Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

597results about "Mounting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

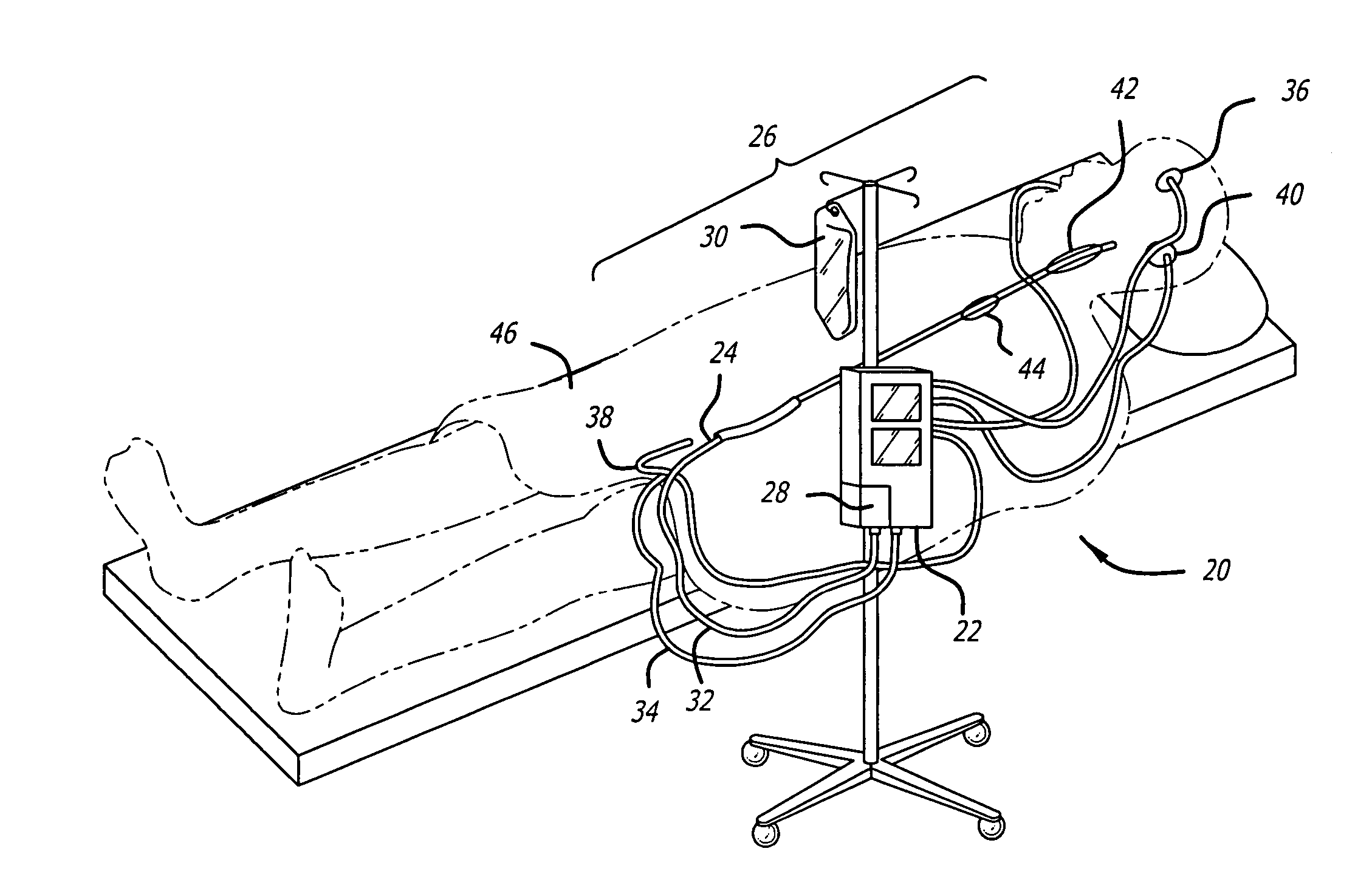

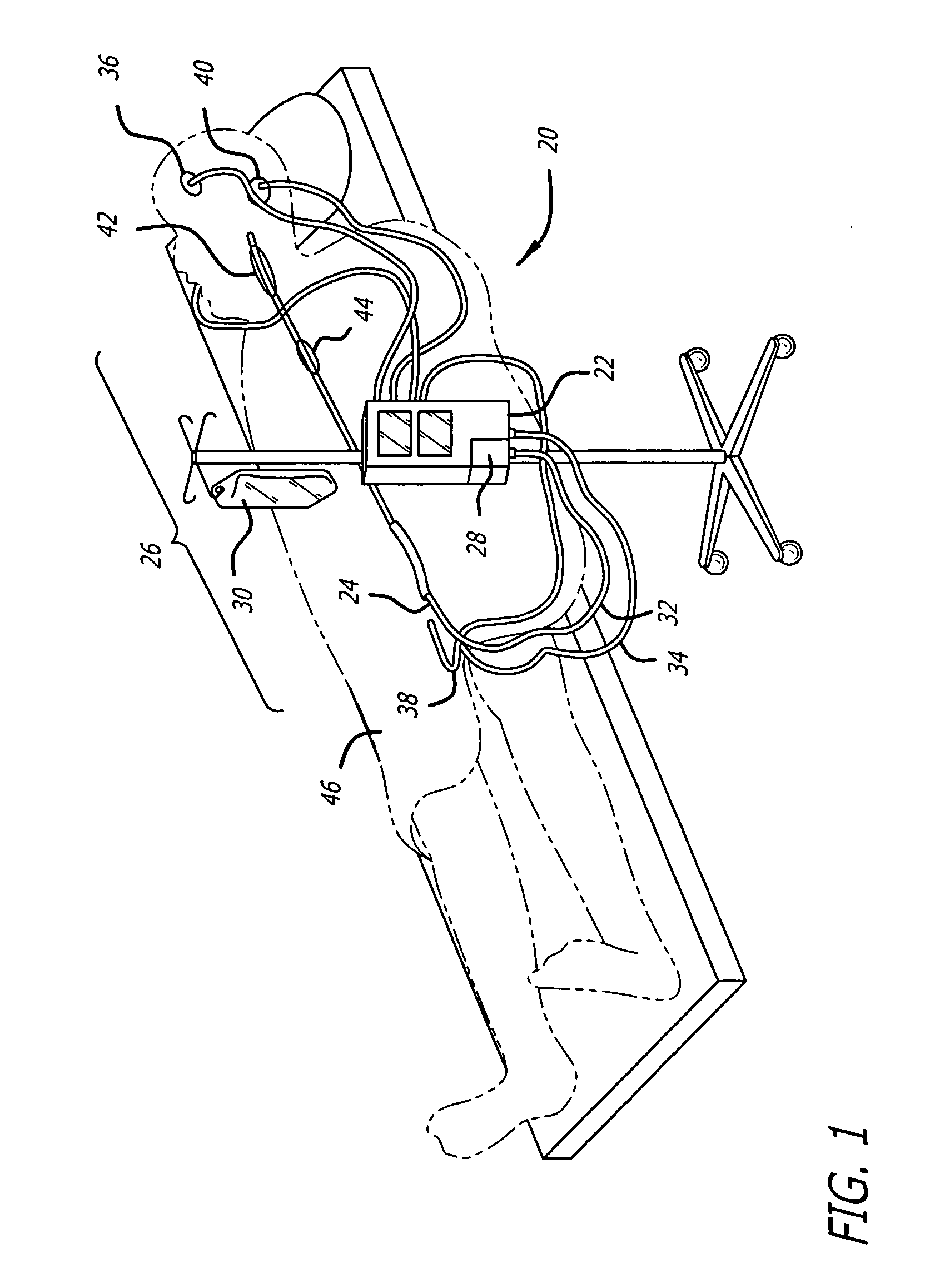

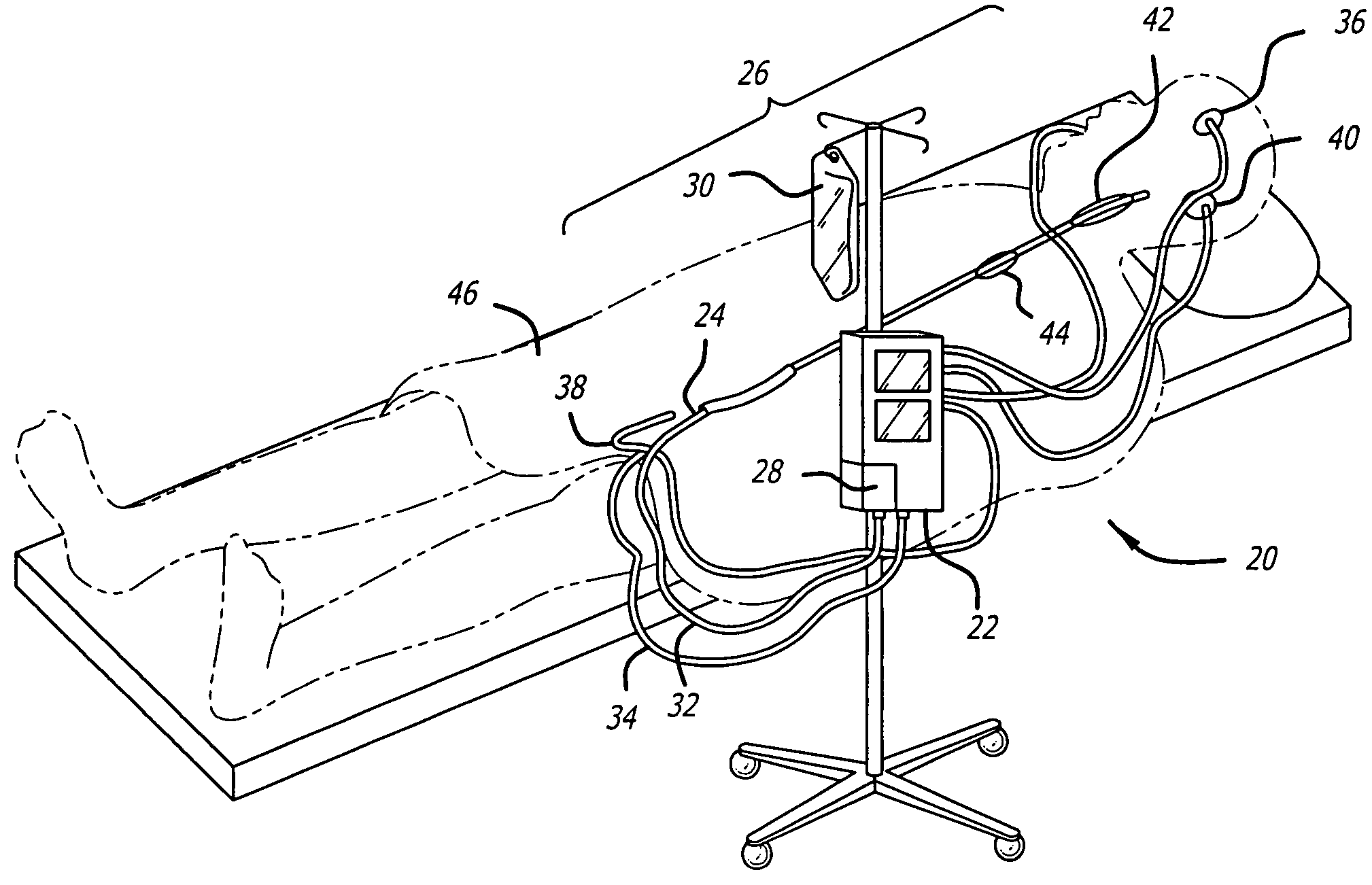

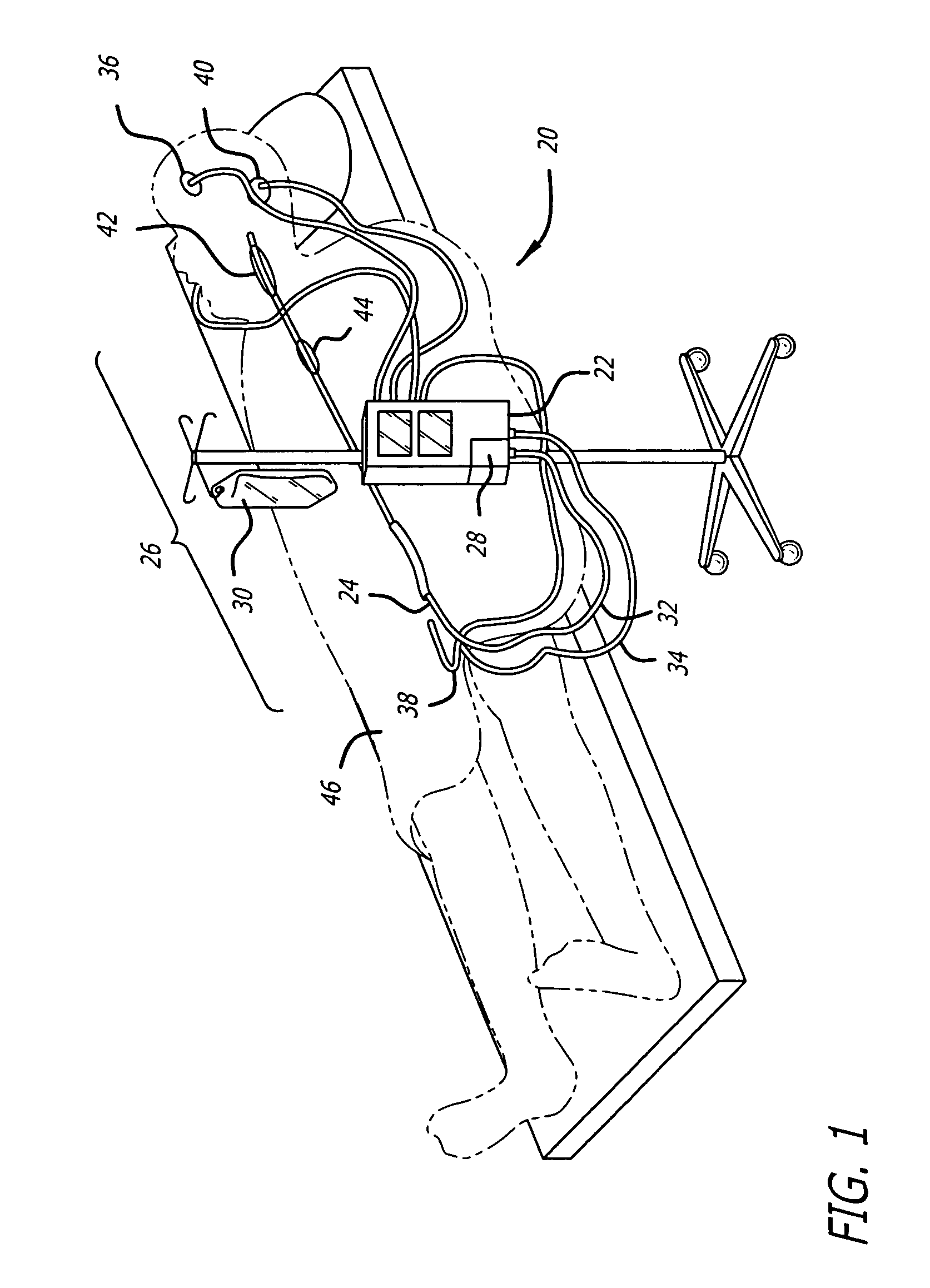

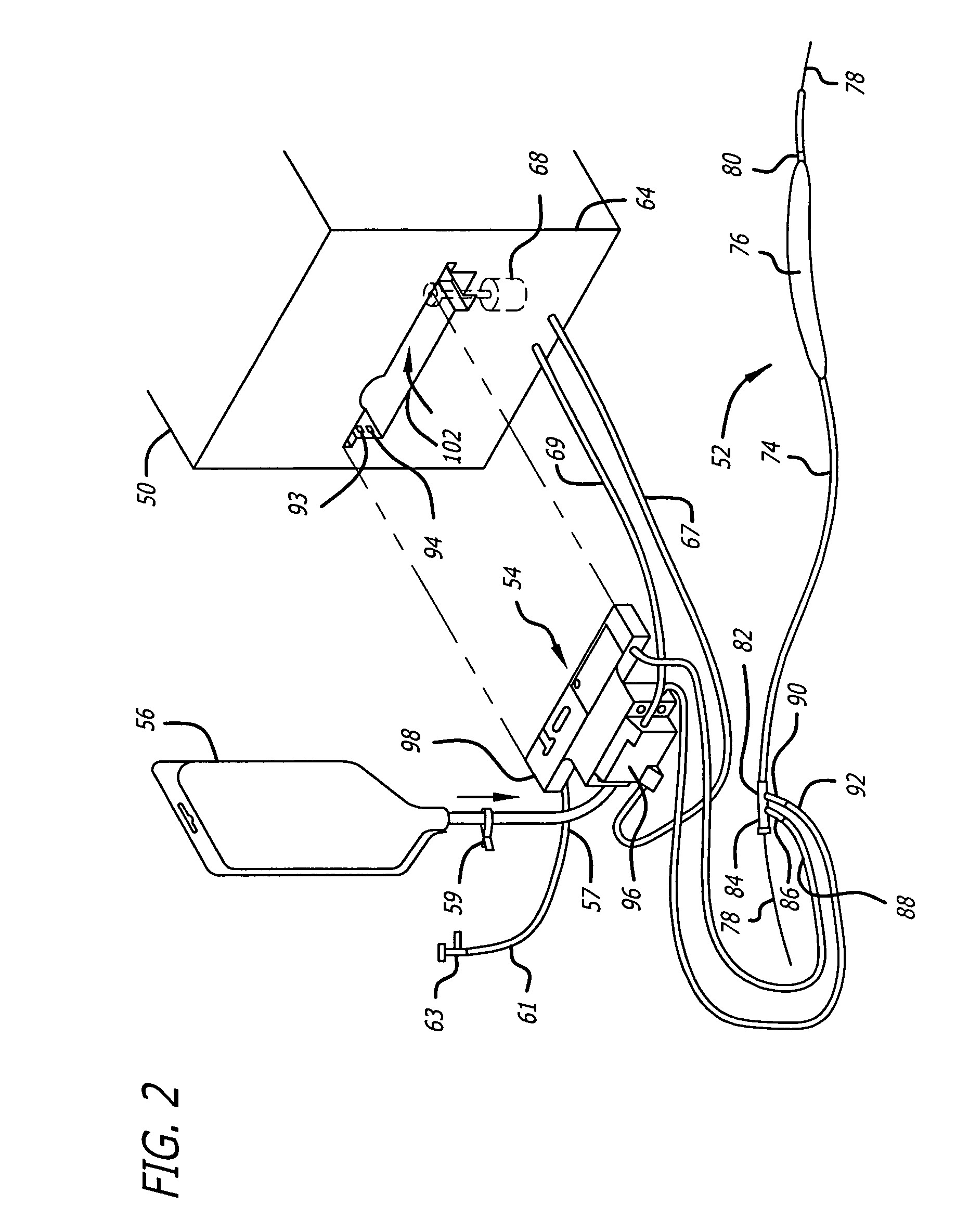

Apparatus and method for providing enhanced heat transfer from a body

ActiveUS20060293734A1Avoid possibilityIncrease volumeMedical devicesIndirect heat exchangersTemperature controlUser input

