Conductive carbon paste for flexible pressure sensor, preparation method thereof and pressure sensor

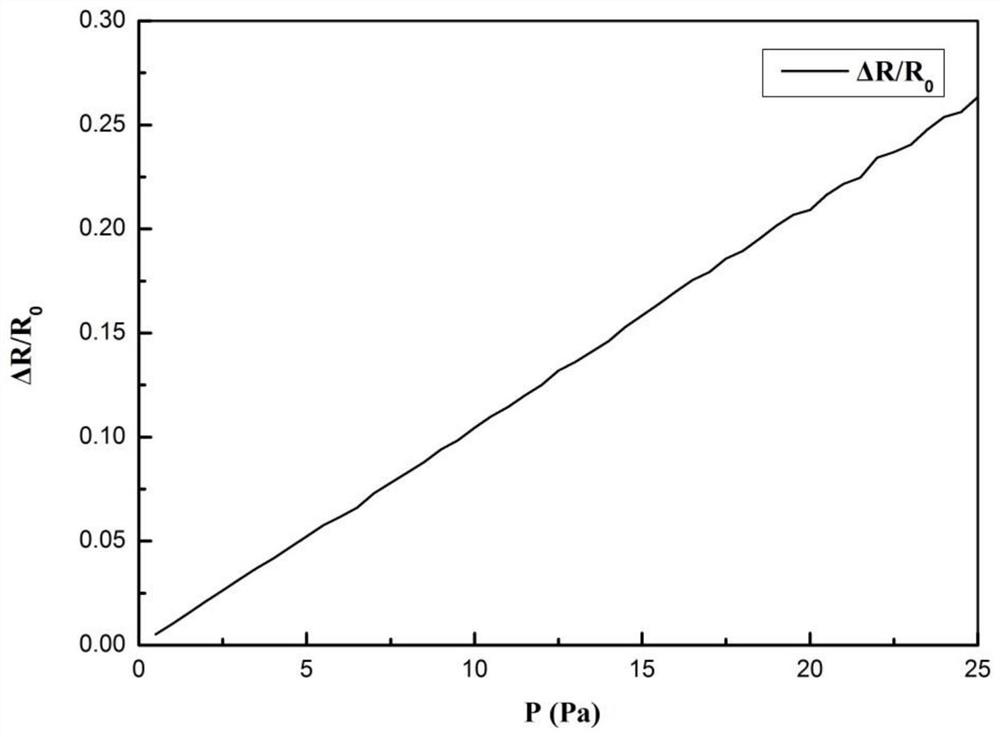

A technology of pressure sensor and conductive carbon, which is applied in the field of conductive carbon paddle for flexible pressure sensor, conductive carbon paddle for flexible pressure sensor and its preparation, and can solve the problems of low sensitivity, unscrupulous rubbing, and poor bending resistance, etc. Achieve high pressure sensitivity, low detection limit, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

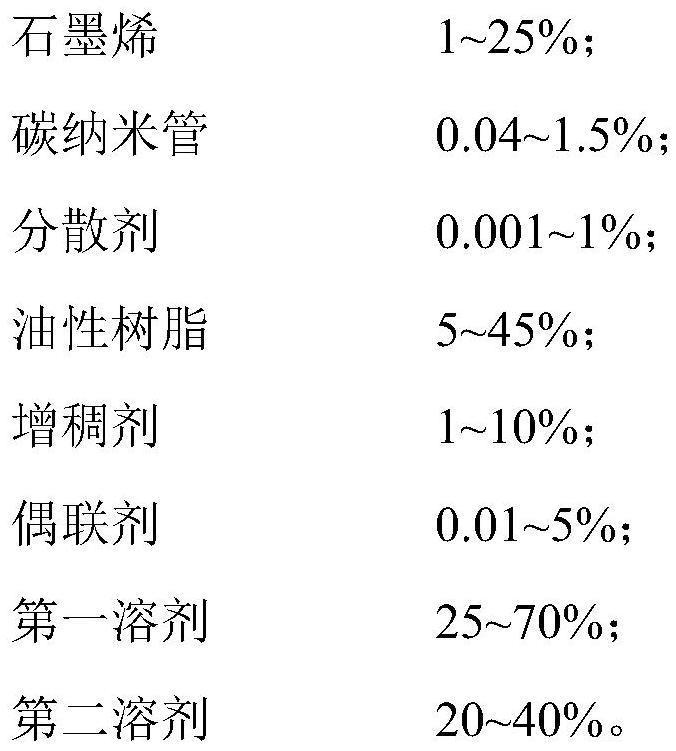

[0050] The conductive carbon paste for the flexible pressure sensor provided in this embodiment, in terms of mass percentage, its raw material formula includes: graphene 8%, carbon nanotube 0.4%, ethylene glycol 50%, polyvinyl alcohol 0.05%, polyethylene Pyrrolidone 0.2%, oleoresin 12%, silane coupling agent 0.05%, locust bean gum 2%, ethylene glycol butyl ether 10% and N-methylpyrrolidone 17.3%.

