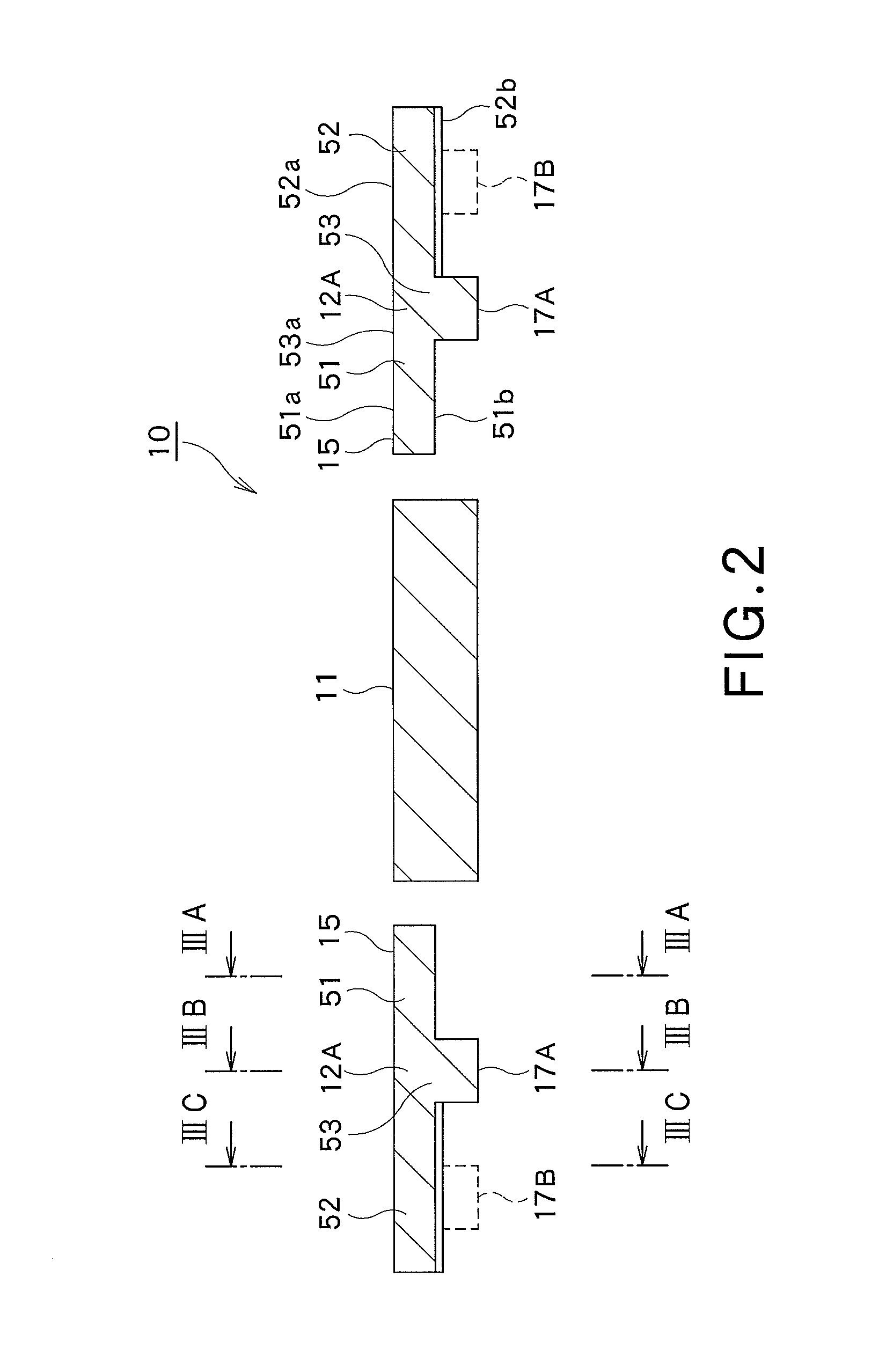

Lead frame, method for manufacturing lead frame, semiconductor device, and method for manufacturing semiconductor device

ActiveUS20140319663A1Small thicknessInhibition strength declineLine/current collector detailsSemiconductor/solid-state device detailsPower semiconductor deviceEtching

A lead frame includes a die pad and a plurality of lead portions each including an internal terminal and an external terminal. The external terminals of the plurality of lead portions are arranged in an alternately staggered form such that the respective external terminals of a pair of lead portions adjacent to each other are alternatively located on an inside or an outside. A lead portion has an inside region located on the inside of a first external terminal, an outside region located on the outside of the first external terminal, and an external terminal region having the first external terminal. The inside region and the outside region are each formed thin by means of half etching. A maximum thickness of the outside region is larger than a maximum thickness of the inside region.

Owner:DAI NIPPON PRINTING CO LTD

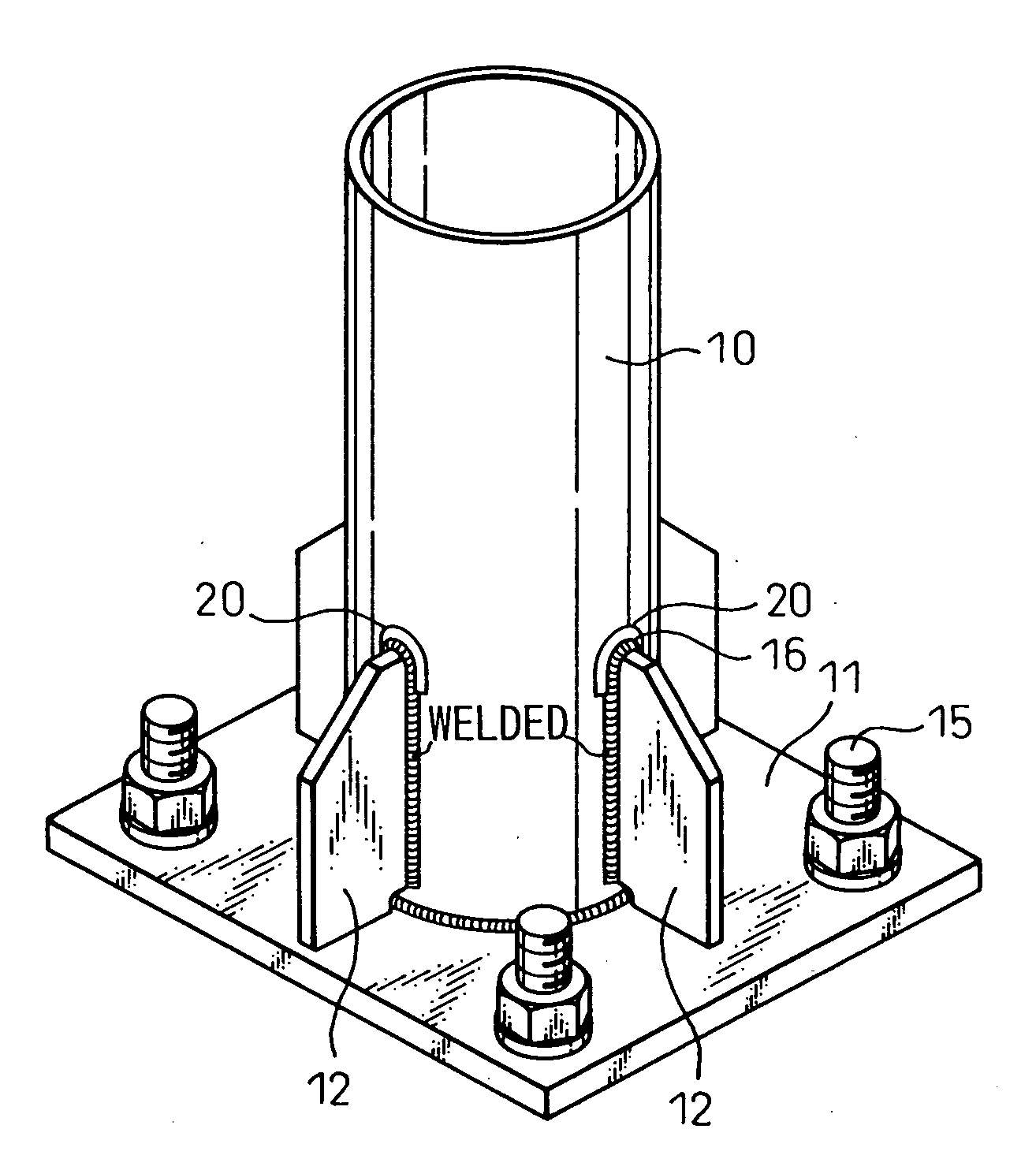

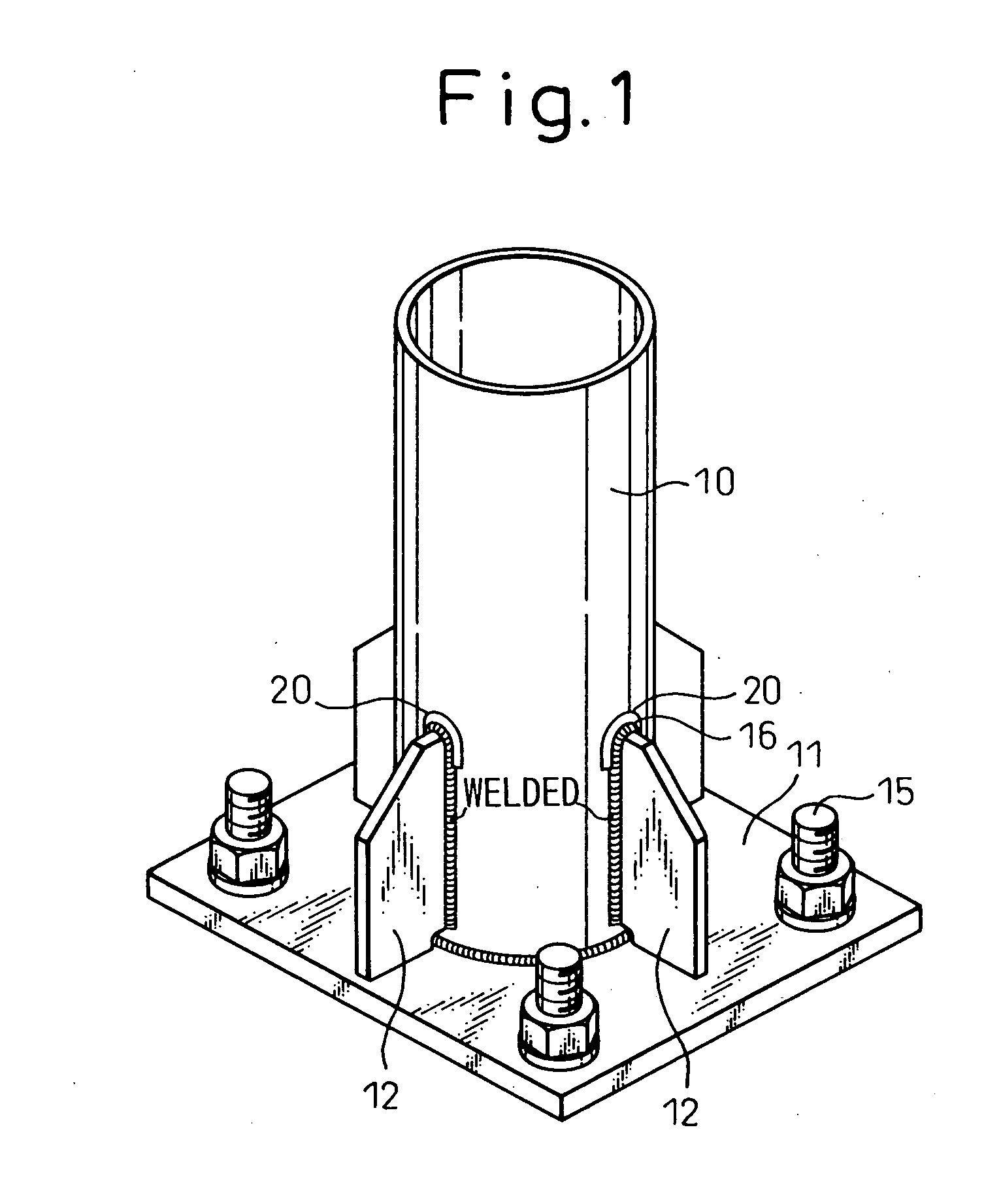

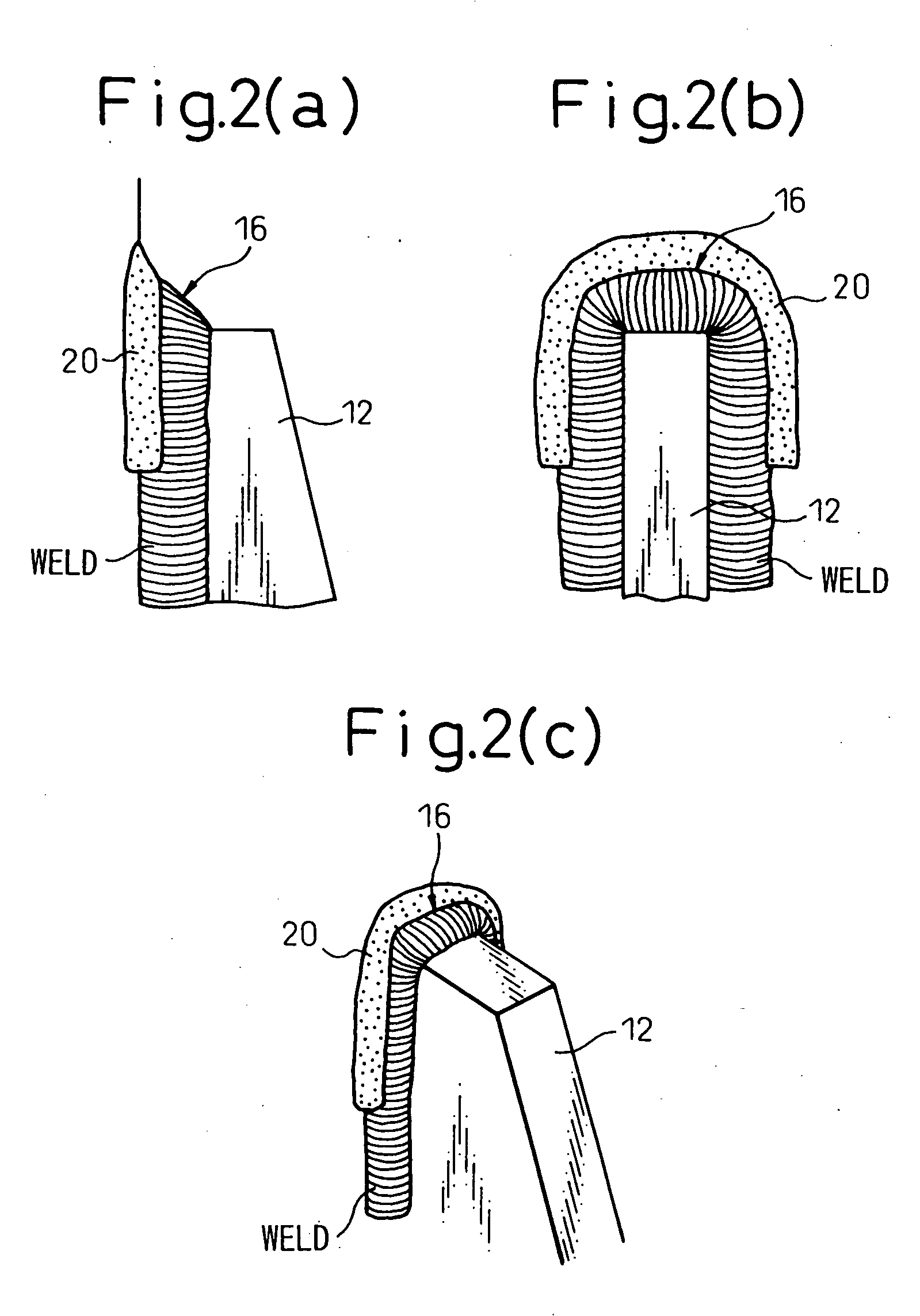

Steel pipe pole base and reinforcing method thereof

InactiveUS20050166485A1High energyRelaxing stress concentrationTowersBulkheads/pilesStress concentrationUltrasonic vibration

The present invention: provides a steel pipe pole base and a method for reinforcing the steel pipe pole base that do not allow the strength to lower in the vicinity of the weld toe of a rib even in the event of applying repeated bending moment; and is characterized by forming peening processed portions 20 by ultrasonic vibration at the weld toes 16 of tabular ribs 12 welded to the base of a steel pipe pole 10 in the form of a T-joint or the weld toes of inverted-U shaped ribs 13 or inverted-V shaped ribs 14, the ribs being bent at the upper end portions, welded to the base of a steel pipe pole 10 in the form of a T-joint. Preferable treatment conditions are 20 to 50 μm in amplitude and 10 to 50 kHz in frequency. In particular, the present invention makes it possible to remarkably improve the fatigue property because stress concentration is relaxed by the synergetic effect of bending the upper end portions 16 of the ribs 13 and applying a peening treatment.