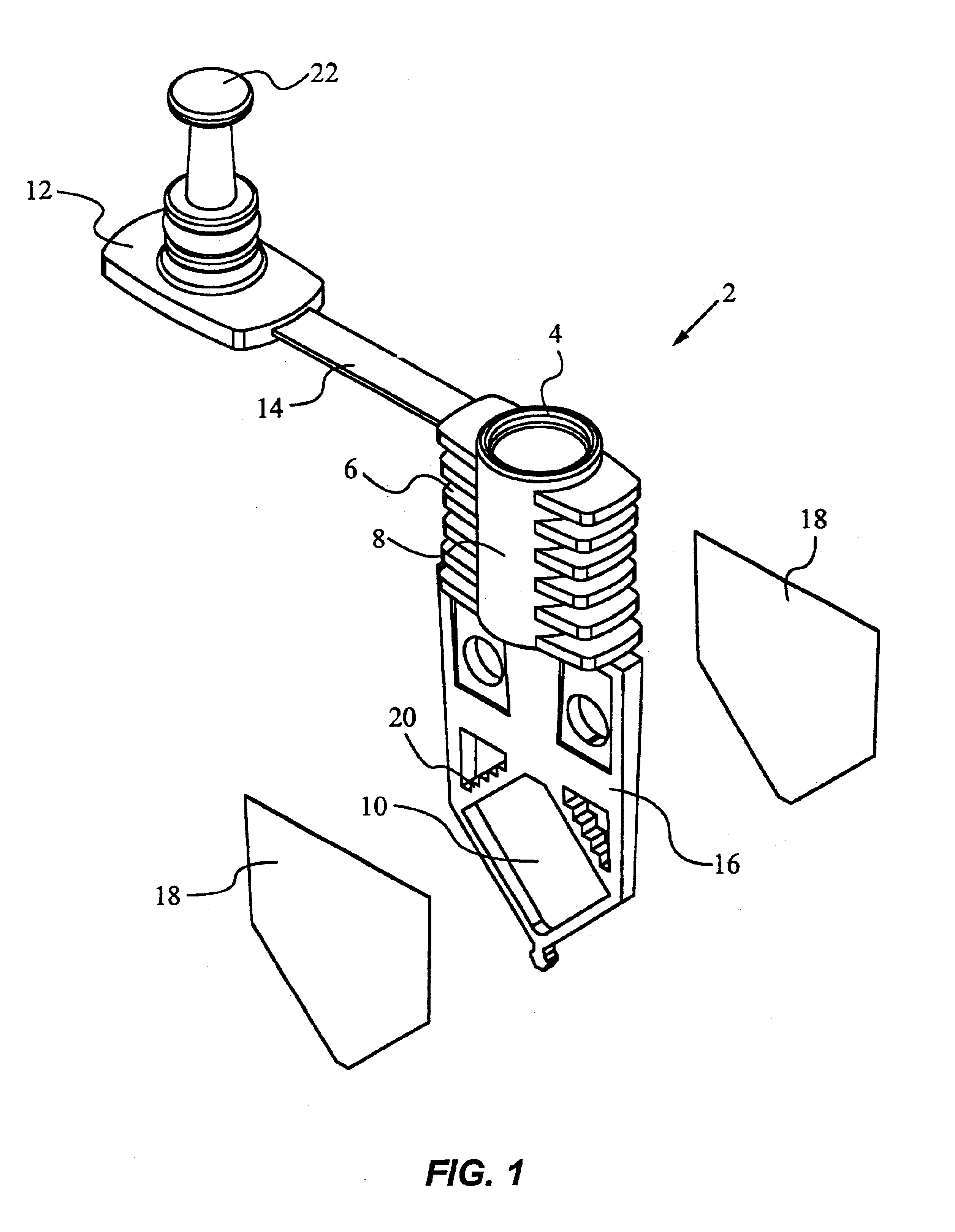

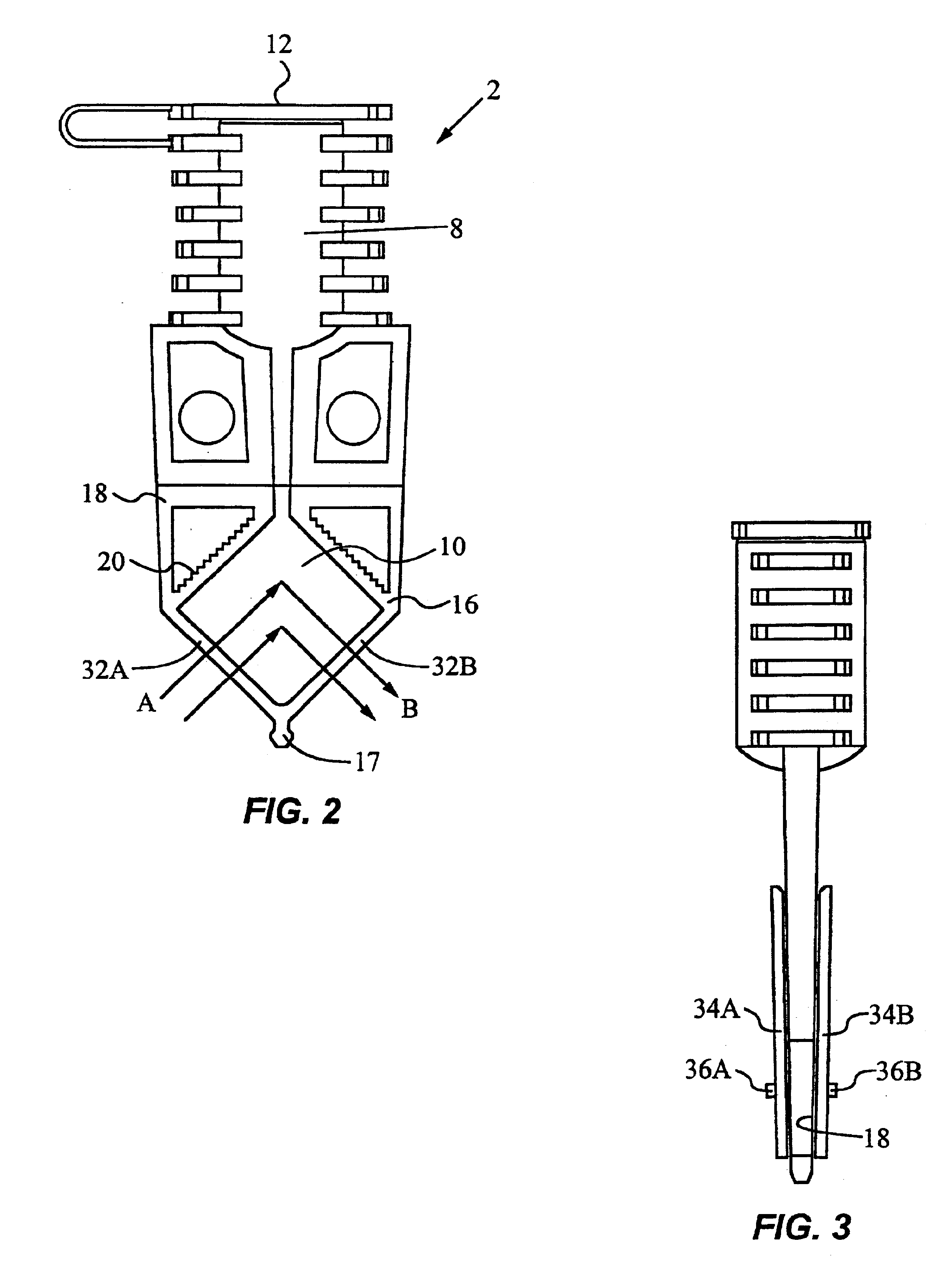

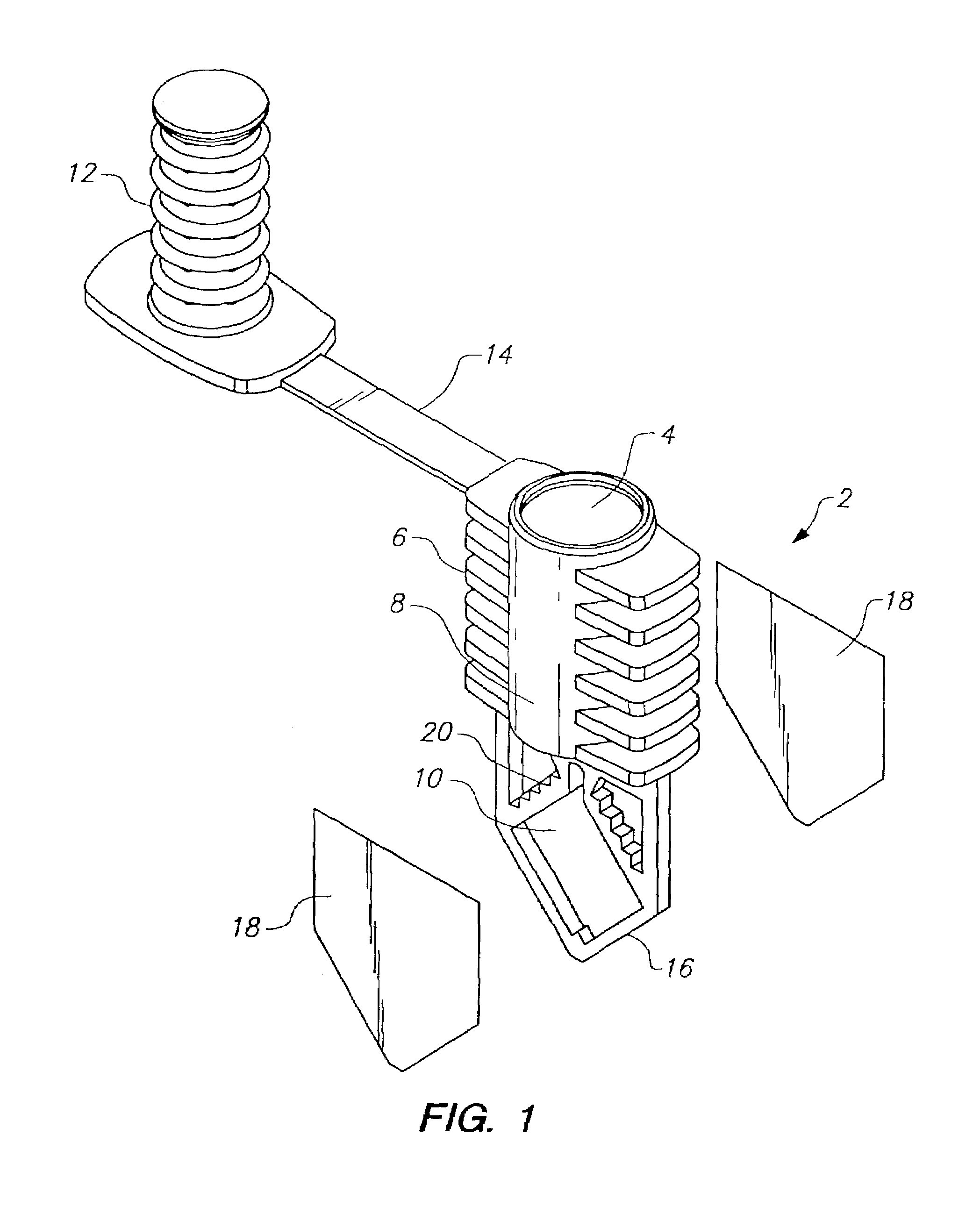

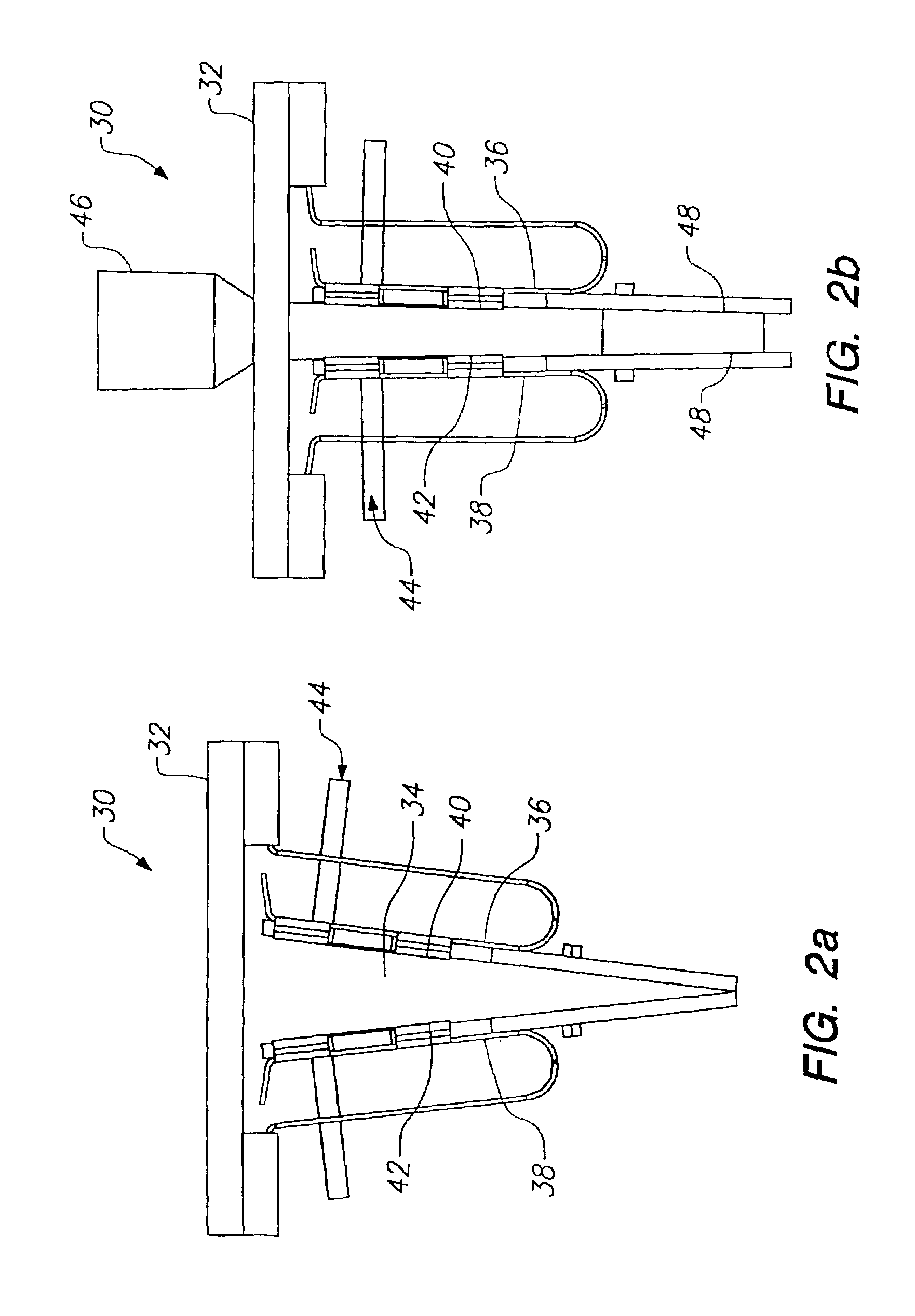

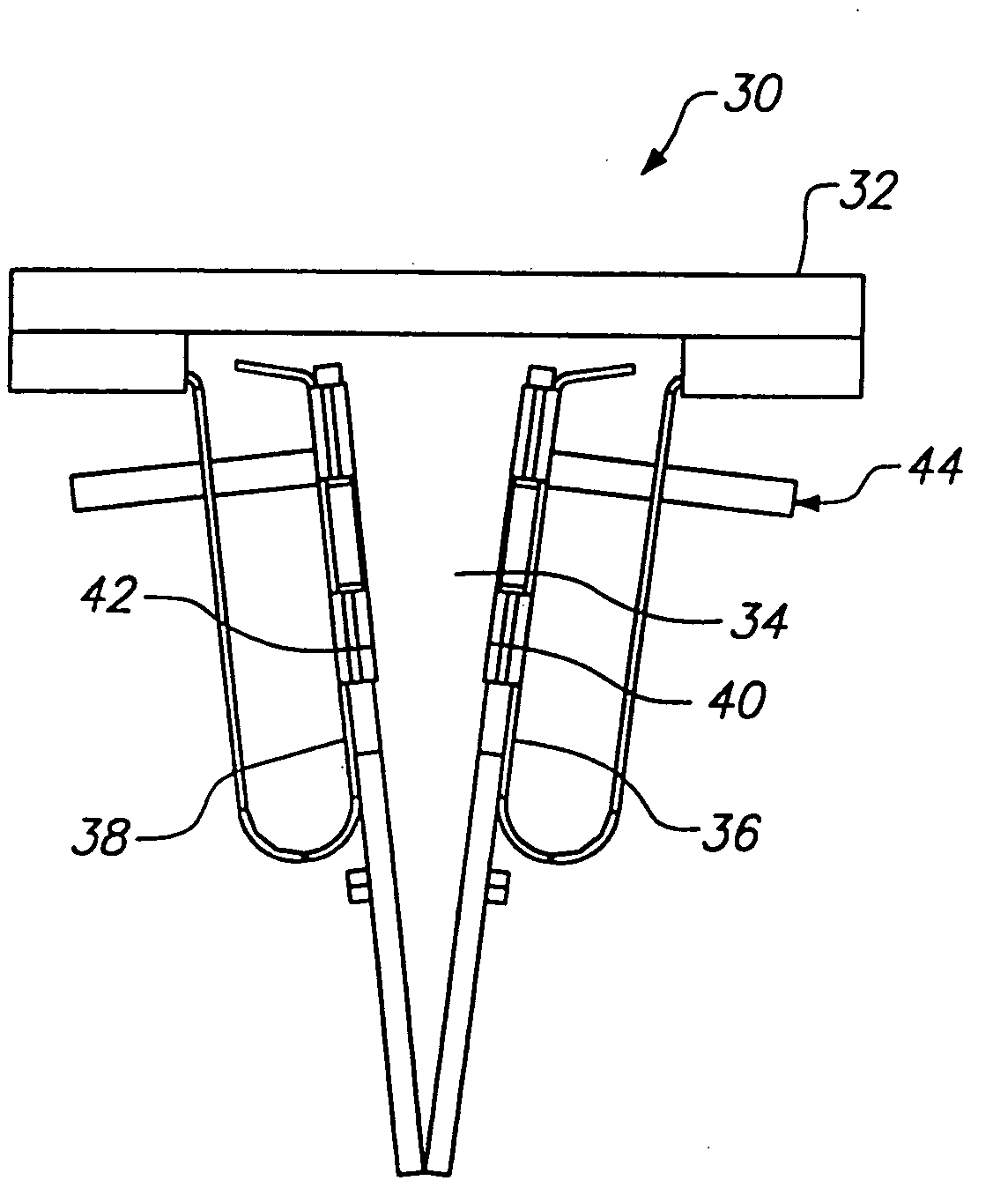

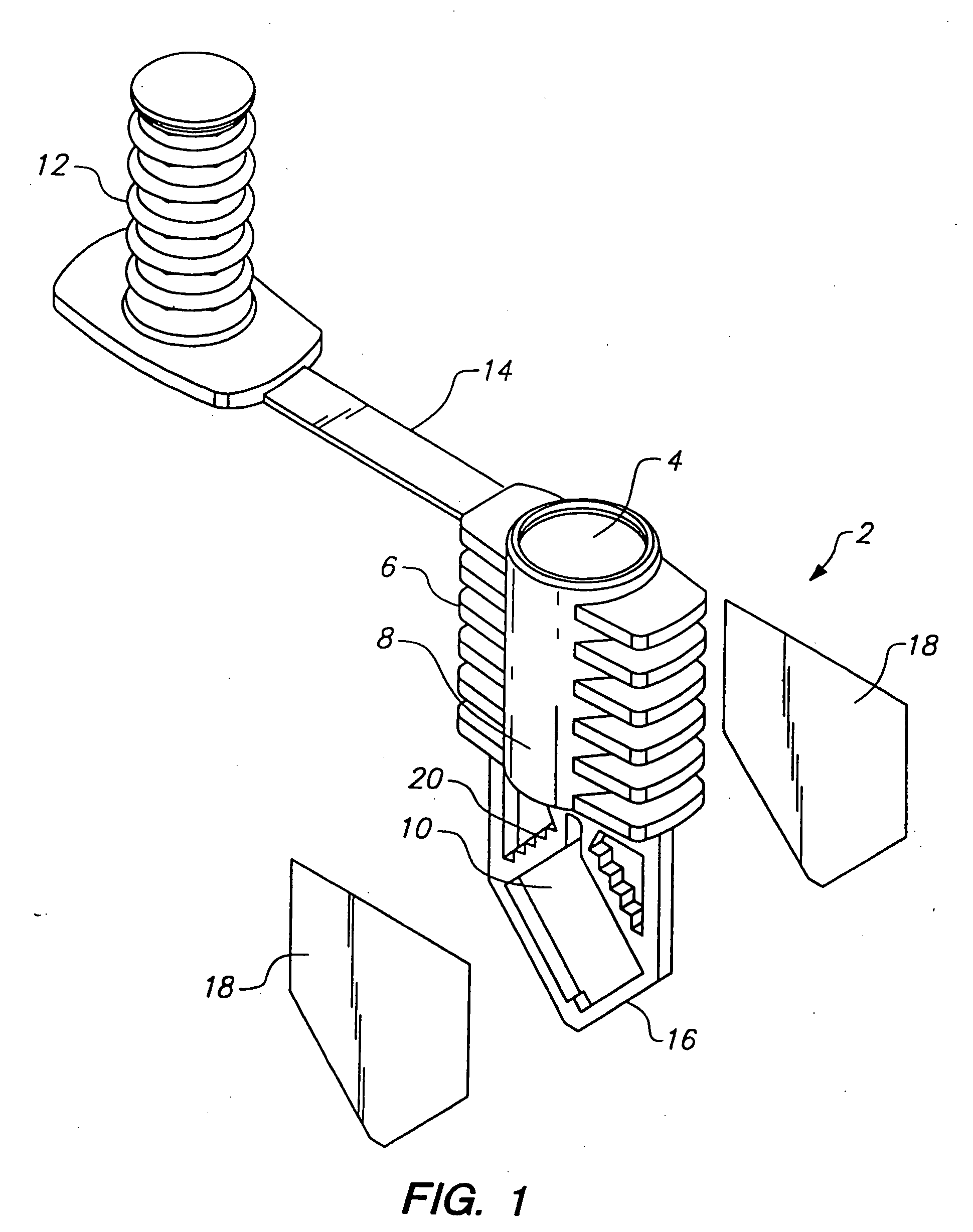

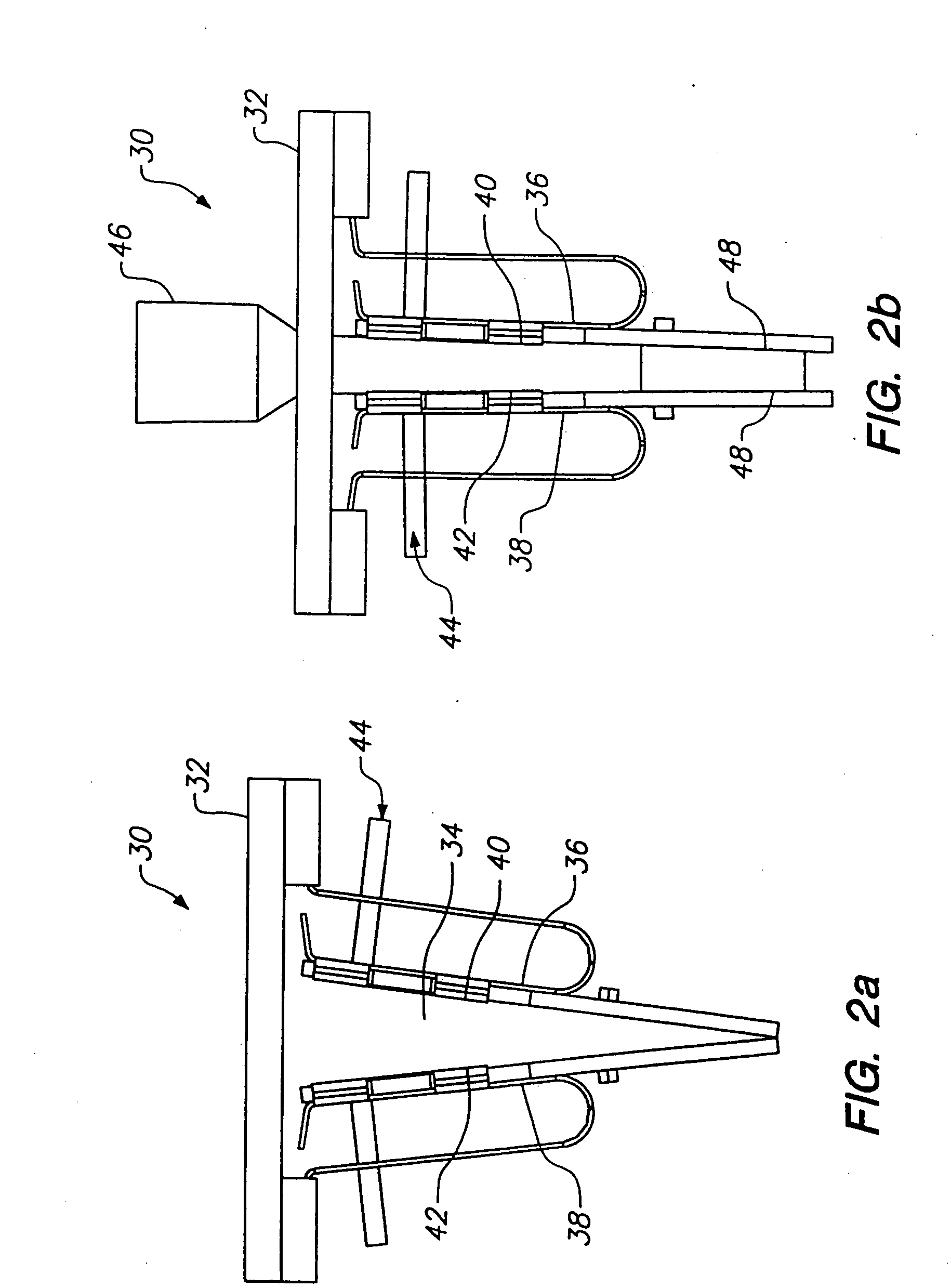

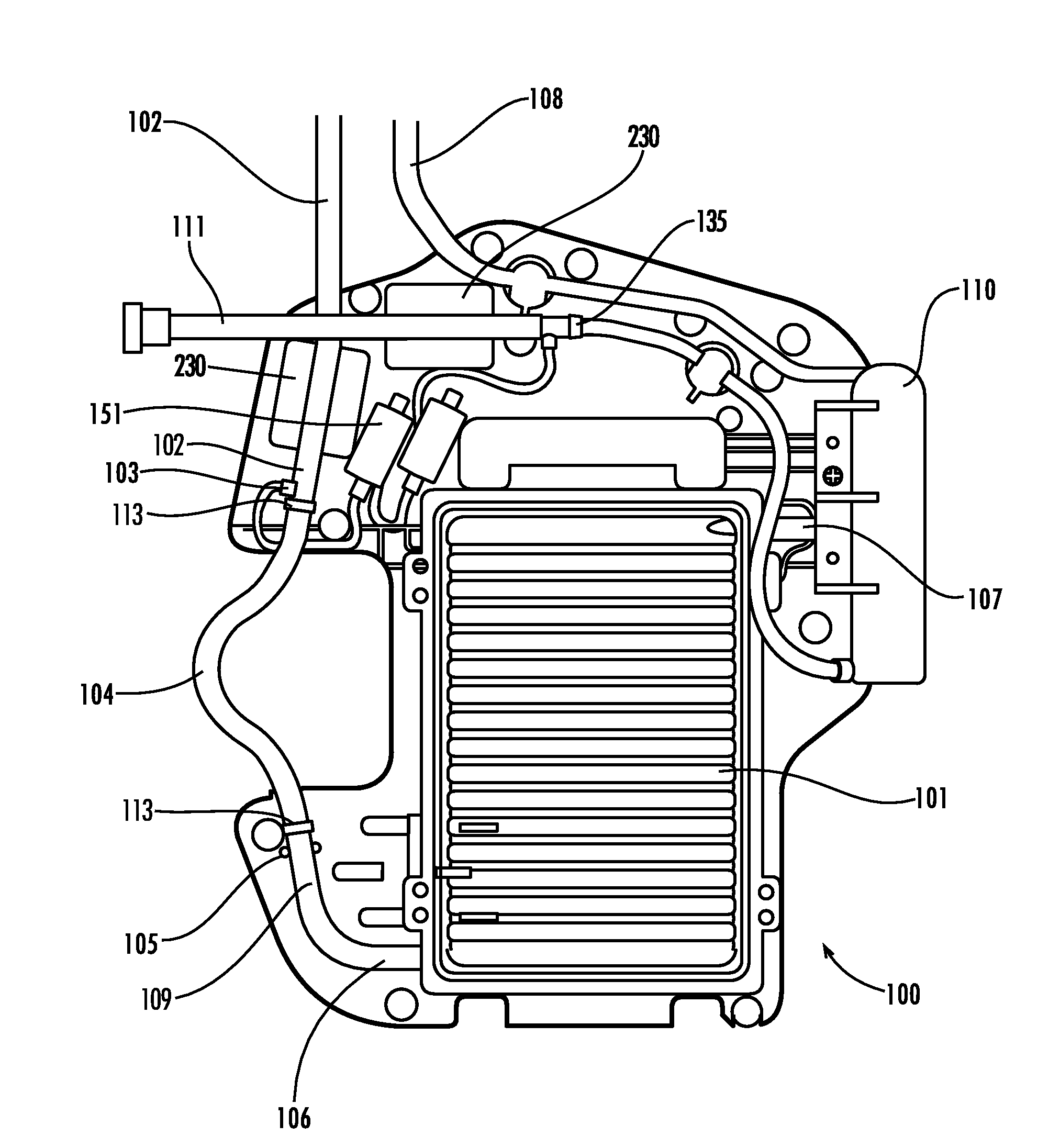

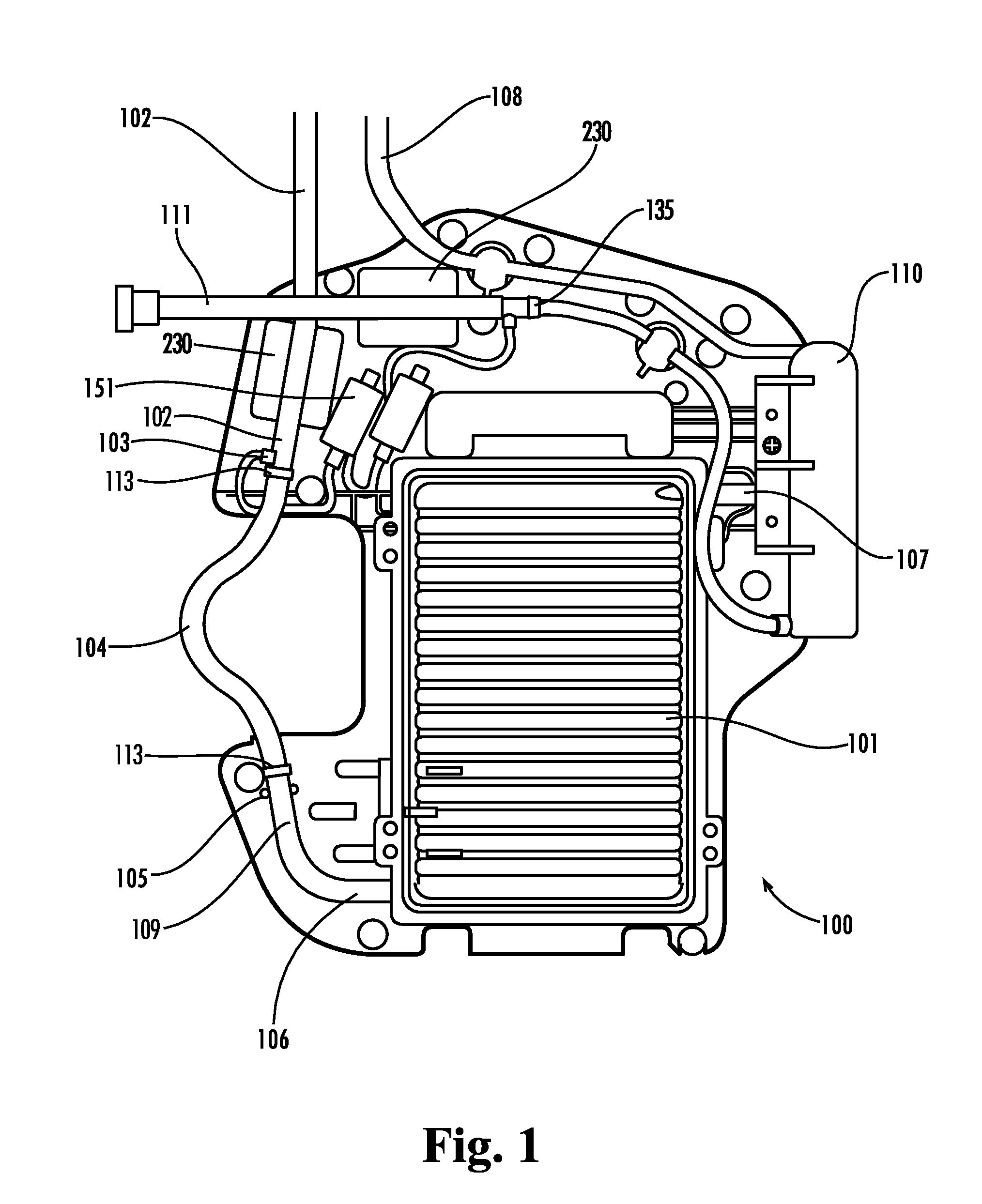

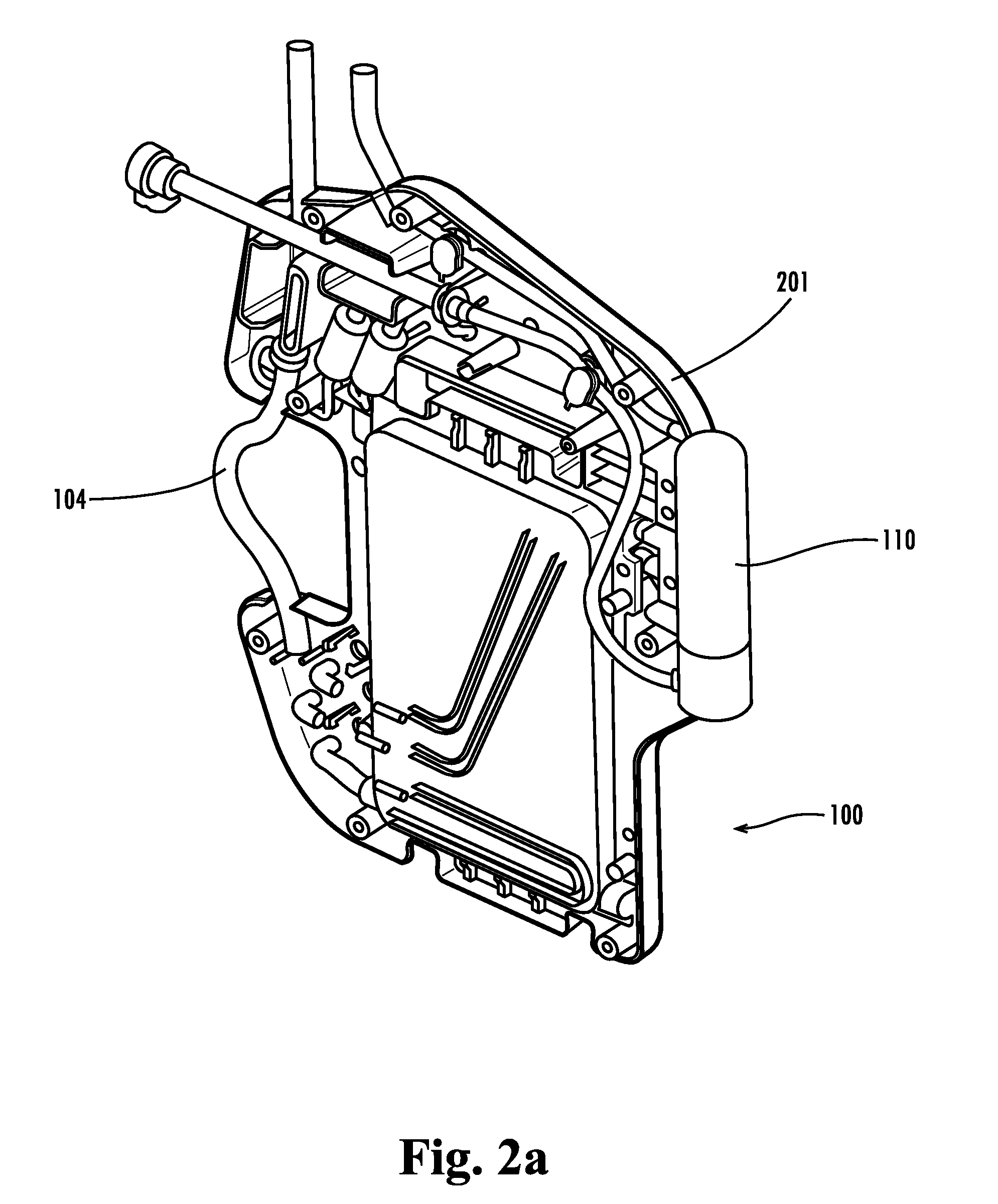

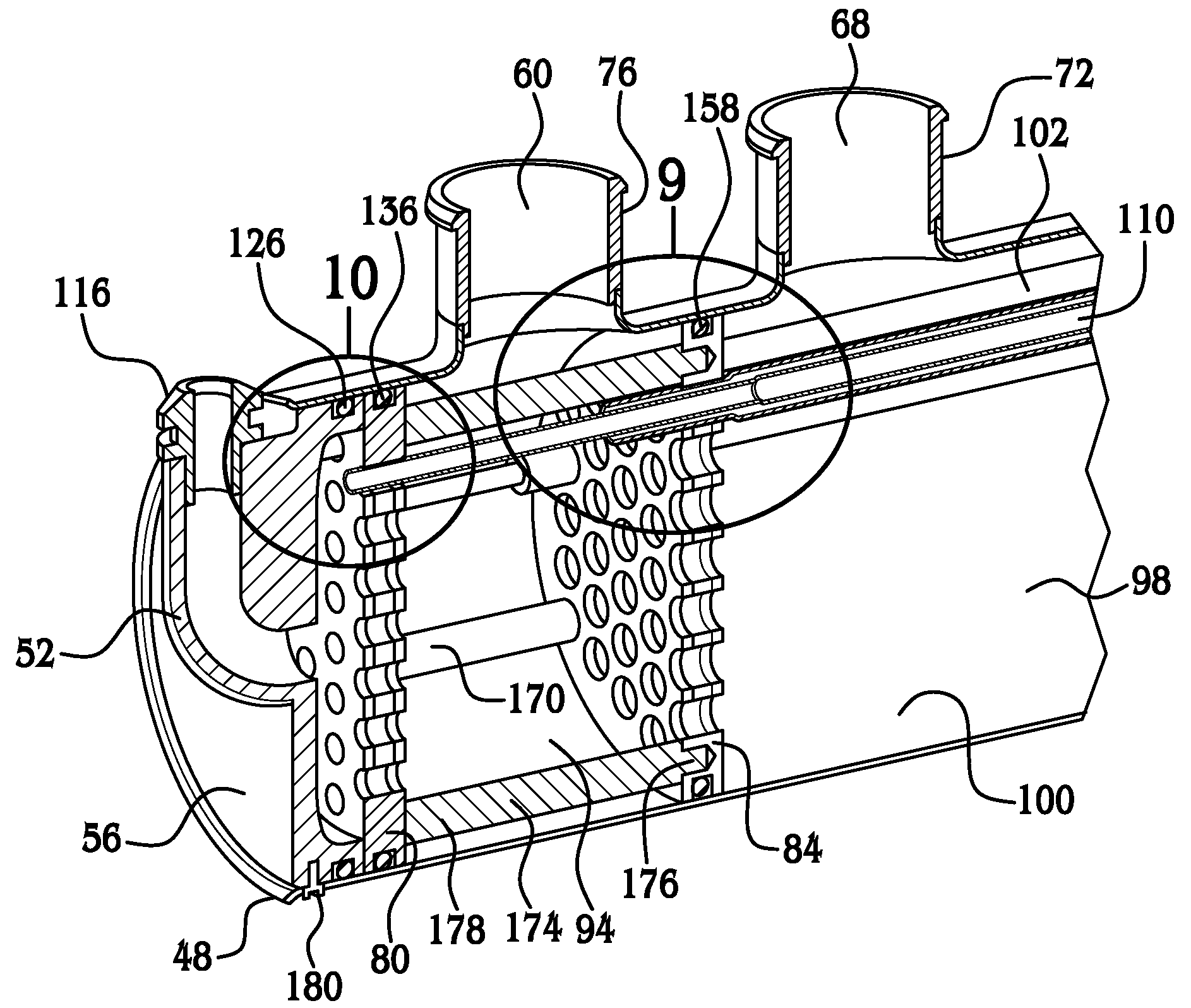

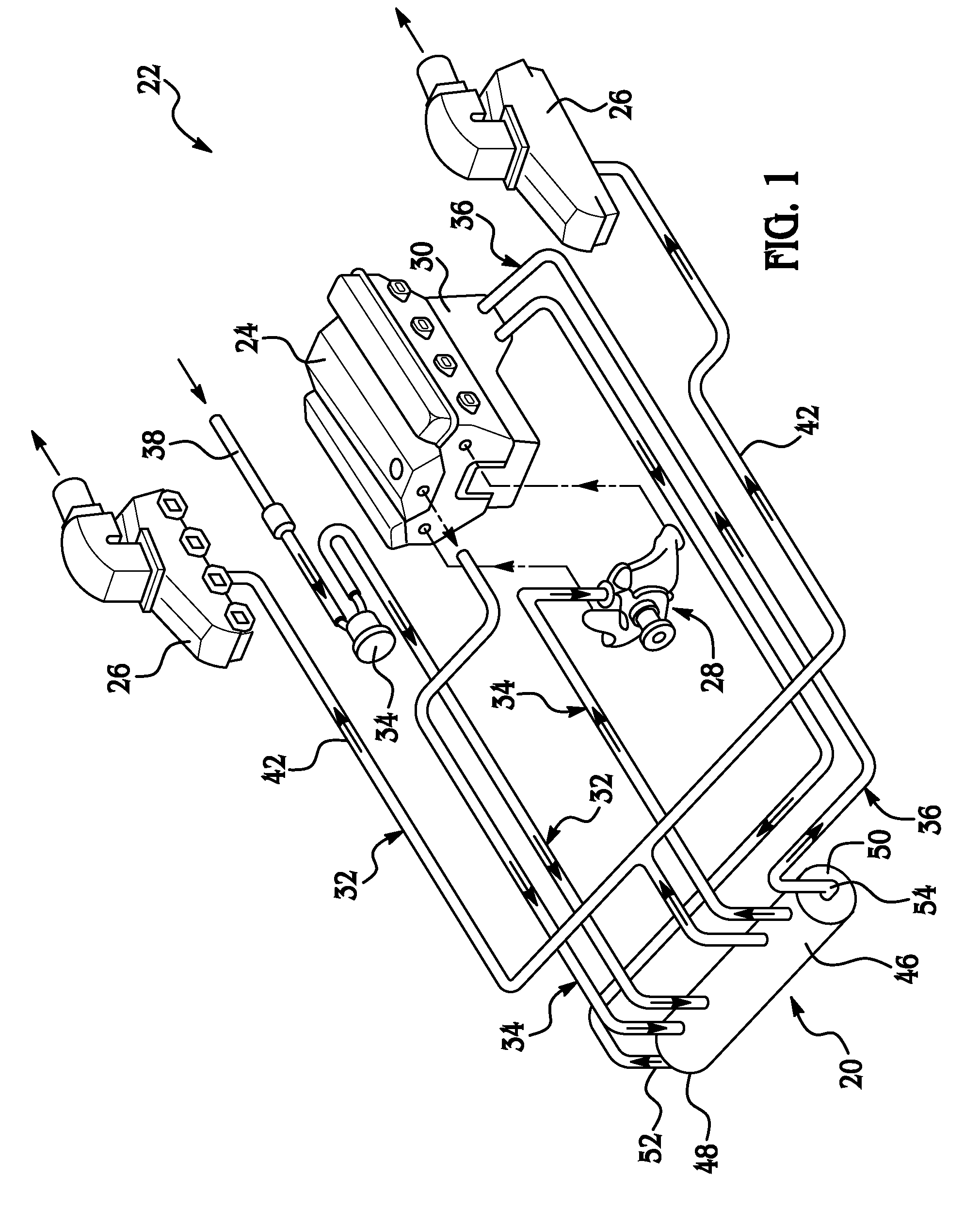

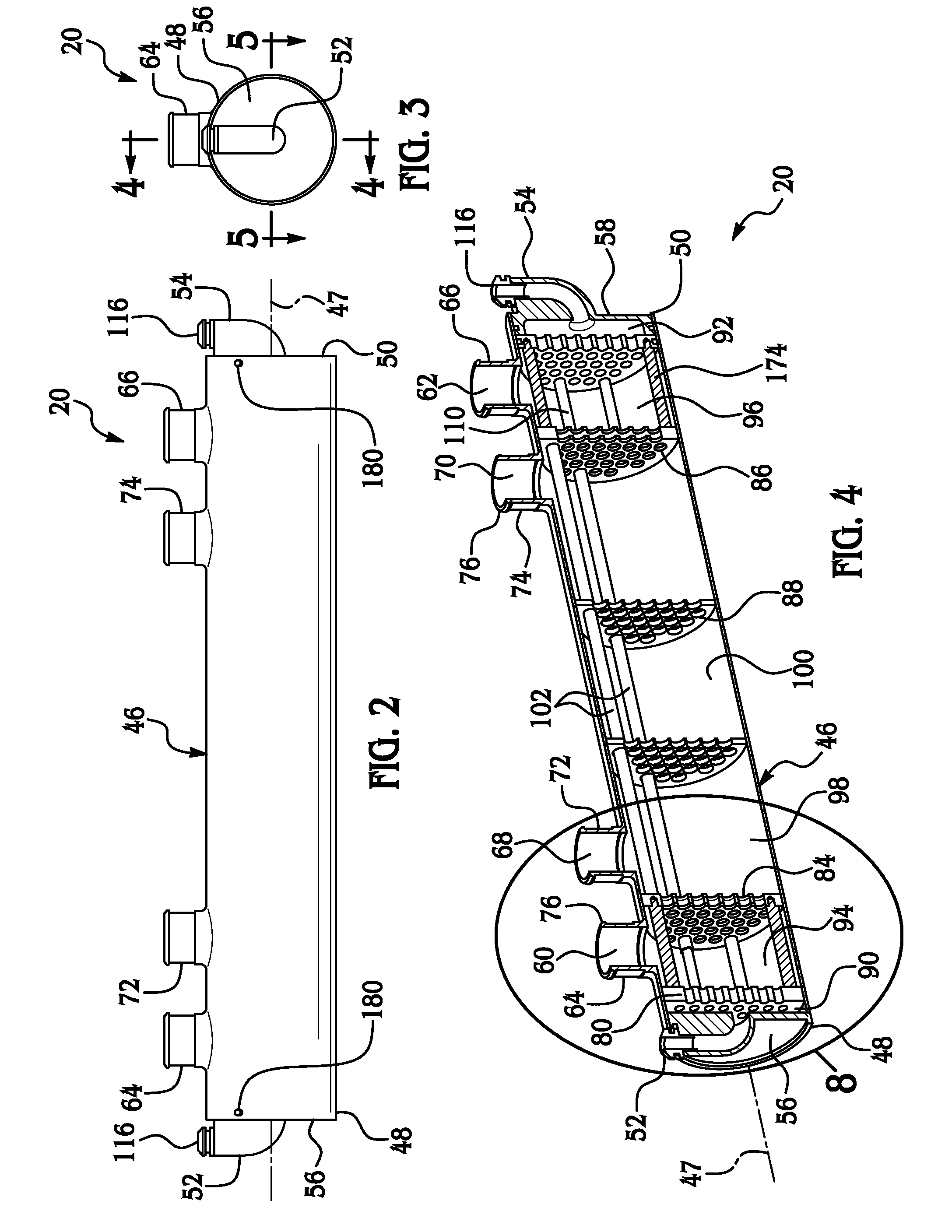

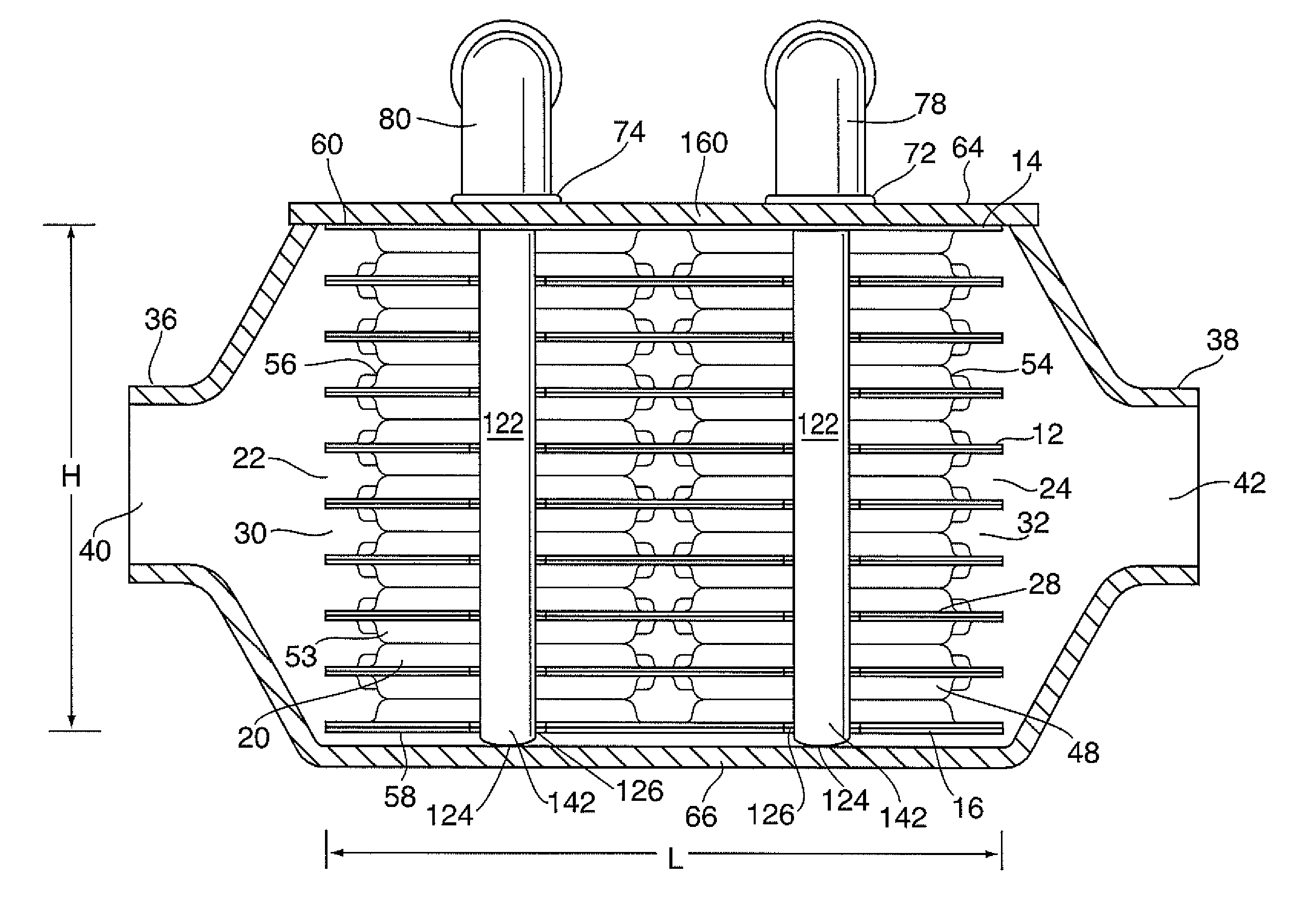

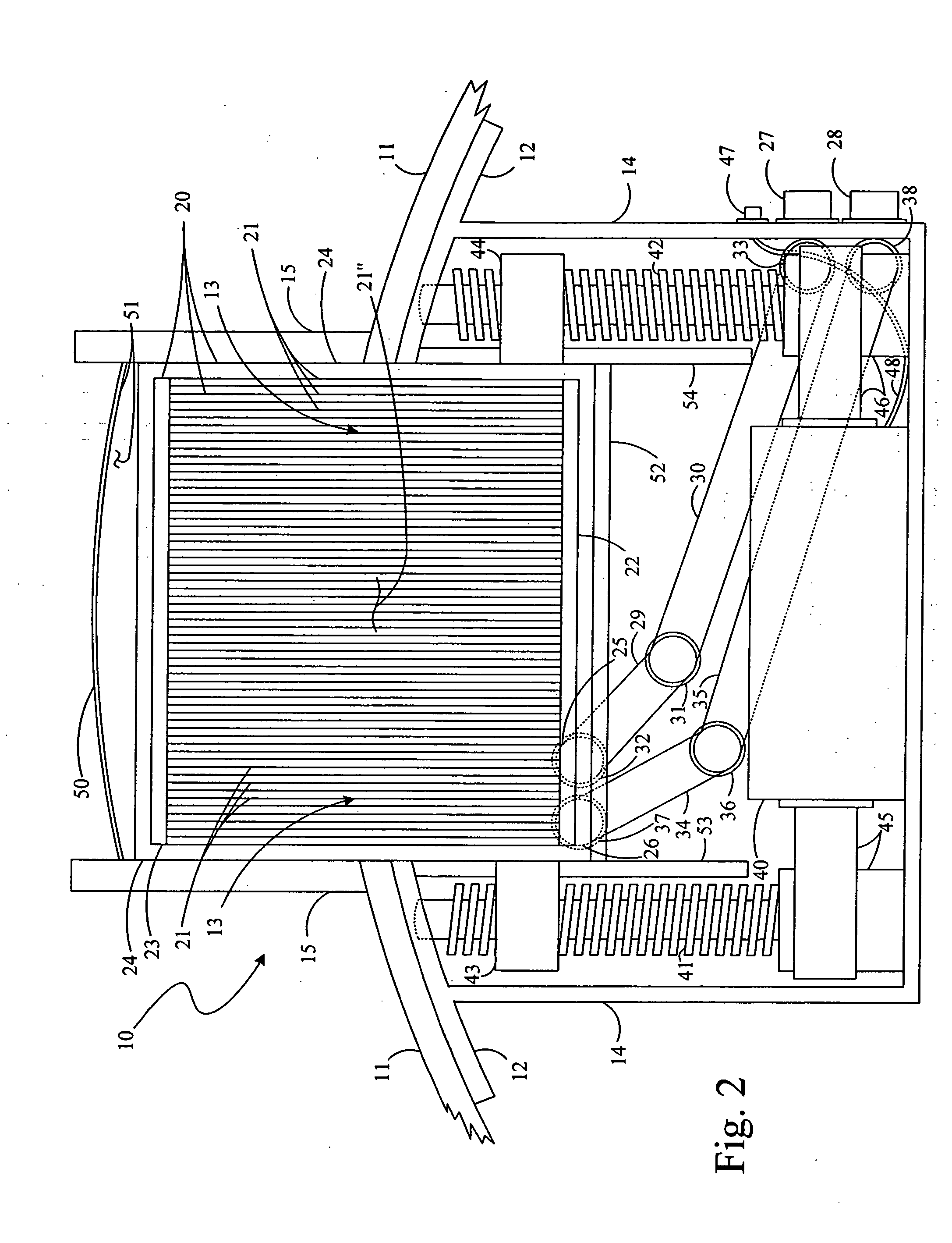

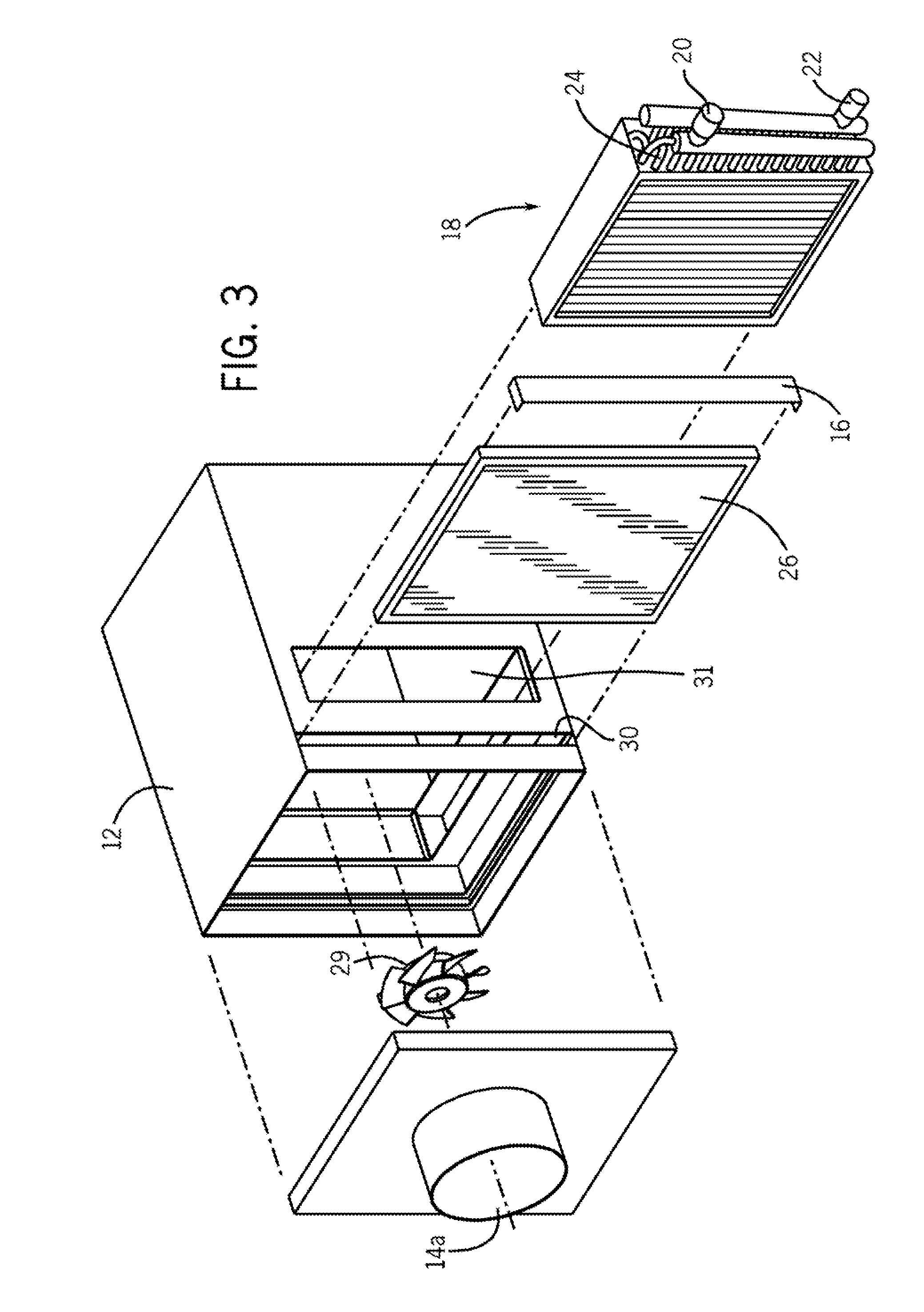

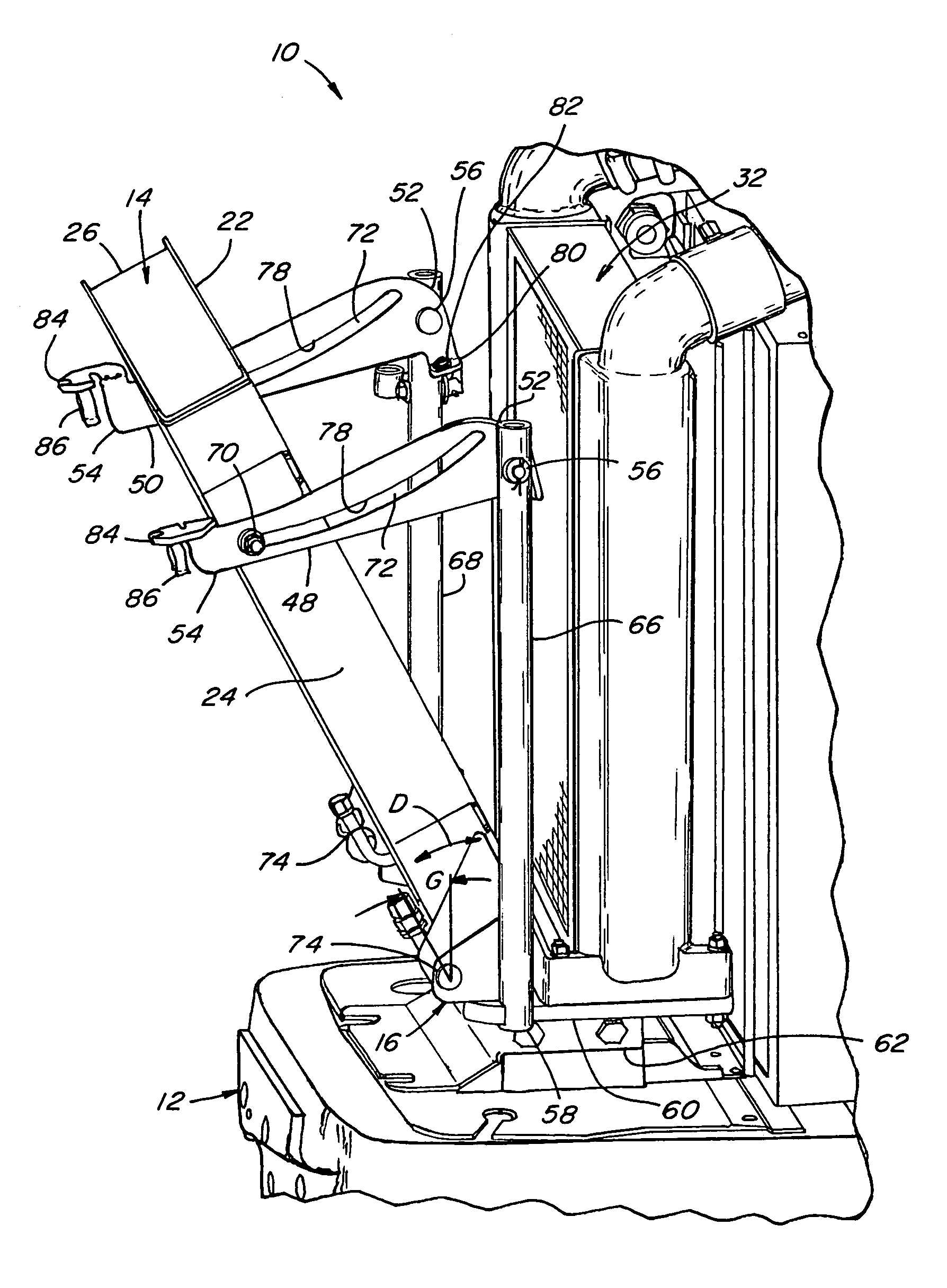

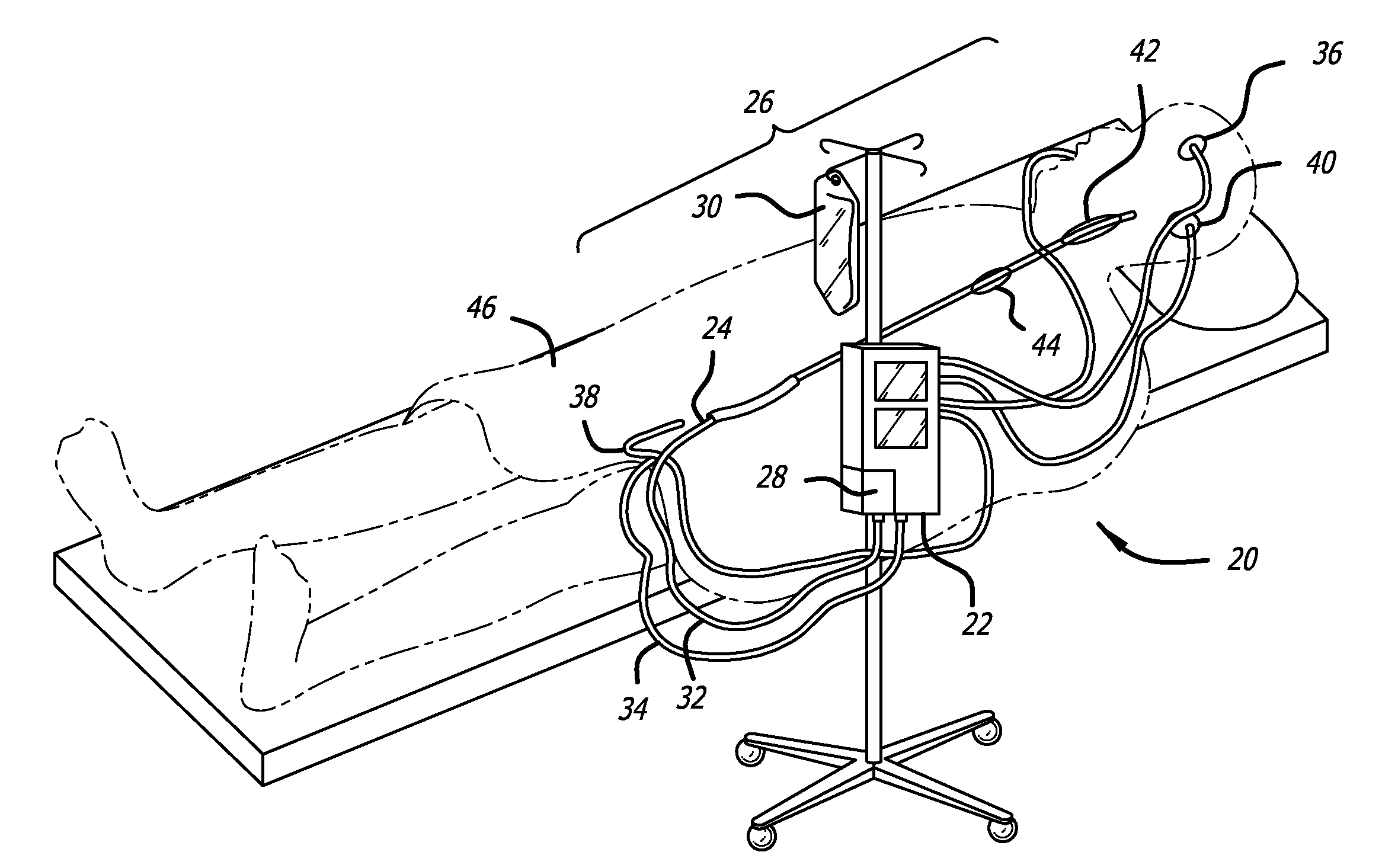

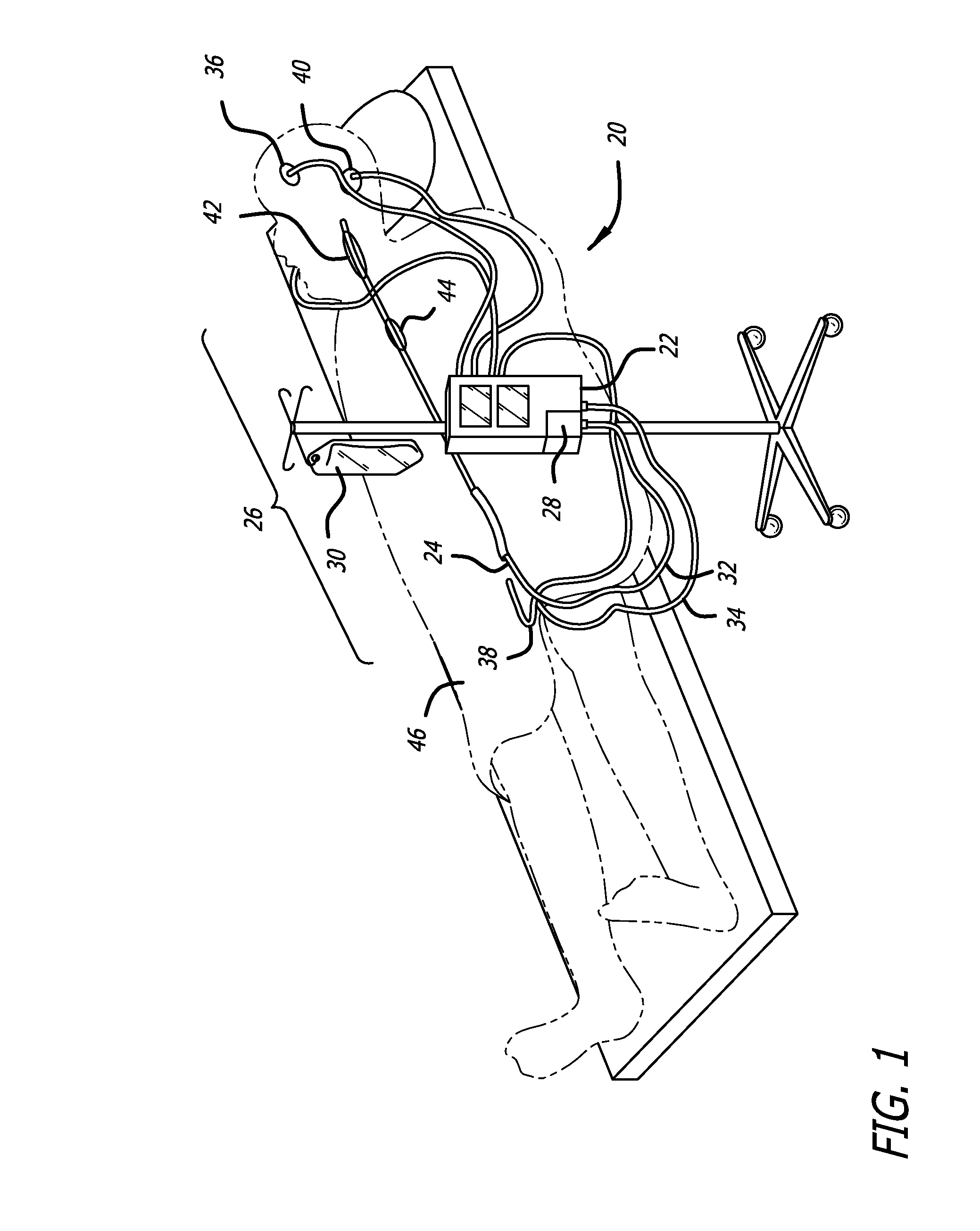

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette is attached to the circulatory conduits of the catheter, the heat exchange cassette being sized to engage a cavity within a control unit. The control unit includes a heater / cooler device for providing heated or cooled fluid to a heat exchanger in thermal communication with the fluid heat exchange medium circulating to the heat exchange catheter, a user input device, and a processor connected to receive input from various sensors around the body and the system. A temperature control scheme for ramping the body temperature up or down without overshoot is provided.

Owner:ZOLL CIRCULATION

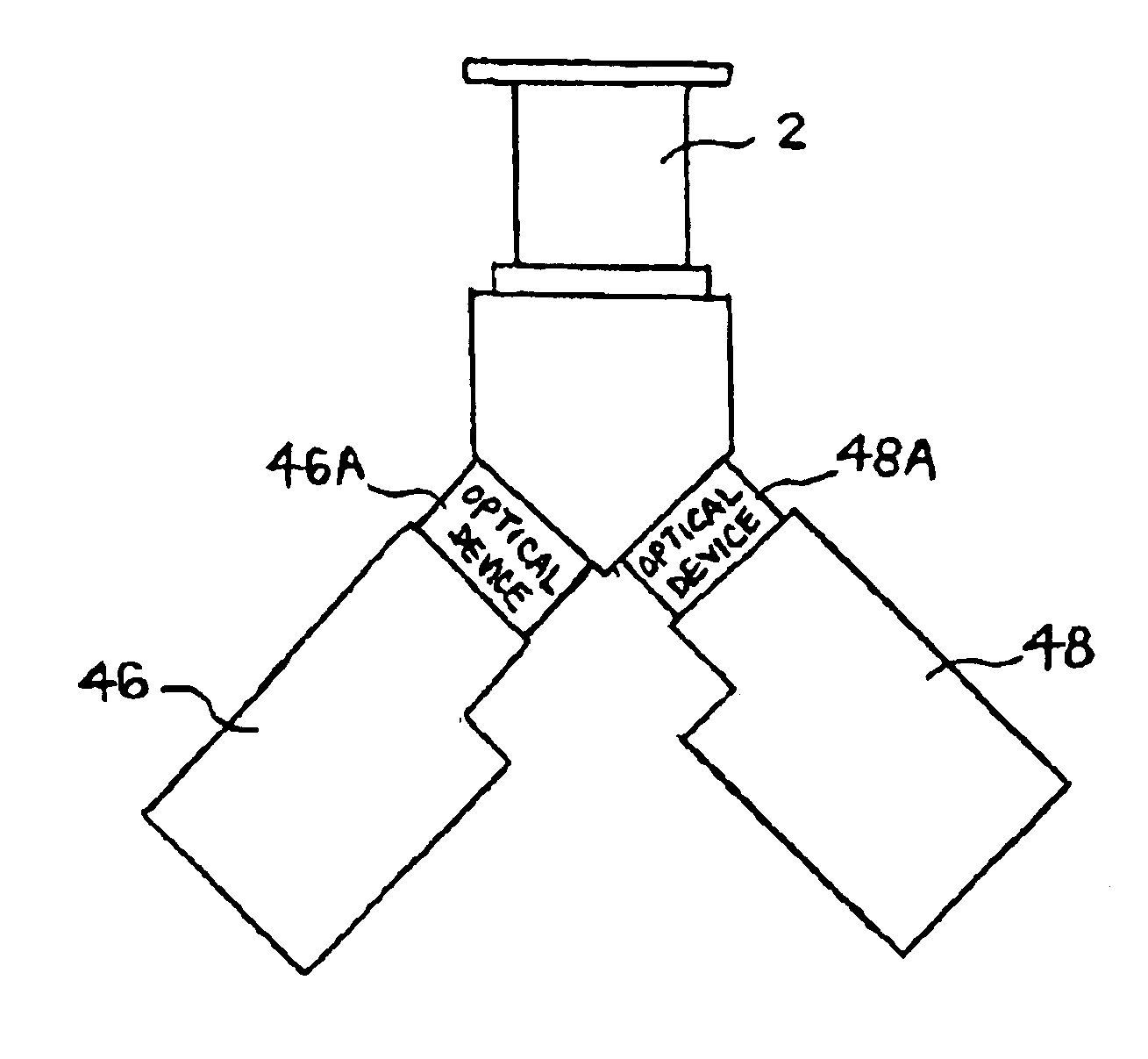

Multi-channel optical detection system

InactiveUS6940598B2Low costReduce maintenanceOptical radiation measurementHeating or cooling apparatusExcitation beamAnalyte

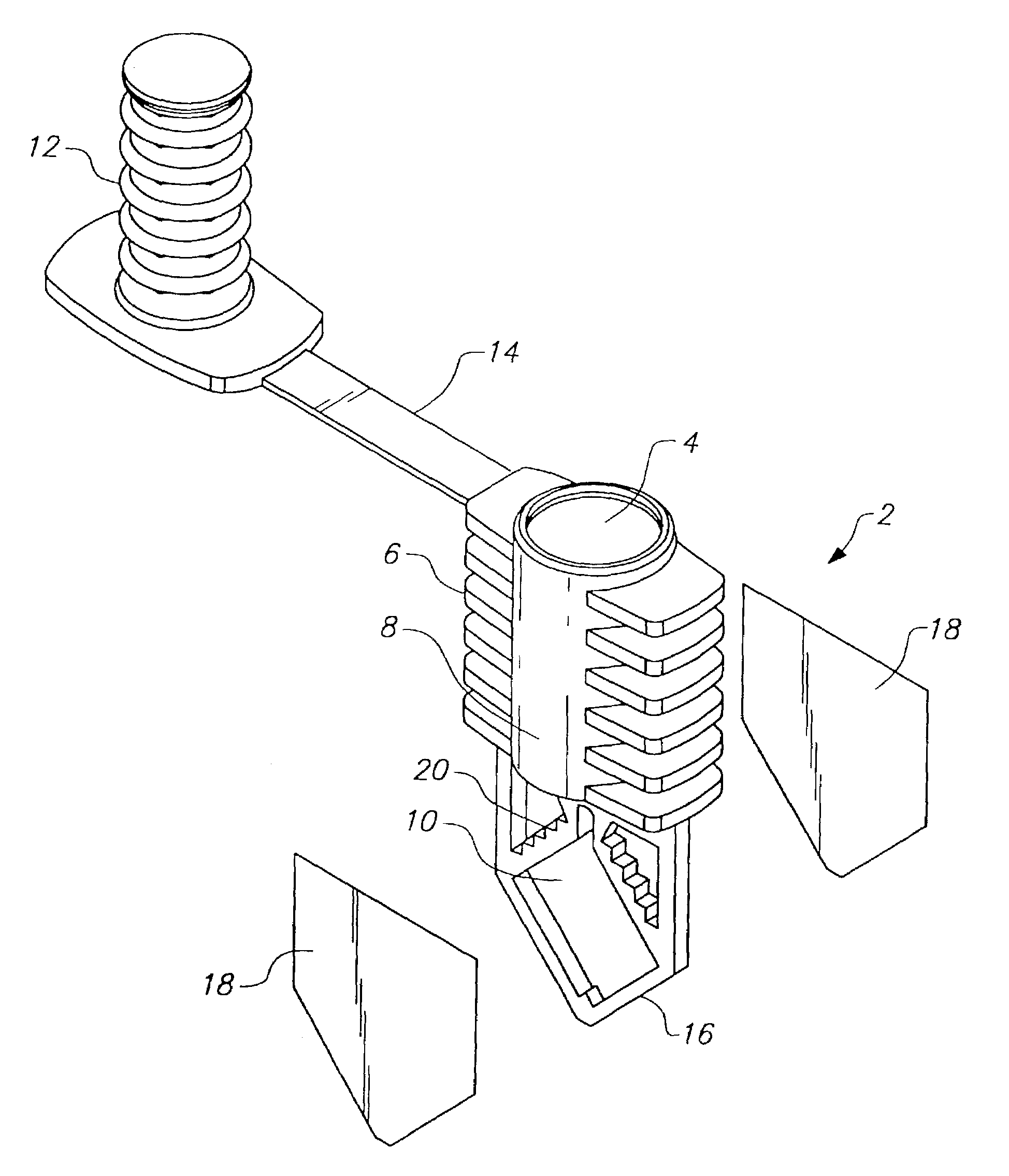

An apparatus for thermally controlling and optically interrogating a reaction mixture includes a vessel [2] having a chamber [10] for holding the mixture. The apparatus also includes a heat-exchanging module [37] having a pair of opposing thermal plates [34A, 34B] for receiving the vessel [2] between them and for heating / and or cooling the mixture contained in the vessel. The module [37] also includes optical excitation and detection assemblies [46,48] positioned to optically interrogate the mixture. The excitation assembly [46] includes multiple light sources [100] and a set of filters for sequentially illuminating labeled analytes in the mixture with excitation beams in multiple excitation wavelength ranges. The detection assembly [48] includes multiple detectors [102] and a second set of filters for detecting light emitted from the chamber [10] in multiple emission wavelength ranges. The optics assemblies [46,48] thus provide a multi-channel system for detecting a plurality of different target analytes in the mixture.

Owner:CEPHEID INC

