Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

174results about How to "Improve market adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

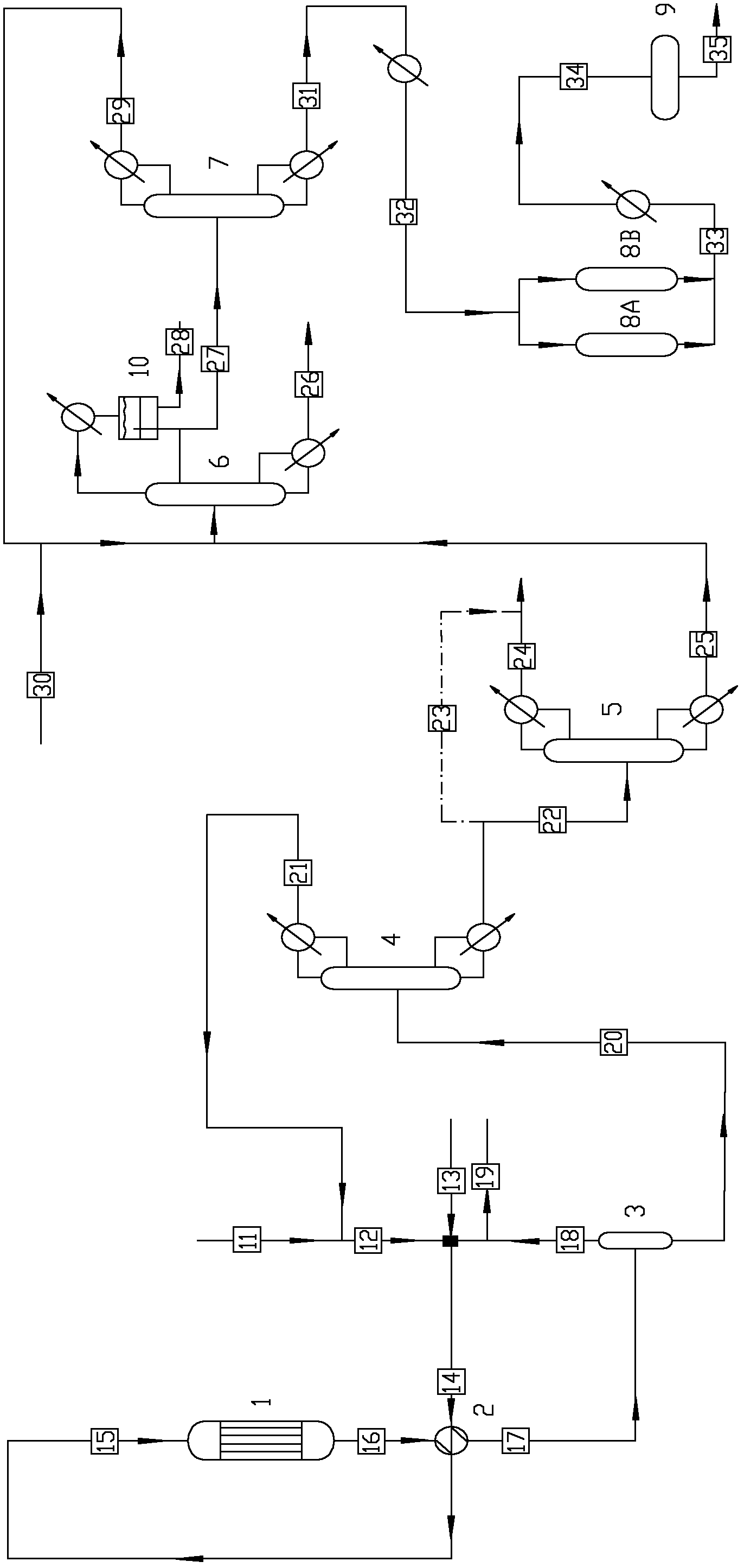

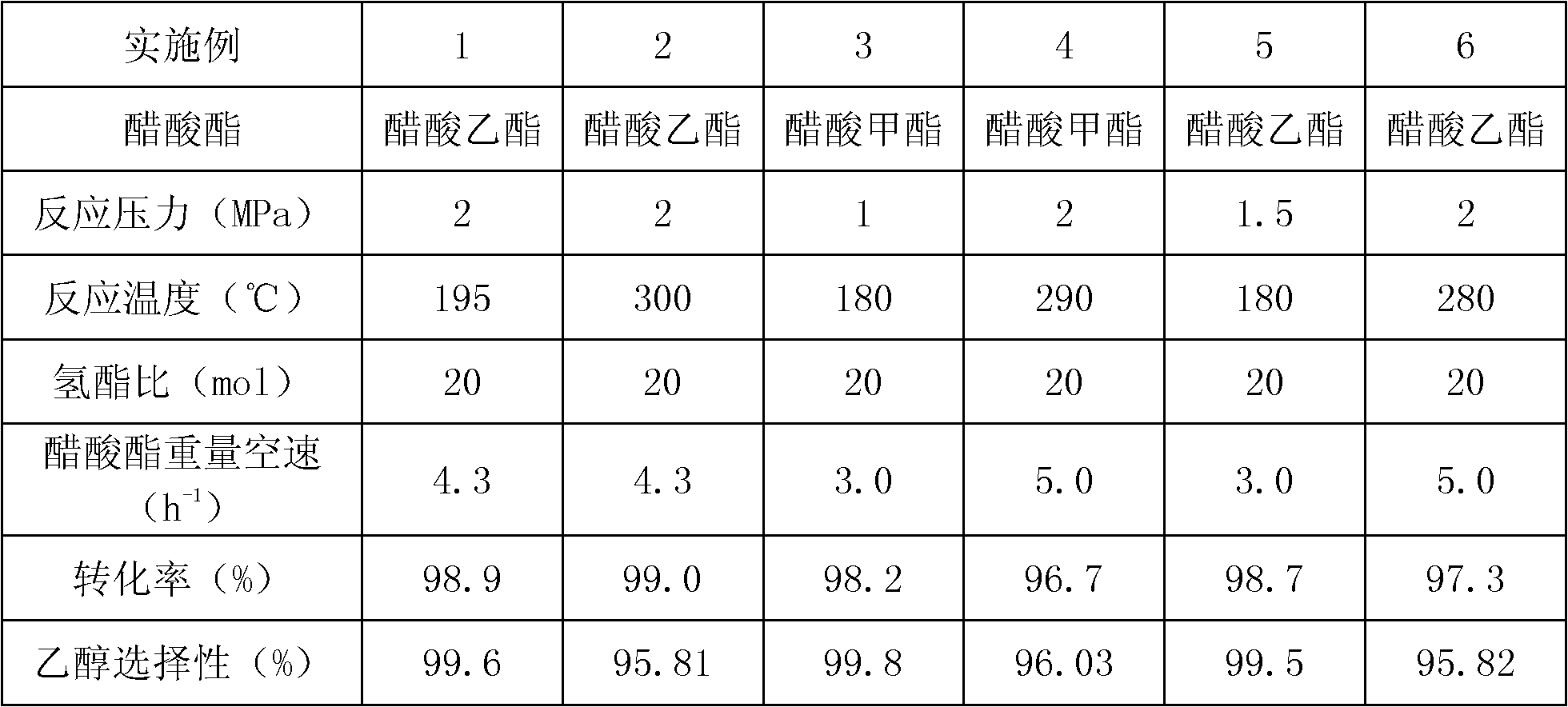

Process for producing alcohol and selectively co-producing 2-butanol by utilizing acetate and matching process system thereof

ActiveCN102659513AHigh selectivityHigh activityOrganic compound preparationHydroxy compound separation/purificationProcess systemsSec-Butanol

The invention relates to a process for producing alcohol and selectively co-producing 2-butanol by hydrogenising acetate and a matching process system thereof. After industrial acetate is hydrogenised and purified, a product is rectified, purified and dehydrated, thereby obtaining alcohol and co-producing 2-butanol. Cu-Zn-M is taken as an active component of a catalyst adopted in the process, wherein M is selected from the compound of one and more of Ir, Mn, W, Ru and Zr. 2-butanol is selectively co-produced by adjusting the reaction temperature. The catalyst, process and device adopted by the invention have the characteristics of high activity, high selectivity, high yield, strong market adaptability, less equipment investment, environmental protection, simpleness in preparing process, economical and practical properties, and the like. Meanwhile, conversion per pass is high and reaction heat is effectively utilized, so that the load for separating rough products is greatly relieved, the production flow is shortened and the energy consumption of production is also greatly reduced.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

