Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve the stability of electrical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

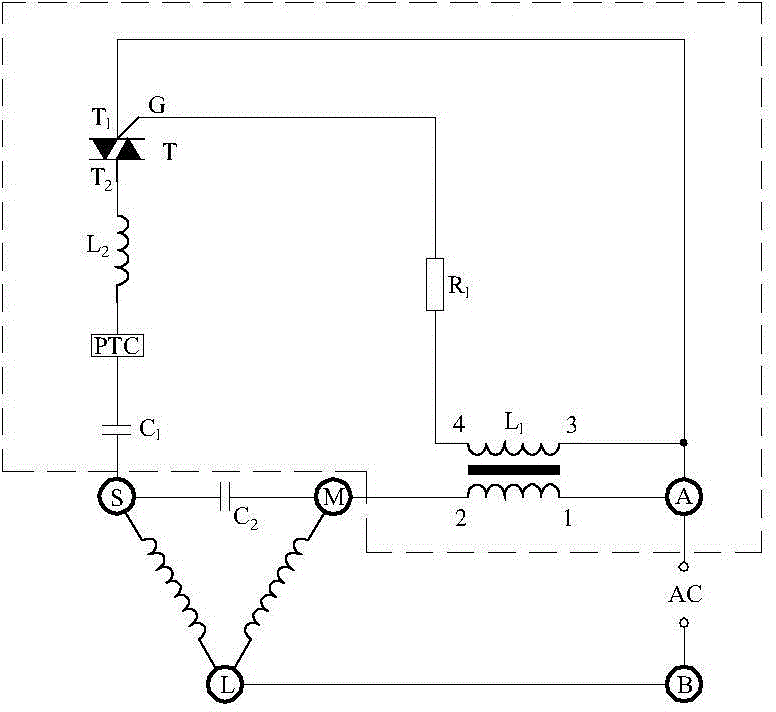

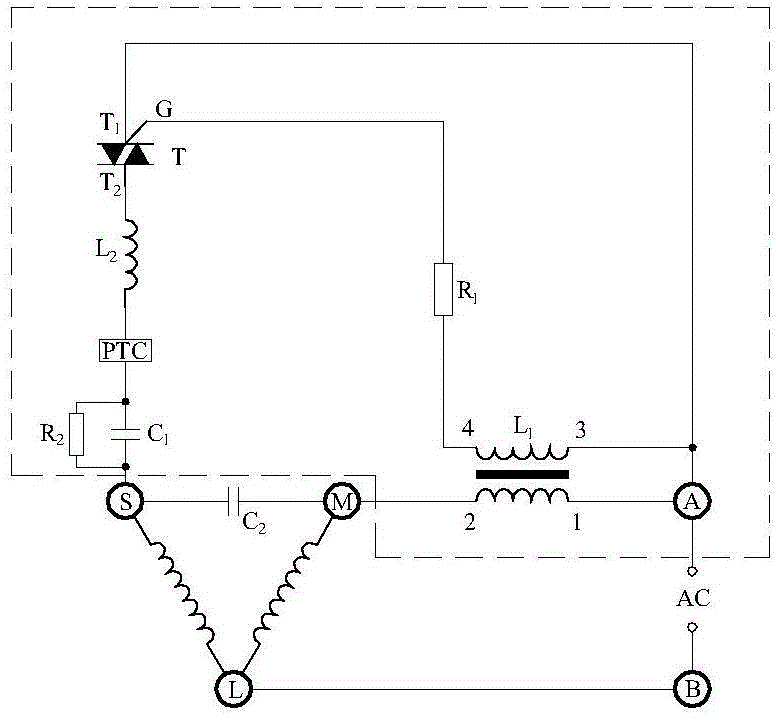

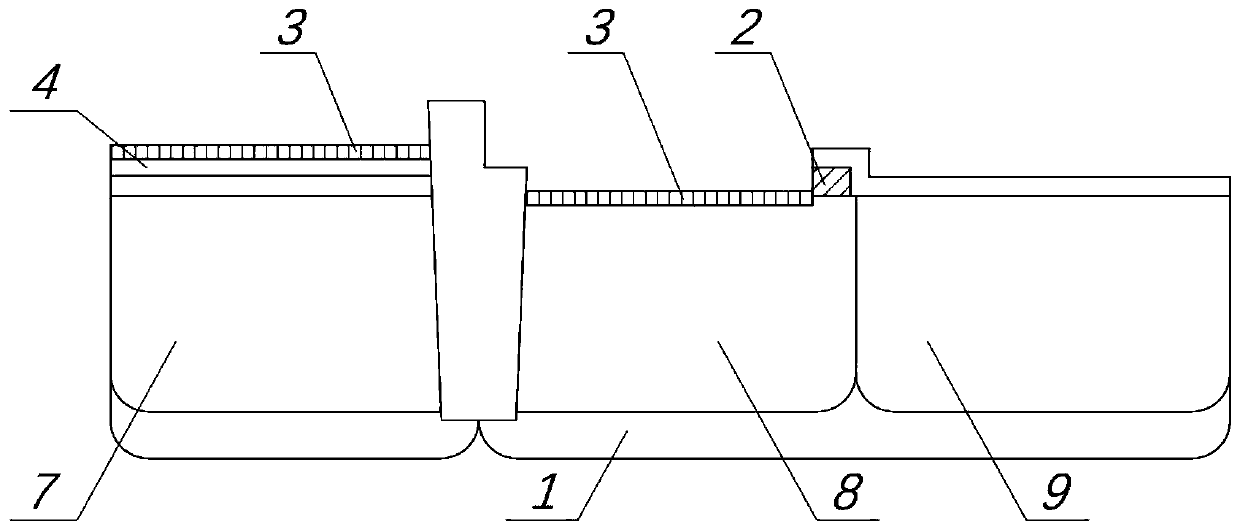

Power-consumption-free starter for commercial refrigeration compressor

InactiveCN104579024AImprove securityImprove matchSingle-phase induction motor startersRefrigeration compressorCapacitance

The invention belongs to the technical field of motor starting devices and provides a power-consumption-free starter for a commercial refrigeration compressor. The power-consumption-free starter comprises a current transformer L1, a bidirectional controllable silicon T, an inductor L2, a PTC element and a starting capacitor C1. One end of a primary coil and one end of a secondary coil of the current transformer L1 and the T1 pole of the bidirectional controllable silicon T are jointly connected with one end of an alternating current power source. The other end of the primary coil of the current transformer L1 is connected with the leading-out end M of a main winding of the motor, the other end of the secondary coil of the current transformer L1 is connected with the G pole of the bidirectional controllable silicon T, the inductor L2, the PTC element and the starting capacitor C1 are sequentially in series connection between the T2 pole of the bidirectional controllable silicon T and the leading-out end S of an auxiliary winding of the motor, and the combined leading-out end L of the main winding and the auxiliary winding of the motor is connected with the other end of the alternating current power source. The power-consumption-free starter can effectively reduce consumption of reactive power and meet the requirements for energy saving and environment friendliness; a coil of the auxiliary winding can bear large current, and the electrical property is stable; the power-consumption-free starter is good in generality and high in safety.