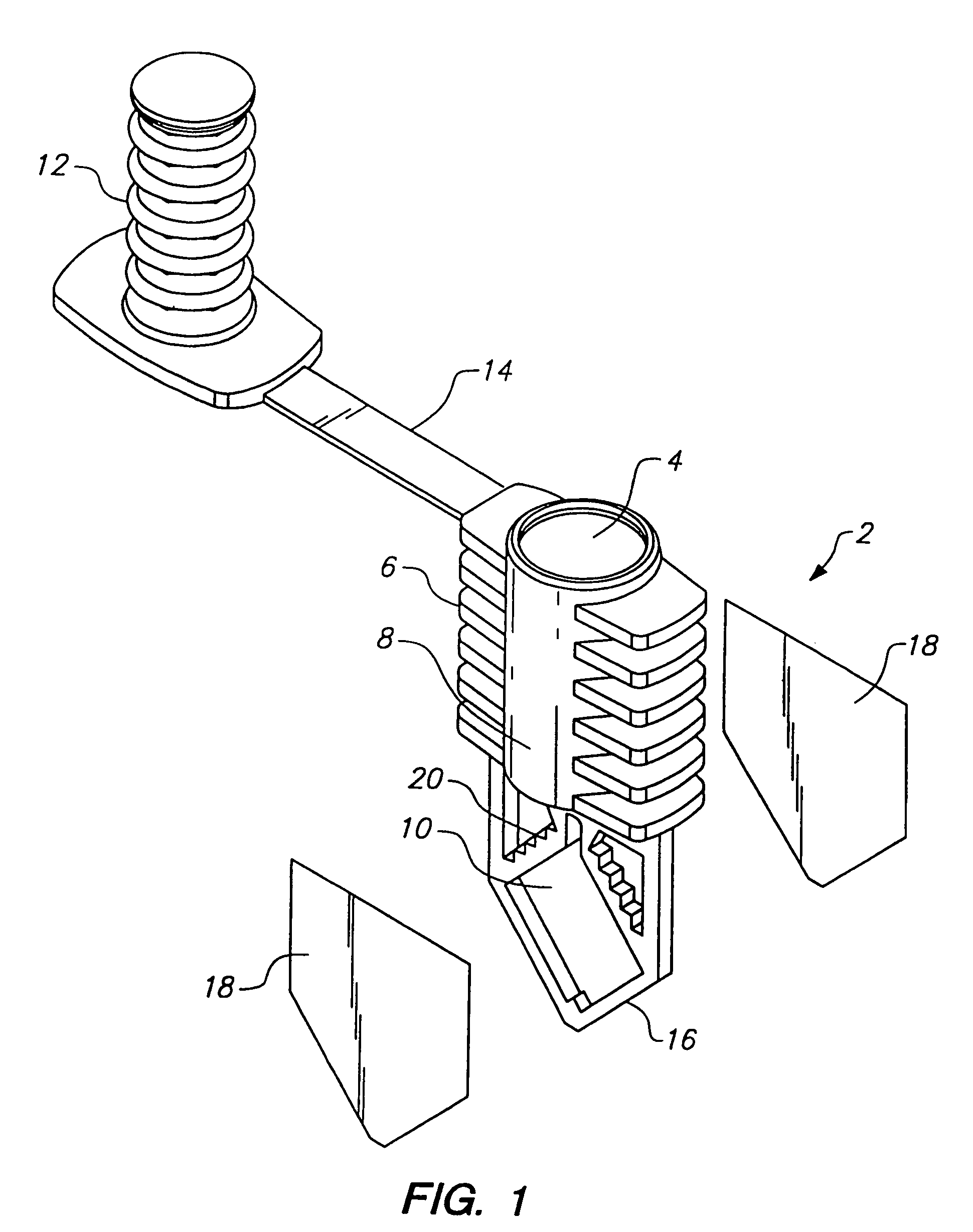

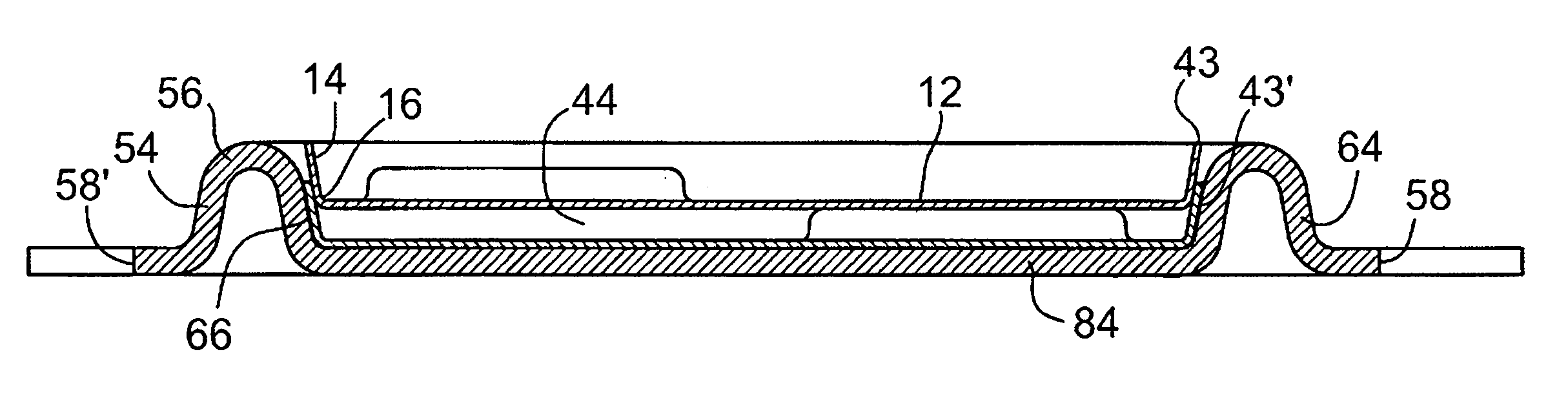

Apparatus and reaction vessel for controlling the temperature of a sample

InactiveUS7255833B2Optimal thermal transferEfficient optical viewing of chemical reactionAnalysis using chemical indicatorsHeating or cooling apparatusOptical observationReaction chamber

This invention provides an apparatus for rapidly heating and / or cooling a sample in a reaction vessel. In some embodiments, the apparatus includes optics for the efficient detection of a reaction product in the vessel. The invention also provides a reaction vessel having a reaction chamber designed for optimal thermal conductance and for efficient optical viewing of reaction products in the chamber.

Owner:CEPHEID INC

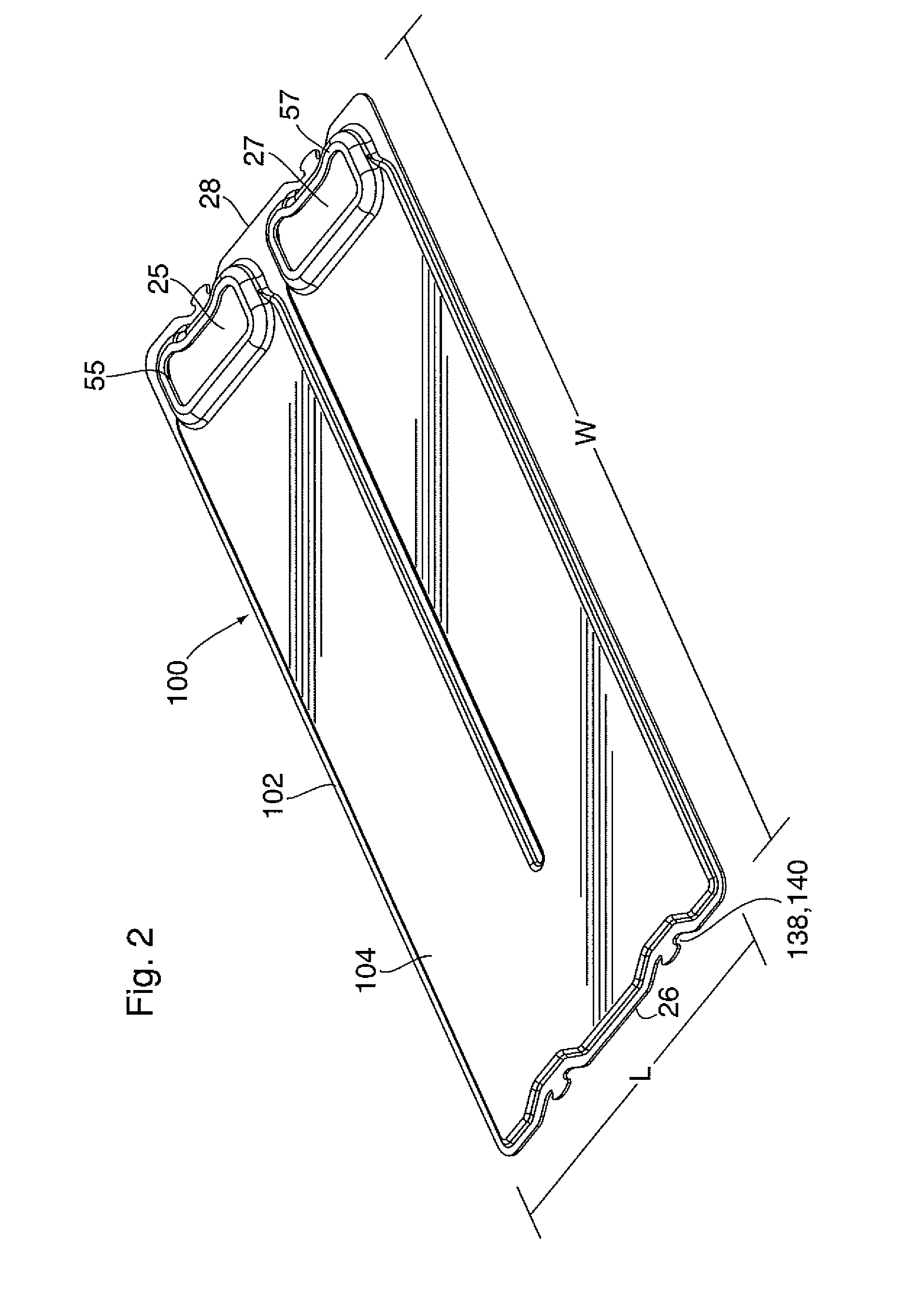

Integrated cooling fin and frame

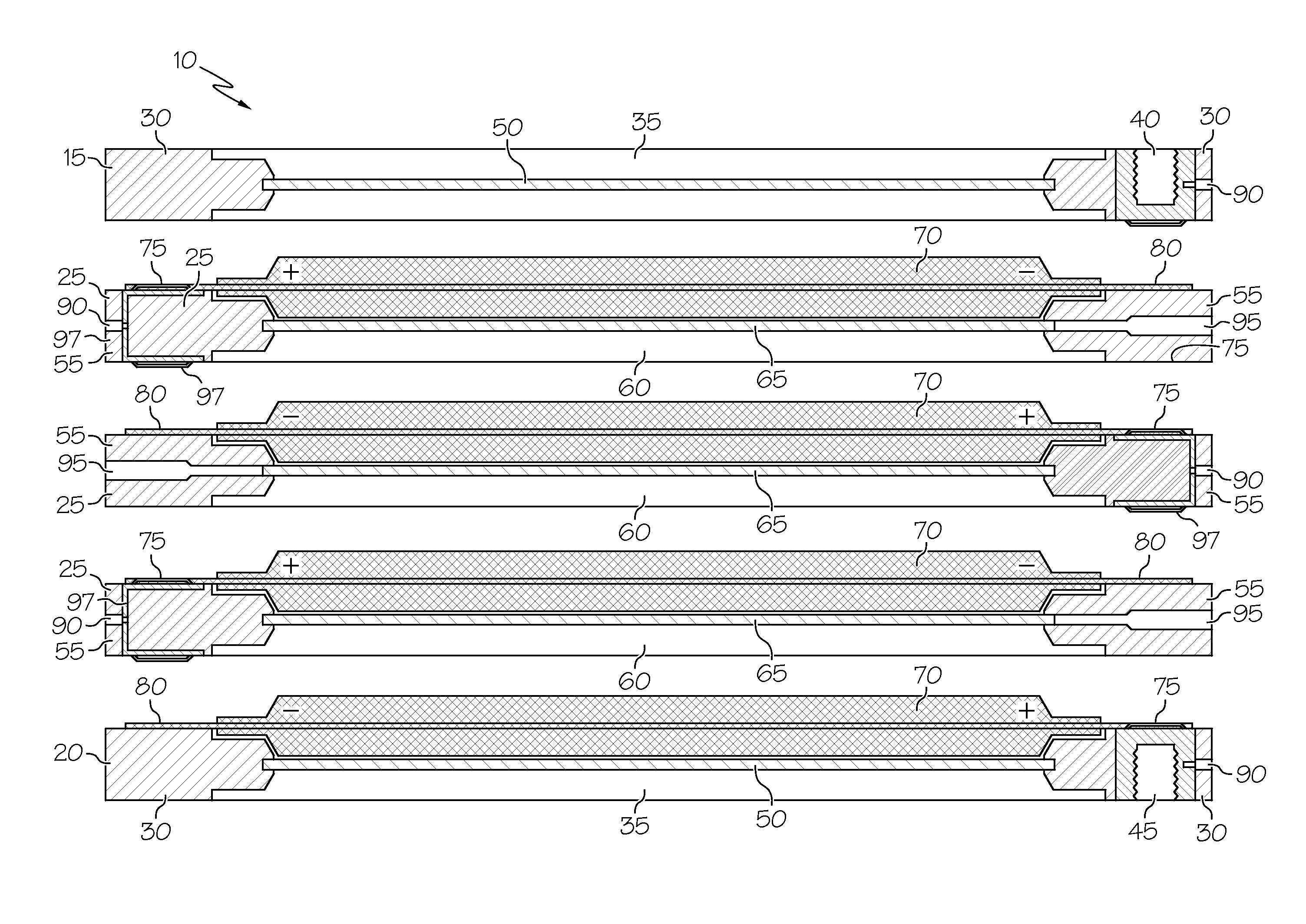

An integrated cooling fin and frame is described. The integrated cooling fin and frame includes a cooling fin having a cooling channel adjacent to at least one edge, the cooling channel having an inlet and an outlet; and a frame around the cooling fin and covering the edges of the cooling fin, the frame having an opening for the inlet and outlet of the cooling channel. A battery pack containing the integrated cooling fin and frame and a method of making the integrated cooling fin and frame are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

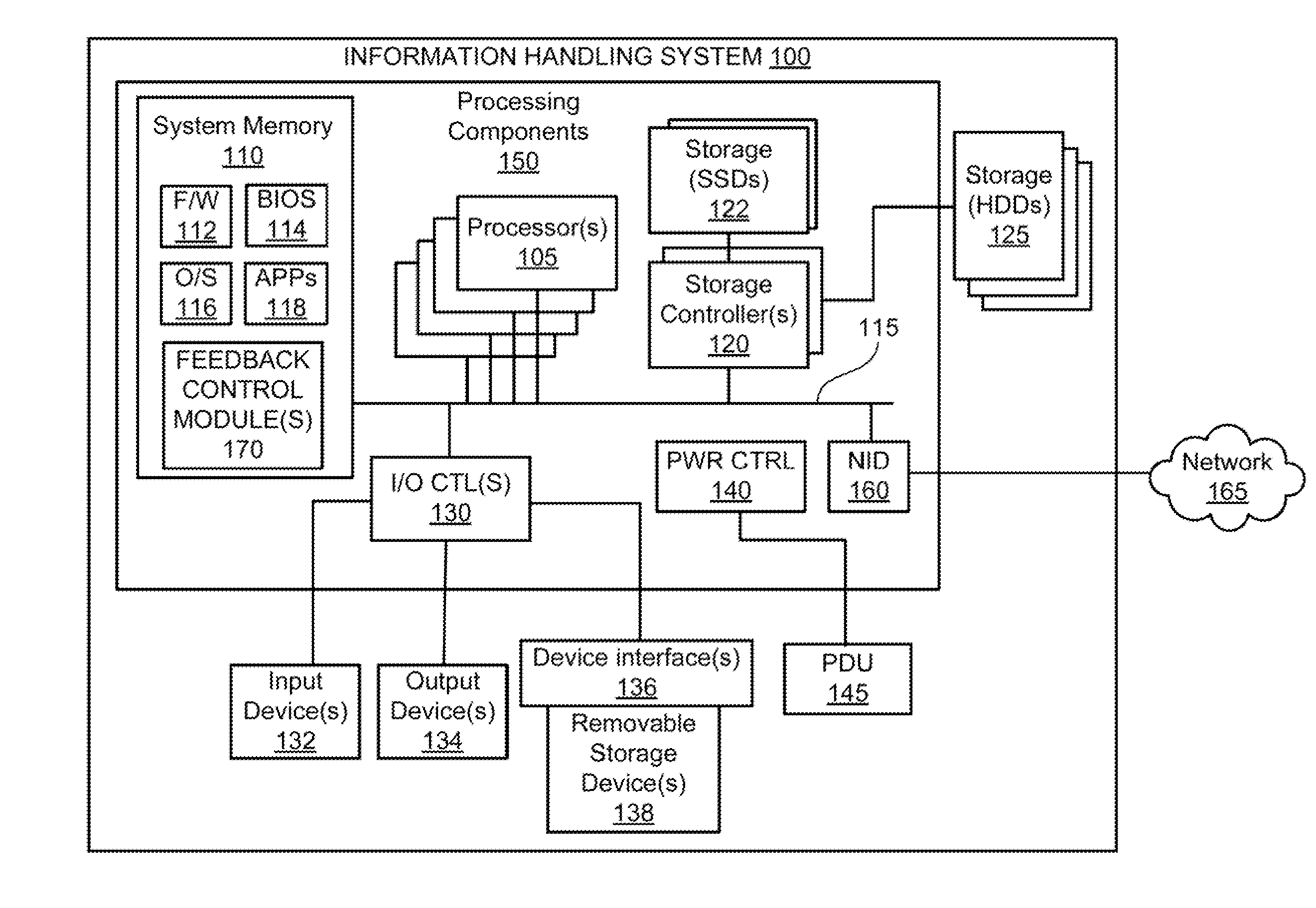

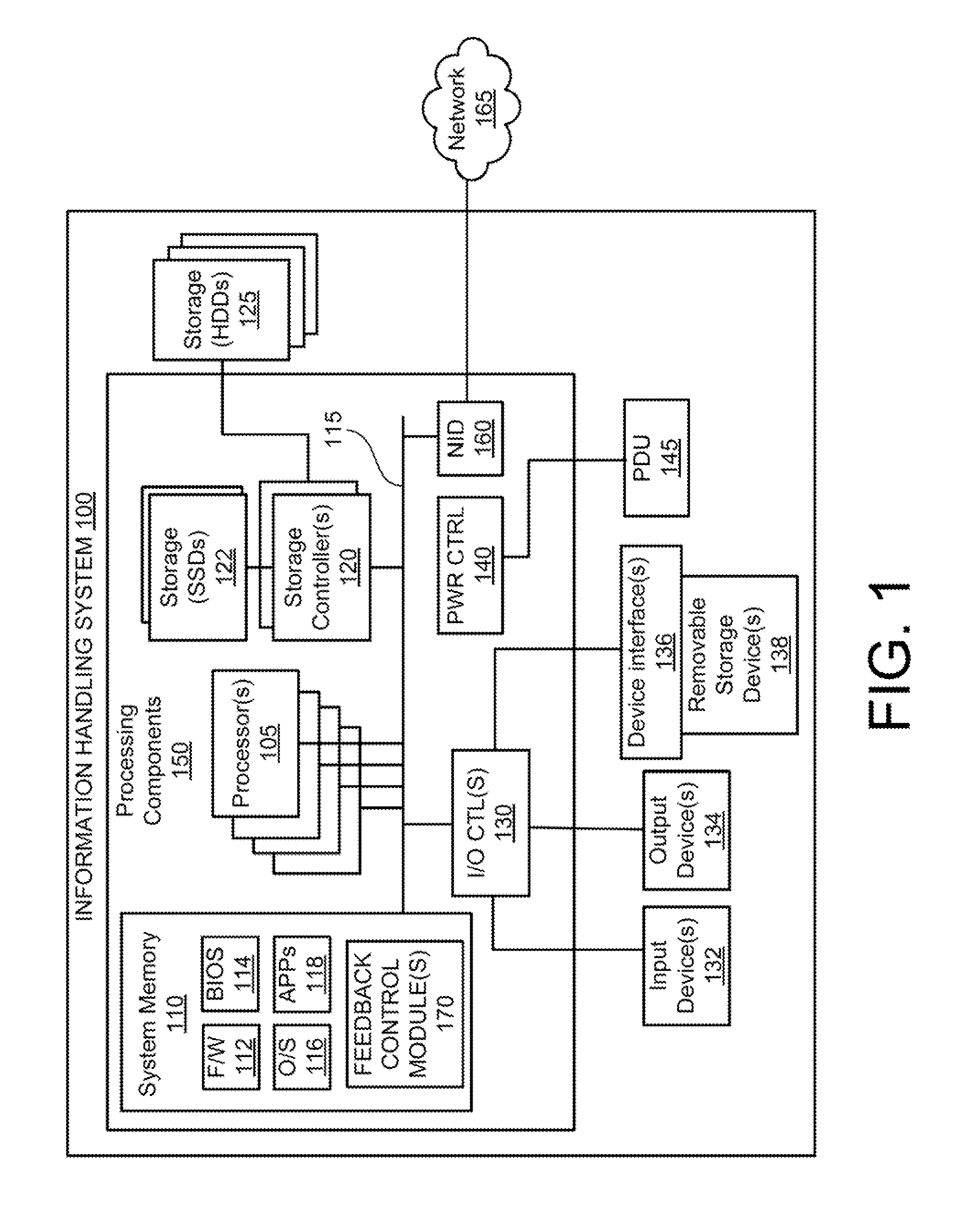

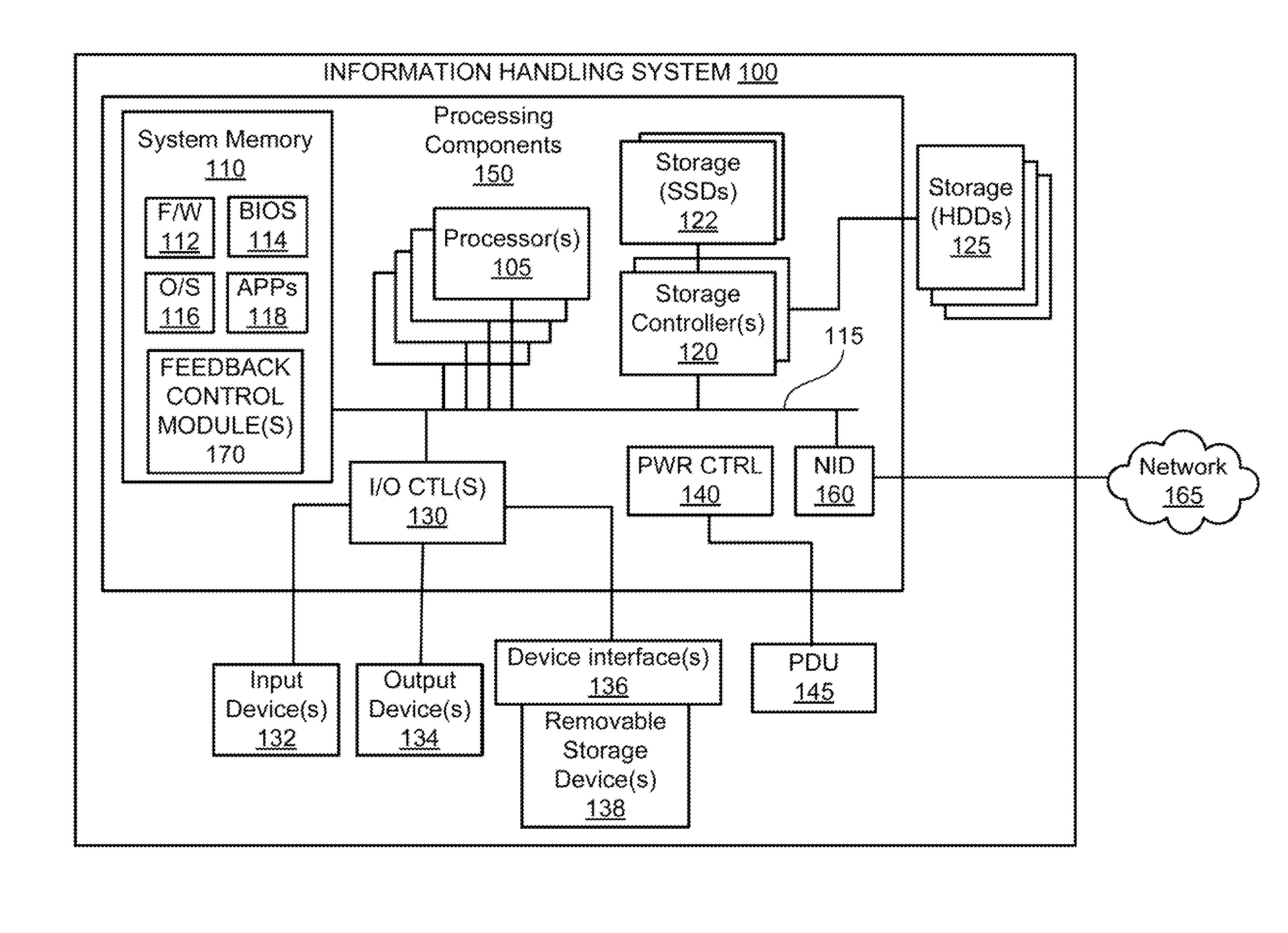

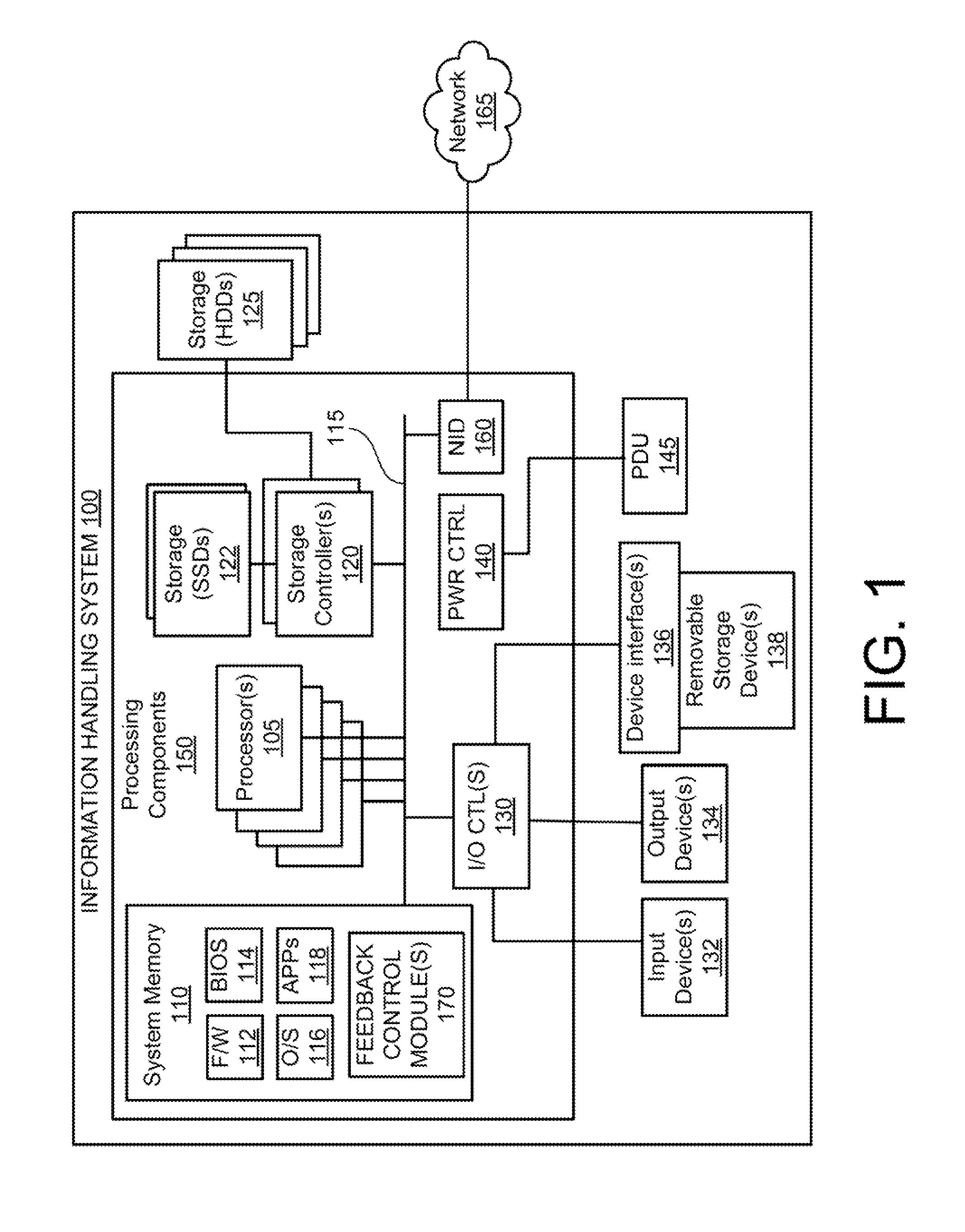

Scalable, Multi-Vessel Distribution System for Liquid Level Control Within Immersion Cooling Tanks

ActiveUS20140216711A1Increase volumeLevel controlIndirect heat exchangersControl systemDistribution system

A fluid level control system includes: a first immersion cooling tank having a first volume of immersion cooling liquid and an inlet / outlet pipe extending from a base wall of the tank by which immersion cooling liquid can flow into and out of the first immersion cooling tank; at least one second volume of cooling liquid held within a liquid containing unit having a corresponding inlet / outlet pipe; and a pipe distribution system that physically connects the second volume of immersion cooling liquid to the first volume of immersion cooling liquid via respective inlet / outlet pipes and which enables fluid equilibrium to be maintained between the first volume of liquid and the second volume of liquid via gravitational equilibrium and / or passive level control such that a first volume level of the first volume of immersion cooling liquid remains substantially equal to a second volume level of the second volume of immersion cooling liquid.

