Method for joining metallic member and resin member to each other, manufacturing method for cooler, and cooler

一种树脂构件、金属构件的技术,应用在将金属构件和树脂构件彼此接合、冷却器的制造及冷却器领域,能够解决强度下降、残留、树脂增多等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. However, this should not be construed that the present invention is limited to the following embodiments. The following description and drawings are simplified as necessary for clarity of illustration.

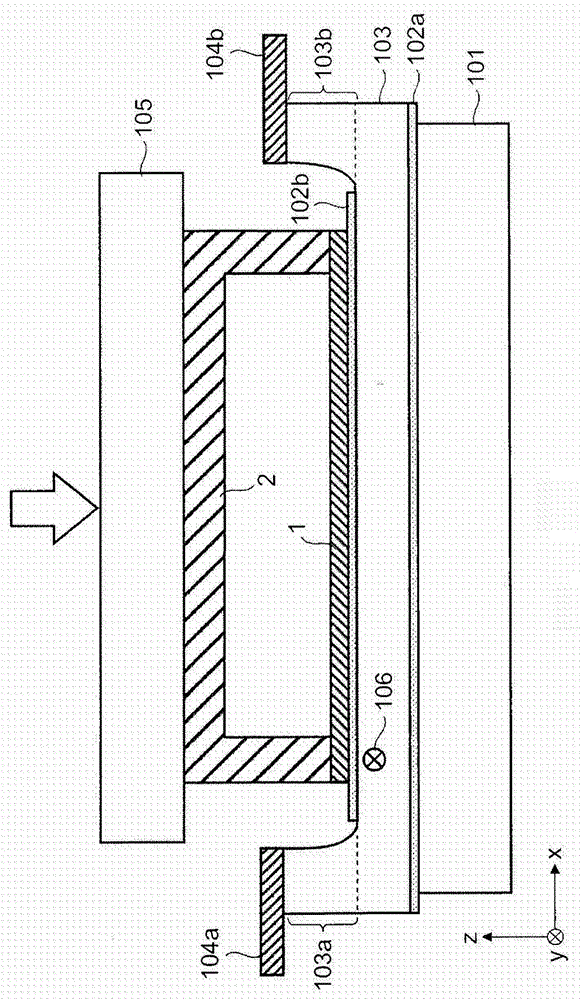

[0029] First, combine figure 1 The joining device according to the embodiment is explained. figure 1 is a schematic cross-sectional view showing the engagement device according to the embodiment. The joining device according to the embodiment is a joining device for joining the metal member 1 and the resin member 2 .

[0030] Such as figure 1 As shown in , the bonding device according to the described embodiment comprises a cooling panel 101 , insulating plates 102 a , 102 b , a heater 103 , electrodes 104 a , 104 b , a pressure plate 105 and a thermocouple 106 . Naturally, for convenience, use figure 1 The right-handed xyz coordinate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal degradation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com