Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Increase pouring temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

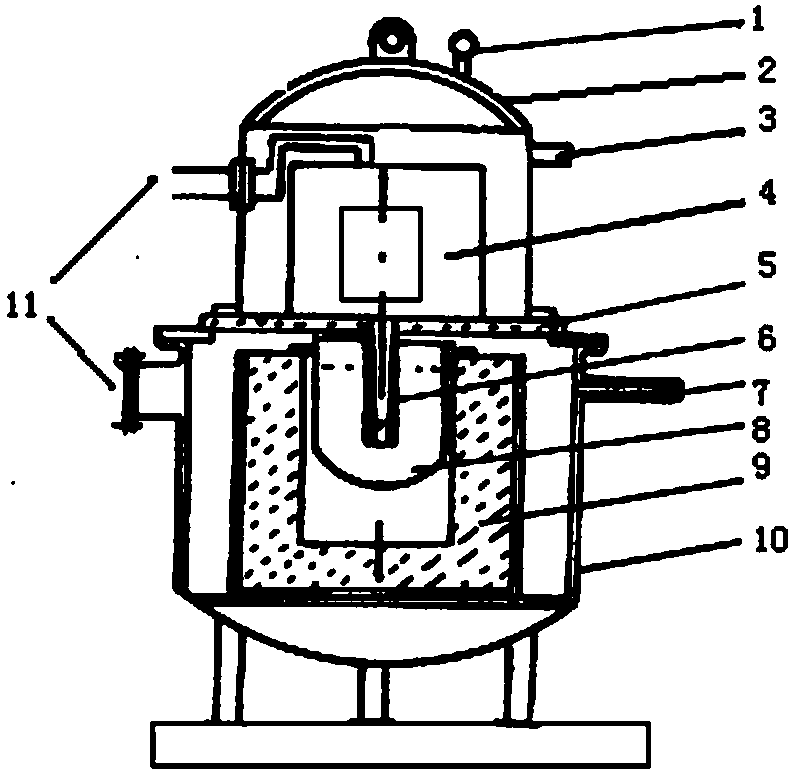

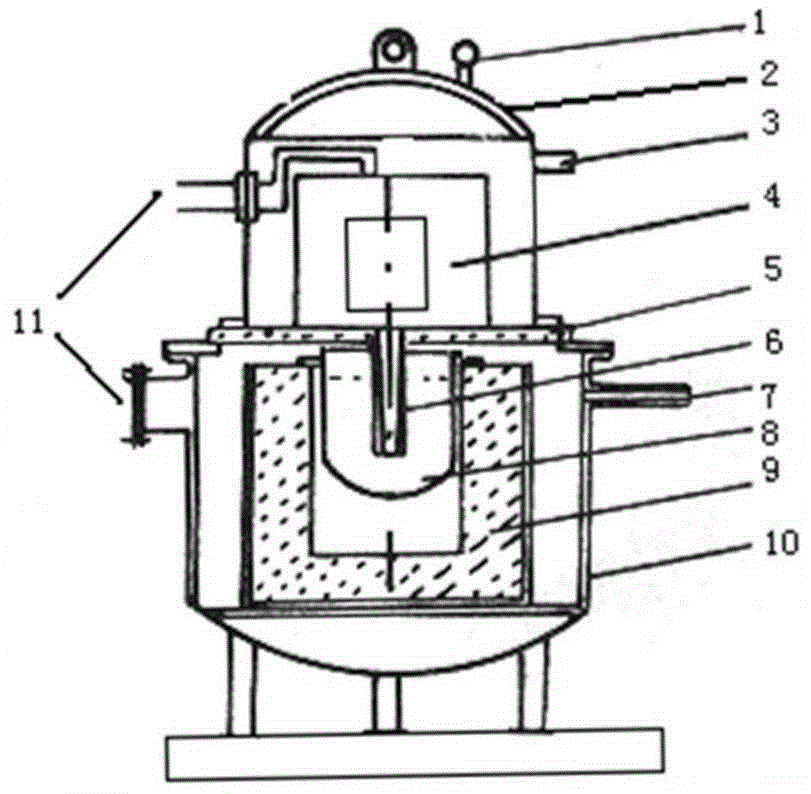

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

Iron pattern sand-lined casting process

InactiveCN104289677AIncrease pouring temperatureHigh surface finishFoundry mouldsFoundry coresSurface finishProcess conditions

The invention discloses an iron pattern sand-lined casting process, belonging to the technical field of casting. According to the technical problem to be solved, the invention provides an iron pattern sand-lined casting process through which the casting dimension is high in precision, the surface smoothness is high and the deformation amount is small. With the adoption of the technical scheme, the pouring temperature of molten iron is 1450 to 1600 DEG C, the pouring time is less than 60 seconds, and the stress deformation of the casting is reduced by other process conditions. The axle housing casting manufactured by adopting the process disclosed by the invention is high in surface smoothness, high in dimensional accuracy and small in deformation amount.

Owner:SHANXI LINFEN INTEGRITY CASTING

Process for casting gearbox body of centrifugal compressor

InactiveCN102909348AControl fireControl slag holeMolten metal pouring equipmentsFoundry mouldsCentrifugal compressorMaterials science

A process for casting a gearbox body of a centrifugal compressor comprises the following steps: 1), preparing a mould box, wherein a gearbox adopts two resin sand box molds, a plurality of U-shaped ceramic pipes are arranged on the parting surface of the lower box, two ends of each U-shaped ceramic pipe are connected with a filter and a horizontal runner, a U-shaped ceramic pipe is arranged at the bottom of the lower box, and two ends of the U-shaped ceramic pipe at the bottom of the lower box are connected to the horizontal runner and a flange at the bottom of the lower box, so as to form an upper stepped inner runner, a middle stepped inner runner and a lower stepped inner runner for feeding iron liquid; 2), carrying out brushing or flow coating, that is, conducting brushing or flow coating on a cavity and a mud core; 3), carrying out mold assembling, wherein residual sand in the cavity and the mud core is cleaned up, the mud core is lowered into the cavity smoothly, a filter disc is placed into a filter, a box sealing strip and glue are placed, positioning pins are placed into positioning holes, and mold assembling is carried out smoothly; and 4), pouring: a casting head is well placed, an air exhaust core is well surrounded by sand, the pouring temperature is controlled to be 1400 to 1350 DEG C, and the pouring time is controlled to be 80 to 90 minutes. According to the invention, the problem that casts produced according to the original process have scrapped gas pores is effectively solved; the production cost is reduced; and the productivity effect is improved.

Owner:上海华新合金有限公司

Process for fabricating template pipe-containing cast part in manner of pre-embedding stainless steel pipeline

ActiveCN104384443AImprove corrosion resistanceExtended service lifeFoundry mouldsFoundry coresPre embeddingSteel pipeline

The invention discloses a process for fabricating a template pipe-containing cast part in a manner of pre-embedding a stainless steel pipeline. The process comprises the following steps: 1) fabricating a wood pattern according to a drawing, and manufacturing a water outlet pipe groove in an inner cavity of the wood pattern; 2) selecting an appropriate sand box according to the wood pattern, and fabricating a sand mold of a lower box with the water pipe groove surface being upwards; 3) selecting an appropriate special upper box after finishing the sand mold of the lower box, fixing the upper box on the lower box, and then assembling an appropriate quantity of tooling bars into a track groove in a sand box; 4) fixing the tooling bars, and then beginning to fabricate a sand mold of the upper box; 5) bending a water pipe; 6) dividing the fabricated sand mold; 7) fixing the tooling bars with a stainless steel pipe, so that the periphery of the stainless steel pipe cannot directly contact the sand mold, and reserving a gap; 8) closing the boxes, and casting; and 9) solidifying and cooling a to-be-cast part, taking out the to-be-cast part, separating the upper box, and transporting the cast part to a cleaning region. According to the process disclosed by the invention, fastening and connection between the water pipe and the sand boxes are ensured, stress deformation of the stainless steel pipe caused by heating is removed, and thus not only is the geometrical tolerance of the water pipe ensured, but also the yield is improved.