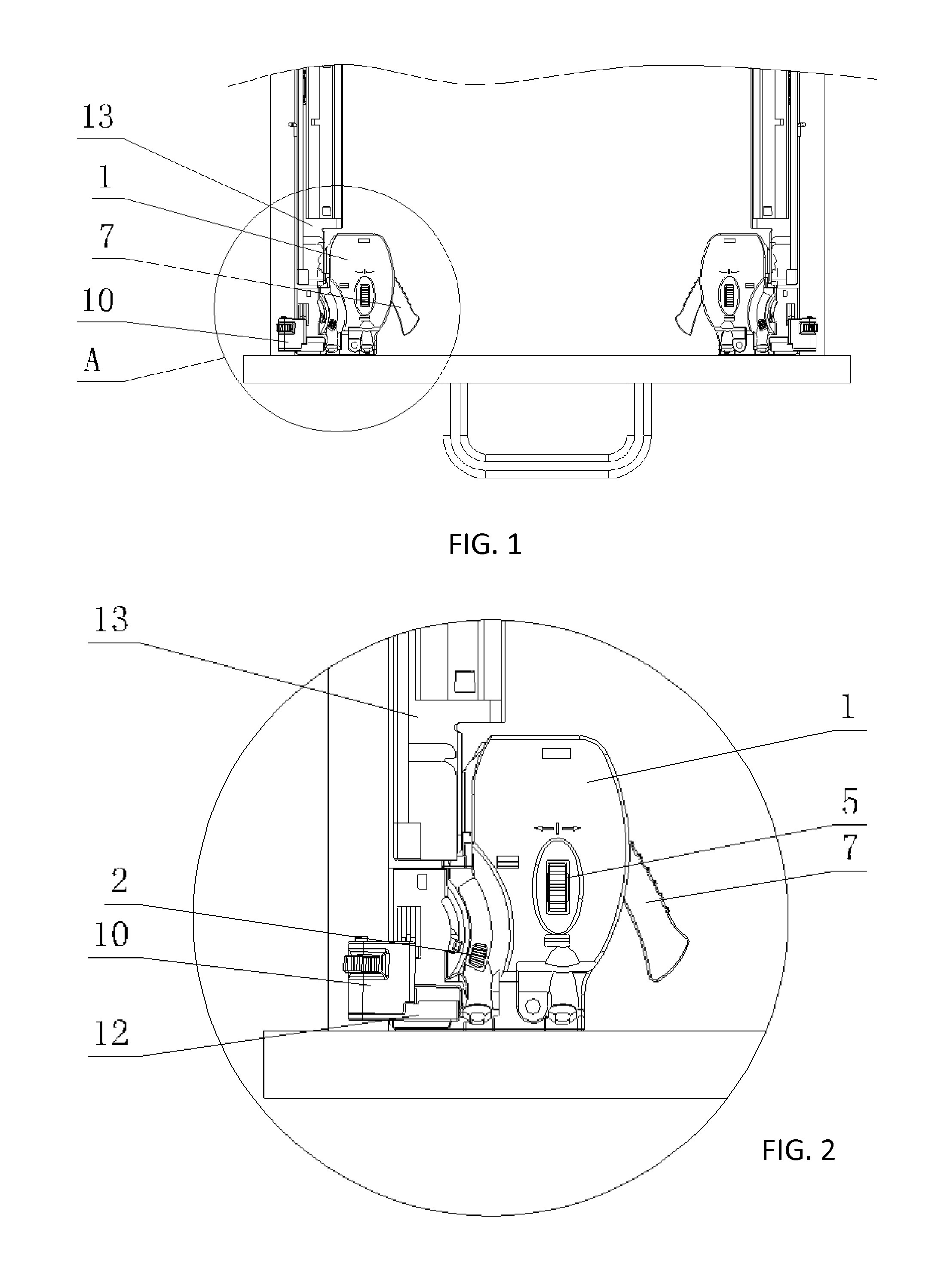

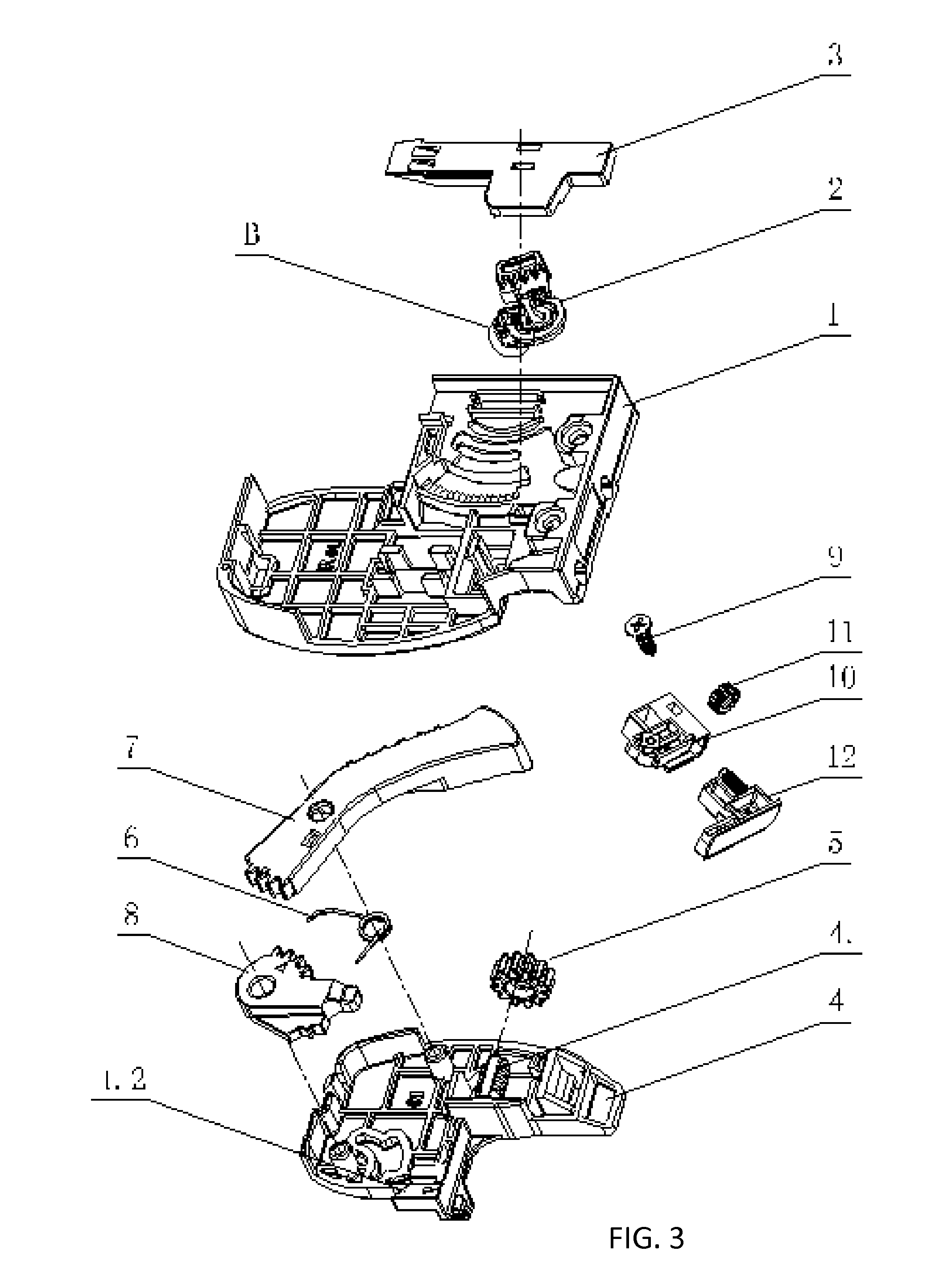

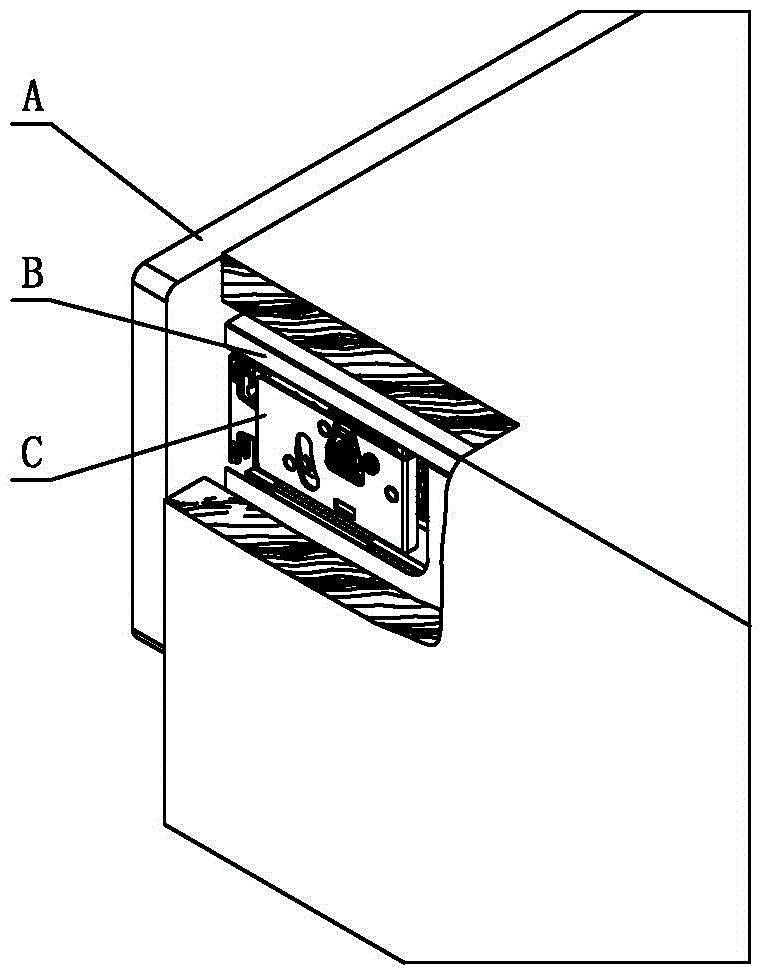

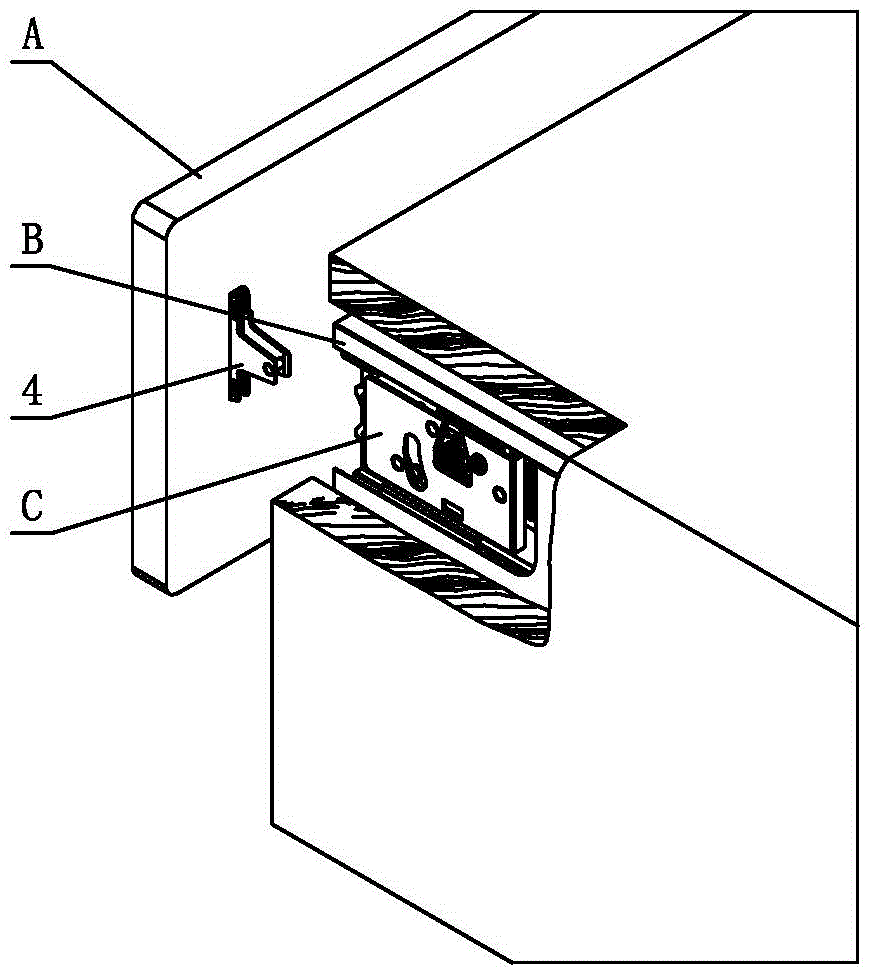

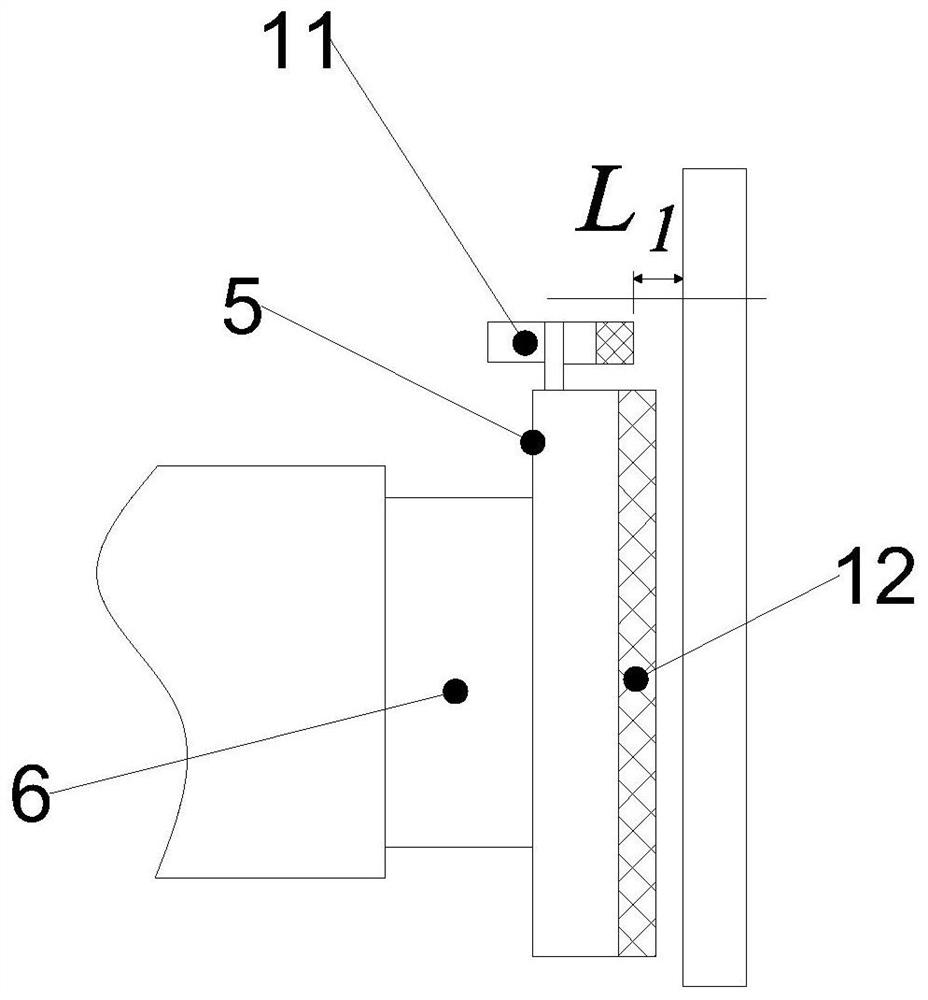

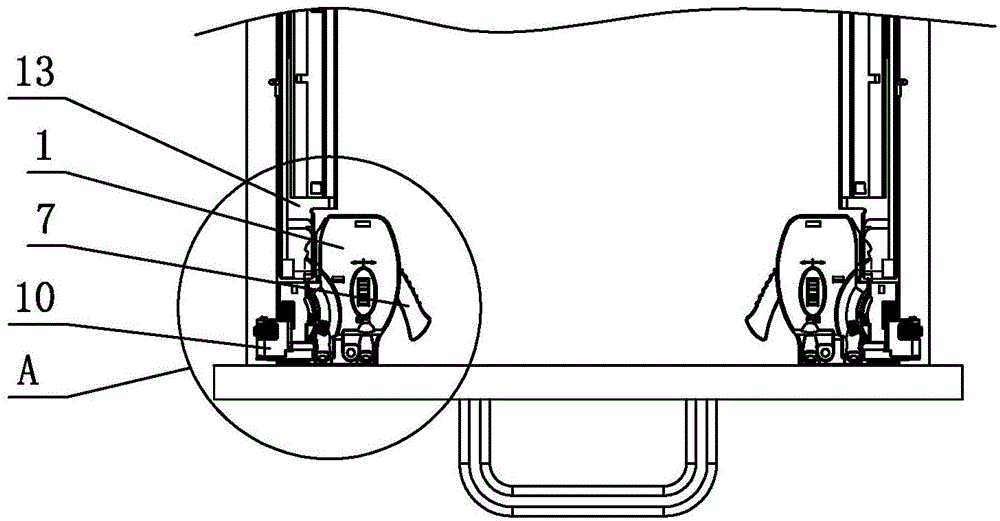

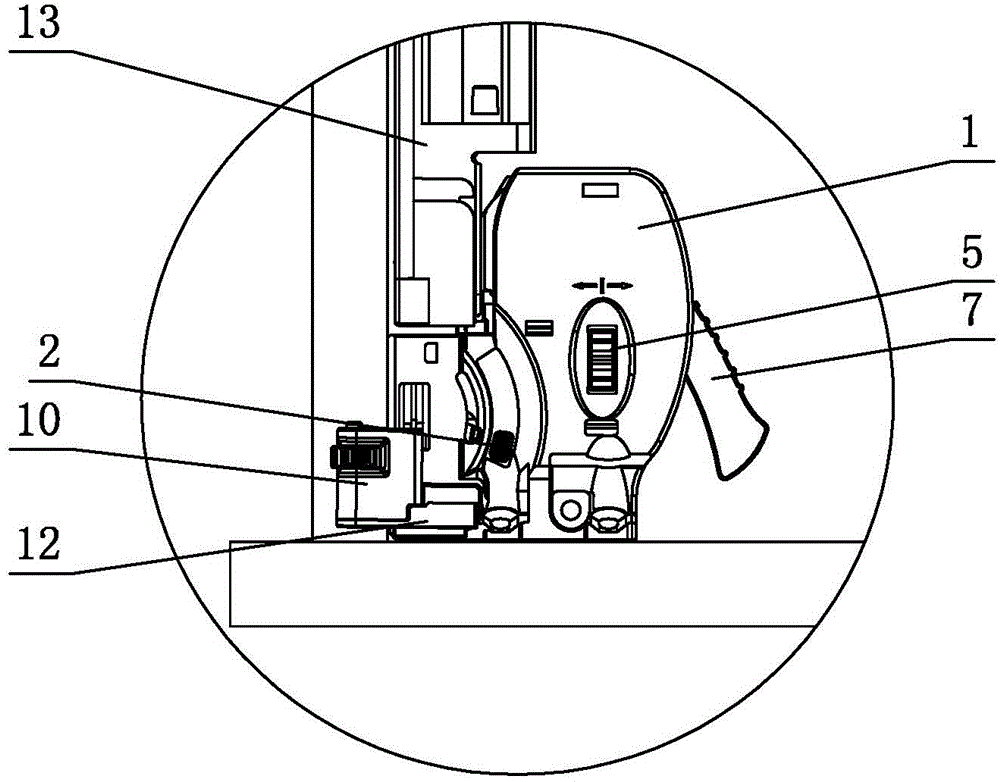

Locking regulation device for drawer slide rail

InactiveUS20160128476A1Simple and reasonable structureImprove performanceBuilding locksConstruction fastening devicesControl theoryMechanical engineering

A locking regulating device for drawer slide rail, comprising a slide rail component and a drawer, wherein the drawer is fixedly connected with the movable rail on the slide rail component, characterized in that, a locking regulating device fixed on the drawer is also included, the drawer is designed to latch the square hole on the movable rail through the locking regulating device to realize mutual connection; the locking regulating device comprises a locking mechanism and a regulating mechanism; the locking mechanism is composed of a handle and a lock catch through mutual transmission; through the lock catch, the regulating device is self-locked on the movable rail and acts on the handle to complete unlocking of the lock catch; the regulating mechanism is designed to respectively make three-dimensional regulation to the drawer from up / down, left / right and front / back directions. The present utility model realizes locking and three-dimensional regulation through the locking mechanism and the regulating mechanism. The locking mechanism is designed to realize self-locking by locking the movable rail through lock catch and perform unlocking through handle transmission to lock catch, so as to conveniently realize the unlocking and separation between drawer and movable rail. The regulating mechanism is designed to respectively make regulation to the drawer in the up / down, left / right and front / back direction, thus contributes to the coordination between drawer and movable rail and meets the demand of different consumers.

