Filter for purifying smelting molten steel

A filter and purification technology, which is applied in the field of superalloys, can solve the problems of low filtration efficiency and difficulty in reusing superalloy returned materials, and achieve the effects of improved filtering effect, simple structure and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

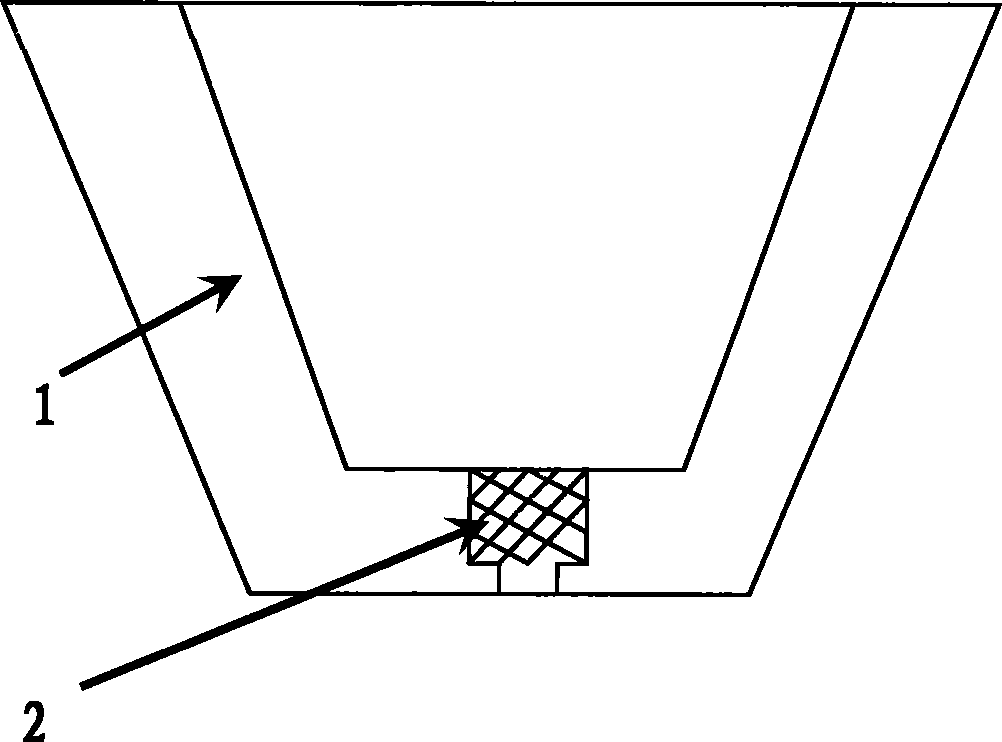

[0021] like figure 2 As shown, the purified molten steel filter of the present invention consists of two layers of filter screens (the first layer of filter screen 3 and the second layer of filter screen 5) and the solid ceramic ball layer 4 in the middle of the two layers of filter screens. The first layer of filter 3 and the second layer of filter 5 can respectively have a multi-layer filter layer structure, and the meshes between the layers are interlaced and communicated. in,

[0022] The upper filter screen (the first filter screen 3) is set inside the filter 1. Its main function is to filter the larger inclusions in the molten steel. You can choose zirconia, alumina or other commonly used foam ceramics to filter according to different alloy materials for smelting. Net, the pore size of the first layer of filter is generally 10-30PPi;

[0023] The role of the solid ceramic ball layer 4 in the middle of the two filter screens is to absorb fine inclusions in the molten s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com