Owner:滁州鑫诺实业有限公司

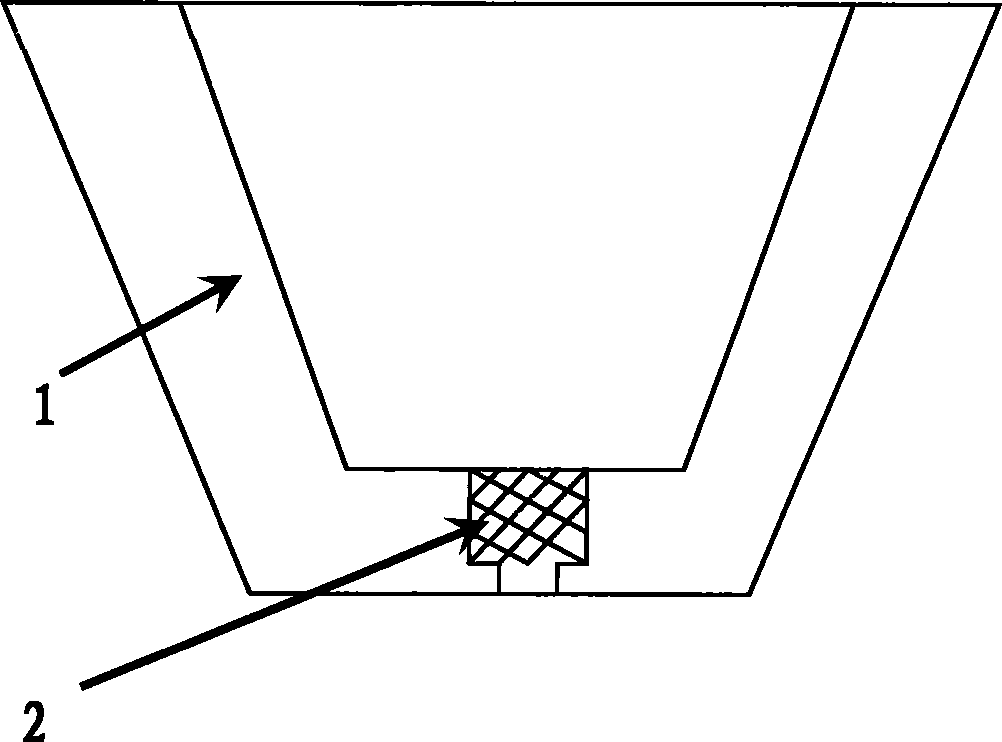

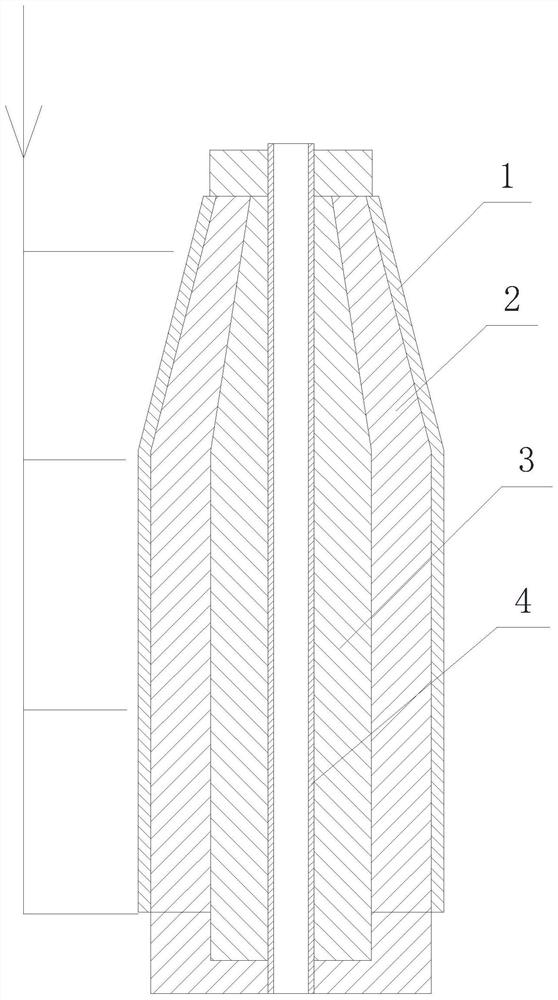

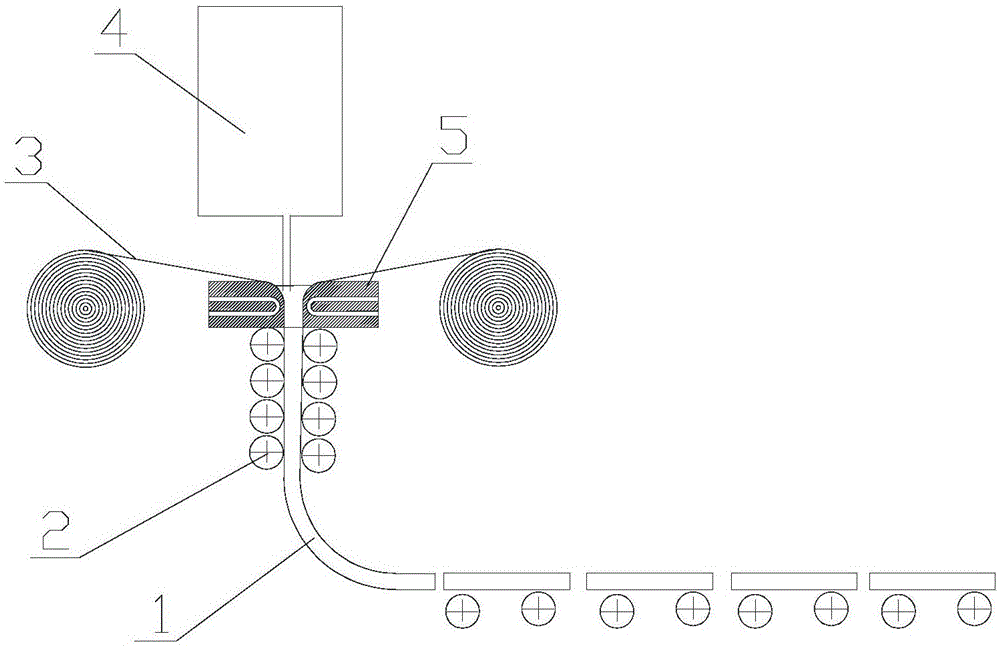

Filter for purifying smelting molten steel

ActiveCN101440432AIncrease pouring temperatureSimple structureLoose filtering material filtersProcess efficiency improvementFiltrationIngot

The invention belongs to the technical field of high-temperature alloy, and in particular relates to a filter for purifying molten steel, which consists of an upper layer of filter screen, a lower layer of filter screen, and a solid ceramic ball layer in the middle of two layers of the filter screens. The filter is pre-placed at a shell-shaped cap opening of an ingot mould or a cast element; when the molten steel flows through the filter, the molten steel flows through a first layer of the filter screen, and large impurities in the molten steel are filtered; then the molten steel enters into a ceramic ball, and small impurities in the molten steel are adsorbed; and finally the molten steel flows through a second layer of the filter screen the aperture of which is flexural and fine, the small impurities in the molten steel are further adsorbed, and the purified molten steel is finally obtained. The filter can solve the problems of low filtration efficiency and difficult reutilization of high-temperature alloy returning materials in the prior filter for purifying and melting the molten steel of the high-temperature alloy, and improves filtration effect greatly compared with the prior filter method; the filtration efficiency can reach more than 70 percent; and according to difference of materials used for the filter screens and the ceramic ball, the filter can be widely applied to producing purified high-temperature alloy and various alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

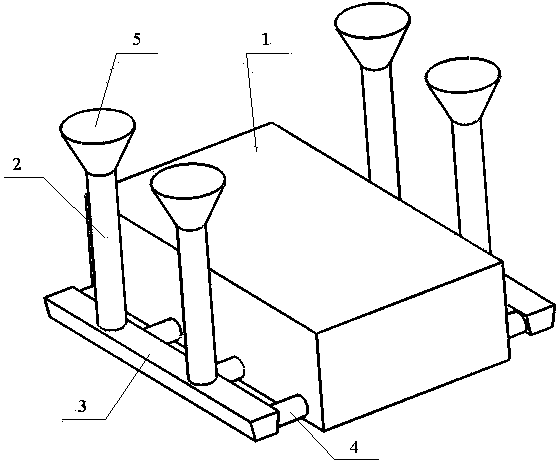

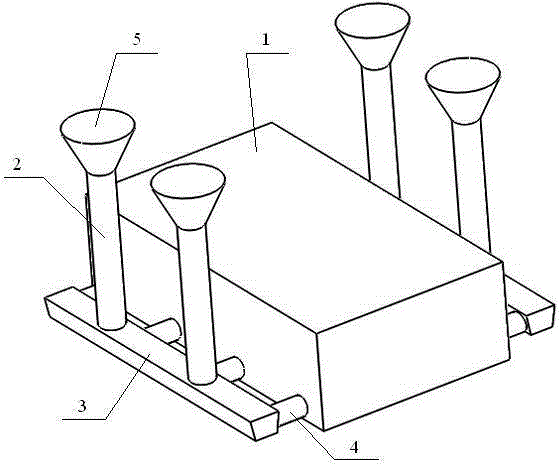

Full-mold casting method of resin sand without dead head

InactiveCN103639361AReduce injection volumeDid not enterFoundry mouldsFoundry coresFlue gasPollution

The invention discloses a full-mold casting method of resin sand without a dead head. The full-mold casting method comprises the steps of manufacturing a pattern and a casting system, molding, smelting casting, forming and cleaning, wherein working allowance is preset on the upper surface of the manufactured pattern, and no dead head is arranged in the molding step; the casting system comprises a plurality of sprues with funnel-shaped pouring cups at the top ends, the volume of the pouring cup is more than that of the sprue, the bottom of the sprue is communicated with a cross gate, the lower end surface of the cross gate is leveled with the bottom surface of the pattern or is slightly higher than the bottom surface of the pattern, the length of the cross gate is 95% of the length of the pattern, and a plurality of ingates communicated with the pattern are arranged on the cross gate at intervals; and molten metal is poured by the plurality of pouring cups simultaneously during casting, and the speed of filling the molten liquid into each pouring cup can ensure the molten liquid in the pouring cup to close the sprues. According to the full-mold casting method, no dead head is arranged, no flue gas and no pollution are caused during production, the production steps are simplified and the cost is reduced.