Owner:NIPPON STEEL CORP

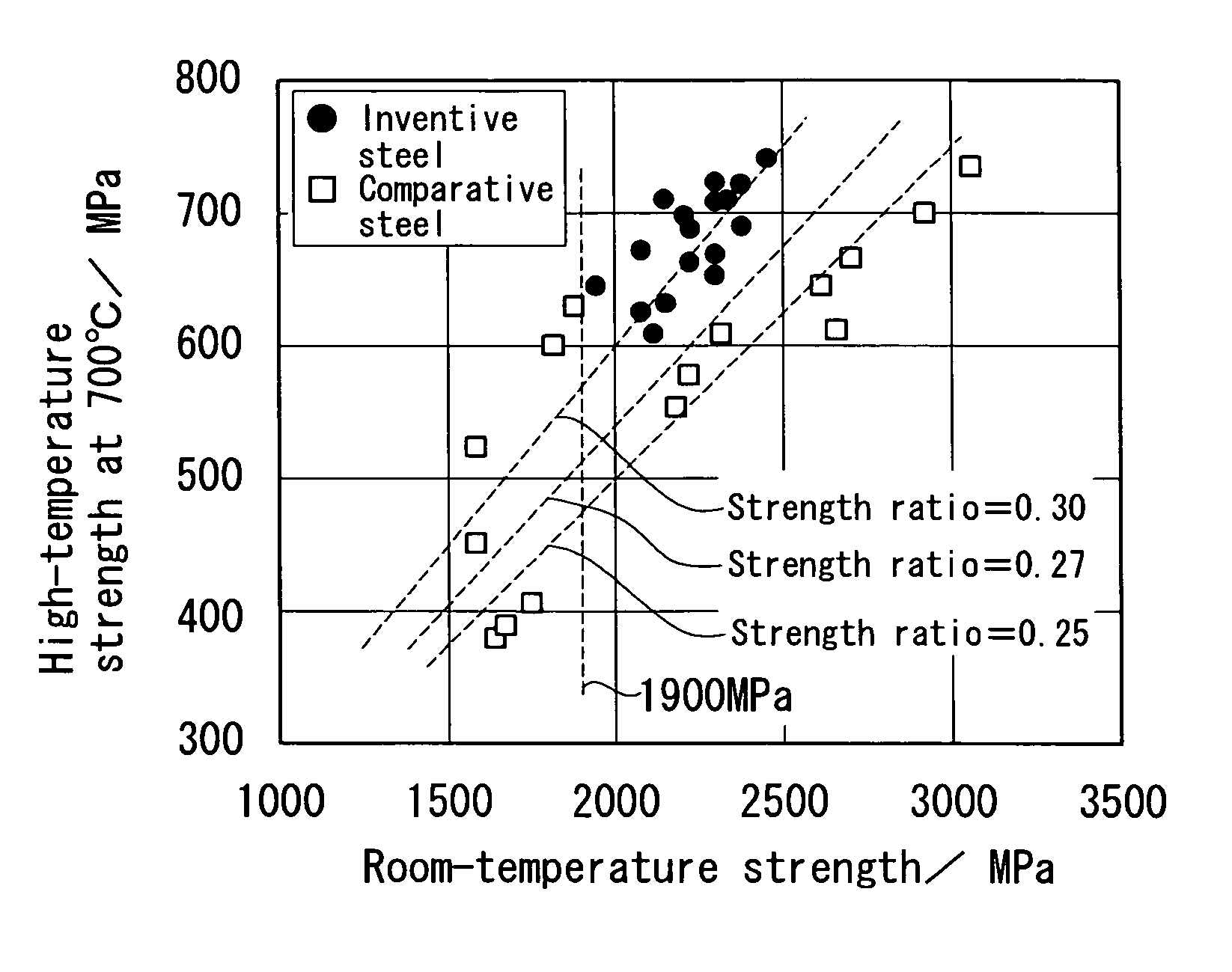

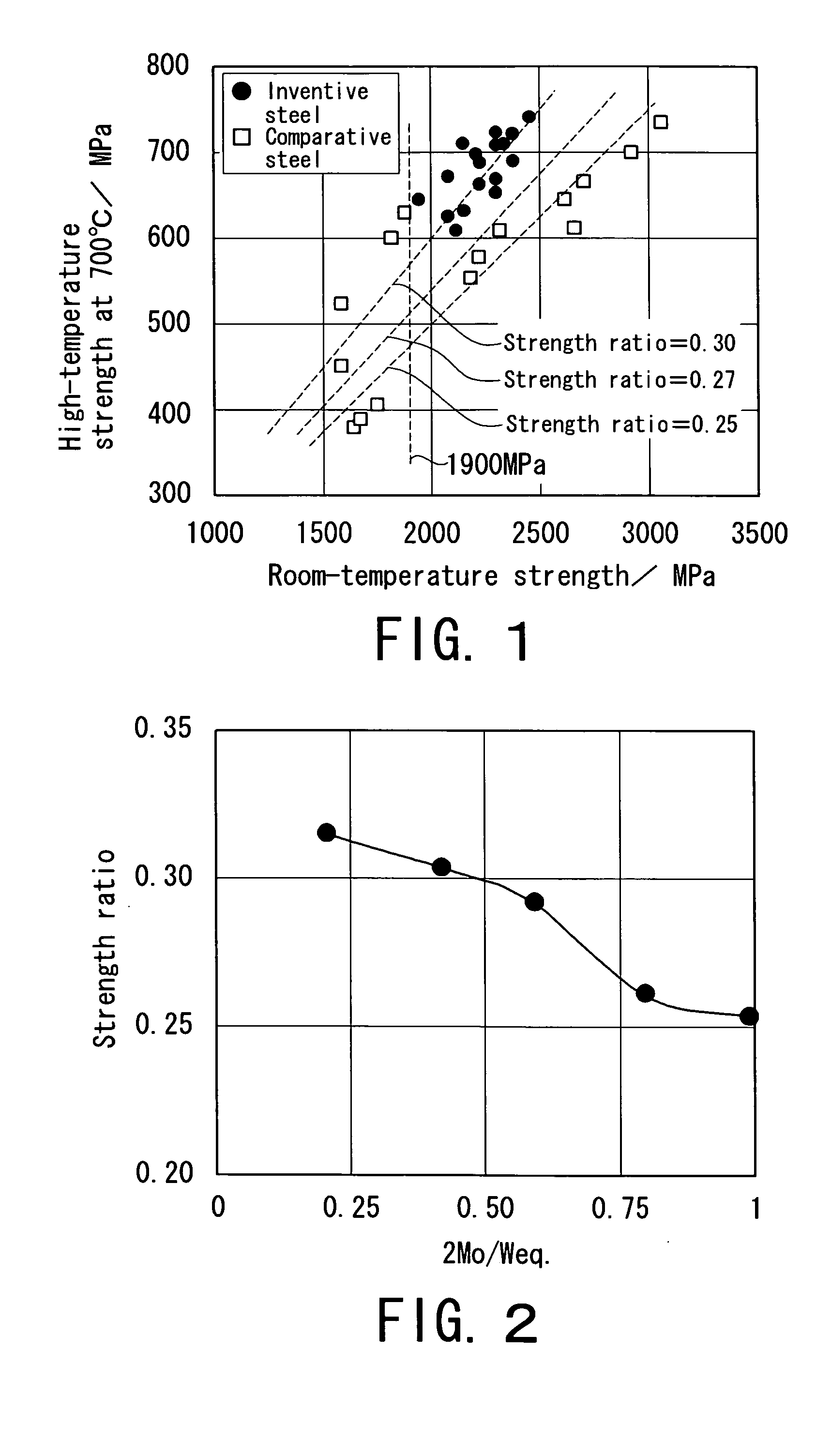

Alloy tool steel

InactiveUS20050161125A1Extended service lifeInhibition strength declineFurnace typesIncreasing energy efficiencyRoom temperatureAlloy

To provide an alloy tool steel having high-temperature strength at an operating temperature of the order of 700° C., while maintaining room-temperature strength as high as that of a conventional matrix high-speed tool steel. The steel contains from 0.45 wt % to 0.65 wt % C, from 0.10 wt % to 1.00 wt % Si, from 0.20 wt % to 2.00 wt % Mn, not more than 0.020 wt % P, not more than 0.015 wt % S, not more than 1.00 wt % Cu, not more than 1.00 wt % Ni, from 3.50 wt % to 5.00 wt % Cr, from 0.00 wt % to 3.00 wt % Mo, from 0.00 wt % to 10.00 wt % W, from 1.00 wt % to 2.00 wt % V, from 0.00 wt % to 8.00 wt % Co, not more than 0.10 wt % Al, not more than 0.01 wt % O, not more than 0.02 wt % N, and the balance substantially constituted of Fe and unavoidable impurities, in which Weq is from 2.0 to 10.0, 2Mo / Weq is not more than 0.60, and ΔC is from −0.3 to 0.0.

Owner:DAIDO STEEL CO LTD

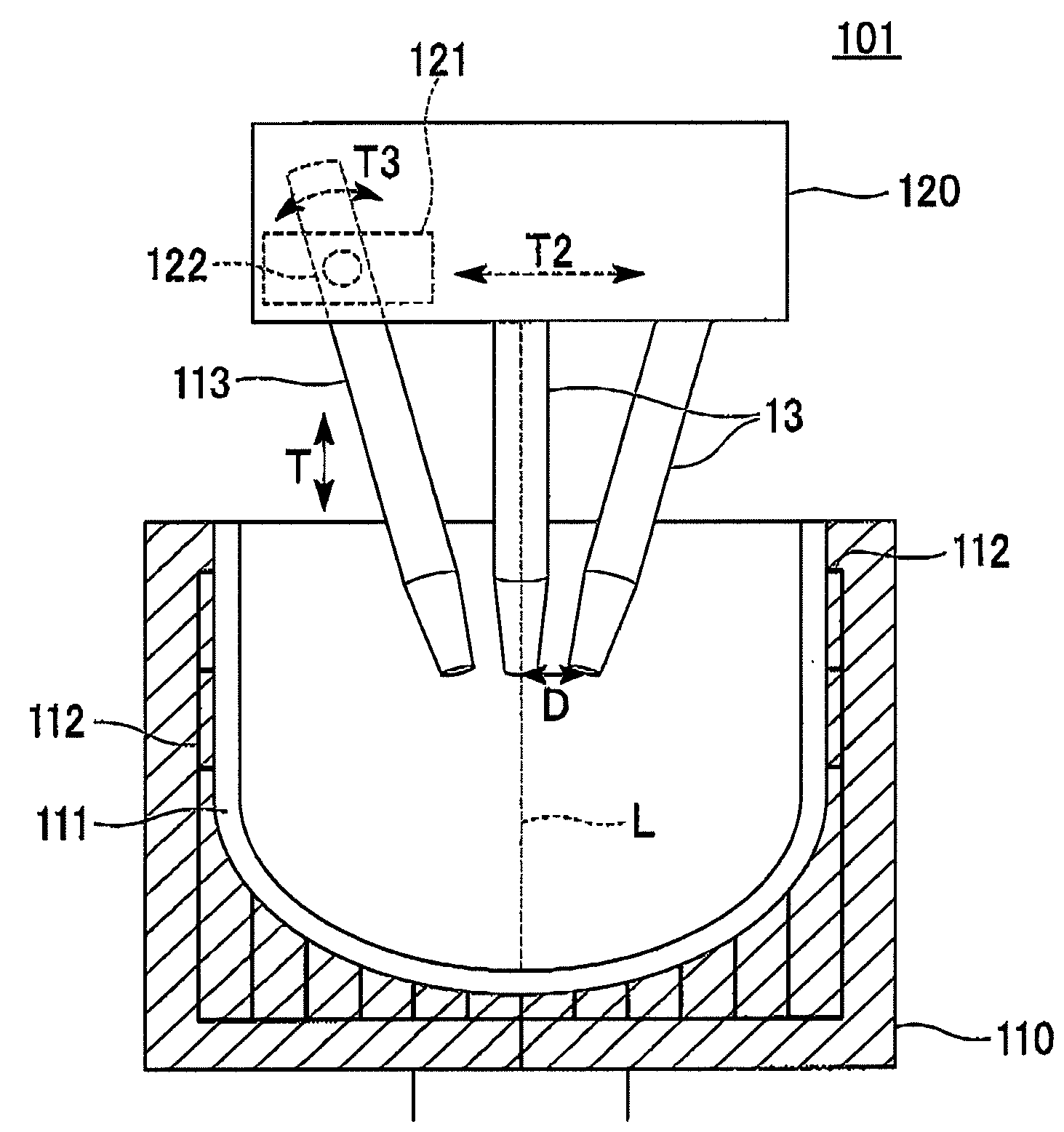

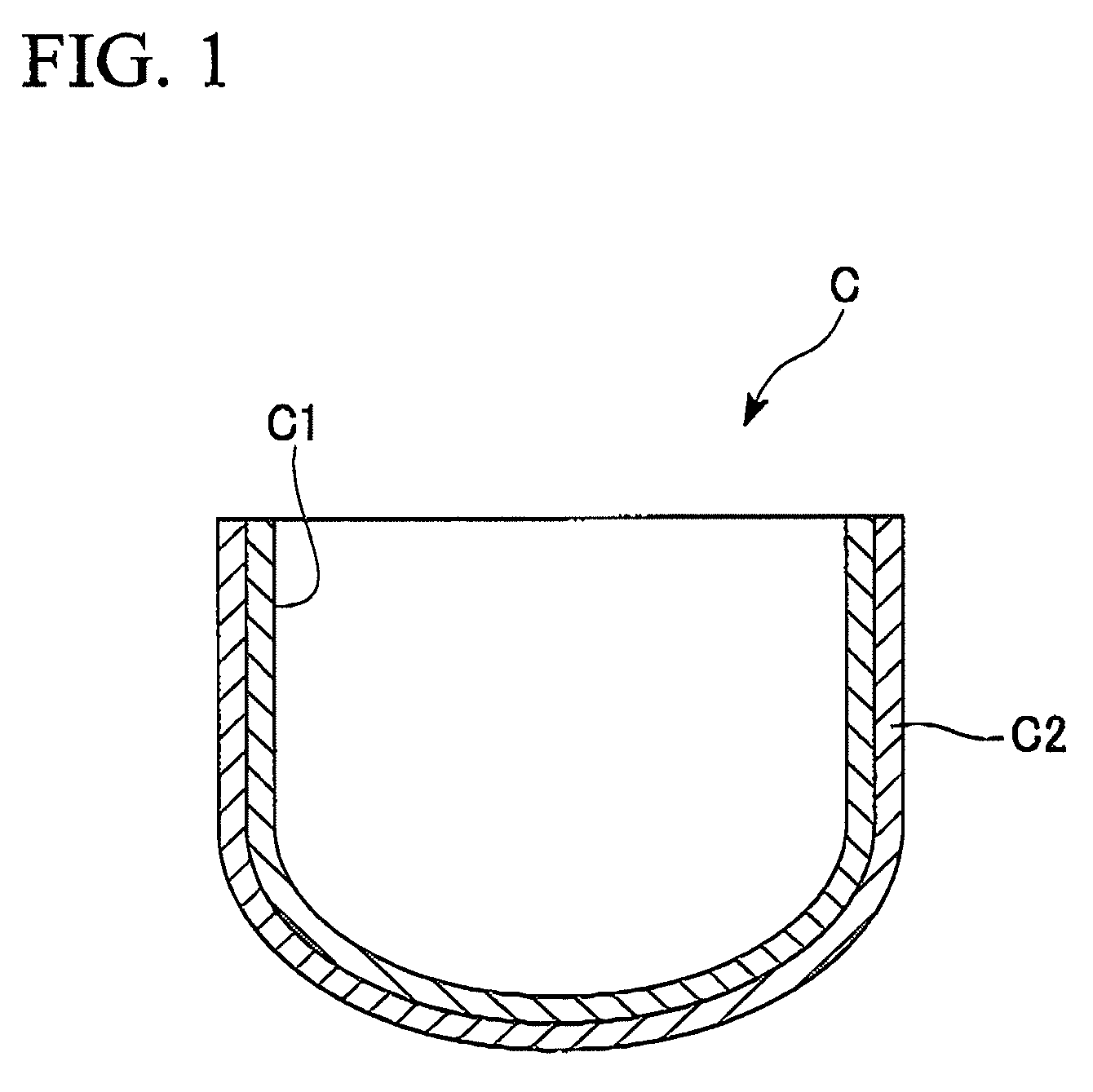

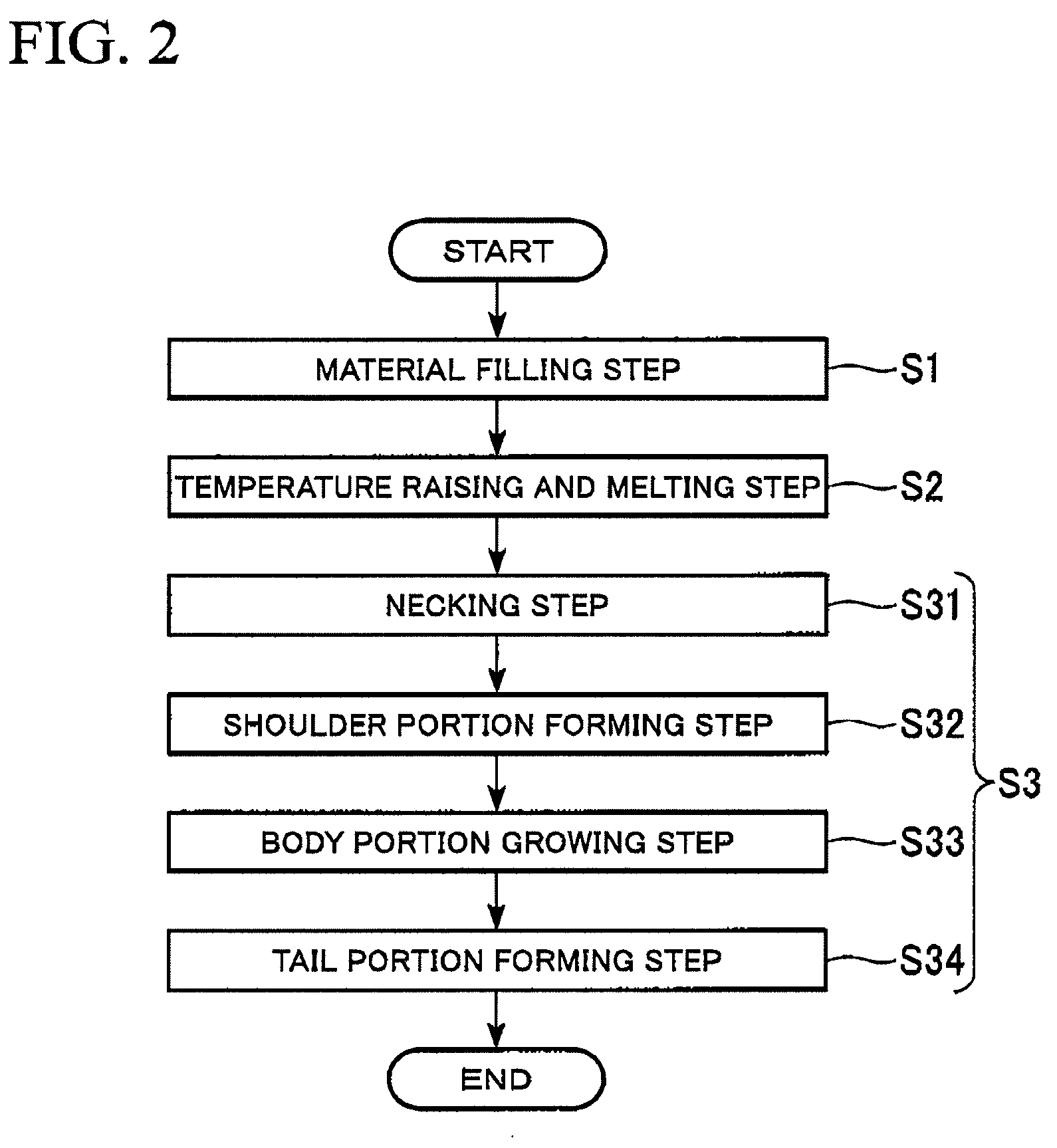

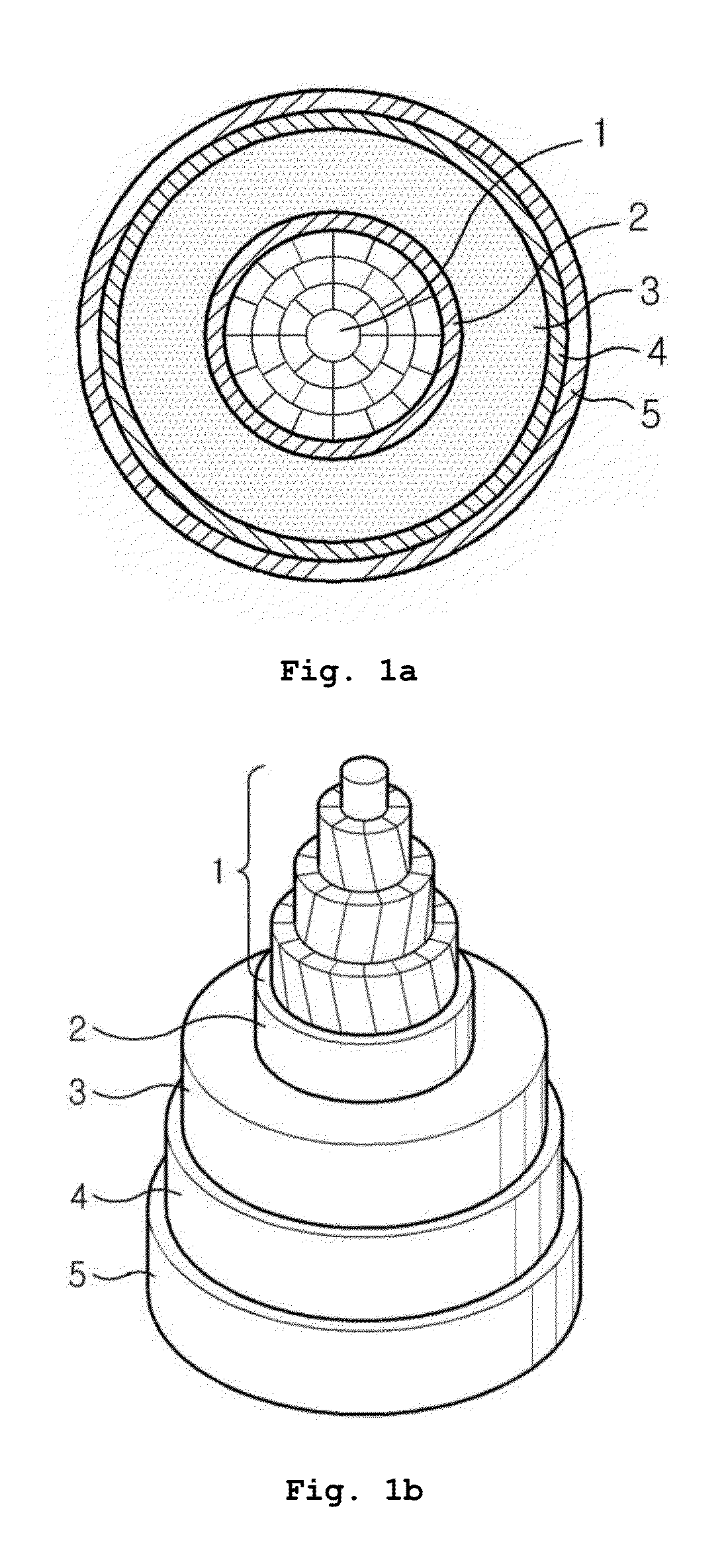

Vitreous silica crucible

InactiveUS20090145351A1Increase productionInhibition strength declinePolycrystalline material growthBy pulling from meltCrucibleSingle crystal

The present invention relates to a vitreous silica crucible for pulling up silicon single crystals by a pulling-up process having a first stage and a second stage after the first stage. The crucible comprises a transparent inner layer containing inner layer bubbles, and an outer layer containing outer layer bubbles. The second stage expansion coefficient X2 of the inner-layer bubbles during the second stage is set to ⅓ or less of the first stage expansion coefficient X1 of the inner-layer bubbles during the first stage.