Owner:GUANGDONG TAIMING METAL PROD

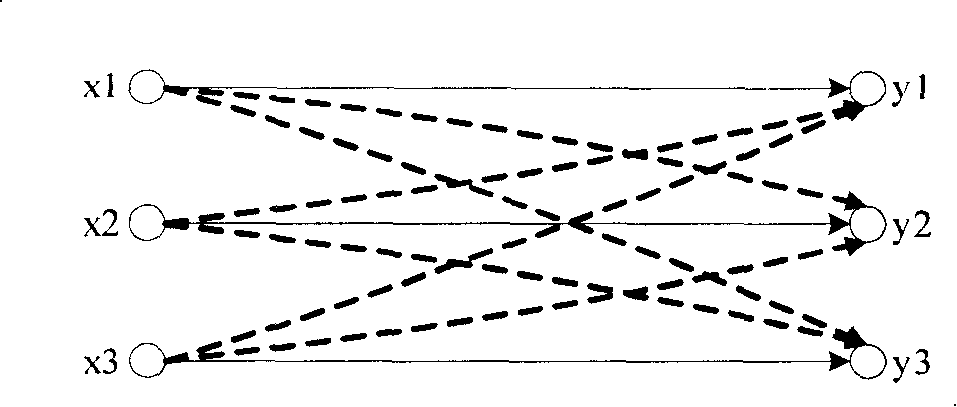

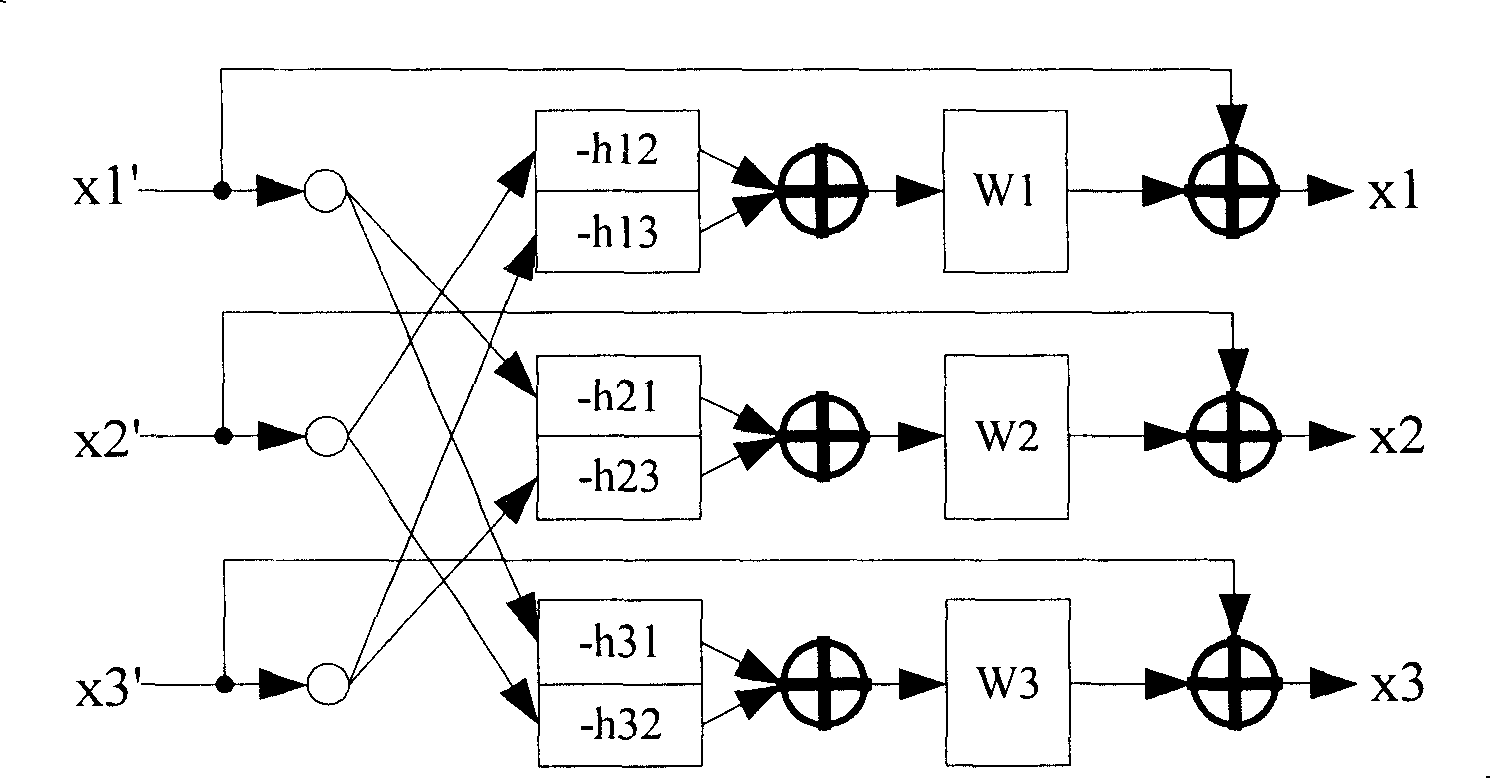

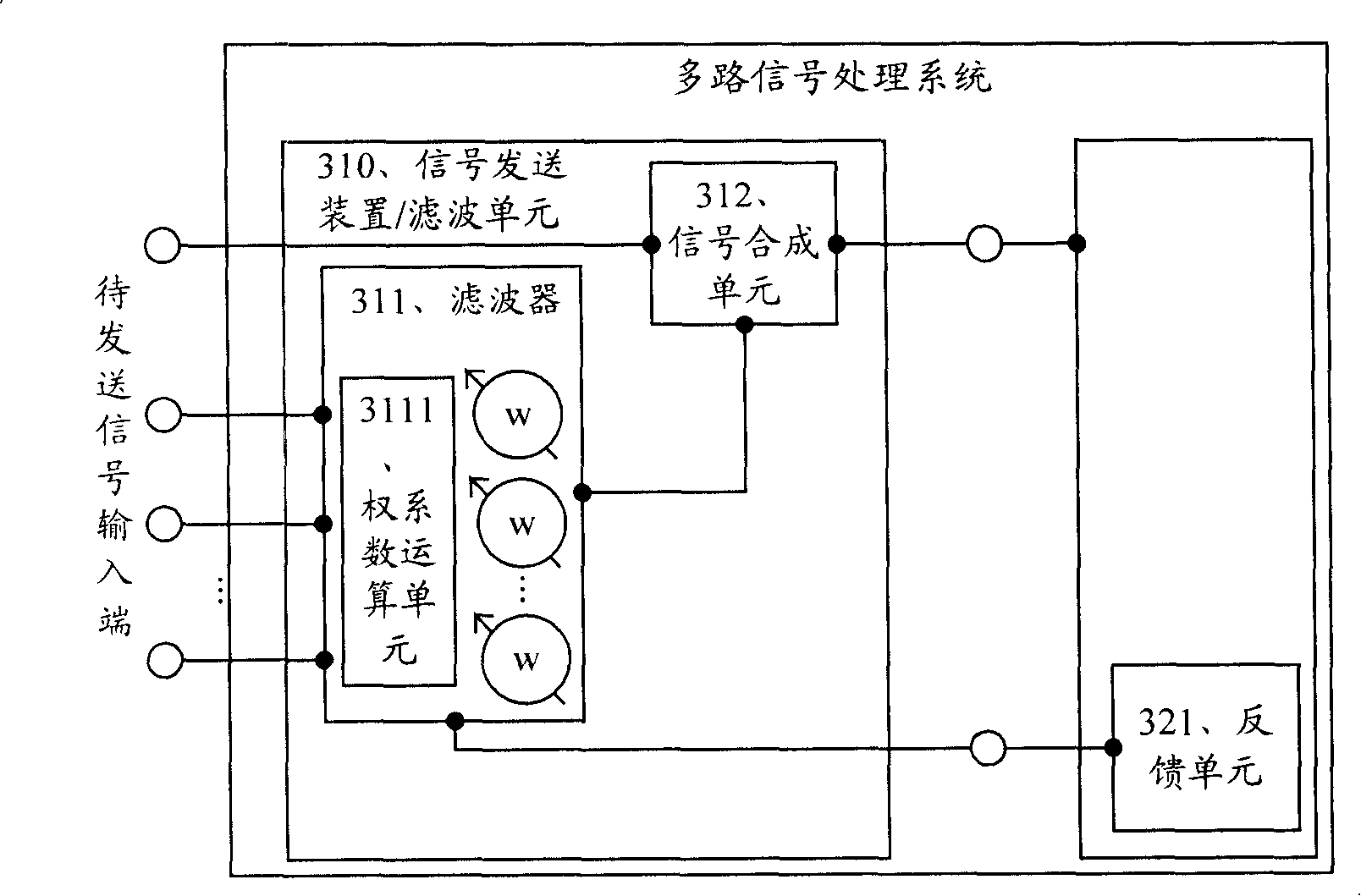

Signal processing system, chip, circumscribed card, filtering and transmitting/receiving device and method

ActiveCN101197798AImprove elimination effectAvoid difficultiesUnbalanced current interference reductionCross-talk reductionEngineeringCrosstalk

The invention provides a multi-channel signal processing system, a multi-channel signal processing chip, a method thereof, a manufacturing method thereof, a filtering device, an external signal processing card and a signal transmitting and receiving device. The multi-channel signal processing system comprises a filtering unit which is arranged on a signal transmitting end and a feedback unit which is arranged on a signal receiving end; the filtering unit comprises a signal synthesis unit and a filter, and the signal synthesis unit inputs a signal waiting for transmission; wherein, the filter is used for filtering a crosstalk source signal of the signal waiting for transmission; the signal synthesis unit is used for synthesizing the signal waiting for transmission and the crosstalk source signal after filtering; the feedback unit feeds back according to the received signal waiting for transmission, wherein, the filter is also used for performing subsequent filtering according to information which is acquired by feedback. The invention can self-adaptively cancel a far end crosstalk signal.

Owner:HUAWEI TECH CO LTD

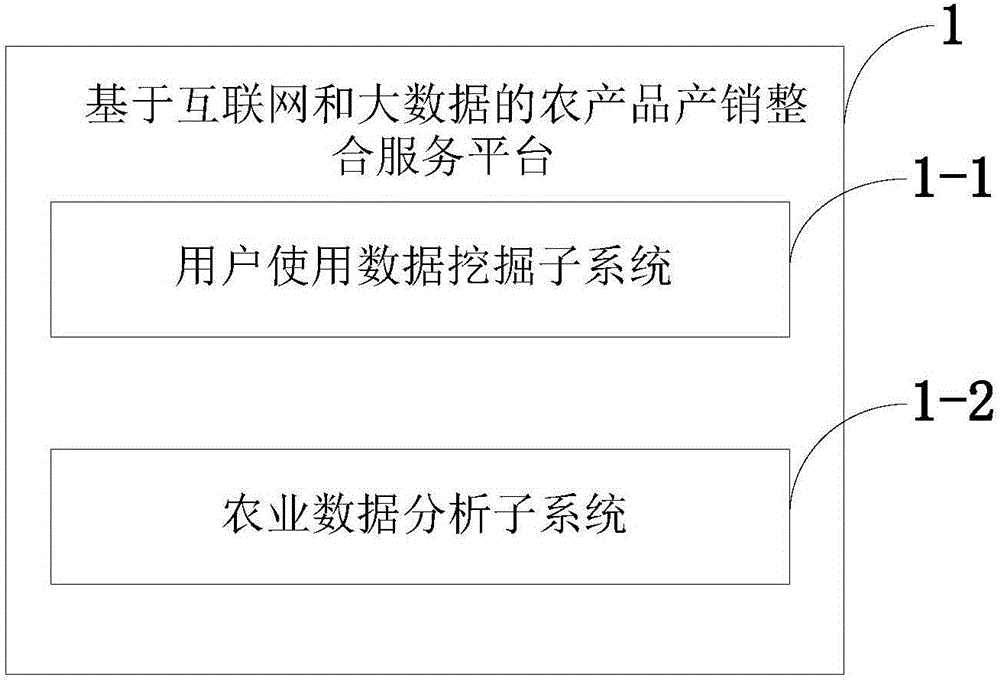

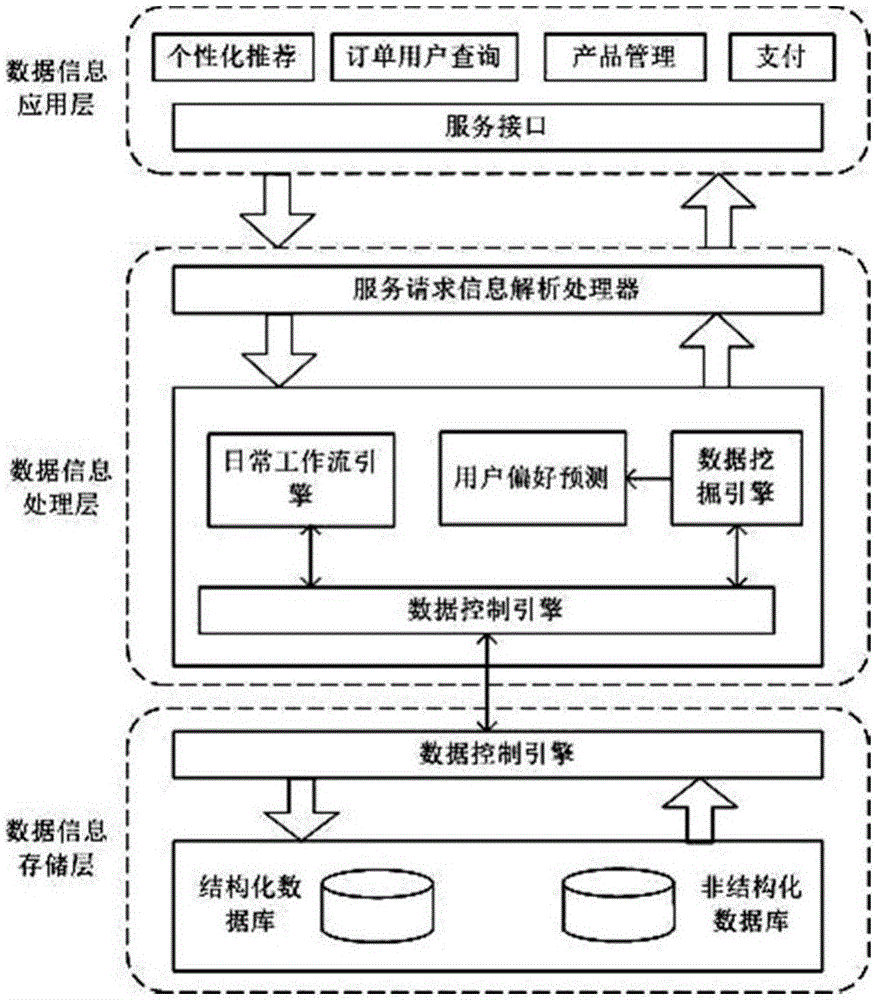

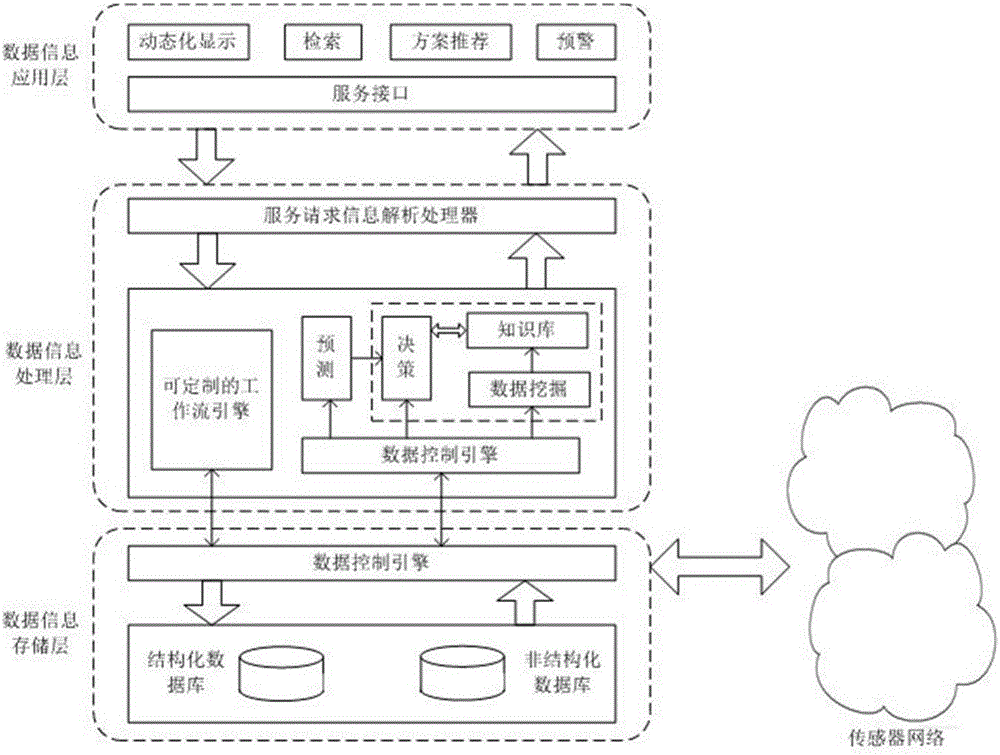

Agricultural product production and marketing integration service platform based on Internet and large data

PendingCN106251234AEasy to manageQuality improvementData processing applicationsUser needsPersonalization

The invention discloses an agricultural product production and marketing integration service platform based on Internet and large data. The platform comprises a data excavation subsystem used by a user and an agricultural data analysis subsystem, wherein the data excavation subsystem is used for effective collection needed by the user and excavating data; and the agricultural data analysis subsystem is used for carrying out refinement management on agricultural production In the invention, production and market demands are tightly cooperated, an effective service is realized and an original profit mode is changed; the service is integrated with a production and marketing service of agricultural products, services are provided for a consumer, an agricultural producer or a cooperative, and a final purpose is to realize a customized and multi-type C2B order type agricultural production and marketing service mode; and the agricultural product production and marketing integration service platform is constructed and an agricultural product production and marketing integration service is realized so that an agricultural production level can be effectively increased and the agriculture performs a great effect in GDP growth, and simultaneously an income level of agricultural population is improved, acceptance of labor forces is increased and new rural construction is promoted.