Owner:BOTOU DONGJIAN CASTING

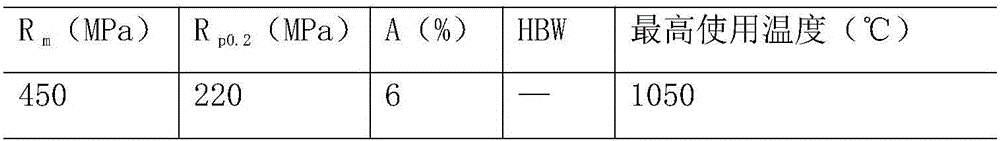

Heat treatment method of large heat-resistant high alloy steel castings

The invention relates to a heat treatment method of large heat-resistant high alloy steel castings in the technical field of steel casting heat treatment. The heat treatment method of the large heat-resistant high alloy steel castings includes the process of high-temperature diffusion annealing, gating and risering system cutting, normalizing air cooling, primary tempering and secondary tempering,and it is set that carbon arc air gouging dressing is performed on the surfaces of the castings between the primary tempering and the secondary tempering. The method solves the problem that the largeheat-resistant high alloy steel castings with a ZG12Cr9Mo1CoNiVNbNB material are prone to cracking in the heat treatment process, and makes various normal temperature and high temperature mechanicalproperties of the steel castings meet the using requirement.

Owner:RUGAO OUTONG MACHINERY FITTINGS

Casting infiltration coating used for ferrous matric composite, preparation method and method for preparing casting infiltration coat by means of casting infiltration coating

The invention discloses casting infiltration coating used for a ferrous matrix composite, a preparation method, and a method for preparing a casting infiltration coat by means of the casting infiltration coating. The casting infiltration coating comprises the following components including 1.8-2.2% of rosin resin, 0.9-1.1% of phenolic resin, 0.4-0.6% of polyvinyl butyral, 1.0-1.5% of organobentonite, 4.0-6.0% of solvent naphtha, 11-13% of silicon carbide, 8-12% of ferrochromium powder and the balance absolute ethyl alcohol. The casting infiltration coating used for the ferrous matrix compositehas the advantages of good suspension property, high strength and good breathability and levelling property, and meanwhile, coating is moderate in viscosity and good in brushability. According to detecting results, the viscosity change rate based on change of the rotating speed is above 0.057, the 2h suspension property is above 99.9%, the 24h suspension property reaches above 87.6%, the shakeoutflushing amount is above 0.14, the breathability can reach above 2.0, and the levelling property reaches above 510 mm.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