Owner:CHANGSHU TIANYN ELECTROMECHANICAL

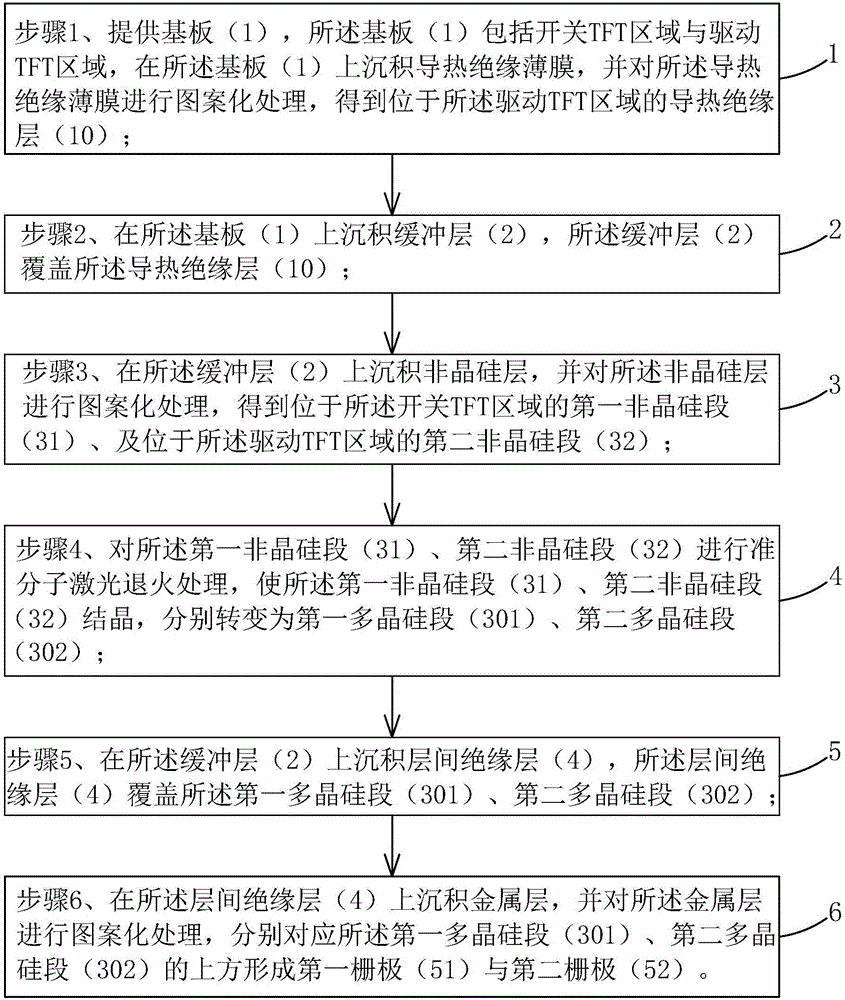

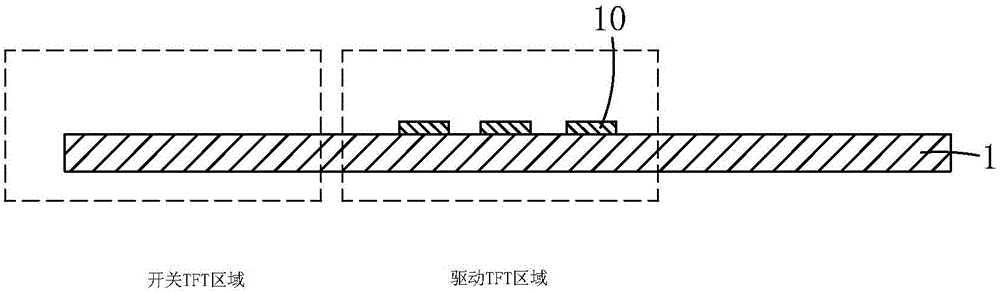

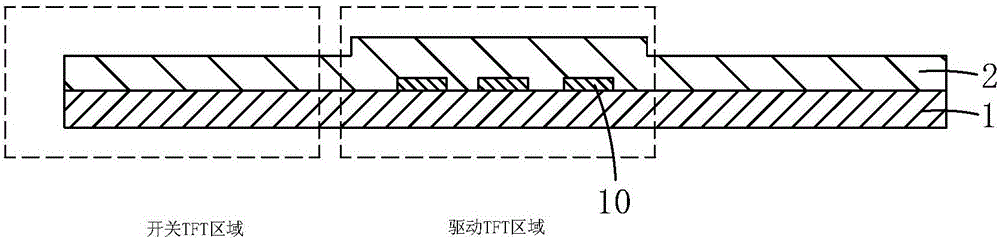

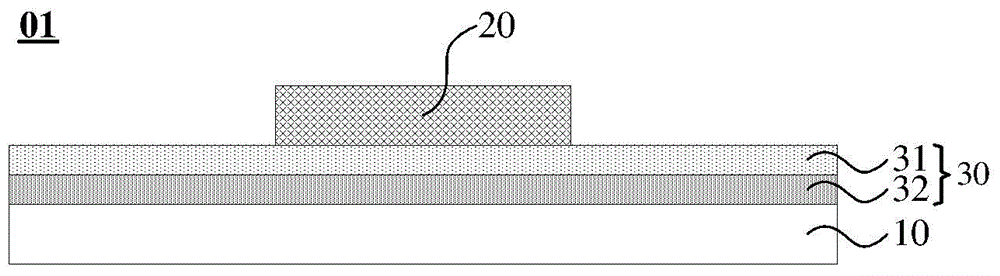

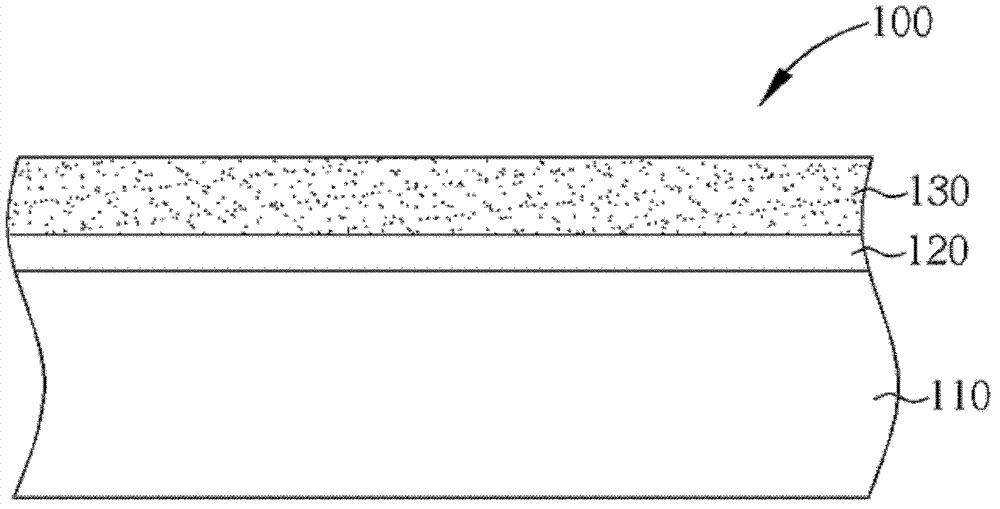

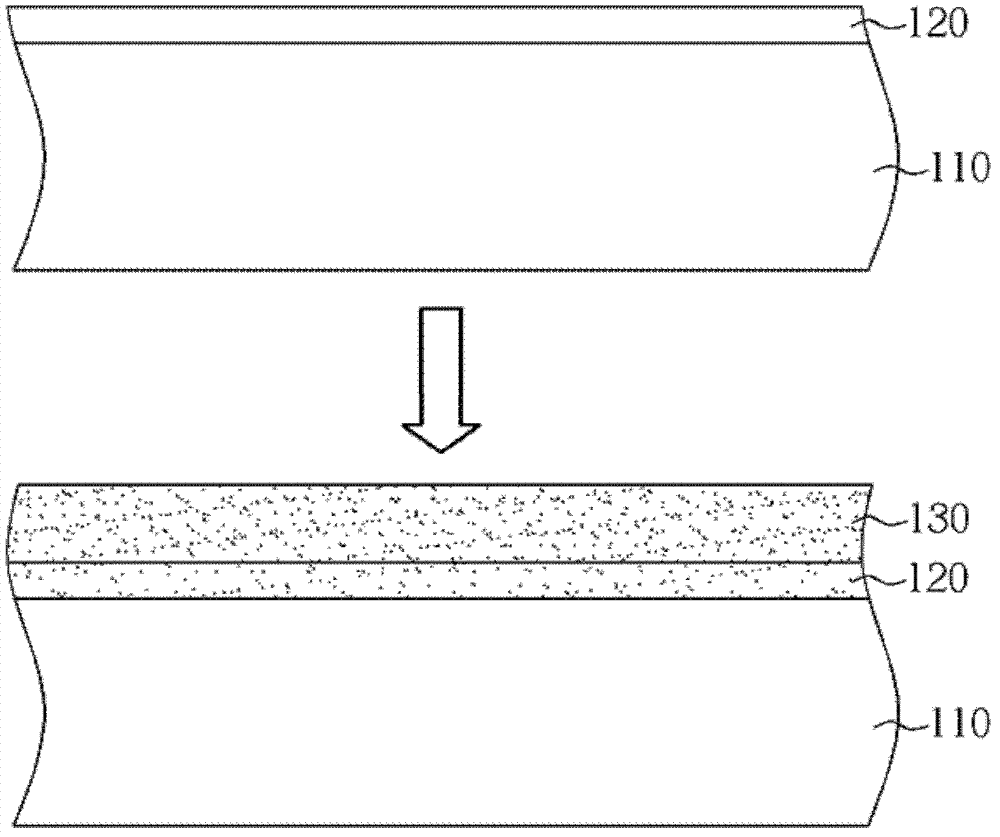

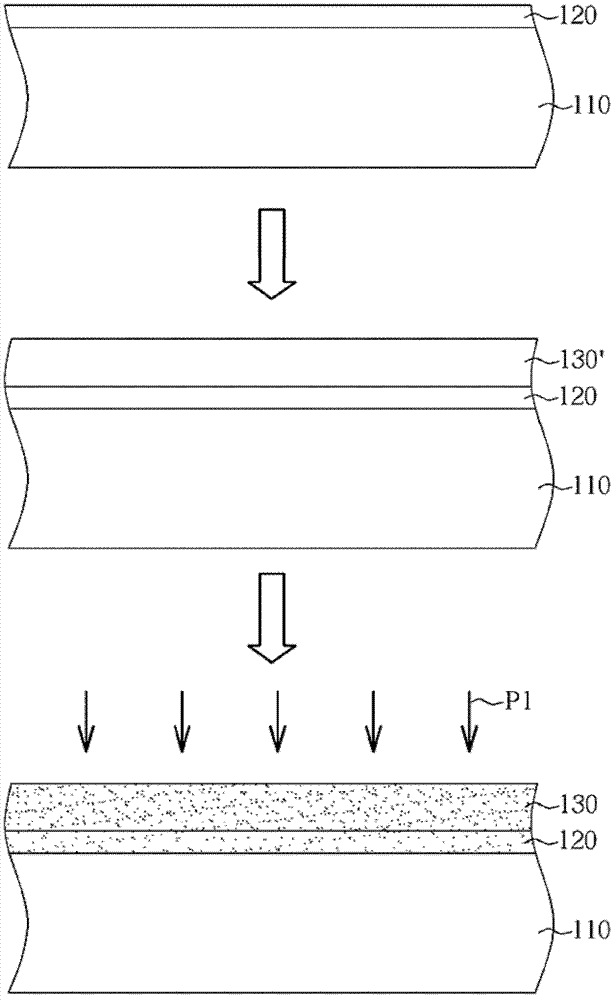

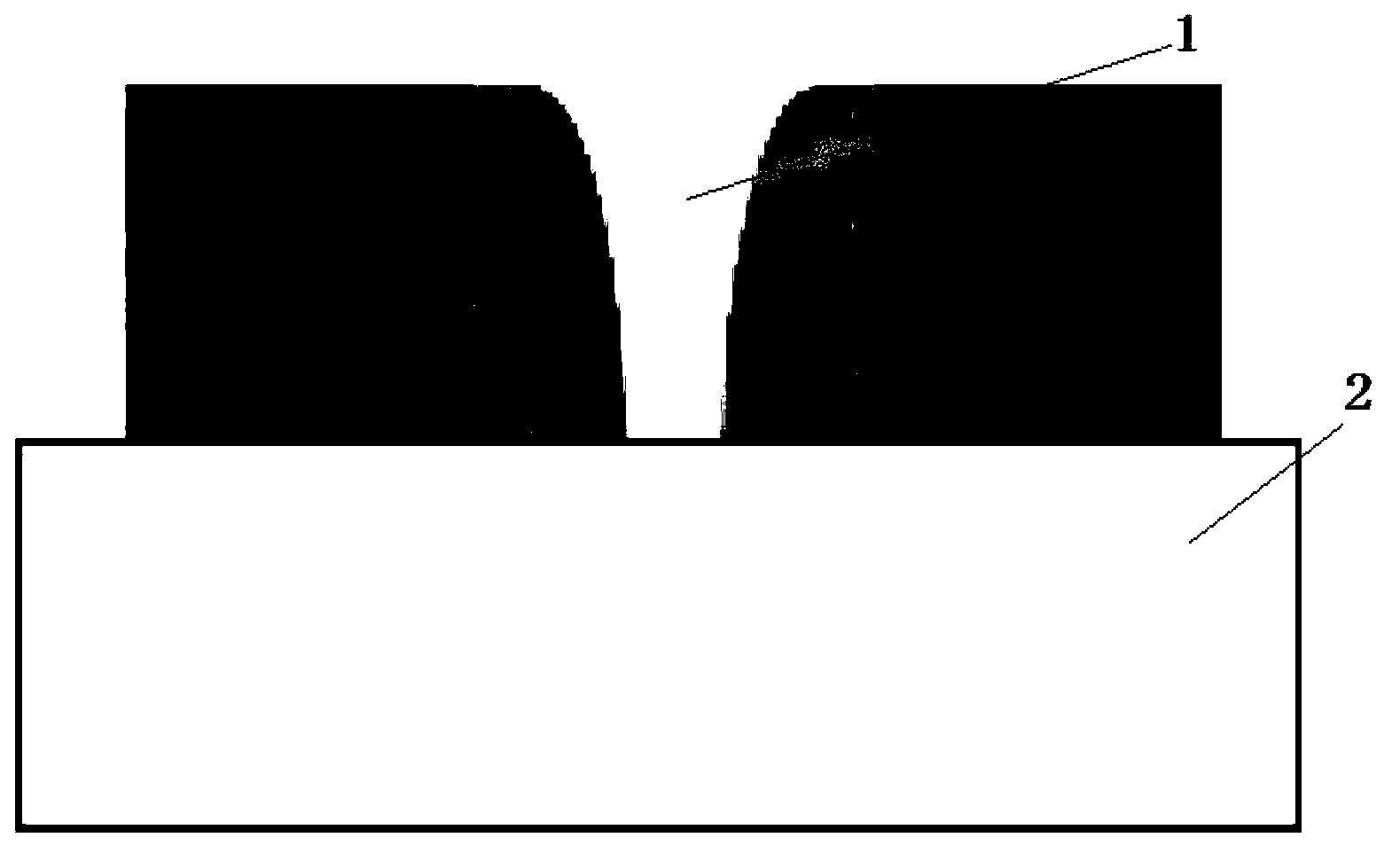

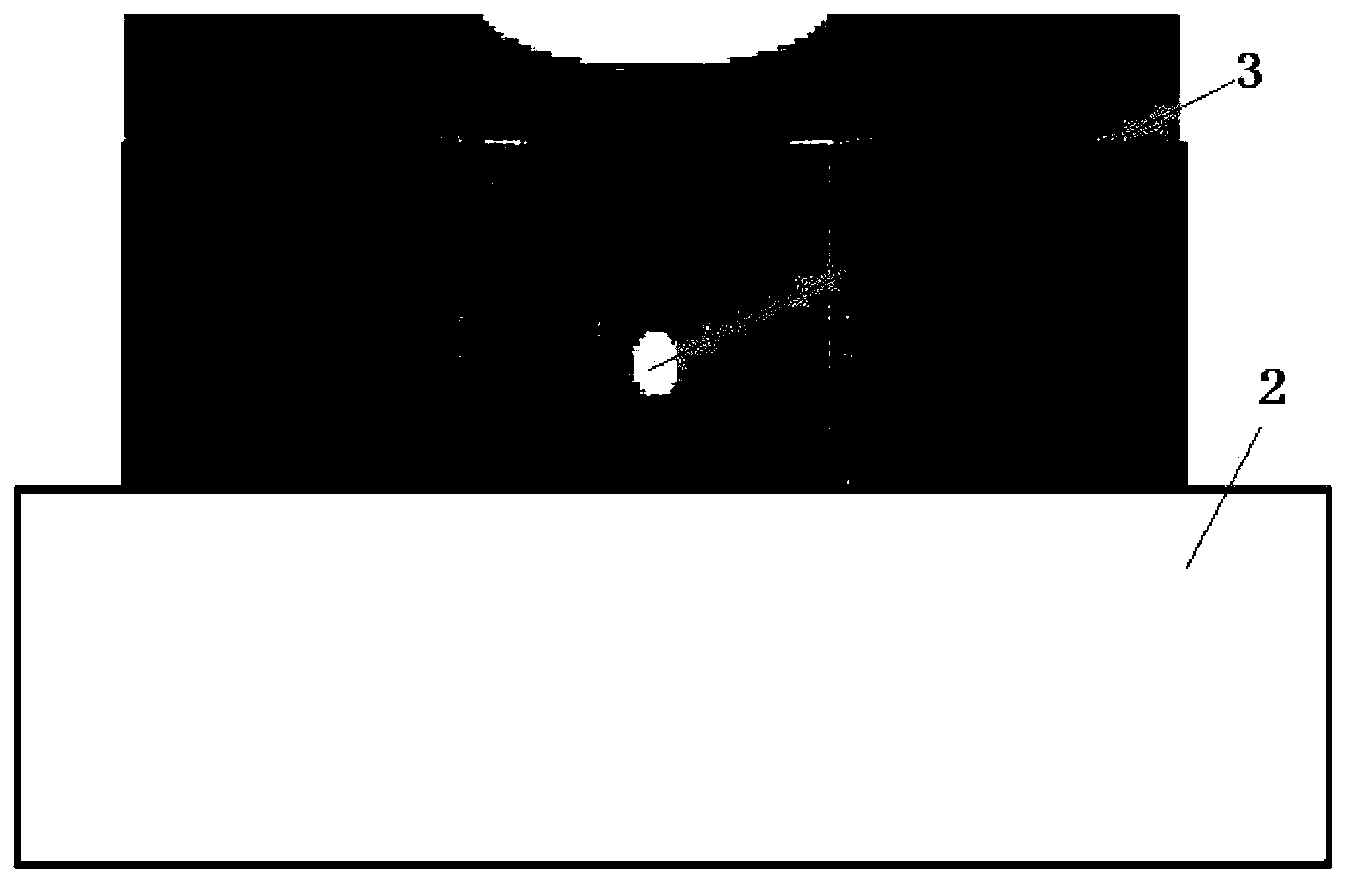

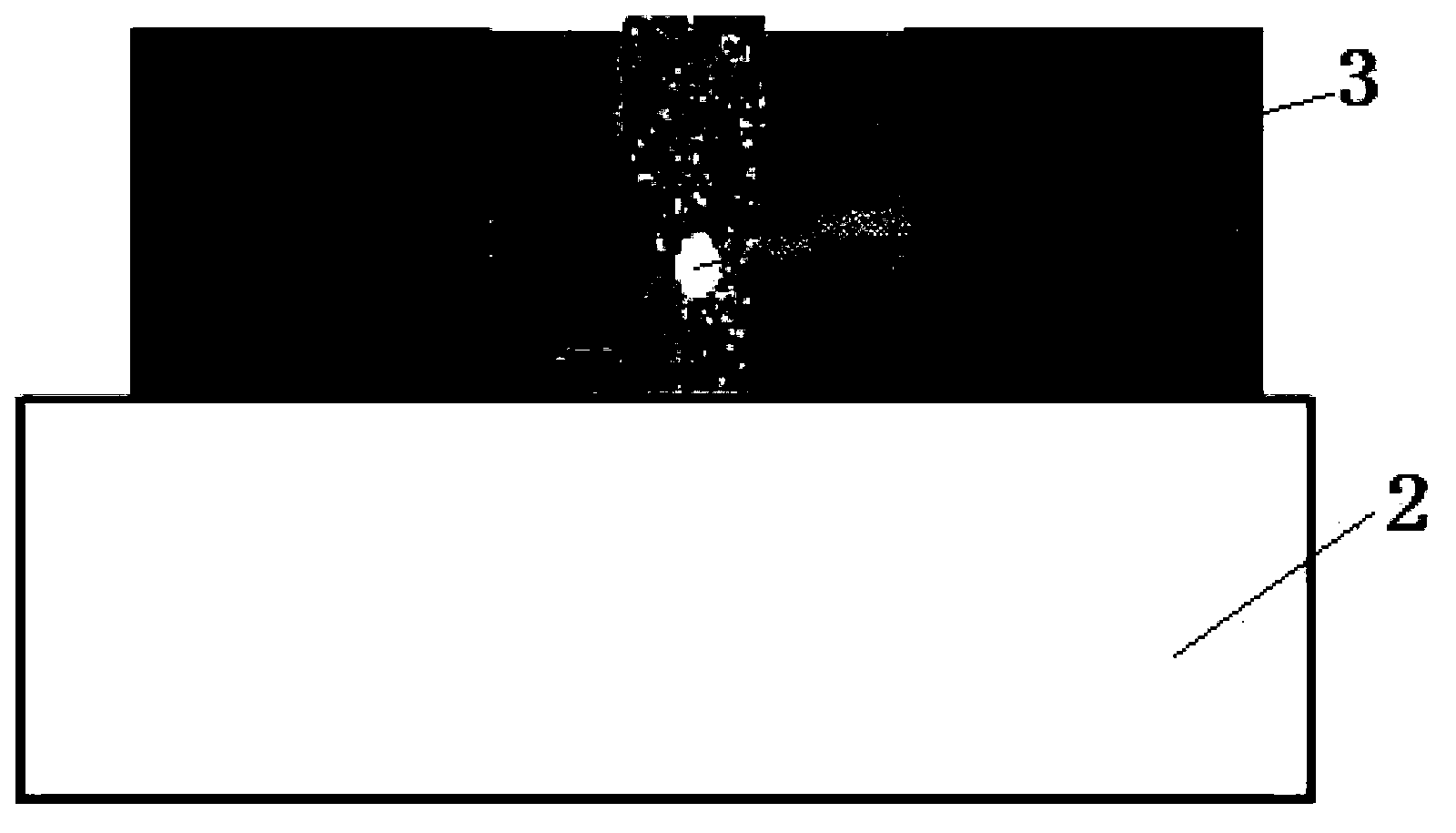

Fabrication method of low-temperature polycrystalline silicon thin-film transistor (TFT) substrate structure and low-temperature polycrystalline silicon TFT substrate structure

ActiveCN105097667AFast coolingLarge grainSolid-state devicesSemiconductor/solid-state device manufacturingHeat conductingOptoelectronics

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

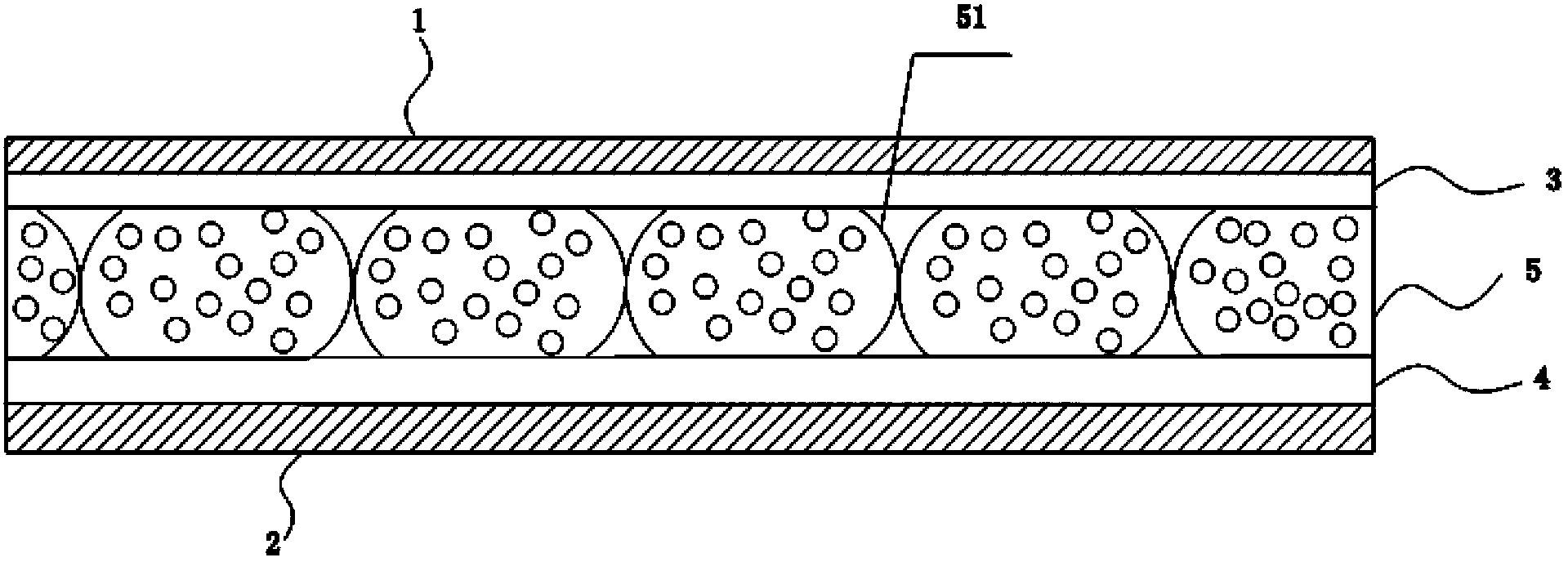

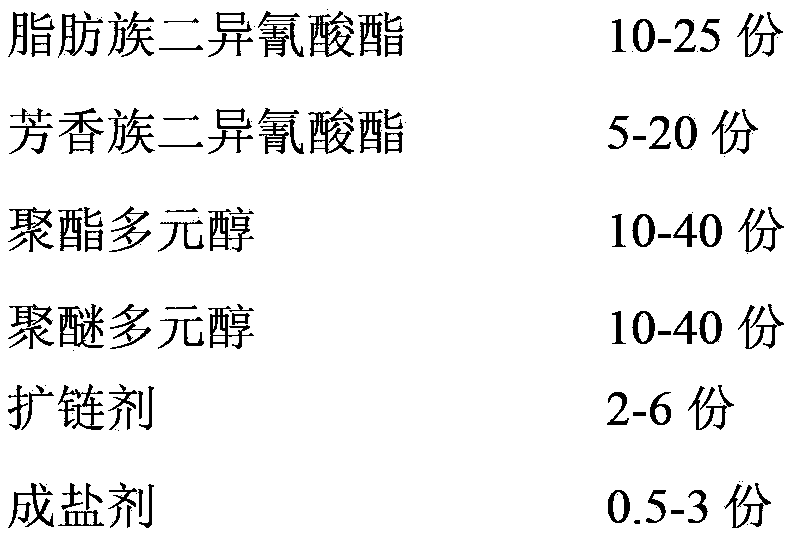

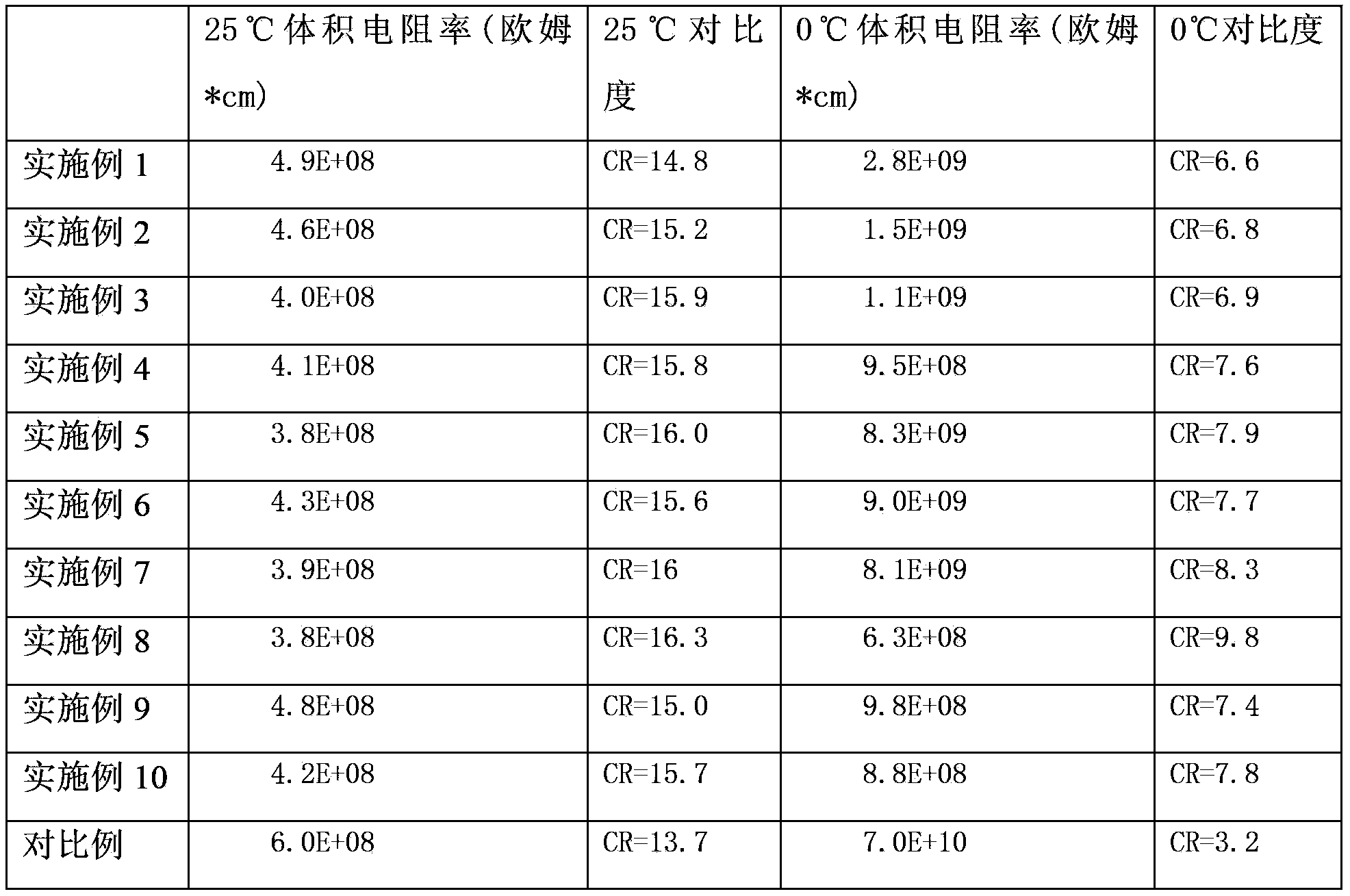

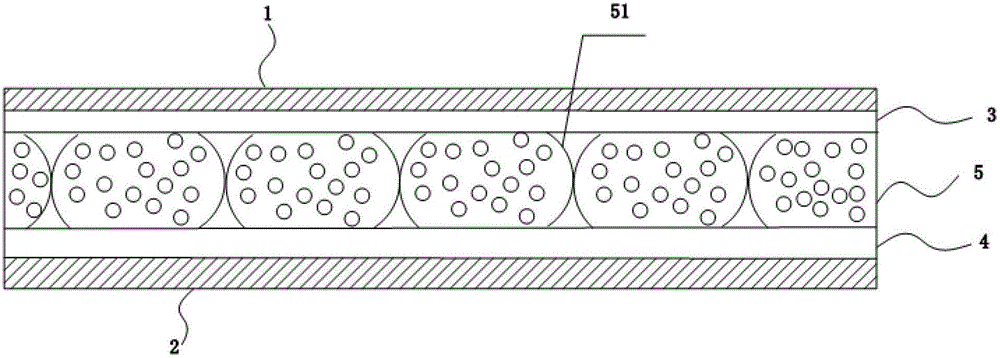

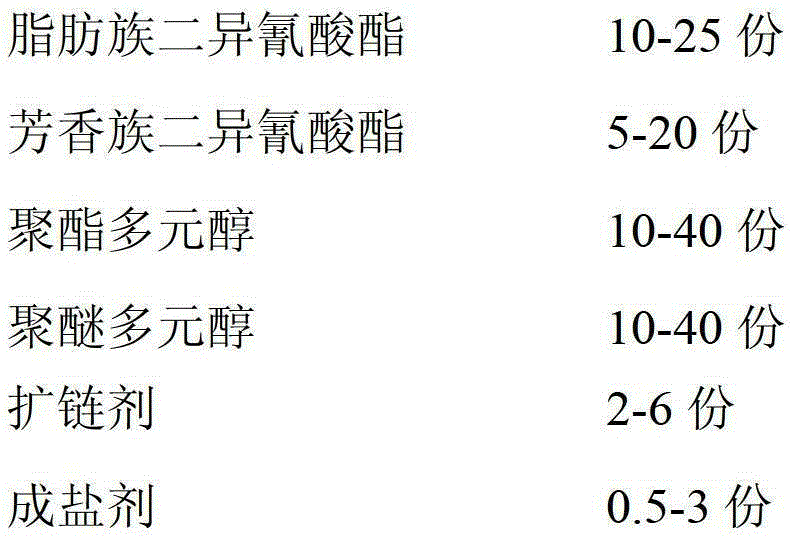

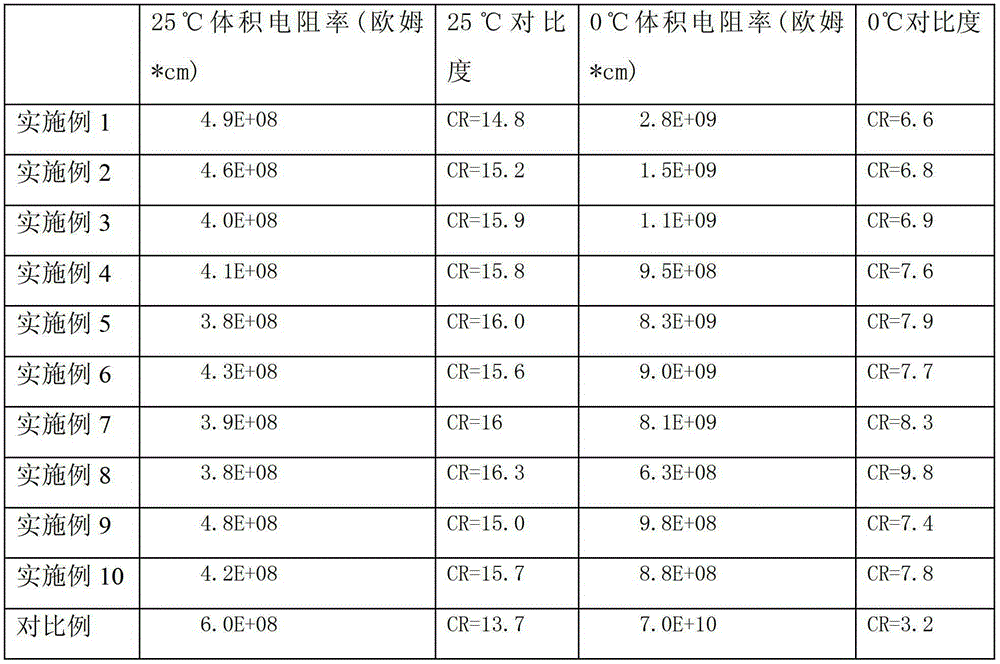

Adhesive applicable to low temperature and used for electronic paper, and preparation method and application thereof

ActiveCN104073210ASmall fluctuationImprove adaptabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterElectricity

The invention provides an adhesive applicable to low temperature and used for electronic paper. The adhesive comprises a waterborne polyurethane emulsion which is prepared from diisocyanate, polyester polyol with number-average molecular weight of 300 to 3000, polyether polyol with number-average molecular weight of 400 to 3000, a chain extender and a salt forming agent through polymerization, emulsification and dispersion. The invention also provides a preparation method for the adhesive and application of the adhesive in an electrophoretic display apparatus. The electrical properties of the adhesive for the electronic paper have small fluctuation with changes of temperature, and volume resistivity of the adhesive at about 0 DEG C changes a little compared with volume resistivity of the adhesive at normal temperature. The adhesive for the electronic paper can be used as a lamination adhesive in the electrophoretic display apparatus, enables the contrast of the electrophoretic display apparatus to be maintained in a good range when the electrophoretic display apparatus is used at a low temperature (about 0 DEG C) and improves adaptability of the electrophoretic display apparatus to the environment.