Owner:DELL PROD LP

Electronic device cooling system and electronic device cooling apparatus

InactiveUS20090100848A1Avoid condensationEasy constructionCompression machines with non-reversible cycleEvaporators/condensersElectronics coolingRefrigerant

An electronic cooling apparatus has a cabinet which is open at the front and rear sides thereof and accommodates plural electronic devices each having a fan, and a rear door which is provided with an evaporator. Air blown by the fan is cooled by the evaporator and then returned to a room. An expansion valve and control. A drain pan with an extension portion having hole portions through which refrigerant pipes extend is provided. A drain hose discharges drain water from the drain pan. An exhaust heat temperature detecting unit and a control for controlling the refrigerant supply to the evaporator are provided. When the exhaust heat temperature is equal to or less than a set exhaust temperature, the controller stops the refrigerant supply to the evaporator. When the exhaust heat temperature exceeds the set temperature, the controller starts the refrigerant supply.

Owner:SANYO ELECTRIC CO LTD

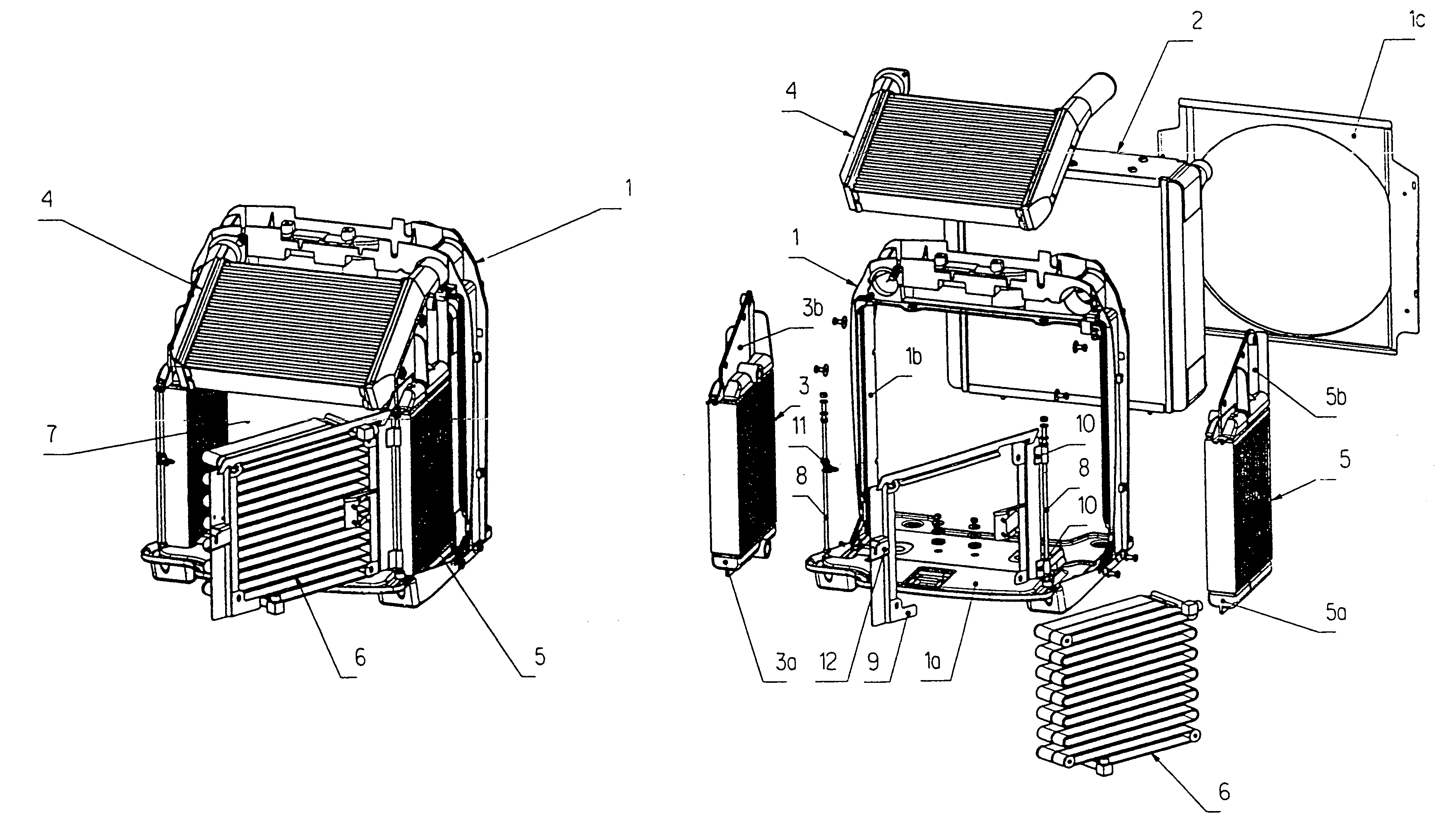

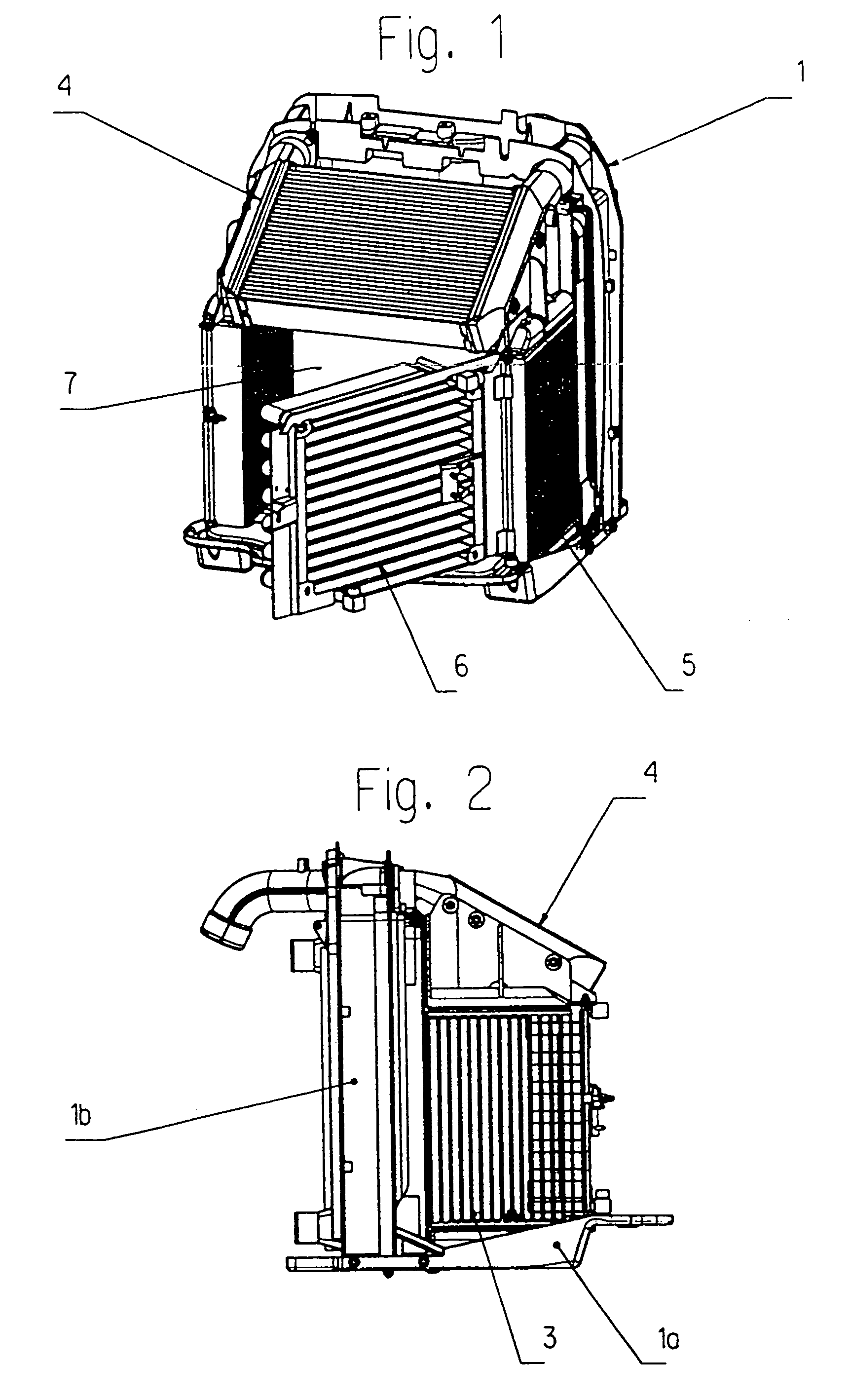

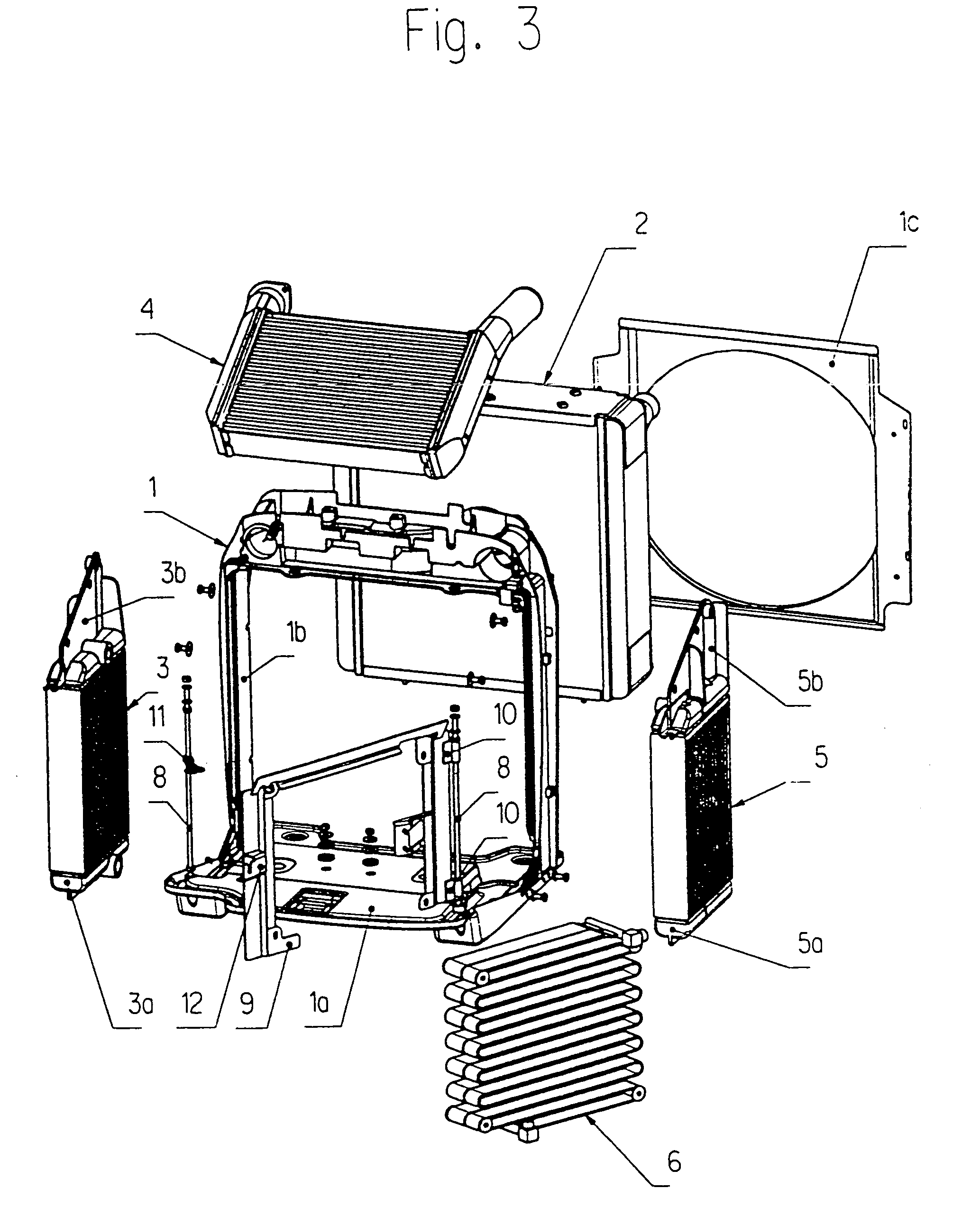

Vehicle cooling radiator arrangement

InactiveUS7128178B1Easy maintenanceLow flow resistanceAir-treating devicesInternal combustion piston enginesHeat spreaderAgricultural tractor

An arrangement of radiators (2–6) for a utility vehicle, e.g., an agricultural tractor, comprising three or more cooling radiators which together define a chamber (7), optionally with some of the walls formed by perforated plates instead of radiator elements. One of the radiator elements may be pivotally mounted with respect to the others to provide access to the chamber. The arrangement of radiators may be mounted on a common support (1).

Owner:AGCO GMBH

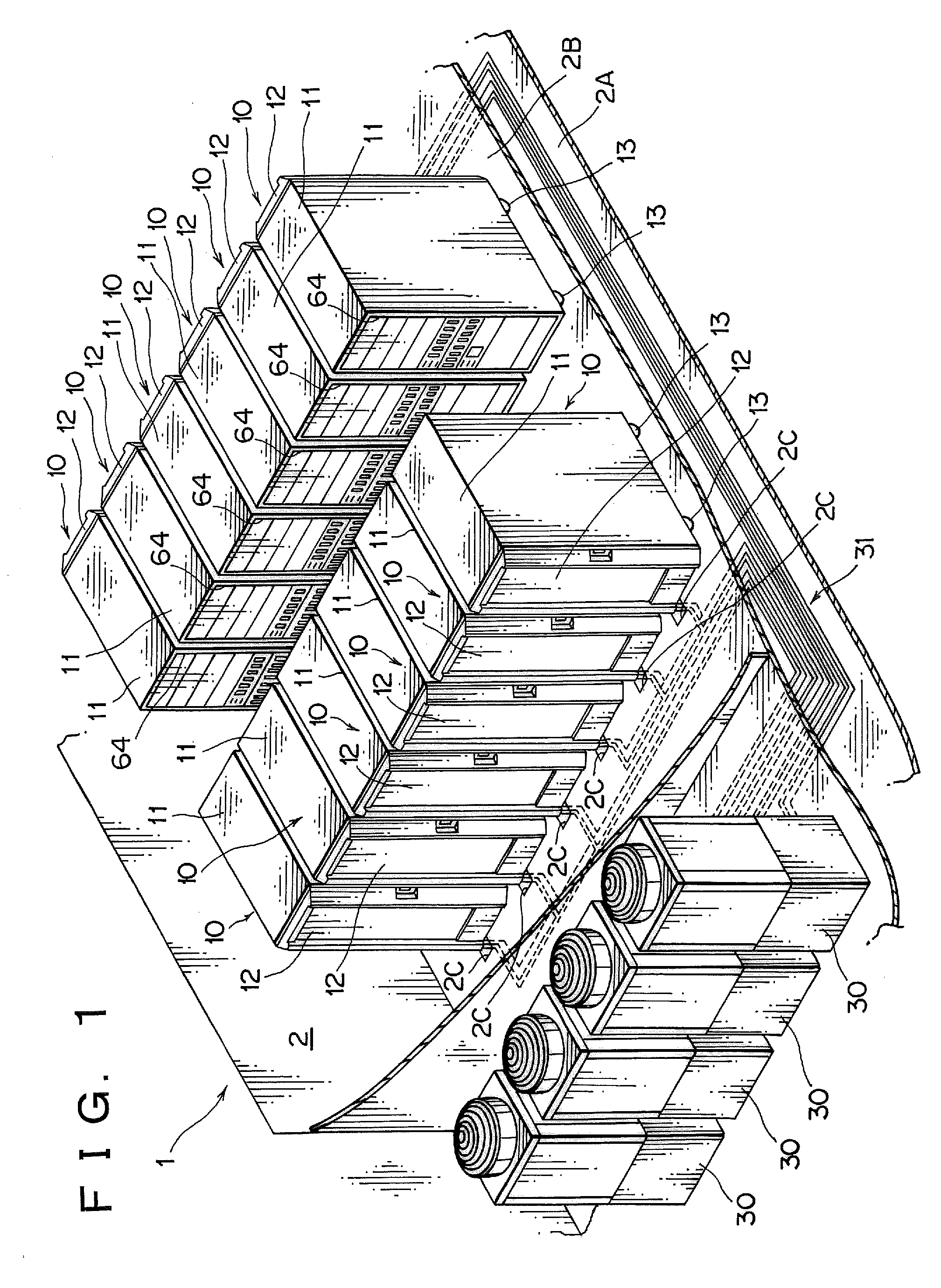

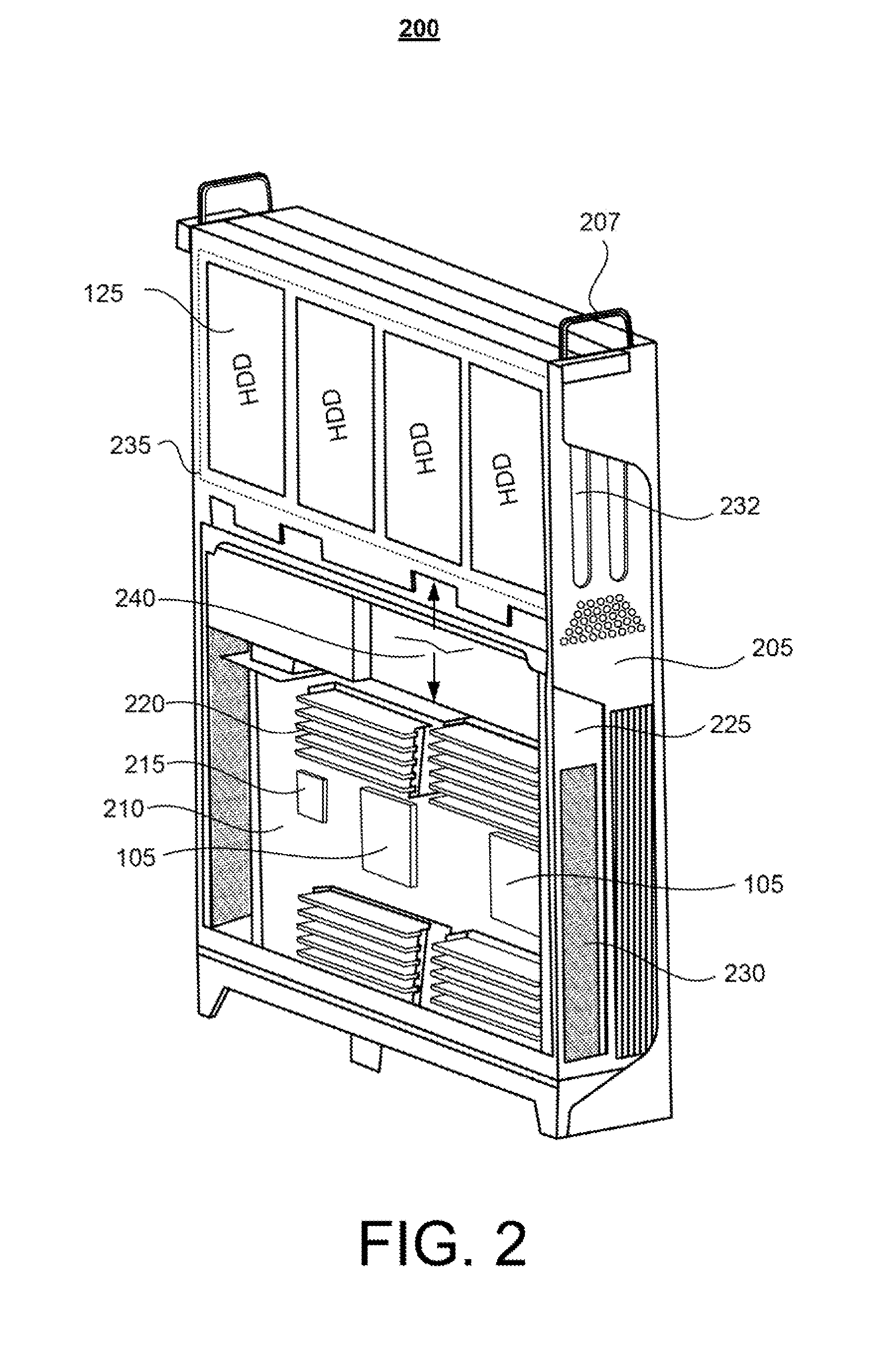

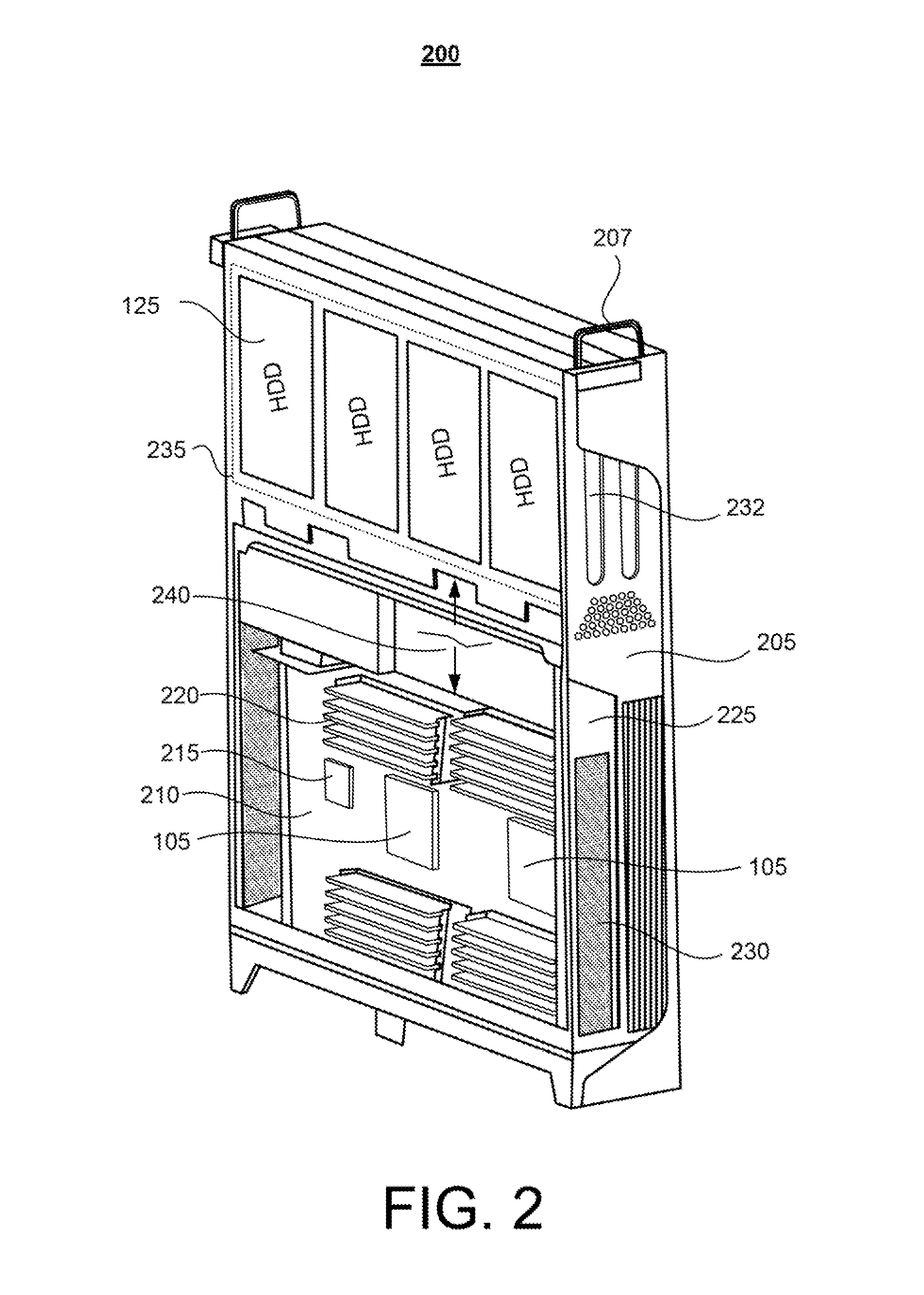

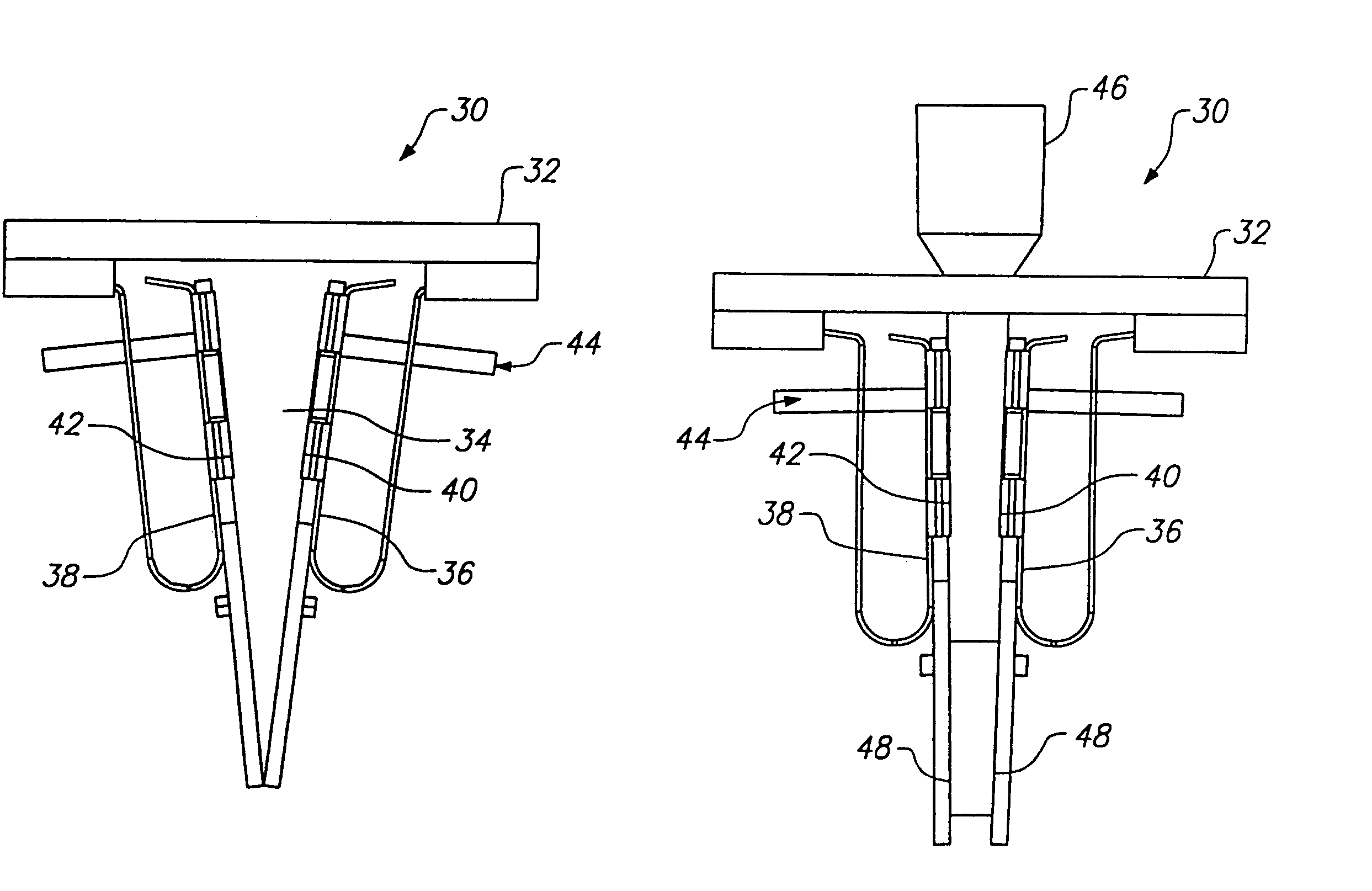

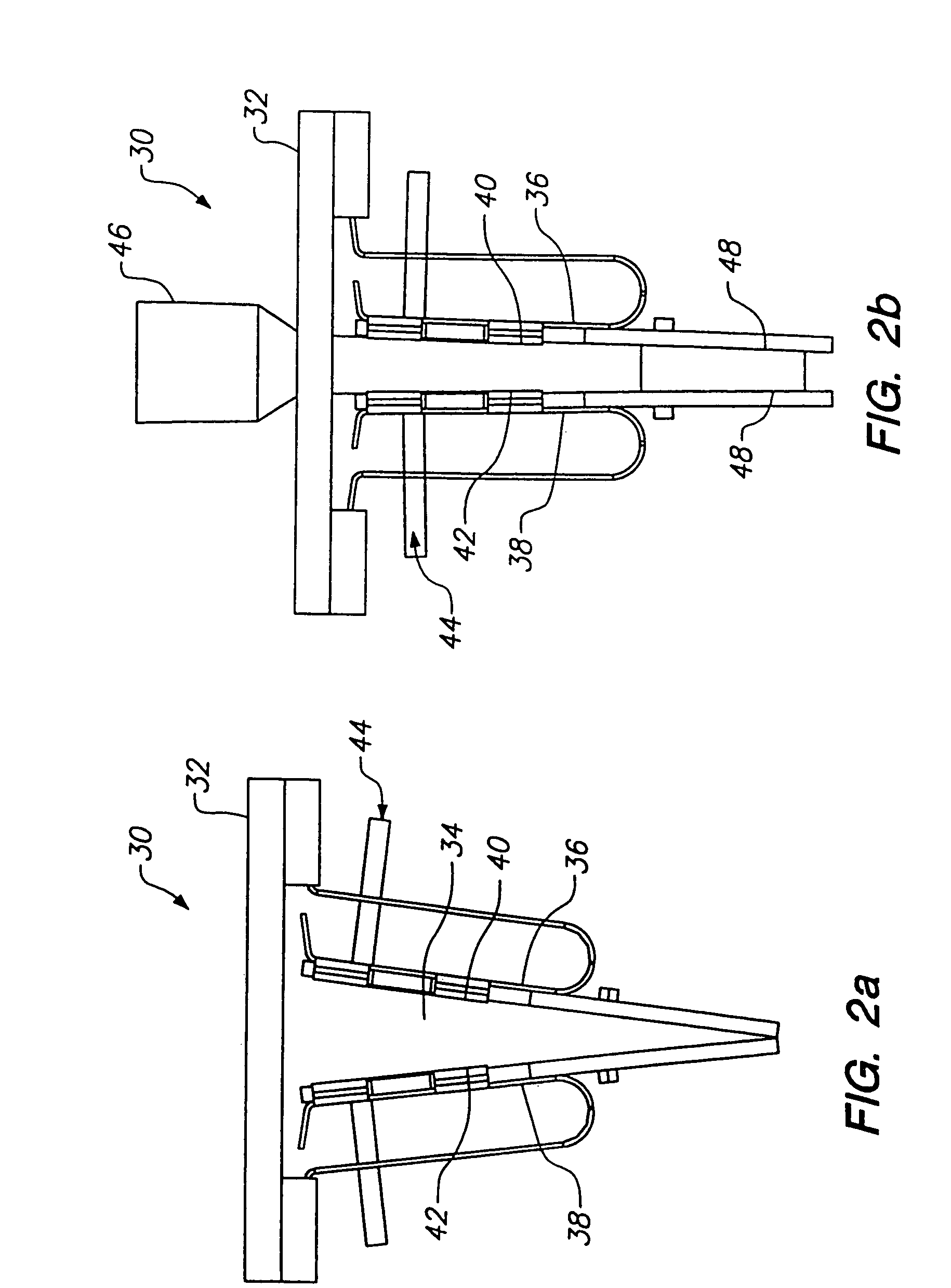

Partitioned, Rotating Condenser Units to Enable Servicing of Submerged IT Equipment Positioned Beneath a Vapor Condenser Without Interrupting a Vaporization-Condensation Cycling of the Remaining Immersion Cooling System

ActiveUS20140216686A1Safety devices for heat exchange apparatusDigital data processing detailsIt equipmentBoiling point

An immersion cooling tank includes: a tank comprised of a base wall, and perimeter walls, and having a lower tank volume in which a liquid can be maintained and heated to a boiling point to generate a rising plume of vapor; a rack structure within the tank volume that supports insertion of multiple, heat dissipating electronic devices in a side-by-side vertical configuration; and a condenser configured as a plurality of individually rotatable condenser sub-units, with each condenser sub-unit located above a vertical space that extends vertically from the lower tank volume and within which an electronic device can be inserted. Each individual condenser sub-unit can be opened independent of the other sub-units and each other condenser sub-unit can remain in a closed position while a first condenser sub-unit is opened to allow access to a first vertical space and any existing electrical device contained therein below the first condenser sub-unit.

Owner:DELL PROD LP

Thermal cycler with optical detector

InactiveUS20080254532A1Optimal thermal transferEfficient optical viewingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringThermal cycler

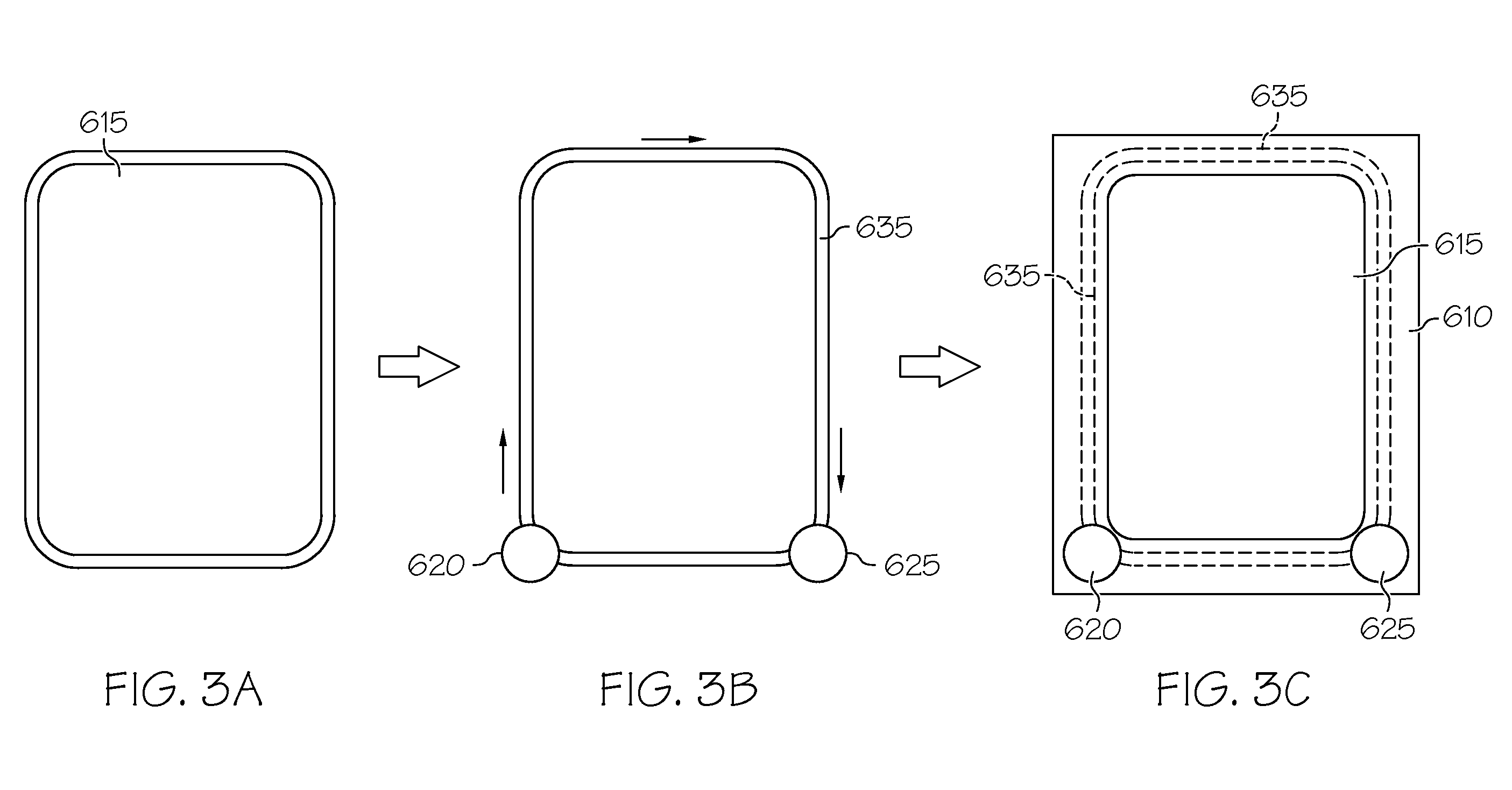

A reaction vessel having a reaction chamber for holding a sample is fabricated by producing a housing having a rigid frame defining the minor walls of the chamber. The housing also defines a port for introducing fluid into the chamber. At least one sheet or film is attached to the rigid frame to form at least one major wall of the chamber. In preferred embodiments, two sheets or films are attached to opposite sides of the rigid frame to form two opposing major walls of the chamber, the major walls being connected to each other by the minor walls.