Owner:JAPAN SUPER QUARTZ CORP

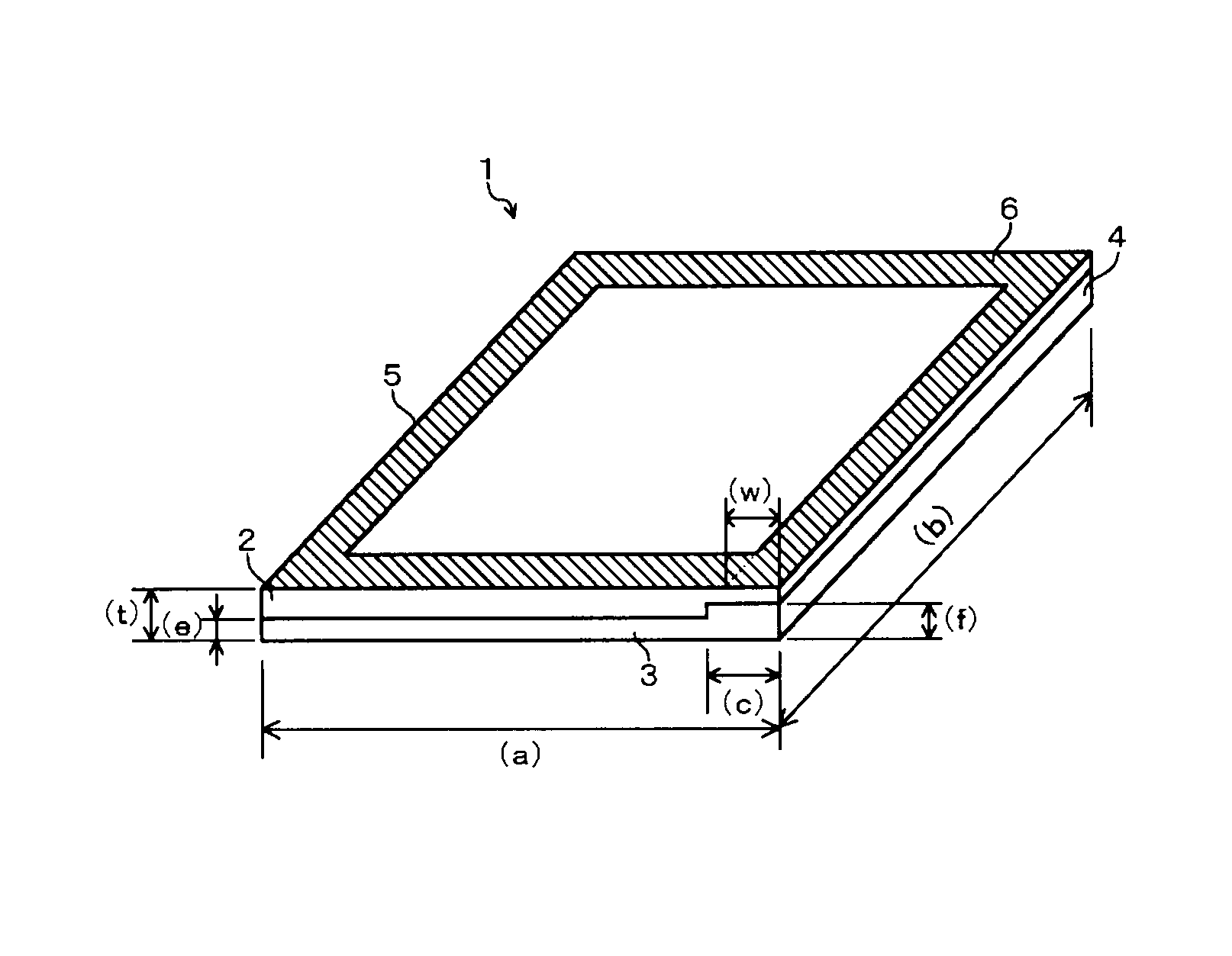

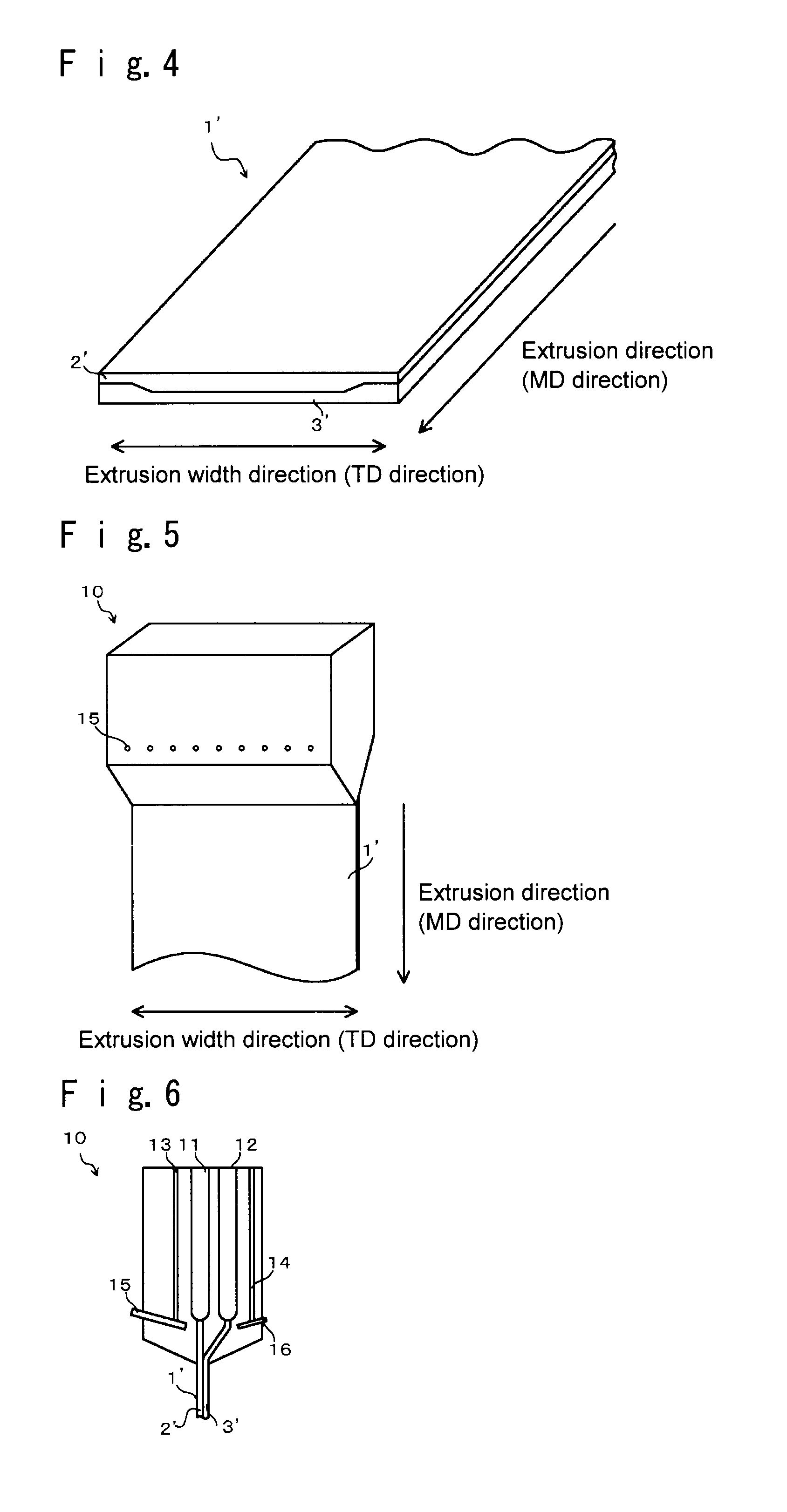

Cation exchange membrane, production process thereof and electrolytic cell using the same

ActiveUS8349155B2Suppress deterioration of strength of membraneLow costTurning machine accessoriesFinal product manufactureFluoropolymerTotal thickness

A cation exchange membrane which shows suppressed deterioration of the strength of the membrane in the upper portion of an electrolytic cell when the membrane is employed in the electrolytic cell and used for a long term, which can perform electrolysis with good production efficiency, and which can be produced simply with low cost; its production process and; such an electrolytic cell; are provided.A cation exchange membrane to be used for an electrolytic cell, which has a laminate structure comprising a first layer containing a fluoropolymer having sulfonic groups and a second layer containing a fluoropolymer having carboxylic groups and adjacent to the first layer, and which has a rectangular shape with a constant thickness;wherein the cation exchange membrane has an attachment region along one (or each) of opposed sides of the cation exchange membrane and a main region other than the attachment region;the value of the ratio (the thickness of the second layer) / (the total thickness of the first and second layers) in the attachment region is larger than the value of the ratio in the main region. Further, its production process and an electrolytic cell to which the cation exchange membrane is attached.

Owner:AGC INC

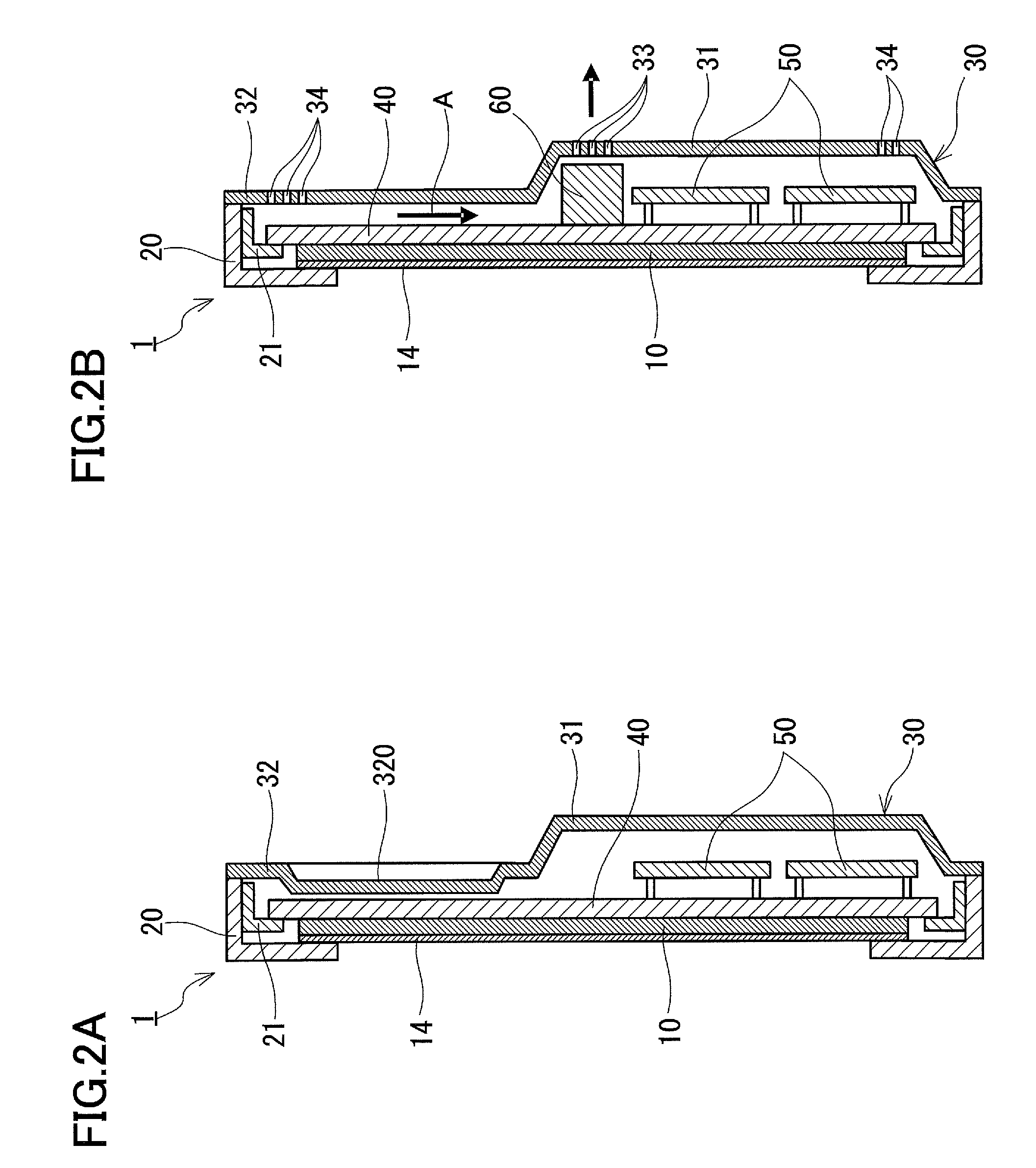

Image display device

InactiveUS20110063532A1Reduce thicknessHigh strengthTelevision system detailsCasings/cabinets/drawers detailsDisplay deviceChassis

The image display device is provided with a panel for displaying images, a chassis supporting the display panel on its front surface, circuit boards arranged within a specific region of the back surface of the chassis, and a back cover having an edge portion that covers the outside of the specific region of the back surface of the chassis, and a projecting portion that projects inside the edge portion toward the side opposite to the chassis and that accommodates the circuit boards. The edge portion has a plurality of drawn portions extending toward a particular direction.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