Owner:GUANGZHOU OED TECH INC

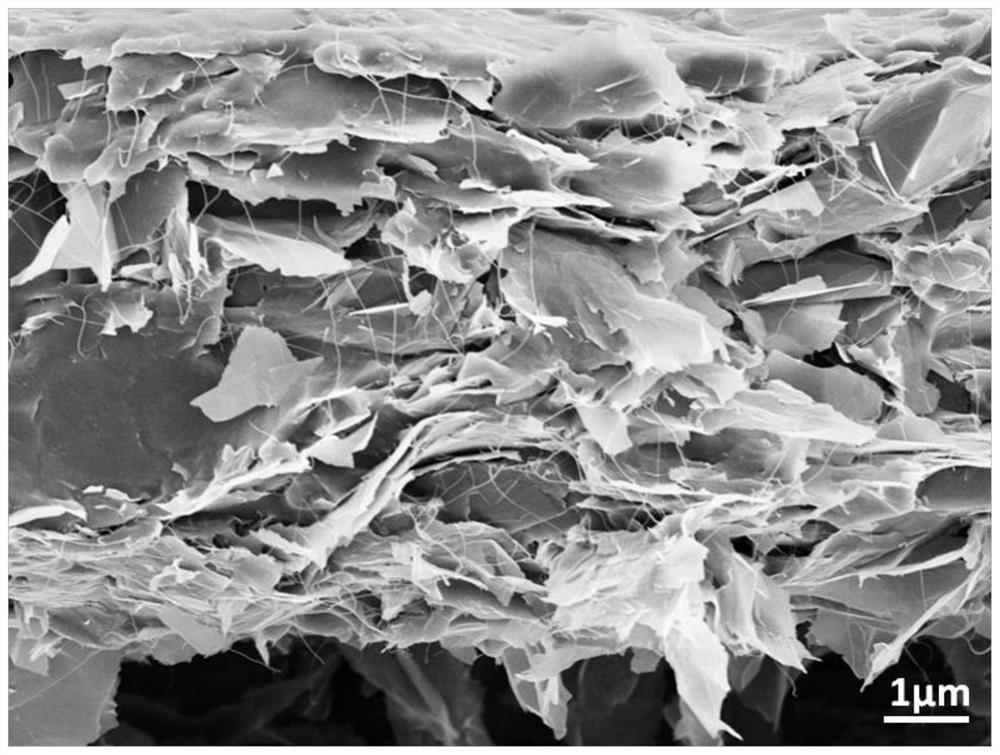

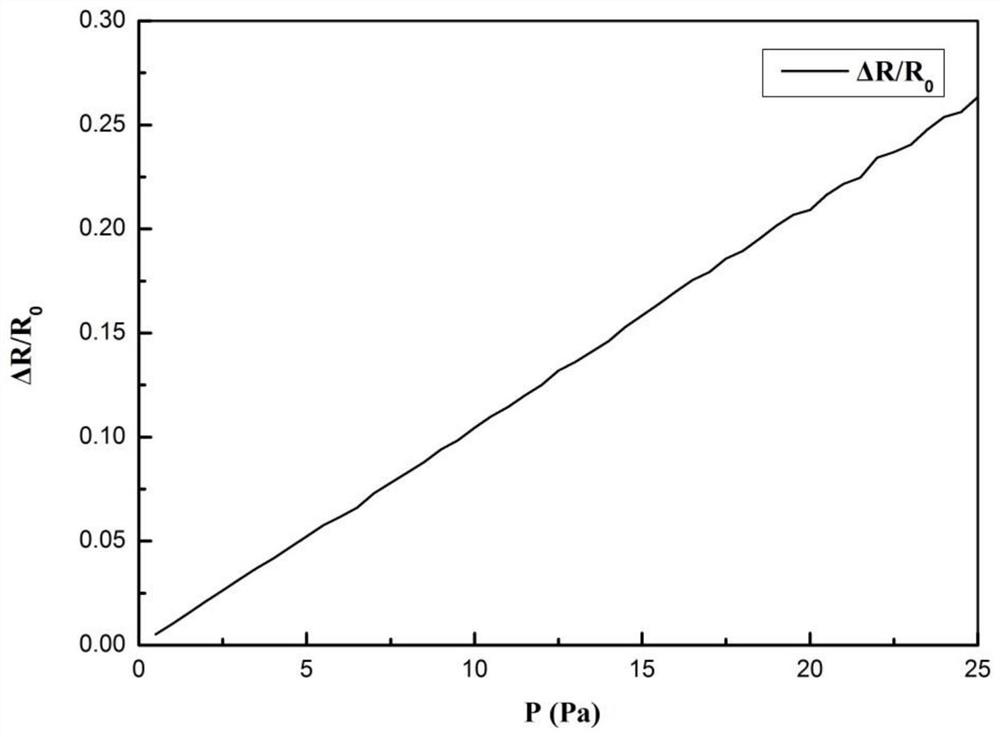

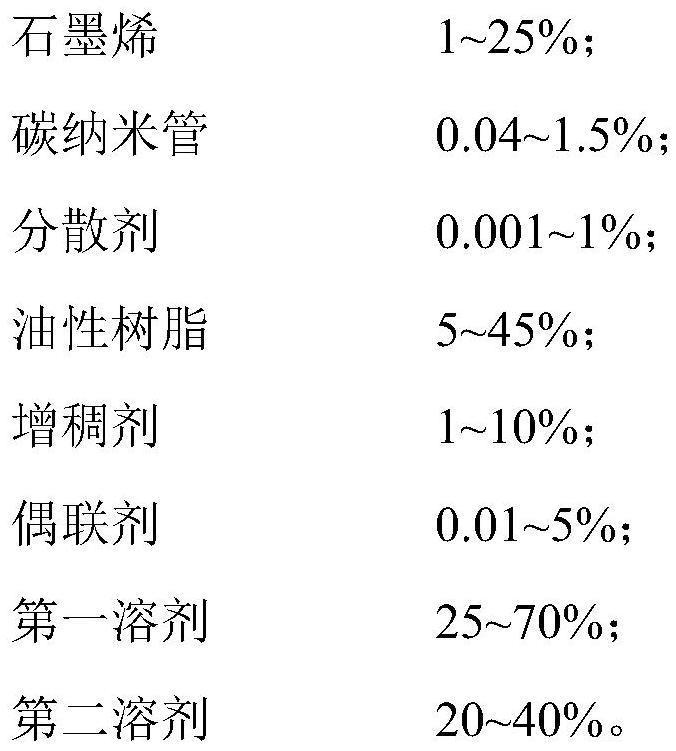

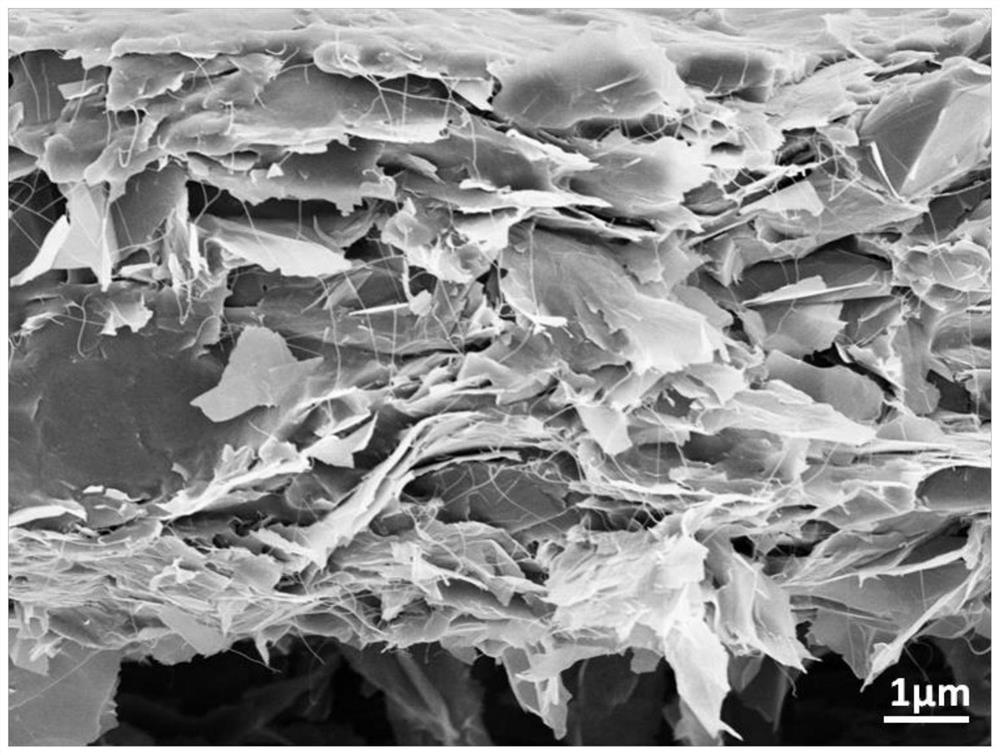

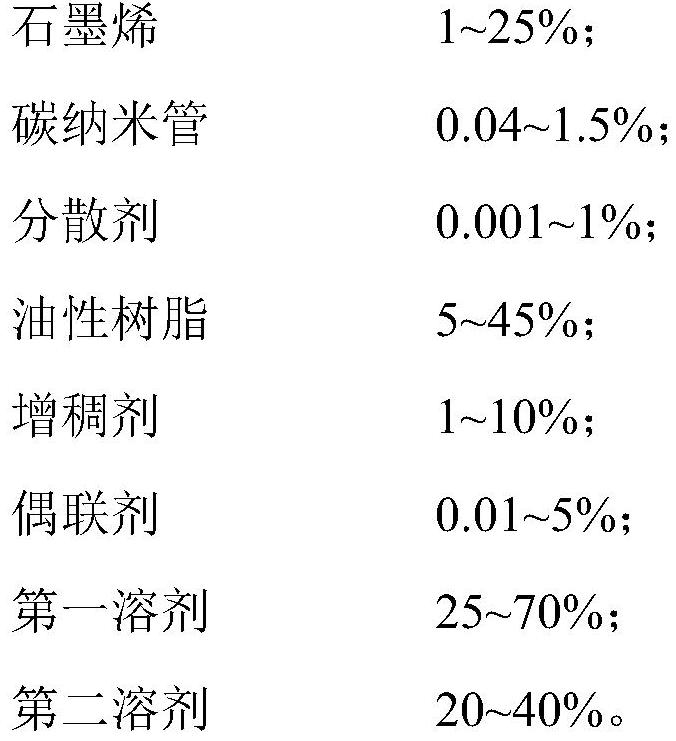

Conductive carbon paste for flexible pressure sensor, preparation method thereof and pressure sensor

ActiveCN112254850AIncreased sensitivityImprove stabilityForce measurementMaterial strength using steady bending forcesPlasticizerGraphene flake

The invention relates to a conductive carbon paste for a flexible pressure sensor, a preparation method thereof and the pressure sensor. The conductive carbon paste comprises the following raw materials in percentage by mass: 1-25% of graphene, 0.04-1.5% of carbon nanotubes, 0.001-1% of a dispersing agent, 5-45% of oleoresin, 1-10% of a thickening agent, 0.01-5% of a coupling agent, 25-70% of a first solvent and 20-40% of a second solvent. According to the conductive carbon paste disclosed by the invention, the graphene sheet and a small amount of carbon nanotubes are added into a resin system, and the dispersing agent, the coupling agent and the plasticizer are matched for use, so that the prepared conductive carbon paste has the advantages of high sensitivity, high stability, low minimumdetection limit, bending resistance, strong adhesive force with a flexible substrate and the like. Under the action of pressure, a conductive network formed by graphene and carbon nanotubes in a cured conductive carbon paste resin system is changed, the resistance of the cured conductive carbon paste is increased, the pressure sensitivity is high, and tiny pressure change can be sensed.

Owner:SU ZHOU CSTAR MATERIAL TECH CO LTD

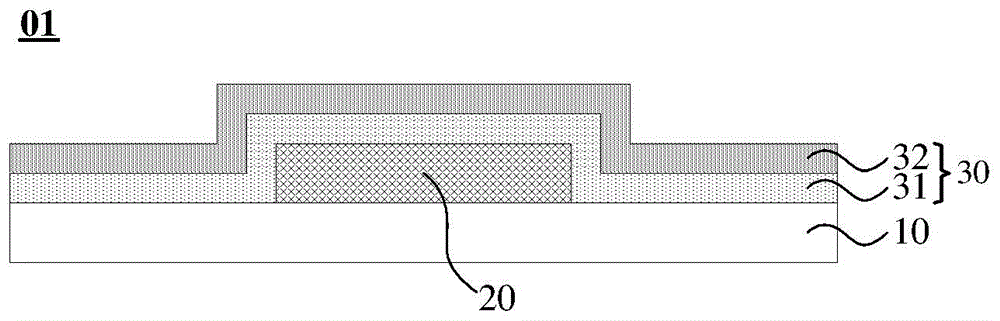

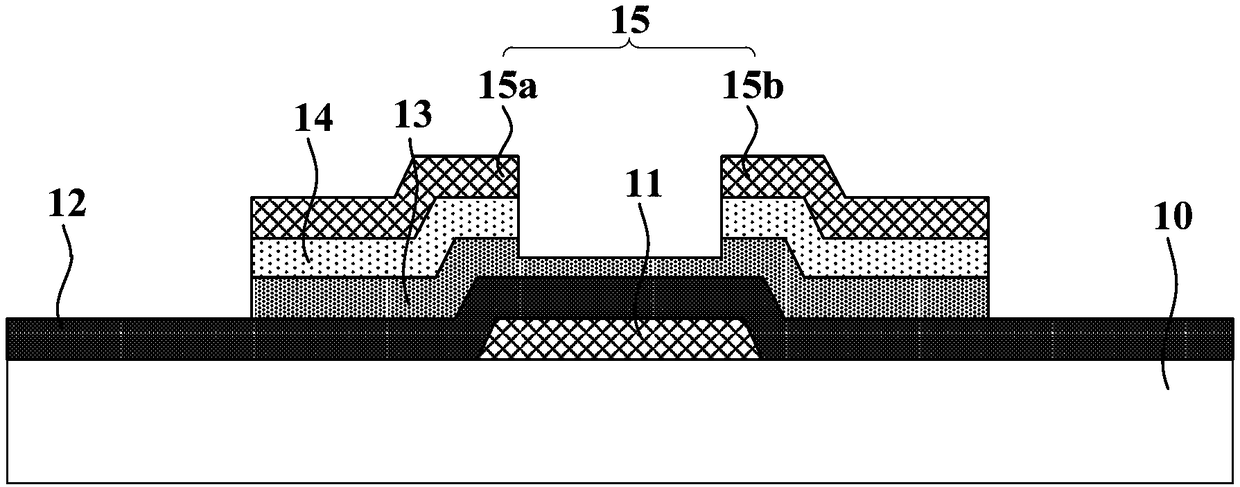

Thin film transistor, array substrate, preparation method therefor, and display device

InactiveCN105097902AImprove the stability of electrical propertiesTransistorSolid-state devicesInsulation layerDisplay device

Embodiments of the invention provide a thin film transistor, an array substrate, a preparation method therefor, and a display device, relating to the technical field of displays. Interface shortcomings of an insulation layer in contact with an active layer can be effectively overcome, and electric performance stability of the TFT (thin film transistor) in conduction is improved. The preparation method comprises: a step of forming active layers and insulation layers that are arranged layer by layer and in mutual contact on a substrate; the step of forming the insulation layers comprises: forming at least one layer of first insulation layer, wherein one layer of the at least one layer of the first insulation layer is in contact with the active layer; the step of forming the first insulation layer comprises: forming first insulation thin films formed by silicon oxide; repairing the first insulation thin films by a repairing source containing filling atoms to enable at least part of silicon dangling bond of the first insulation thin films to be combined with the filling atoms to form the first insulation layer. The preparation method is used for preparation of the thin film transistor, the array substrate comprising the thin film transistor as well as the display device.

Owner:BOE TECH GRP CO LTD

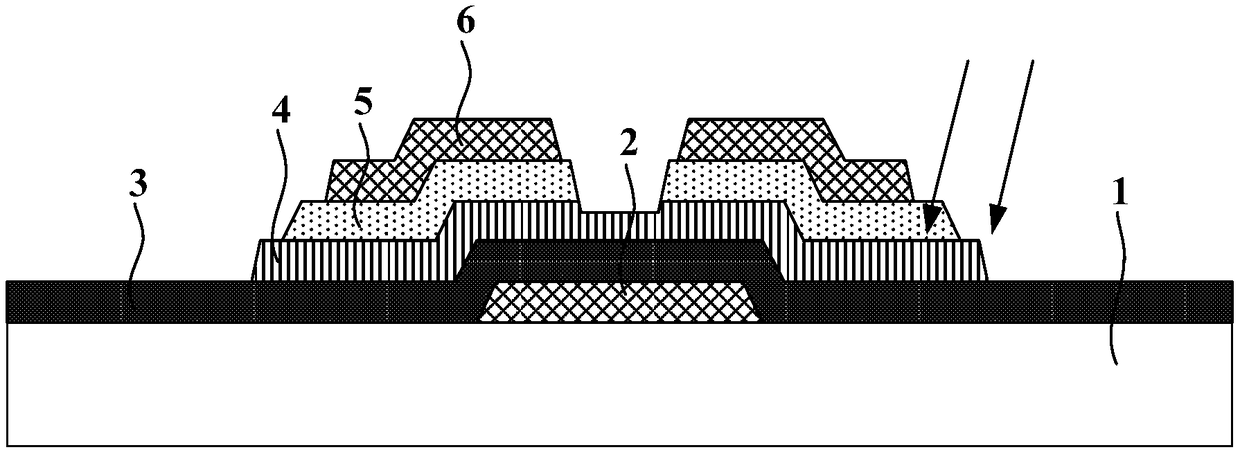

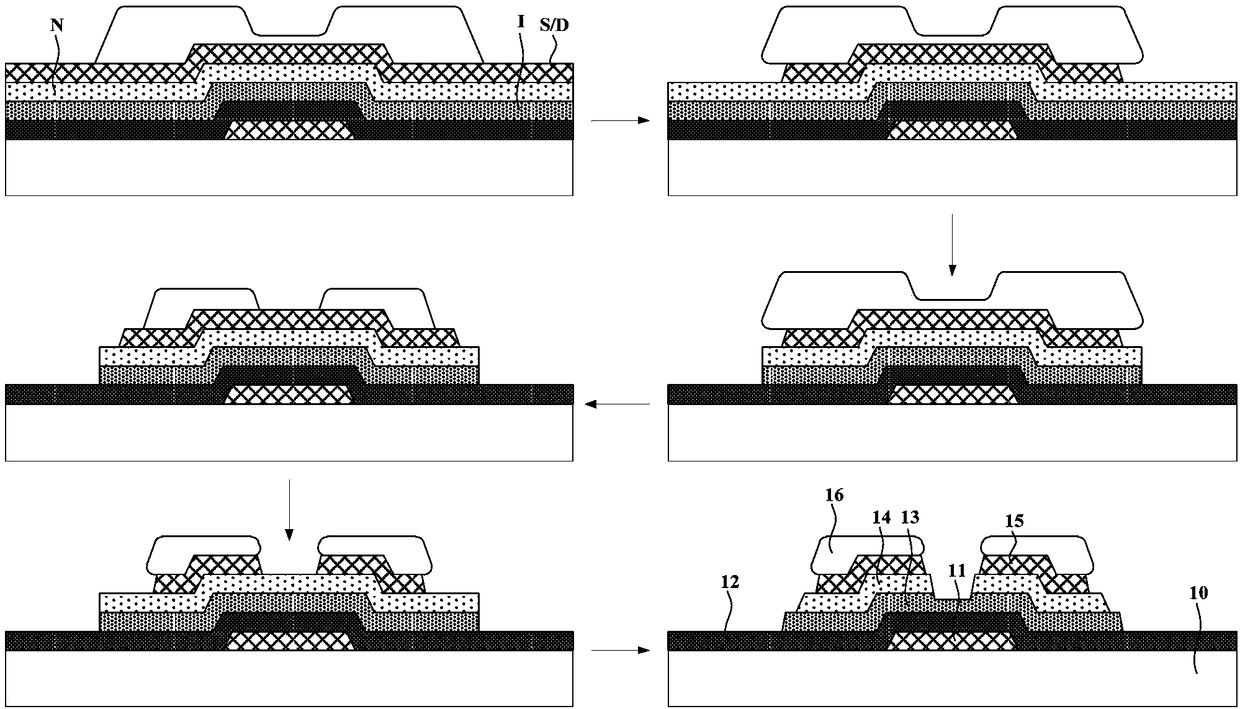

Thin film transistor, manufacturing method thereof and display panel

InactiveCN108615771ALeakage current does not increaseImprove the stability of electrical propertiesTransistorSemiconductor/solid-state device manufacturingInsulation layerElectrical performance

The embodiment of the invention discloses a thin film transistor, a manufacturing method thereof and a display panel. The thin film transistor comprises a substrate, a gate, a gate insulation layer, asemiconductor layer, a doping layer and a source-drain, wherein the gate, the gate insulation layer, the semiconductor layer, the doping layer and the source-drain are sequentially formed on the substrate, and the semiconductor layer is used for absorbing a light ray with wavelength larger than 760 nanometers. In the thin film transistor disclosed by the embodiment of the invention, the light raycannot be absorbed by the semiconductor layer of the thin film transistor due to the characteristic that visible light is not absorbed by the semiconductor layer even the light ray radiates the semiconductor layer of the thin film transistor, the light ray cannot react with the visible light to generate a light leakage current, so that the leakage current of the thin film transistor cannot be increased. Compared with the prior art, the leakage current of the thin film transistor is reduced, the electrical performance stability of the thin film transistor is improved, and the power consumptionof the display panel also can be reduced when the thin film transistor is applied to the display panel.