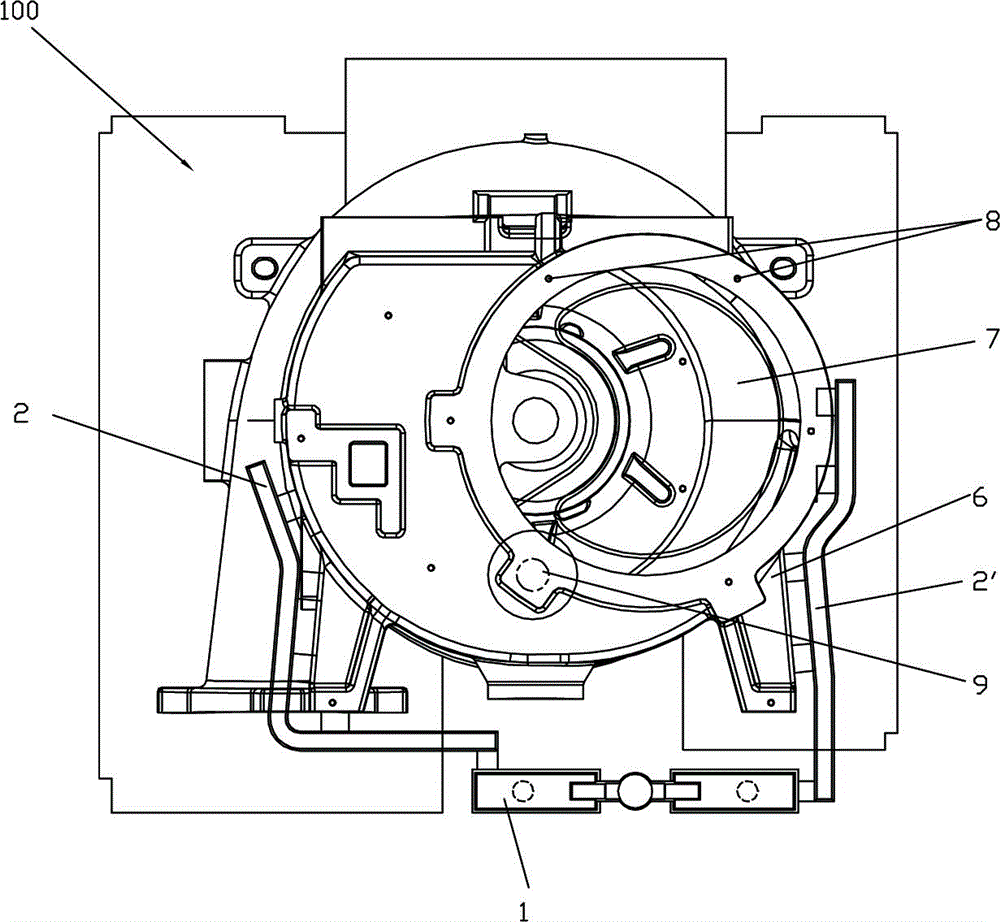

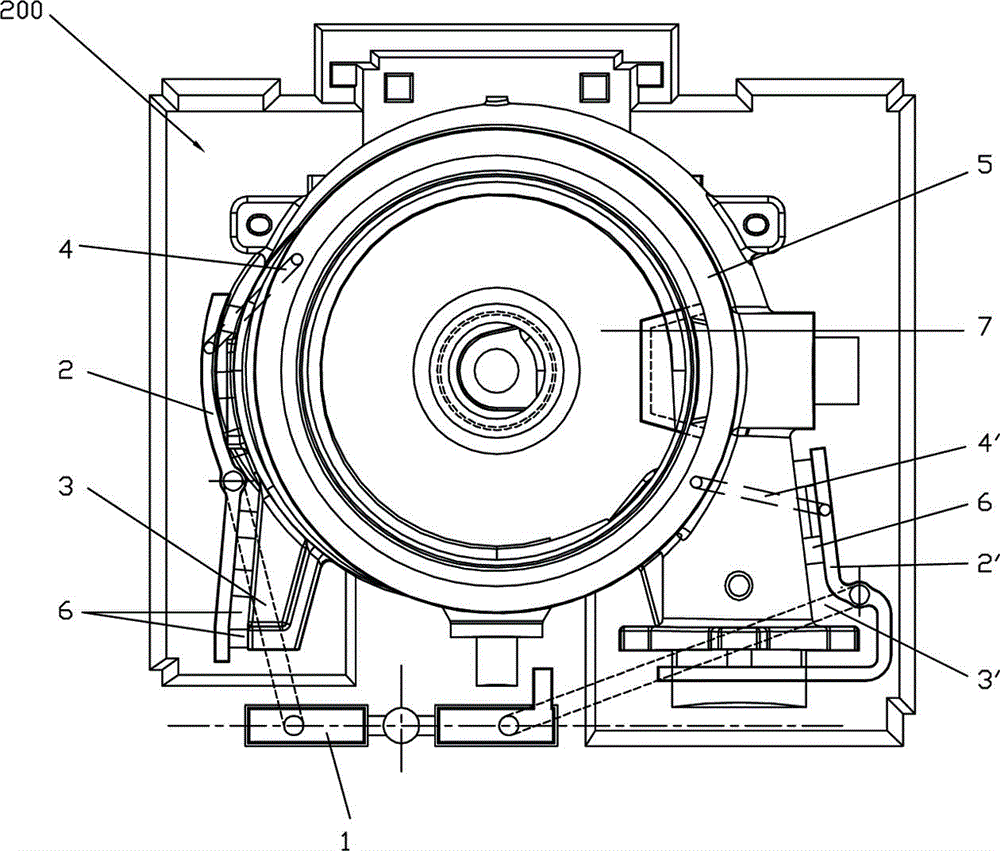

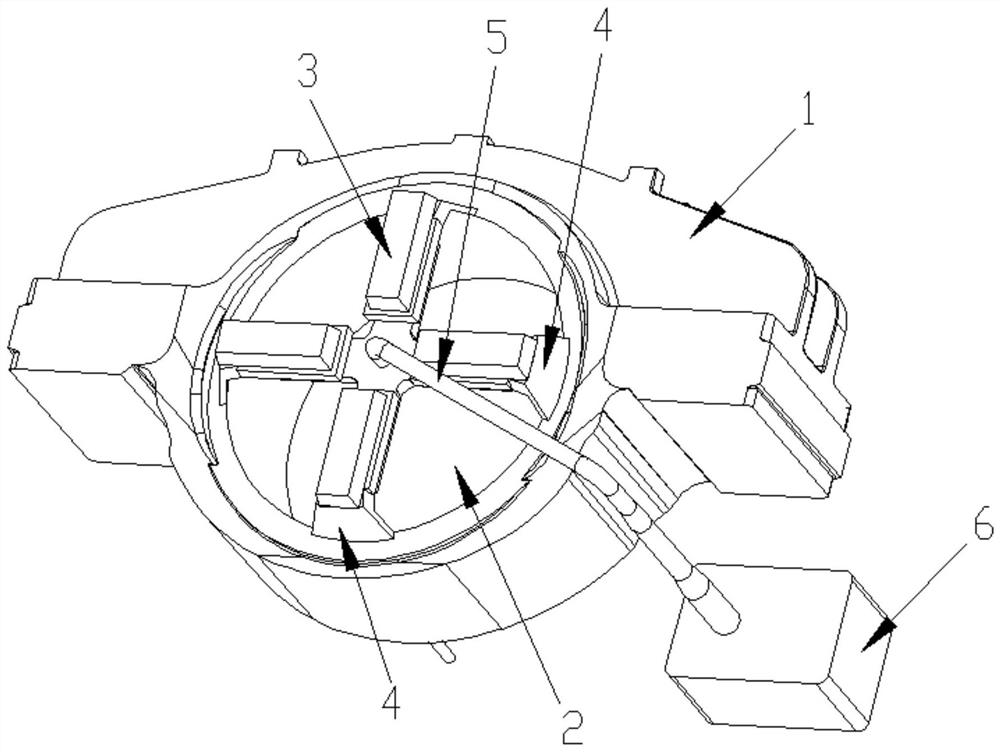

A thin-wall heat-resistant steel exhaust manifold casting method

The invention discloses a thin-walled heat resistant steel exhaust gas manifold casting method, and belongs to the technical field of heat resistant steel exhaust gas manifold casting. The casting method comprises the following steps of core manufacturing, modeling, smelting, pouring and sand shakeout. Through the reasonable design of the amount of molten iron entering a pouring channel and the section ratio of each unit in a pouring system and strict control of the iron mold sand covering layer thickness, the mold cavity exhaust gas system and pouring temperature and the sand shankout box opening time, the thickness of the prepared exhaust gas manifold is 3.2-3.6mm, the wall is thin, the grain size level is 5.5, and the technical property reaches the required index. The prepared exhaust gas manifold has the thin wall and low weight, is stable in property, solves the problem that a common wet sand technology is difficult to form, effectively lowers the integral weight, and achieves light-weight design of an engine.