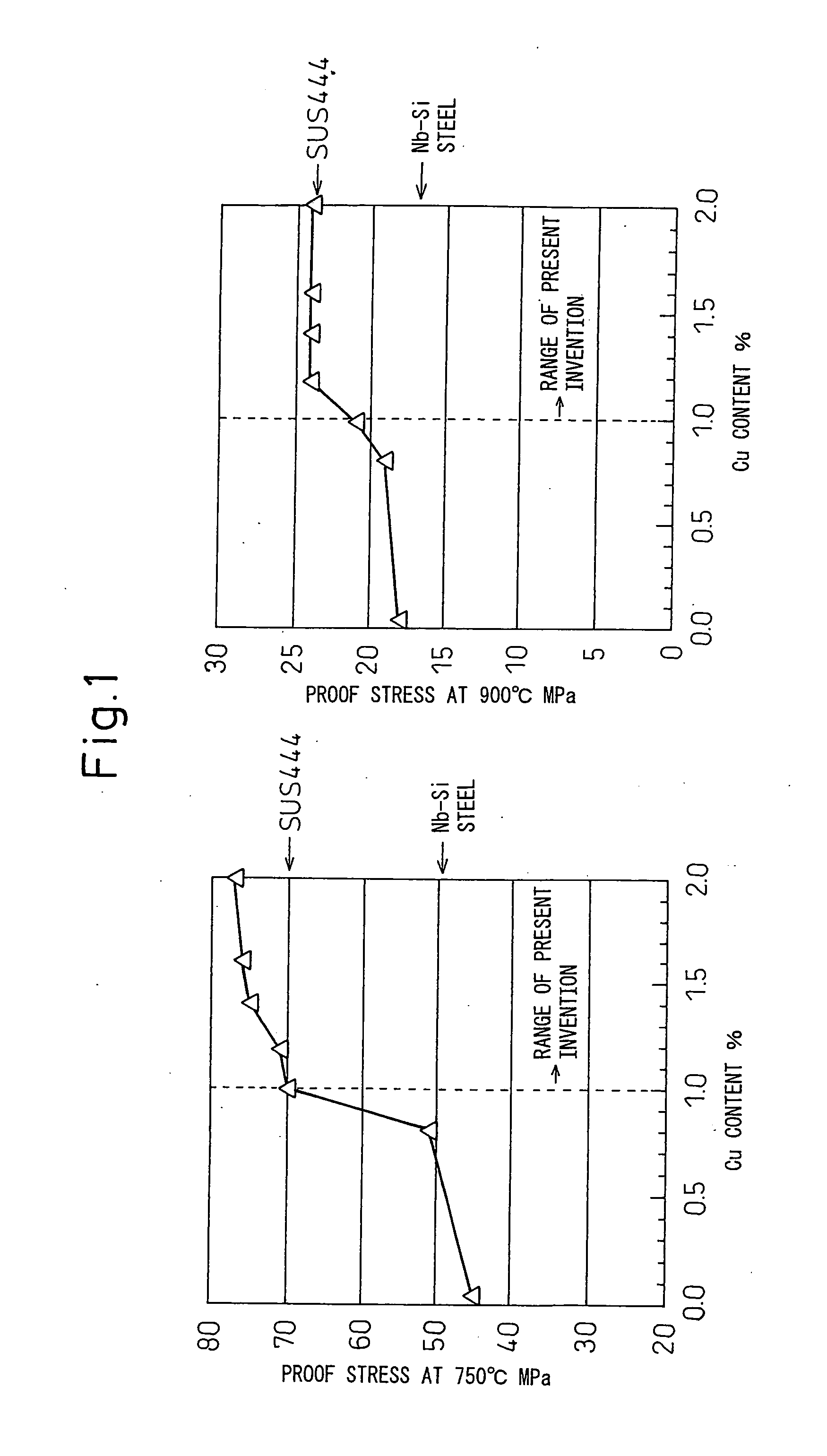

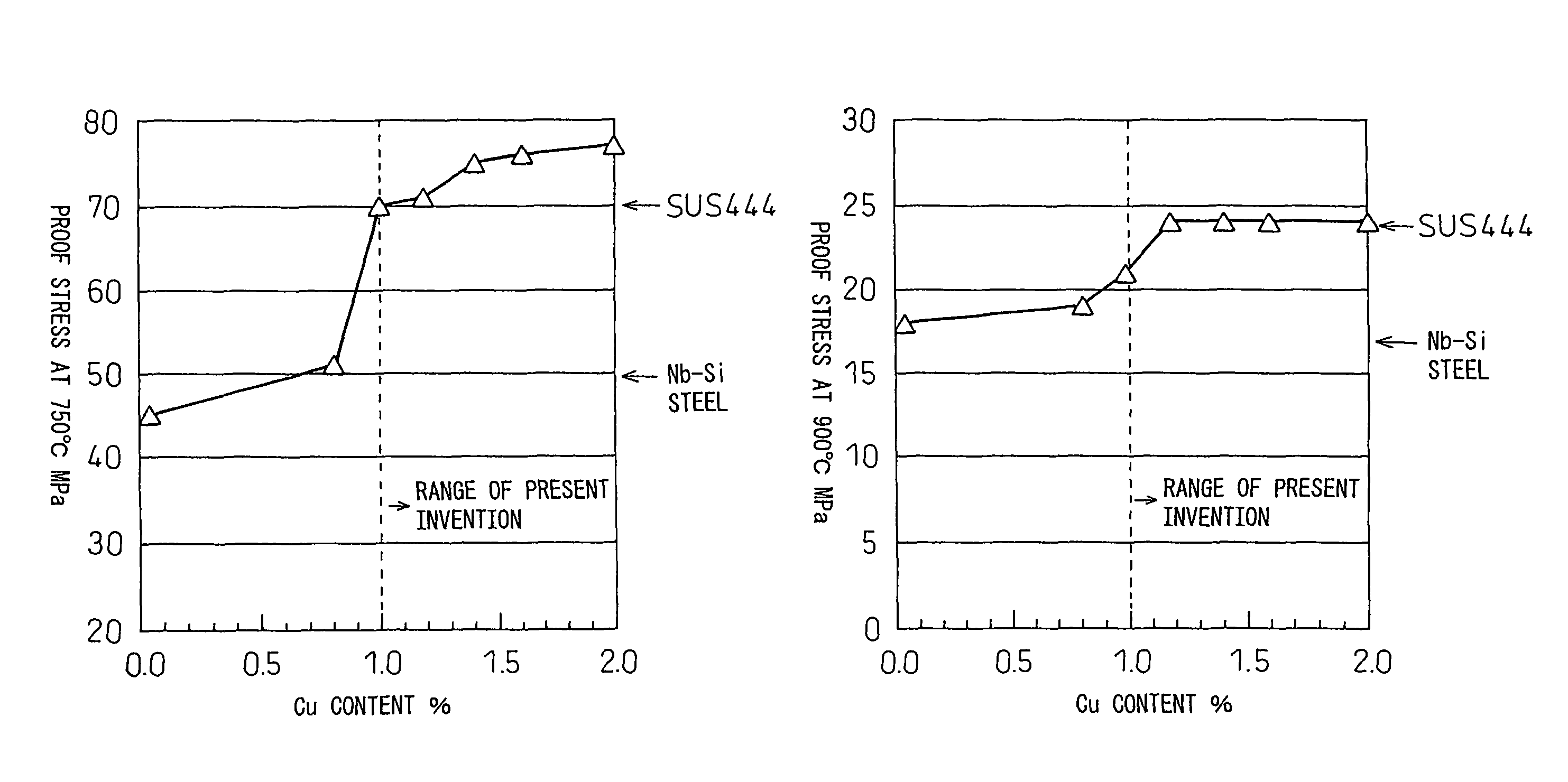

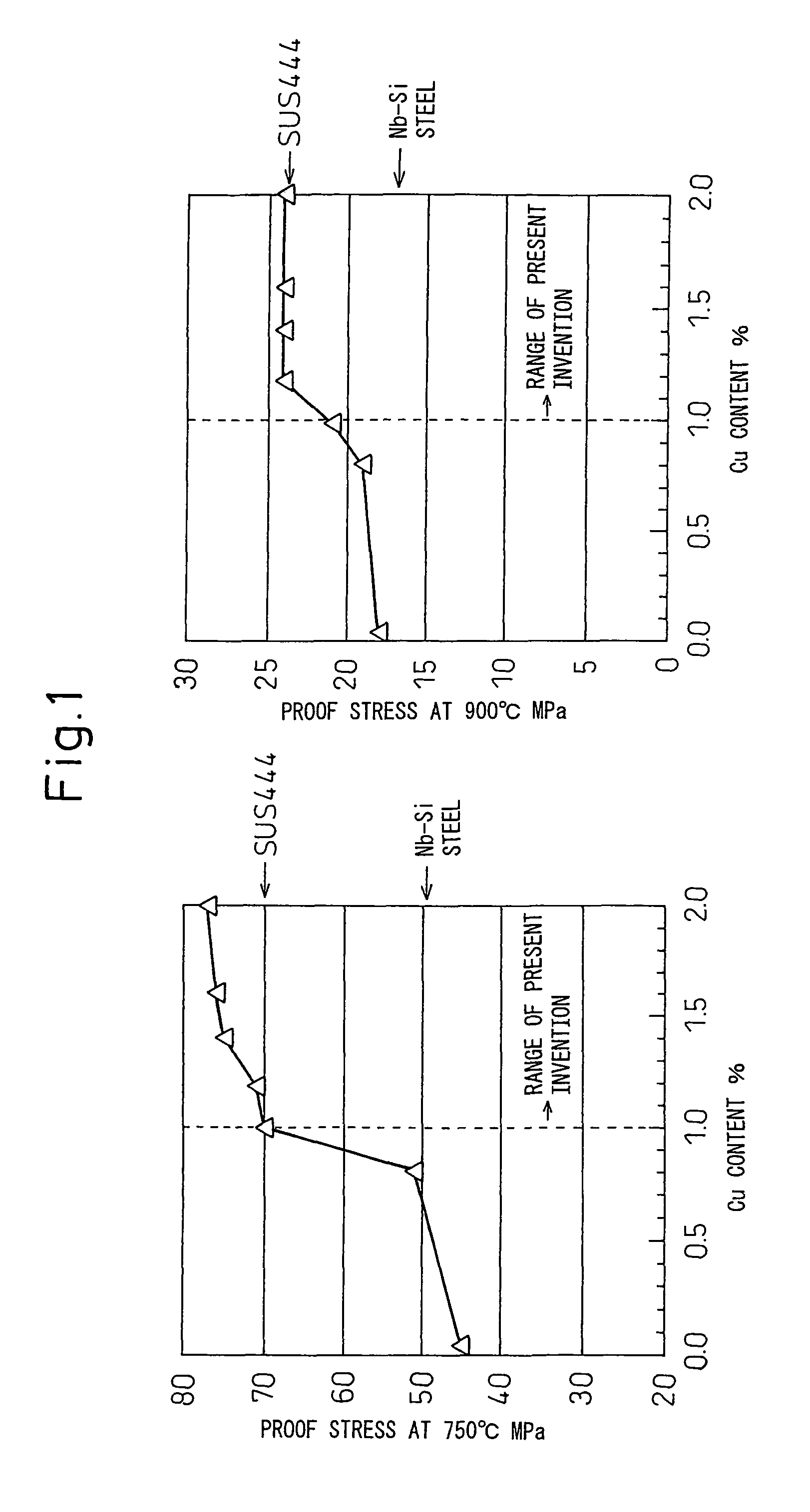

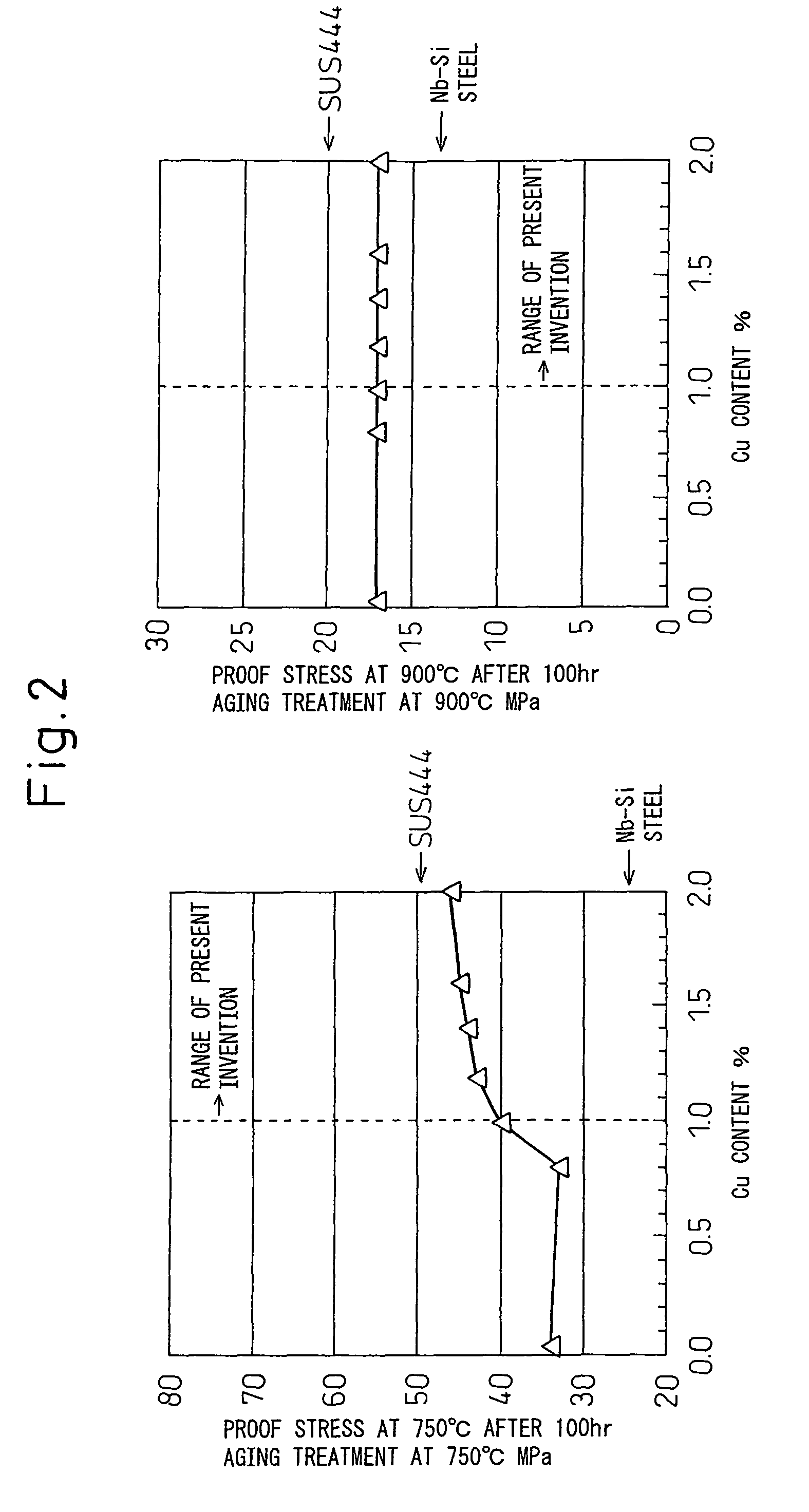

Ferritic Stainless Steel Sheet Superior in Heat Resistance

ActiveUS20090092513A1Suppression of drop in strengthSuppression problemExhaust apparatusSilencing apparatusMetallurgyHeat resistance

The present invention provides, as a material superior in heat resistance in a hot environment where the maximum temperature of the exhaust gas becomes 750 to 900° C., ferritic stainless steel sheet superior in heat resistance in a broad temperature region of 750 to 900° C. with long term stability by a smaller amount of addition of Mo than SUS444 containing about 2% of expensive Mo, that is, ferritic stainless steel sheet superior in heat resistance characterized by containing, by mass %, C: 0.01% or less, N: 0.02% or less, Si: 0.05 to 1%, Mn: 0.1 to 2%, Cr: 10 to 30%, Mo: 0.1 to 1%, Cu: 1 to 2%, Nb: 0.2 to 0.7%, Ti: 0.01 to 0.3%, and B: 0.0002 to 0.0050%, having a balance of Fe and unavoidable impurities, and having a 0.2% yield strength at 750° C. of 70 MPa or more.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

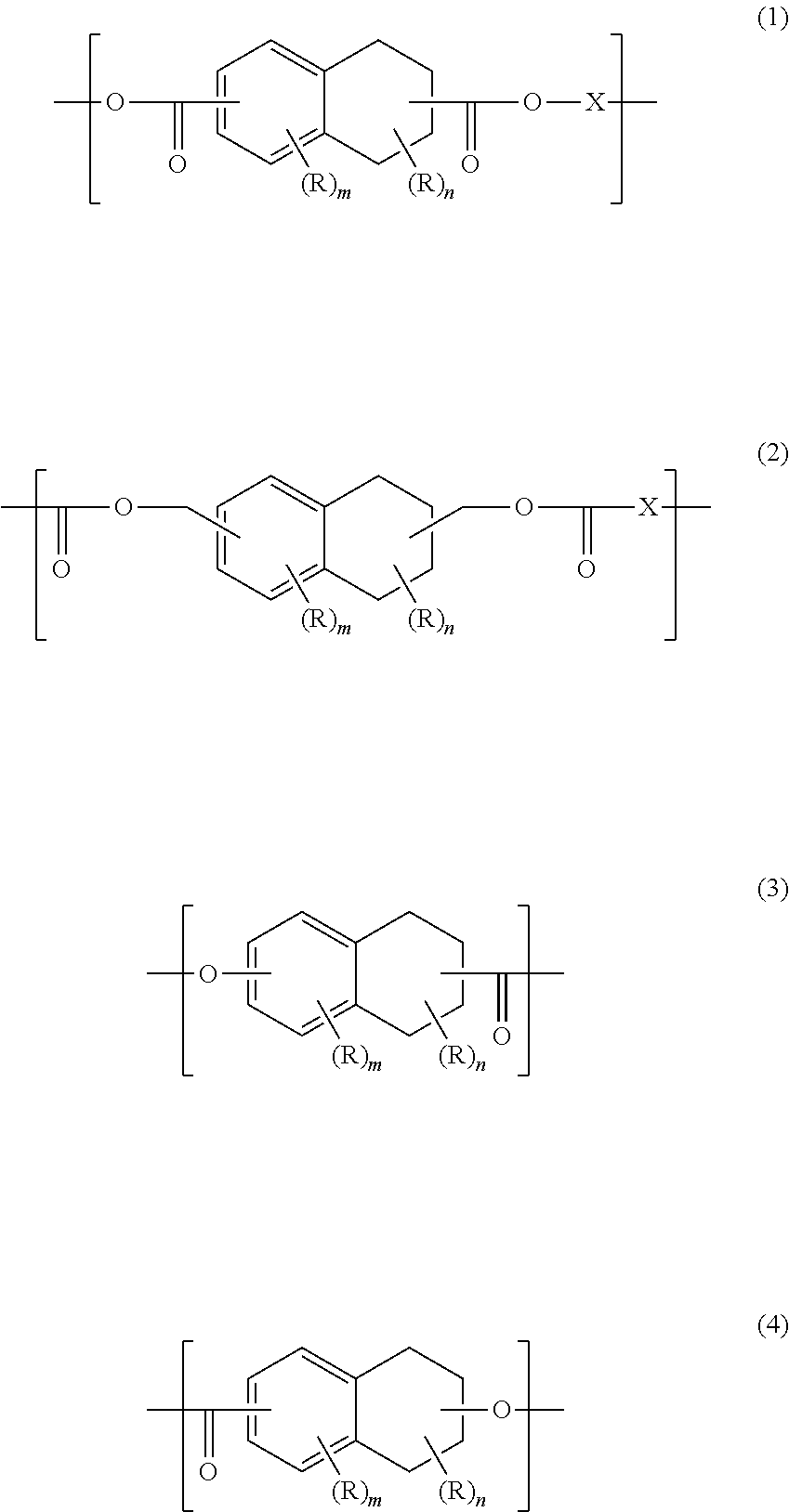

Oxygen-absorbing resin composition and oxygen-absorbing multilayer injection-molded article and oxygen-absorbing multilayer container using same

ActiveUS20160017092A1Improve performanceHigh strengthBottlesSynthetic resin layered productsPolyesterPolymer chemistry

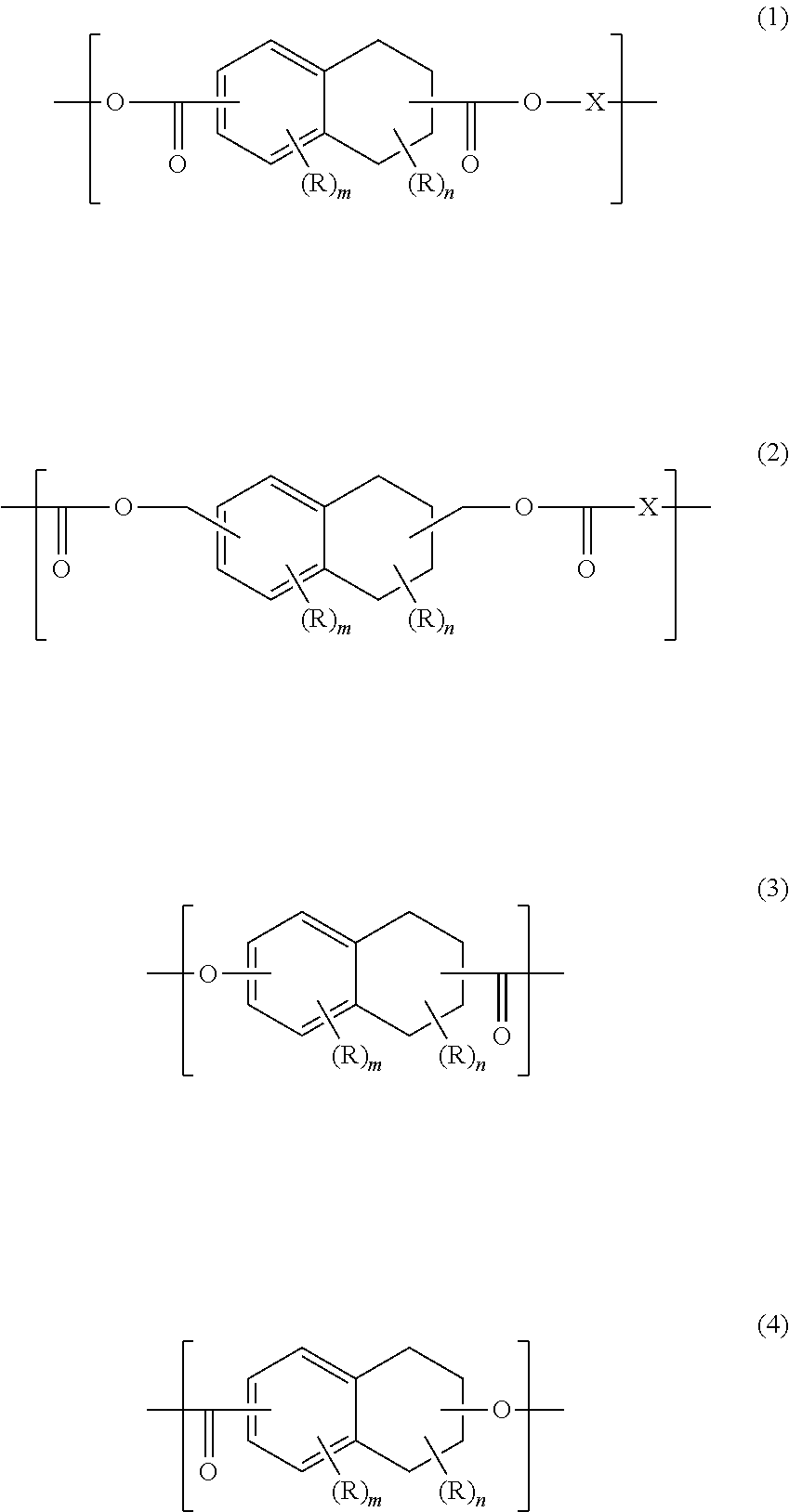

An oxygen-absorbing resin composition containing a polyester compound and a transition metal catalyst, wherein the polyester compound has at least one constituent unit having a tetralin ring selected from the group consisting of constituent units represented by general formulas (1) to (4) and wherein the polyester compound is a polyester compound having a tetralin ring obtained by synthesis using a zinc compound.

Owner:MITSUBISHI GAS CHEM CO INC

Cell culture device and method of manufacturing the same

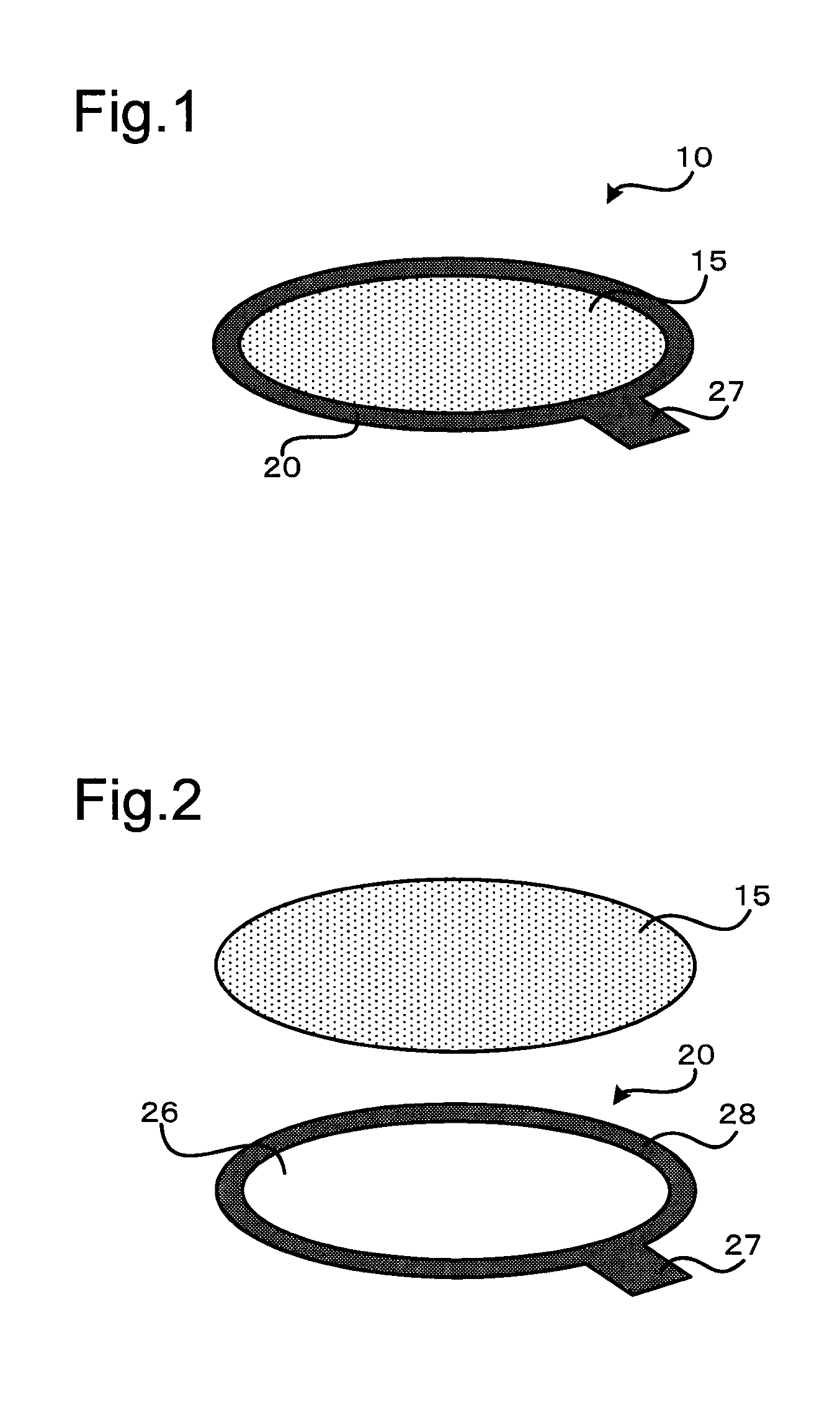

ActiveUS20170037353A1Improve the fixing strengthPrevent elutionApparatus sterilizationCell culture supports/coatingUltimate tensile strengthContact region

A cell culture device comprises a cell culture membrane and a substrate fixed to the cell culture membrane. The cell culture membrane is made from a thermosetting resin and has a plurality of pores that are open to at least one surface including a surface on a side that is in contact with the substrate. The substrate is made from a thermoplastic resin. In a contact region between the cell culture membrane and the substrate, part of the substrate is extended to form bulges in the pores of the cell culture membrane that are open in the contact region. This configuration suppresses reduction of the strength of the cell culture membrane and reduction of the flatness of the cell culture membrane (membrane accuracy) in the cell culture device in which the cell culture membrane and the substrate are fixed to each other.