Owner:四川省巴食巴适电子商务有限公司

Pure natural essence oil mosquito-repellent liquid and preparation method thereof

InactiveCN105816365AImprove stabilityImprove solubilityCosmetic preparationsToilet preparationsPelargonium x hortorumHigh concentration

The invention discloses pure natural essence oil mosquito-repellent liquid and a preparation method thereof .The mosquito-repellent liquid is prepared from, by volume, 10-20 parts of pelargonium hortorum essence oil, 5-10 parts of lavender essence oil, 10-20 parts of citronella essence oil, 1-5 parts of chamomile essence oil, 10-20 parts of sorbitan quatraoleate and 40-60 parts of deionized water .The mosquito-repellent liquid has the advantages of being wide in adaptability, obvious in effect, free of irritation, free of chemical reagent addition, safe, efficient and the like, is particularly suitable for pregnant women, babies and people with sensitive skin to use, can solve the problems that sanitary pesticide components such as deet and insectifuge ester are used in existing mosquito-repellent toilet water and are irritative and allergic to skin, and can solve the problems that traditional toilet water contains high-concentration ethyl alcohol, accordingly skin moisture loss, ageing and wrinkles are caused, and some safety hidden hazards can be caused.

Owner:GUIZHOU YIPO YIPIN BIOLOGICAL TECH CO LTD

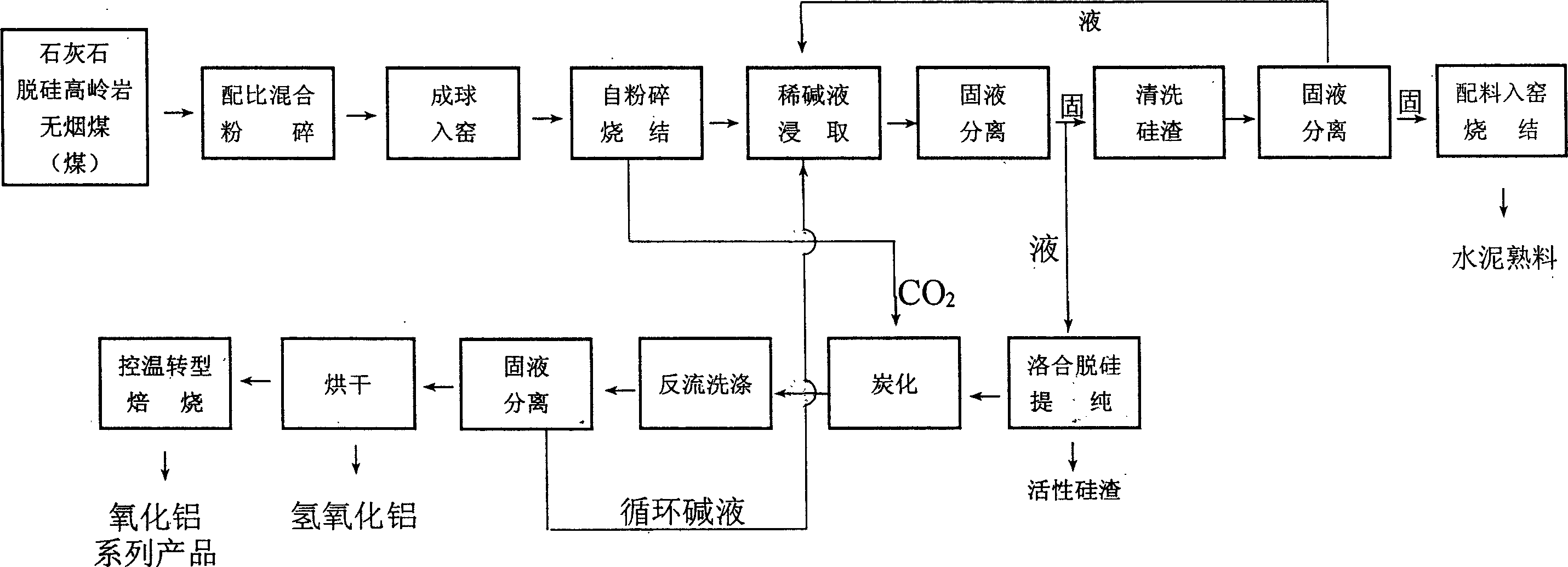

Technology for producing aluminium oxide

InactiveCN1623901AAddress resource shortagesHigh purityAluminium oxide/hydroxide preparationKaoliniteAluminium hydroxide

A process for preparing aluminium oxide features that the kaolinite and powdered coal ash are predesiliconized to make the Al-Si ratio is greater than 4, the self-breaking sinter method is used, the diluted solution of sodium carbonate is used for extracting, and the complex reaction is used for purifying. The pure CO2 gas generated by sintering and NaAl2O3 solution take part in carbonizing reaction to generate aluminium hydroxide. Changing the crystalline structure of aluminium hydroxide can obtain aluminium oxide.

Owner:郭长征 +1

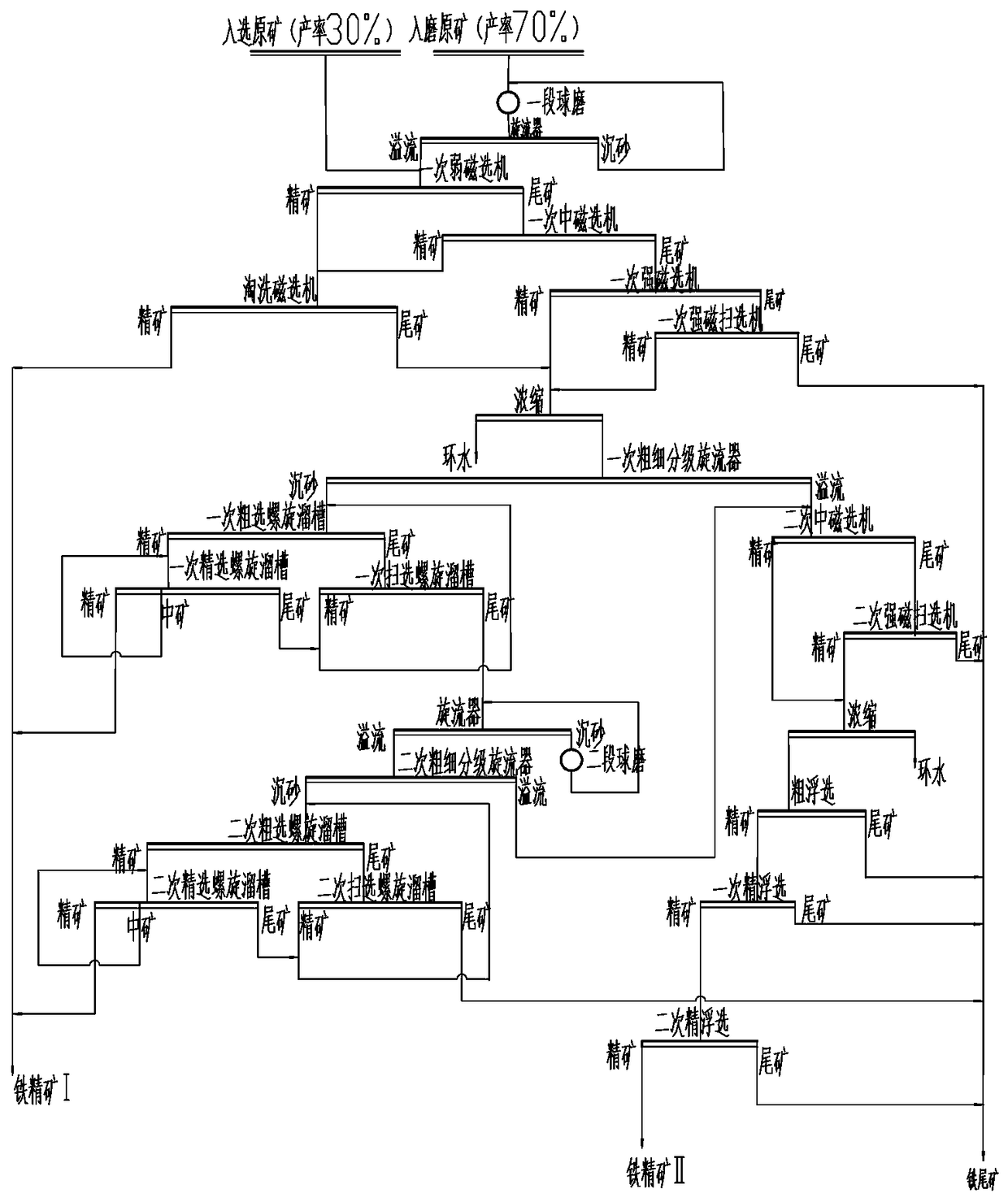

Beneficiation technology of surface hematite and magnetite mixture with high slime viscosity

InactiveCN109046753AReduce consumptionLengthen the number of working segmentsWet separationReverse flotationEarth surface

The invention relates to a beneficiation technology of a surface hematite and magnetite mixture with the high slime viscosity. The technology is characterized in that the processed ore is the hematiteand magnetite mixture with the iron grade being 41.8% and the slime content being 30%; and the technology comprises three crushing processes including coarse crushing operation, intermediate crushingoperation and fine crushing operation and further comprises a beneficiation process composed of one-stage ball milling-swirler closed circuit ore grinding operation-primary magnetic separation operation, primary gravity concentrating operation, primary coarse and fine grading swirler operation, two-stage ball milling-swirler closed circuit ore grinding operation, secondary coarse and fine gradingswirler operation, secondary gravity concentrating operation, secondary magnetic separation operation and reverse flotation operation. The beneficiation technology has the advantages that the blockage problem in crushing operation is effectively solved, concentrate can be classified into iron concentrate I with the grade being 62% and iron concentrate II with the grade being 60%, the iron concentrate I is higher in price and capable of being used as pellet feed, the iron concentrate II is relatively low in price and capable of being used as sintering materials, and the market adaptability ofthe iron concentrate is expanded.

Owner:中冶北方(大连)工程技术有限公司

New type functional food and preparation method thereof

The invention relates to a new type functional food and a preparation method thereof. The functional food or health care food is processed by using raw thorn sea cucumber as a main raw material, using some Chinese herbal medicine and fruit as assistant materials and adopting a biological enzymatic method as a basic production technology, wherein the sea cucumber and a biological enzyme comprise any one or a plurality of kinds of sea cucumber or any one or a plurality of biological enzymes which are proved to be edible by people through scientific tests or experience of life. The food is specifically an industrialized food which can sufficiently display the functions of body defense, adjustment of circadian rhythms, disease prevention, recovery promotion and the like to human bodies. The functional food is prepared by carrying out a processing technology with higher technological content on 90 to 96 parts of the raw thorn sea cucumber, 2 to 3 parts of corsvenor momordica fruit, 2 to 3 parts of cordyceps militaris, 3 to 5 parts of haw, 5 to 8 parts of medlar and a proper quantity of various biological active enzymes. The food has the obvious characteristics of simple technology, low cost, specific and definite functions, strong market adaptability and the like.

Owner:秦德文

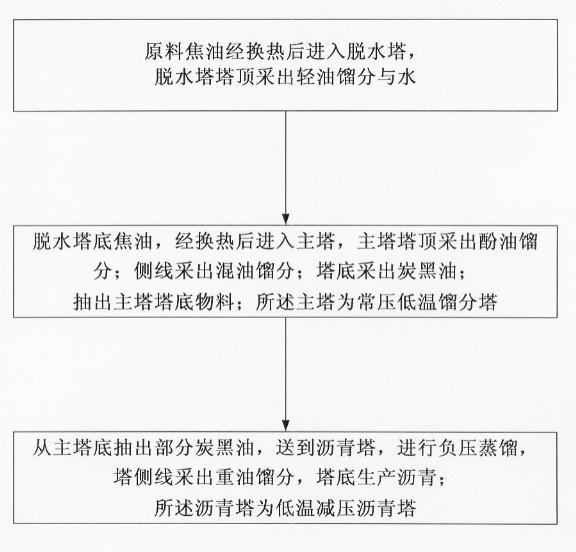

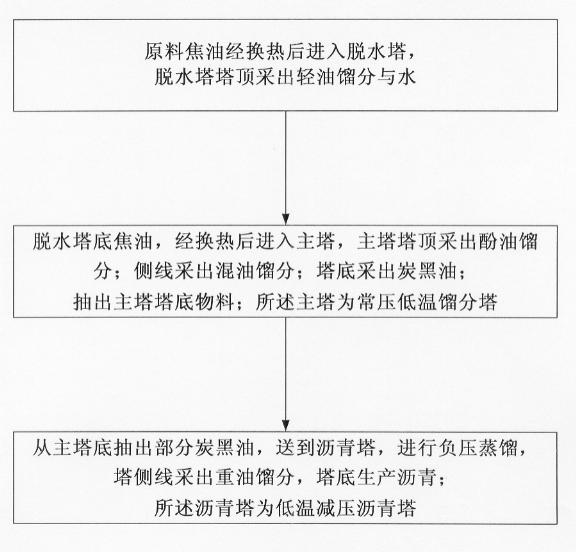

Coal tar alkali-free normal/reduced-pressure distillation process and device

ActiveCN102161901AReduce sodium ion contentAvoid corrosionTar working-up by water removalTar working-up by distillationAlkali freeDistillation

The invention relates to a coal tar alkali-free normal / reduced-pressure distillation process and a coal tar alkali-free normal / reduced-pressure distillation device. In the process, raw material coal tar is subjected to heat exchange and delivered into a dehydrating tower, and light oil distillate and water are collected from the top of the dehydrating tower; the coal tar at the bottom of the dehydrating tower is subjected to heat exchange and delivered to a main tower, and a carbolic oil distillate is collected from the top of the main tower; a mixed oil distillate is collected from a lateralline; carbon black oil or soft asphalt is collected from the bottom of the tower; bottom material of the main tower is pumped out; part of soft asphalt is pumped out from the bottom of the main towerand delivered to an asphalt tower for distillation under a negative pressure, a heavy oil distillate is collected from a lateral line of the tower, and asphalt is produced at the bottom of the tower;and the main tower is a normal-pressure low-temperature distillate tower, the asphalt tower is a low-temperature reduced-pressure asphalt tower, and all distillates are not added with alkali in the whole flow. In the device, the bottom of the dehydrating tower is connected with the middle of the main tower through a pipe, and the bottom of the main tower is connected with the middle of the asphalt tower through a pipe. The internal circulation at bottom of the main tower is realized through a heating furnace, and internal circulation at the bottom of the asphalt tower is realized through a heating furnace. The process and the device have the advantages that: all distillates are not added with alkali; distillates are cut according to market demands and temperature gradient; direct super-heated steam is not used; new process waste water is avoided; the energy consumption is low; the product quality is high; and the like.