Owner:西峡飞龙特种铸造有限公司 +1

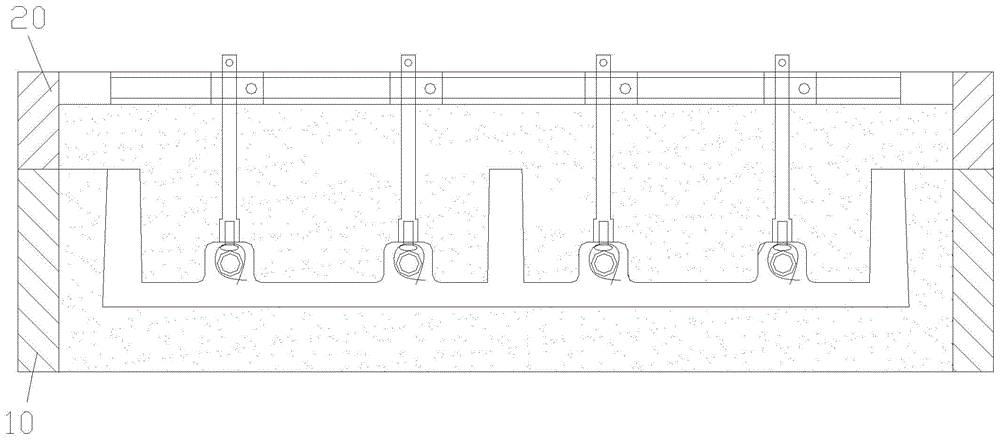

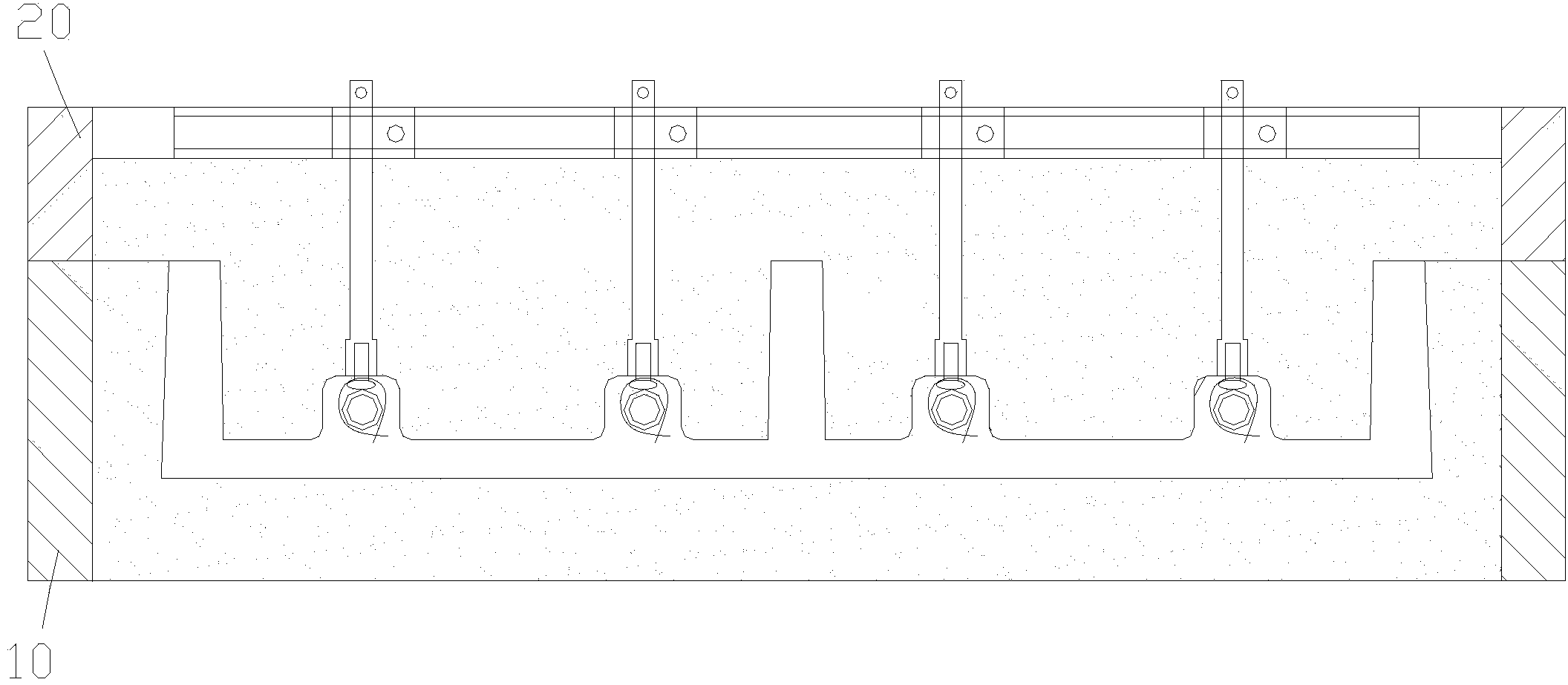

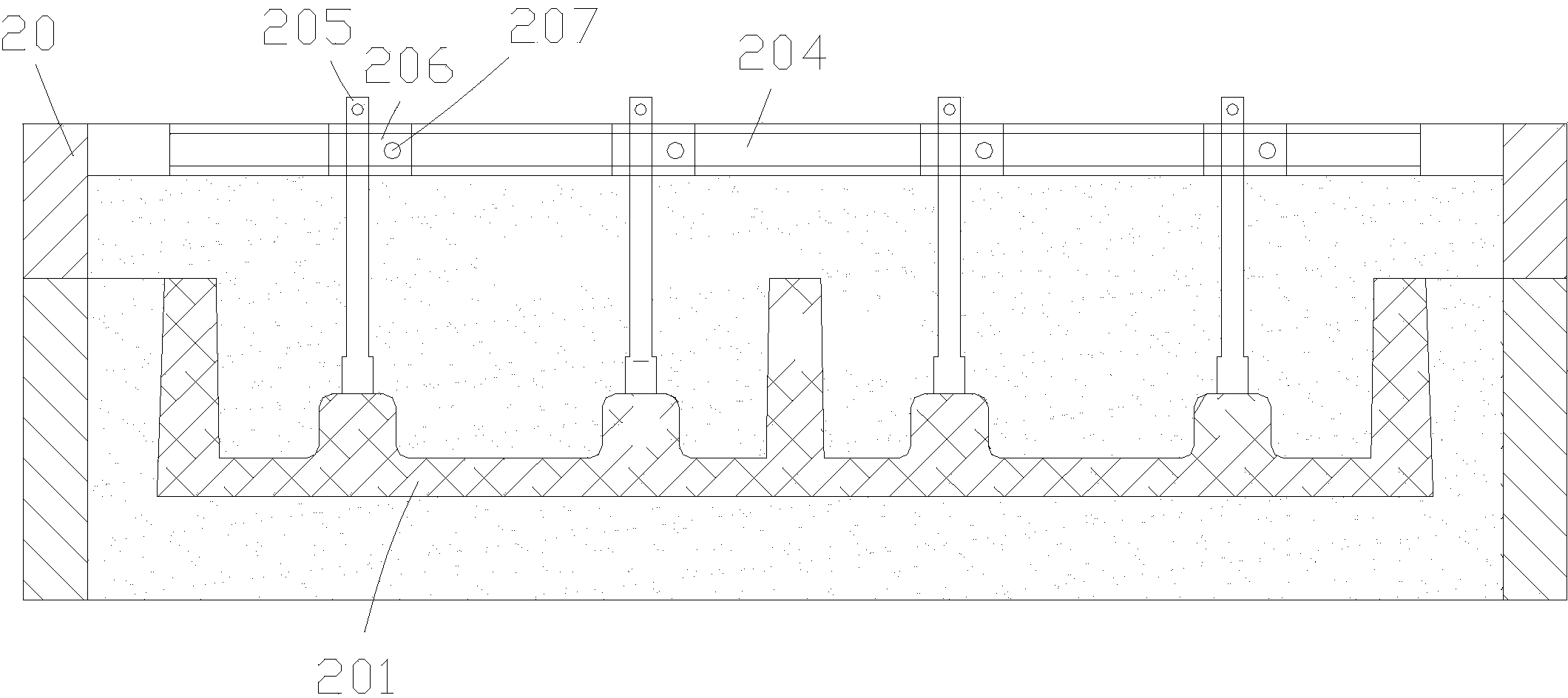

Template type pipe casting-containing stainless steel water pipe fixing structure

ActiveCN104399942AEliminate the process of milling groove buried pipeShorten the timeMoulding flasksEngineeringScrew thread

The invention discloses a template type pipe casting-containing stainless steel water pipe fixing structure. The structure comprises a sand mold upper box, wherein a rail is arranged at the upper end of the sand mold upper box; slide blocks are arranged in the rail at intervals; a through hole is formed in the middle of each slide block; a connecting rod is connected into each through hole; one end of each connecting rod is connected in the through hole in the corresponding slide block through screw threads and extends into the upper part of the corresponding through hole; the lower end of each connecting rod is positioned at the bottom of the sand mold upper box; a screw hole is formed in the lower end of each connecting rod; a fixing screw with the diameter of 1mm binding wire penetrates through each screw hole; a clearance with the diameter of 3 to 5mm is formed between the end part of each fixing screw and the bottom end of the corresponding connecting rod; the fixing screw is used for connecting a stainless steel water pipe; a binding wire on each fixing screw is used for fixing the stainless steel water pipe; the fixed stainless steel water pipe is in a suspension state; the surrounding of the stainless steel water pipe is not in direction contact with the sand mold upper box and a clearance is reserved, otherwise, the cast steel pipe is exposed on the surface of a casting.

Owner:CHUZHOU JINNUO INDAL

Casting tin bronze water-based environmental protection coating for lost foam

The invention relates to the technical field of lost foam casting tin bronze coatings, and discloses a casting tin bronze water-based environmental protection coating for lost foam. The environmentalprotection coating contains a fire-resistant substrate, based on the fire-resistant substrate, relative to 100 parts by mass of the fire-resistant substrate, the environmental protection coating is further prepared from the components in parts by mass: 4-6 parts of sodium bentonite, 0.2-0.4 part of CMC, 6-9 parts of silica sol, 0.4-0.6 part of PAM, and 0.15-0.3 part of xanthan gum, wherein carrierliquid is water; and the fire-resistant substrate is prepared from the components in percentage by mass: 10-20% of mica, 20-30% of diatomite powder and 50-70% of pearlite powder. According to the casting tin bronze water-based environmental protection coating, in the lost foam casting application of tin bronze parts, obtained castings have no holes, and cracks and marks can be avoided.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Centrifugal casting process for large heat-resistant steel furnace bottom roller body

The invention discloses a casting process for a large heat-resistant steel furnace bottom roller. The centrifugal casting process is adopted, and the interval between two supporting wheels at the rear end of a rolling wheel centrifugal machine adopted by centrifugal casting is set to be 1366 mm. The centrifugal casting process has the following advantages that (1) when the length of a casting exceeds the capability scope of the centrifugal machine, equipment can be modified and a short shaft system of the centrifugal machine is replaced by a long shaft system so as to meet the operation requirement of a casting mold under the condition that the motor power, the centrifugal rotating speed, the machine body strength and the wheel interval of the equipment can bear the long shaft system; and (2) vibration of the casting mold is reduced as much as possible, a water cooling measure is not adopted for the casting mold so as to avoid large temperature jump during solidification of the casting, a coating layer is thin and even so as to avoid and impede contraction of the casting, and therefore the cracking defect can be better prevented.

Owner:黄力

Method for preparing hard xylitol candy

InactiveCN108208285AReduce the temperatureReduce energy consumptionFood thermal treatmentConfectionerySugarEnergy consumption

The invention discloses a method for preparing hard xylitol candy. The method comprises the following steps: weighing 90% of a formula amount of xylitol, heating the weighed xylitol to 100 DEG C in order to melt the xylitol, and performing heat insulation at 93-95 DEG C; adding other raw materials and auxiliary materials to the obtained sugar solution in a heat insulation state, and performing heat insulation; stirring all above materials, adding the remaining 10% of the formula amount of xylitol, and performing uniform stirring; allowing the obtained sugar solution to automatically flow intoa casting trough through a 92-96 DEG C interlayer heat insulation pipeline; and cooling, demolding and packaging the sugar solution. The method solves a problem that the hard xylitol candy cannot be continuously produced for a long term. The casting temperature is increased, so the crystallizing and demolding time is prolonged, the obtained product has fine particles, a uniform size and a beautiful appearance, the yield is large, and the energy consumption is low.

Owner:李圣仓

Casting method for engine exhaust for petroleum drilling

The invention discloses a casting method for an engine exhaust for petroleum drilling. The casting method comprises the following steps that during casting, high-strength low-air generation film coated sand is adopted, the air generation amount is controlled to be lower than 12 ml / g, the normal temperature extension strength is 2.2 MPa or above, the core surface is coated with alcohol based coating, and air outlet holes are punched in all exposed core heads; the cross section of a pouring gate is increased, a sprue is increased from phi 30 cm to phi 40 cm, the cross section of a cross gate isincreased from 3.2 cm<2> to 4 cm<2>, the cross section of an ingate is 4 cm<2>, the height of the sprue is increased to 50 cm, and pressing heads are heightened; and the casting temperature is improved from 1380 DEG C to 1450 DEG C, and generated gas can be conveniently overflowed out of pieces. According to the casting method, the aim of quick mold filling is achieved, relatively high pressure isbuilt in molds, gas generated by sand cores in the early period and entering iron liquid and can float out of the pieces, the above measures are effectively and stably controlled, and high finished product rate of series castings can be obtained possibly.