Owner:HKC CORP LTD +1

Liquid crystal display panel and preparation method thereof

InactiveCN106200155AImprove the stability of electrical propertiesEliminate process static effectsNon-linear opticsLiquid-crystal displayElectrical stability

The invention discloses a liquid crystal display panel and a preparation method thereof. A dummy pixel used for improving the uniformity of an active area is built on the liquid crystal panel, wherein data lines of the dummy pixel are connected with polycrystalline silicon layers; pixel electrodes of the dummy pixel are connected with a common electrode; the polycrystalline silicon layers of the dummy pixel are disconnected from the common electrode. According to the liquid crystal display panel and the preparation method thereof, the electrostatic influence, generated by the dummy pixel of the liquid crystal display panel, of the process can be effectively eliminated by eliminating dangling electrodes in the dummy pixel; compared with the prior art, the electrical stability of the liquid crystal display panel is greatly improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Semiconductor structure, preparation method and application thereof

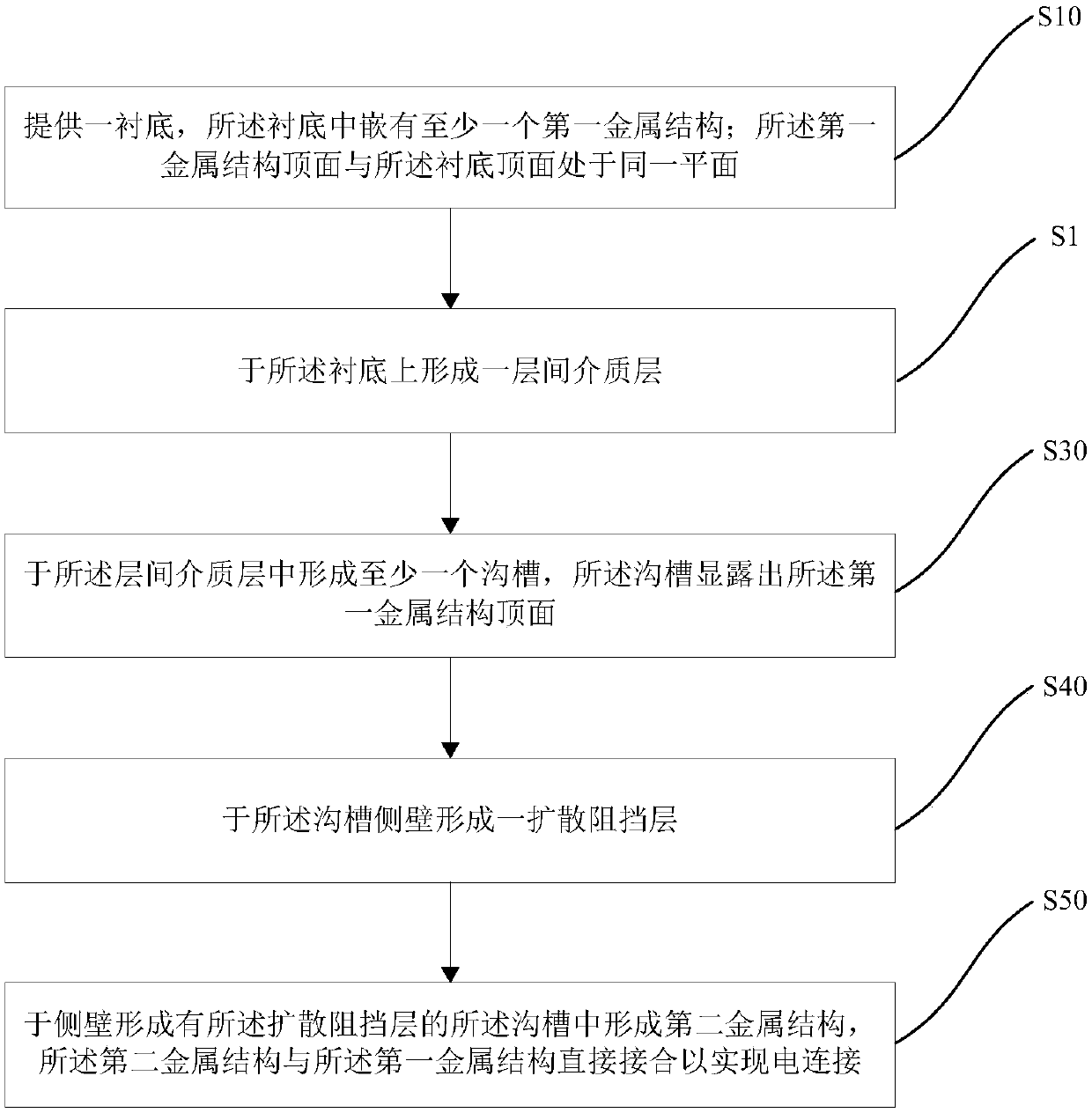

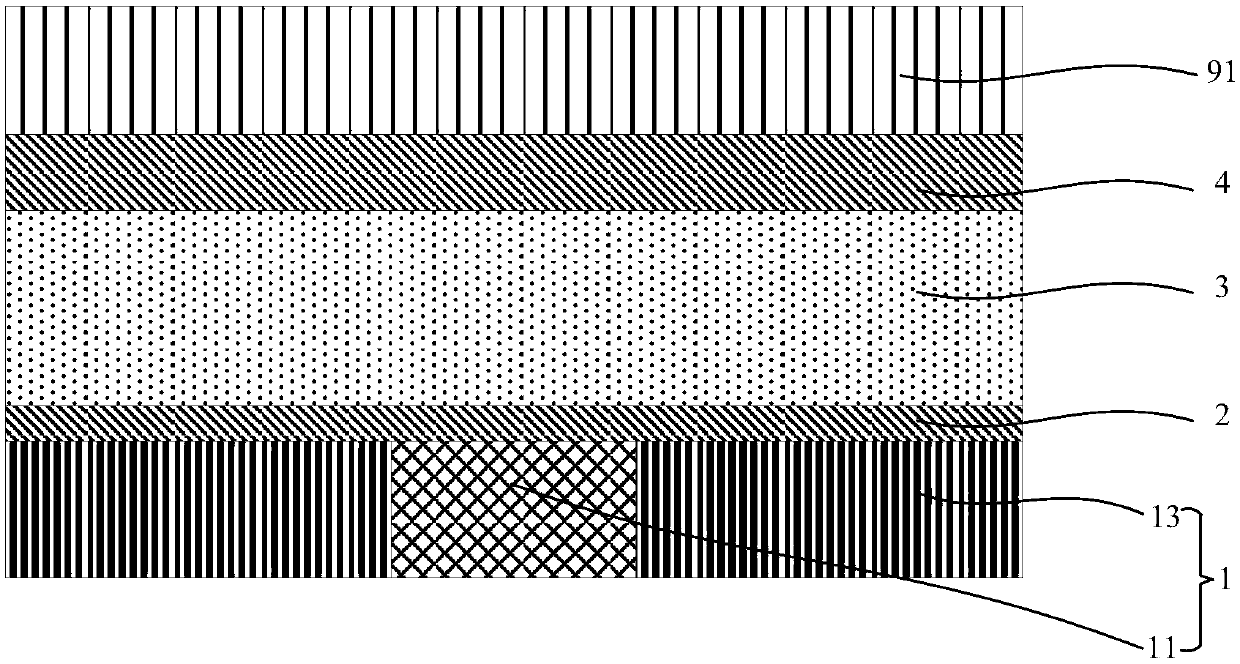

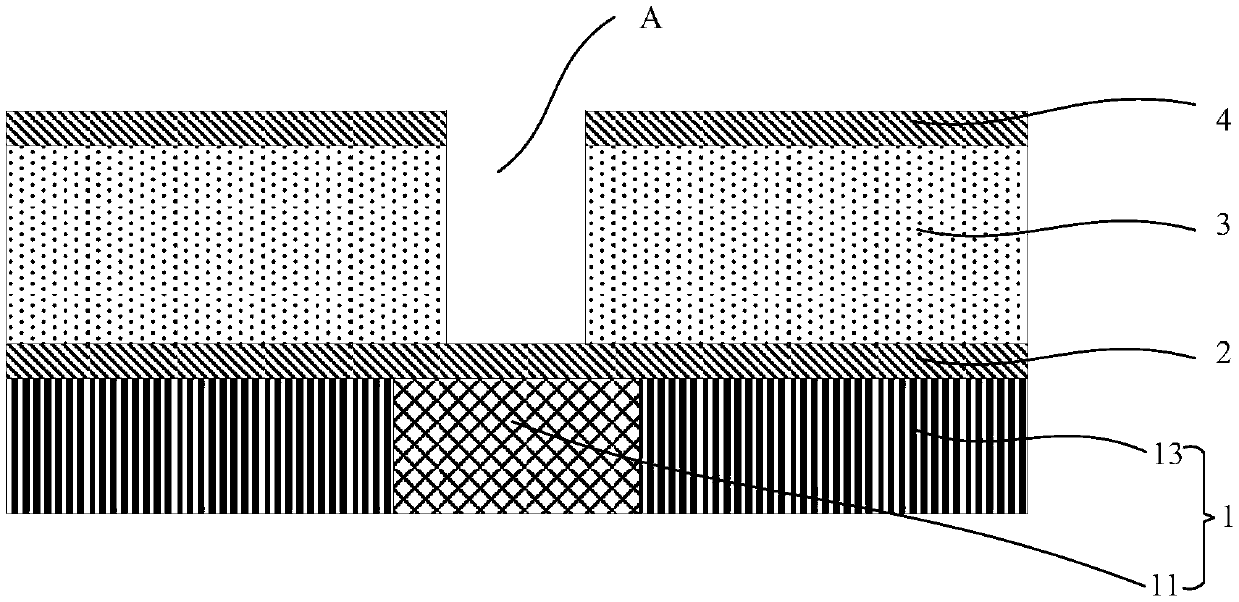

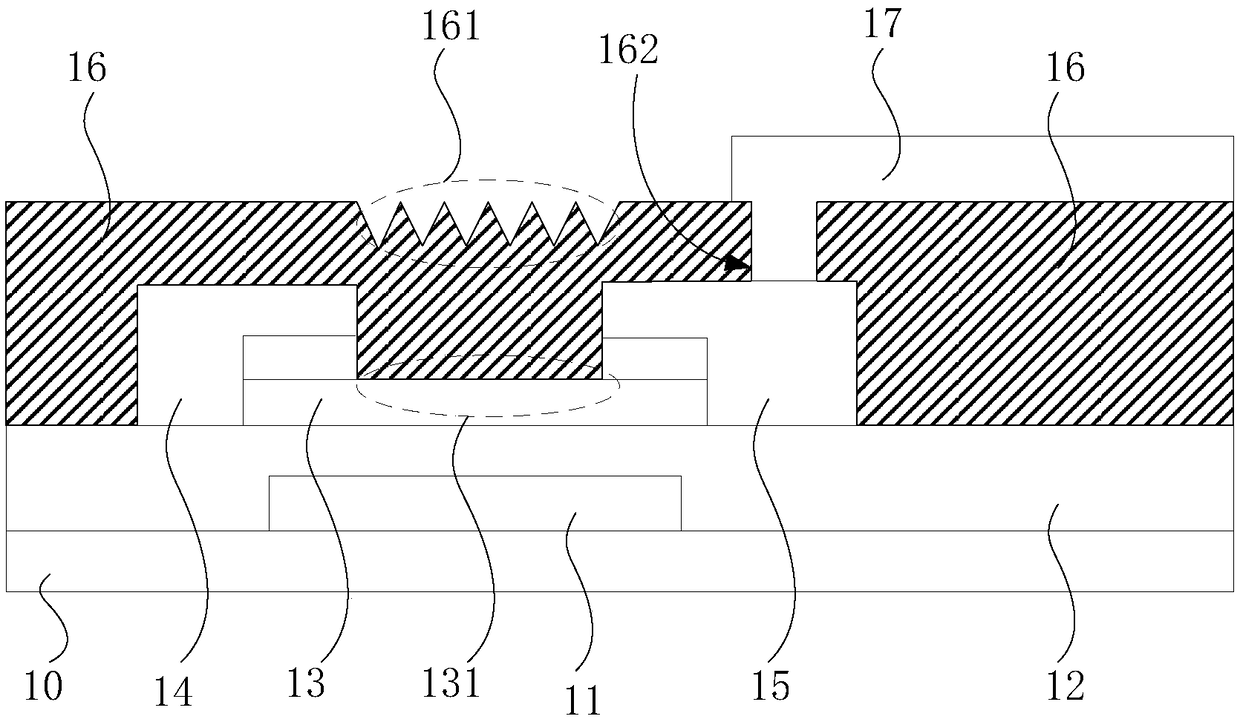

PendingCN110943070AIncrease speedGuaranteed reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceSemiconductor structure

The invention provides a semiconductor structure, and a preparation method and application thereof, and the preparation method comprises the steps: providing a substrate, wherein at least one first metal structure is embedded in the substrate; the top surface of the first metal structure and the top surface of the substrate are located on the same plane; forming an interlayer dielectric layer on the substrate; forming at least one groove in the interlayer dielectric layer, wherein the groove is exposed out of the top surface of the first metal structure; forming a diffusion barrier layer on the side wall of the trench; and forming a second metal structure in the trench on which the diffusion barrier layer is formed, wherein the second metal structure is directly bonded with the first metalstructure to realize electrical connection. According to the invention, by removing the diffusion barrier layer at the bottom, the interconnection contact resistance is reduced, RC delay is reduced,the dielectric layer between the layers can be protected, the through hole filling quality is improved, and in addition, an insulating material can be used as the diffusion barrier layer, so that theelectrical performance stability and reliability of the device are improved.