Owner:BAOSTEEL ENG & TECH GRP

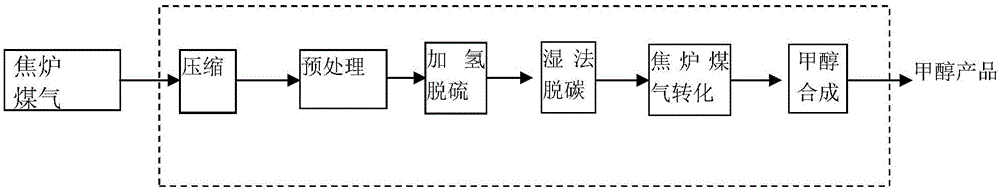

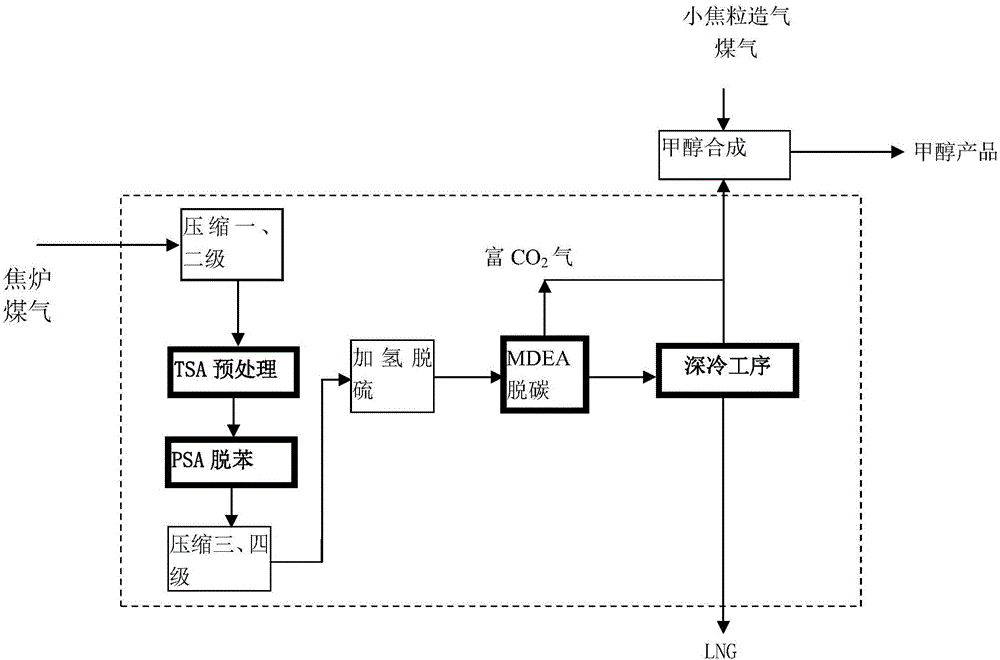

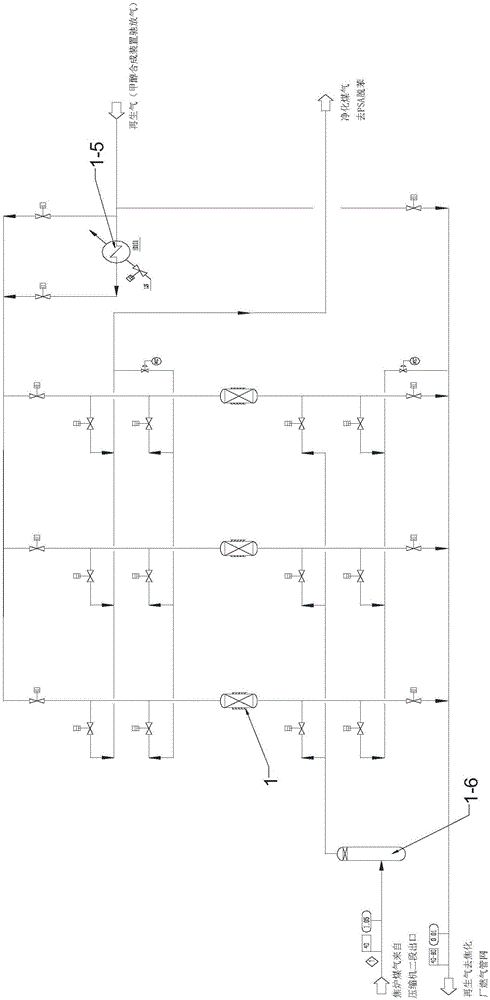

Method and device using coke stove gas to prepare LNG (liquefied natural gas) and jointly produce methyl alcohol

PendingCN106753628AGood market adaptabilityGood economic benefitsOrganic compound preparationGaseous fuelsTarChemistry

The invention relates to the technical field of comprehensive utilization of coke stove gas of coking / steel plant industry, in particular to a method and a device using coke stove gas to prepare LNG (liquefied natural gas) and jointly produce methyl alcohol. The method is characterized by sequentially comprising the following steps of pressurizing the coke stove gas by a compressor, removing naphthalene, tar, NH3 (ammonia), benzene and other heavy hydrocarbon compounds by TSA (temperature swing adsorption) pretreatment and PSA (pressure swing adsorption) debenzolization, pressurizing by a coke stove gas compressor, sending into a hydrogenation and desulfurizing device to desulfurize, sending into an MDEA (methyldiethanolamine) decarbonizing device to remove carbon, and performing LNG deep-cold separation, so as to obtain an LNG product. Compared with the prior art, the method has the advantages that the coke stove gas is outputted by a secondary outlet of the compressor, and then is sequentially subject to the TSA pretreatment and the PSA debenzolization, so that the coke stove gas does not contain the naphthalene, tar, benzene and other matters; after the coke stove gas returns back into a third inlet of the compressor, the sewage is not drained in the third stage and fourth stage of the compressor, so that the treatment burden of a sewage treatment plant is reduced.

Owner:上海汉兴化工科技有限公司

Sugarfree inonotuso bliquus(Fr )Pilat health-care beverage and making method thereof

InactiveCN105918743AImprove drinking tasteImprove market adaptabilityFood ingredient as mouthfeel improving agentBlood pressureBlood lipids

The invention relates to the technical field of processing production of beverages, in particular to a sugarfree inonotuso bliquus(Fr )Pilat health-care beverage and a making method thereof. The sugarfree inonotuso bliquus(Fr )Pilat health-care beverage is prepared from the following raw materials in parts by weight: 100 parts of inonotuso bliquus (Fr) Pilat, 0.5-2 parts of steviol glycoside, and 2400-2600 parts of water. The making method comprises the steps of performing crushing, performing soaking, performing filtering, adjusting mouth feel, performing filling and the like. The sugarfree inonotuso bliquus (Fr) Pilat health-care beverage provided by the invention has the beneficial effects that the sugarfree inonotuso bliquus (Fr) Pilat health-care beverage is slightly sweet in mouth feel, sugarfree, suitable for being drunk by diabetics, and good in medical and health-care effects, and can have the effects of reducing blood pressure and blood lipid. According to the sugarfree inonotuso bliquus(Fr) Pilat health-care beverage, the organism immunity is improved, and the generation of complication is avoided.