Owner:CEPHEID INC

Plastic heat exchanger

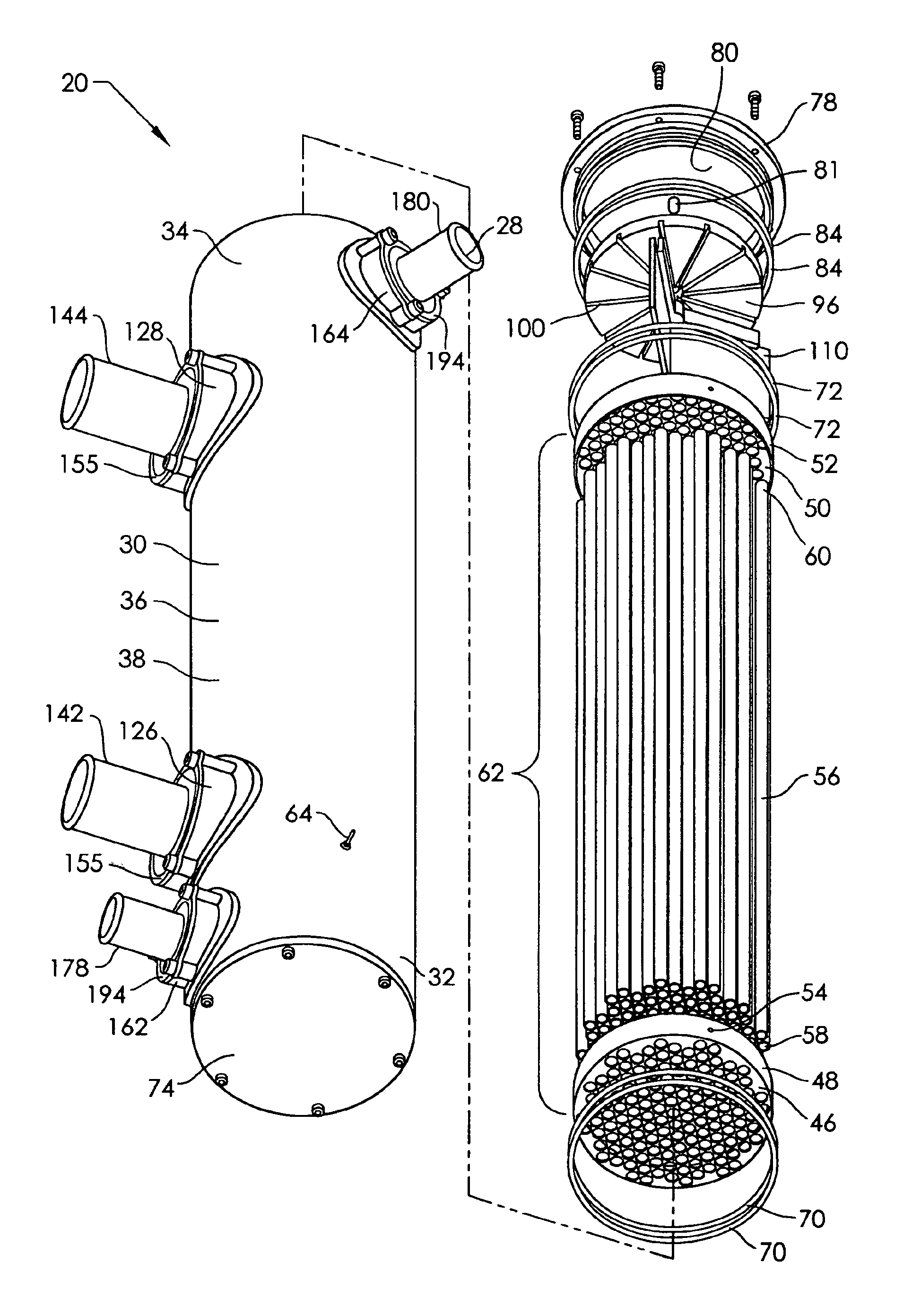

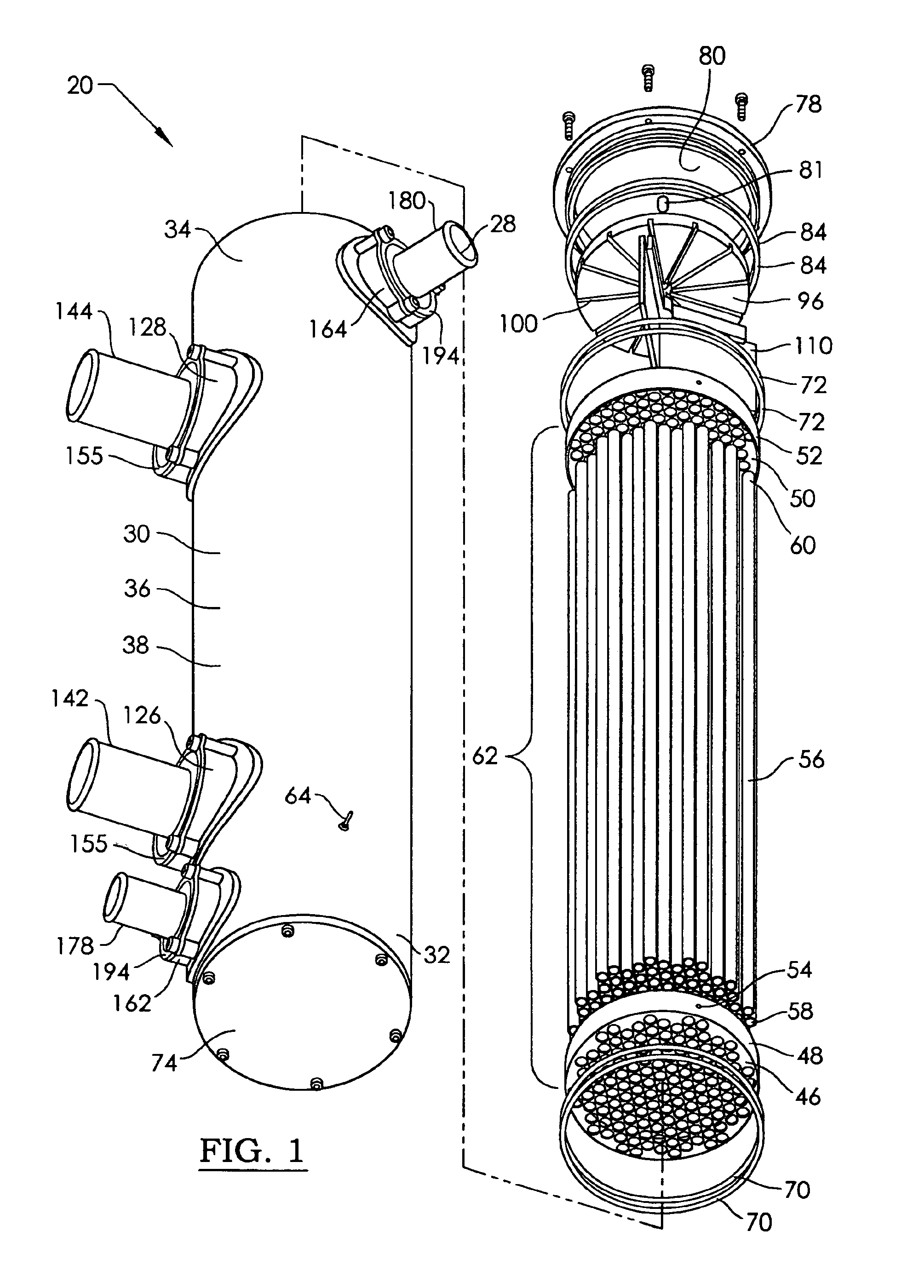

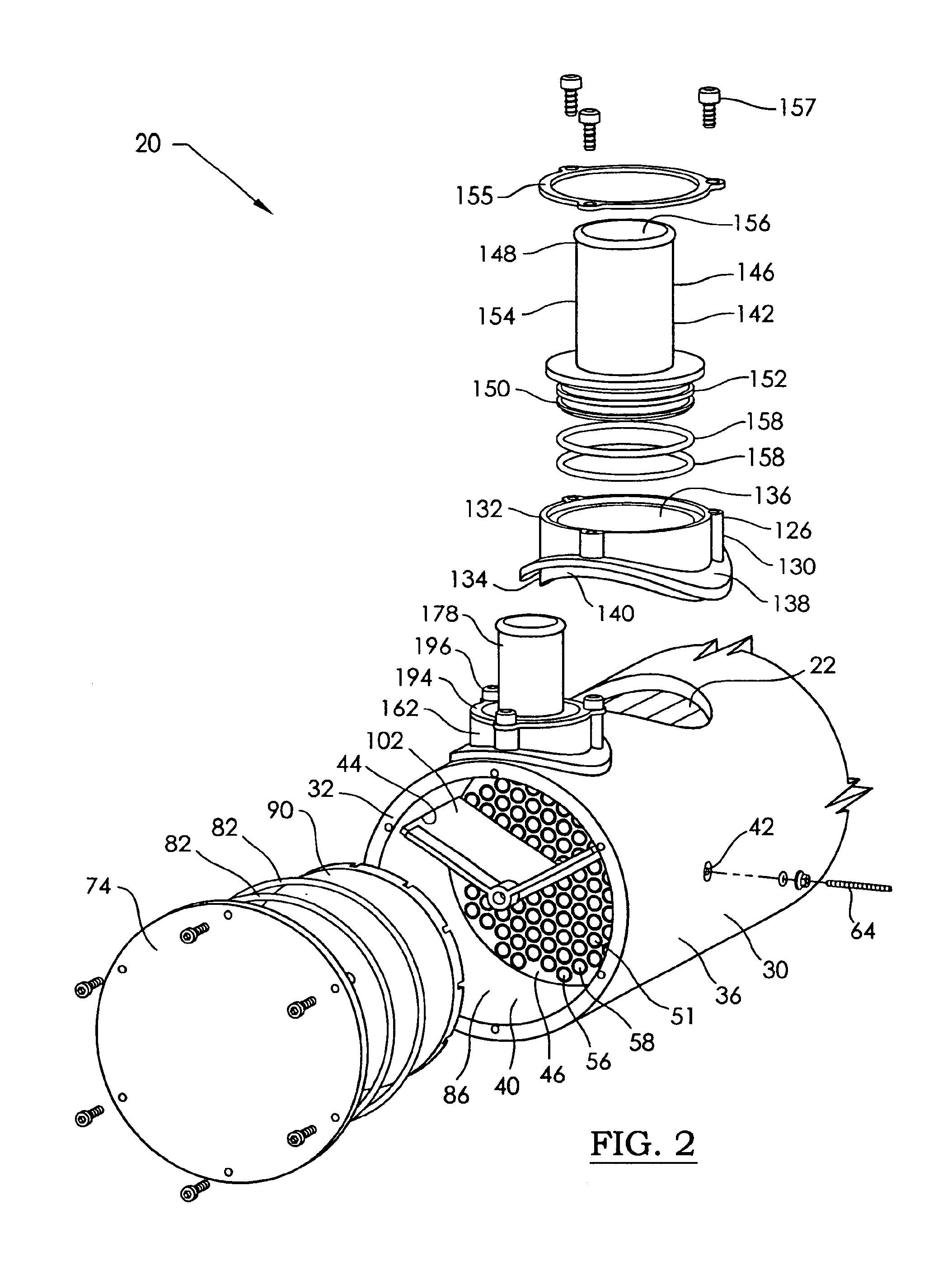

ActiveUS6899169B1Safety devices for heat exchange apparatusHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

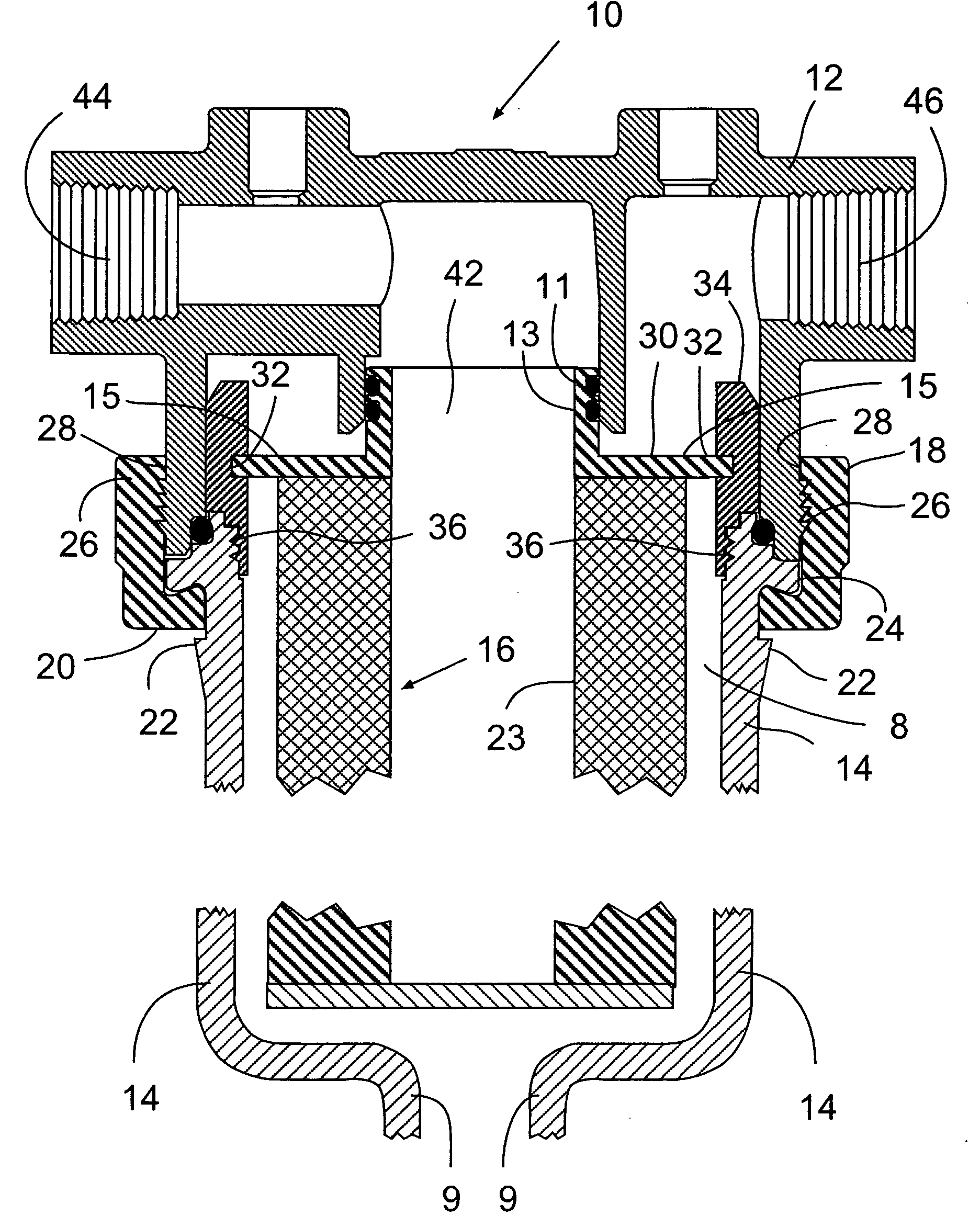

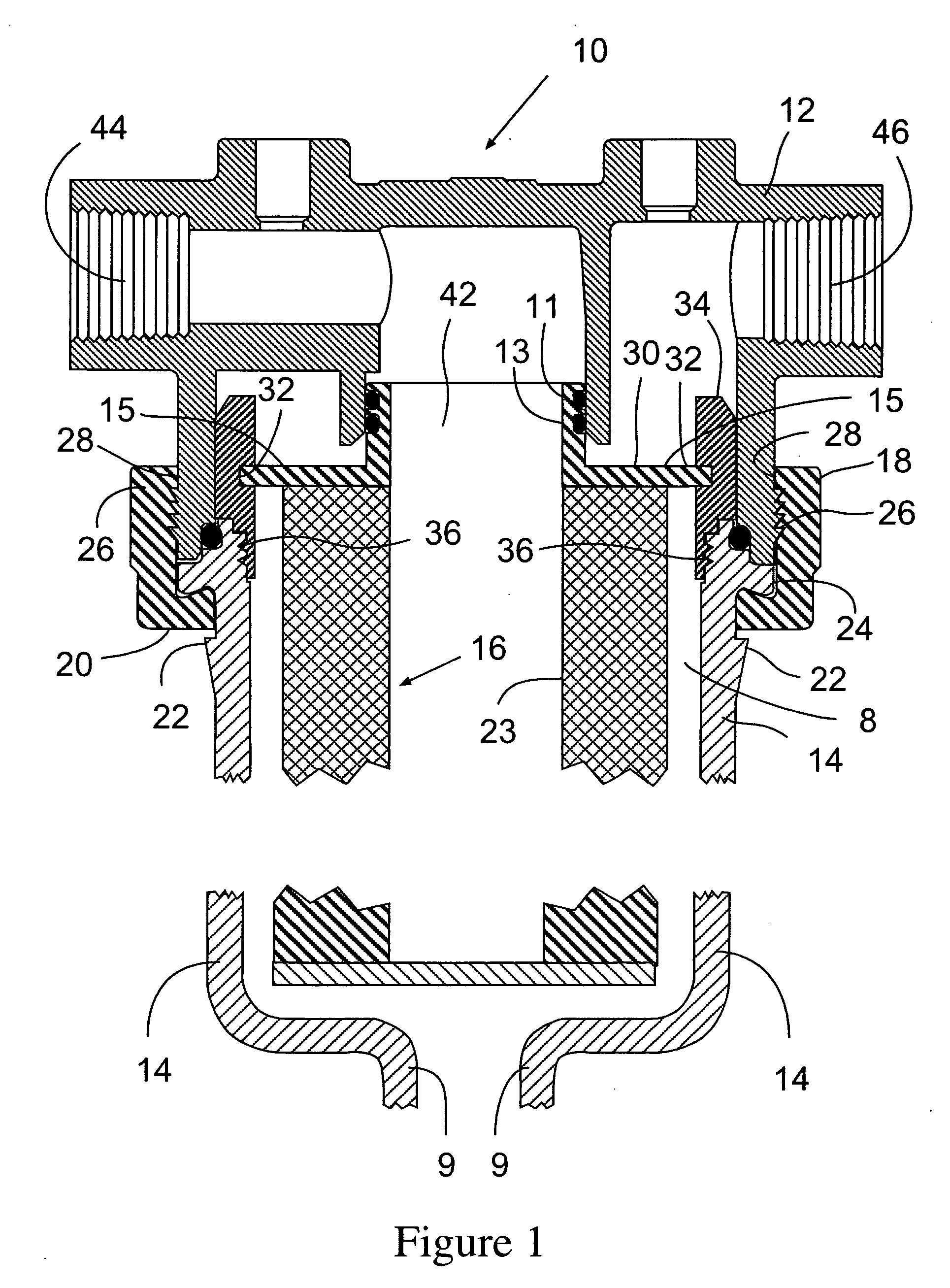

A shell and tube heat exchanger has two shell coolant and two tube coolant passageways communicating with a cavity in a shell. Removably received in the shell cavity is a tube bundle with tube headers. A locating screw extends through the shell to engage a locating recess in one tube header. The screw locates the tube bundle angularly about the central axis and longitudinally along the central axis, and is also used to electrically ground the tube bundle. An end cover, a flow separator, and resilient disc to take up thermal expansion are installed in each end of the shell to direct coolant through the tube bundle in multiple passes. Receivers with rotatable connectors are bonded to each shell coolant and tube coolant passageway. Angled connector nozzles can be connected to external conduits in any orientation.

Owner:R&D ENTERPRISES

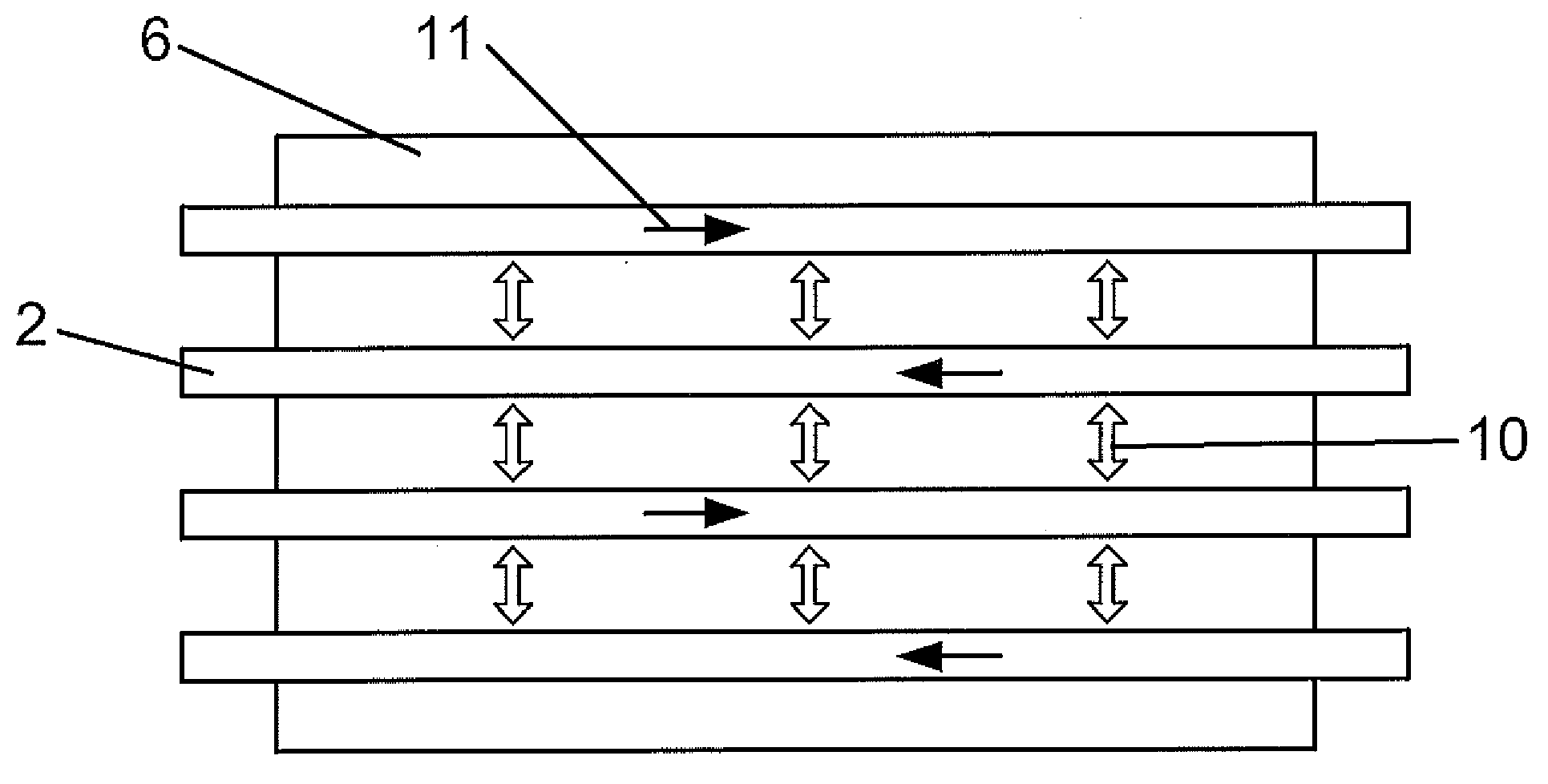

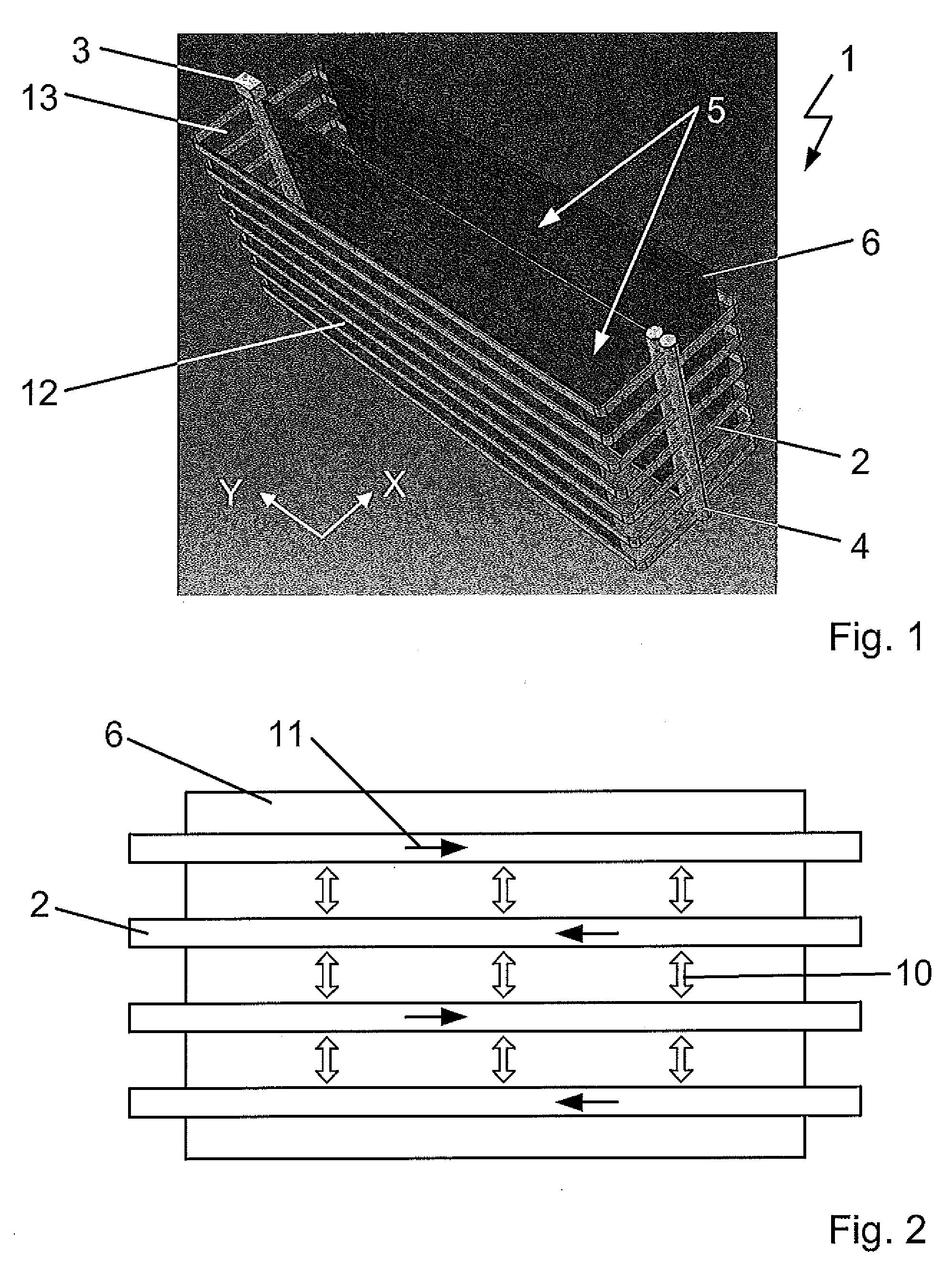

Heat exchanger and method of manufacture thereof

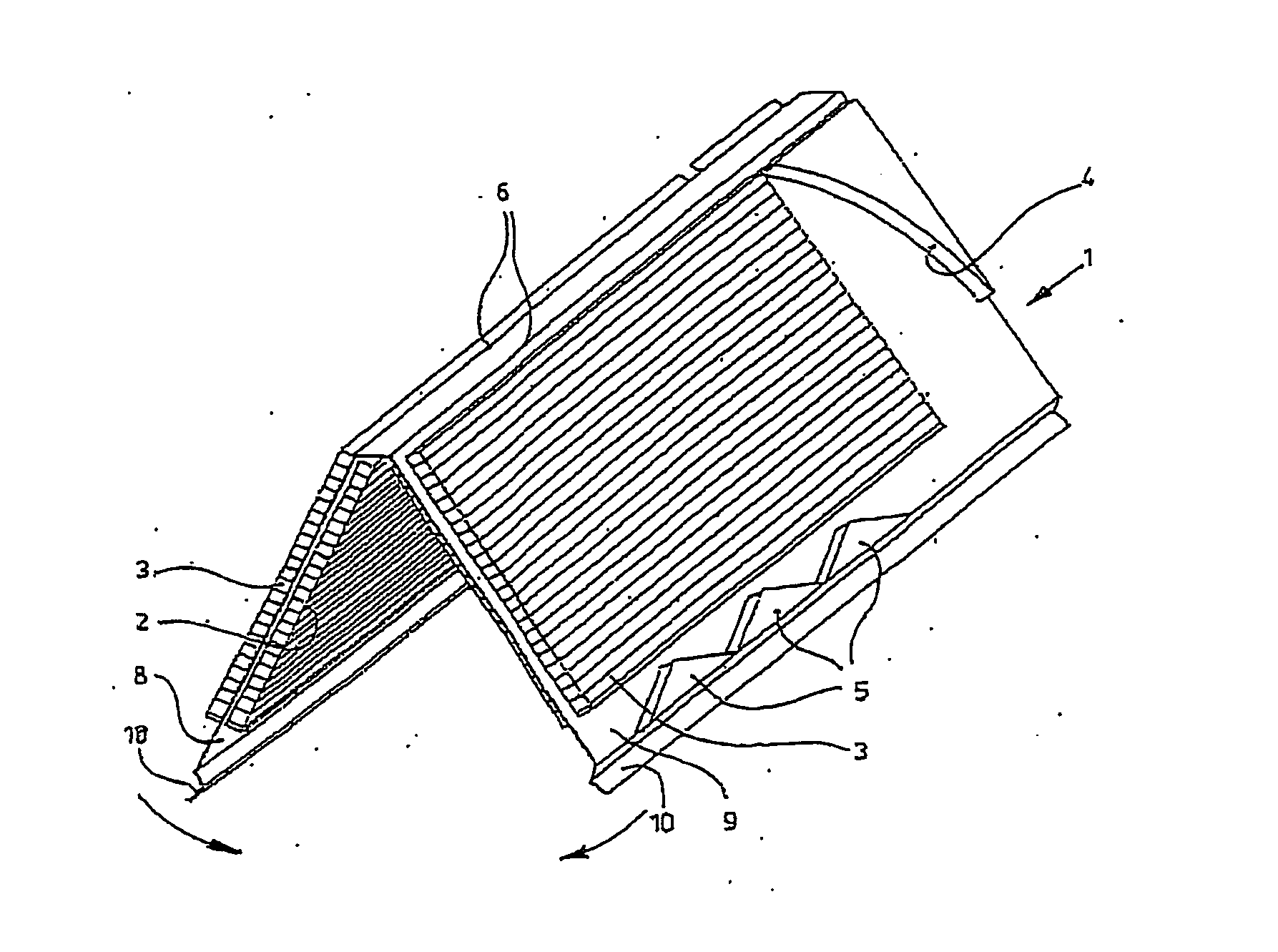

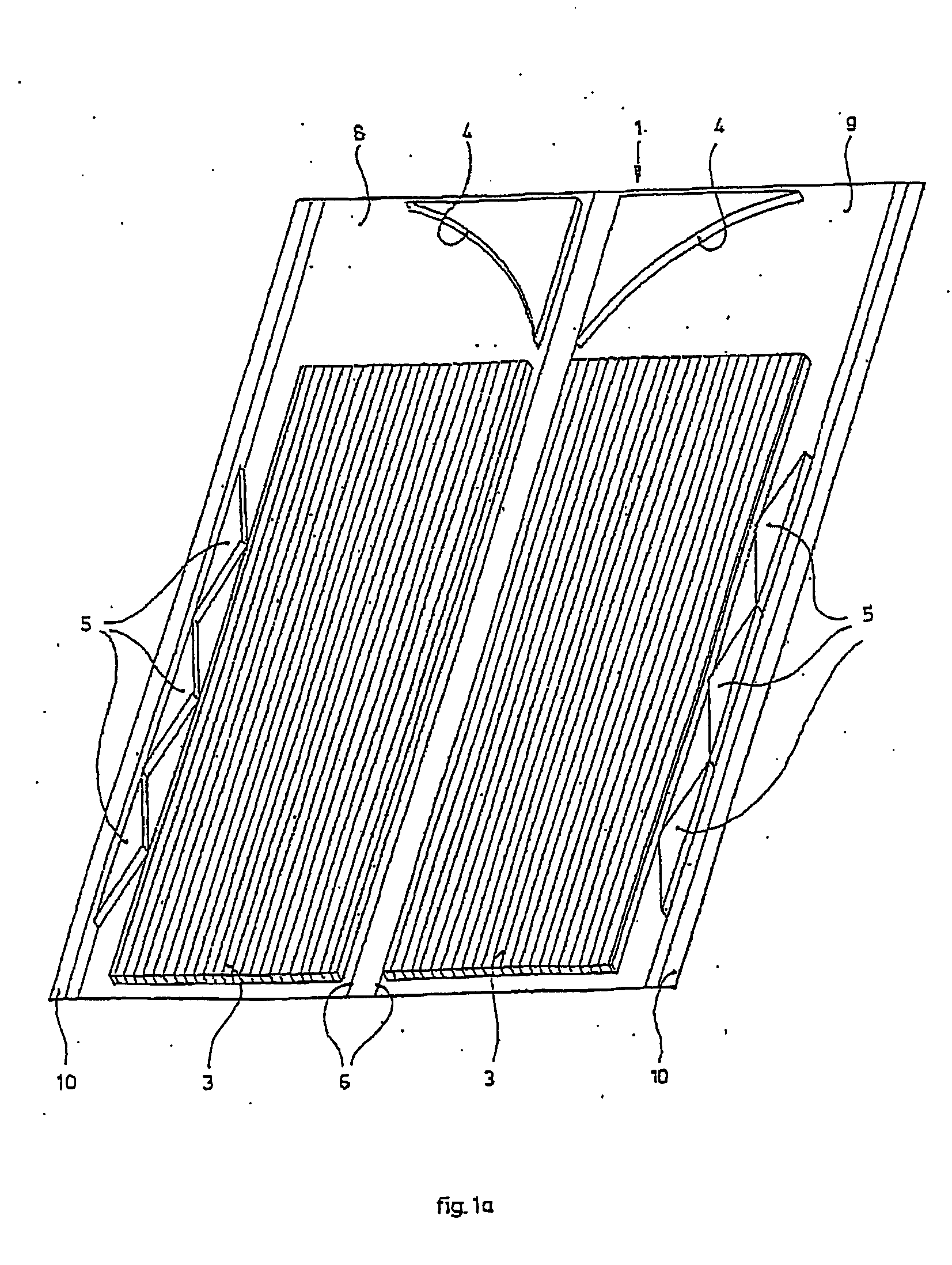

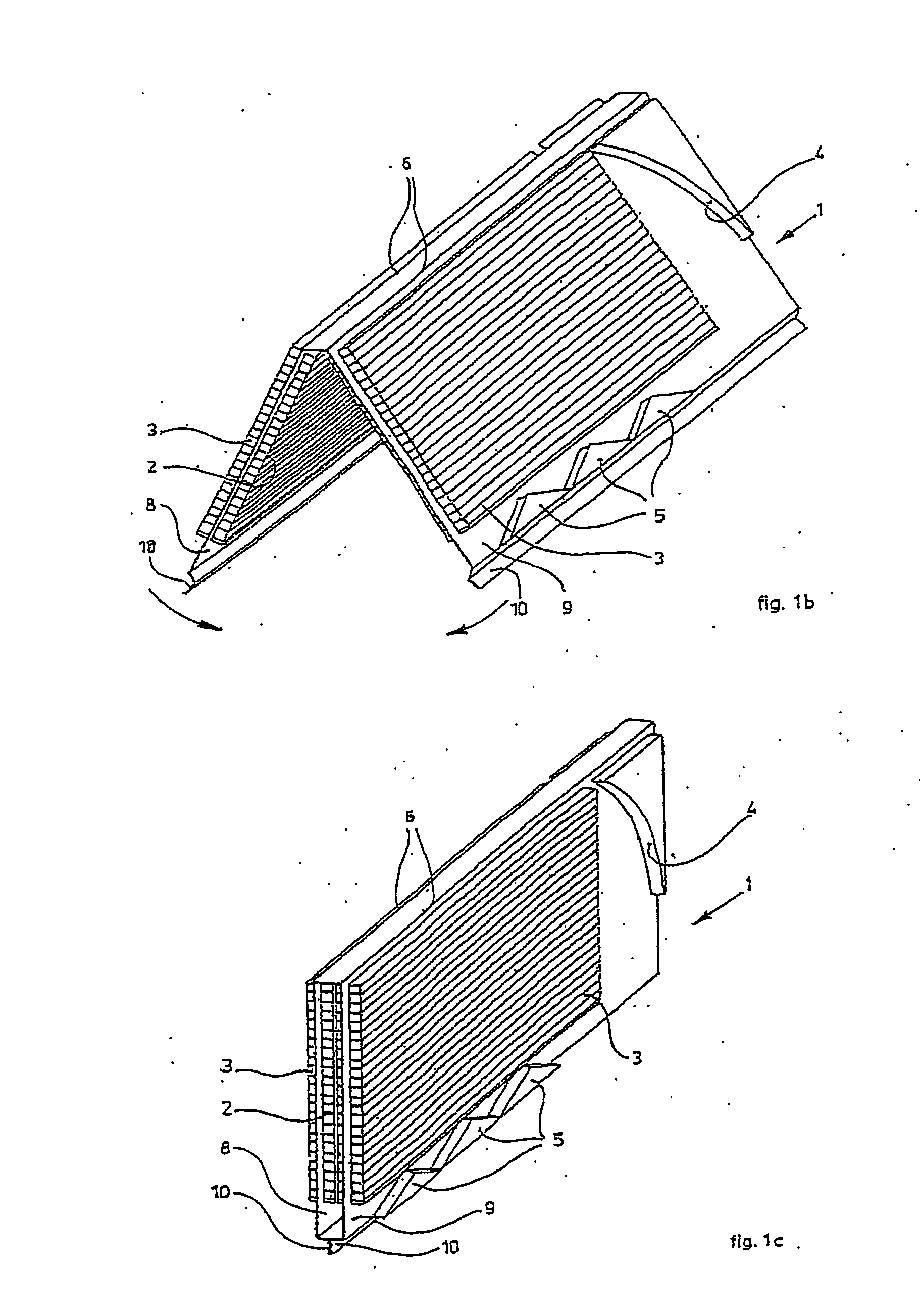

InactiveUS20060124287A1Improve heat transfer performanceEasy to produceSafety devices for heat exchange apparatusFree-cooling systemsEngineeringMetal

Method of manufacturing a heat exchanger from a formable laminate (1, 11, 105) of a metal layer and a heat-seal layer whereby the laminate is sealed under heat and pressure to itself or to another similar laminate to form a flow channel for a heat exchange medium. Preferably the heat exchanger includes a series of fins (3, 106, 107) formed on the laminate (1, 11, 105) to increase heat transfer and may also include a water retaining layer (204).

Owner:OXYCOM BEHEER BV

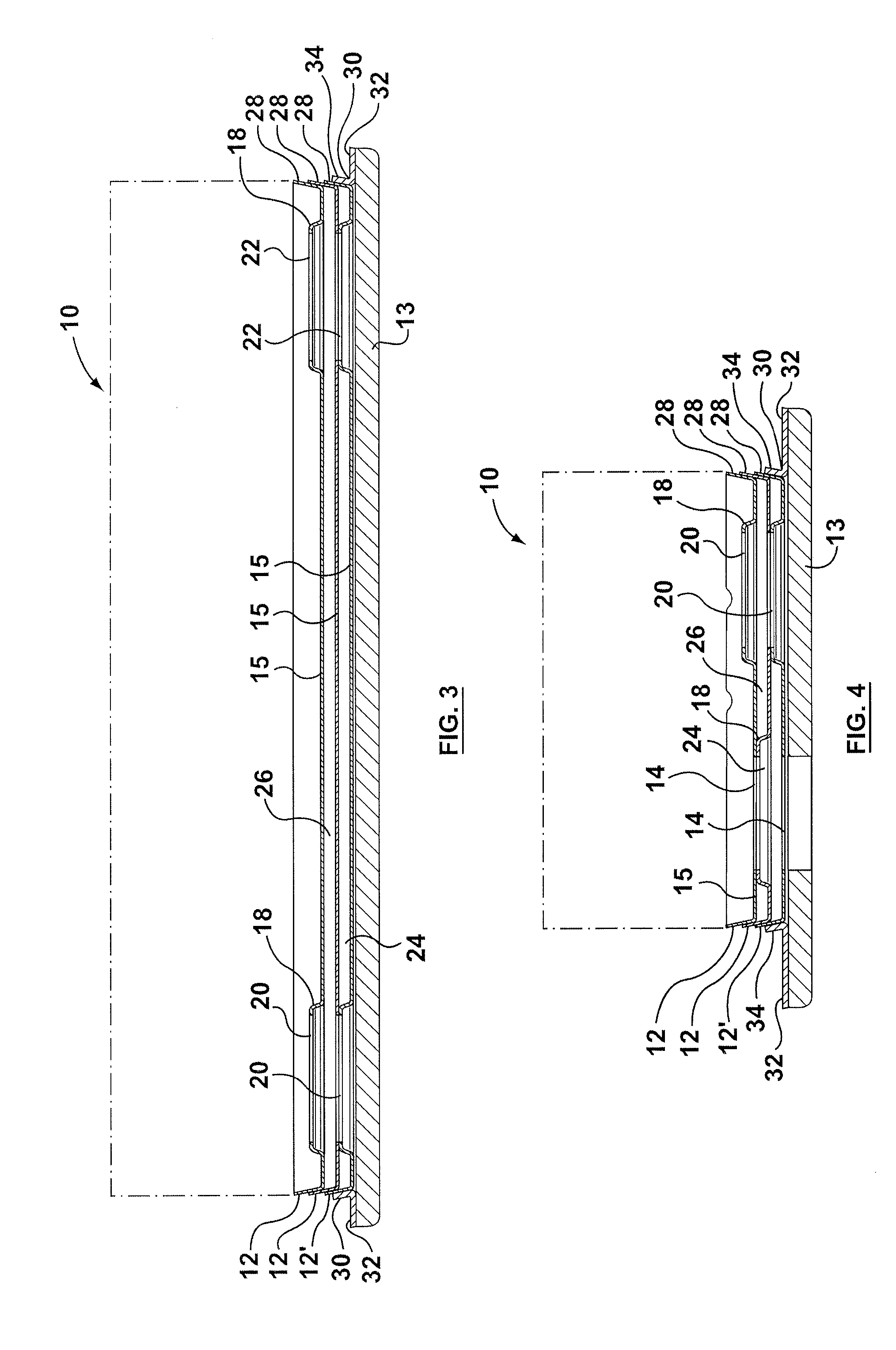

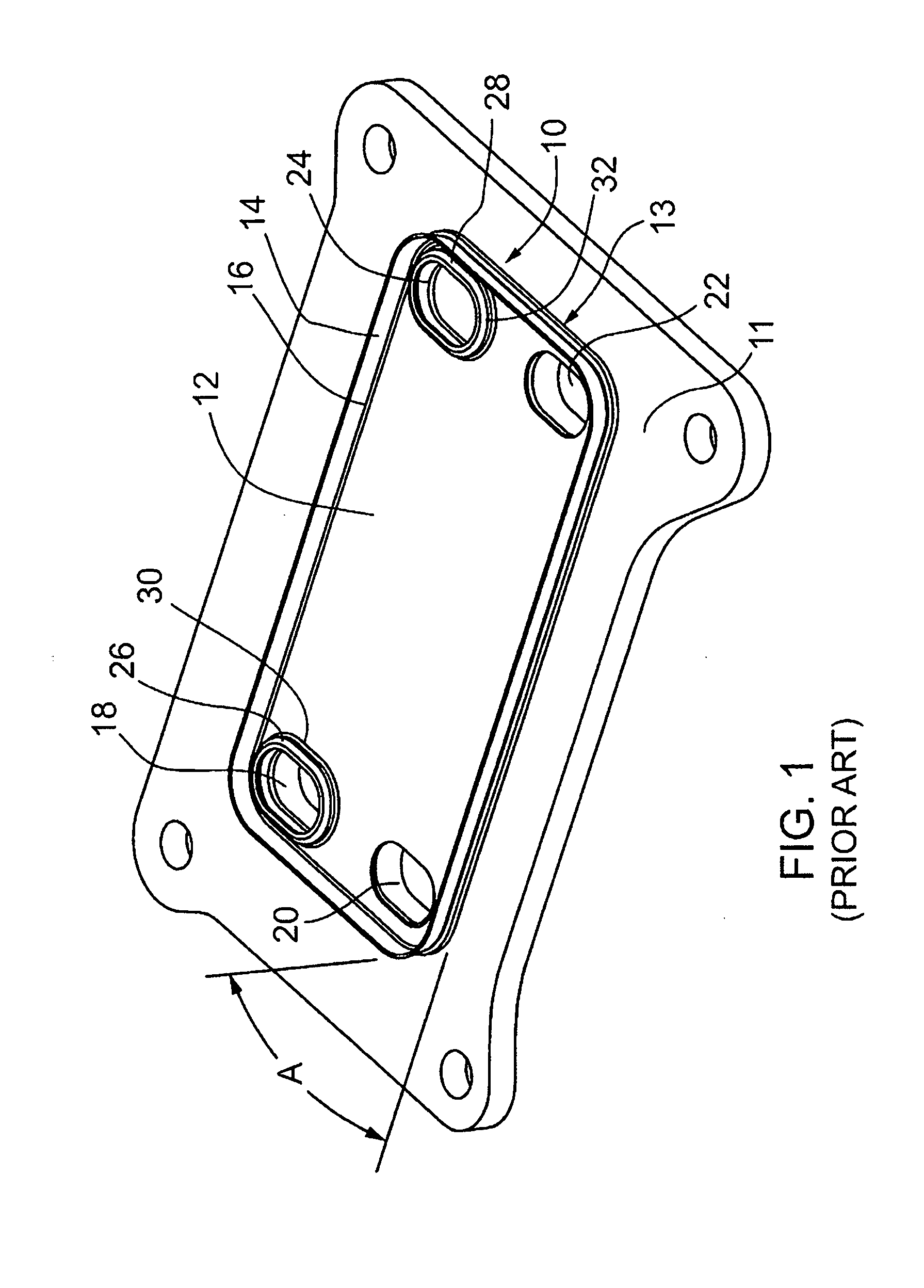

Reinforcement for dish plate heat exchangers

A reinforcing element for a heat exchanger of the type having nested dish plates with inclined, peripheral, overlapping walls, where at least one of the nested dish plates is attached to a mounting plate, the mounting plate extending beyond the outer periphery of the walls of the nested dish plates. The reinforcing element has a base flange attached to the mounting plate extending beyond the outer periphery of the walls of the nested dish plates. The reinforcing element also has a peripheral flange located in parallel, overlapping engagement with the inclined peripheral wall of the at least one dish plate attached to the mounting plate.