Owner:CHANGXIN MEMORY TECH INC

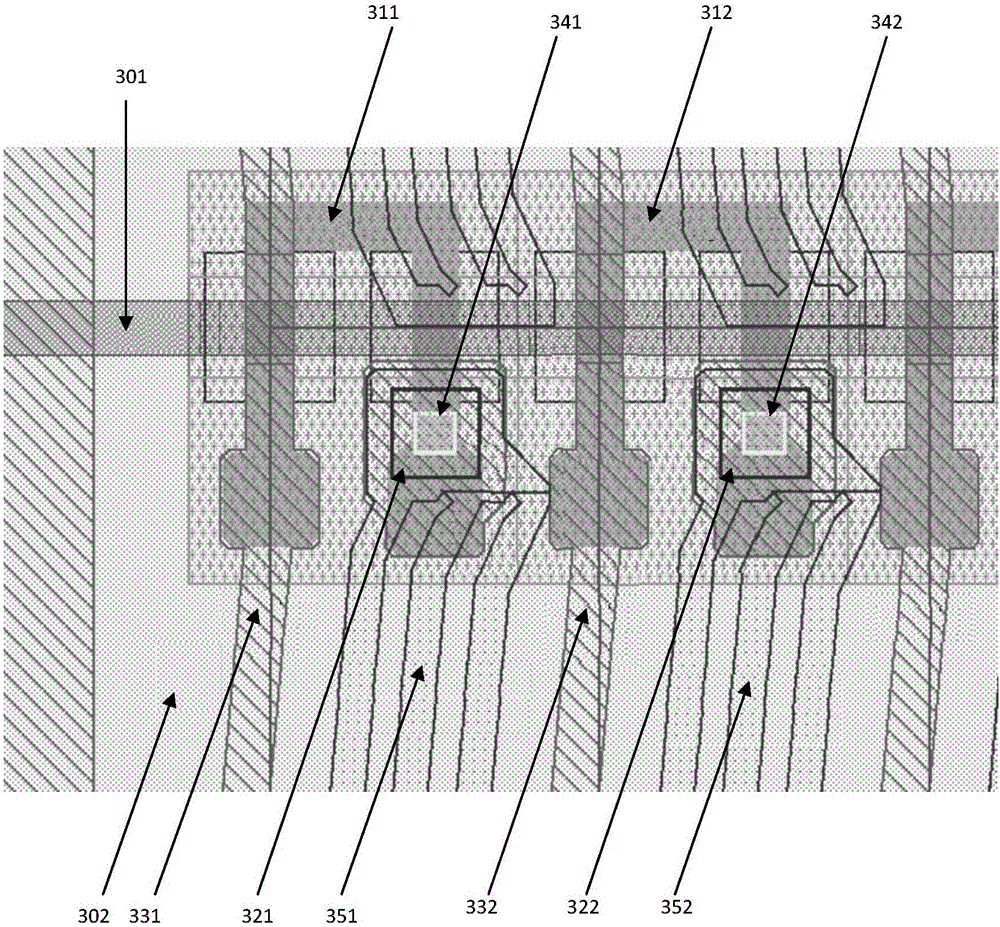

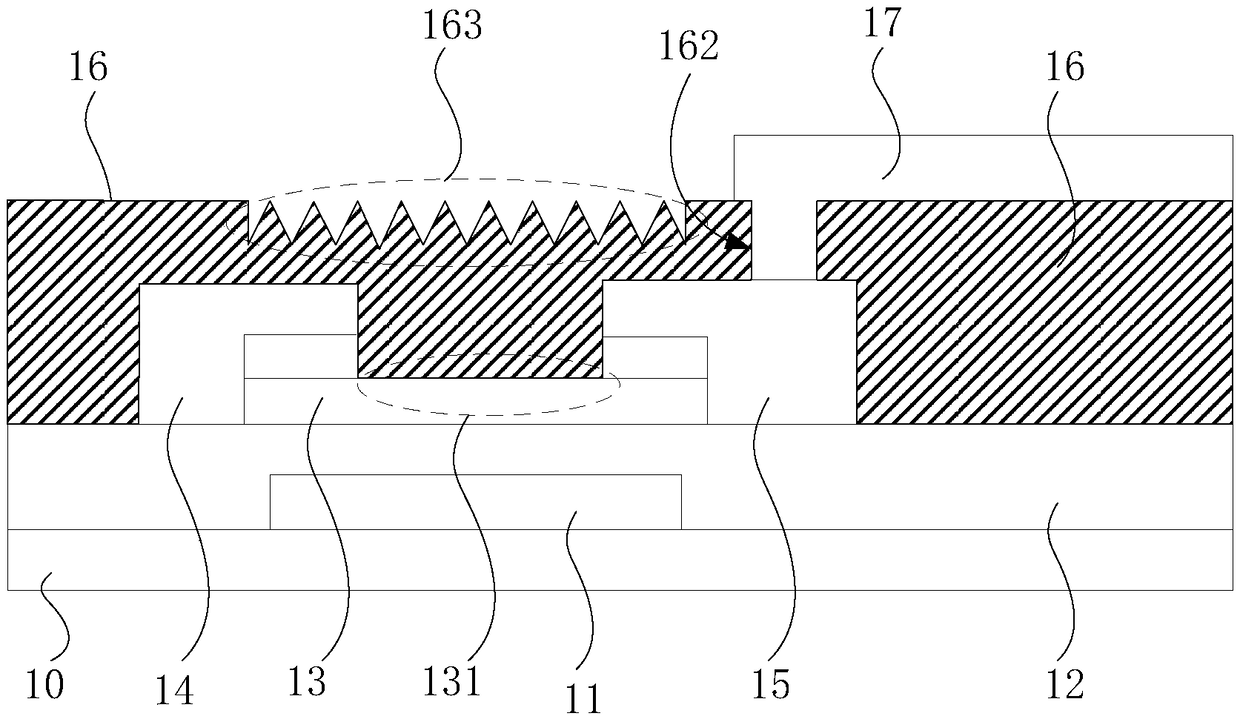

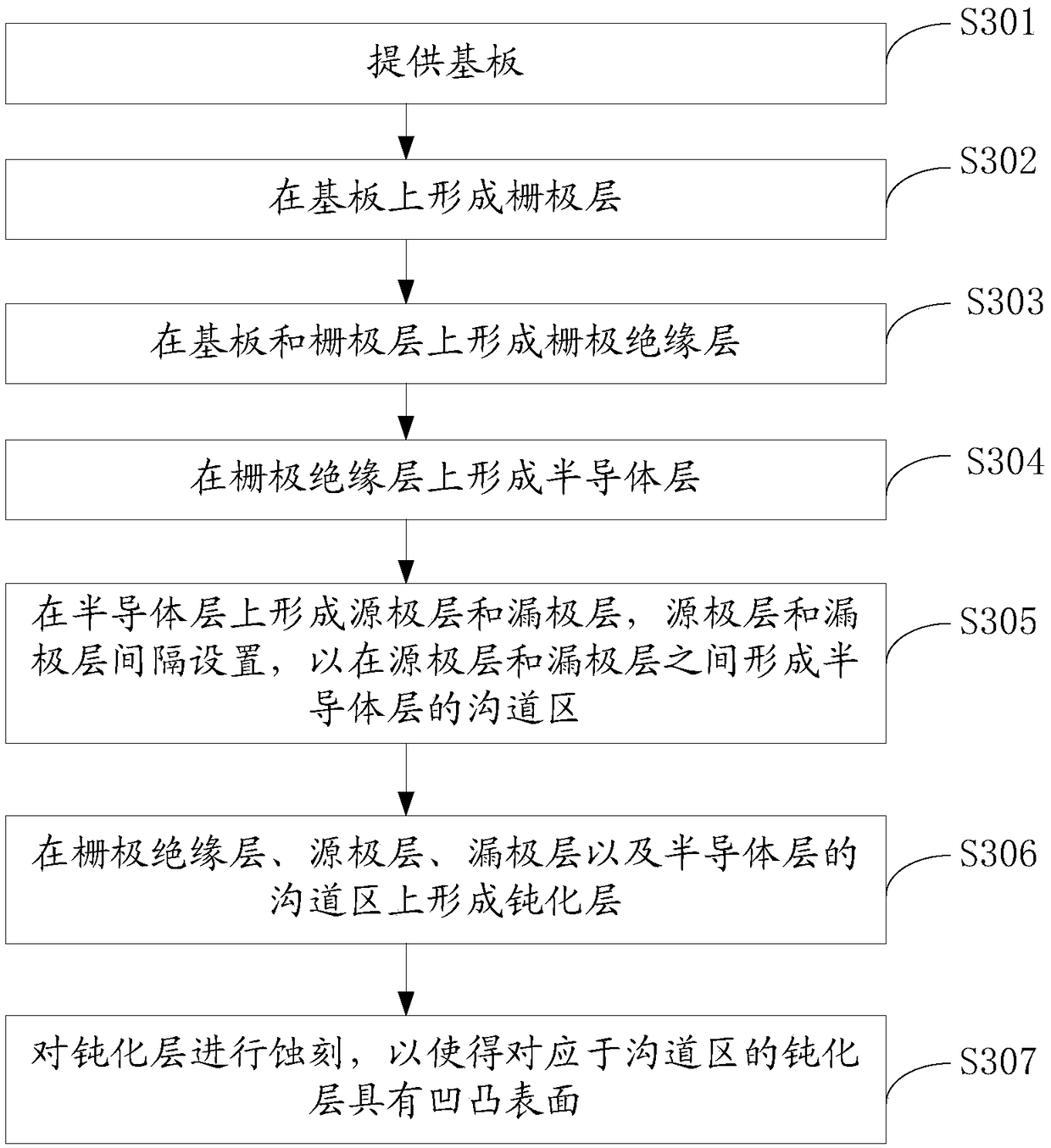

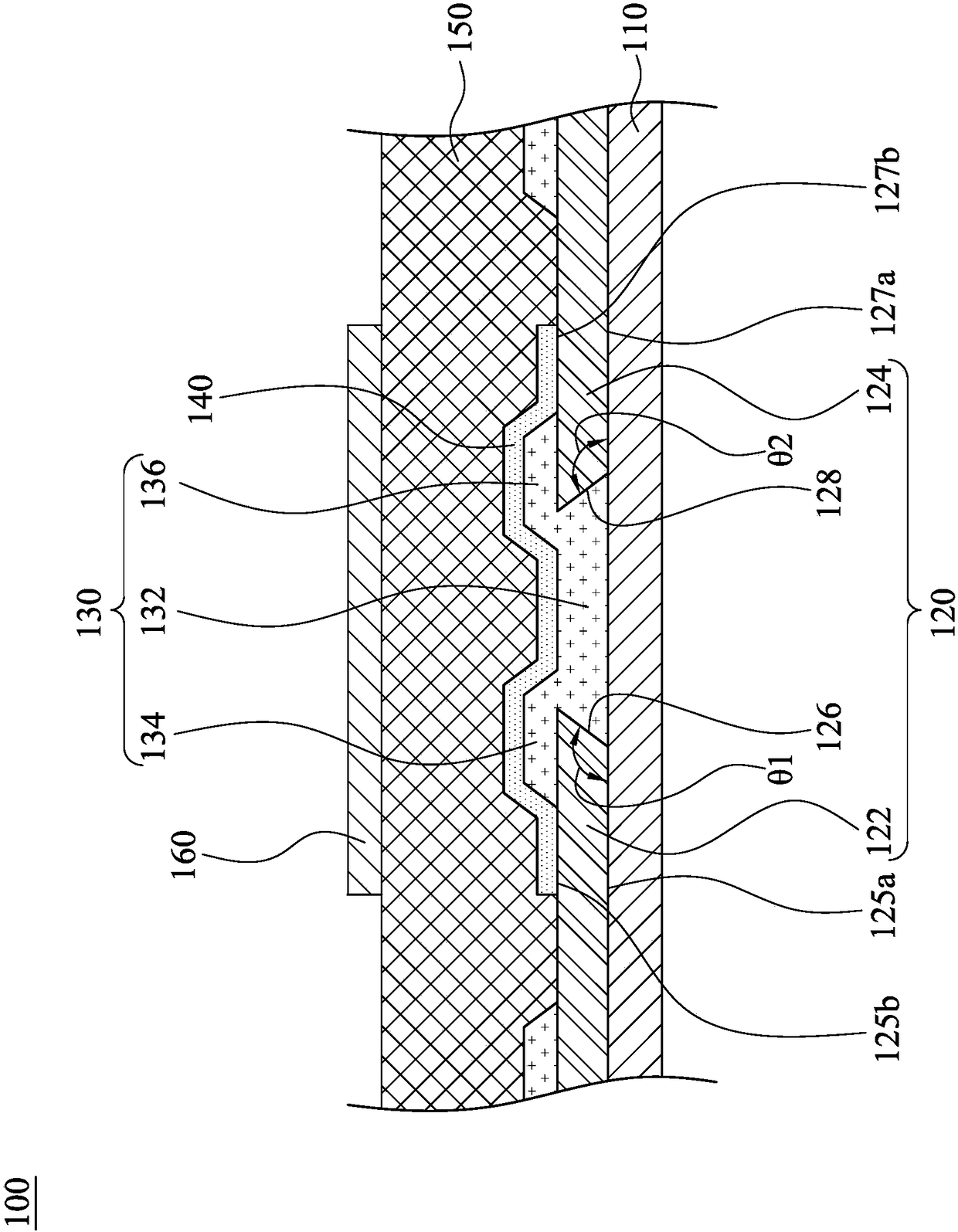

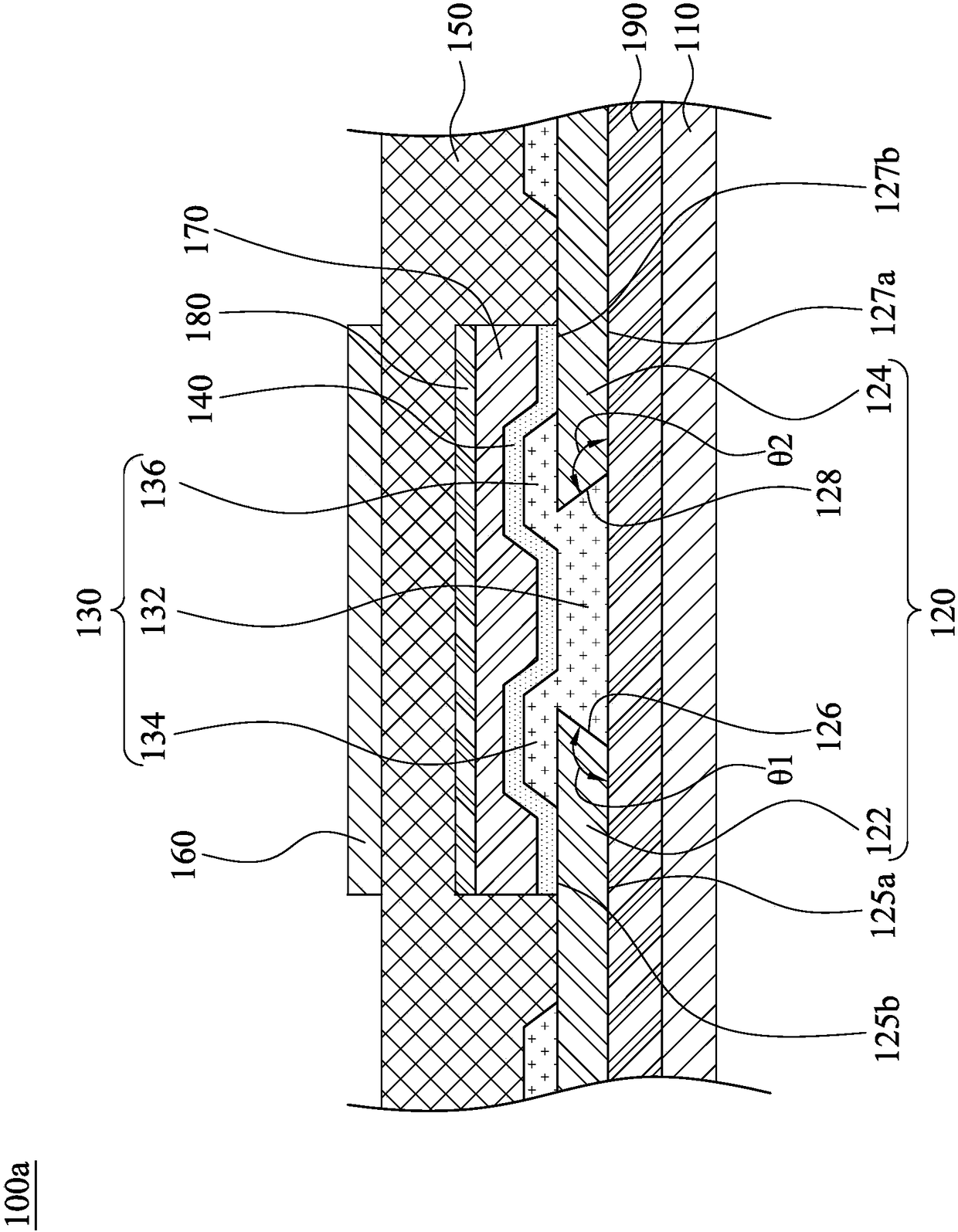

Thin film transistor and method of manufacturing same

InactiveCN109378345AGuaranteed opening rateImprove stabilityTransistorSemiconductor/solid-state device manufacturingEngineeringOxide thin-film transistor

The embodiment of the present application discloses a thin film transistor and a method of manufacturing the same. In the thin film transistor, a gate layer, a gate insulating layer, a semiconductor layer, a source layer, a drain layer, and a passivation layer are sequentially formed on a substrate; the passivation layer is formed on the gate insulating layer, the source layer, the drain layer, and the semiconductor layer of a channel region, wherein the passivation layer corresponding to the channel region has a concave-convex surface, and in the above manner, the aperture ratio can be ensured, the light that is irradiated onto the channel region of the semiconductor layer of the thin film transistor can be reduced, which is advantageous for improving the stability of the thin film transistor.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method of ceramic substrate for medium-free copper-coated gold-deposited light-emitting diode (LED) package

InactiveCN105489713AChemical reaction stabilityImprove thermal conductivitySemiconductor devicesVulcanizationChemical reaction

The invention discloses a preparation method of a ceramic substrate for medium-free copper-cladding gold-deposited light-emitting diode (LED) package. The preparation method comprises the following steps of sintering a ceramic wafer, in which ceramic powder is subjected to die forming and then placed in an environment at 1,000-1,020 DEG C for sintering for 8 to 10 minutes to obtain the ceramic wafer; coating copper, in which copper is coated on the upper surface of the ceramic wafer by a vacuum mist plating method to form a copper foil; etching, in which the useless copper foil is corroded with dilute sulphuric acid according to a process flow diagram to reserve the useful copper foil as a circuit; depositing gold, in which gold liquid medicine passes through the substrate with the circuit already etched so that the gold is deposited on the copper foil to obtain a finished product. According to the preparation method, a medium-free copper cladding technique is adopted, and the excellent heat conduction performance of primary copper and ceramic is maintained; and the gold is deposited on the copper, the chemical reaction of the gold is stable, the vulcanization problem is effectively solved, and the electrical property of the product and the long-term maintenance rate of light refraction are further improved.

Owner:郭垣成

Preparation method of semiconductor structure

InactiveCN110060927APrevent oxidationAvoid lossSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor structure

The invention provides a preparation method of a semiconductor structure. The preparation method comprises the following steps of providing a semiconductor substrate, wherein an oxide layer is formedon at least a first part of the surface of the semiconductor substrate, and a photoresist layer is formed on at least the second part of the surface; removing the oxide layer with the partial thickness by wet etching so as to retain a residual oxide layer with a preset thickness; and removing the photoresist layer by dry etching. Due to the fact that the residual oxide layer with the preset thickness is still kept in the wet etching process, oxidation and loss of substrate silicon caused by direct exposure of the substrate silicon during dry etching can be prevented. According to the preparation method of the semiconductor structure, the oxide layer with the partial thickness is removed by wet etching, no other process steps need to be added or changed, and the electrical stability of thedevice can be improved on the premise that the cost is not increased.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Structure of semiconductor and manufacture process of semiconductor

ActiveCN103117297AImprove equivalent work function valueReduce NBTI (negative bias temperature instability) valueSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureFluorine containing

The invention discloses a structure of a semiconductor and a manufacture process of the semiconductor. The structure of the semiconductor comprises a substrate, a dielectric layer and a metal layer with fluorine contained, wherein the dielectric layer is located on the substrate, and the metal layer with the fluorine contained is located on the dielectric layer. In addition, further disclosed is the manufacture process of the semiconductor, and the manufacture process is capable of forming the structure of the semiconductor.

Owner:UNITED MICROELECTRONICS CORP

Display device and electronic equipment

PendingCN111710238AAvoid the risk of shortingImprove stabilityShielding materialsPrinted circuit aspectsMechanical engineeringDisplay device

The invention provides a display device and electronic equipment, and belongs to the technical field of display. The display device comprises a display panel, a main circuit board, a bridging circuitboard and a first shielding adhesive tape. Wherein the main circuit board is arranged on the back surface of the display panel; the bridging circuit board is arranged on one side, far away from the display panel, of the main circuit board and is in binding connection with the main circuit board; a first shielding adhesive tape is arranged on the side, away from the display panel, of the main circuit board and exposes the bridging circuit board. The display device can improve stability.

Owner:BOE TECH GRP CO LTD +1

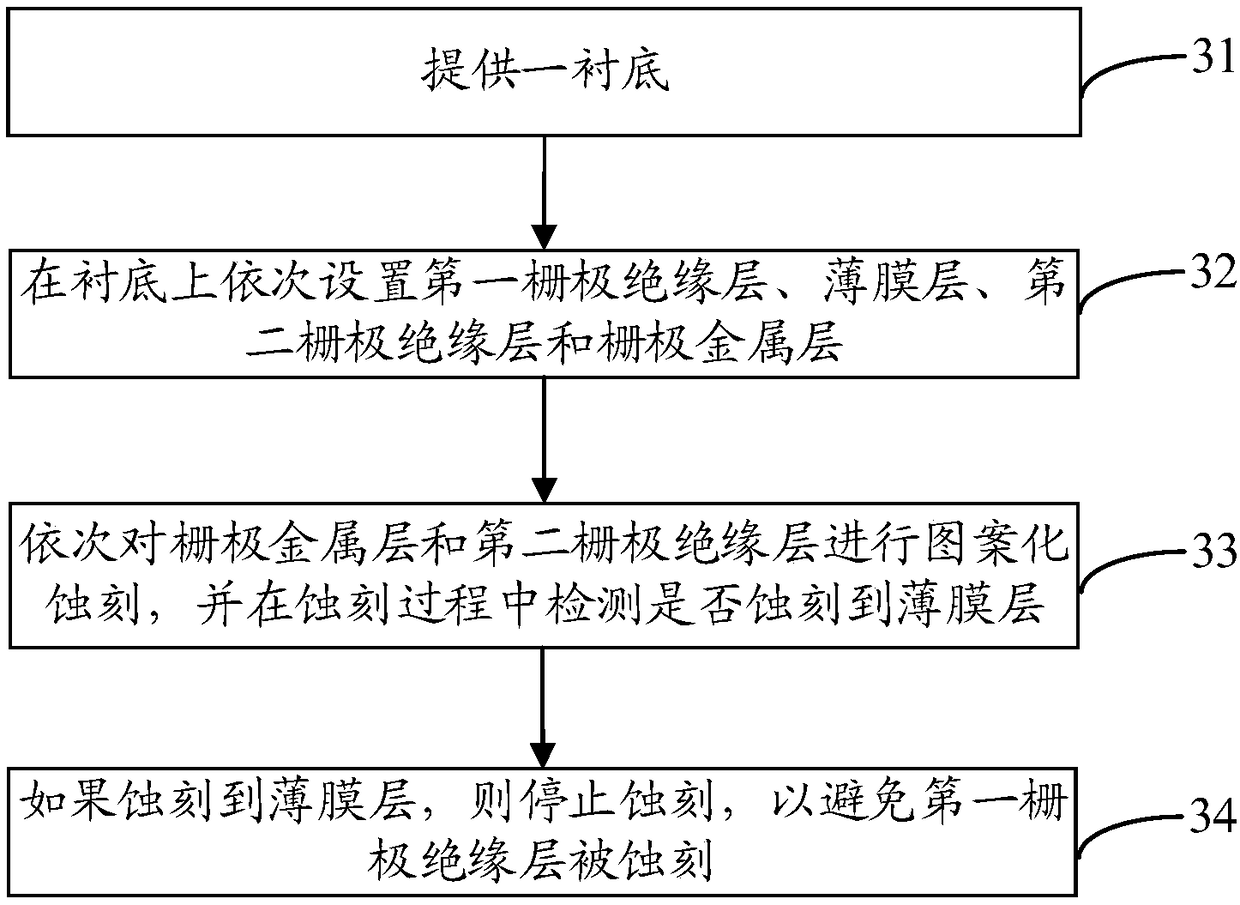

Manufacturing method of array substrate, array substrate and display panel

InactiveCN108807424AAvoid etchingLeave a performance guaranteeSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerOptoelectronics

The invention discloses a manufacturing method of an array substrate, the array substrate and a display panel. The method comprises steps as follows: providing a substrate; sequentially arranging a first gate insulation layer, a film layer, a second gate insulation layer and a gate metal layer on the substrate; sequentially performing pattern etching on the gate metal layer and the second gate insulation layer, and detecting whether the film layer is etched in the etching process; if the film layer is etched, stopping etching to prevent the first gate insulation layer from being etched, wherein the material of the film layer is different from that of the second gate insulation layer. With the adoption of the scheme, the ion implantation uniformity can be improved, and the electric stability can be enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

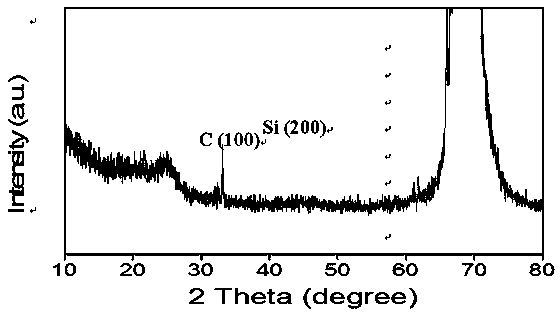

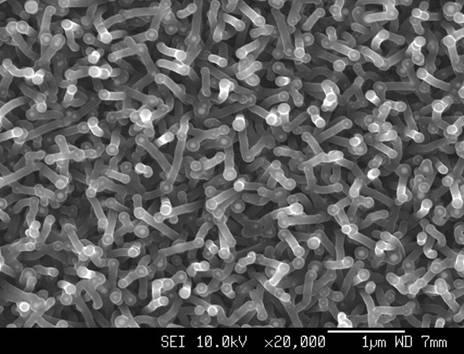

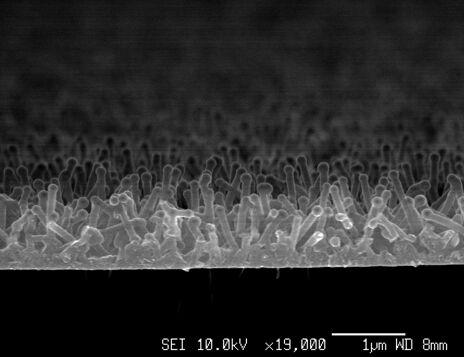

Processing method of flexible vibration sensor for monitoring Parkinson syndrome

ActiveCN111150368AReduce power consumptionImprove stabilityDiagnostic recording/measuringSensorsMedicineEngineering

The invention discloses a processing method of a flexible vibration sensor for monitoring Parkinson syndrome. The processing method includes the following steps of spin-coating photoresist, exposure,development, evaporation Ni film, removing glue and cleaning, growing CA self-crosslinking array, transferring to flexible substrate, clean and stripping, and sensor production. The flexible vibrationsensor produced by the processing method has the advantages of low power consumption, high stability and high sensitivity, so that the flexible vibration sensor has huge application potential in wearable health monitoring and has great potential in the direction of manufacturing low-cost and durable flexible sensors.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for preparing flexible electron and flexible electron

ActiveCN113840471ASimple manufacturing processImprove fill rateFinal product manufactureCircuit metal processingManufacturing technologyLiquid state

The invention provides a method for preparing a flexible electron. The method comprises the following steps: S1, pouring liquid GaIn liquid metal or liquid GaInSn liquid metal into a silicone tube by using a negative pressure method; s2, the silicone tube filled with the liquid metal is stored in a low-temperature environment until the liquid metal is crystallized and solidified; s3, the crystallized and solidified liquid metal is taken out of the silicone tube, and a metal wire is obtained; s4, constructing a circuit pattern by using metal wires to obtain a target circuit; s5, using liquid silica gel to package the target circuit; and S6, after the liquid silica gel is cured, heating is carried out, so that the solid metal wires are molten into liquid, and the flexible electron is obtained. The invention also provides a flexible electronic equipment. The method has the beneficial effects that the manufacturing process for preparing the flexible electronics from the liquid metal can be simplified, the yield is improved, and the cost is reduced.

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

Semiconductor structure and its fabrication process

ActiveCN103117297BImprove equivalent work function valueImprove the stability of electrical propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureFluorine containing

The invention discloses a semiconductor structure and its manufacturing process. The semiconductor structure includes a base, a dielectric layer and a fluorine-containing metal layer. The dielectric layer is on the substrate. A fluorine-containing metal layer is on the dielectric layer. In addition, the present invention also provides a semiconductor manufacturing process, which can form the aforementioned semiconductor structure.

Owner:UNITED MICROELECTRONICS CORP

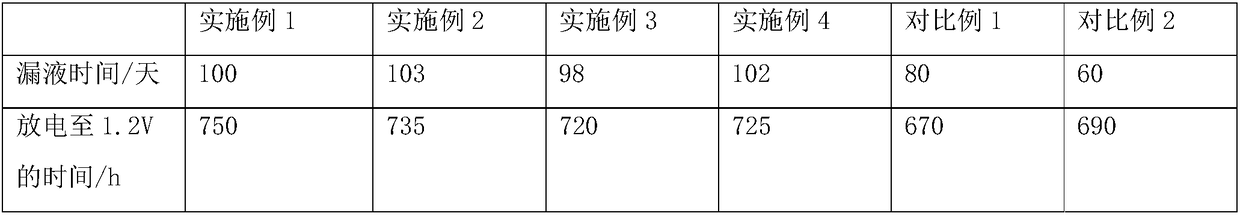

A kind of mercury-free silver oxide button battery and its preparation method

ActiveCN106025223BReduce expansionLong storage timePrimary cell manufactureCell electrodesIndium(III) hydroxidePowder mixture

Owner:东莞市天球实业有限公司

Conductive carbon paste for flexible pressure sensor, preparation method thereof, and pressure sensor

ActiveCN112254850BIncreased sensitivityImprove stabilityForce measurementMaterial strength using steady bending forcesPlasticizerGraphene flake

Owner:SU ZHOU CSTAR MATERIAL TECH CO LTD

Method for improving gap filling capability

InactiveCN103426723AReduce aspect ratioImproved void filling capabilitySemiconductor/solid-state device manufacturingEtchingEconomic benefits

The invention relates to a method for improving a gap filling capability. The method comprises the following steps: step one, carrying out etching to form a spacer region having a certain depth-to-width ratio; step two, carrying out secondary etching on the spacer region; and step three, carrying out corresponding filling on the spacer region according to the requirement of the method. According to the method, primary and secondary etching or acid pickling processes are added based on the traditional method; the depth-to-width ratio of the spacer region is reduced; and the gap filling capability during the chip manufacturing is enhanced. The possibility of hole occurrence during the filling process is reduced with the enhancement of the gap filling capability, so that the possibility of occurrence of problems of short circuit and the like due to the hole existence is also reduced; and hence, the electrical stability of the chip is enhanced, thereby improving the yield of the finished chip and the economic benefits.