Owner:TOYODA GOSEI CO LTD +1

Electric driving device

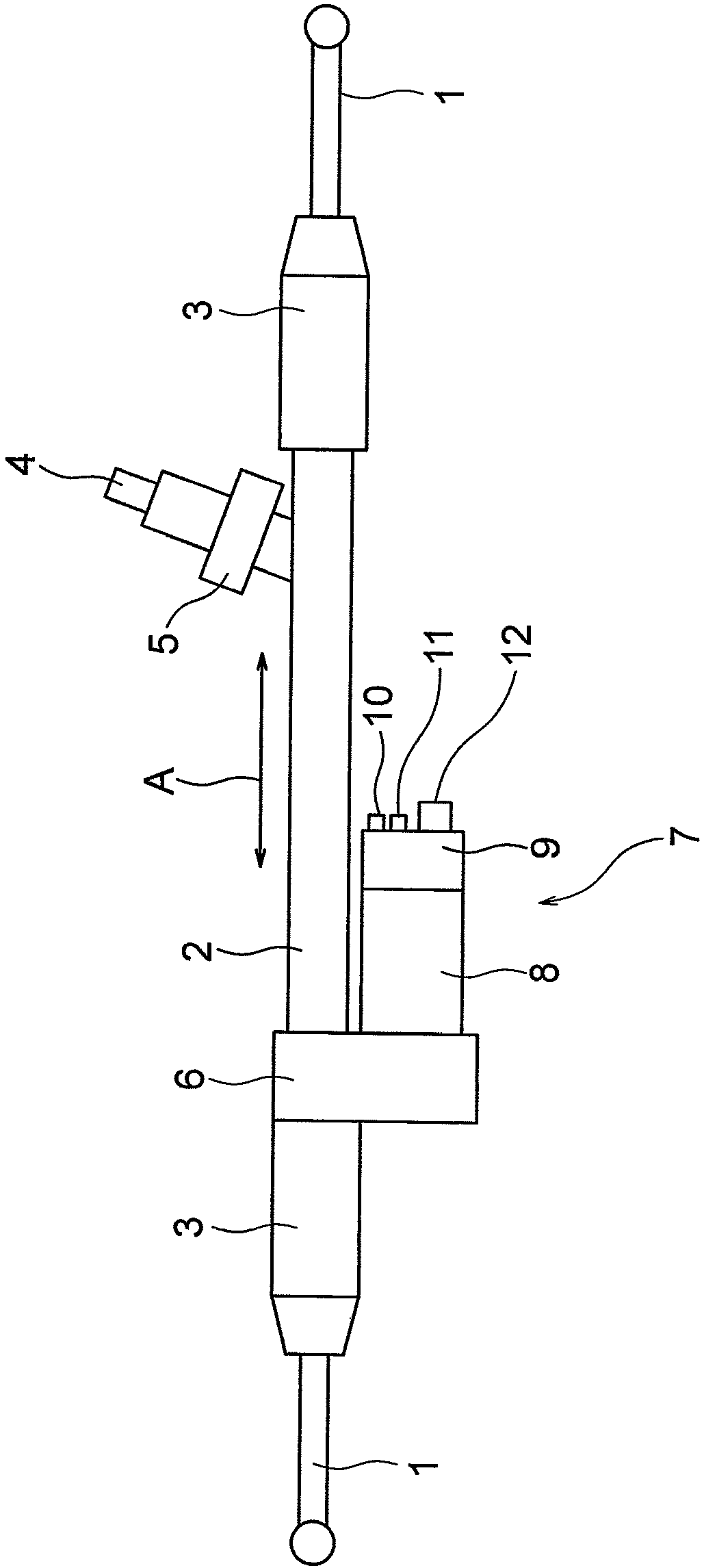

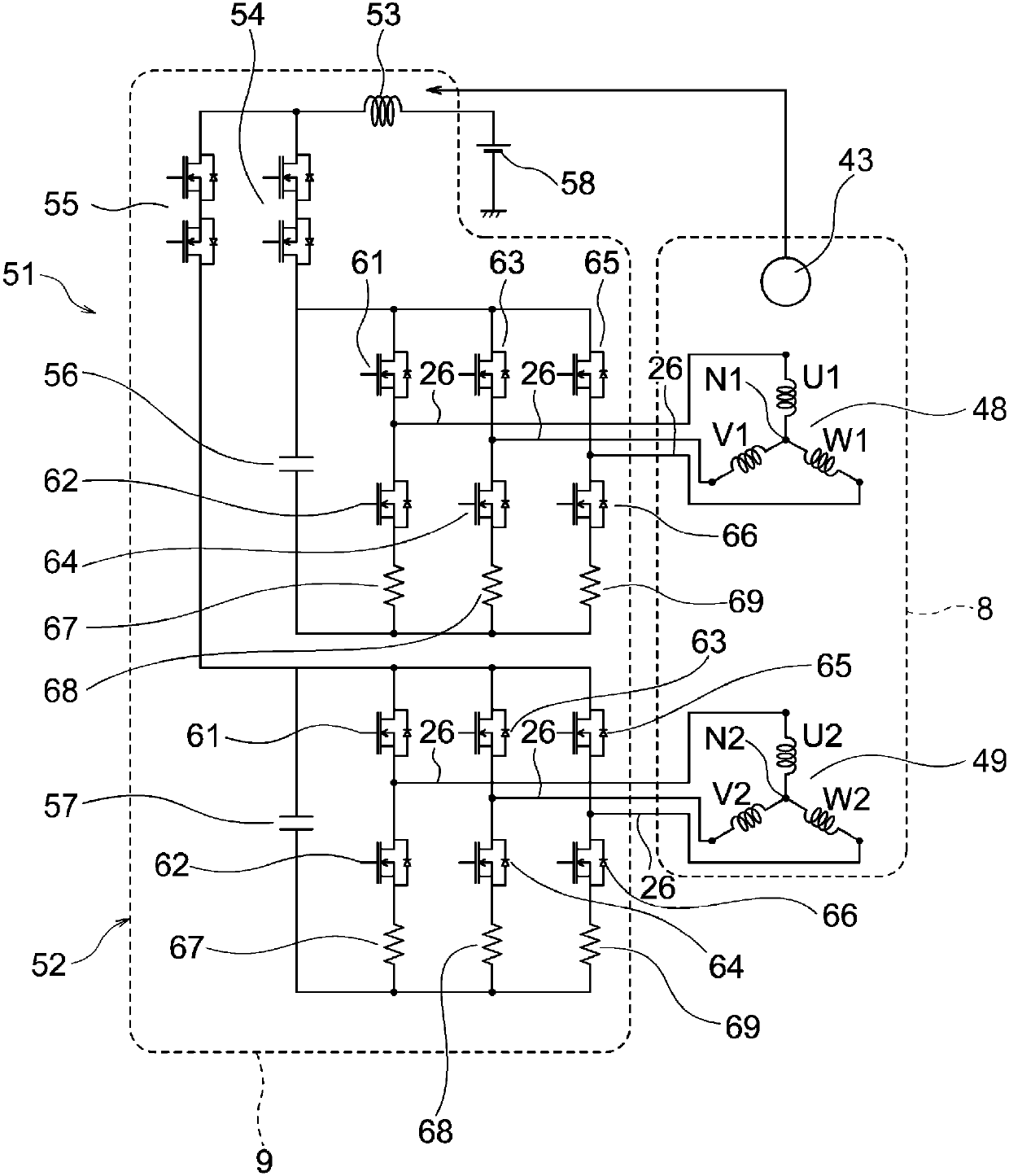

ActiveCN107592955AReduce performanceAvoid oversizingAssociation with control/drive circuitsCooling/ventillation arrangementEngineeringRotation sensor

An electric driving device, in which a sensor magnet is fixed to a first end section of the rotation shaft of a motor. A sensor device has a rotation sensor for detecting the magnetic field of the sensor magnet. The rotation sensor faces the sensor magnet along the axial direction of the rotation shaft. A control unit mounted on the motor has an inverter circuit connected to the armature coil of the motor via a plurality of power supply wires. The inverter circuit is disposed, with respect to the axial direction of the rotation shaft, at a position further from the sensor magnet than the rotation sensor. A shield plate comprising a magnetic material is disposed between the rotation sensor and the inverter circuit.

Owner:MITSUBISHI ELECTRIC CORP

Sintered ceramsite adopting tailings generated during germanium extraction of lignite as main raw material and preparation method of sintered ceramsite

InactiveCN103819174ASolve pollutionSolve resource problemsCeramic materials productionClaywaresKaolin clayMuffle furnace

The invention discloses a sintered ceramsite adopting tailings generated during germanium extraction of lignite as a main raw material and a preparation method of the sintered ceramsite. The sintered ceramsite comprises the components of tailings generated during germanium extraction of lignite, kaolin and water; the tailings are ground; kaolin and water are fed into the ground tailings; the mixture is stirred to be uniform; ageing is carried out for pelletizing; the finished balls are placed in a muffle furnace for preheating and calcining to obtain the sintered ceramsite. The preparation is simple in technology, low in energy consumption, relative high in waste utilization, and good in product performance.

Owner:LINCANG TEACHERS COLLEGE

Ignition plug and method for manufacturing ignition plug

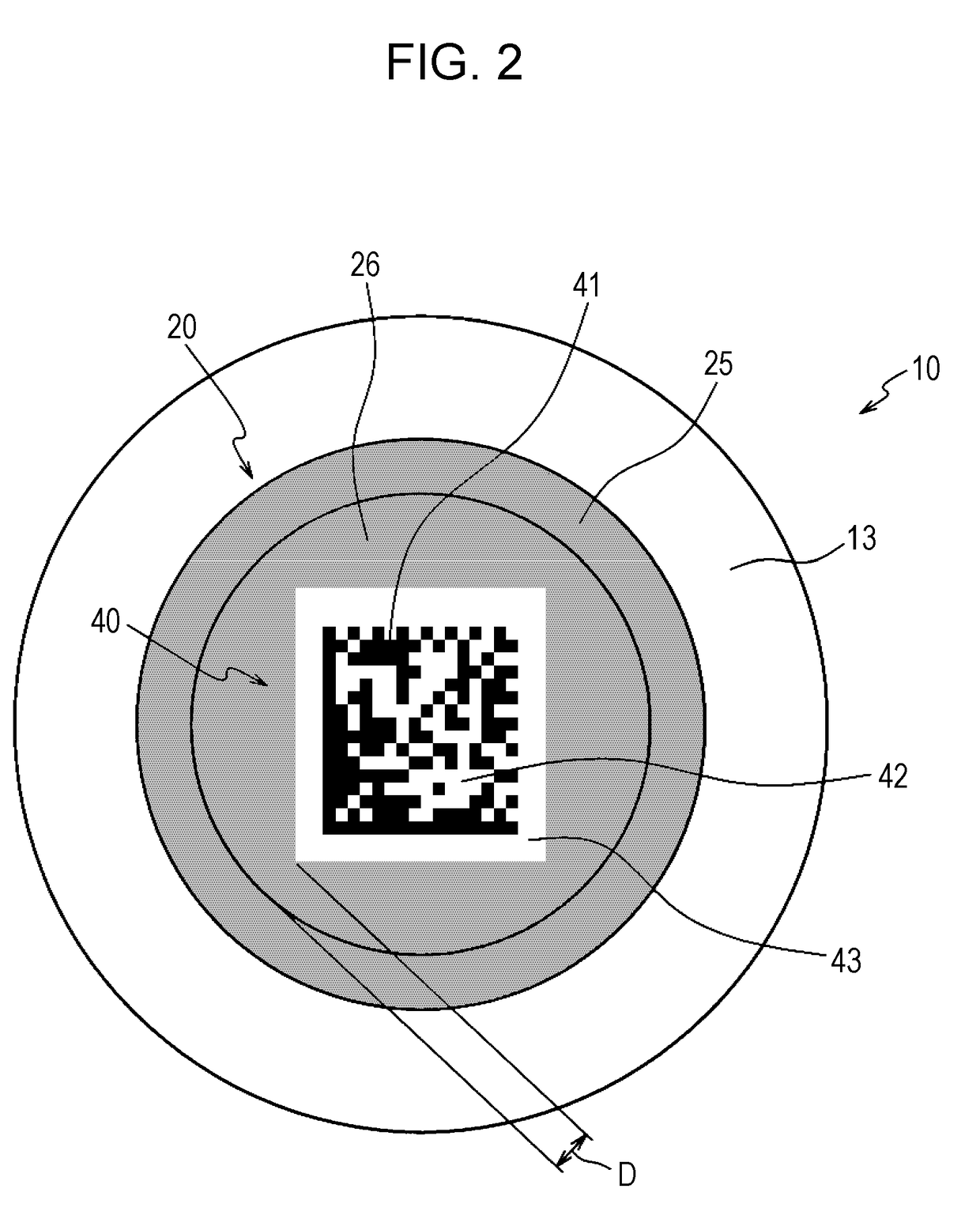

ActiveUS20180331511A1Reduced strengthImprove reading accuracyDigitally marking record carriersAblative recordingEngineeringInternal combustion engine

An ignition plug such as a spark plug or a glow plug configured to ignite an air-fuel mixture in an internal combustion engine includes a mark that is formed of an oxide film generated on the surface of a metal member or is formed of the metal member and the oxide film. The mark is formed by promoting formation of the oxide film on the surface of the metal member or removing the oxide film through radiation of a laser beam onto the surface of the metal member.

Owner:NGK SPARK PLUG CO LTD

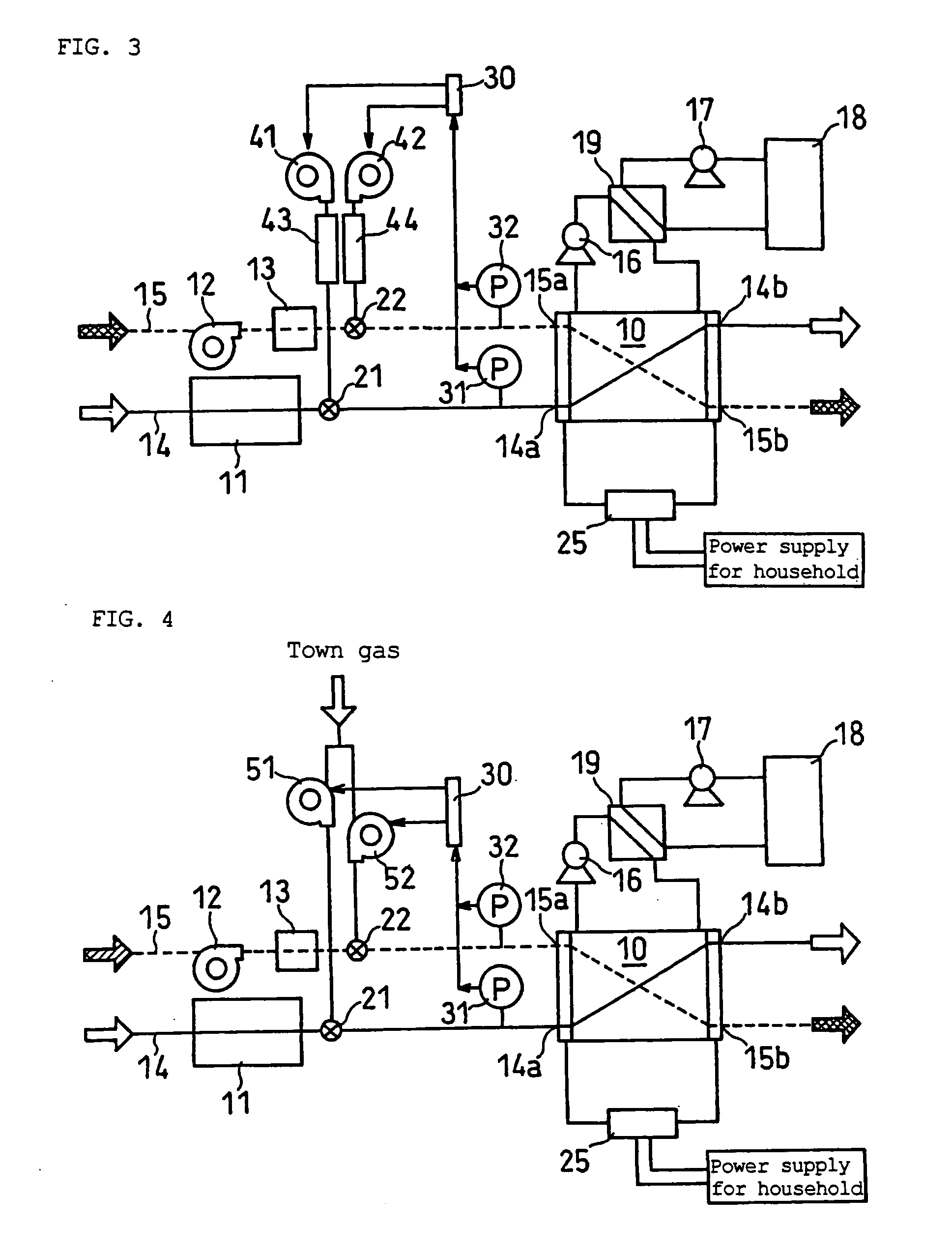

Fuel Cell System

ActiveUS20070292728A1Suppress degradation of strengthImprove reliabilityFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsDifferential pressure

A fuel cell system includes a fuel cell that is subjected to a purge operation of supplying an inert gas to an anode and / or cathode upon shut-down of the fuel cell. The differential pressure ΔP is defined as ΔP=Pa−Pc where Pa is the pressure in an inlet-side flow path leading to the anode and Pc is the pressure in an inlet-side flow path leading to the cathode. The differential pressure during the purge operation is controlled such that the differential pressure during operation ΔPo and the differential pressure during the purge operation ΔPp satisfy the relation: 0<ΔPo×ΔPp. This makes it possible to reduce the stress exerted on a solid electrolyte membrane and improve the long-term reliability of the fuel cell.