Owner:DANA CANADA CORP

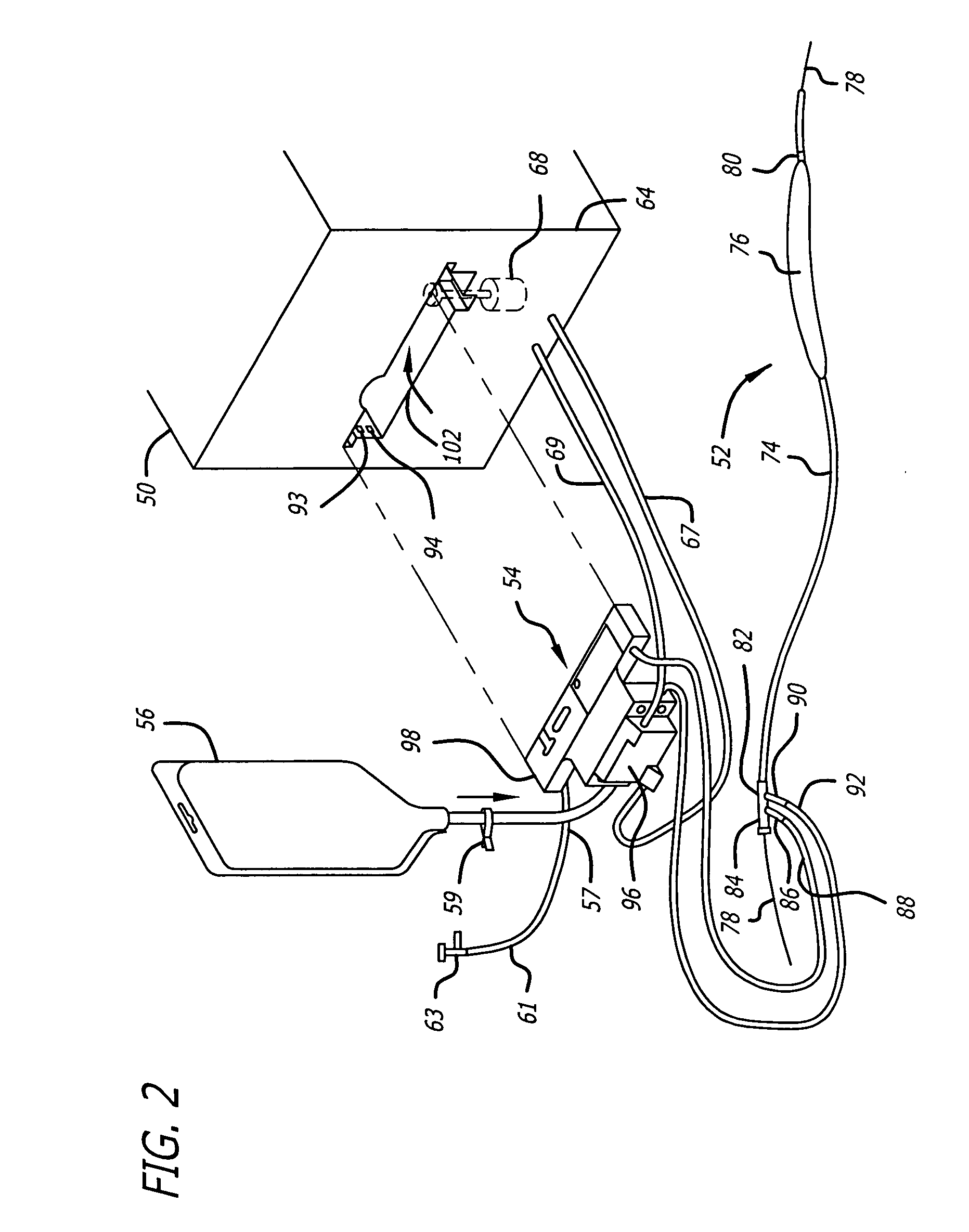

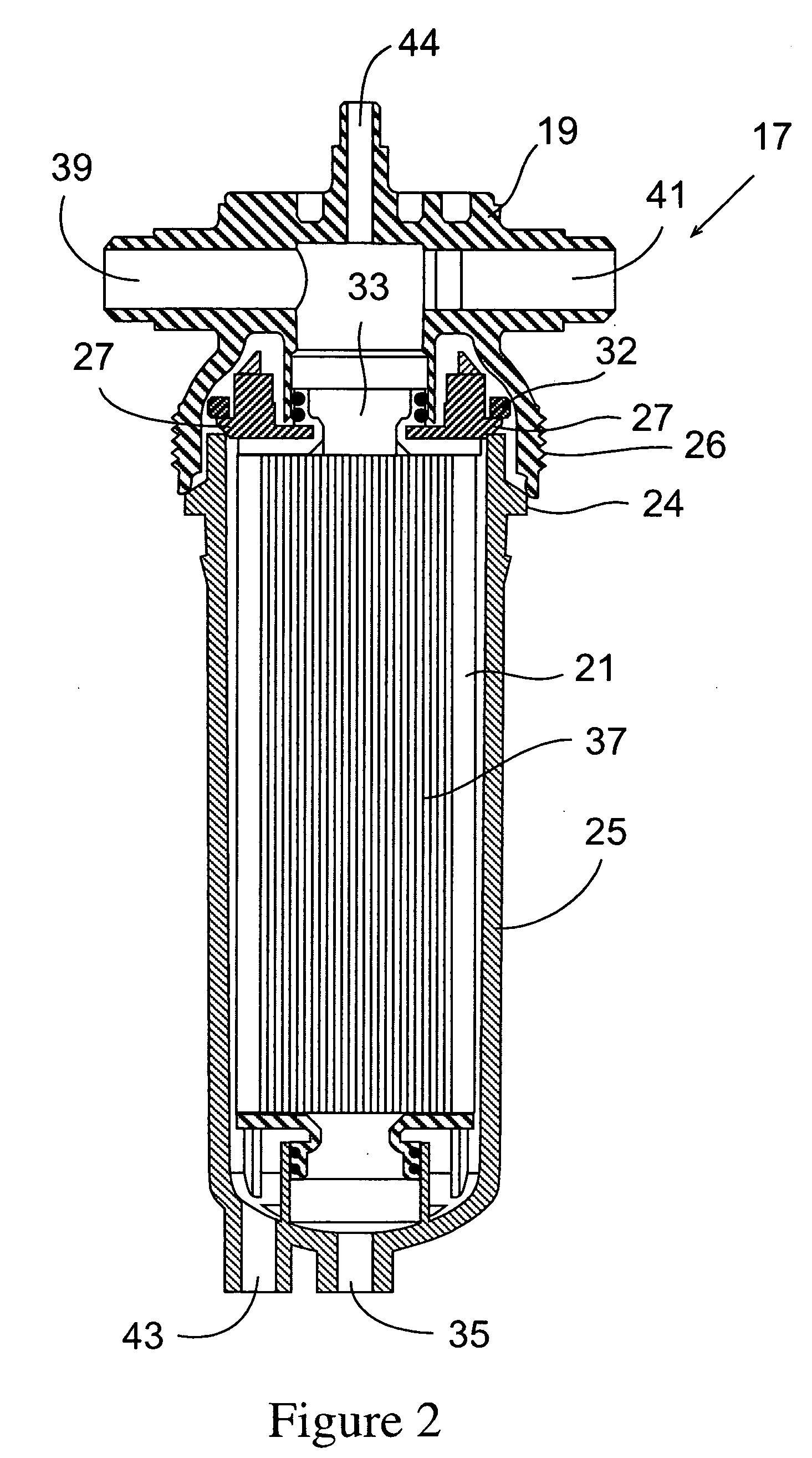

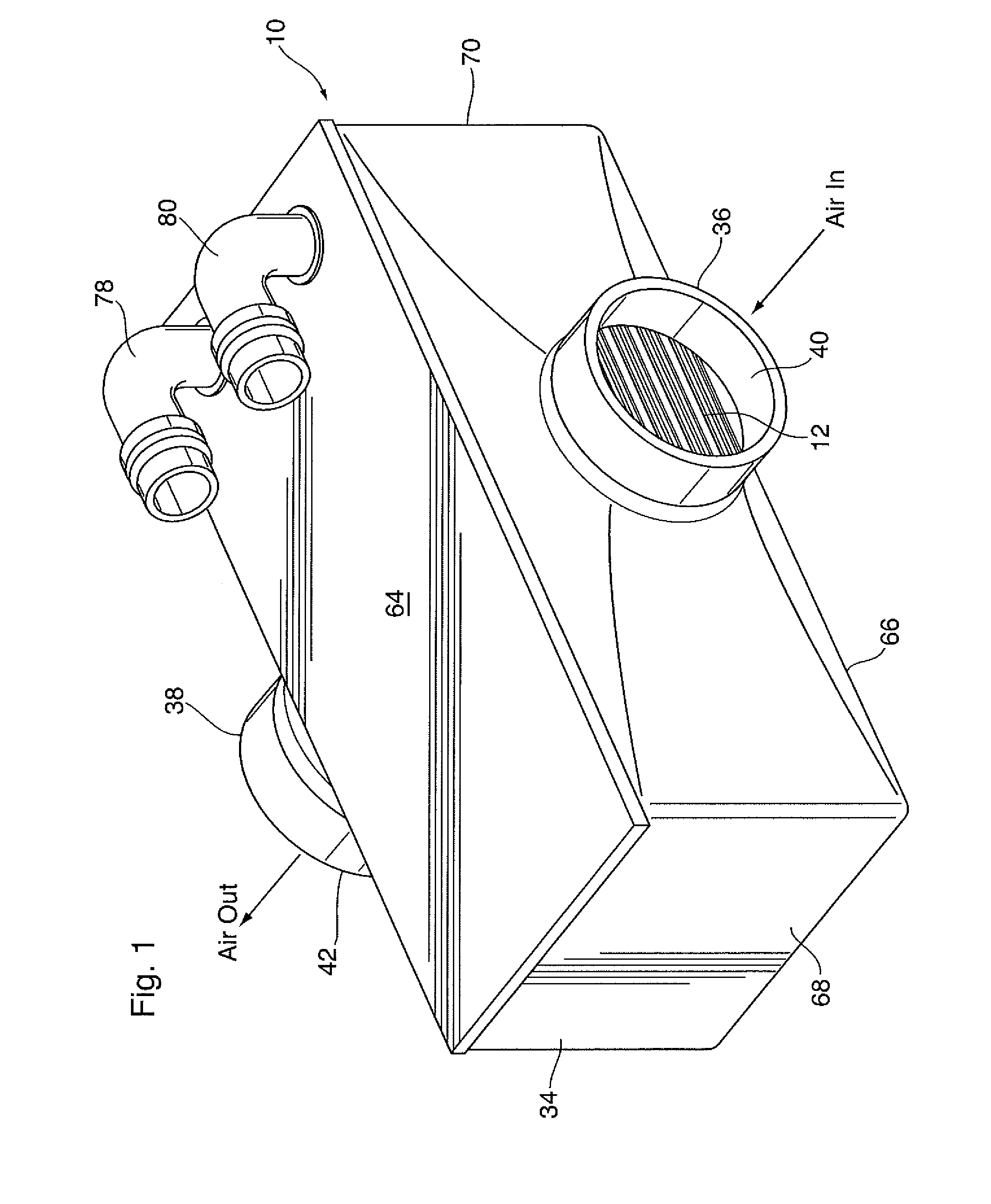

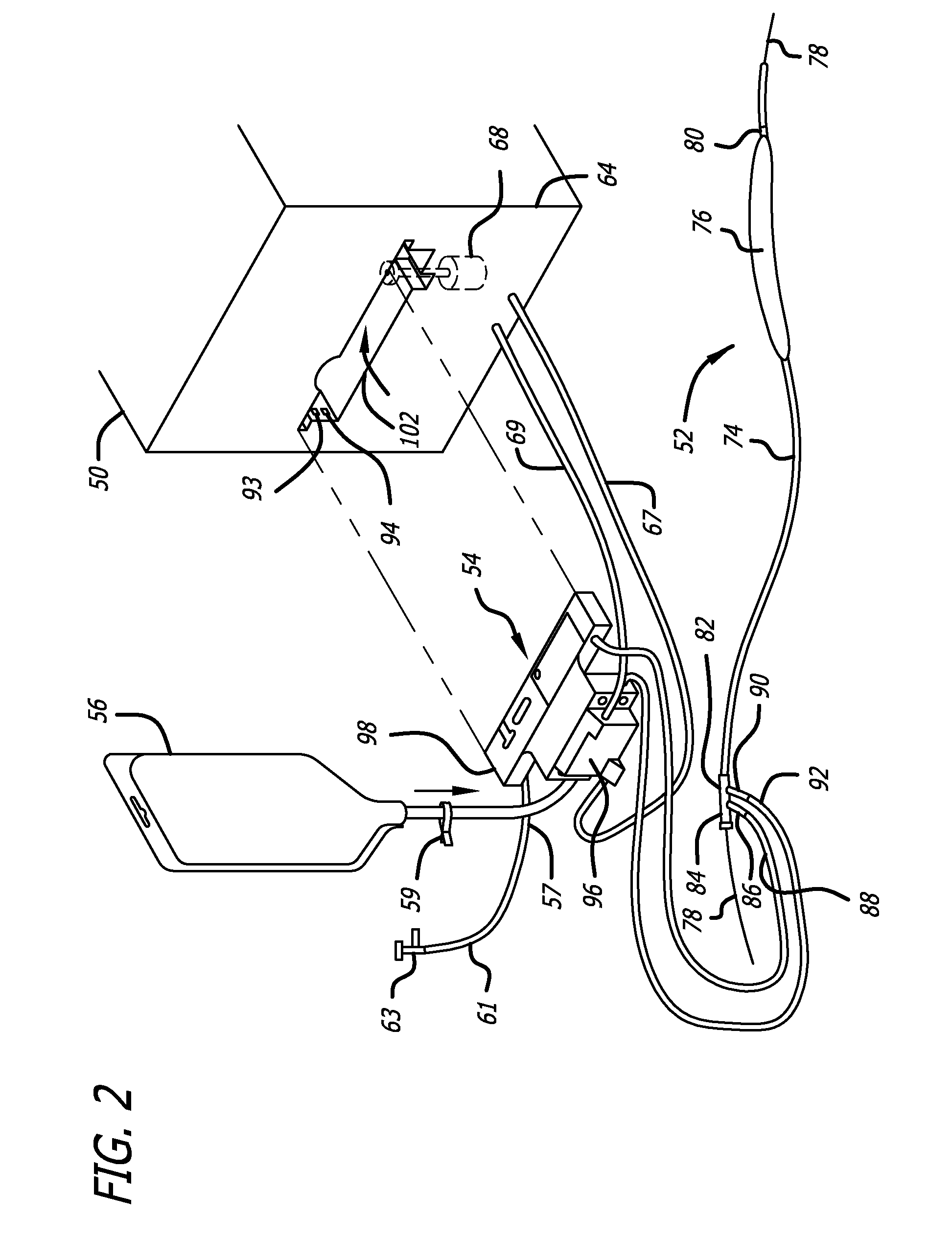

Heat Exchange System For A Pump Device

ActiveUS20080156476A1Easy to control accuratelyReduce riskHeater elementsIndirect heat exchangersEngineeringConductive materials

A heat exchange system selectably controls the temperature of a fluid being delivered to a patient's body by a pump device. The heat exchange system includes a thermal element and a heat exchanger that is removably coupled under pressure to the thermal element. The heat exchanger includes a first half made from thermally conductive material that correspondingly mates with the thermal element, a second half made from thermally conductive material opposite the first half, and an internal heat exchange zone existing between the first half and the second half, wherein fluid flows therethrough. The thermal element of the heat exchange system may controllably and safely warm and / or cool the fluid prior to delivery.

Owner:SMISSON CARTLEDGE BIOMEDICAL

Tubular heat exchanger

InactiveUS20090008074A1Easy to replaceOmissionStationary conduit assembliesHeat exchanger casingsEngineeringMechanical engineering

A tubular heat exchanger preferably of a multi-pass design, has a cylindrical shell with open ends that are releasable covered and sealed by preferably two end caps. Located removably in the shell and axially between the end caps is a core having a plurality of outer tubes and preferably a plurality of inner tubes with each one of the inner tubes extending through a respective one of the outer tubes. A plurality of perforated plates disposed in the shell are sealed releasably to respective ends of the inner and outer tubes thereby forming a plurality of liquid tight chambers for the flow of a plurality of segregated mediums and the transfer of heat therebetween.

Owner:VAMVAKITIS DIMITRI L +3

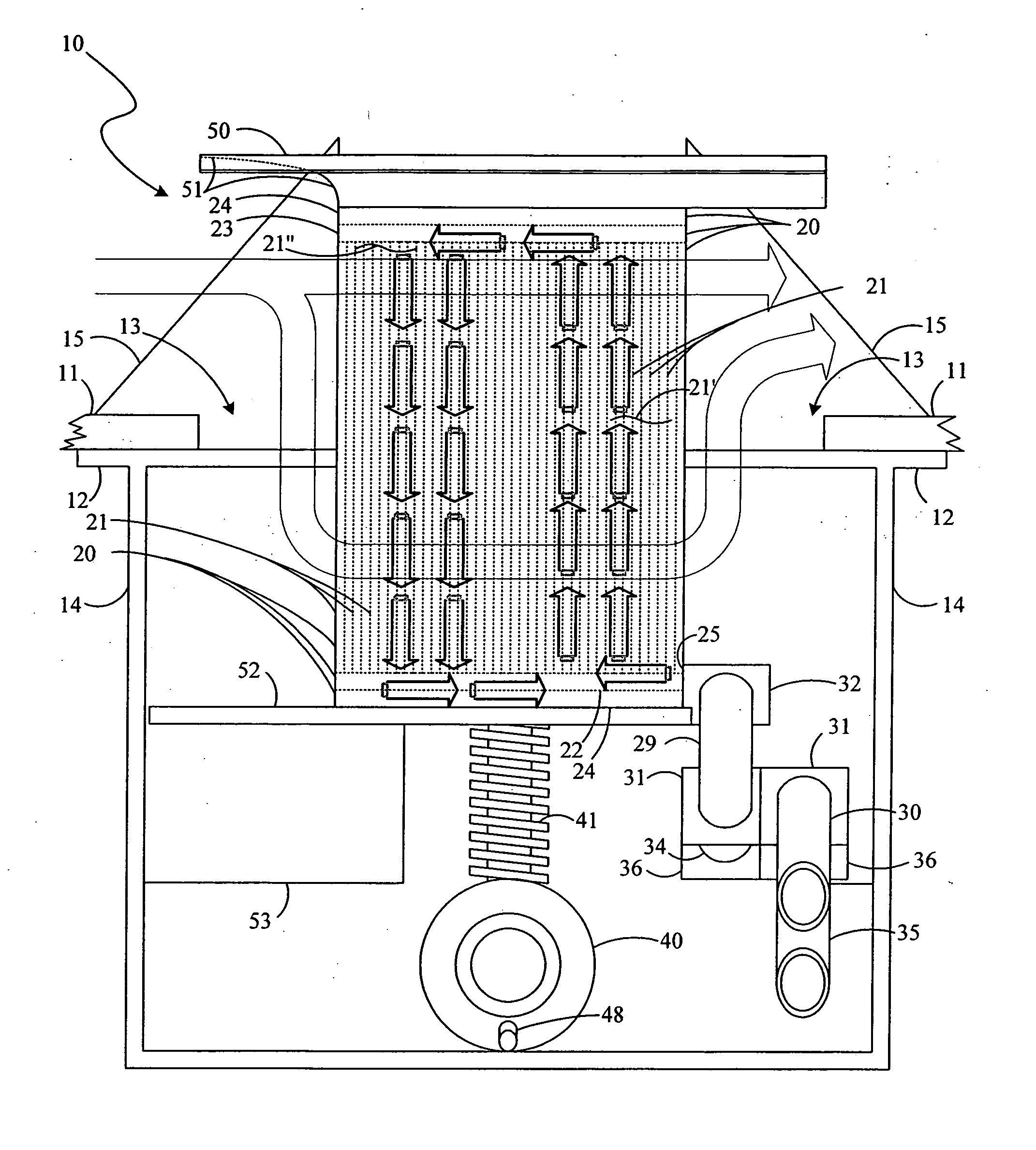

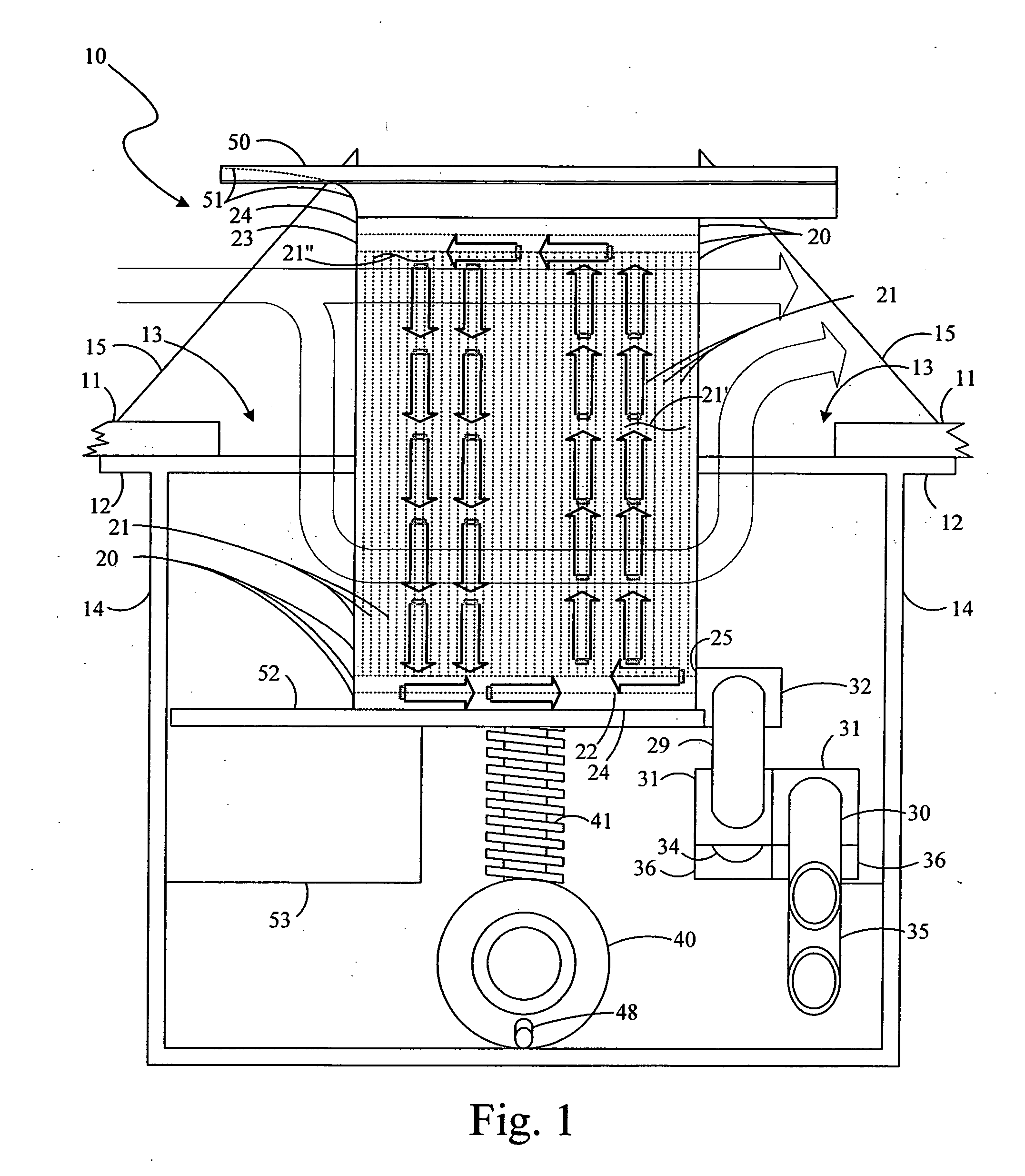

Mass or energy transfer cartridge and module

A mass transfer or energy transfer module is provided which includes a manifold, a cartridge and a bowl which houses the cartridge. The cartridge and bowl are connected to each other at least two flanges which fit into slots of the bowl to form a unitary construction.

Owner:ENTEGRIS INC

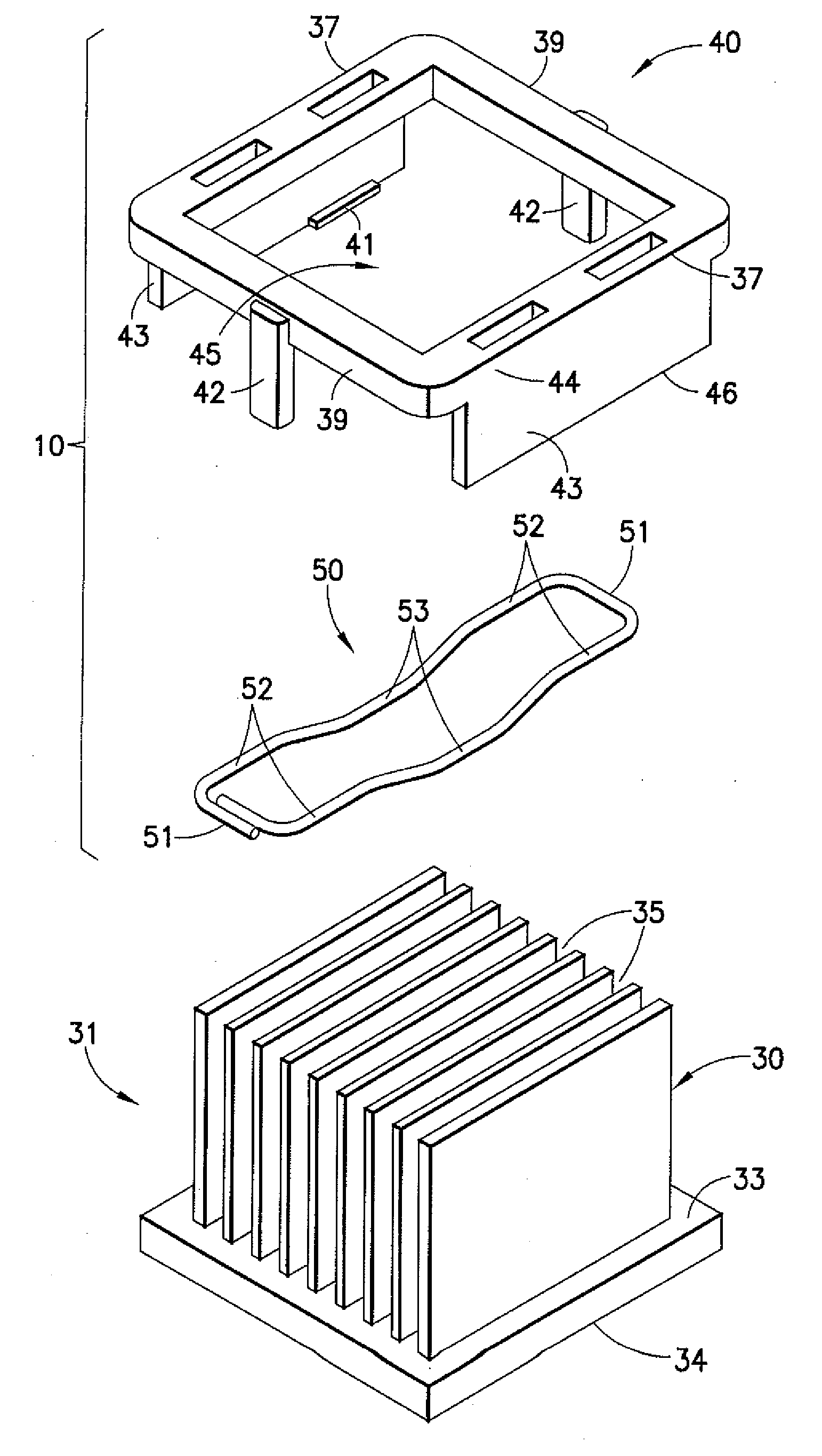

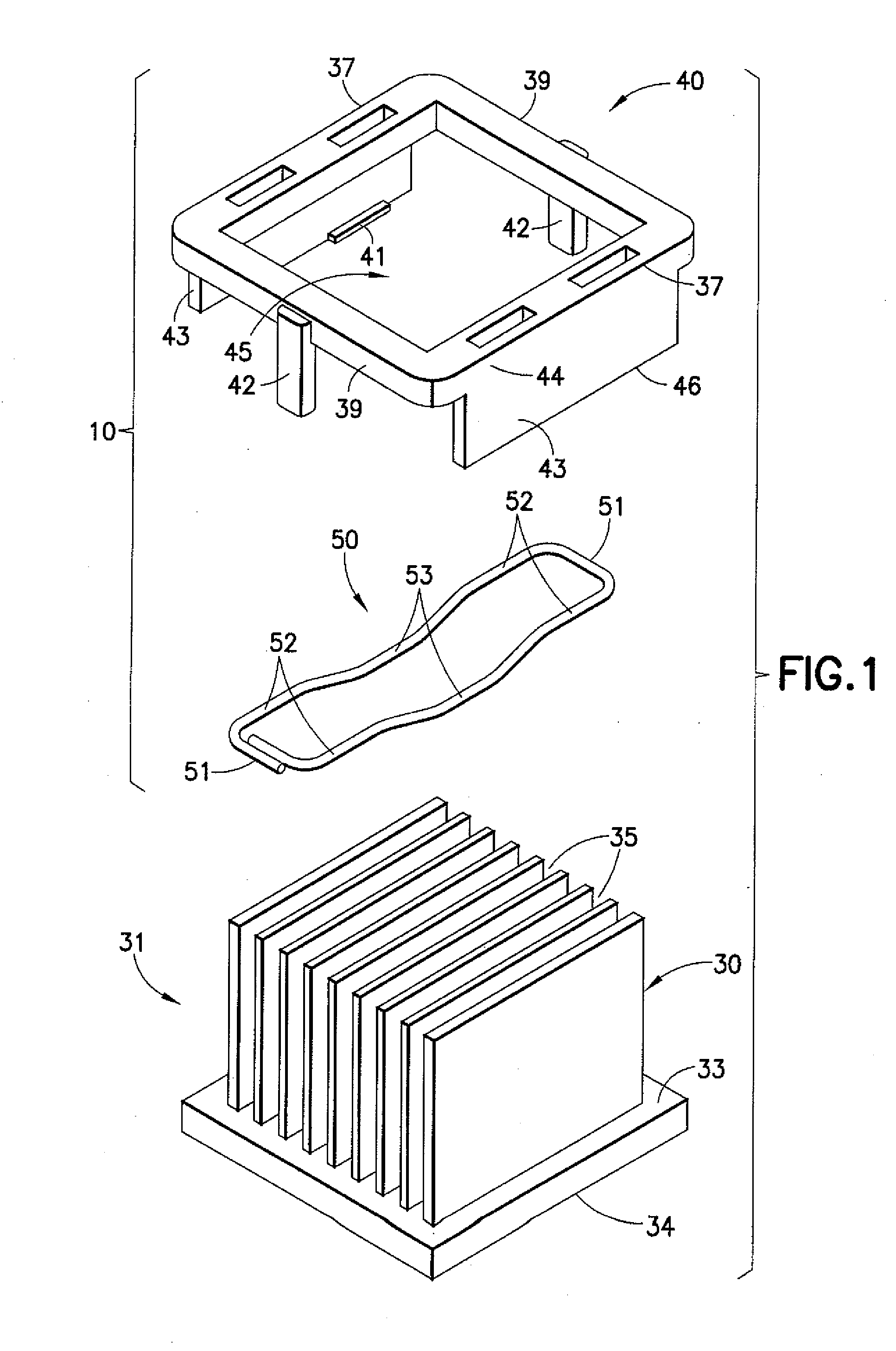

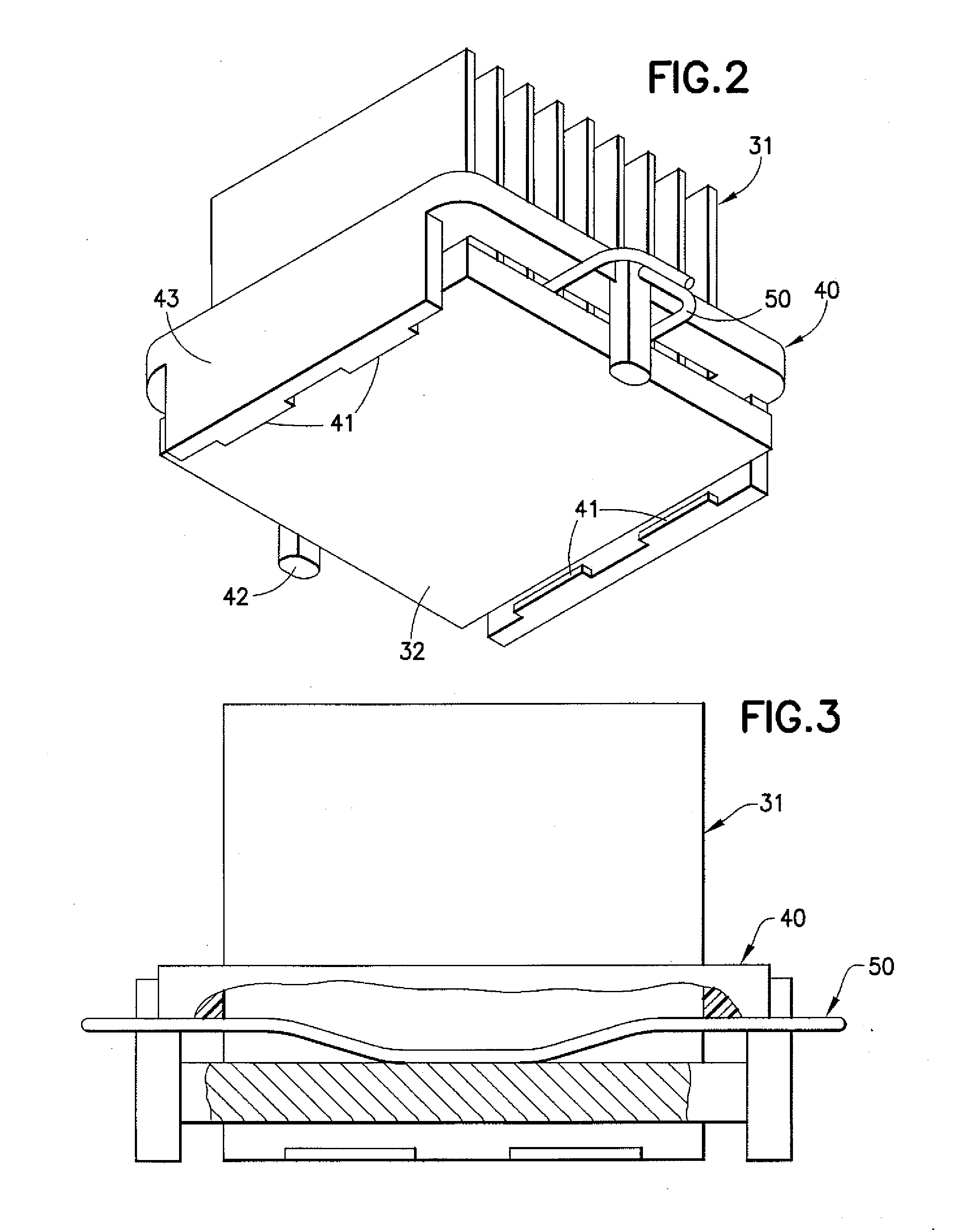

Heat Sink Mount and Assembly

ActiveUS20120186779A1Good thermal contactSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

An assembly for a heat sink having a contact plate with opposing first and second faces, a plurality of fins extending from the first face of the contact plate, and a plurality of gaps between the fins. A retaining device has a first pair of opposing sides and a second pair of opposing sides, the first and second pairs of opposing sides surrounding an opening, the first pair of opposing sides having primary framing members, at least some of the primary framing members having a first end at a respective side and a distal free end, with at least one engagement member positioned proximate the distal free ends. The primary framing members define a receiving space for the heat sink. A metal spring is configured in a closed shape cross-section for engagement with the retaining device. The metal spring has a pair of elongated sides, a pair of truncated sides and heat sink engagement regions. The heat sink engagement regions are positioned against the contact plate when the metal spring is engaged with the retaining device, to urge the contact plate towards the engagement members. The assembly is particularly well suited for use with ball grid array packages to interface electronic components in such packages with the heat sink.