Owner:HEJIAN TECH SUZHOU

Organic thin film transistor

ActiveCN108878650AIncreasing the thicknessUniform thicknessSolid-state devicesSemiconductor/solid-state device manufacturingElectrical stabilitySemiconductor

Owner:E INK HLDG INC

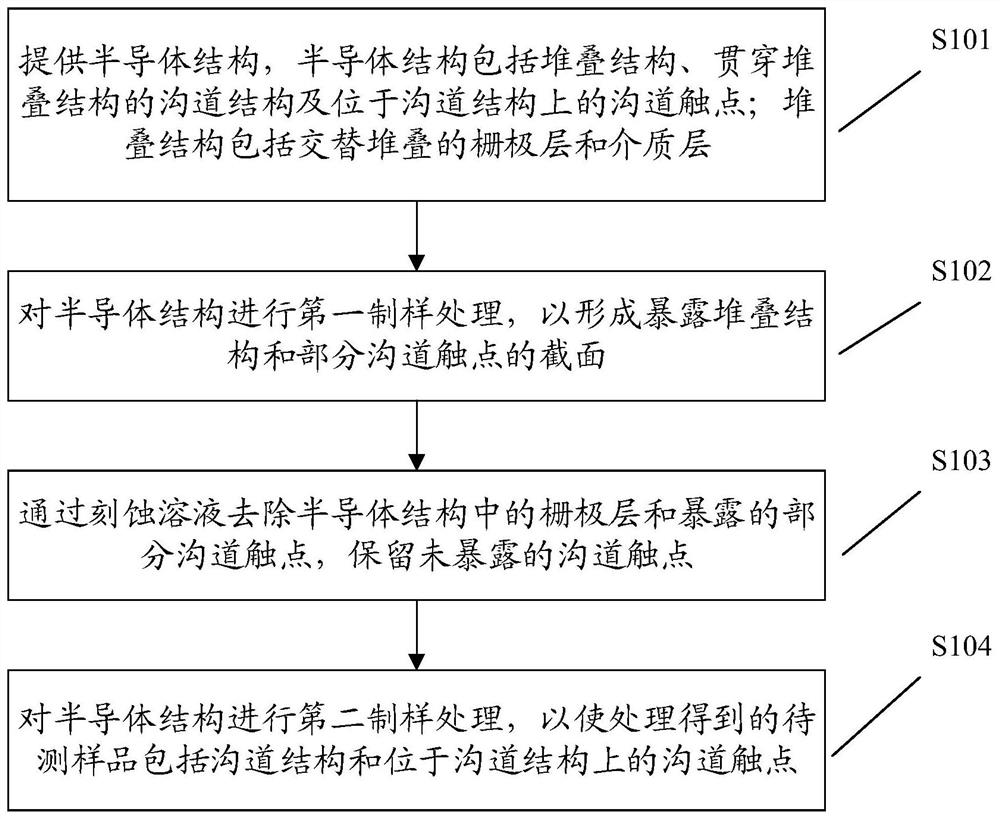

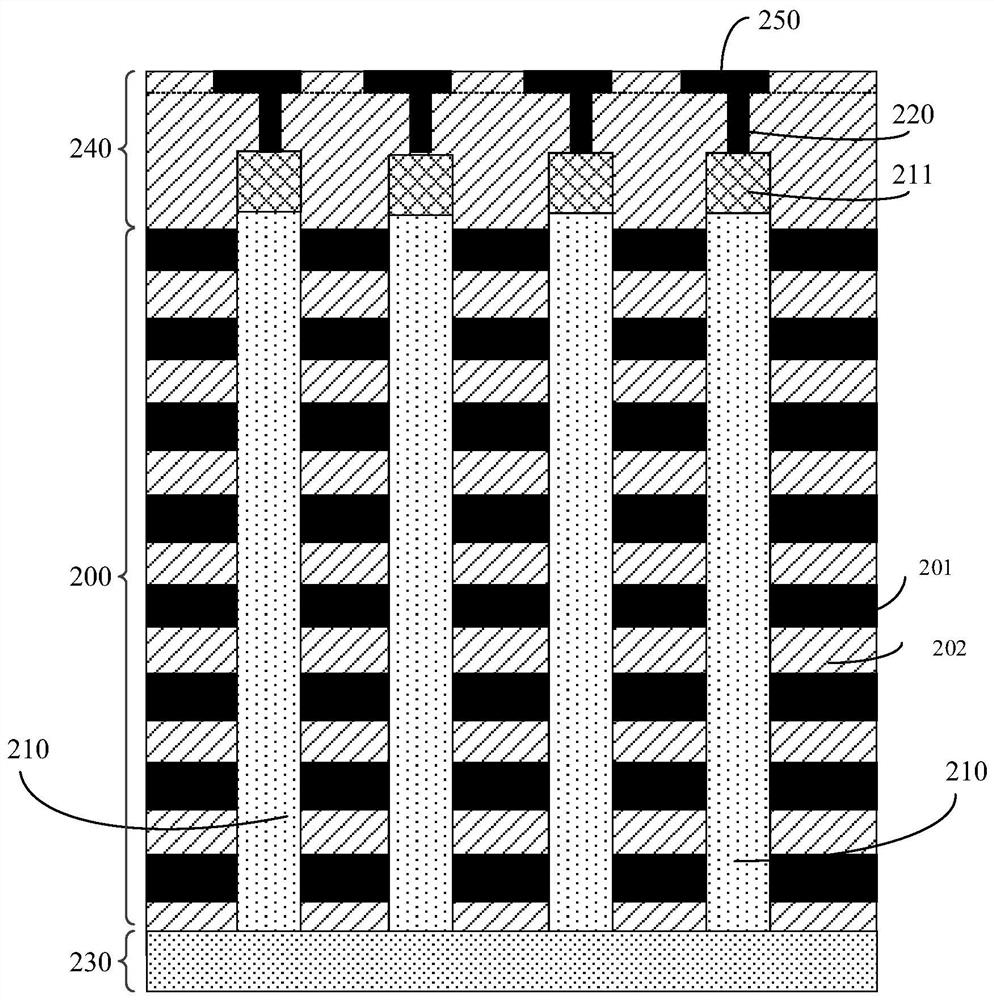

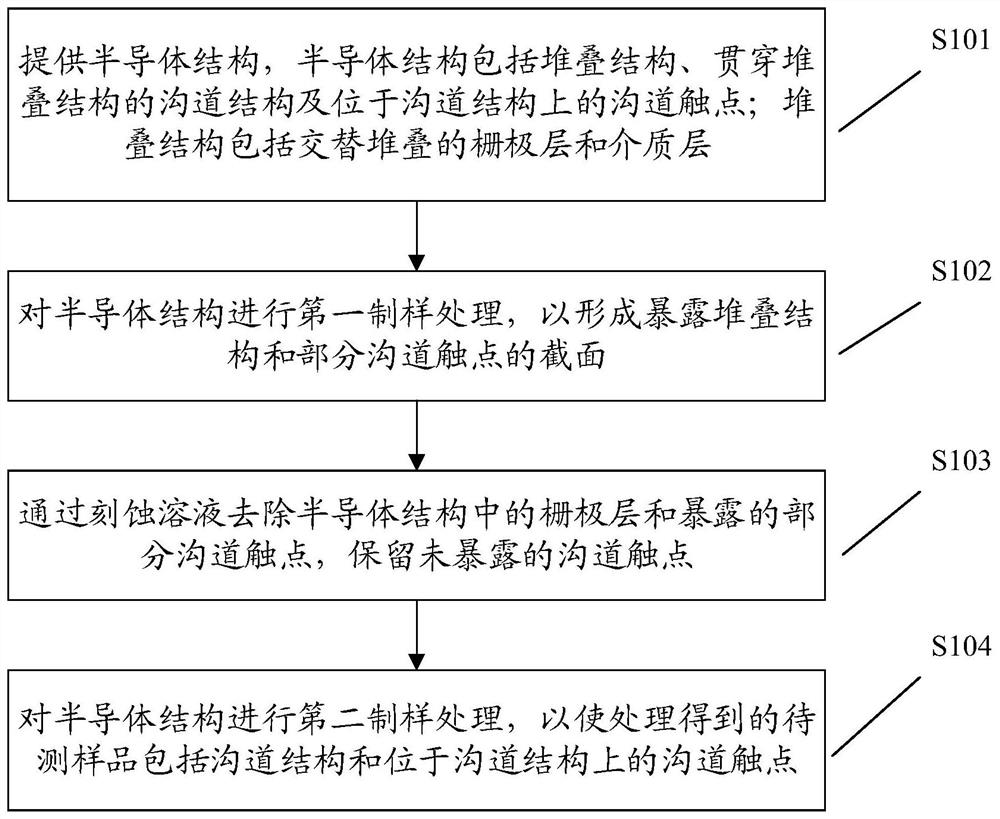

Sample preparation method

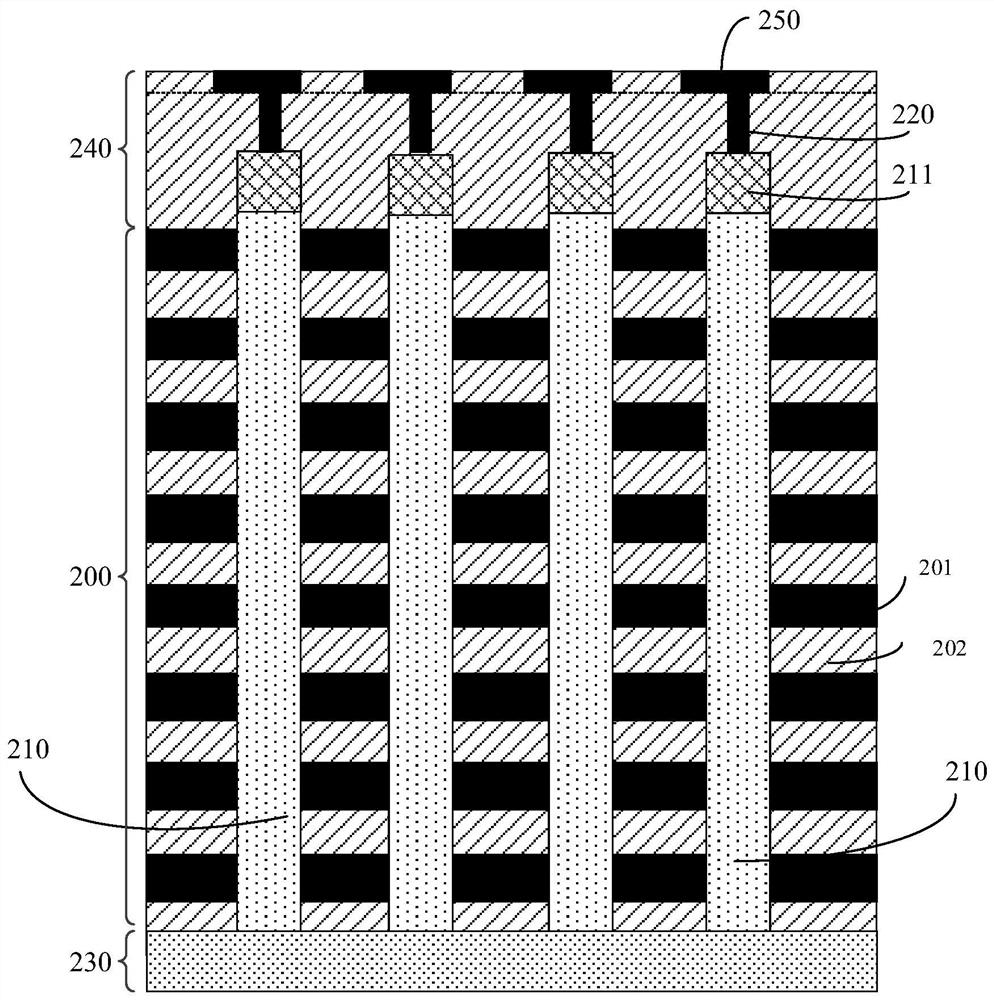

ActiveCN113314542AImprove the stability of electrical propertiesMeet the requirements of electrical testingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor structureTest sample

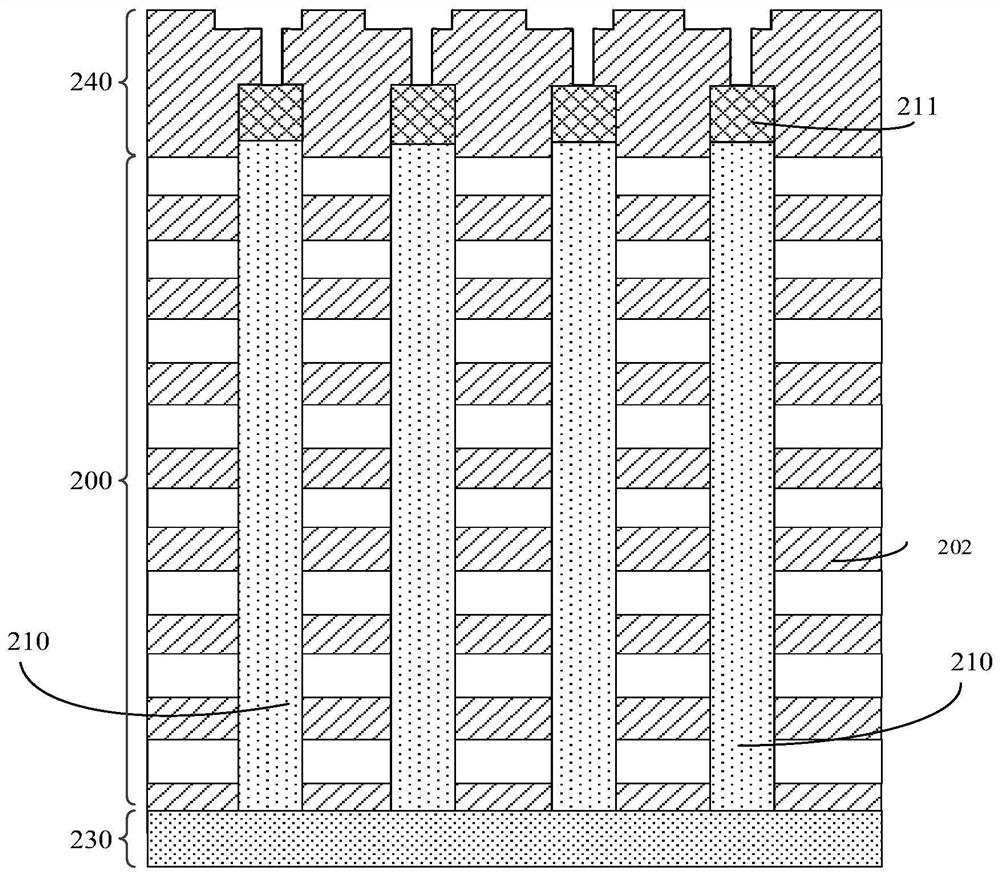

The invention discloses a sample preparation method, and the method comprises the steps: providing a semiconductor structure which comprises a stacking structure, a channel structure penetrating through the stacking structure, and a channel contact located on the channel structure, wherein the stacked structure comprises gate layers and dielectric layers which are alternately stacked; performing first sample preparation processing on the semiconductor structure to form a cross section exposing the stack structure and a part of the channel contact; removing the gate layer in the semiconductor structure and the exposed part of the channel contact through an etching solution, and reserving the unexposed channel contact; and carrying out second sample preparation treatment on the semiconductor structure, so that a to-be-tested sample obtained through treatment comprises the channel structure and the channel contact located on the channel structure.

Owner:YANGTZE MEMORY TECH CO LTD

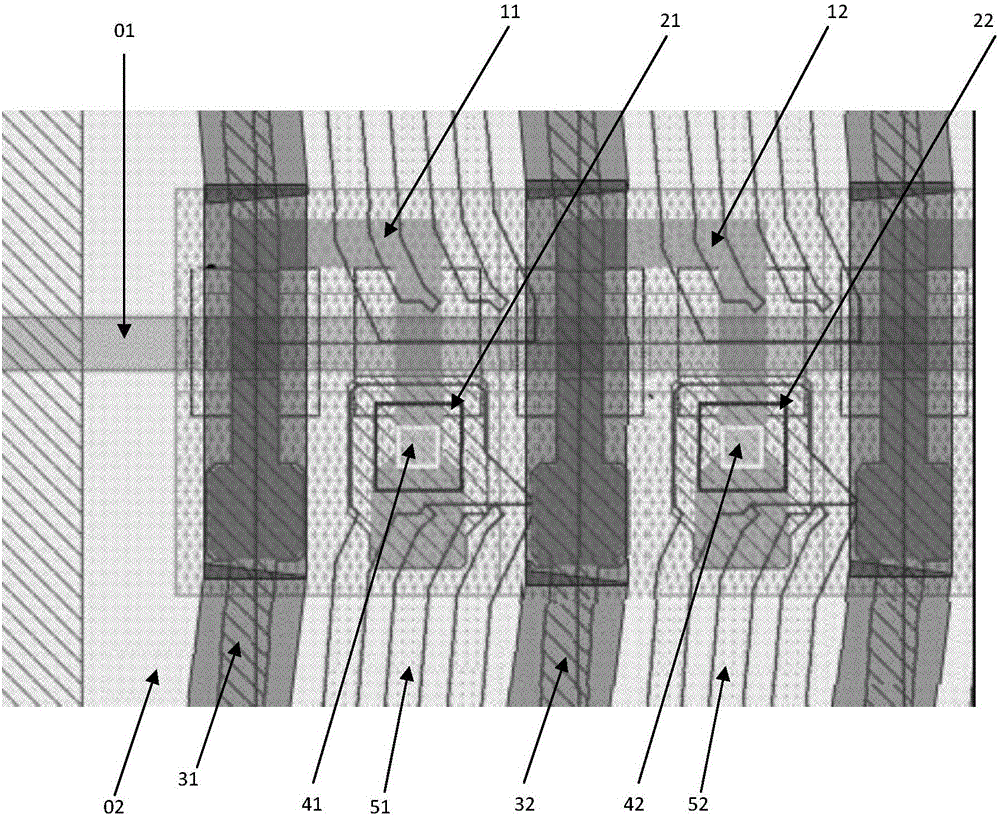

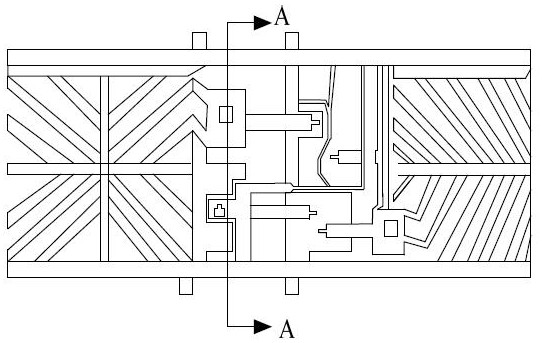

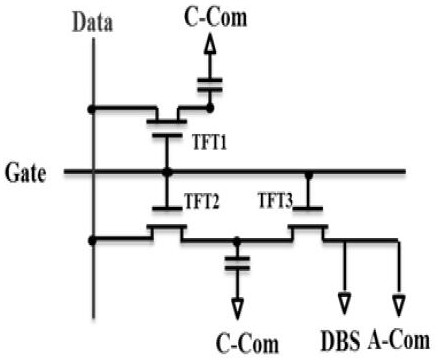

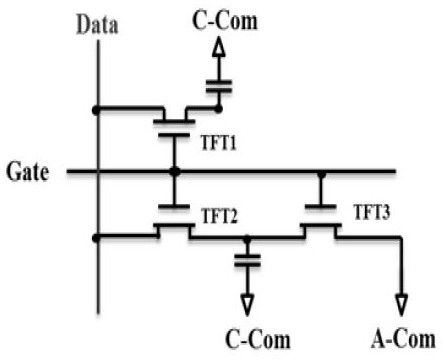

A kind of array substrate and display panel

ActiveCN109298574BReduce longitudinal span lap lengthReduces the risk of disconnection of cross-wire connectionsSolid-state devicesNon-linear opticsScan lineAperture ratio

The present invention provides an array substrate and a display panel, wherein the array substrate includes: a plurality of scanning lines and a plurality of data lines respectively intersecting the plurality of scanning lines to define a plurality of pixel units; each pixel unit It includes a master pixel area and a slave pixel area, and the slave pixel unit includes a slave pixel electrode; a plurality of DBS electrode lines are arranged above the plurality of data lines; For the shared thin film transistor, the gate of the shared thin film transistor is connected to the corresponding scanning line, the source of the shared thin film transistor is connected to the slave pixel electrode, and the drain of the shared thin film transistor is connected to the corresponding DBS electrode line. The present invention removes the deep hole connection between the source or drain of the shared thin film transistor and the A-com common electrode in the prior art, increases the area of the display area of the product, increases the aperture ratio, and thus improves the electrical properties of the 3T structure design stability.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