Owner:PANASONIC CORP

Oxygen-absorbing Resin Composition and Oxygen-absorbing Container Comprising the Same

ActiveUS20100317514A1Improve abilitiesDecrease in cohesive forceOther chemical processesPolyesterPolyolefin

An oxygen-absorbing resin composition having excellent performance is provided which contains an oxygen-absorbing polyester and a polyolefin and has enhanced compatibility between the polymers to give an oxygen-absorbing layer inhibited from having a reduced cohesive force or an appearance failure such as roughness unevenness. The oxygen-absorbing resin composition is characterized by being obtained by melt-kneading the following ingredients (A) and (B) together with the following ingredient (C) as a compatibilizing agent. Ingredient (A): an oxygen-absorbing polyester; Ingredient (B): a polyolefin; and Ingredient (C): a copolymer of ethylene and a vinyl monomer having a hydroxy group or an ester bond, the copolymer having an ethylene proportion of 70-99 mol %.

Owner:TOYO SEIKAN KAISHA LTD

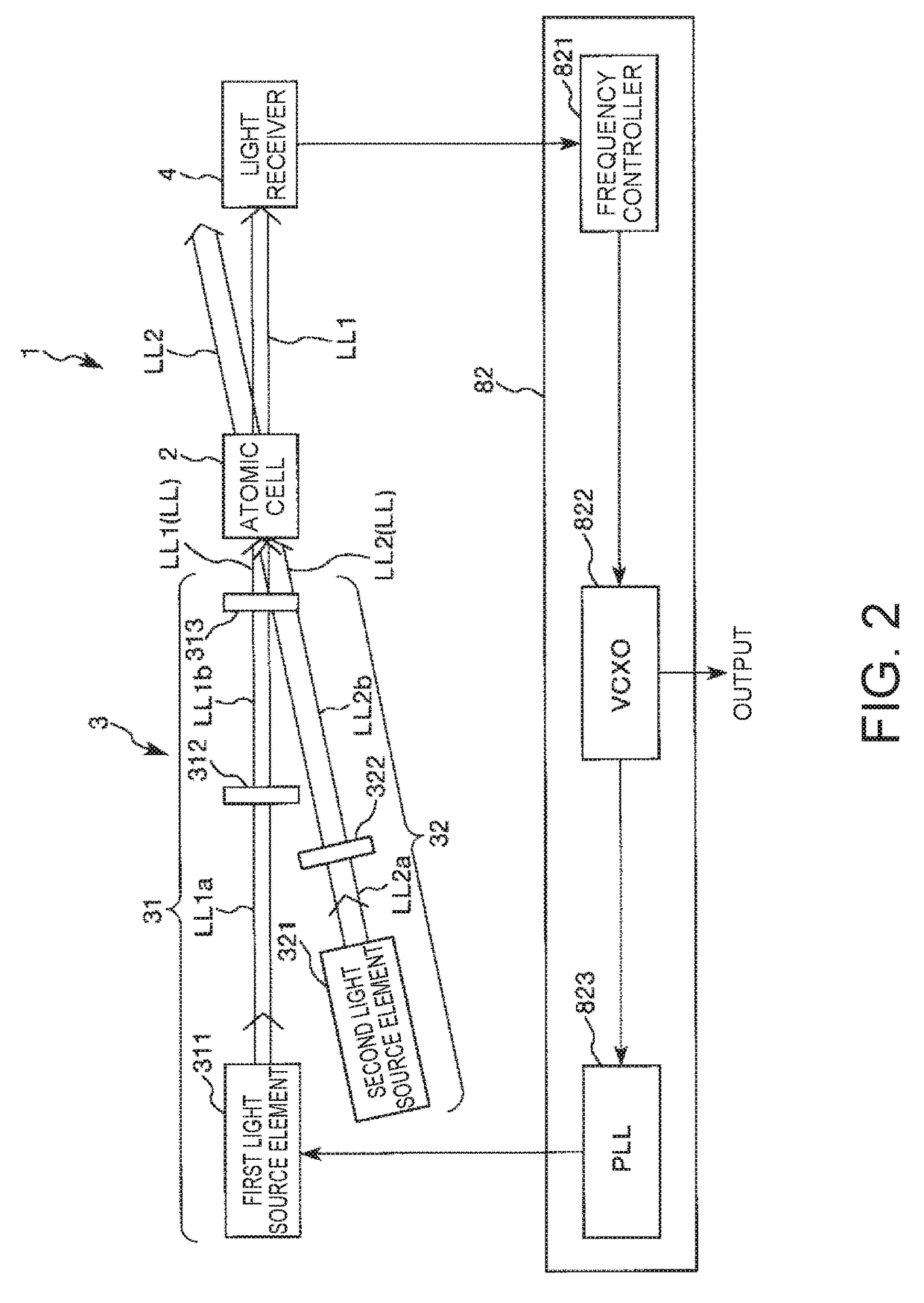

Quantum interference device, atomic oscillator, and electronic apparatus

InactiveUS20180241407A1Improve featuresImprove heat resistancePulse automatic controlApparatus using atomic clocksResonanceElectron

A quantum interference device includes an atomic cell which has an internal space enclosing an alkali metal, a first light source which emits a resonance light pair that is circularly polarized in the same direction as each other and excites the alkali metal, a second light source which emits an adjustment light, and a light receiver, wherein the atomic cell includes an inner wall surface which is formed of a material containing a compound having a polar group and surrounds the internal space, a first layer which is provided on the inner wall surface and contains a compound derived from a first compound having a functional group that undergoes an elimination reaction with the polar group, and a second layer which is provided on the first layer and contains a compound derived from a second compound that is a nonpolar olefin-based polymer.

Owner:SEIKO EPSON CORP

Insulation composition for DC power cable and DC power cable prepared by using the same

ActiveUS20140076609A1Decrease of breakdown voltageSuppress decrease of DC dielectric strength and breakdown voltagePlastic/resin/waxes insulatorsSpecial tyresPower cableUltimate tensile strength

The present invention relates to an insulation composition for a DC power cable and the DC power cable prepared using the same. Specifically, the present invention relates to an improved insulation composition for a DC power cable, which can prevent decrease of DC dielectric strength and decrease of impulse strength caused by accumulation of space charges, and the DC power cable prepared using the same.

Owner:LS CABLE & SYST LTD

Oxygen-absorbing resin composition

ActiveUS20160008800A1Improve performanceSatisfactory molding processabilityHydrogenGas treatmentPolyesterTetralin

The oxygen-absorbing resin composition of the present invention at least contains a polyester compound containing a constitutional unit (a) having a predetermined tetralin ring and a constitutional unit (b) derived from a predetermined polyfunctional (trivalent or more) compound, and a transition metal catalyst.

Owner:MITSUBISHI GAS CHEM CO INC

Ferritic stainless steel sheet superior in heat resistance

ActiveUS8062584B2Inhibition strength declineSuppression problemExhaust apparatusSilencing apparatusMetallurgyHeat resistance

The present invention provides, as a material superior in heat resistance in a hot environment where the maximum temperature of the exhaust gas becomes 750 to 900° C., ferritic stainless steel sheet superior in heat resistance in a broad temperature region of 750 to 900° C. with long term stability by a smaller amount of addition of Mo than SUS444 containing about 2% of expensive Mo, that is, ferritic stainless steel sheet superior in heat resistance characterized by containing, by mass %, C: 0.01% or less, N: 0.02% or less, Si: 0.05 to 1%, Mn: 0.1 to 2%, Cr: 10 to 30%, Mo: 0.1 to 1%, Cu: 1 to 2%, Nb: 0.2 to 0.7%, Ti: 0.01 to 0.3%, and B: 0.0002 to 0.0050%, having a balance of Fe and unavoidable impurities, and having a 0.2% yield strength at 750° C. of 70 MPa or more.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

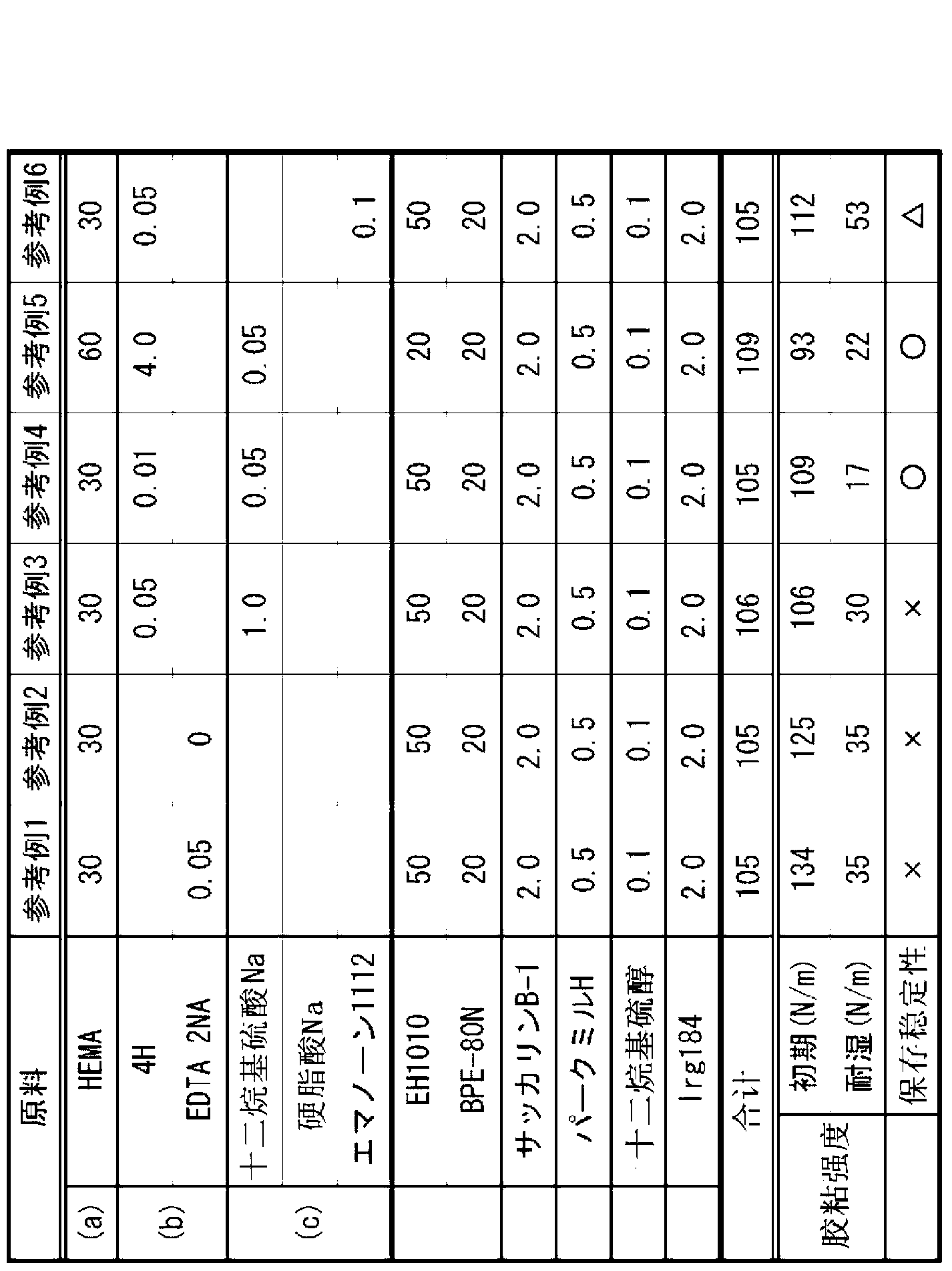

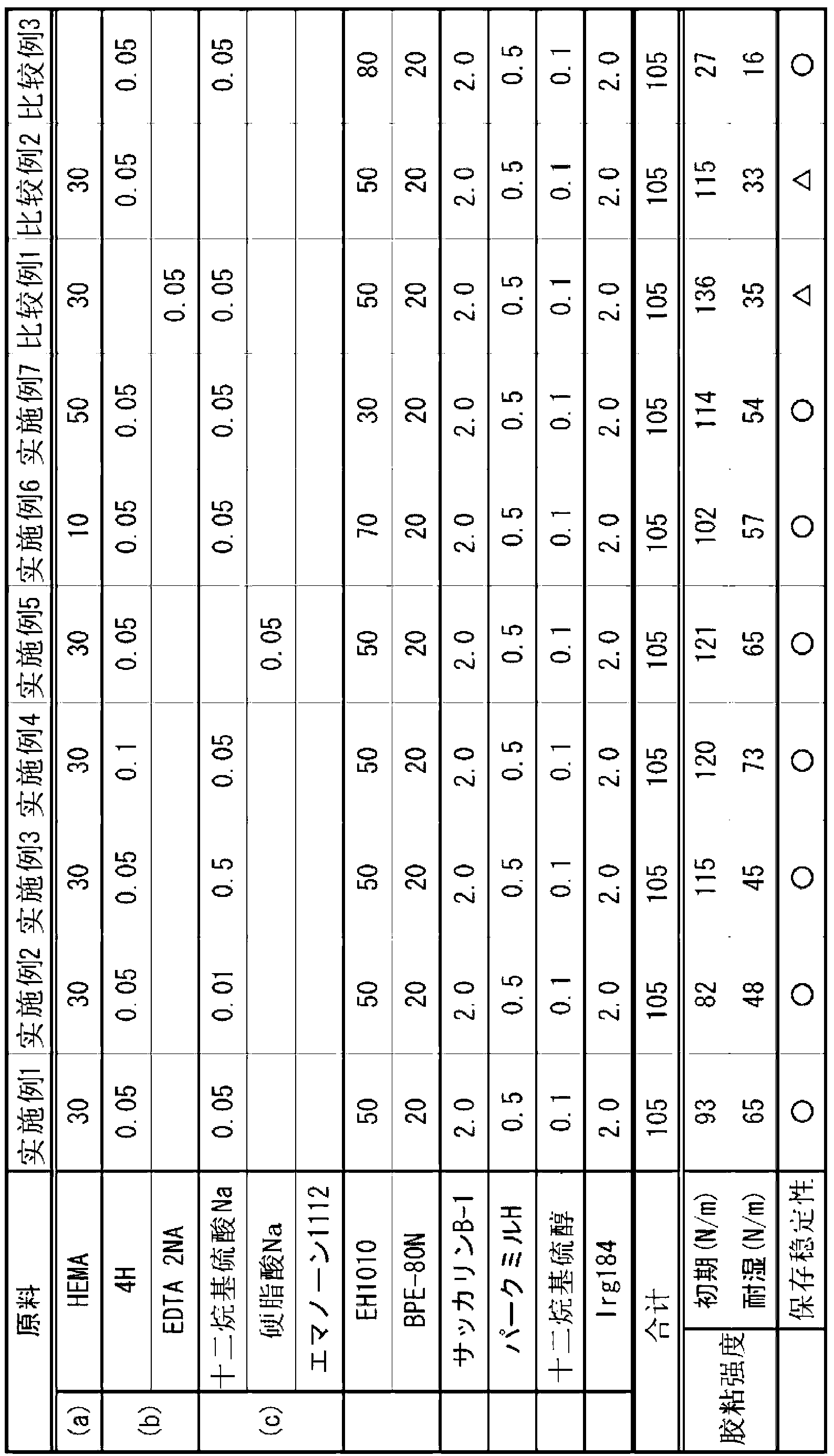

Curable composition

ActiveCN103237821AInhibition strength declineOther chemical processesOrganic non-macromolecular adhesiveMeth-Oligomer

Owner:THREEBOND FINE CHEM CO LTD

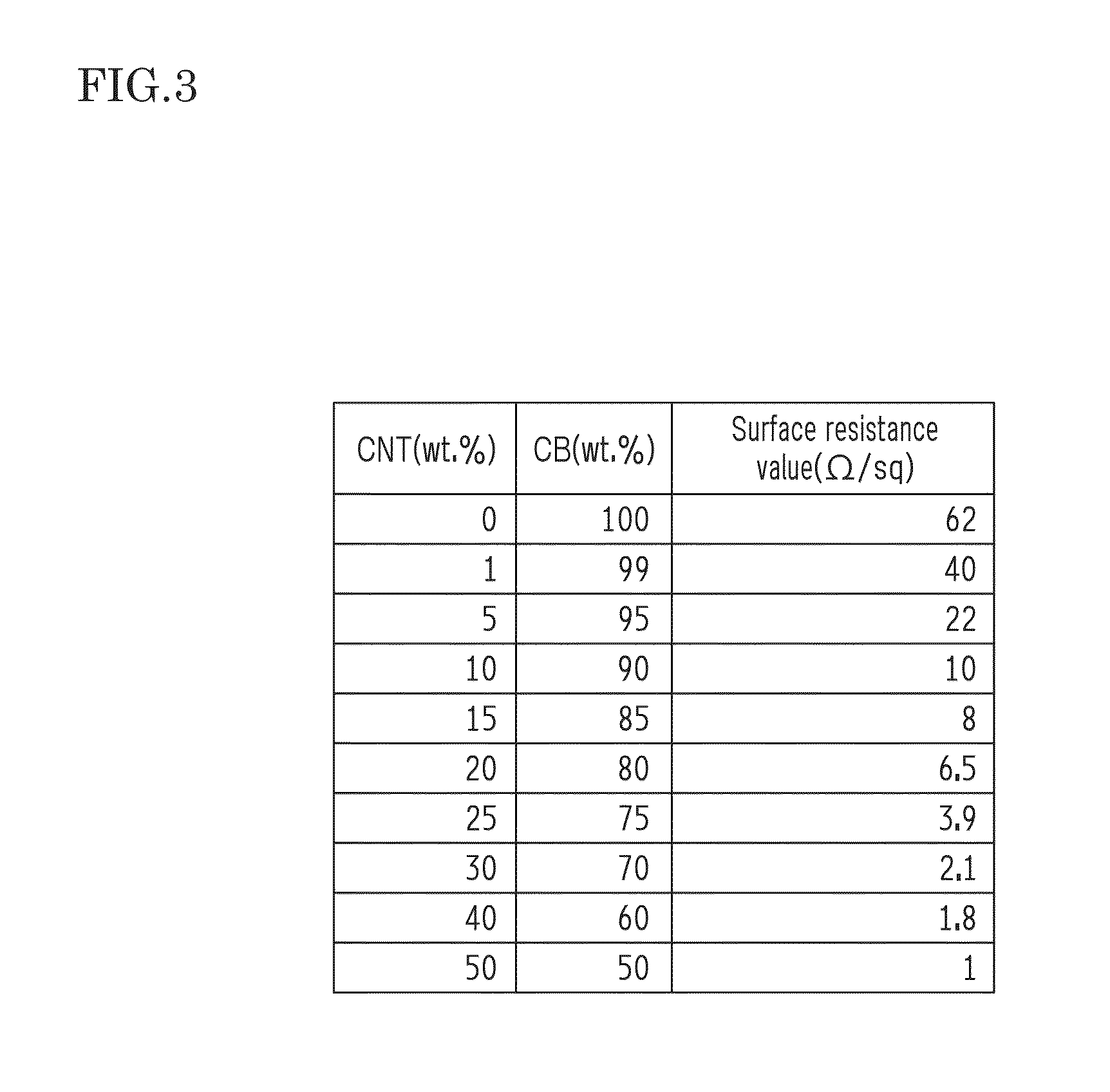

Conductive sheet, method for manufacturing the same, carbon composite paste, carbon composite filler, conductive resin material and conductive rubber material

ActiveUS20160268017A1Excellent conductivityDeterioration in strengthShielding materialsNon-conductive material with dispersed conductive materialCarbon blackCarbon nanotube

A conductive sheet capable of improving conductivity by suppressing reaggregation of carbon nanotubes, and a manufacturing method thereof are provided. Also, carbon composite paste and carbon composite filler are provided. The conductive sheet is characterized in that carbon nanotubes and carbon black as conductive materials are dispersed in a resin material. Carbon composite filler, which is composed of the carbon nanotubes in an amount of 10-30 wt. % and the carbon black in an amount of 90-70 wt. %, is dispersed uniformly in the resin material. The conductive sheet is composed of the carbon composite filler in an amount of 10-50 wt. % and the resin material in an amount of 90-50 wt. %, whose surface resistance value is 1-10 Ω / sq.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