Owner:AAVID THERMALLOY LLV

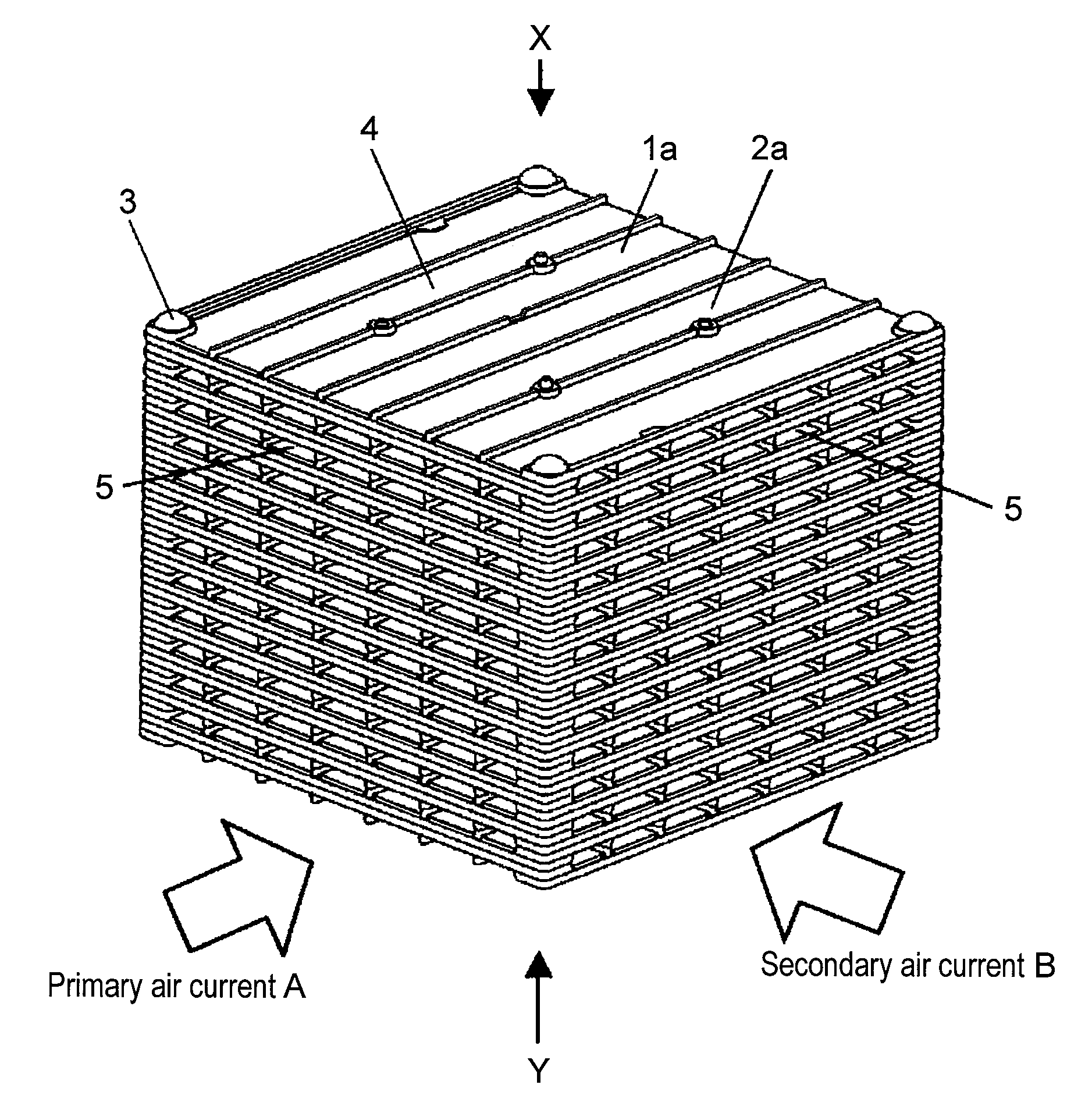

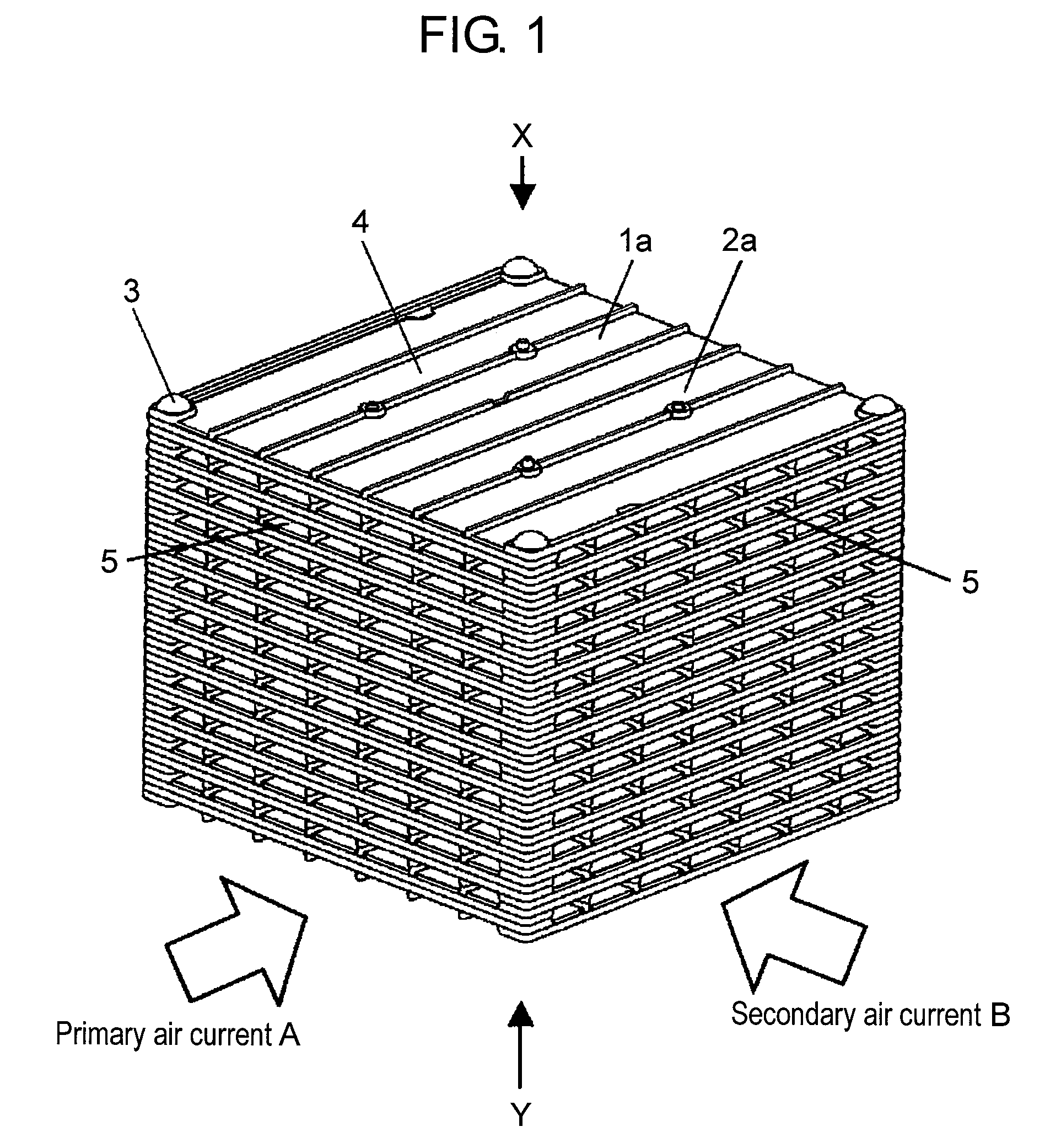

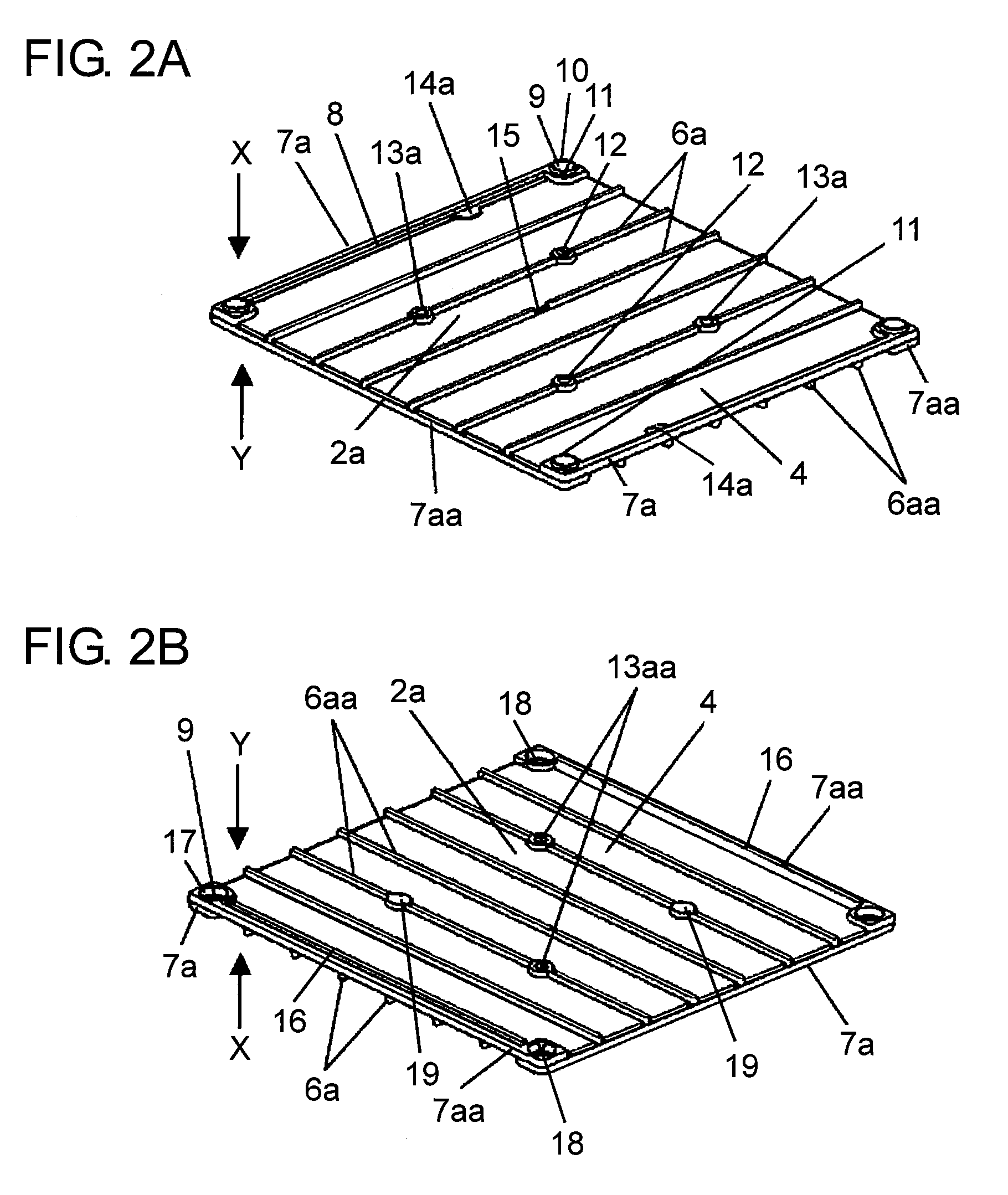

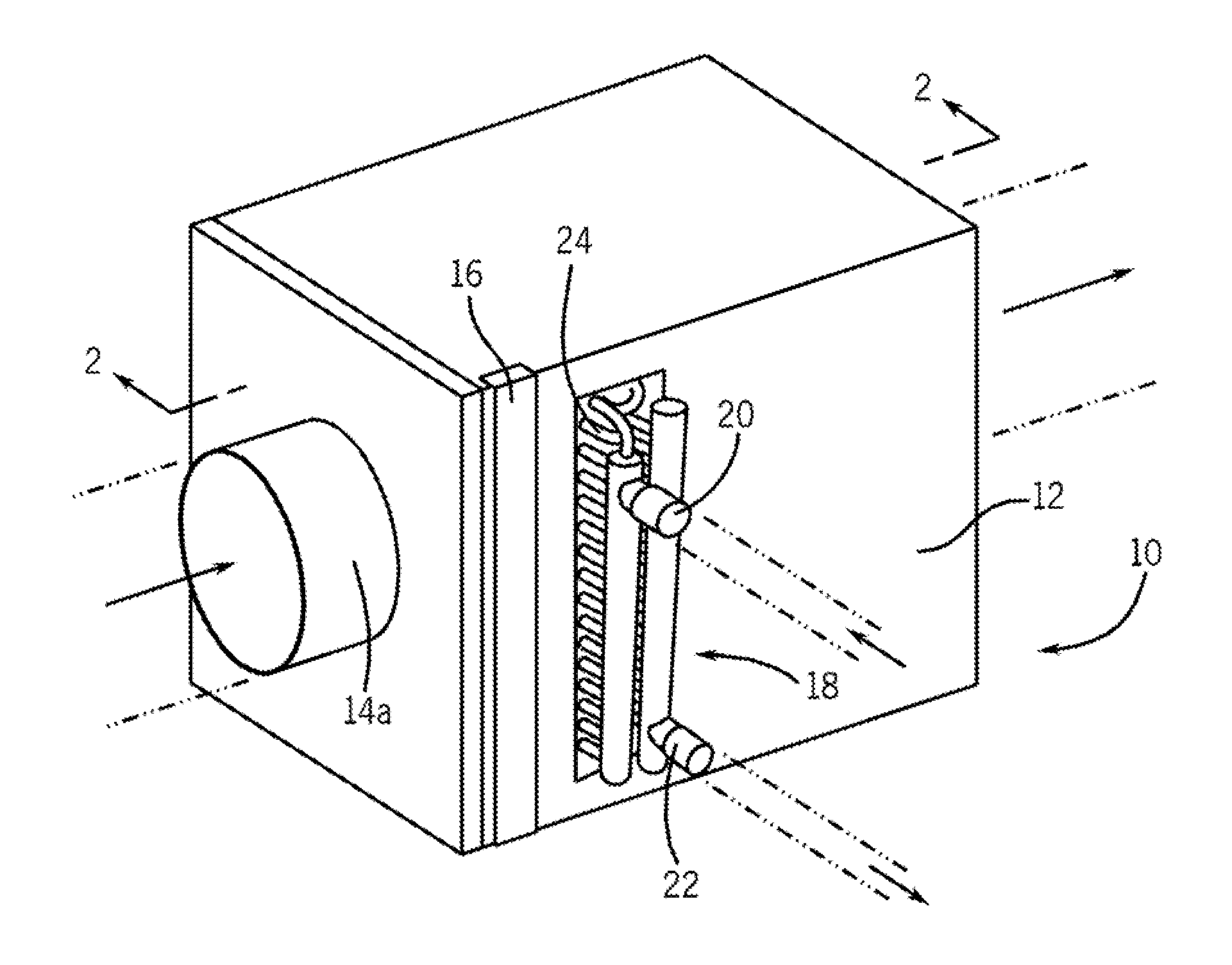

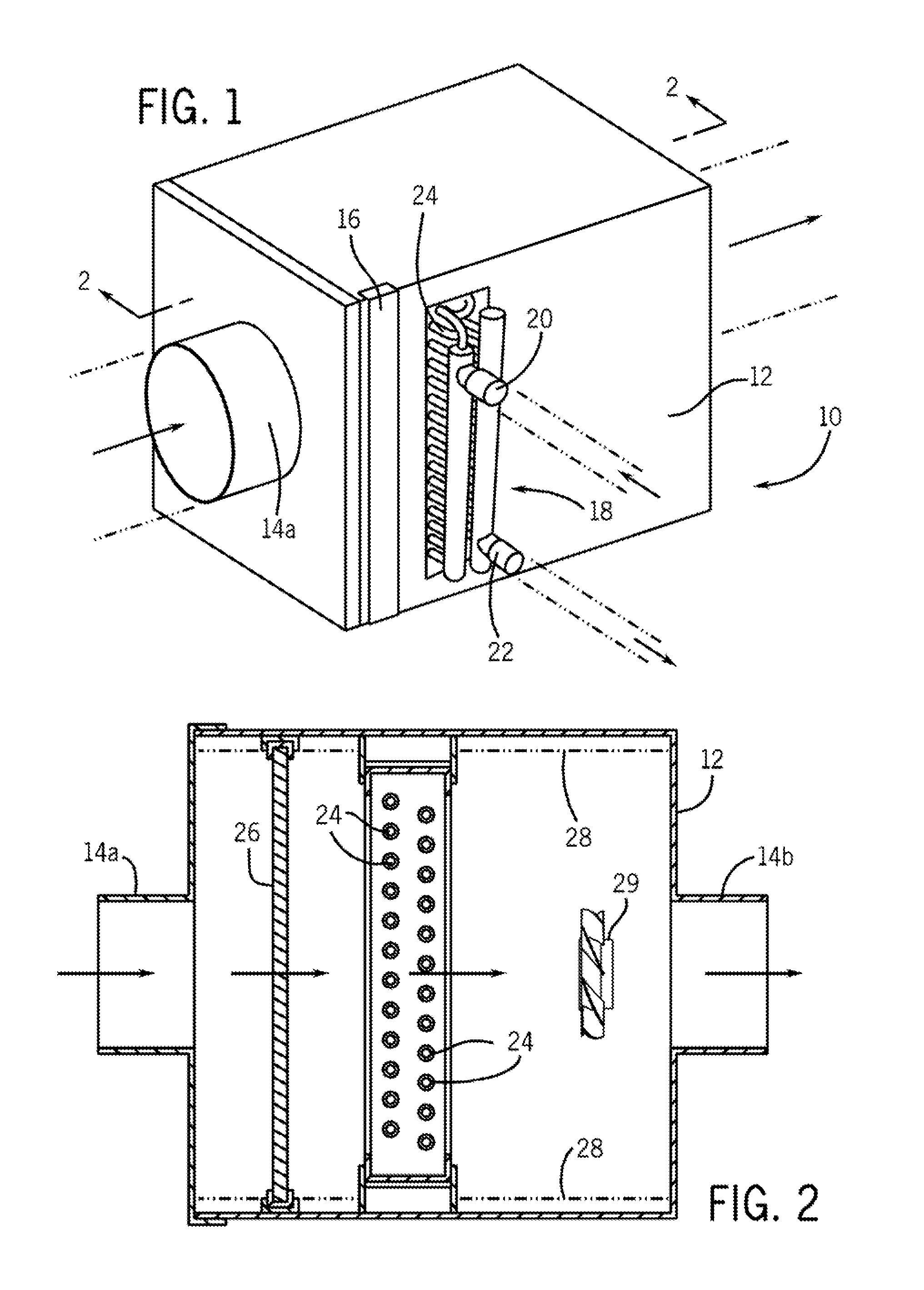

Heat exchanger and its manufacturing method

ActiveUS20090032232A1Prevent leakageIncrease productivityMetal-working apparatusMountingEngineeringMicro heat exchanger

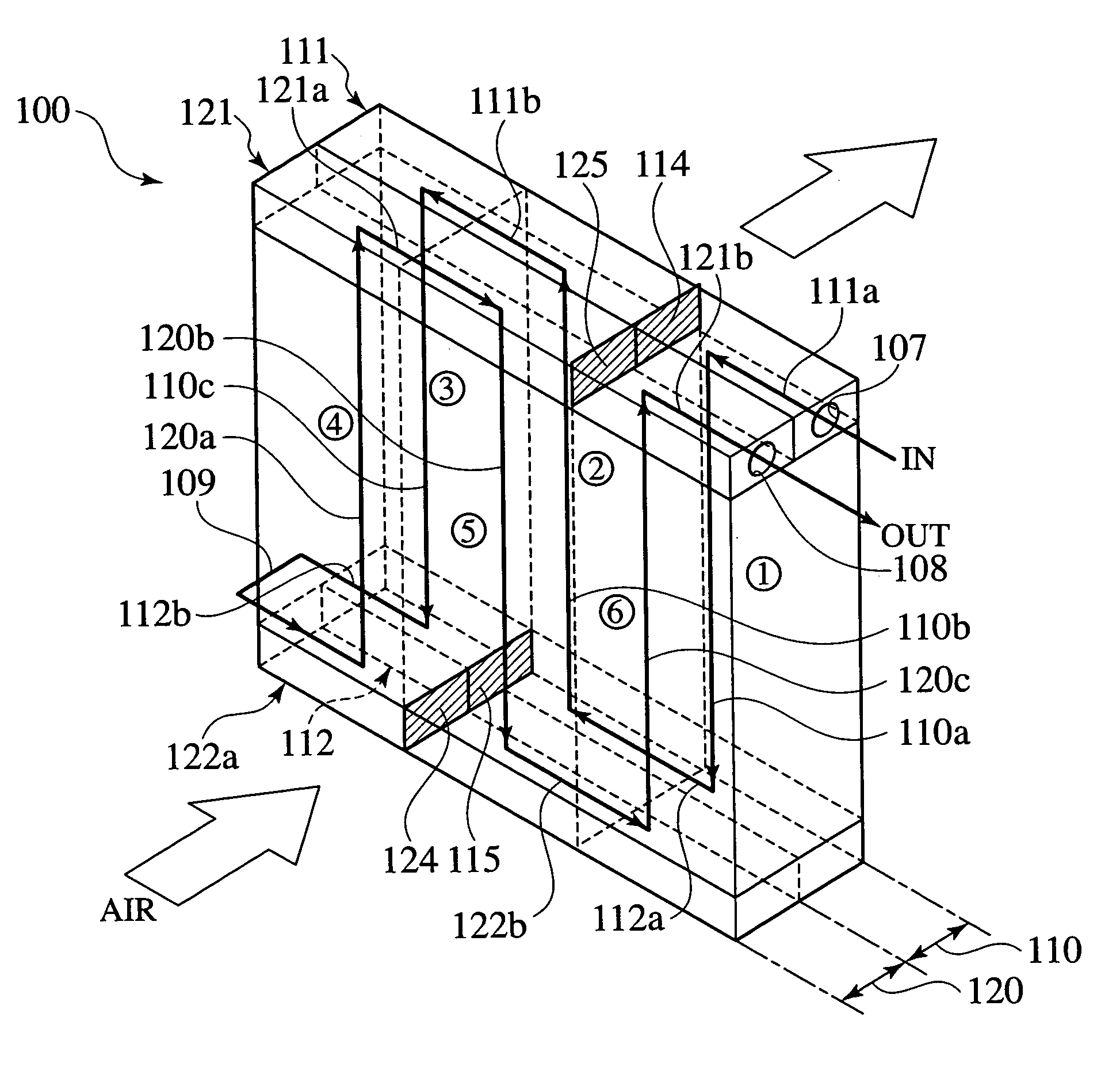

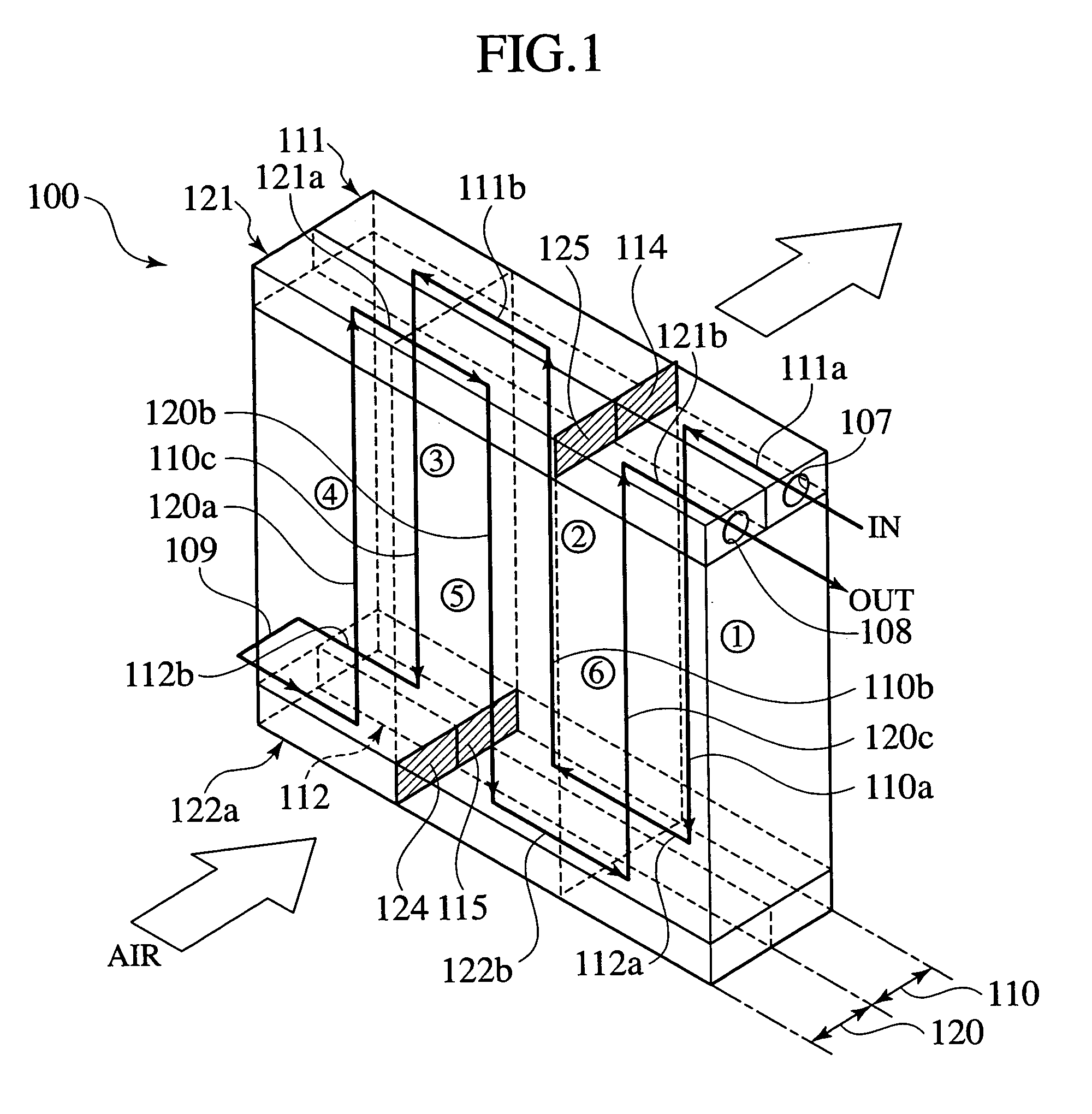

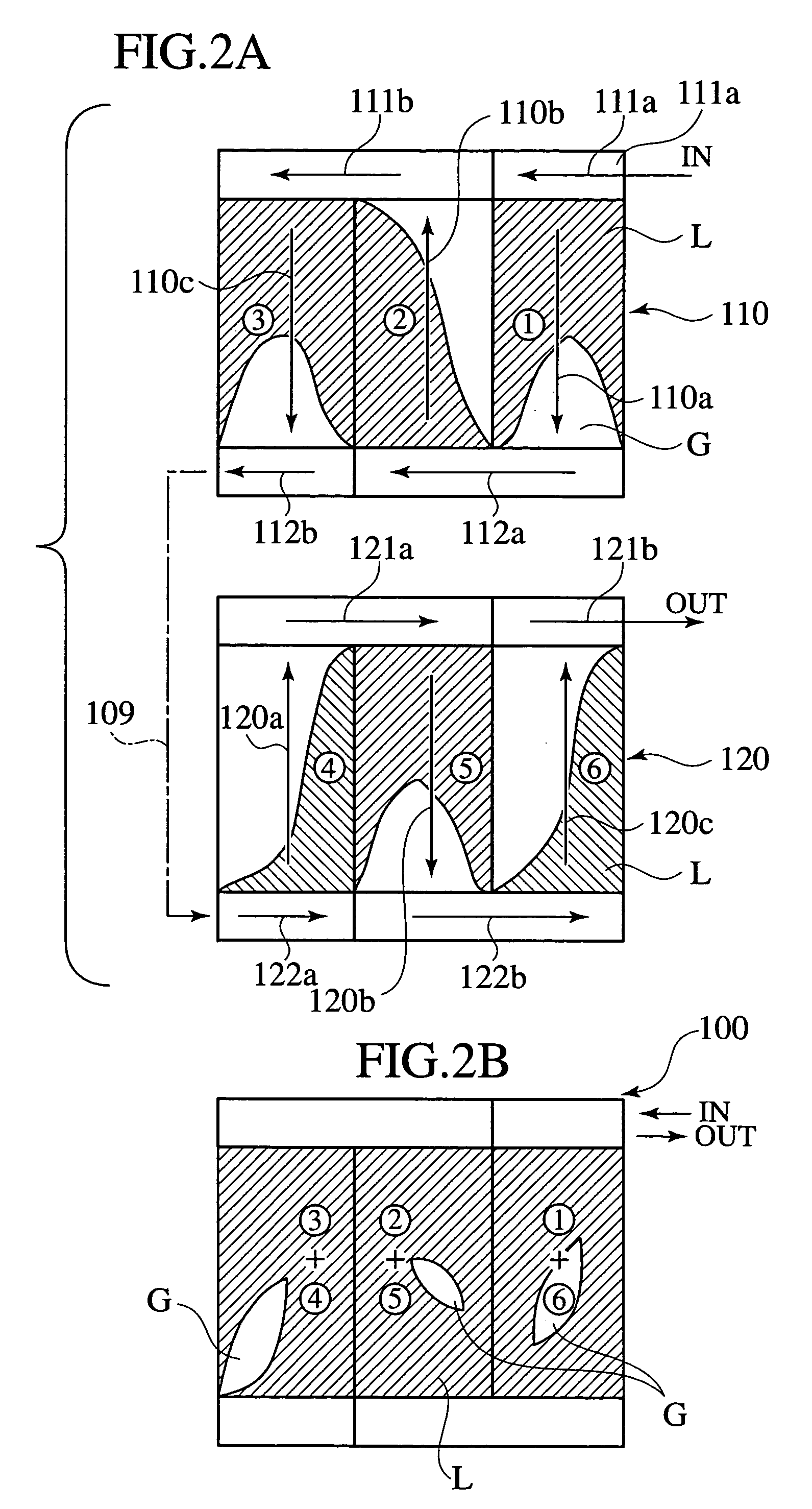

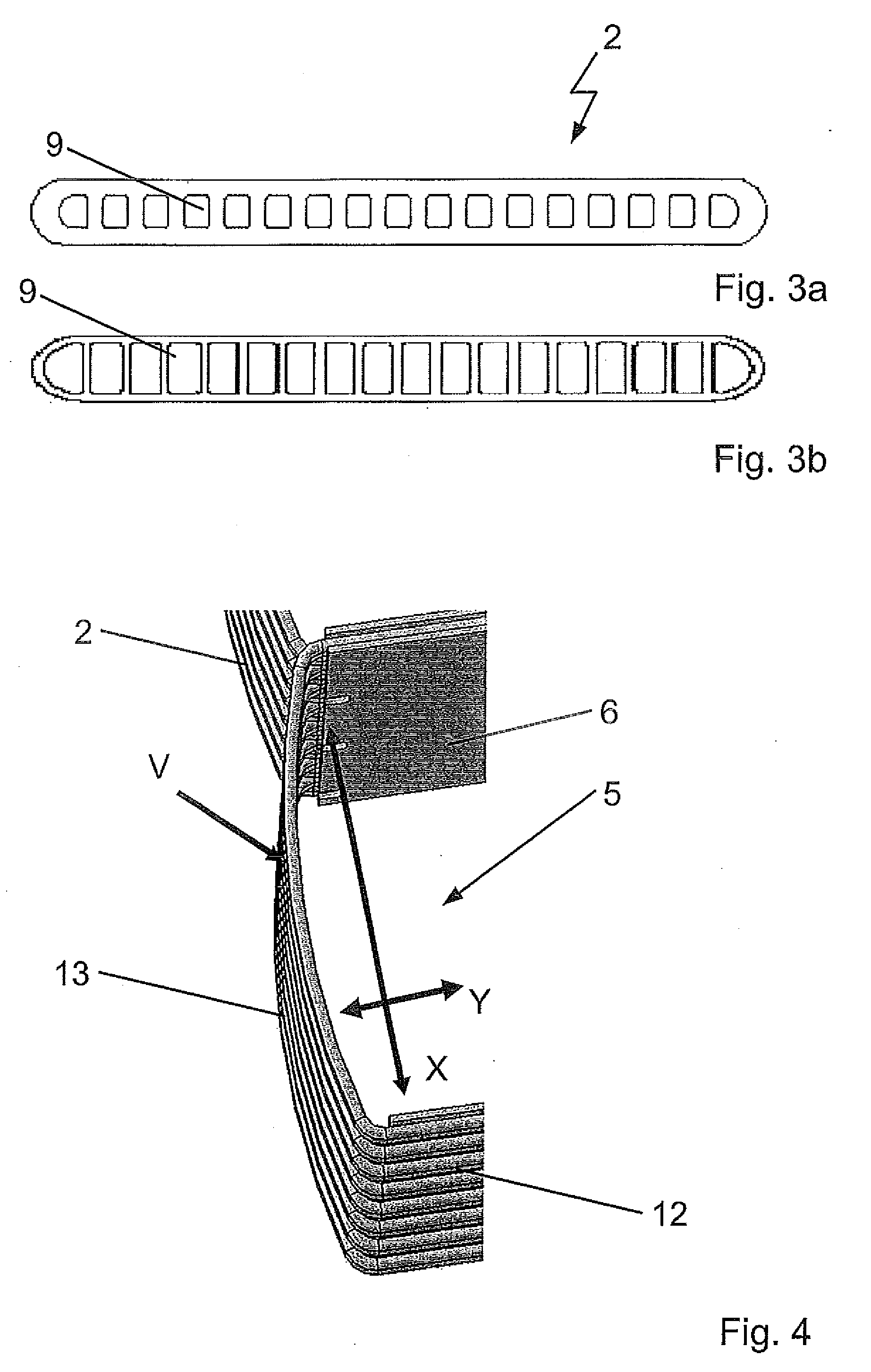

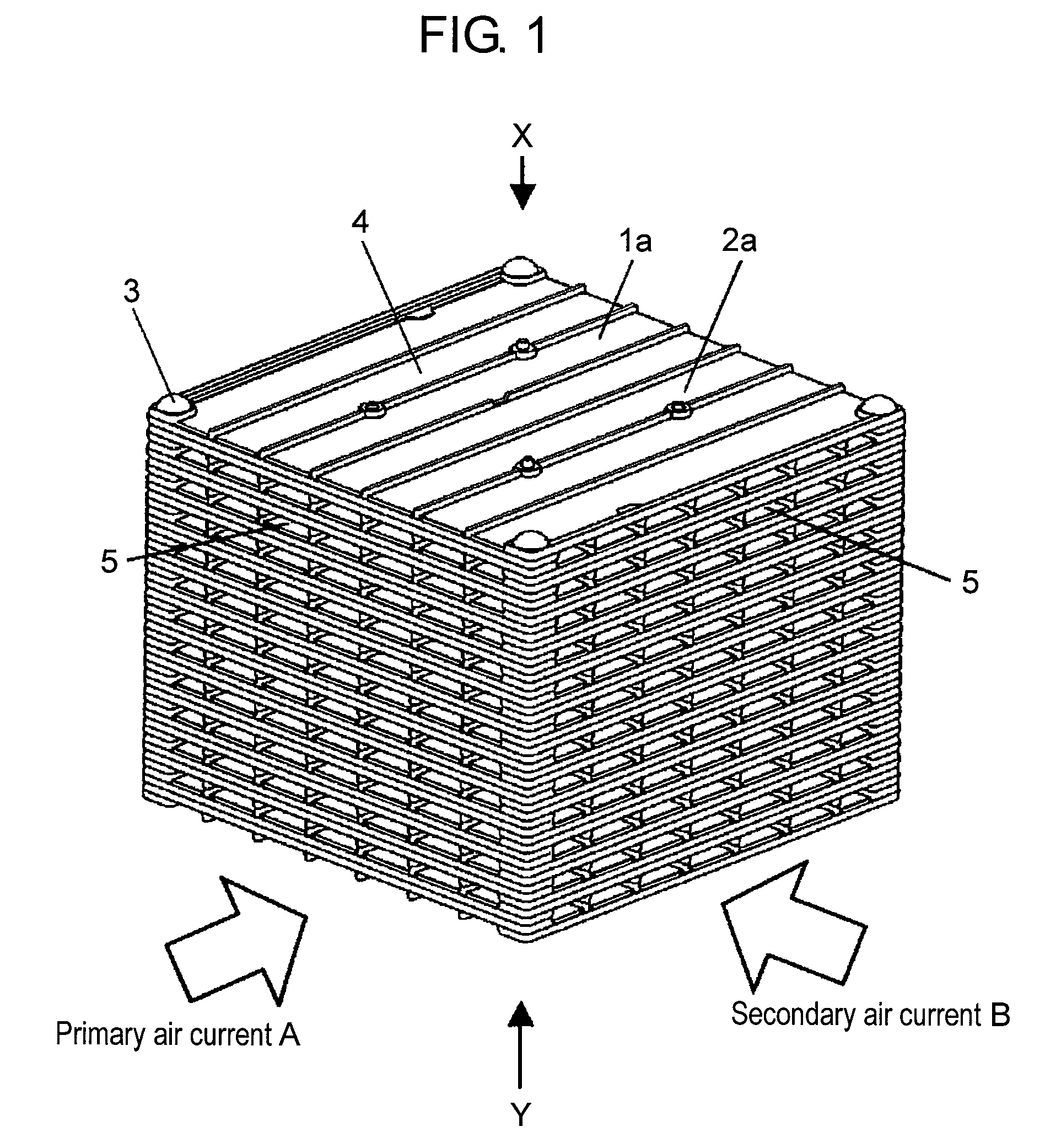

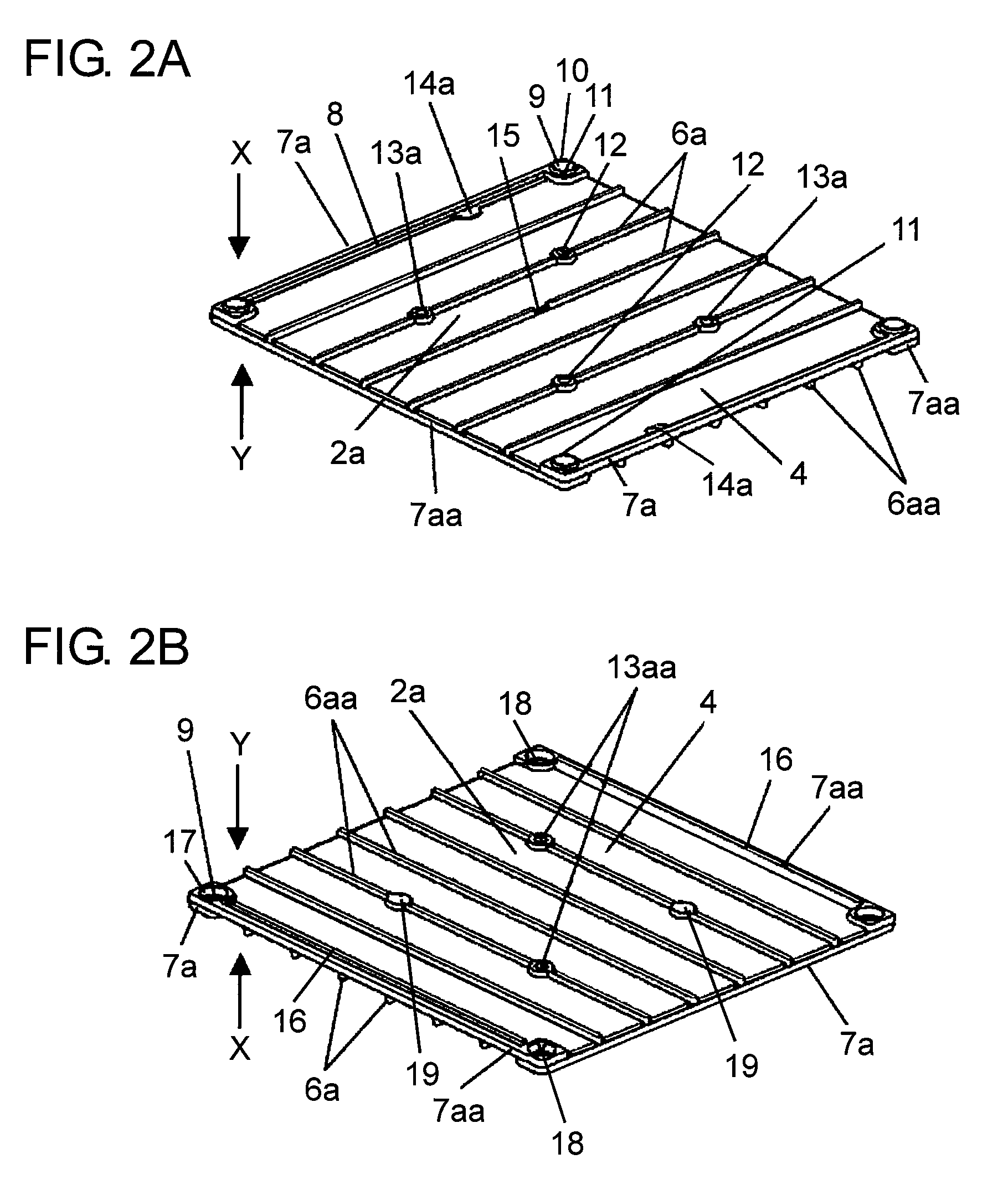

A heat exchanger for exchanging heat through a heat transfer plate by flowing a primary air current and a secondary air current to a ventilation path is provided. An unit element including the heat transfer plate, and the ventilation path formed between the heat transfer plates by stacking the unit element in plural are arranged. The unit element is configured by integrally molding a spacing rib for holding a spacing of the heat transfer plate, and a shield rib for shielding leakage of the air current with resin. Furthermore, the unit element includes a stacking error detecting unit for determining a stacking error when they are stacked.

Owner:PANASONIC CORP

Heat Exchanger with Self-Retaining Bypass Seal

ActiveUS20160097596A1Increasing the thicknessInternal combustion piston enginesStationary conduit assembliesHeat exchangerElectrical and Electronics engineering

A gas / liquid heat exchanger comprises a stack of flat tubes, defining liquid flow passages. Spaces between the flat tubes define gas flow passages, with the sides of the core having an irregular comb-like arrangement. The heat exchanger further comprises a housing having side covers over the sides of the core, and being spaced from the sides of the core. The core has at least one portion of reduced width, so as to provide channels extending throughout the height of the core. The heat exchanger further comprises a pair of side seals at least partly received in the gap between the side cover of the housing and the core, and more particularly in the channels along the sides of the core. The side seal extends throughout the height of the core and has a thickness which is greater than that of the gap.

Owner:DANA CANADA CORP

Air-oil heat exchanger

A heat exchange system for use in fluid operated equipment to provide air and working fluid heat exchanges to cool the working fluid in airstreams on a stream side of a wall. An actuator is mounted to be substantially located on a side of the wall opposite the stream side thereof having a positionable motion effector. A heat exchanger core having a plurality of passageway structures therein to enable providing the working fluid to, and removal therefrom. The heat exchanger core is mounted on the motion effector so as to be extendable and retractable thereby through the opening for selected distances into that region to be occupied by the airstreams.