Owner:QINGDAO HONGXINTIAN MACHINERY CO LTD

A plaster mold casting method for large complex thin-walled magnesium alloy parts

ActiveCN104209497BSolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresPlaster mold castingMold filling

The invention relates to a gypsum mold casting method for large complex thin-walled magnesium alloy parts. The surface of the assembled pattern is coated with in-situ paint, and an amorphous cold iron is arranged at the hot joint. It is 1.25% phenol resin, 0.4% toluenesulfonic acid, 1-1.5% boric acid, 2% bentonite, and the balance is chromite sand of 70-140 mesh. The casting is poured in the pressure regulating casting device, and the gypsum made by pouring the pattern The mold is placed at the pouring position of the pressure regulating casting machine, and the dry air or CO2 atmosphere containing 0.1%-1.0%SF6 is filled in the tank, and vacuum pouring and pressurized solidification are carried out. The pouring temperature is 710°C-750°C, and the initial filling mold The vacuum degree is -0.6~-0.8Mpa, and the solidification pressure is 0.020-0.025Mpa. By adopting the method of the invention, oxidation can be prevented, mold filling ability can be improved, shrinkage cavity and porosity inside the casting can be reduced, and magnesium alloy casting with higher density can be obtained.

Owner:山西银光华盛镁业股份有限公司

Manufacturing method of breaking hammerhead and breaking hammerhead

ActiveCN106363154AHigh external hardnessImprove toughnessFurnace typesGrain treatmentsAlloyTitanium carbide

The invention discloses a manufacturing method of a breaking hammerhead and the breaking hammerhead. The manufacturing method of the breaking hammerhead comprises the following steps that a, hydroxy iron powder, titanium carbide powder and graphite powder are mixed, compression molding is conducted after absolute ethyl alcohol is added to serve as a molding agent, and a long strip-shaped panel blank is made, wherein the mass of the titanium carbide powder accounts for 20%-40% of the total mass of the raw materials; b, the obtained long strip-shaped panel blank is sintered in a vacuum furnace, so that a titanium carbide steel-bonded hard alloy panel is obtained; c, molten carbon steel obtained after smelting is poured into the hammerhead by using green sand for hammerhead molding, and the titanium carbide steel-bonded hard alloy panel obtained in the prior step is inlaid in the end of the hammerhead in a cast mode; d, falling sand and a casting head are removed; and e, the hammerhead is quenched in a muffle furnace and then taken out, and water quenching is conducted on the hammerhead. The internal tenacity of the hammerhead is good, and the external hardness of the hammerhead is high; and the hammerhead is not prone to brittle fracture in use, base metal and the panel are bonded precisely, the bonding strength is improved, the surface hardness of the hammerhead is improved, and accordingly the abrasion resistance of the hammerhead is improved.

Owner:PANZHIHUA UNIV

A preparation method of cast-infiltration coating and preparation method of cast-infiltration coating

ActiveCN110090917BPromote meltingPromote decompositionFoundry mouldsFoundry coresPolyvinyl alcoholFerrochrome

The invention discloses casting infiltration coating used for a ferrous matrix composite, a preparation method, and a method for preparing a casting infiltration coat by means of the casting infiltration coating. The casting infiltration coating comprises the following components including 1.8-2.2% of rosin resin, 0.9-1.1% of phenolic resin, 0.4-0.6% of polyvinyl butyral, 1.0-1.5% of organobentonite, 4.0-6.0% of solvent naphtha, 11-13% of silicon carbide, 8-12% of ferrochromium powder and the balance absolute ethyl alcohol. The casting infiltration coating used for the ferrous matrix compositehas the advantages of good suspension property, high strength and good breathability and levelling property, and meanwhile, coating is moderate in viscosity and good in brushability. According to detecting results, the viscosity change rate based on change of the rotating speed is above 0.057, the 2h suspension property is above 99.9%, the 24h suspension property reaches above 87.6%, the shakeoutflushing amount is above 0.14, the breathability can reach above 2.0, and the levelling property reaches above 510 mm.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for eliminating cracks of thin-walled cylinder casting

PendingCN112496266AReduce shrinkage barriersCrack phenomenon eradicationFoundry mouldsFoundry coresCrazingThin walled

The invention provides a method for eliminating cracks of a thin-walled cylinder casting. The method comprises the following steps that S1, a sand core is put into a sand mold, and a cavity for casting the thin-walled cylinder casting is formed between the outer wall of the sand core and the inner wall of the sand mold; and S2, molten iron is injected into the cavity, the pouring temperature is higher than 1360 DEG C, the surface layer of the sand core is burnt to be crisp after the cavity is filled with the molten iron, a surface sand layer resin framework is damaged, and shrinkage of the sand core during casting solidification is not hindered. According to the method for eliminating the cracks of the thin-walled cylinder casting, cracking during cooling solidification is avoided, the pouring yield is greatly increased, resource waste is avoided, the production cost is reduced, and the production benefits are increased.

Owner:宁波茸发新材料科技有限公司

Type plate with pipe casting stainless steel water pipe fixed structure

ActiveCN104399942BEliminate the process of milling groove buried pipeShorten the timeMoulding flasksScrew threadWater pipe

The invention discloses a template type pipe casting-containing stainless steel water pipe fixing structure. The structure comprises a sand mold upper box, wherein a rail is arranged at the upper end of the sand mold upper box; slide blocks are arranged in the rail at intervals; a through hole is formed in the middle of each slide block; a connecting rod is connected into each through hole; one end of each connecting rod is connected in the through hole in the corresponding slide block through screw threads and extends into the upper part of the corresponding through hole; the lower end of each connecting rod is positioned at the bottom of the sand mold upper box; a screw hole is formed in the lower end of each connecting rod; a fixing screw with the diameter of 1mm binding wire penetrates through each screw hole; a clearance with the diameter of 3 to 5mm is formed between the end part of each fixing screw and the bottom end of the corresponding connecting rod; the fixing screw is used for connecting a stainless steel water pipe; a binding wire on each fixing screw is used for fixing the stainless steel water pipe; the fixed stainless steel water pipe is in a suspension state; the surrounding of the stainless steel water pipe is not in direction contact with the sand mold upper box and a clearance is reserved, otherwise, the cast steel pipe is exposed on the surface of a casting.

Owner:CHUZHOU JINNUO INDAL

Novel compound crystal sand powder shell-making material and production technology thereof

InactiveCN108356210ASuitable for high temperature pouringIncrease pouring temperatureFoundry mouldsFoundry coresSuperalloyTitanium alloy

The invention discloses a novel compound crystal sand powder shell-making material and a production technology thereof. The shell-making material comprises no less than 80% of Al2O3, no more than 18%of SiO2, no more than 0.06% of Fe2O3 and no more than 0.1% of preparation agents, and is applicable for all metal castings and alloy castings thereof, such as high manganese steel, low carbon stainless steel, high temperature alloy steel and titanium alloy, with the casting temperature of 1750 DEG C or below; the casting temperature can be increased effectively, and easy treatment and placement ofmaterials used in a factory are ensured; and the relative mechanical strength of the castings can be improved, and the production cost is reduced obviously.