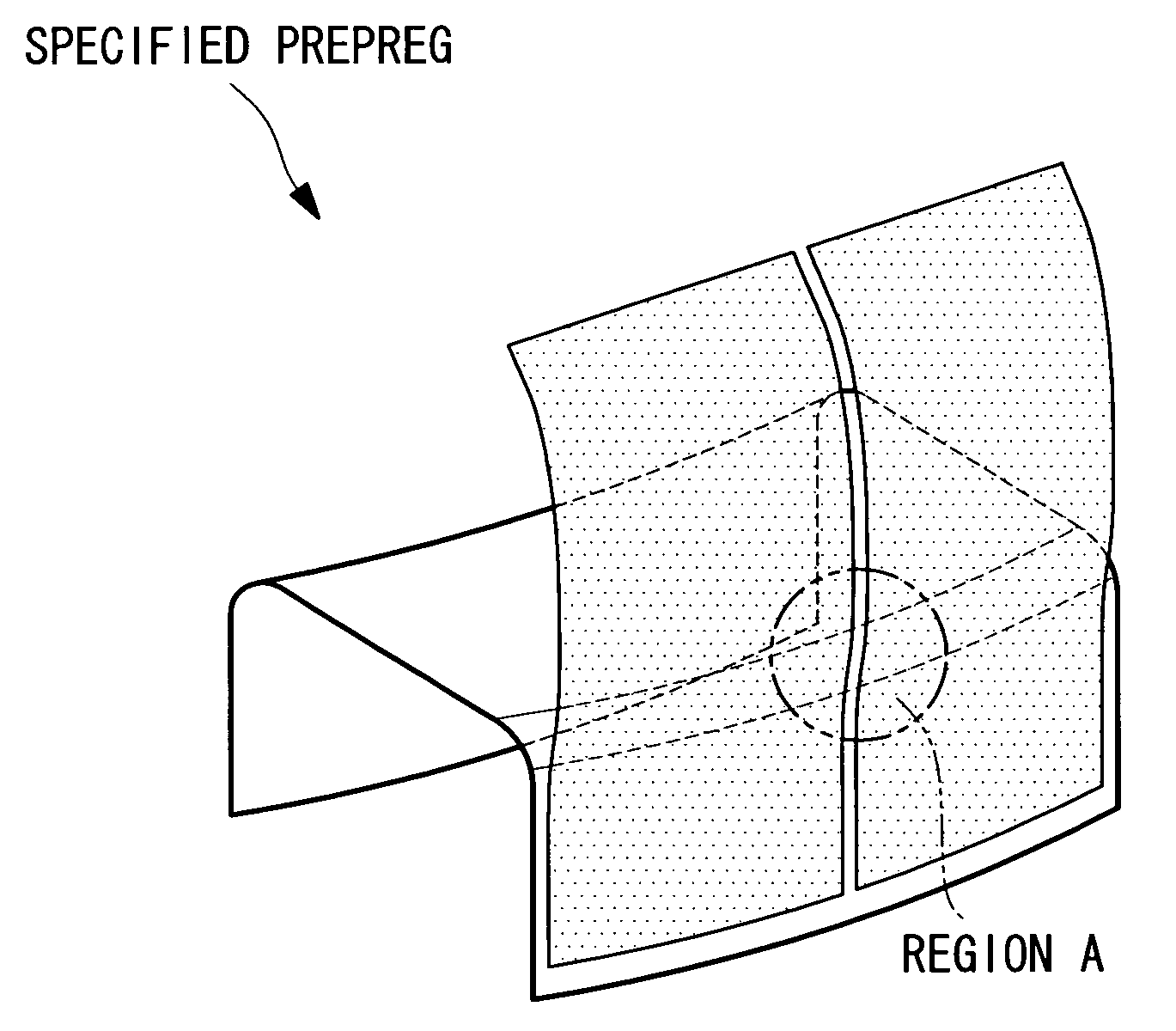

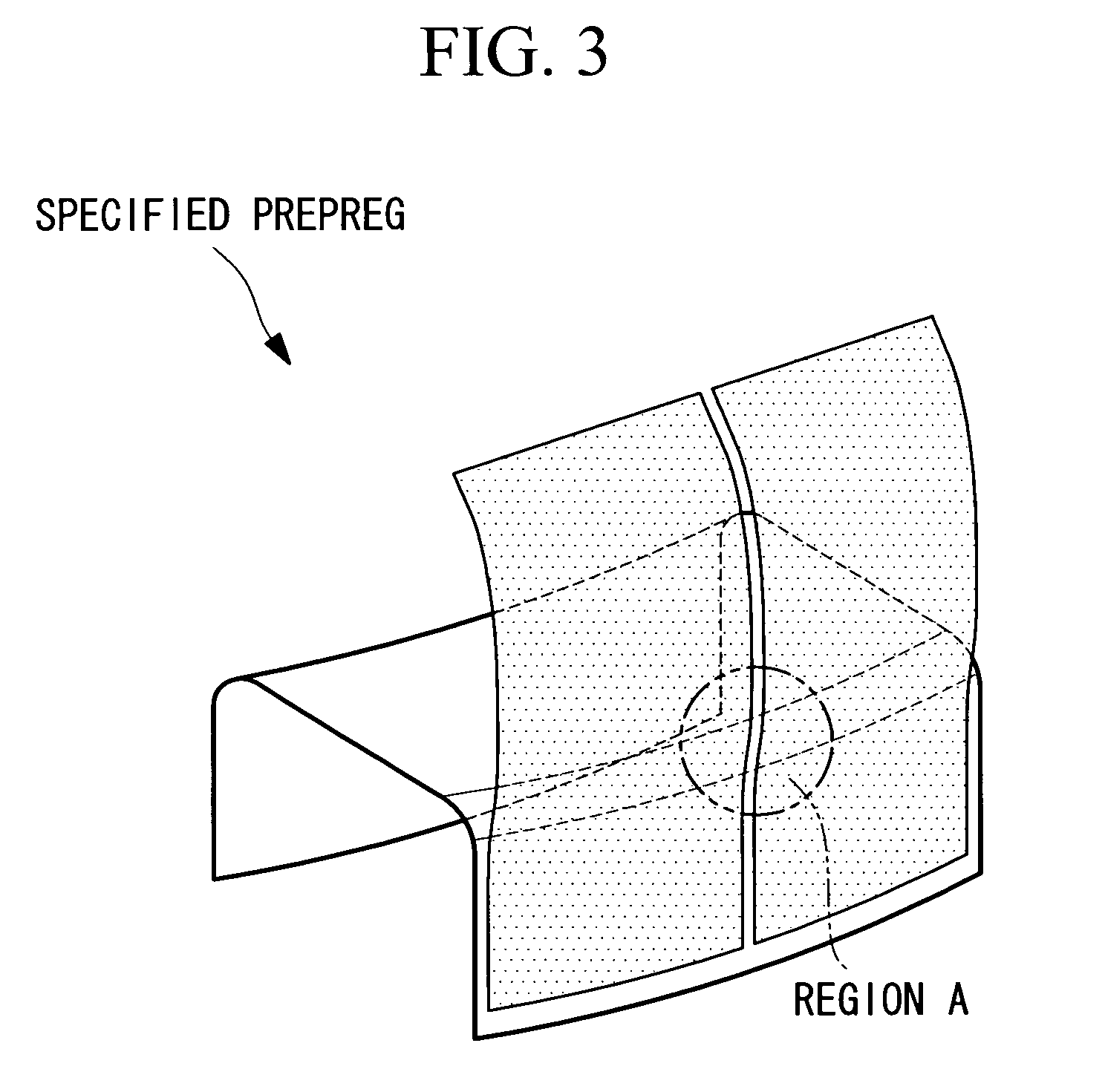

Method of Molding Composite Material Structural Member and Composite Material Structural Member

InactiveUS20100227115A1Avoid it happening againQuality improvementLamination ancillary operationsLaminationShell moldingFiber orientation

The present invention relates to a method of molding a composite material structural member used mainly within structural members such as channel materials or angle materials, and also to a composite material structural member. An object of the invention is to provide a method of molding a composite material structural member that is capable of suppressing fiber creasing even for very long shapes having non-developable surfaces, and also to provide a composite material structural member.When pressing a prepreg laminate against a molding die, the method comprises a preparation step of preparing a prepreg laminate for molding by laminating a plurality of prepregs with different fiber orientations into a flat plate shape, and a pressure application step of pressing the prepreg laminate for molding prepared in the preparation step against the molding die, and in the preparation step, a specified prepreg having a fiber orientation that coincides with, or is close to, the direction of creasing occurrence is split, either within the region of creasing occurrence or in the vicinity thereof, along a direction that is effective in inhibiting creasing occurrence, and the split prepreg is then used in preparing the prepreg laminate.

Owner:MITSUBISHI HEAVY IND LTD

Heat exchanger and method of manufacturing the same

InactiveUS7798205B2Reduced strengthInhibition strength declineSoldering apparatusCorrosion preventionPlate heat exchangerPotential difference

In a heat exchanger having a core portion in which aluminum flat tubes and aluminum fins are disposed alternatively and brazed with each other, each fin has one side portion located at one side of the tube and the other side portion located at the other side of the tube. The one side portion of the fin is higher in pitting potential than the other side portion of the fin, and the pitting potential difference between the one side portion of the fin and the other side portion of the fin is 40 to 200 mV. The pitting potential difference can be formed by the Zn concentration difference in the aluminum alloy constituting the fin.

Owner:SHOWA DENKO KK

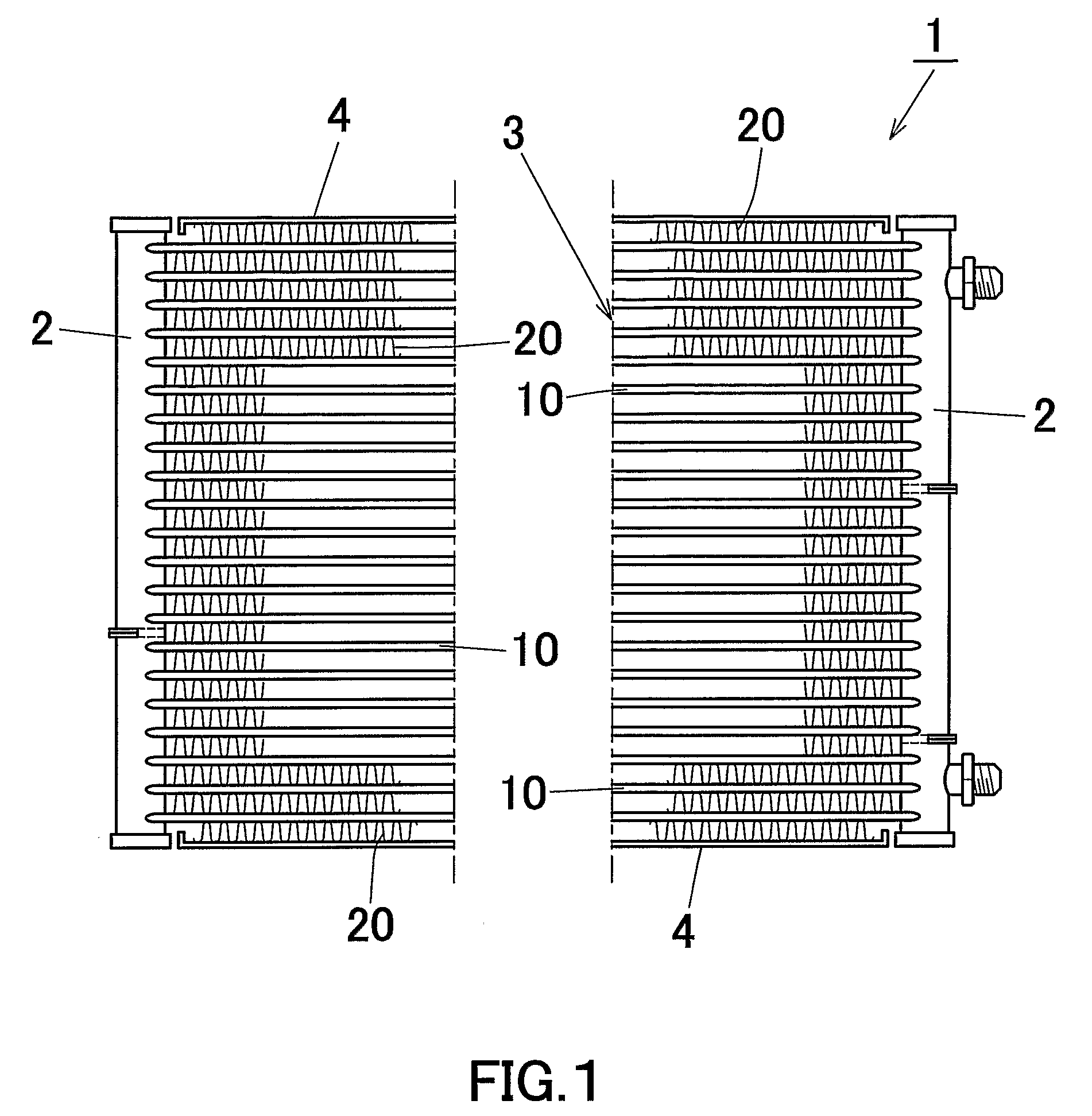

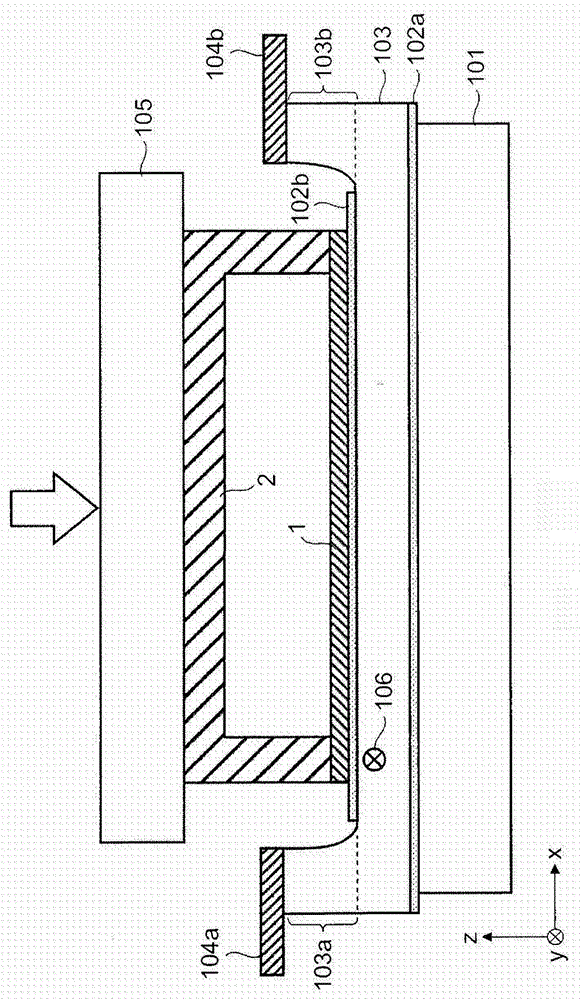

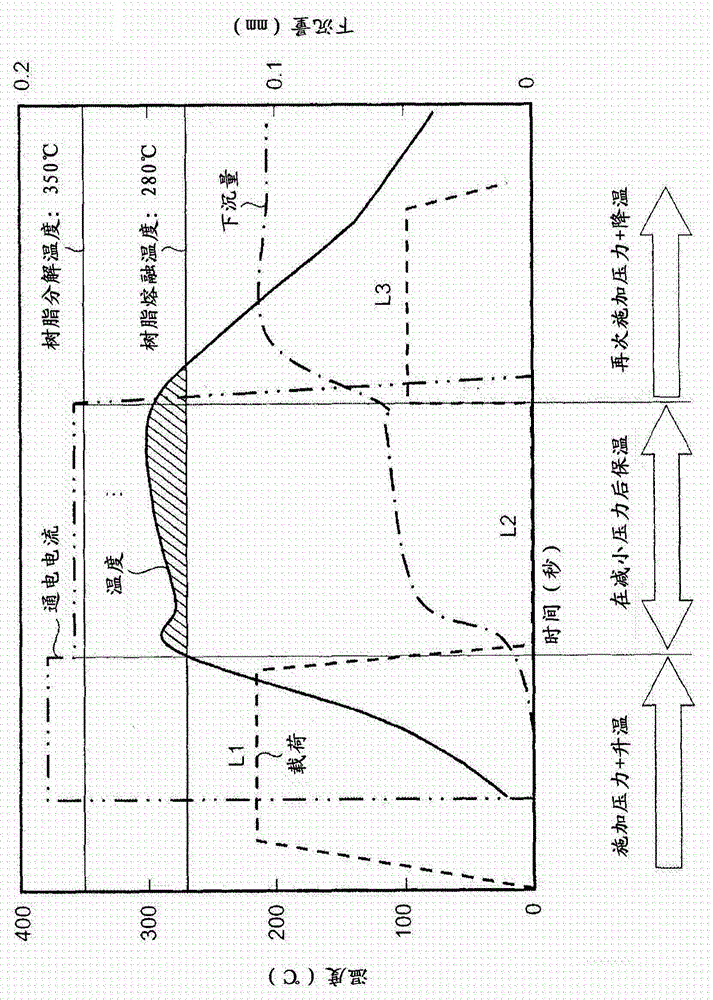

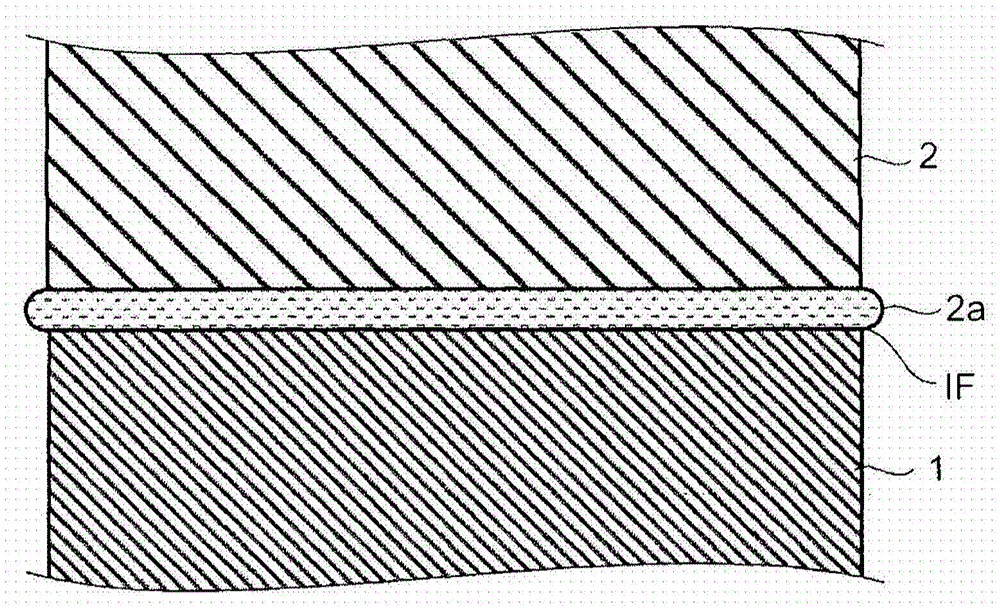

Method for joining metallic member and resin member to each other, manufacturing method for cooler, and cooler

InactiveCN105555506AInhibitionInhibition strength declineSemiconductor/solid-state device detailsAdhesive processes with surface pretreatmentMelt temperatureMelting temperature

Owner:TOYOTA JIDOSHA KK

Casting steel having high strength and low thermal expansion

InactiveUS6846368B2High strengthReduced strengthBlade accessoriesMachines/enginesHigh intensityThermal expansion

The present invention provides a cast steel for ring-shaped components that has a low average coefficient of thermal expansion in a temperature range of 20° C. to 500° C. and high strength and good oxidation resistance at 500° C., which are required for ring-shaped components for use as blade rings and seal ring retainers of gas turbines, and that can hence be used for blade rings and seal ring retainers of gas turbines. Specifically, the present invention provides a high-strength and low-thermal expansion cast steel comprising, on a mass percentage basis, 0.1 to 0.8% of C, 0.1 to 1.0% of Si, 0.1 to 1.0% of Mn, 0.01 to 0.1% of S, greater than 40% and up to 50% of Ni, not greater than 4% (inclusive of 0%) of Co, greater than 1.5% and up to 4% of Cr, 0.01 to 0.1% of Al, and 0.001 to 0.1% of Mg, the remainder being substantially Fe.

