Method for reducing hot rolling burning loss of high-silicon electric steel

A high-silicon electrical steel and electrical steel technology, applied in the field of continuous casting process equipment, can solve the problems of many surface defects of hot-rolled plates, affecting normal production, and large rolling temperature drop, so as to improve surface quality and reduce burning loss and surface defects, and the effect of improving the rolling yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The chemical composition wt% of electrical steel is: C0.002%, Si2.20%, Mn0.32%, P0.021%, S0.005%, Als0.20%, the remainder is iron and unavoidable impurities.

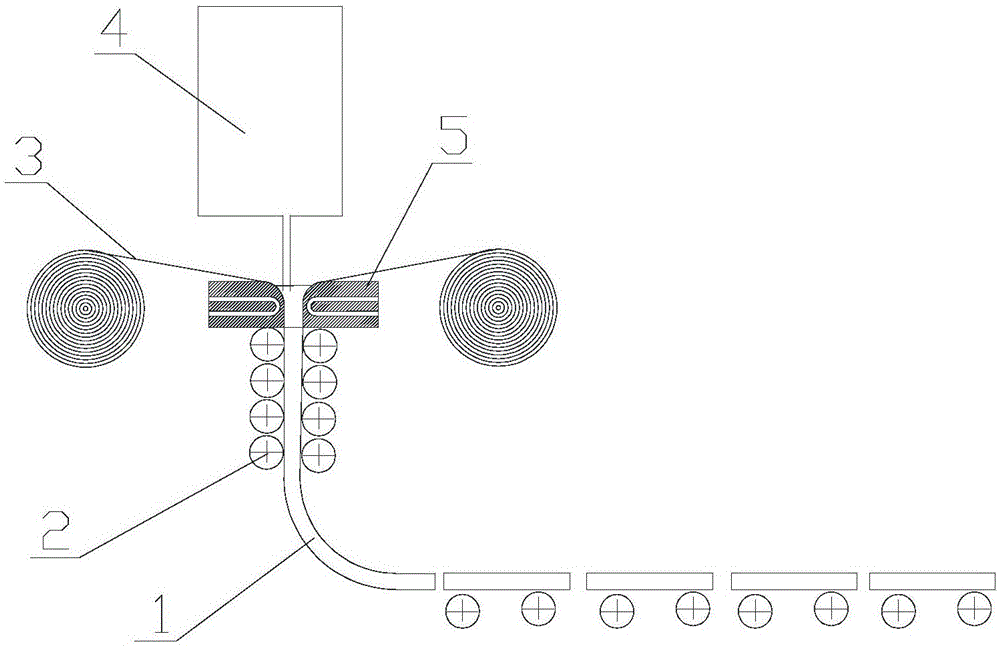

[0019] Using converter smelting, RH refining treatment. The continuous casting adopts electrical steel thin strip 3 with Si1.0wt% and thickness 1.0mm, and the electrical steel thin strip 3 adhered to the surface of casting slab 1 moves together with casting slab 1 during continuous casting, and the molten steel adopts protective atmosphere to isolate air, continuously The casting speed is 0.9m / min, the degree of superheat is 10°C, and the thickness of the slab is 230mm.

[0020] The cast slab 1 is heated at 1150° C. and continuously rolled until a 2.3 mm thin plate is coiled.

[0021] After cold rolling to 0.5mm, it is annealed at 900°C.

Embodiment 2

[0023] The chemical composition wt% of electrical steel is: C0.002%, Si3.20%, Mn0.22%, P0.025%, S0.004%, Als0.28%, the remainder is iron and unavoidable impurities.

[0024] Using converter smelting, RH refining treatment. The continuous casting adopts electrical steel thin strip 3 with Si2.0wt% and thickness 0.5mm, and the electrical steel thin strip 3 adhered to the surface of casting slab 1 moves together with casting slab 1 during continuous casting, and the molten steel adopts protective atmosphere to isolate air, continuously The casting speed is 2.0m / min, the degree of superheat is 20°C, and the thickness of the slab is 135mm.

[0025] The cast slab 1 was heated at 920°C, held for 2 minutes, and cold rolled to 0.5mm after normalization treatment.

[0026] Steel coils are annealed at 910°C.

Embodiment 3

[0028] The chemical composition wt% of electrical steel is: C0.003%, Si1.65%, Mn0.22%, P0.025%, S0.003%, Als0.21%, the remainder is iron and unavoidable impurities.

[0029] Using converter smelting, RH refining treatment. Continuous casting adopts electrical steel thin strip 3 with Si0.8wt% and thickness 2mm. The electrical steel thin strip 3 adhered to the surface of casting slab 1 moves together with casting slab 1 during continuous casting. The molten steel adopts protective atmosphere to isolate air, and continuous casting The speed is 2.5m / min, the degree of superheat is 25°C, and the thickness of the slab is 100mm.

[0030] The cast slab 1 is heated at 1140° C. and continuously rolled until a 2.0 mm thin plate is coiled.

[0031] Cold rolling to 0.5mm coiling, the steel coil is annealed at 900°C.

[0032] The effects of Examples 1 to 3 are shown in the table below.

[0033] Example Iron loss W / kg Magnetic induction value T Example 1 3.38 1.67 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com