Owner:ANHUI HUSN KEWAN SPECIAL CASTING

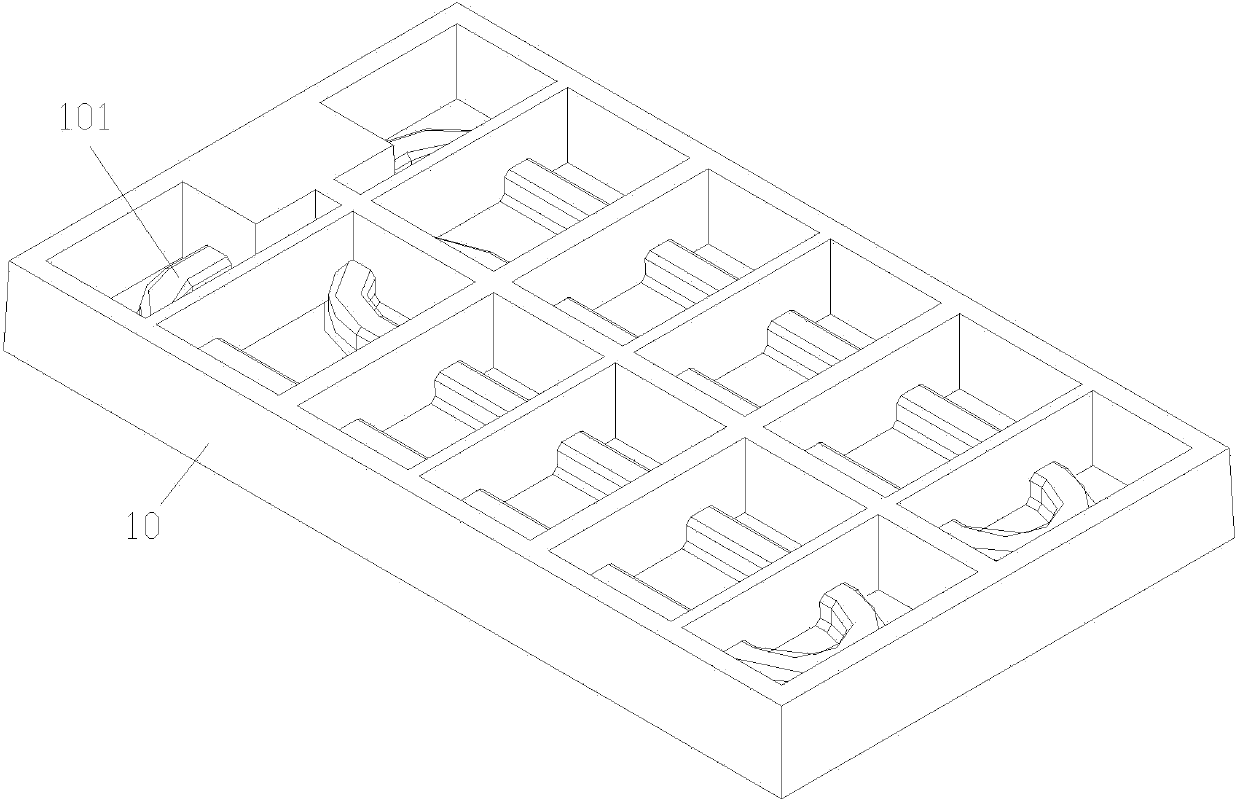

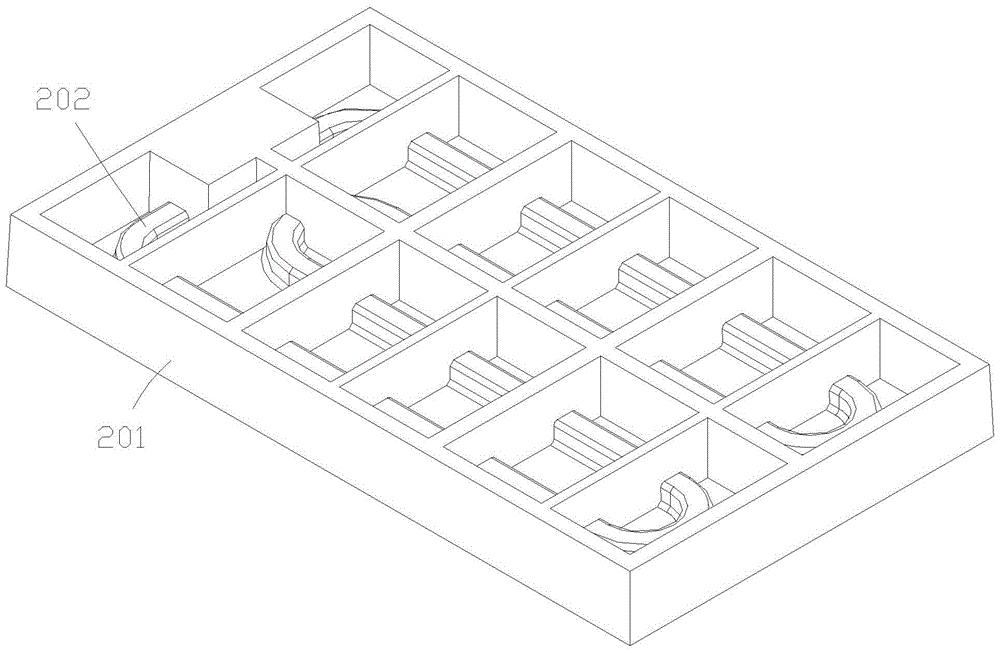

Special sand box for type plate castings with pipes

ActiveCN104368770BEliminate the process of milling groove buried pipeShorten the timeMoulding flasksSS - Stainless steelScrew thread

The invention provides a special sand box for plate type tube-containing castings. The special sand box comprises a lower box and an upper box matched with the lower box, wherein the upper box is fixed on the top of the lower box; a wooden mold is arranged in the upper box; a water tube seat is arranged in the inner cavity of the wooden model; a stainless steel tube is arranged in the water tube seat; a rail groove is formed in the upper part of the upper box; a tool rod is connected to the wooden mold and located directly above the water tube seat; the head of the fixture rod is fixed directly above the water tube seat and contacts with the water tube seat; a slider is arranged on the rail groove; the tail of the tool rod is in threaded connection with the slider; a threaded hole is formed in the slider; the slider is fixed on the rail groove of the sand box by use of a fixing screw via the threaded hole; a fixing screw with a tying wire with the diameter of 1mm penetrates through the head of the tool rod, a gap of 3-5mm is reserved between the end portion of the fixing screw and the head of the tool rod, and after the bent stainless steel tube is placed in position, the stainless steel tube is fixed by use of the tying wire on the fixing screw. The special sand box for plate type tube-containing castings is capable of achieving the purpose of replacing a red copper tube with the stainless steel tube; as the price of the stainless steel tube is about 1 / 3 of that of the red copper tube, the cost is saved.

Owner:CHUZHOU JINNUO INDAL

A kind of riserless resin sand solid mold casting method

InactiveCN103639361BReduce injection volumeDid not enterFoundry mouldsFoundry coresFlue gasPollution

Owner:BOTOU DONGJIAN CASTING

Casting process of bearing seat

ActiveCN109136732BImprove surface propertiesReduce formationFoundry mouldsFoundry coresWind powerBloomery

The invention discloses a bearing block casting process. The bearing block casting process. The bearing block casting process includes: heating to melt smelting furnace charge in an electric furnace,and discharging when the temperature reaches 145 DEG C, wherein the smelting furnace charge comprises, by weight percentage, 30-45% of pig iron, 35-55% of waste steel, 5-20% of foundry returns and 1%of carburant; during molten iron discharge, washing antimony into a casting ladle along with flow, and injecting into balling ladle; after the molten iron is injected into the balling ladle from a ladle mouth, refining the molten iron in the first pit of the balling ladle, and subjecting the molten iron to balling inoculation in the second pit and the third pit of the balling ladle after the molten iron overflows the dam of the balling ladle, wherein the balling agent is Elkem5813, the balling agent is covered with an Elkem inoculant, the inoculant is covered with a covering agent, and the balling temperature is 1440-1460 DEG C; when the temperature of the molten iron reaches 1350-1370 DEG C, using a high-temperature slow pouring process coordinated with a fash pouring method to pour a wind power cast in a resin sand mould. The bearing block casting process has the advantages that pouring temperature is increased, pouring speed is lowered, slagging is benefited, and cast surface performance is increased.

Owner:惠尔信机械(泰兴)有限公司

Method for reducing hot rolling burning loss of high-silicon electric steel

The invention provides a method for reducing hot rolling burning loss of high-silicon electric steel. For a high-silicon electric steel casting blank with Si content of 1.5-3.5 wt%, four electric steel thin strips are respectively arranged between a casting roll and molten steel and between two narrow surfaces, and the molten steel flows space among the electric steel thin strips via a long nozzle from a tundish and is solidified to form a casting blank; the inside of the casting roll is fed with water and is cooled; and water-cooled jackets with water-cooling parts are arranged on outer sides of the four electric steel thin strips, the continuous casting speed is 0.5-3 m / min, the degree of superheat is 5-30 DEG C, and the molten steel is isolated from air by a protective atmosphere. A continuous casting machine does not have a crystallizer, so that costs for equipment and spare parts can be reduced, casting powder is saved, pollution of the casting powder to steel is reduced, degree of purity of the steel is improved, adhesion between the molten steel and the casting roll can be prevented, and the surface quality of the casting blank is improved. The electric steel thin strips adhered to the surface of the casting blank does not affect ingredients of a steel blank matrix, furthermore, oxidation of the casting blank in a followed-up heating process can be greatly reduced, hot rolling burning loss and surface defects are reduced, and yield of rolling is improved.

Owner:ANGANG STEEL CO LTD

Thin-walled heat resistant steel exhaust gas manifold casting method

ActiveCN108515149AImprove performanceLight weightFoundry mouldsFoundry coresLayer thicknessThin walled

The invention discloses a thin-walled heat resistant steel exhaust gas manifold casting method, and belongs to the technical field of heat resistant steel exhaust gas manifold casting. The casting method comprises the following steps of core manufacturing, modeling, smelting, pouring and sand shakeout. Through the reasonable design of the amount of molten iron entering a pouring channel and the section ratio of each unit in a pouring system and strict control of the iron mold sand covering layer thickness, the mold cavity exhaust gas system and pouring temperature and the sand shankout box opening time, the thickness of the prepared exhaust gas manifold is 3.2-3.6mm, the wall is thin, the grain size level is 5.5, and the technical property reaches the required index. The prepared exhaust gas manifold has the thin wall and low weight, is stable in property, solves the problem that a common wet sand technology is difficult to form, effectively lowers the integral weight, and achieves light-weight design of an engine.