Owner:HITACHI METALS LTD +1

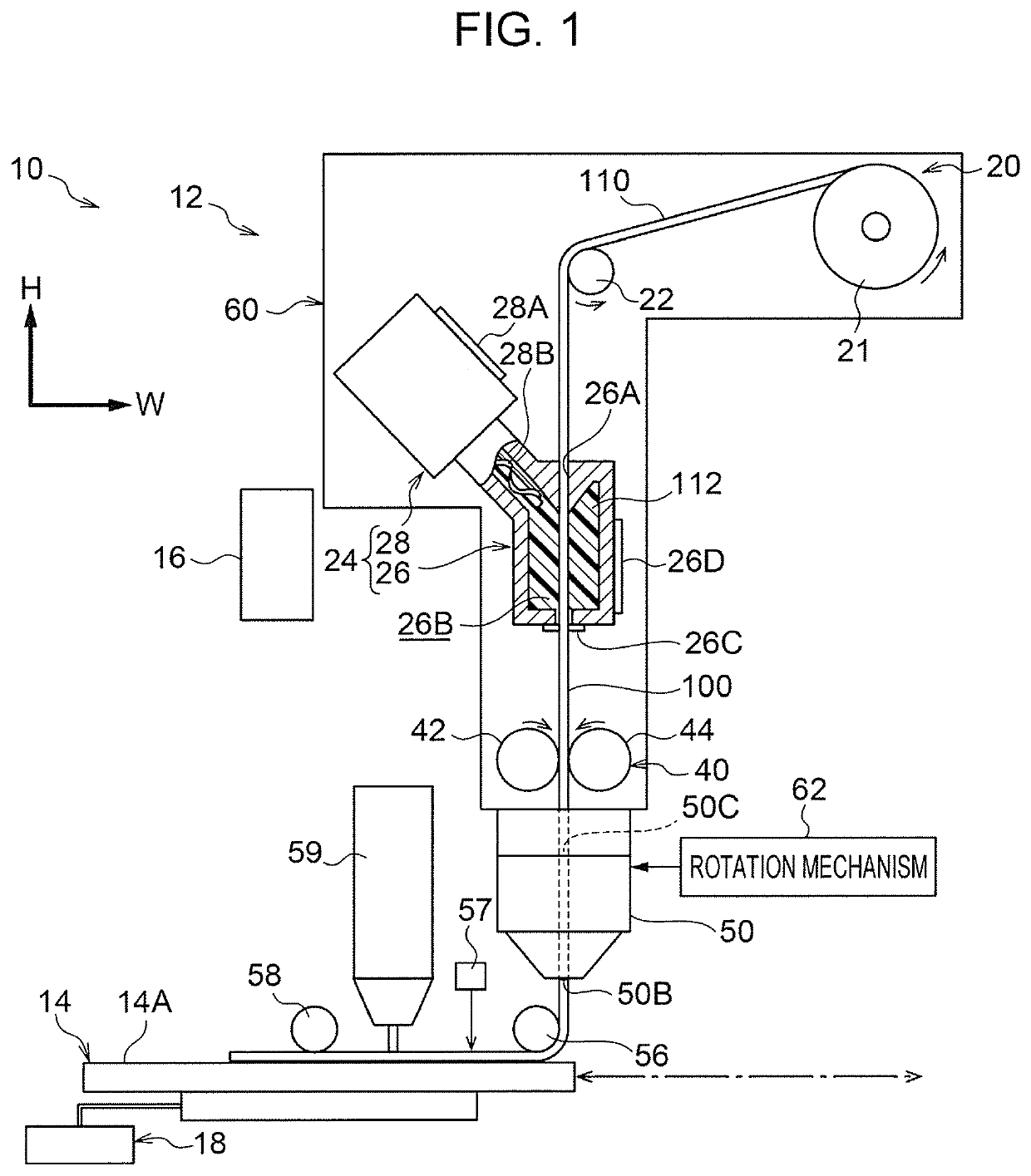

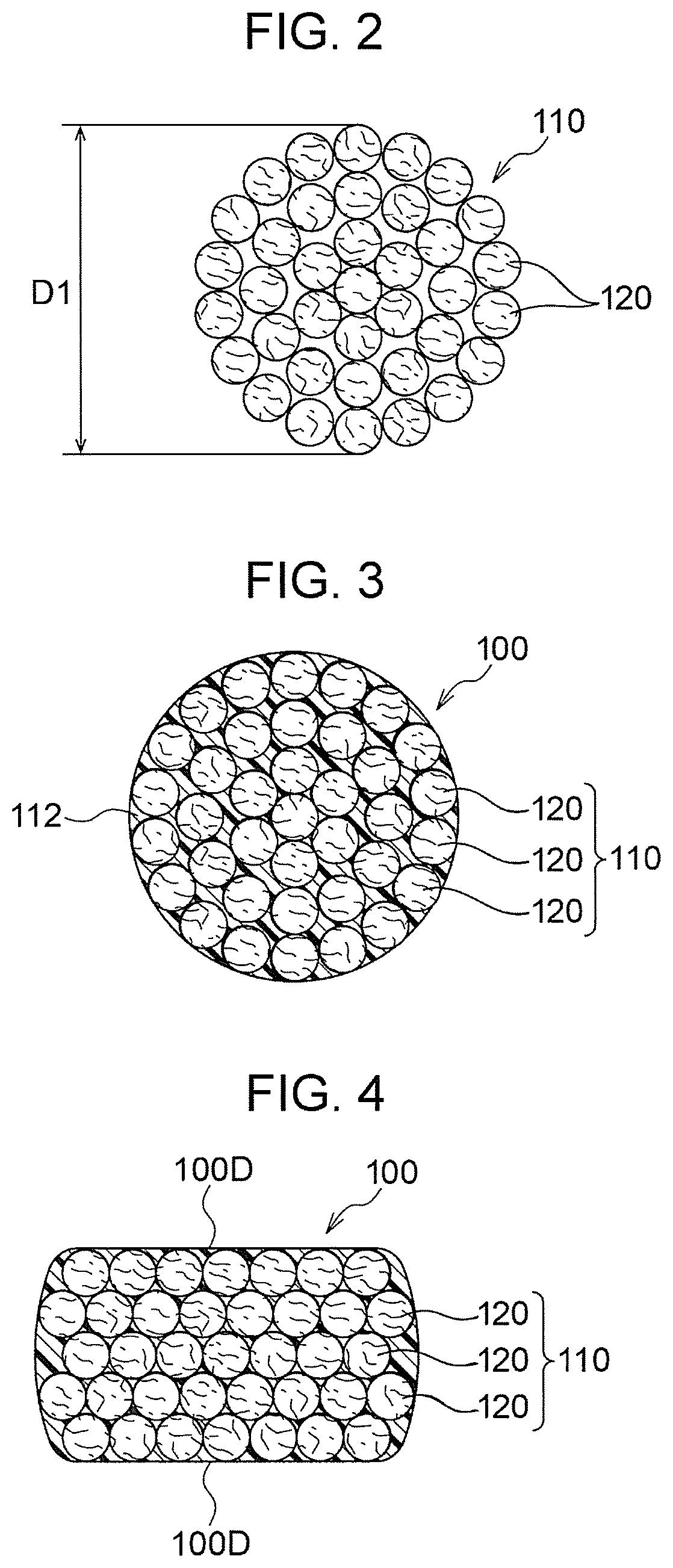

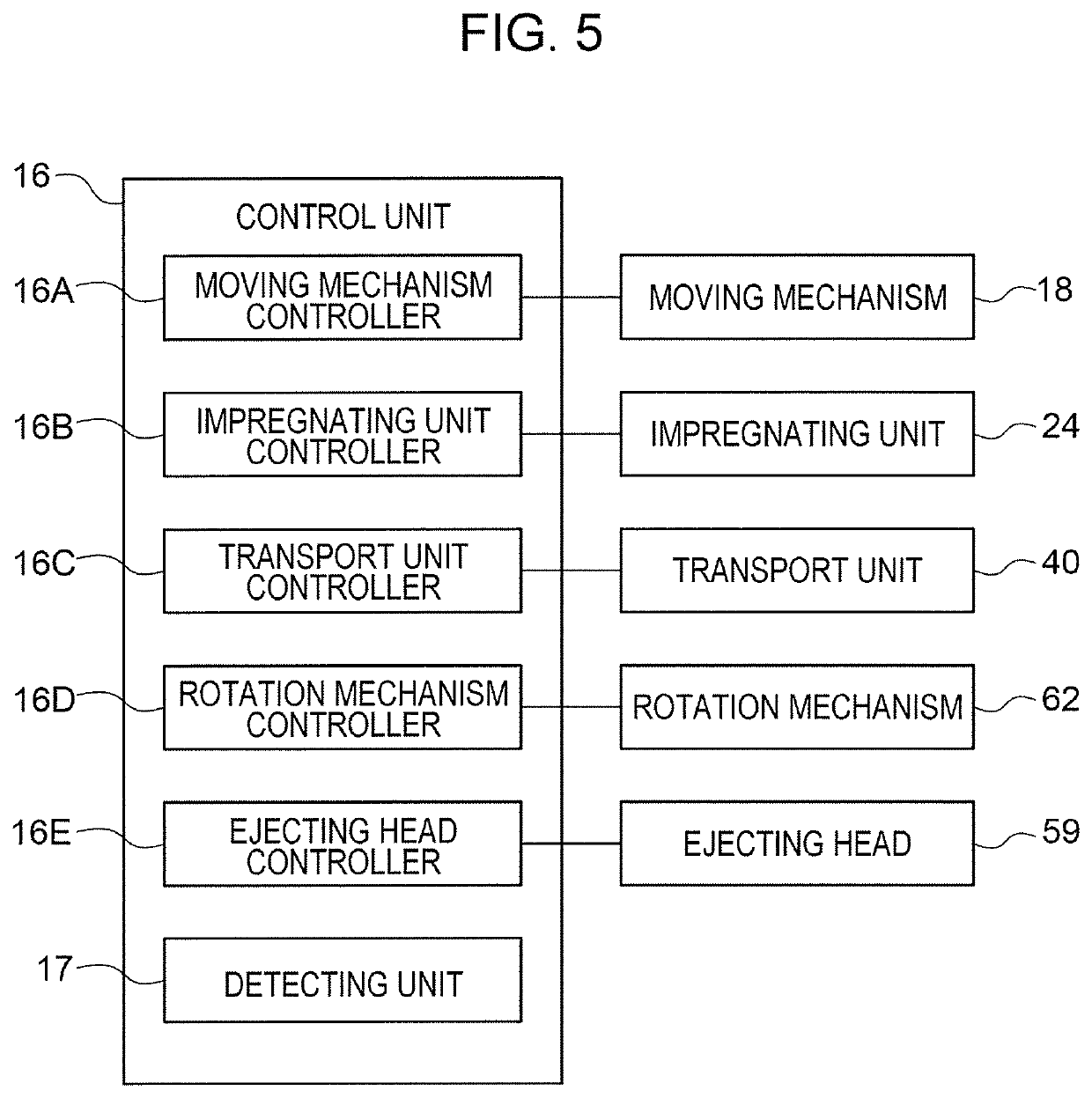

Molding apparatus

InactiveUS20200298484A1Decrease in strengthReduced strengthManufacturing driving meansAdditive manufacturing with liquidsManufacturing engineeringFiber bundle

A molding apparatus includes: a receiving part on which a wire-shaped molding material that is formed of a bundle of continuous fibers impregnated with resin is discharged; a discharge part that discharges the molding material on the receiving part; and a rotation mechanism that rotates the discharge part to spirally twist the molding material being discharged from the discharge part.

Owner:FUJIFILM BUSINESS INNOVATION CORP

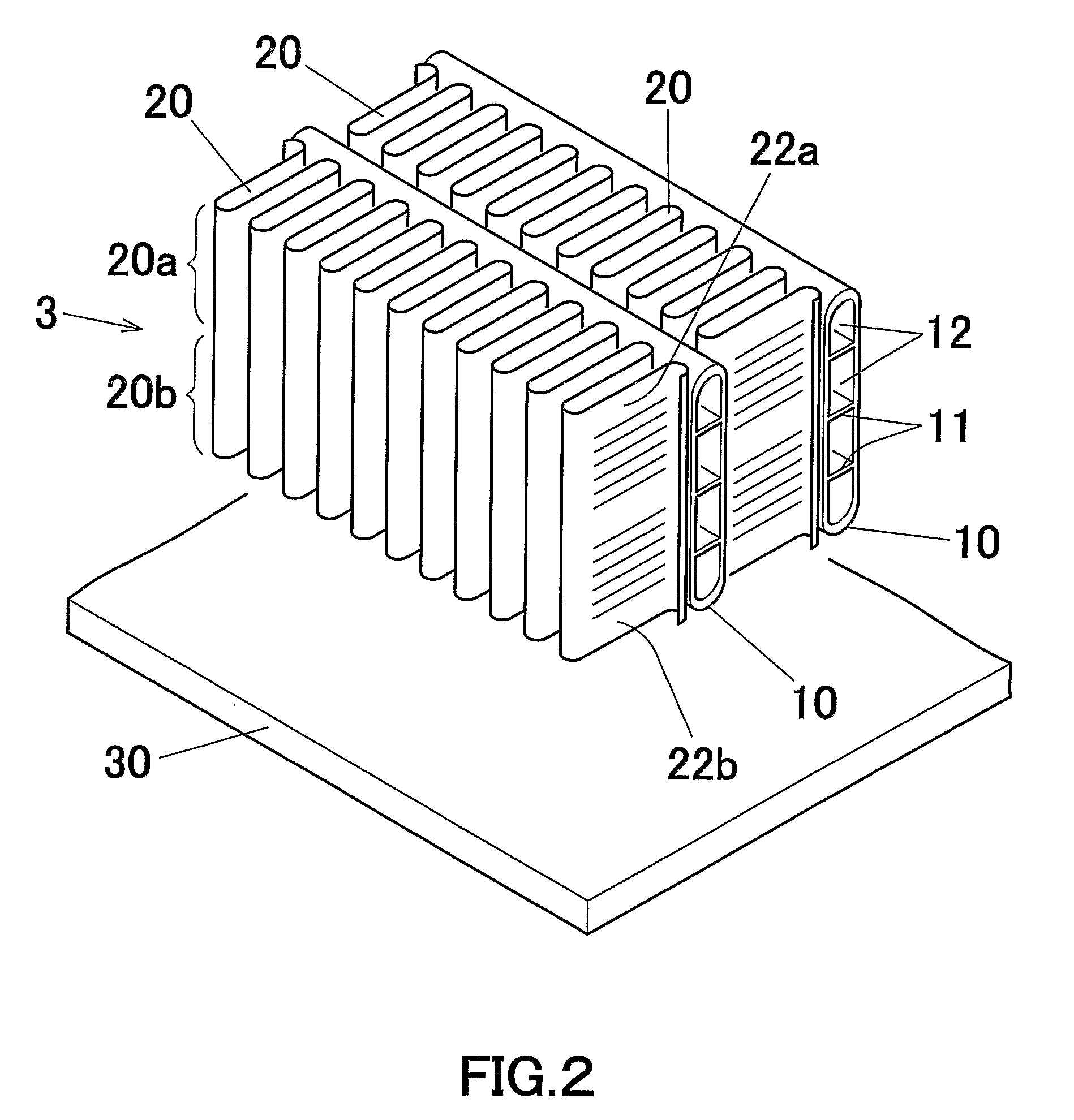

Electricity storage device

ActiveUS20130157103A1Avoid deformationHigh strengthPrimary cell to battery groupingProtecting/adjusting hybrid/EDL capacitorElectricityEngineering

An electricity storage device includes: a plurality of cells that are aligned in a predetermined direction; a pair of end plates that sandwich the plurality of cells in the predetermined direction; and a restraining member that extends in the predetermined direction, is fixed to the pair of end plates, and exerts a restraining force on the plurality of cells in the predetermined direction via the end plates. Each of the end plates includes a first plate and a second plate. The first plate has a plurality of ribs on a surface that faces the adjacent cell and is formed of insulating material. The second plate is fixed to the first plate on a side opposite to the surface that faces the adjacent cell and is formed of material stronger than the insulating material for the first plate.

Owner:TOYOTA JIDOSHA KK +1

Oxygen-absorbing resin composition

InactiveUS20150144838A1Excellent oxygen absorption performanceKeep the lookHydrogenOther chemical processesPolymer sciencePolyolefin

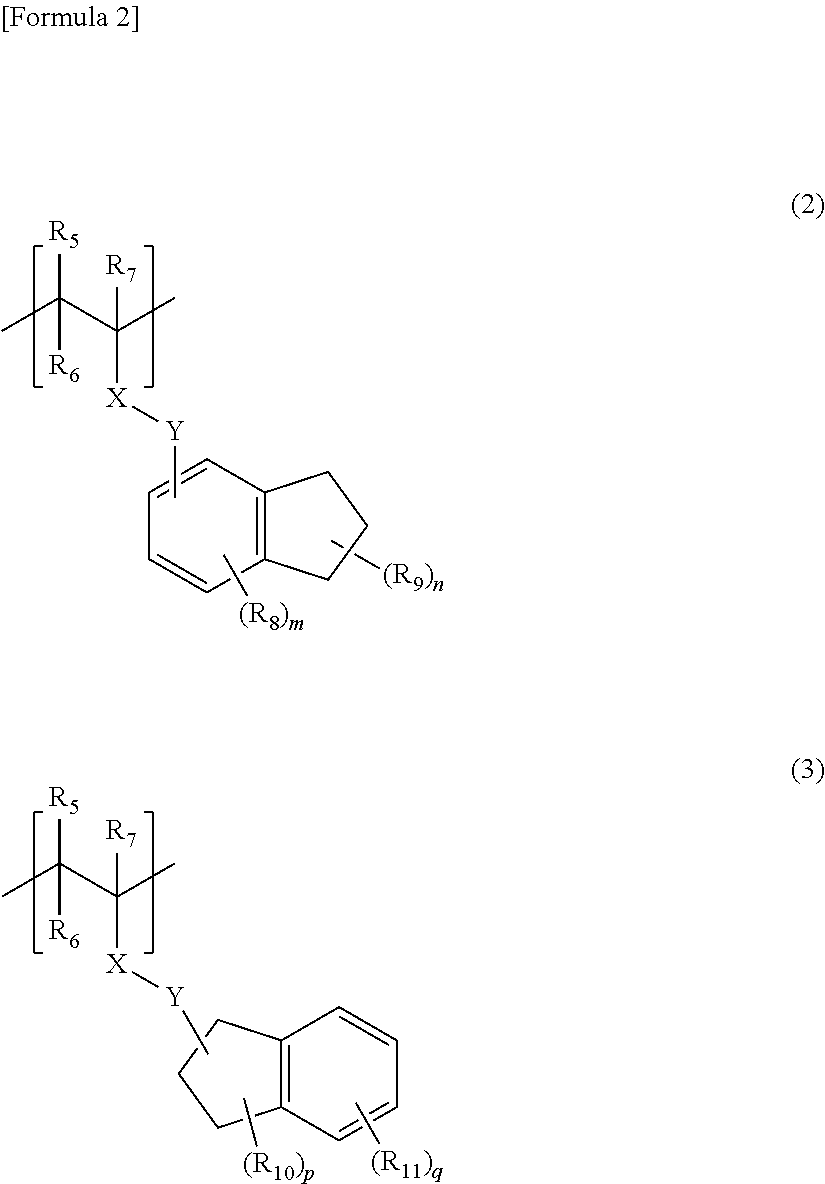

An oxygen-absorbing resin composition copolymerized polyolefin compound including a copolymerized polyolefin compound and a transition metal catalyst, wherein the copolymerized polyolefin compound is a copolymerized polyolefin compound including at least one of constitutional unit (a) selected from the group consisting of the constitutional units represented by the general formula (1), and at least one of the constitutional unit (b) having an indane ring, selected from the group consisting of the constitutional units represented by the general formulas (2) and (3).

Owner:MITSUBISHI GAS CHEM CO INC

Oxygen-absorbing resin composition and oxygen-absorbing container comprising the same

An oxygen-absorbing resin composition having excellent performance is provided which contains an oxygen-absorbing polyester and a polyolefin and has enhanced compatibility between the polymers to give an oxygen-absorbing layer inhibited from having a reduced cohesive force or an appearance failure such as roughness unevenness. The oxygen-absorbing resin composition is characterized by being obtained by melt-kneading the following ingredients (A) and (B) together with the following ingredient (C) as a compatibilizing agent. Ingredient (A): an oxygen-absorbing polyester; Ingredient (B): a polyolefin; and Ingredient (C): a copolymer of ethylene and a vinyl monomer having a hydroxy group or an ester bond, the copolymer having an ethylene proportion of 70-99 mol %.

Owner:TOYO SEIKAN KAISHA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com