[0051]Among them, the oily resin is polyurethane resin, the mass ratio of polysiloxane resin and acrylic resin is 1:2:7, the polyurethane resin is purchased from Dongguan Baojing Chemical Co., Ltd., and the model is MR-917; the polysiloxane resin is purchased from Wacker Chemicals (China) Co., Ltd., the model is MSE100; acrylic resin was purchased from Weifang Fule New Material Co., Ltd., the model is CFT8260.

[0052] The model of the silane coupling agent is Momentive A187.

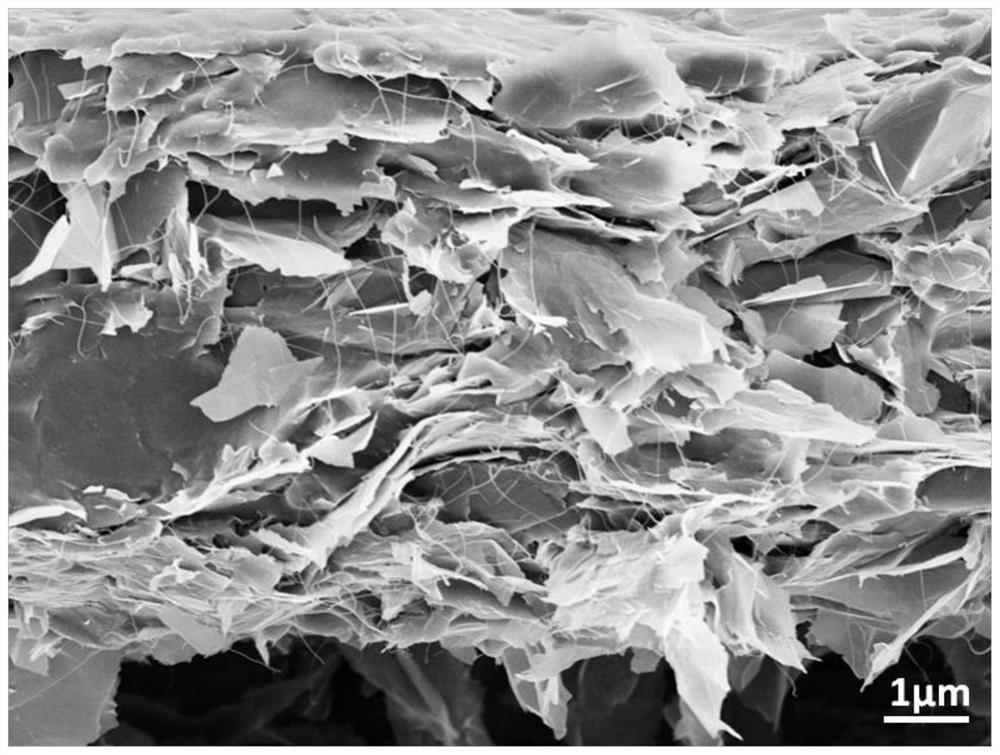

[0053] Graphene is thin-layer graphene with 1-5 layers, the source is self-made, and the multi-layer grap...

Embodiment 2

[0062] The conductive carbon paddle used in the flexible pressure sensor provided in this embodiment has a raw material composition as shown in Table 1, wherein the oily resin is polyurethane resin, and the mass ratio of polysiloxane resin to acrylic resin is 2:3:7.

[0063] The dispersant is lysine.

[0064] The second solvent is butyl glycol ether and N-methylpyrrolidone.

Embodiment 3

[0066] For the conductive carbon paddle used in the flexible pressure sensor provided in this embodiment, its raw material formula is shown in Table 1, and the others are the same as in Embodiment 1, wherein,

[0067] The resin is polyurethane resin, polysiloxane resin and acrylic resin in a mass ratio of 1:2:7.

[0068] The dispersant is polyvinylpyrrolidone.

[0069] The second solvent is N-methylpyrrolidone and diethylene glycol ether acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com