Owner:西峡飞龙特种铸造有限公司 +1

Special sand box for plate type tube-containing castings

ActiveCN104368770AImprove corrosion resistanceExtended service lifeMoulding flasksEngineeringWater pipe

The invention provides a special sand box for plate type tube-containing castings. The special sand box comprises a lower box and an upper box matched with the lower box, wherein the upper box is fixed on the top of the lower box; a wooden mold is arranged in the upper box; a water tube seat is arranged in the inner cavity of the wooden model; a stainless steel tube is arranged in the water tube seat; a rail groove is formed in the upper part of the upper box; a tool rod is connected to the wooden mold and located directly above the water tube seat; the head of the fixture rod is fixed directly above the water tube seat and contacts with the water tube seat; a slider is arranged on the rail groove; the tail of the tool rod is in threaded connection with the slider; a threaded hole is formed in the slider; the slider is fixed on the rail groove of the sand box by use of a fixing screw via the threaded hole; a fixing screw with a tying wire with the diameter of 1mm penetrates through the head of the tool rod, a gap of 3-5mm is reserved between the end portion of the fixing screw and the head of the tool rod, and after the bent stainless steel tube is placed in position, the stainless steel tube is fixed by use of the tying wire on the fixing screw. The special sand box for plate type tube-containing castings is capable of achieving the purpose of replacing a red copper tube with the stainless steel tube; as the price of the stainless steel tube is about 1 / 3 of that of the red copper tube, the cost is saved.

Owner:CHUZHOU JINNUO INDAL

A preparation method of a crushing hammer and the crushing hammer

ActiveCN106363154BHigh external hardnessImprove toughnessFurnace typesGrain treatmentsAlloyTitanium carbide

The invention discloses a manufacturing method of a breaking hammerhead and the breaking hammerhead. The manufacturing method of the breaking hammerhead comprises the following steps that a, hydroxy iron powder, titanium carbide powder and graphite powder are mixed, compression molding is conducted after absolute ethyl alcohol is added to serve as a molding agent, and a long strip-shaped panel blank is made, wherein the mass of the titanium carbide powder accounts for 20%-40% of the total mass of the raw materials; b, the obtained long strip-shaped panel blank is sintered in a vacuum furnace, so that a titanium carbide steel-bonded hard alloy panel is obtained; c, molten carbon steel obtained after smelting is poured into the hammerhead by using green sand for hammerhead molding, and the titanium carbide steel-bonded hard alloy panel obtained in the prior step is inlaid in the end of the hammerhead in a cast mode; d, falling sand and a casting head are removed; and e, the hammerhead is quenched in a muffle furnace and then taken out, and water quenching is conducted on the hammerhead. The internal tenacity of the hammerhead is good, and the external hardness of the hammerhead is high; and the hammerhead is not prone to brittle fracture in use, base metal and the panel are bonded precisely, the bonding strength is improved, the surface hardness of the hammerhead is improved, and accordingly the abrasion resistance of the hammerhead is improved.

Owner:PANZHIHUA UNIV

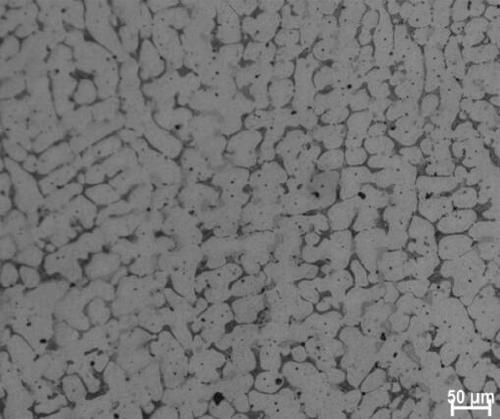

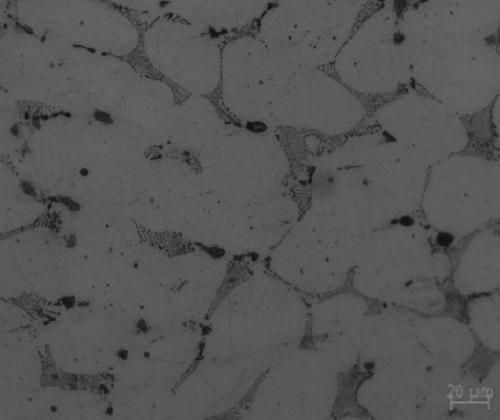

A kind of ultra-high temperature soft core forging method of steel ingot

ActiveCN105268884BQuality improvementImprove uniformityMetal-working apparatusRefrigerator carSemisolid microstructure

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Duplex stainless steel and cast article thereof

InactiveUS20080175742A1Satisfactory resistanceSatisfactory strengthRotary propellersArea ratioMaterials science

A generally Mo-free, ferrite-austenite duplex stainless steel has a ferrite phase area ratio of about 20 to about 60% and a composition containing, in mass %, not more than about 0.08% of C, about 0.5 to about 1.5% of Si, not more than about 1.0% of Mn, about 4.0 to about 8.0% of Ni, about 23 to about 27% of Cr, about 2.0 to about 6.0% of Cu, about 0.05 to about 0.3% of N, and the balance being Fe and generally unavoidable impurities.

Owner:YAMAHA MOTOR CO LTD

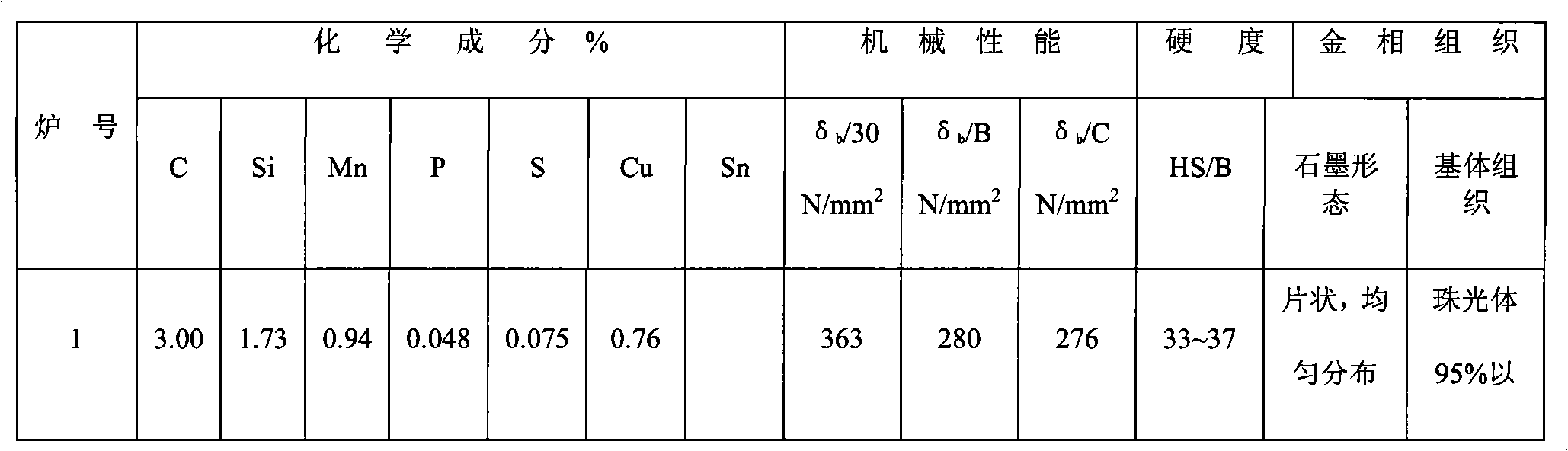

Casting method of thick and large castings

The invention discloses a casting method of thick and large castings. Coke is used as fuel; metal furnace materials are smelted into smelted steel in a cupola furnace; tapped smelted steel, nucleating agent and electrolytic copper are flushed into a casting ladle; the fixed carbon content in the coke is above 87%, thereby the tapping temperature of the smelted steel in the copula furnace can be ensured to be above 1500 DEG C so as to obtain purified smelted steel; the nucleating agent contains 0.2%-0.5% of silicon-barium nucleating agent, 0.2%-0.4% of 75% ferro-silicon and 0.1%-10% of molybdenum-containing nucleating agent based on the weight of the tapped smelted steel; the silicon-barium nucleating agent and the 75% ferro-silicon have the action of increasing the crystallizing core of the graphite in the smelted steel; the graphite in the smelted steel is fine and is distributed uniformly so that the internal and external performances of thick and large castings are consistent; the electrolytic copper and the molybdenum-containing nucleating agent are added to the smelted steel to promote the generation of pearlite matrix organisms and thin the pearlite matrix organisms so that the strength and hardness of the nucleated cast iron are increased, and the internal and external performance tendencies are consistent.

Owner:太仓林飞铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com