Owner:张晓芬

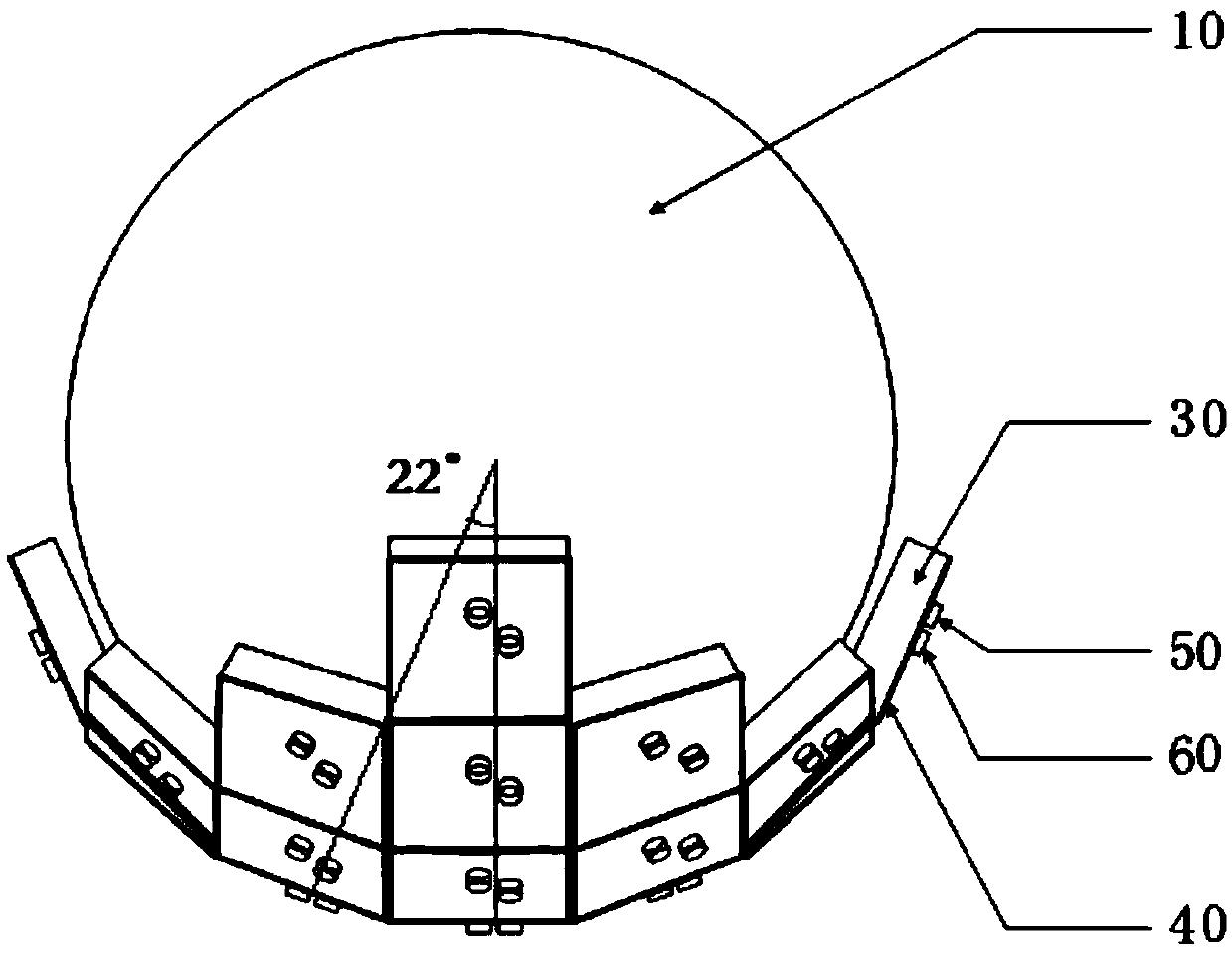

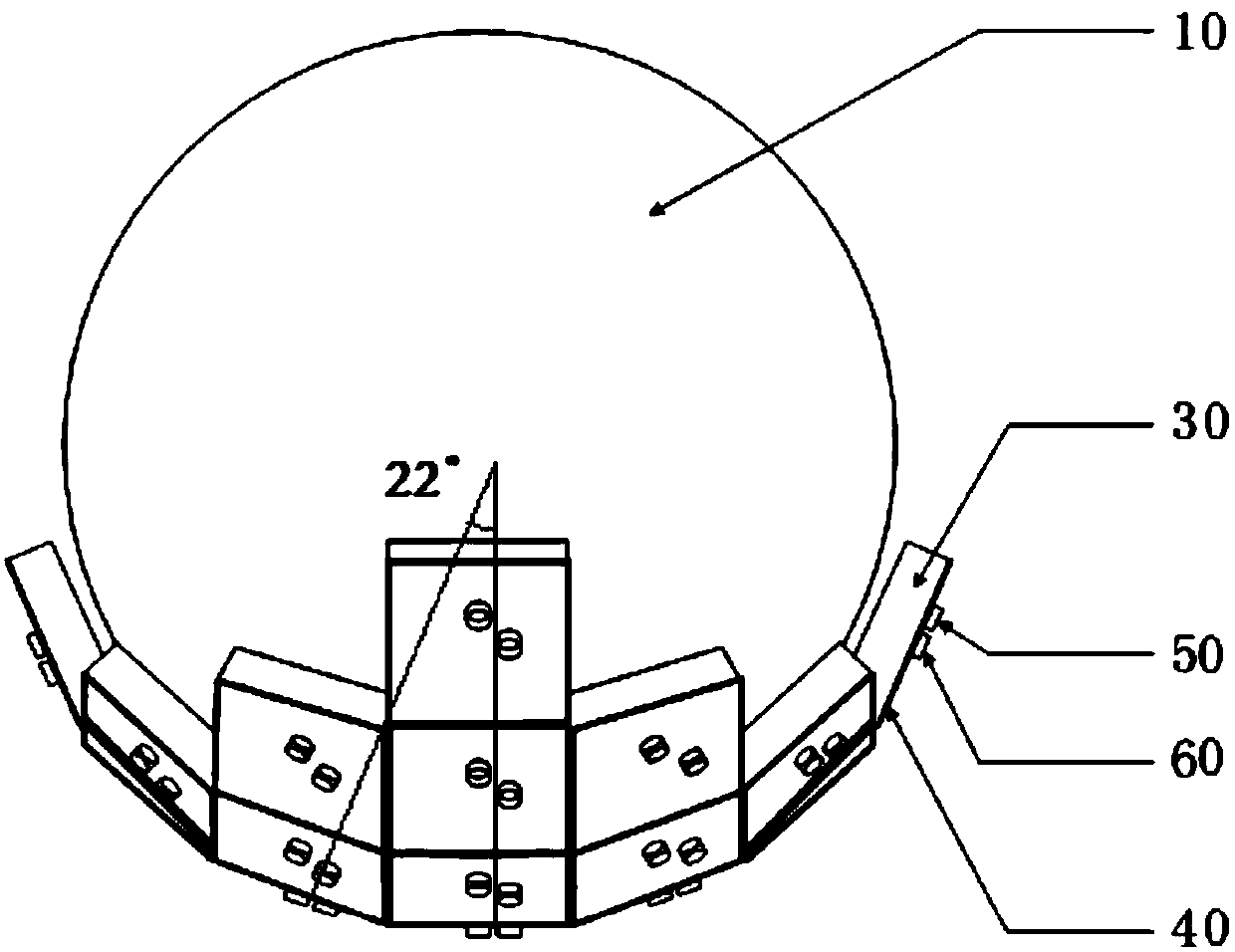

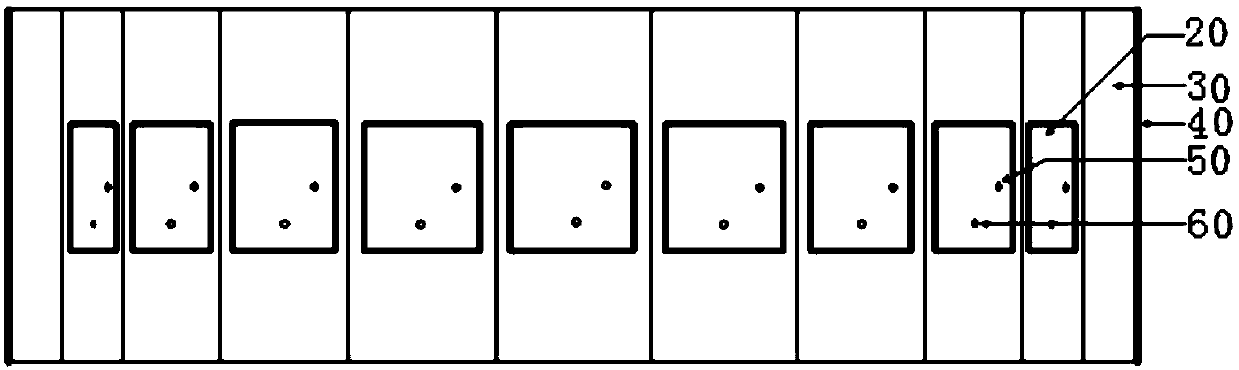

Luneberg lens, low-profile array antenna based on Luneberg lens array and satellite antenna

InactiveCN111009728AReduce complexityReduce design difficultyParticular array feeding systemsIndividually energised antenna arraysSatellite antennasEngineering

The invention provides a luneberg lens. The luneberg lens comprises a luneberg lens unit and an antenna array fixed on the surface of the luneberg lens unit, and the antenna array is arranged on the circumferences of a plurality of concentric circles in a one-dimensional arc line or two-dimensional arc surface along the surface of the luneberg lens unit through a plurality of antenna units. Compared with the prior art, the antenna array is arranged on the surface of the single luneberg lens unit, large-angle beam scanning can be achieved by sequentially feeding the antenna units at the same positions in the antenna array on the surface of each luneberg lens unit, and the complexity and design difficulty of an antenna feed network are reduced. If only a certain angle or a certain directionneeds to be covered, the antenna units in other directions can be cut, so that the antenna array is simplified, the feed network is simplified, and the cost is easy to control.

Owner:HEFEI RHOSOON INTELLIGENT TECH CO LTD

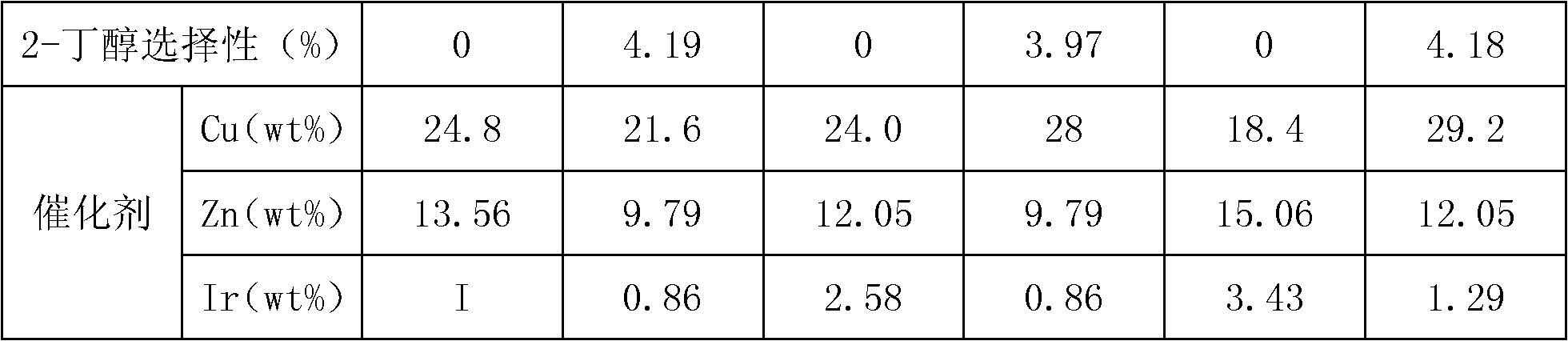

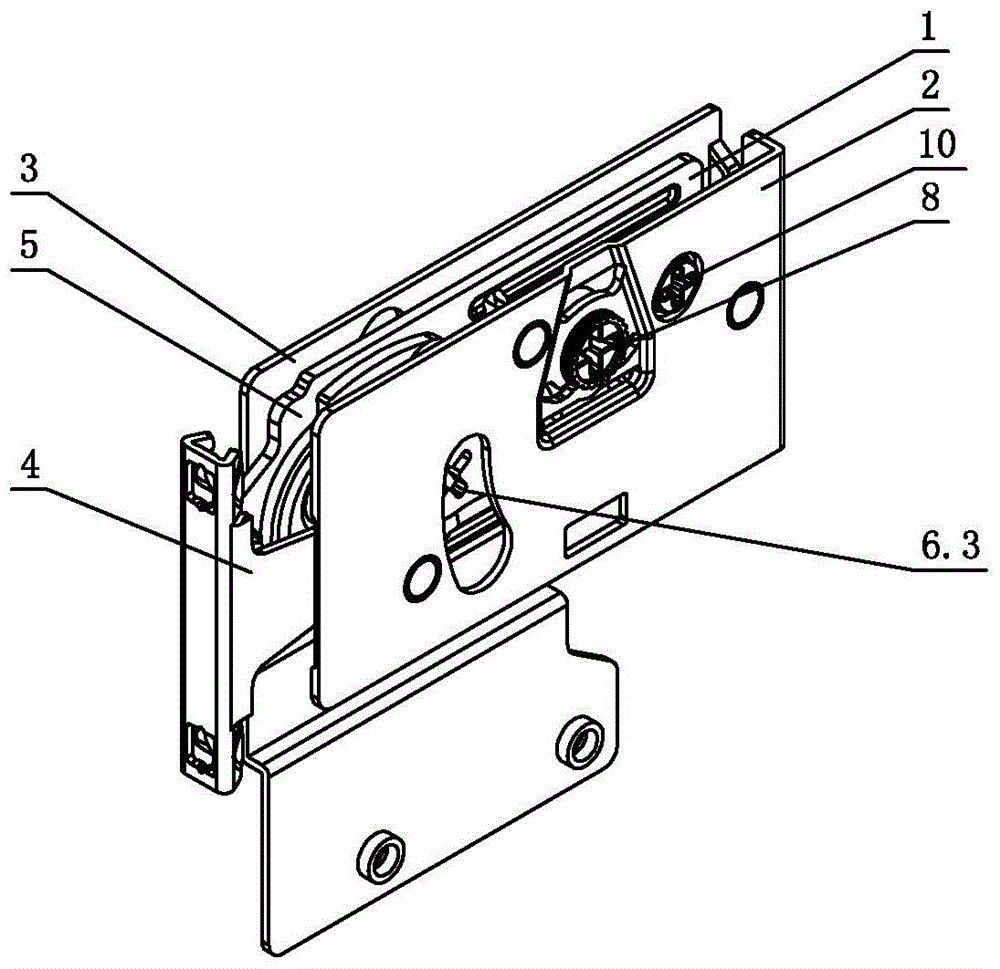

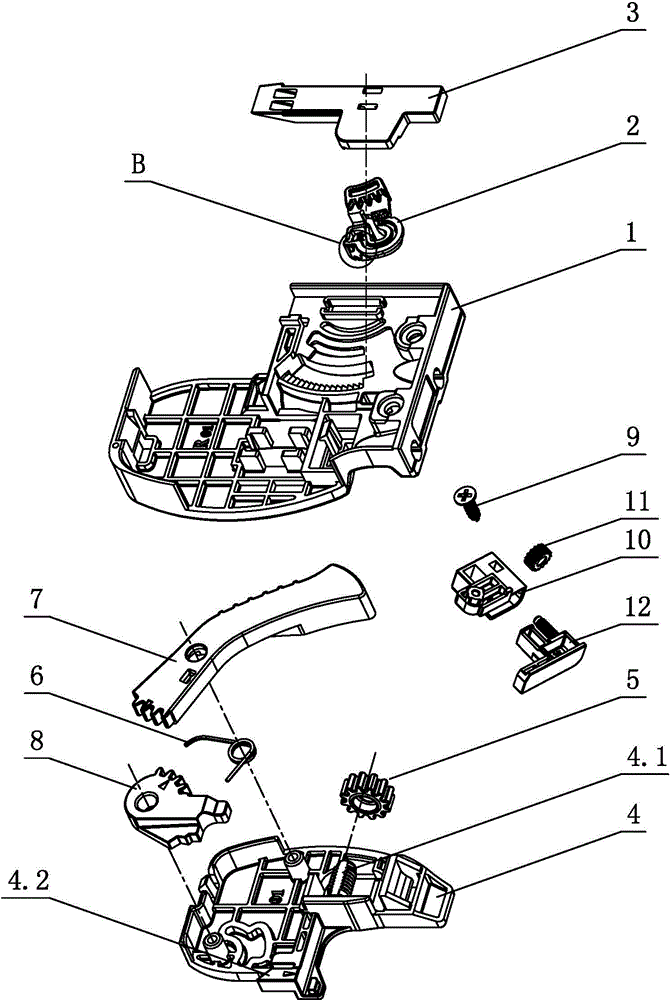

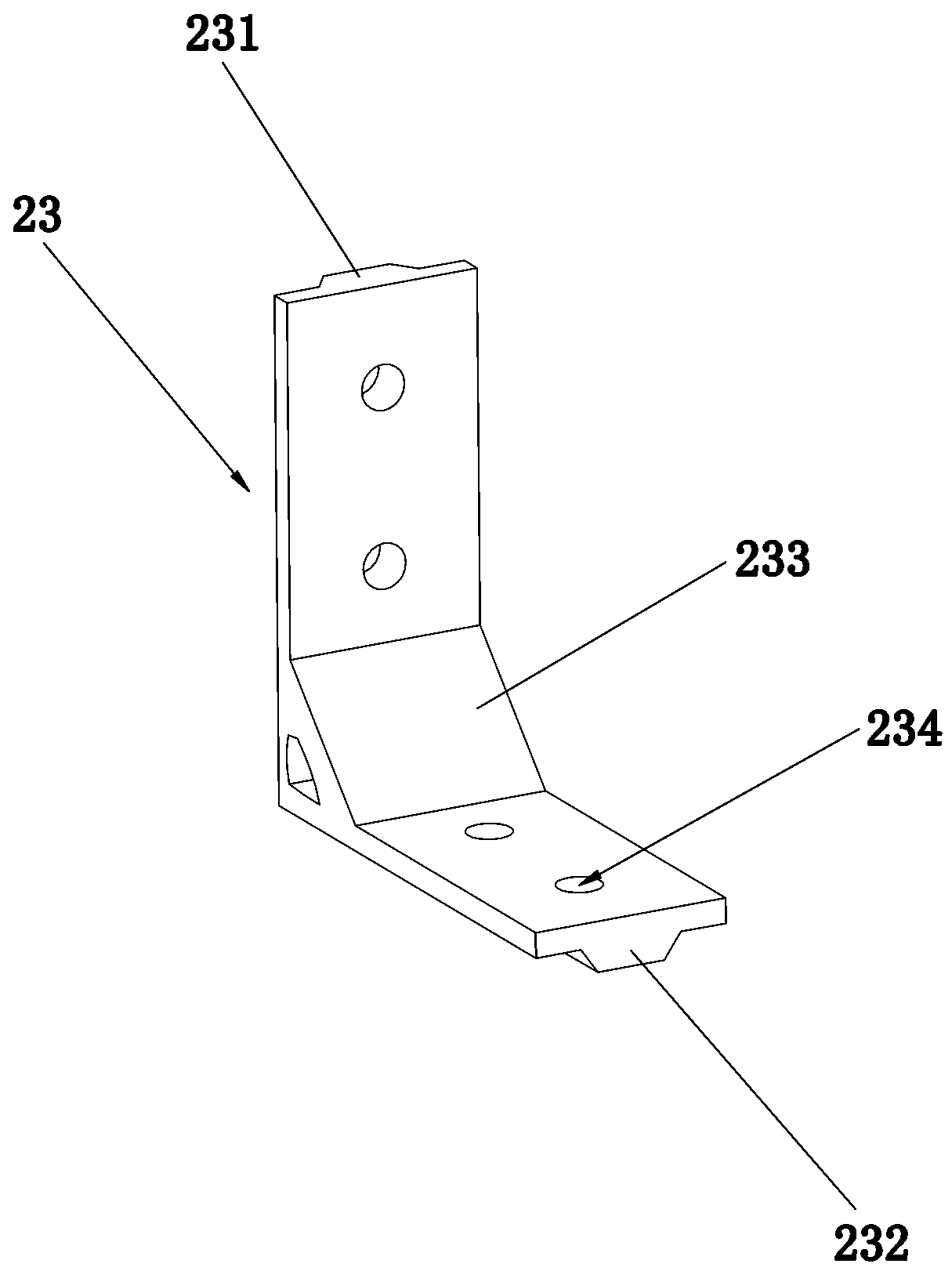

Detachment and installation adjusting device for drawer surface plate

ActiveCN104352091AApplied to drawers of different sizes, it is convenient to use for a long timeEasy to useDrawersMotherboardMental detachment

The invention relates to a detachment and installation adjusting device for a drawer surface plate. The detachment and installation adjusting device comprises side plates, wherein each side plate is provided with the corresponding detachment and installation adjusting device, and a surface plate is provided with front jointers, then is locked with the detachment and installation adjusting devices by the front jointers, and is connected with the side plates. Each detachment and installation adjusting device is characterized in that a locking and disengagement mechanism is arranged in each detachment and installation adjusting device and consists of a slide block, a swing rod and an elastic part, each slide block, each swing rod and each elastic part are respectively assembled on a main plate, each front jointer is locked by the corresponding slide block under the elastic action, each swing rod is acted under the locking state, and then each front jointer is unlocked and separated; each detachment and installation adjusting device is also provided with a height adjusting part and a transverse adjusting part, the height adjusting part and the transverse adjusting part respectively act on the corresponding main plate to do arc-shaped movement and transverse swinging, each front jointer is driven to vertically and transversely move, and then the surface plate is vertically and transversely adjusted. The detachment and installation adjusting device has the characteristics that the structure is simple and reasonable, the property is reliable, multiple functions are realized, the personalized effect and safety are realized, the application range is wide, the cost is low, and the market suitability is high.