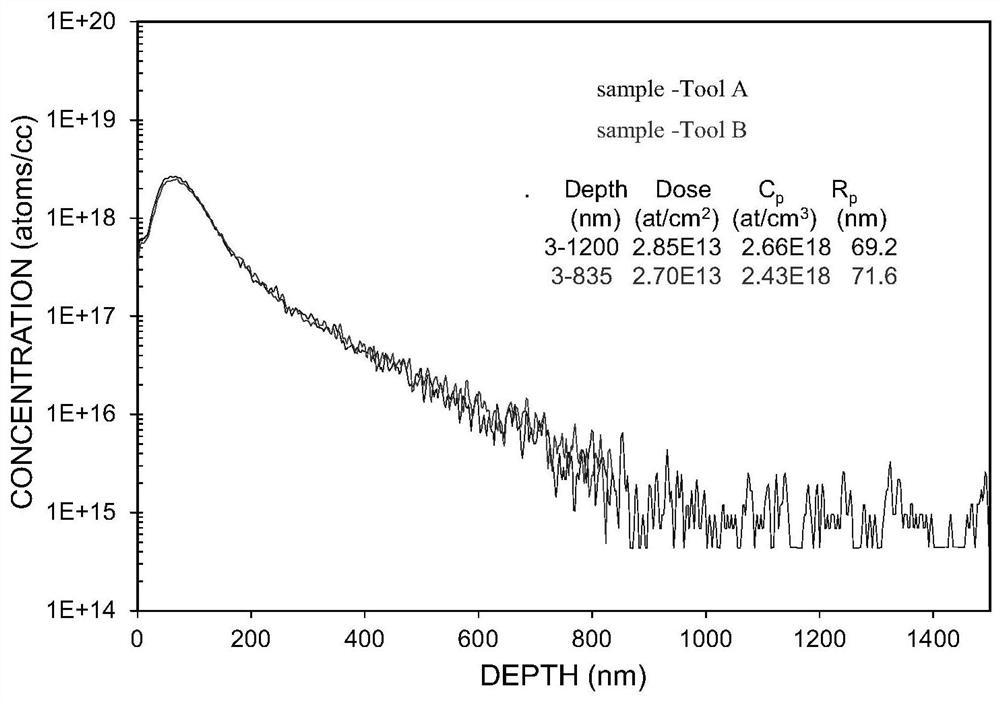

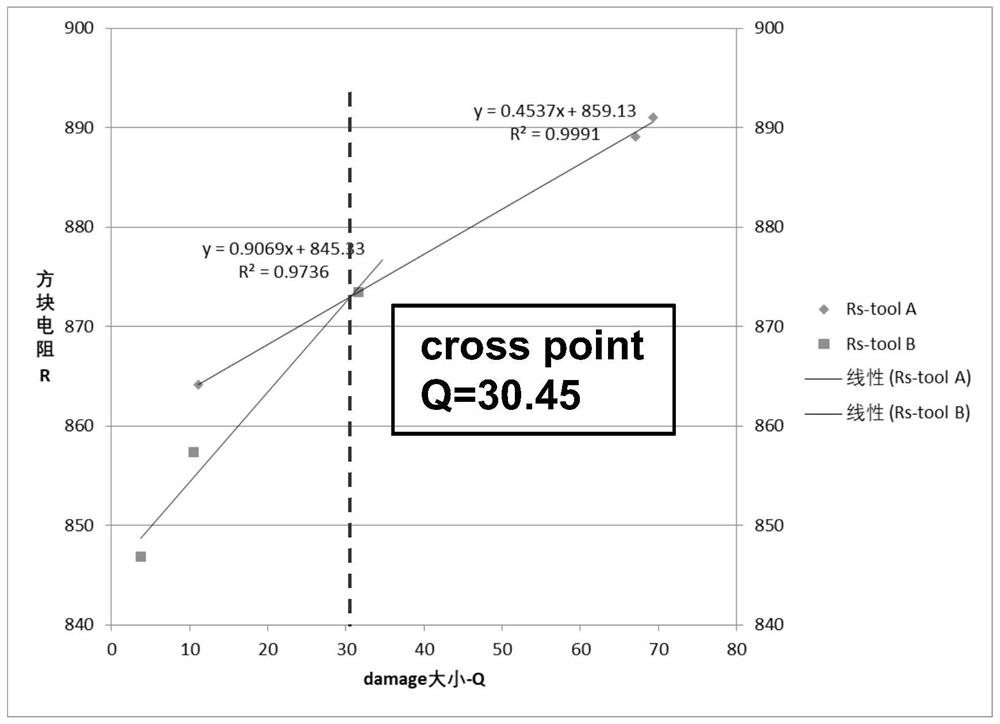

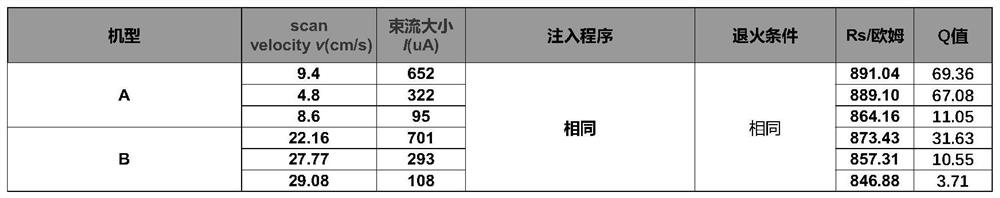

Method for improving precision of ion implantation machine

ActiveCN112687509AHigh precisionImprove the stability of electrical propertiesElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringComputational physics

The invention provides a method for improving the precision of an ion implantation machine. The method comprises the following steps: carrying out a square resistance Rs test by utilizing a reference machine; performing a square resistance sensitivity test on a verified machine; testing a square resistance difference value between the reference machine table and the verified machine under the same test condition, and matching the square resistance Rs of the verified machine with the square resistance Rs of the reference machine by performing dosage fine adjustment of ion implantation on the verified machine; defining a relative damage degree Q of ion implantation, obtaining a curve that the square resistance Rs value changes along with Q according to the relationship between the Q values of the reference machine and the verified machine and the square resistance Rs, and calculating the Rs and Q values corresponding to the intersection point of the curve; finely adjusting test conditions of the reference machine and the verified machine to obtain injection programs corresponding to curve intersection points Rs and Q values; and verifying whether the secondary ion mass spectrum SIMS results of the reference machine and the verified machine are matched or not by utilizing secondary ion mass spectrum analysis.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

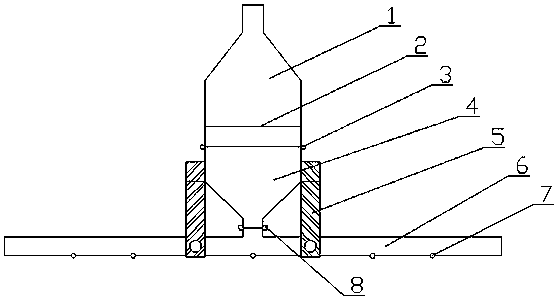

Coating machine head sieving device

InactiveCN108295532AHigh thickness consistencyQuality assuranceLiquid surface applicatorsCoatingsElectrical performanceEngineering

The invention discloses a coating machine head sieving device which includes an upper funnel (1), a lower funnel (4) and a flow divider (6). The coating machine head sieving device is characterized inthat the large opening ends of both the upper funnel (1) and the lower funnel (4) are in buckled connection, a screen cloth (2) is mounted at the bottom of the upper funnel (1), the lower funnel (4)is fixed in a fixing support (5), the bottom of the lower funnel (4) is connected with the flow divider (6), the bottom of the flow divider (6) is provided with a plurality of flow dividing holes (7),the upper funnel (1) and the lower funnel (4) are in symmetric connection through a connecting ring A (3), the lower funnel (4) is connected with the flow divider (6) through a connecting ring B (8),the periphery of the screen cloth (2) is sealed through a seal ring, and the flow dividing holes (7) are evenly formed at the bottom of the flow divider (6). The coating machine head sieving device is excellent, safe, economical, efficient and convenient to operate, the battery coating uniformity is high, the electrical performance stability is high, and the coating machine head sieving device issuitable for popularization and use of the screening in the position of a trough feeding pipe of a lithium ion battery coating machine head.

Owner:贵州贵航新能源科技有限公司

A kind of adhesive for electronic paper suitable for low temperature use, preparation method and application

ActiveCN104073210BImprove the stability of electrical propertiesHigh volume resistivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterElectricity

The invention provides an adhesive applicable to low temperature and used for electronic paper. The adhesive comprises a waterborne polyurethane emulsion which is prepared from diisocyanate, polyester polyol with number-average molecular weight of 300 to 3000, polyether polyol with number-average molecular weight of 400 to 3000, a chain extender and a salt forming agent through polymerization, emulsification and dispersion. The invention also provides a preparation method for the adhesive and application of the adhesive in an electrophoretic display apparatus. The electrical properties of the adhesive for the electronic paper have small fluctuation with changes of temperature, and volume resistivity of the adhesive at about 0 DEG C changes a little compared with volume resistivity of the adhesive at normal temperature. The adhesive for the electronic paper can be used as a lamination adhesive in the electrophoretic display apparatus, enables the contrast of the electrophoretic display apparatus to be maintained in a good range when the electrophoretic display apparatus is used at a low temperature (about 0 DEG C) and improves adaptability of the electrophoretic display apparatus to the environment.

Owner:GUANGZHOU OED TECH INC

A kind of sample preparation method

ActiveCN113314542BImprove the stability of electrical propertiesMeet the requirements of electrical testingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor structureDielectric layer

The present application discloses a method for preparing a sample, the method comprising: providing a semiconductor structure, the semiconductor structure including a stack structure, a channel structure penetrating the stack structure, and a channel contact on the channel structure; The stacked structure includes alternately stacked gate layers and dielectric layers; a first sample preparation process is performed on the semiconductor structure to form a cross section that exposes the stacked structure and a part of the channel contact; removed by an etching solution the gate layer and the exposed part of the channel contacts in the semiconductor structure, leaving the unexposed channel contacts; and performing a second sample preparation process on the semiconductor structure, so that the processed A sample includes the channel structure and the channel contact on the channel structure.