Owner:RAYTHEON TECH CORP

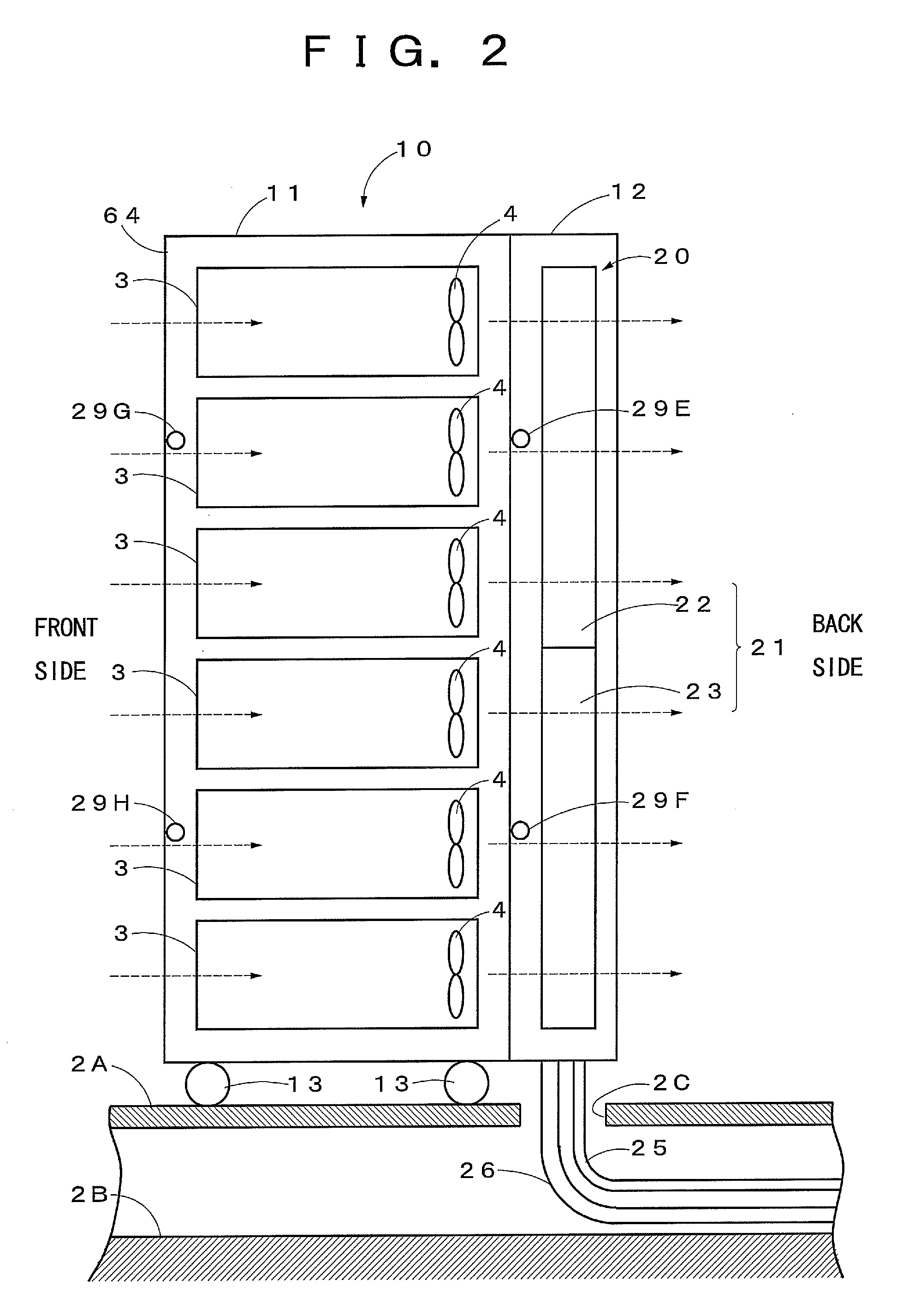

Evaporator having heat exchanging parts juxtaposed

InactiveUS7219511B2Reduce areaIncrease temperatureEvaporators/condensersStationary conduit assembliesCoolant flowEngineering

An evaporator includes a downwind-side heat exchanging part and an upwind-side heat exchanging part. In the heat exchanging part, paths are formed by partitions. In the evaporator, the flowing direction of coolant flowing in the upwind-side path is opposite to the flowing direction of the coolant flowing in the downwind-side path opposing to the upwind-side path. The number of heat exchanging passages in the path where the coolant rises is smaller than the number of heat exchanging passages in the paths where the coolant downs. As a result, the evaporator enables an increasing of the quantity of coolant flowing in the paths. Thus, if superimposing the upwind-side heat exchanging part on the downwind-side heat exchanging part, then it is possible to reduce an area causing a rise in blowout temperature of the coolant due to its short supply.

Owner:CALSONIC KANSEI CORP

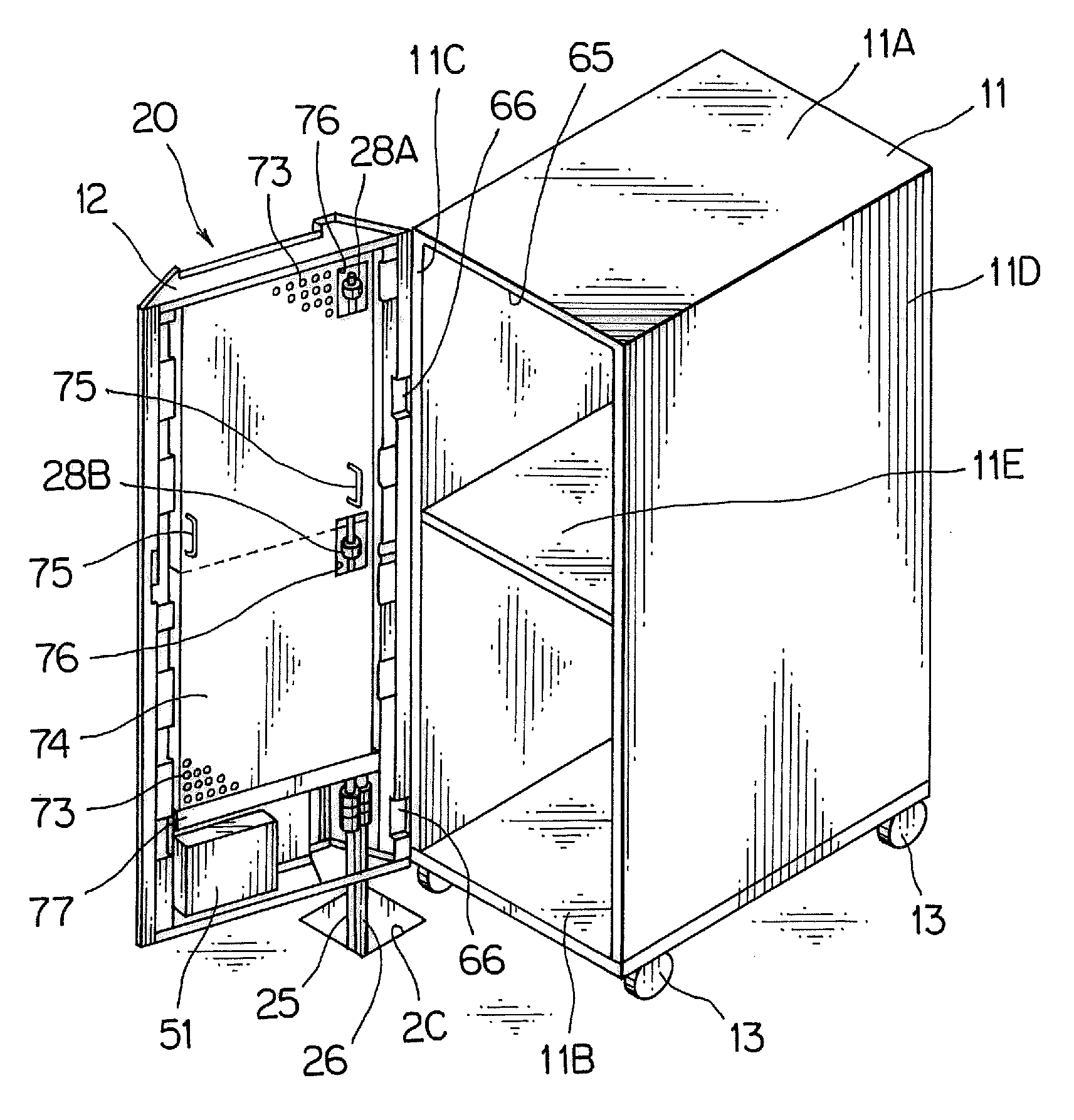

Electronic device cooling system and electronic device cooling apparatus

InactiveUS8113009B2Effectively a cool electronic deviceEffectively cool electronic devices stacked and mounted in a cabinetCompression machines with non-reversible cycleEvaporators/condensersElectronics coolingEngineering

An electronic cooling apparatus has a cabinet which is open at the front and rear sides thereof and accommodates plural electronic devices each having a fan, and a rear door which is provided with an evaporator. Air blown by the fan is cooled by the evaporator and then returned to a room. An expansion valve and control. A drain pan with an extension portion having hole portions through which refrigerant pipes extend is provided. A drain hose discharges drain water from the drain pan. An exhaust heat temperature detecting unit and a control for controlling the refrigerant supply to the evaporator are provided. When the exhaust heat temperature is equal to or less than a set exhaust temperature, the controller stops the refrigerant supply to the evaporator. When the exhaust heat temperature exceeds the set temperature, the controller starts the refrigerant supply.

Owner:SANYO ELECTRIC CO LTD

Heat Exchanger and Technique for Cooling a Target Space and/or Device Via Stepped Sequencing of Multiple Working Fluids of Dissimilar Saturation Temperatures to Provide Condensation-by-Vaporization Cycles

ActiveUS20140216688A1Heat dissipationDifference in saturation temperatureSafety devices for heat exchange apparatusDigital data processing detailsWorking fluidVaporization

A system for heat exchange includes a first condenser that places a first working fluid vapor in proximity to a second working fluid liquid. The two working fluids have respective saturation temperatures that enable the second working fluid to absorb sufficient amounts of heat from the first working fluid vapor to vaporize, while the first working fluid vapor condenses back into a liquid. The second working fluid vapor exits the first condenser via a first conduit and enters a first heat exchanger which places the second working fluid vapor in proximity to a third working fluid. The relative saturation temperatures of the second and third working fluids enables the transfer of sufficient amounts of heat from the second working fluid vapor to cause the second working fluid vapor to condense back into liquid while at least a portion of the third working fluid liquid vaporizes into third working fluid vapor.

Owner:DELL PROD LP

Apparatus and method for providing enhanced heat transfer from a body

ActiveUS7806915B2Avoid possibilityIncrease volumeMedical devicesIndirect heat exchangersTemperature controlUser input

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette is attached to the circulatory conduits of the catheter, the heat exchange cassette being sized to engage a cavity within a control unit. The control unit includes a heater / cooler device for providing heated or cooled fluid to a heat exchanger in thermal communication with the fluid heat exchange medium circulating to the heat exchange catheter, a user input device, and a processor connected to receive input from various sensors around the body and the system. A temperature control scheme for ramping the body temperature up or down without overshoot is provided.

Owner:ZOLL CIRCULATION

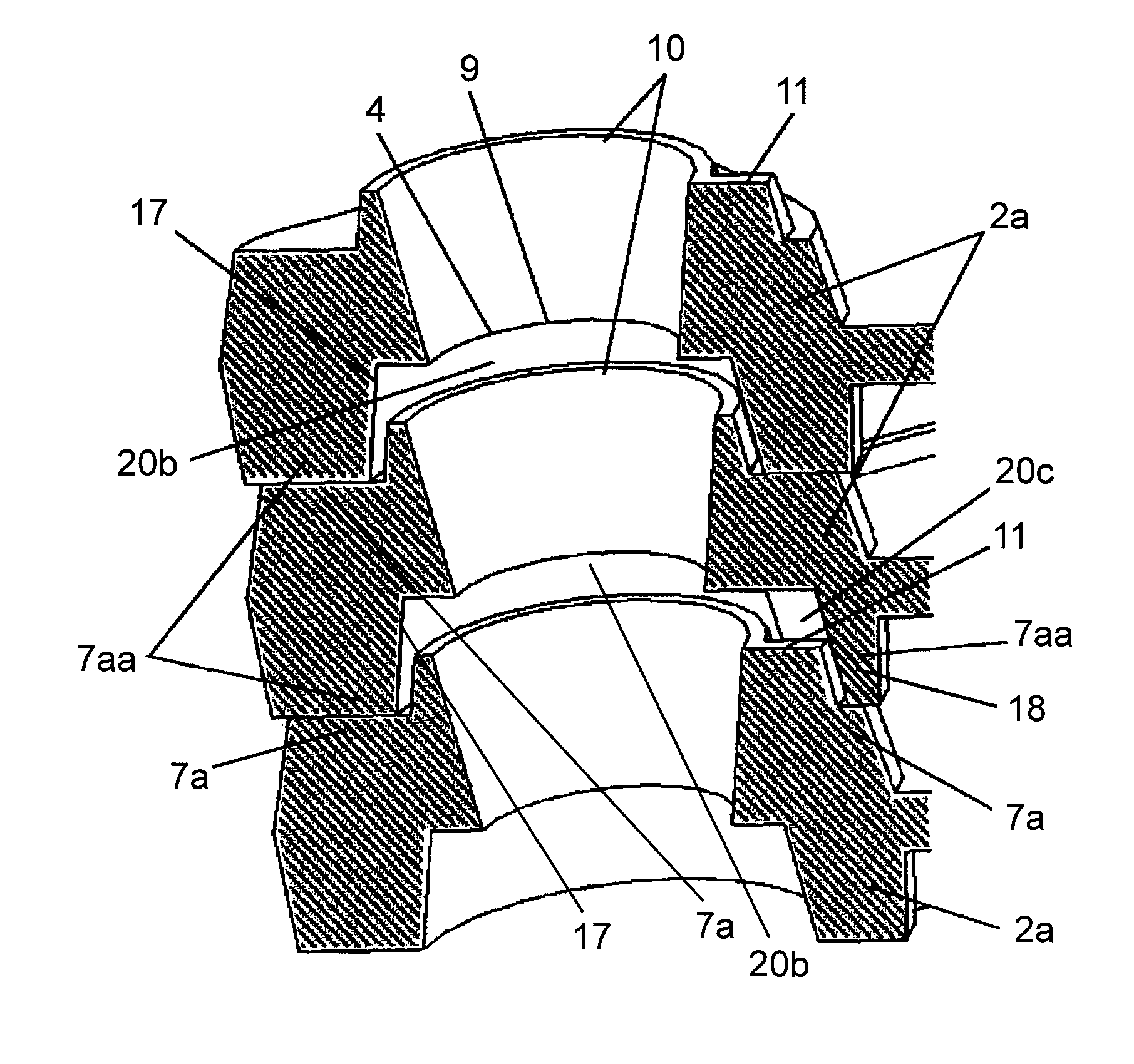

Heat exchanger for temperature control of vehicle batteries

ActiveUS20100147488A1Promote homogenizationSecondary cellsAir heatersTemperature controlPlate heat exchanger

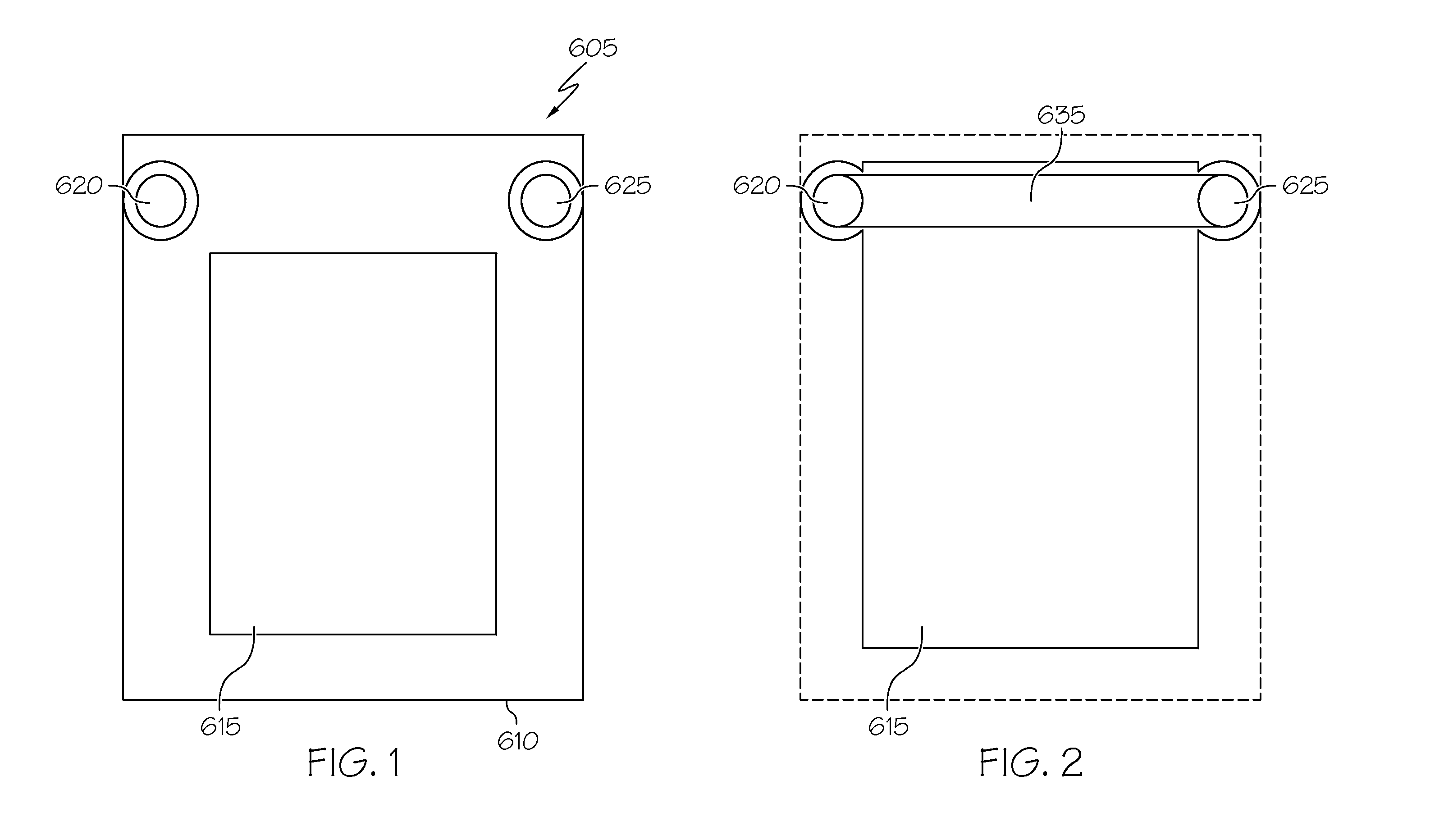

The invention relates to a heat exchanger for temperature controlling and fastening of battery units of the battery of a vehicle. The heat exchanger includes flat tubes that are passable by a heat carrier and a collecting tube and distributing tube for conducting the heat carrier. The flat tubes are established as multi-channel flat tubes. The collecting tube and the distributing tube are connected to each other over the flat tubes so that a holding frame is established that provides a structure forming spaces. The spaces are provided as chambers for accommodating the battery units.

Owner:HANON SYST

Heat exchanger and its manufacturing method

ActiveUS8002023B2Prevent leakageIncrease productivityMetal-working apparatusMountingEngineeringMicro heat exchanger

A heat exchanger for exchanging heat through a heat transfer plate by flowing a primary air current and a secondary air current to a ventilation path. An unit element including the heat transfer plate, and the ventilation path formed between the heat transfer plates by stacking the unit element in plural are arranged. The unit element is configured by integrally molding a spacing rib for holding a spacing of the heat transfer plate, and a shield rib for shielding leakage of the air current with resin. Furthermore, the unit element includes a stacking error detecting unit for determining a stacking error when stacked.

Owner:PANASONIC CORP

Thermal cycler with optical detector

InactiveUS8029733B2Easy transferView effectivelyBioreactor/fermenter combinationsHeating or cooling apparatusThermal cyclerMechanical engineering

A reaction vessel having a reaction chamber for holding a sample is fabricated by producing a housing having a rigid frame defining the minor walls of the chamber. The housing also defines a port for introducing fluid into the chamber. At least one sheet or film is attached to the rigid frame to form at least one major wall of the chamber. In preferred embodiments, two sheets or films are attached to opposite sides of the rigid frame to form two opposing major walls of the chamber, the major walls being connected to each other by the minor walls.

Owner:CEPHEID INC

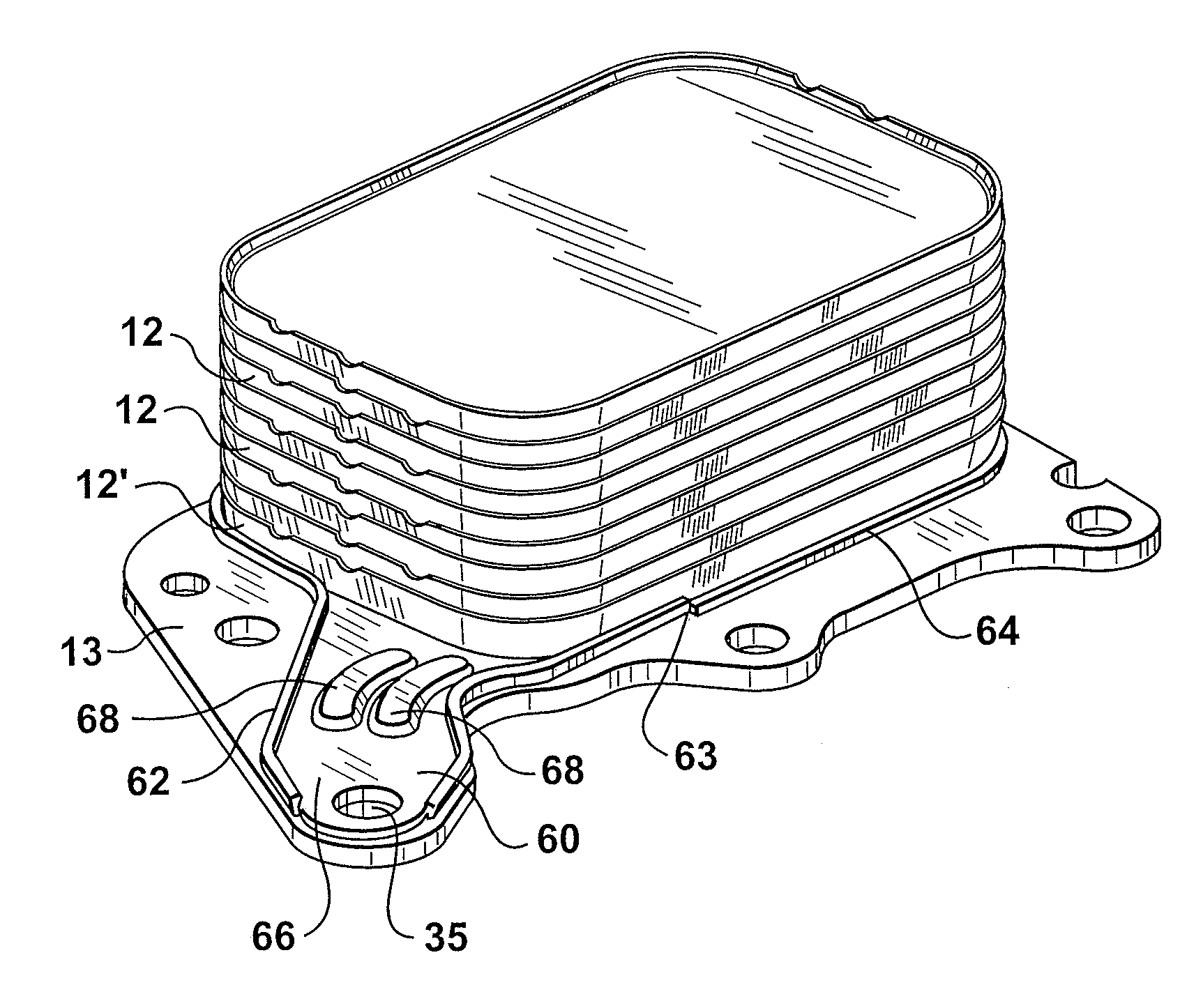

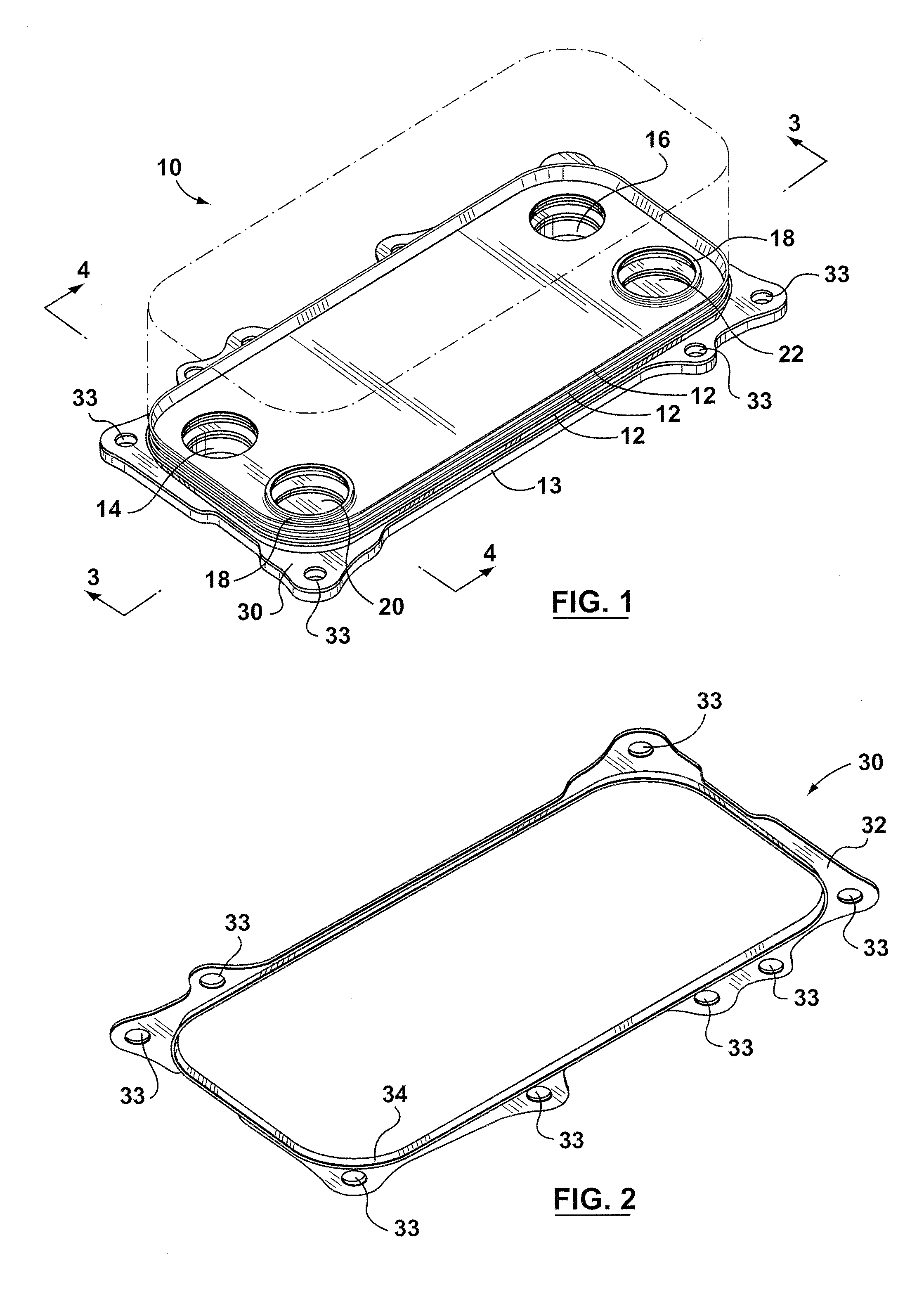

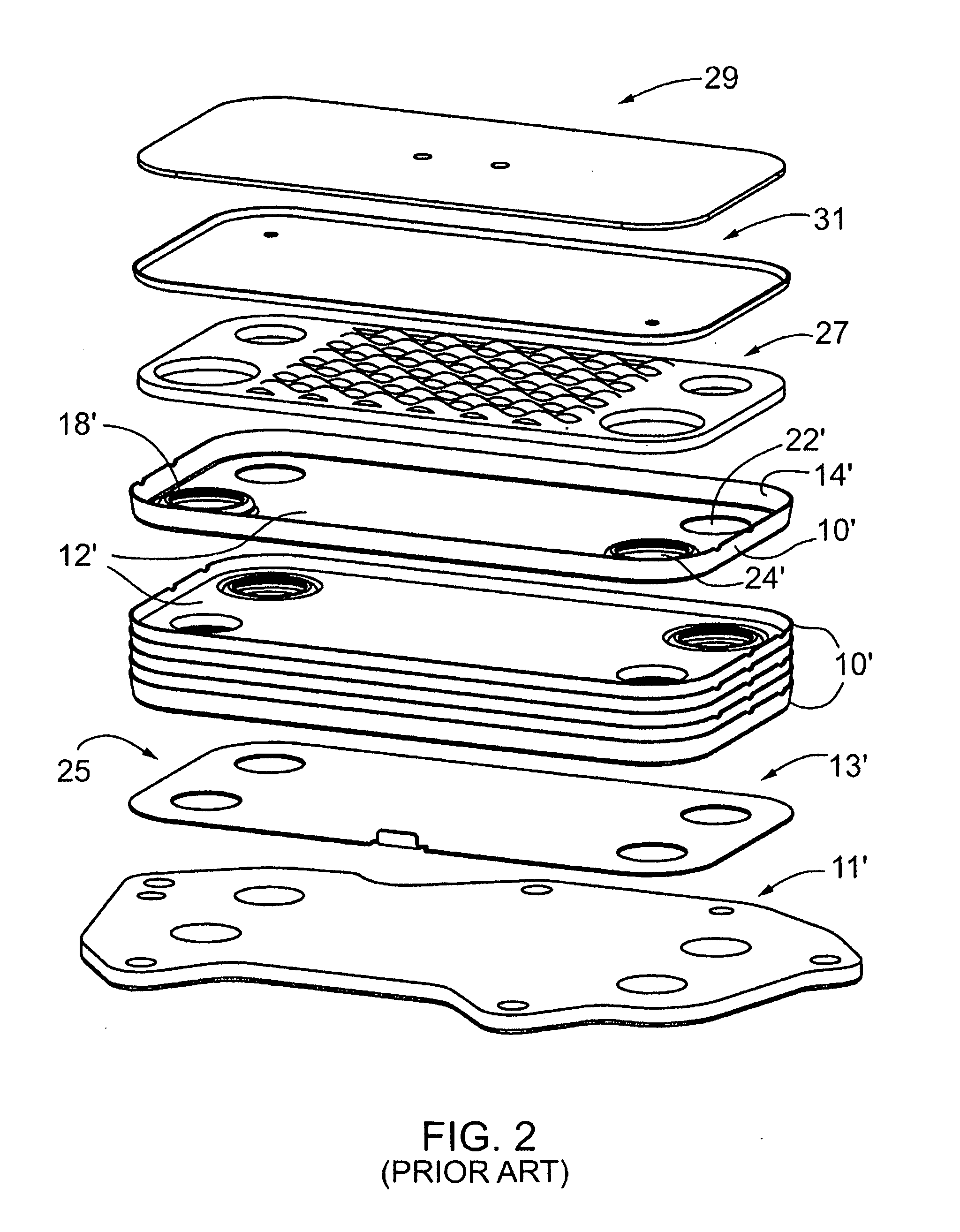

Heat Exchanger with End Plate Providing Mounting Flange

InactiveUS20110024095A1Heat exchanger casingsStationary tubular conduit assembliesEngineeringMotherboard

A heat exchanger for heat exchange between two liquids comprises a core comprised of formed plates connected to one another in a stack, these plates including first and second end plates and intermediate plates. Each of the plates has a central section and the first end plate and the intermediate plates each have an edge wall extending outwardly from its respective central section at an angle. The core has inlet and outlet holes in the main plate sections. The plates are in sealed engagement with one another and the central sections of at least the first end plate and the intermediate plates are spaced apart from respective adjacent central sections to form liquid flow passages. The second end plate is formed with an integral ridge extending snugly along the edge wall of the adjacent plate. This ridge is spaced from the edge of the end plate so as to provide one or more mounting flanges.

Owner:DANA CANADA CORP

Thermal fluid temperature converter

A thermal fluid temperature converter uses temperature from a thermal fluid to preheat or precool incoming air prior to entering a household / workplace / building / appliance. The thermal fluid temperature converter includes a hollow housing, a filter placed inside the hollow housing, and a temperature exchanger placed inside the hollow housing. The temperature exchanger is adapted to receive a thermal fluid that circulates through the coils. The air enters the hollow housing, interchanges temperature with the thermal fluid circulating through the coils, and leaves the hollow housing as a heated air or a cooled air.

Owner:CULLEN FREDRICK THOMAS +1

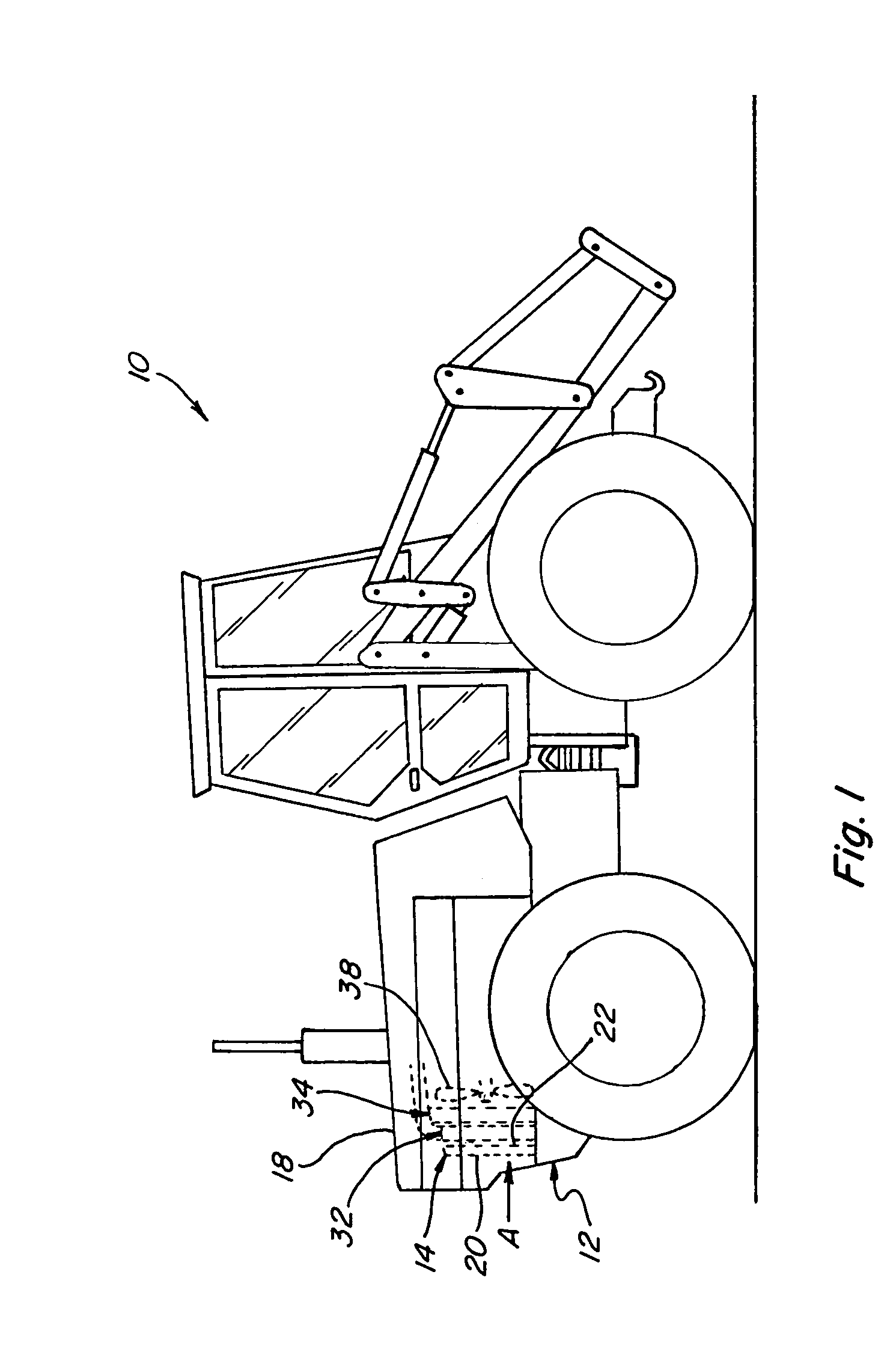

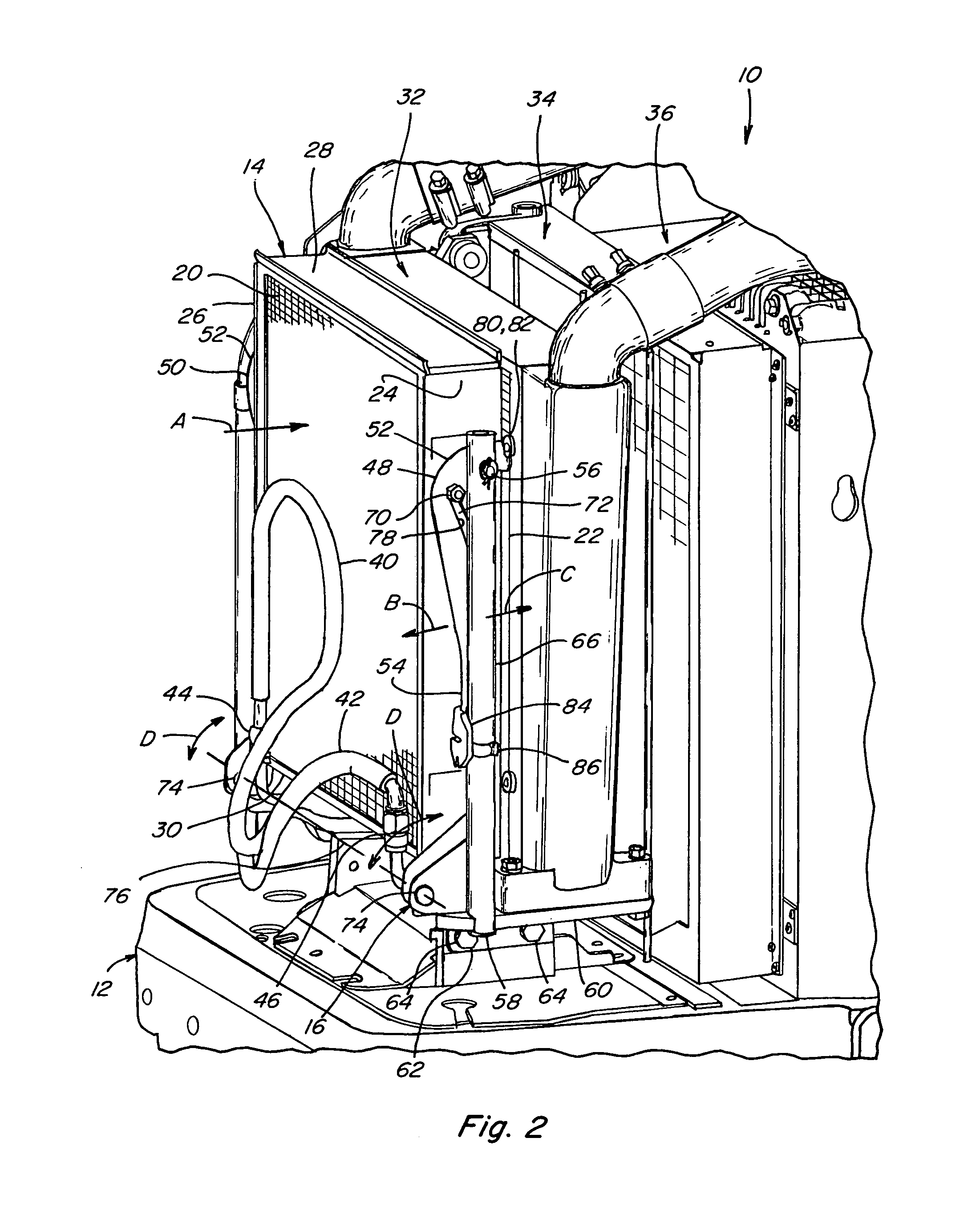

Apparatus for tilting and securing a heat exchanger

InactiveUS7370690B2Solve the lack of spaceAir-treating devicesVehicle heating/cooling devicesAir conditioningMicro heat exchanger

Apparatus for supporting a heat exchanger such as a condenser of an air conditioning system on a vehicle, for pivotal movement between an operational position and a position angularly related to the operational position, for such purposes as inspection, cleaning, service and maintenance, the apparatus being configured for holding the heat exchanger in the operational position, and for guiding and controlling movement thereof to the tilted position, and holding the heat exchanger in the tilted position.

Owner:BLUE LEAF I P INC

Apparatus and method for providing enhanced heat transfer from a body

InactiveUS20110022136A1Avoid possibilityIncrease volumeMedical devicesIndirect heat exchangersTemperature controlMedicine

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette is attached to the circulatory conduits of the catheter, the heat exchange cassette being sized to engage a cavity within a control unit. The control unit includes a heater / cooler device for providing heated or cooled fluid to a heat exchanger in thermal communication with the fluid heat exchange medium circulating to the heat exchange catheter, a user input device, and a processor connected to receive input from various sensors around the body and the system. A temperature control scheme for ramping the body temperature up or down without overshoot is provided.

Owner:ZOLL CIRCULATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com