Owner:GUANGDONG TAIMING METAL PROD

Low profile array antenna based on Luneburg lens array

ActiveCN109841956AReduce complexityReduce design difficultyIndividually energised antenna arraysAntennas earthing switches associationBeam scanningAntenna feed

The invention provides a low profile array antenna based on a Luneburg lens array. The low profile array antenna comprises m Luneburg lenses and a transceiving assembly, wherein the m Luneburg lensesare arranged on the same horizontal plane; each Luneburg lens comprises a Luneburg lens unit and an antenna array fixed to the surface of the Luneburg lens unit, and antenna units with identical pointing angles on different Luneburg lens units are antenna units at the same position; the transceiving assembly comprises a receiving module and a transmitting module; the n antenna units receive n paths of signals; the receiving module selects a plurality of paths of signals from the n paths of signals, and combines the plurality of paths of signals into a path of signals and outputs the path of signals to the transmitting module; and the transmitting module processes the path of signals and realizes multi-path signal output. The low profile array antenna has the advantages of realizing large-angle beam scanning through arranging the antenna arrays on the surface of the single Luneburg lens unit and sequentially feeding the antenna units at the same position in the antenna array on the surface of each Luneburg lens unit, and reducing the complexity and design difficulty of an antenna feeding network.

Owner:HEFEI RHOSOON INTELLIGENT TECH CO LTD

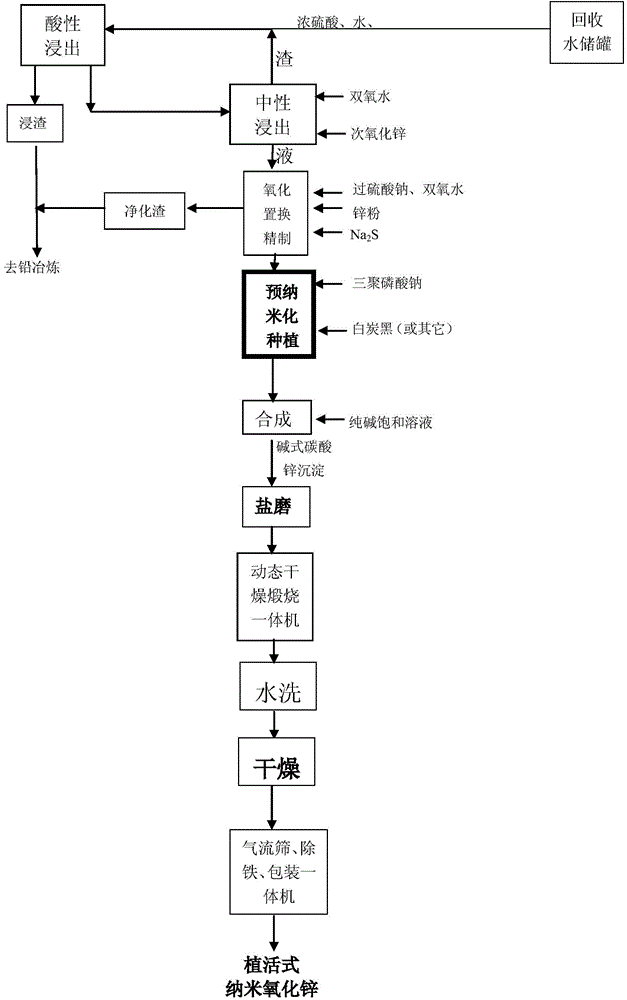

Engraftment type nano-zinc oxide and production process thereof

ActiveCN104591259AReduce contentHigh purityMaterial nanotechnologyZinc oxides/hydroxidesZno nanoparticlesPetrochemical

The invention relates to the technical field of the petrochemical and chemical fine chemicals and particularly relates to an engraftment type nano-zinc oxide and a production process thereof. According to the production process, a leaching purification process is changed to reduce the contents of the heavy metal impurities such as lead, cadmium, copper, arsenic so as to increase the purity and the quality of the product; the concentration of the reactant zinc is changed to increase the yield of the nano-zinc oxide; the catalyst is changed to eliminate the polarity of the zinc oxide and reduce the aggregation degree of the nano-zinc oxide; a salt-milling process is added to reduce the grain size, increase the specific surface area and improve the activity; at the same time, the types of the disperser are added to enrich the types of the product, adapt to various uses and expand the market adaptability of the product.

Owner:黄有余

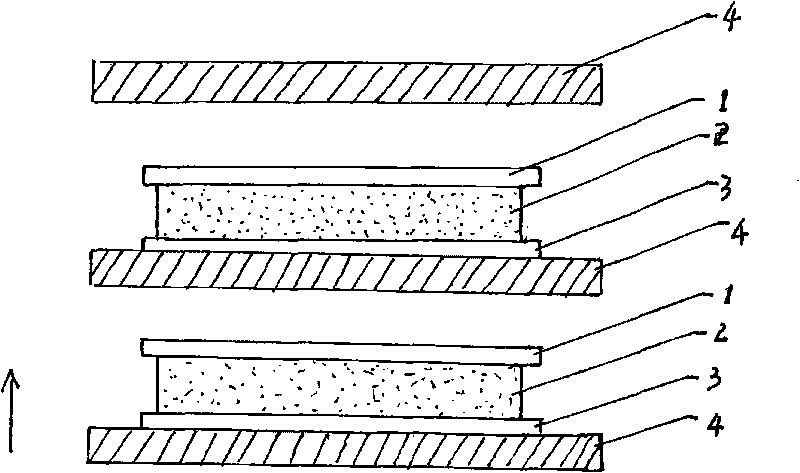

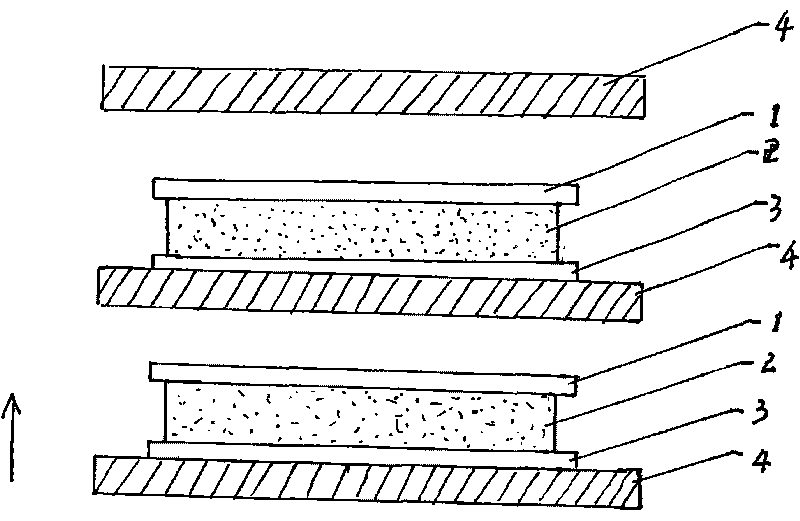

Method for manufacturing medium and high density fiberboards without pre-cured layers

InactiveCN101733811AReduce lossIncrease profitWood working apparatusDomestic articlesProduction lineHigh density

The invention relates to a method for manufacturing medium and high density fiberboards by a multi-layer press. The existing method for manufacturing the medium and high density fiberboards by using the multi-layer press has the problem of thicker pre-cured layers. The invention provides the method for manufacturing the medium and high density fiberboards with no or few pre-cured layers by using the multi-layer press, which can save loss of raw materials and not only be used for manufacturing the thick fiberboards, but also be used for manufacturing the thin medium and high density fiberboards. The technology can be applied in a production line of manufacturing the medium and high density fiberboards of the multi-layer press.

Owner:唐善学

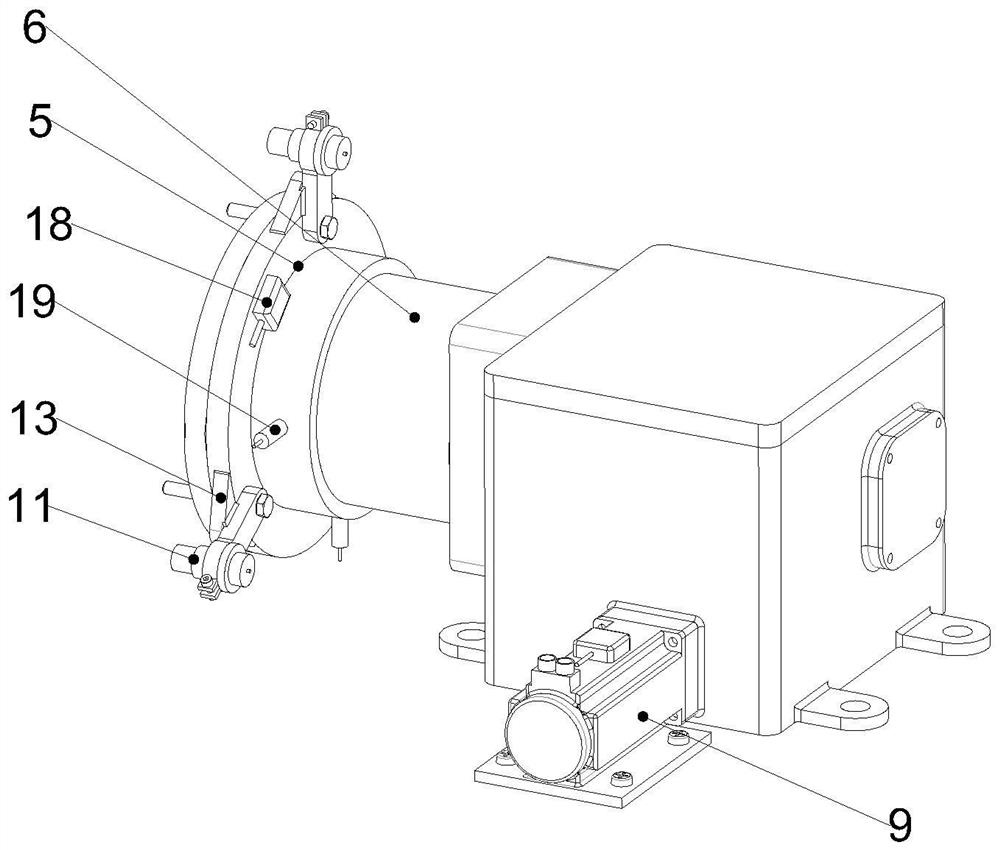

Monitoring system for disc brake of elevator

The invention discloses a monitoring system for a disc brake of an elevator, and relates to the field of elevators. A magnetostriction sensor is installed on a shoe to measure a brake gap, a photoelectric encoder is installed at the shaft end of a roller to monitor the rotating state of the roller, a strain gauge is installed on a shoe push rod to measure the brake positive pressure, a detection unit and a PLC are used cooperatively to achieve self-adaptive feedback adjustment, a servo motor cooperates with a ball screw pair to push the brake shoe, rapid response, on-line brake torque adjustment and self-adaptive brake spacing adjustment can be achieved, vibration sensors are installed in the horizontal direction and the vertical direction of the shoe respectively and are used for detecting the vibration states in the horizontal direction and the vertical direction respectively, the vibration condition of the brake in the working process can be accurately measured, safe operation of abrake system is guaranteed, potential safety hazards are repaired and alarmed timely, the failure rate of the brake is substantially reduced, and reliable braking and stable operation of a mine hoistare guaranteed.

Owner:ANHUI UNIV OF SCI & TECH

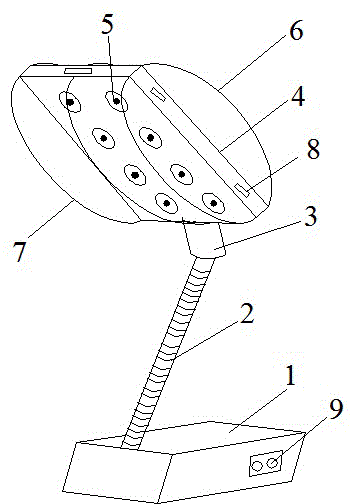

LED (Light Emitting Diode) table lamp

InactiveCN104595785AAvoid blind spotsImprove market adaptabilityPlanar light sourcesPoint-like light sourceEngineeringControl switch

The invention discloses an LED (Light Emitting Diode) table lamp. The LED table lamp comprises a lamp base and a lamp body, wherein the lamp base comprises a base body and a telescopic arm which is made of a threaded pipe, and the lamp body is connected with the telescopic arm through a 360-degree rotating shaft; the lamp body comprises a base plate, a lampshade and LED groups, the LED groups are mounted on two faces of the base plate, the lampshade comprises an upper shell and a lower shell which are connected with the base plate and close the LED groups in the upper and lower shells, and both the upper shell and the lower shell are made of transparent materials; two control switches are formed on the lamp base and are used for respectively controlling the LED groups on the two faces of the base plate. The LED table lamp disclosed by the invention has the beneficial effects that the conception of the traditional table lamps is innovated, functions, such as an angle-adjustable function and a double-face light emitting function, are realized, light-emitting dead angles are avoided, meanwhile, only the LED group of one face can be turned on according to customer needs, and thus, the LED table lamp is flexible and diverse, thereby having better market adaptability.