Owner:YANGTZE MEMORY TECH CO LTD

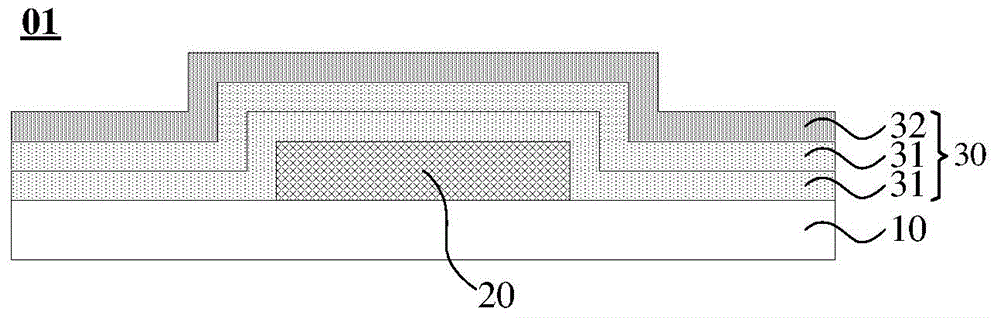

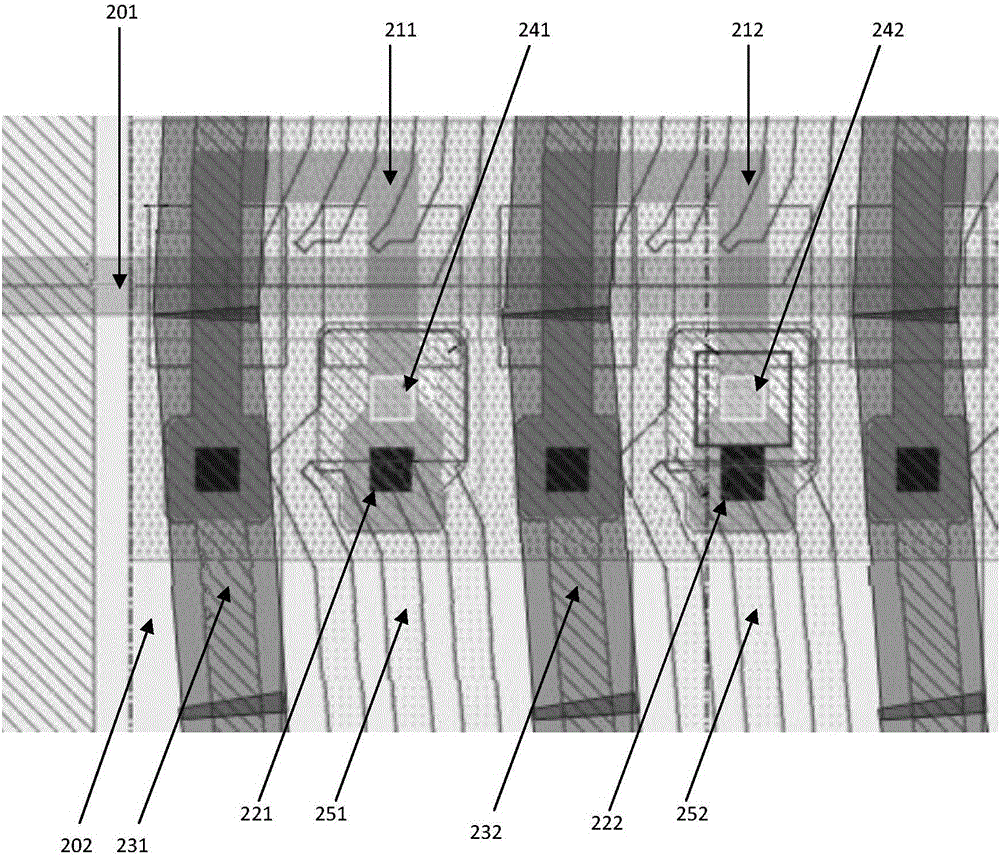

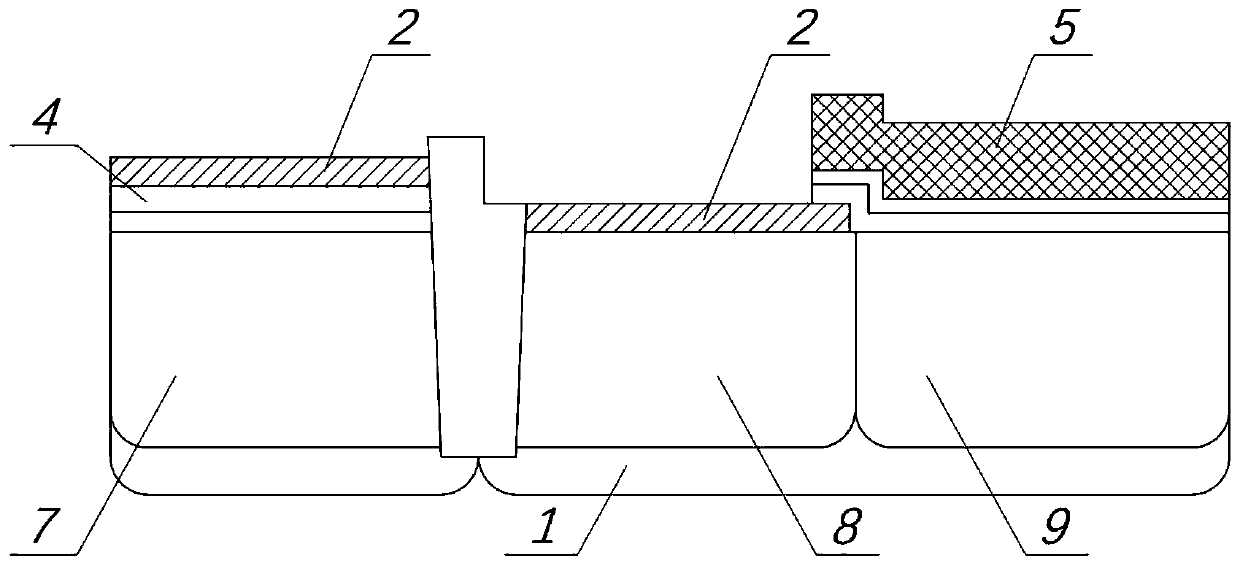

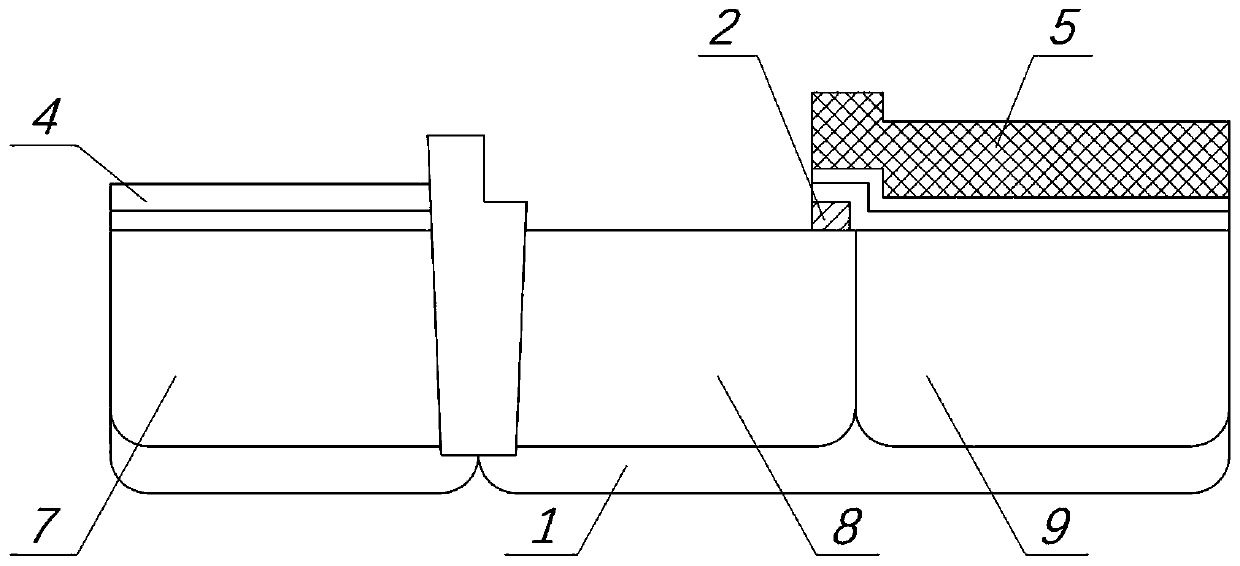

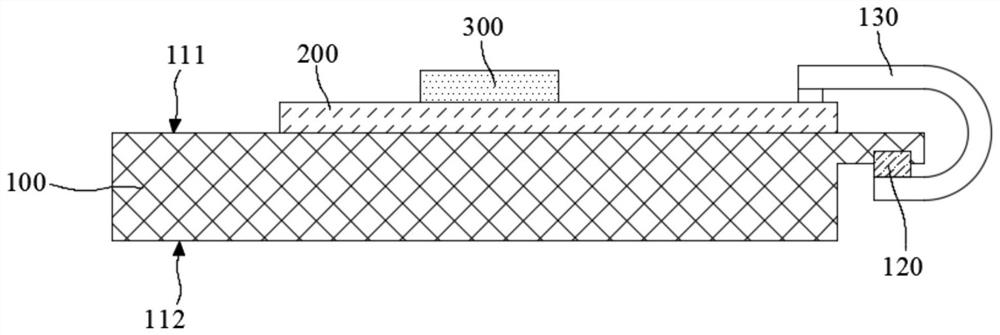

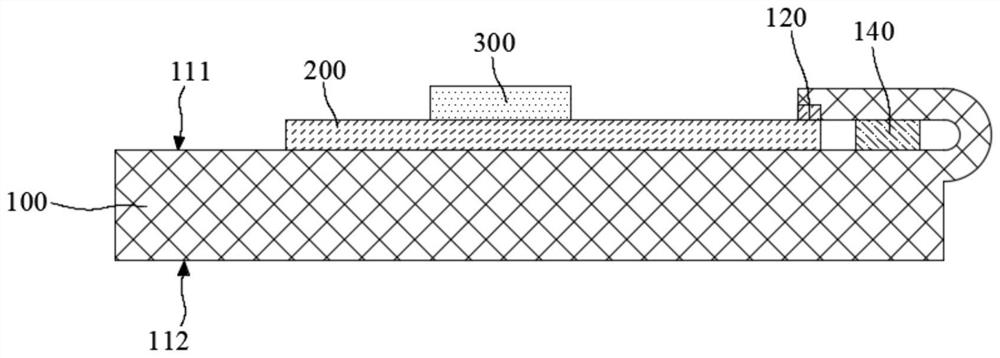

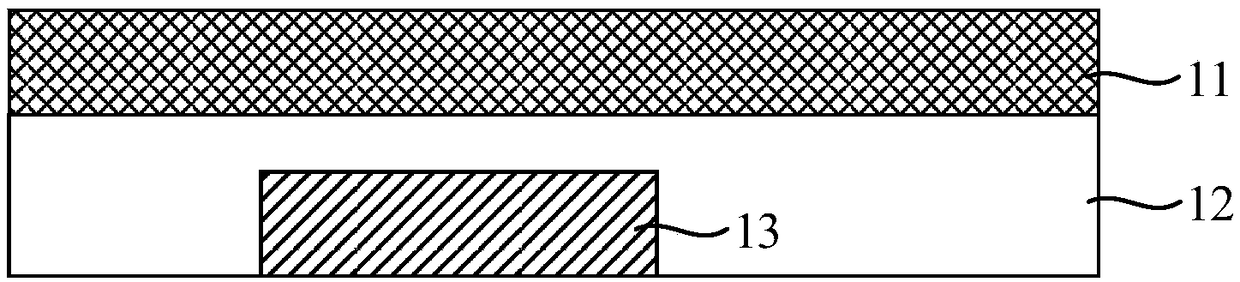

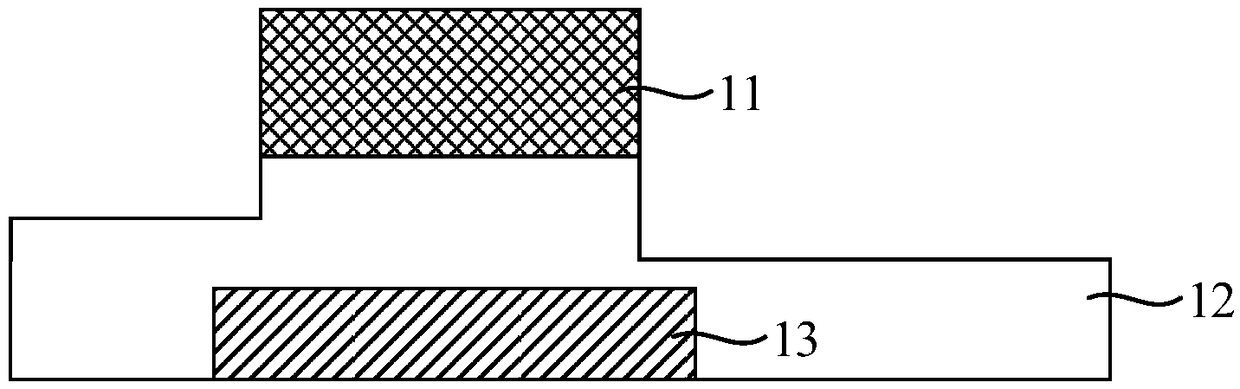

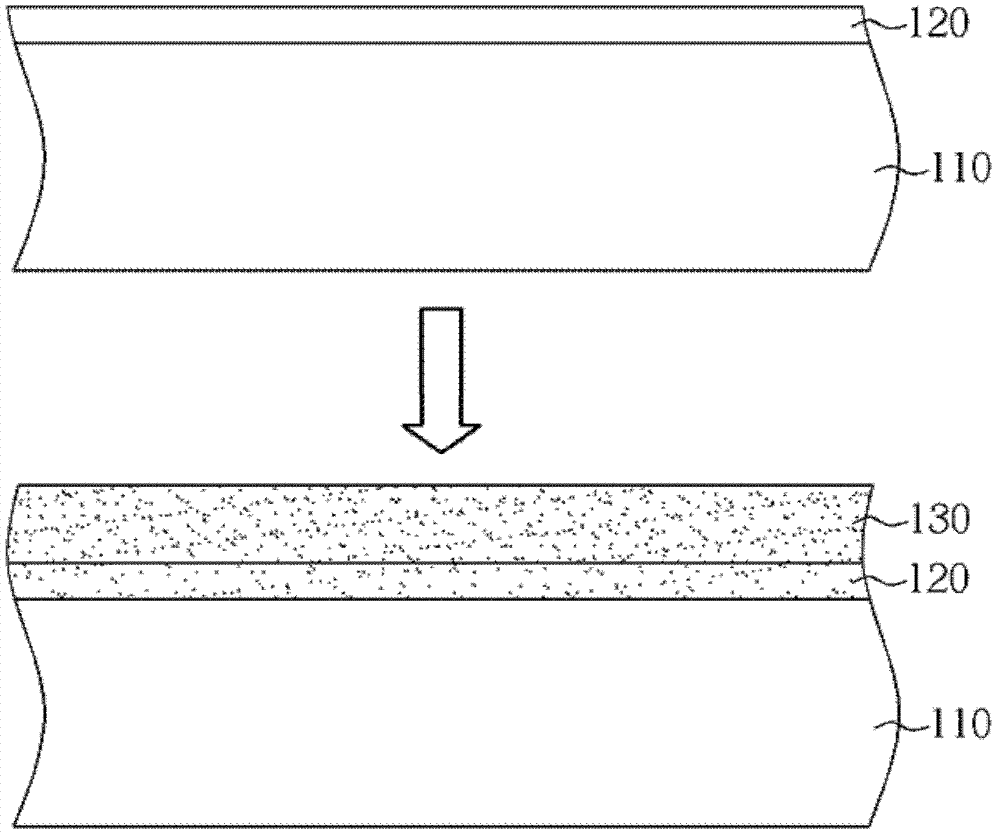

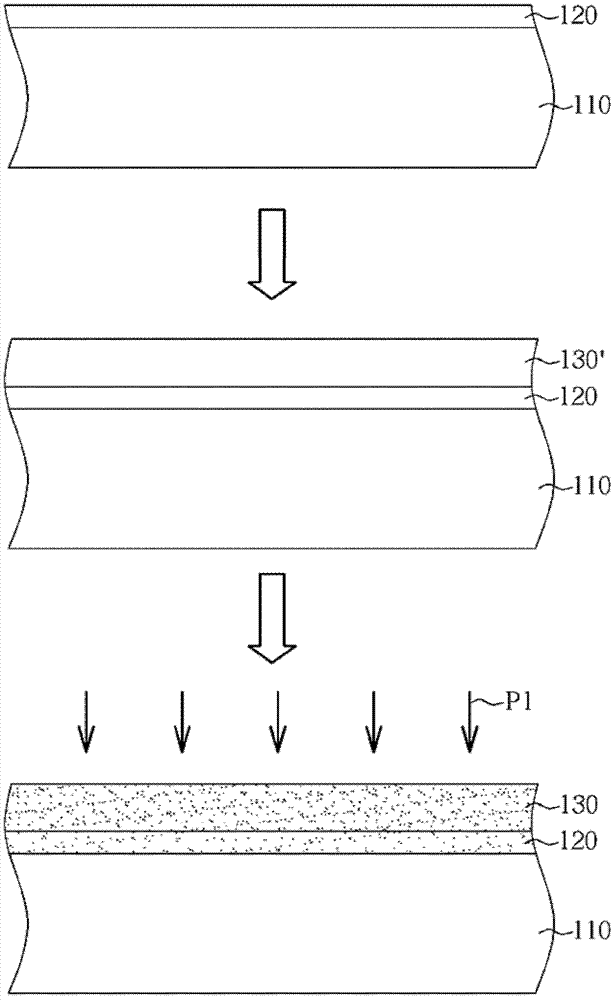

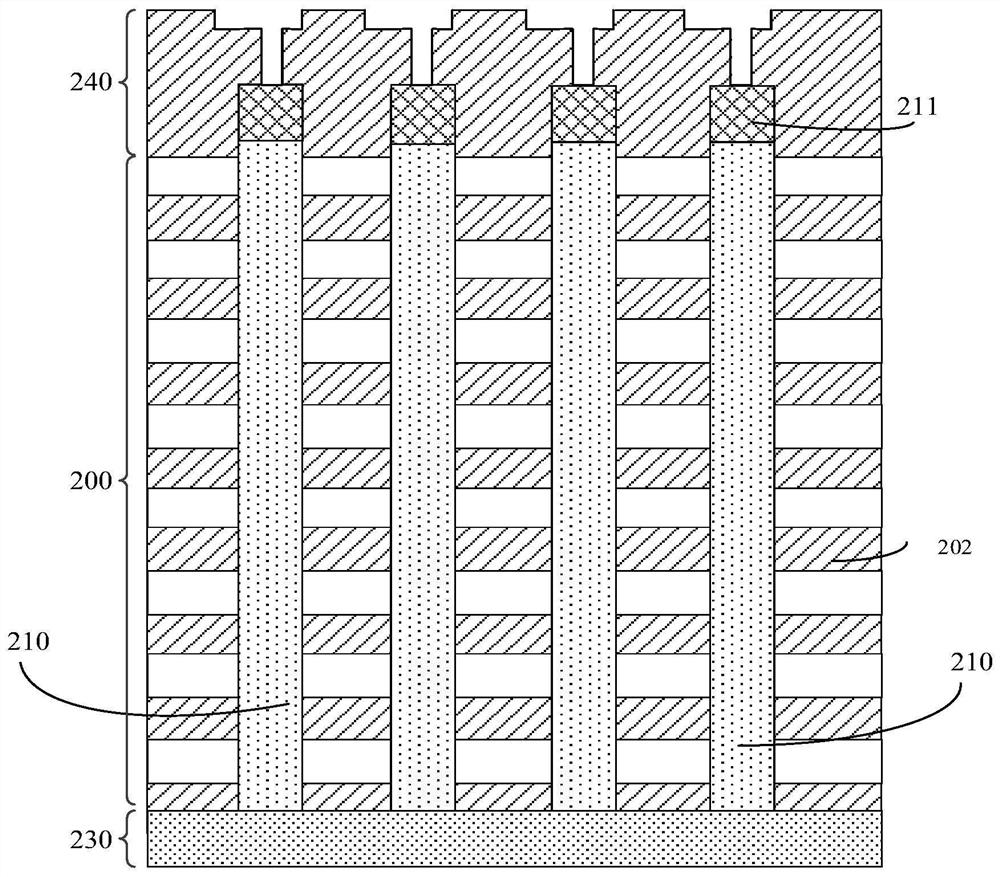

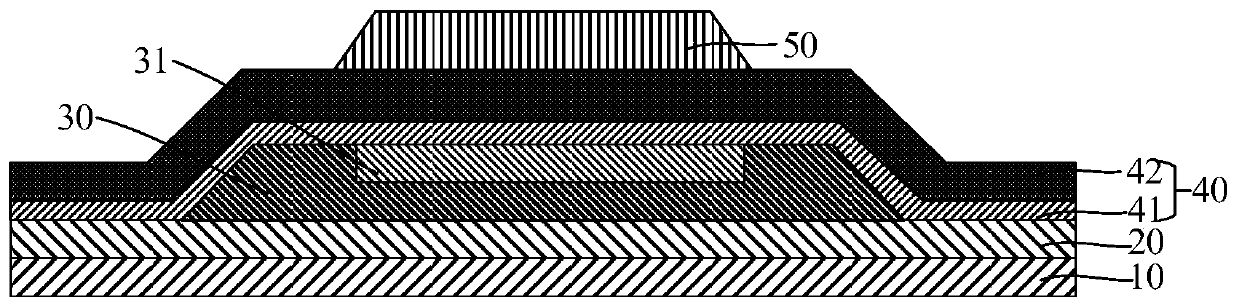

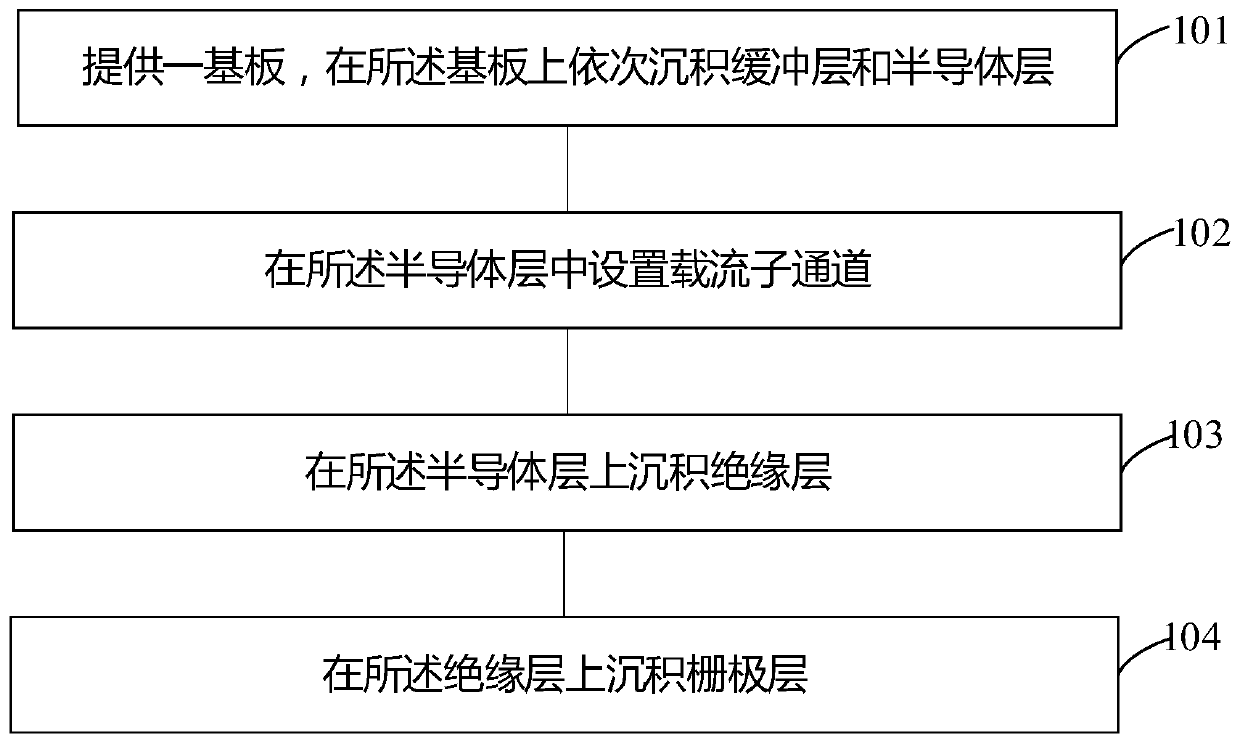

Array substrate and manufacturing method of the array substrate

InactiveCN109817724AImprove the stability of electrical propertiesEnsure stabilityTransistorSolid-state devicesElectrical stabilitySemiconductor

The embodiment of the invention discloses an array substrate and a manufacturing method of the array substrate. The array substrate comprises a substrate, a buffer layer, a semiconductor layer, an insulating layer and a grid layer. The buffer layer is arranged on the substrate; the semiconductor layer is arranged on the buffer layer; the insulating layer covers the buffer layer and the semiconductor layer; the grid electrode layer is arranged on the insulating layer; the semiconductor layer comprises a current carrier channel; the carrier channel is located on one side, facing the insulating layer, of the semiconductor layer; the insulating layer comprises a first thin film layer and a second thin film layer; the first thin film layer covers the semiconductor layer and the buffer layer; the second thin film layer covers the first thin film layer; the grid electrode layer is located on the second thin film layer; the density of the first thin film layer is larger than that of the secondthin film layer; and the carrier channel is connected with the first thin film layer. According to the scheme, the electrical stability of the array substrate can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

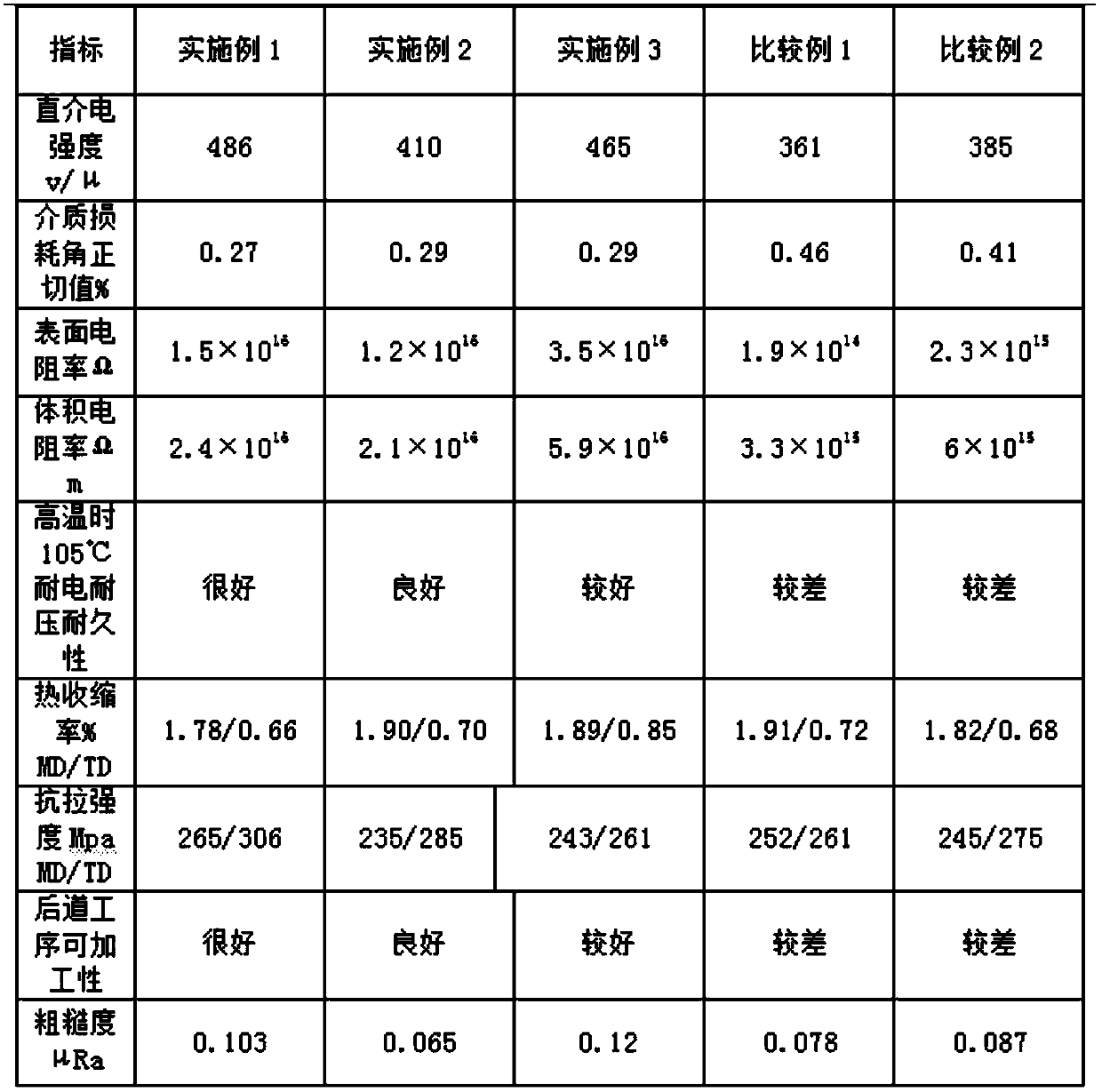

Biaxially stretched polyester film with stable electrical properties and preparation method thereof

The invention discloses a BOPET (biaxially-oriented polyethylene terephthalate) film with stable electrical performance and a preparation method of BOPET film. The BOPET film is prepared from super-bright PET chips containing magnesium acetate, high-concentration nanoscale silicon oxide PET chips and low-concentration silicon oxide PET chips through mixing in a certain ratio, drying, extrusion, filtering, metering, refiltering, film casting, longitudinal drawing, horizontal drawing, hot setting, winding and cutting. Under the condition of thickness guarantee, the BOPET film has higher tensile strength, excellent temperature resistance, stable electrical performance and good workability in follow-up procedures, and is a substrate film applicable to electrical engineering such as capacitors, thermal insulation materials and the like.

Owner:ANHUI TONGAI ELECTRONICS MATERIAL

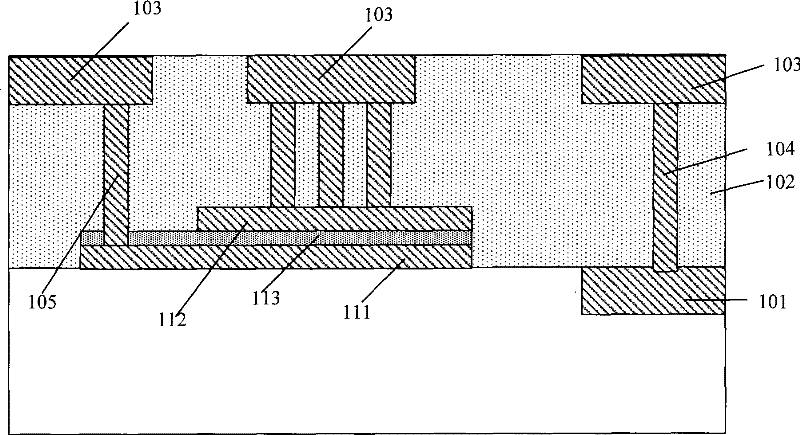

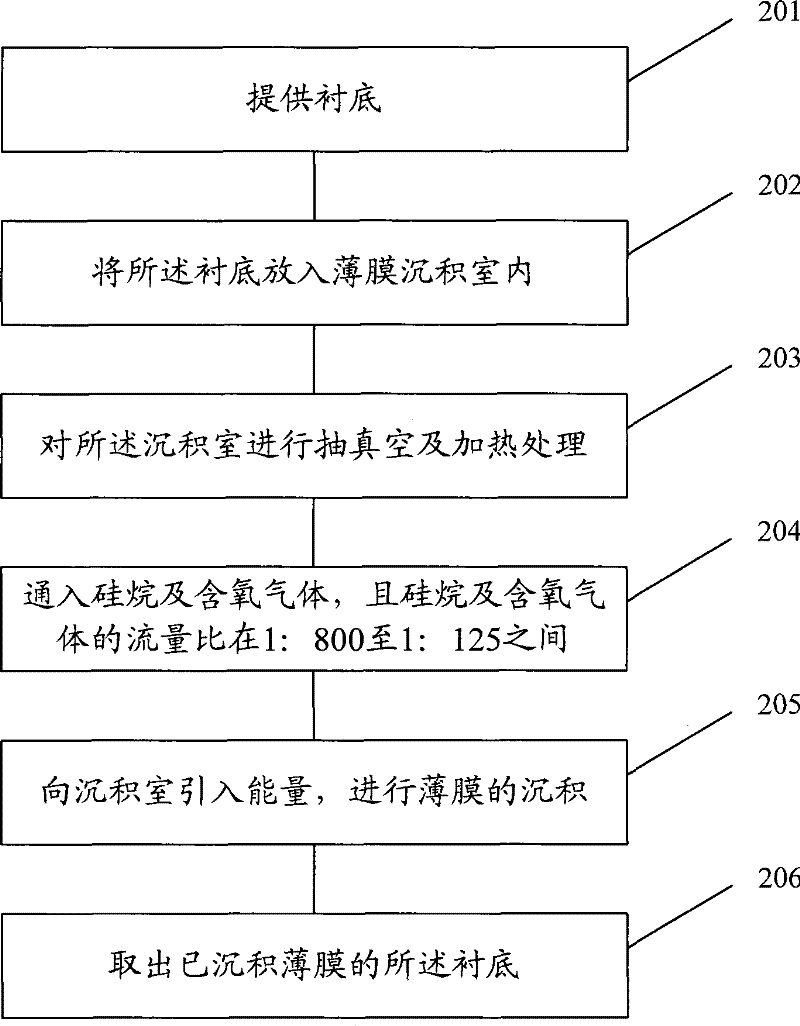

Formation method of silicon oxide film and metal-insulator-metal capacitor

ActiveCN101736314BImprove electrical performanceIncrease deposition powerSemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetal-insulator-metalCapacitance

The invention discloses a formation method of a silicon oxide film, comprising the following steps of: providing a substrate, placing the substrate into a film deposition chamber, vacuumizing the deposition chamber, heating the deposition chamber, introducing silicane and oxygenous gas to the deposition chamber, wherein the flow ratio of silicane to oxygenous gas is between 1:800 and 1:125, introducing energy to the deposition chamber to deposit the film, and taking out the substrate with the deposited film. The invention also discloses a corresponding formation method of a metal-insulator-metal capacitor. The metal-insulator-metal capacitor formed by using the silicon oxide film method reduces and stabilizes a voltage coefficient of capacitance and a temperature coefficient of capacitance of the capacitor, improves the dynamic characteristics of the capacitor and enhances the electrical property stability of the capacitor.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com