Owner:SUZHOU KUNK & SAM LIGHTING TECH CO LTD

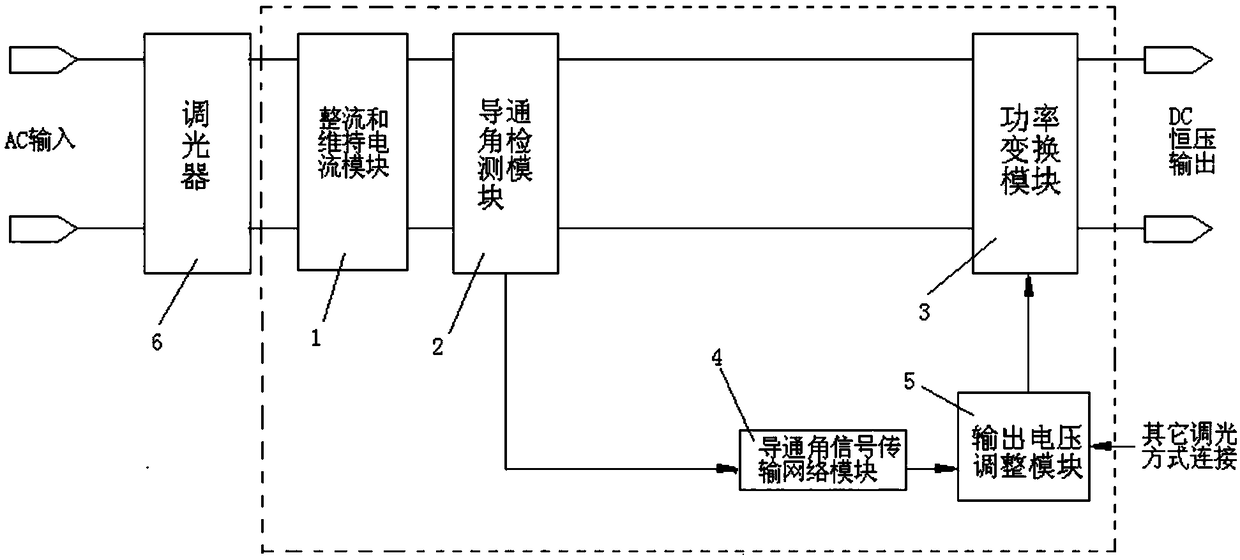

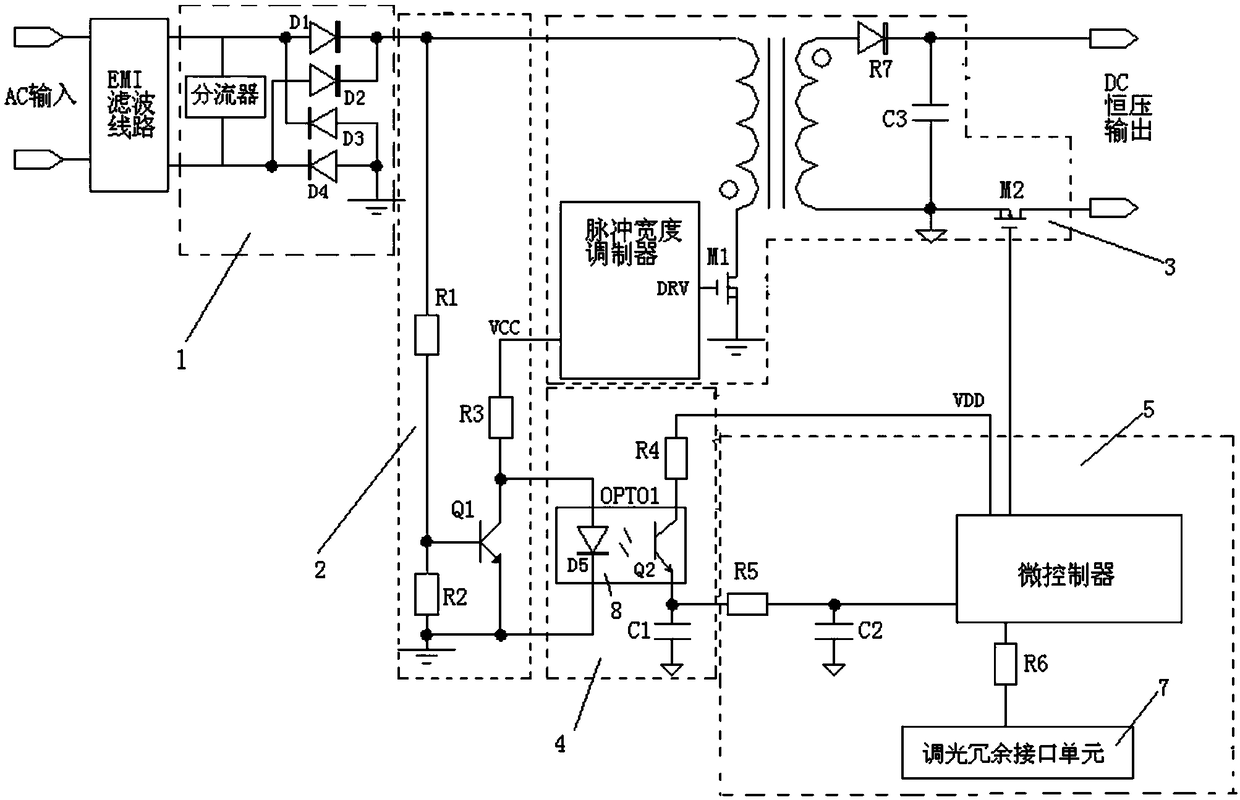

LED power source platform capable of integrating various dimming ways

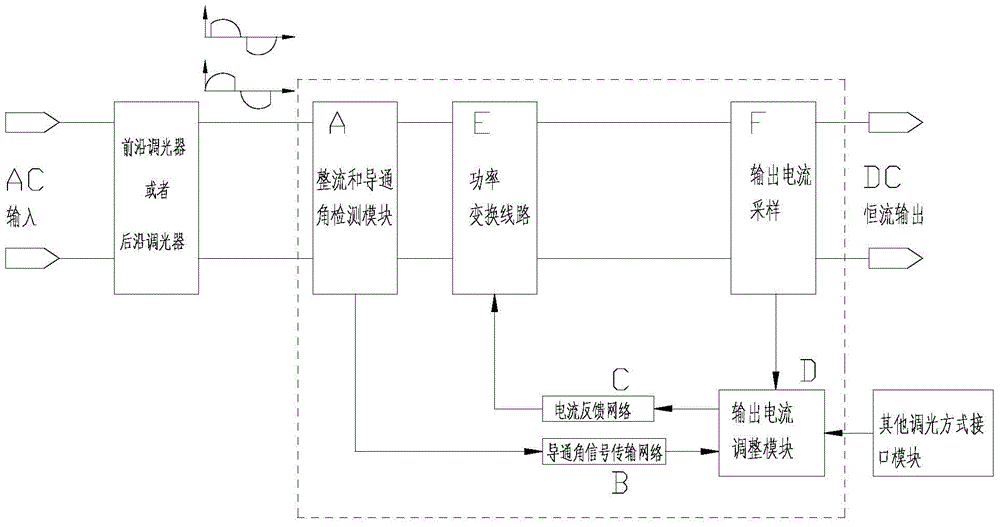

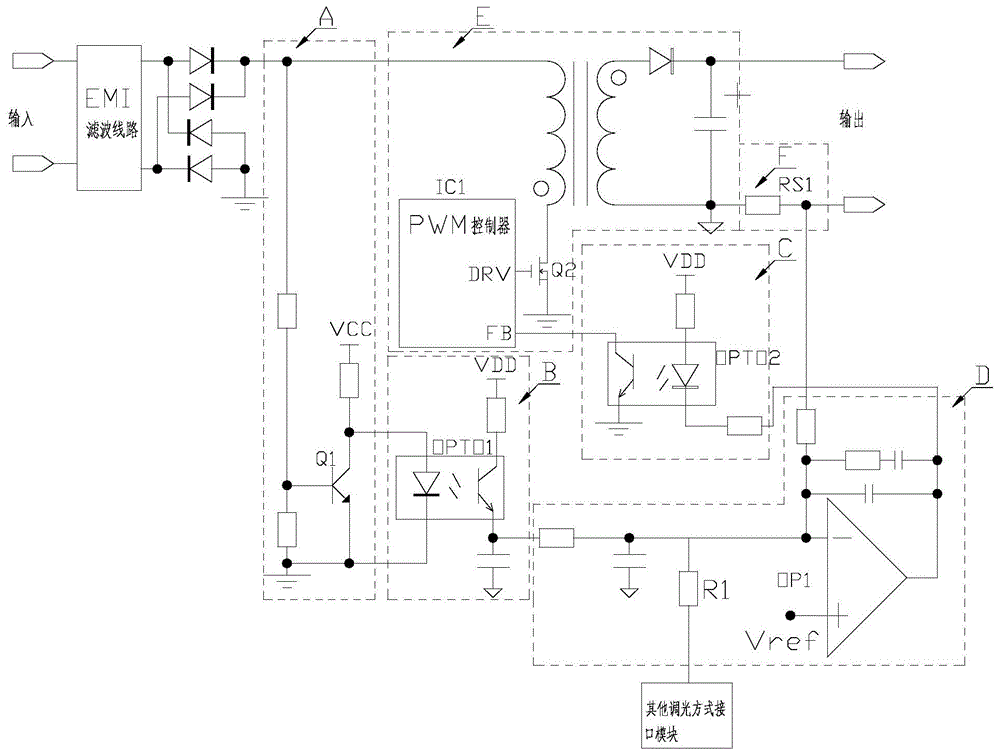

InactiveCN103561528ACost-effectiveImprove market adaptabilityAc-dc conversionElectric light circuit arrangementComputer moduleDimmer

The invention discloses an LED power source platform capable of integrating various dimming ways. The LED power source platform comprises a rectification and conduction angle detection module, a conduction angle signal transmitting network, a current feedback network, an output current adjusting module, a power conversion circuit and an output current sampling module. The rectification and conduction angle detection module is connected with an input end and the conduction angle signal transmitting network, the input end of the output current adjusting module is connected with the conduction angle signal transmitting network or the dimming signal output end of another dimming way interface module, the input end of the output current adjusting module is connected with the output current sampling module, the output end of the output current adjusting module is connected with the current feedback network, the current feedback network is connected with the power conversion circuit, and the output current sampling module is connected with the power conversion circuit. The LED power source platform capable of integrating the various dimming ways can be compatible with various dimmers, the cost performance of an LED dimming light source is improved, and the market adaptive capacity of the LED dimming light source is improved.

Owner:ADPOWER TECH WUXI

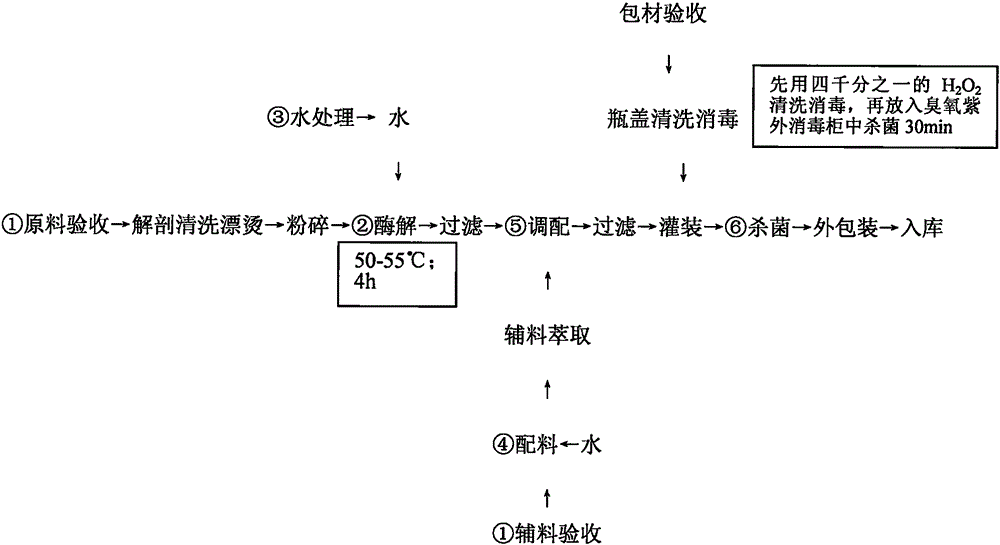

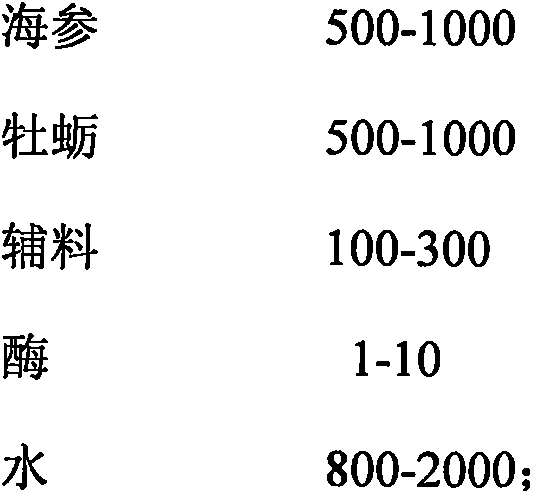

Trepang and oyster enzymolysis oral liquid and preparation method thereof

The invention discloses trepang and oyster enzymolysis oral liquid and a preparation method thereof, and belongs to the technical fields of the research, the development and the industrialization of marine biotechnologies in the biology industry. The trepang and oyster enzymolysis oral liquid which is oral liquid is processed through the following steps of using fresh stichopus japonicus meat and fresh oyster meat as main raw materials, using Chinese herbal medicines and fruits as auxiliary materials, and using a biological enzymolysis method as a basic production technology. The trepang and oyster enzymolysis oral liquid disclosed by the invention is particularly an industrialized food having the functions of improving the immunity of human bodies, resisting weariness, promoting rehabilitation and the like. The trepang and oyster enzymolysis oral liquid is produced by adopting scalded stichopus japonicus and scalded oysters, the auxiliary materials and an appropriate quantity of varied bioactivity enzymes through a technology with a high scientific and technological content. The oral liquid disclosed by the invention has the notable characteristics of being simple in technology, specific and clear in functions, high market adaptability and the like.

Owner:王文进

Horizontal round roller type filter

InactiveCN105080199AEasy to separateContinuous separation effectFatty-oils/fats refiningMoving filtering element filtersDrive shaftEconomic benefits

The invention discloses a horizontal round roller type filter. The filter includes a filter screen disposed outside of the roller, a transmission shaft which is disposed on the steel plate positioned on the back-end face of the roller, two carrying rollers supporting the front-end of the roller; and an oil draining hopper (under which has a frame provided with a vibrator) and a pomace draining hopper disposed below the roller. Four dampers under the frame are connected with a pedestal, and a high pressure air tube is disposed in an upper cover above the frame. The position disposed the roller is sealed with steel plate, and forms a container with the upper cover, oil draining hopper and pomace draining hopper. Edible oil drains from the hole disposed on the filter screen outside of the roller, and the oil residue is stranded in the roller when the motor transmission roller rotates. The oil residue discharges from the pomace draining hopper flowing through an outlet disposed at the back-end of the roller after processed by a scraping plate, a cleaning brush and the high pressure air tube; and the edible oil discharges from the oil draining hopper. The filter separates the cleared fragrant edible oil, and can separate highly efficiently and continuously. The horizontal round roller type filter has simple structure, strong market adaptive capacity, and is easy operation, so that the economic benefit of the product is increased.

Owner:BEIJING ZHONGTIAN JINGGU ELECTROMECHANICAL EQUIP MFG

Locking and adjusting device for drawer slide rail

The invention discloses a locking and adjusting device for a drawer slide rail. The locking and adjusting device comprises a slide rail assembly and a drawer, wherein the drawer is fixedly connected to a moving rail on the slide rail assembly. The locking and adjusting device is characterized by further comprising a locking and adjusting device fixed on the drawer, wherein the drawer is connected with a square hole in a lock catch moving rail of the locking and adjusting device; the locking and adjusting device comprises a locking mechanism and an adjusting mechanism; the locking mechanism is formed by transmission of a handle and a lock catch, and is self-locked on the moving rail by locking the locking and adjusting device; the lock catch is unlocked by using the handle, the adjusting mechanism is used for performing three-dimensional adjustment on the drawer from top, bottom, left, right, front and back. By adopting the locking and adjusting device, locking and three-dimensional adjustment are performed through the locking mechanism and the adjusting mechanism; self-locking of the locking mechanism is realized by locking the lock catch moving rail; the handle is used for driving the lock catch to perform unlocking, so that unlocking and separation of the drawer and the moving rail are realized conveniently. The adjusting mechanism is used for adjusting the drawer from top, bottom, left, right, front and back respectively, so that matching between the drawer and the moving rail is facilitated, and the requirements of different people are met.

Owner:GUANGDONG TAIMING METAL PROD

Modified vitrified micro bubble thermal insulation composite board and preparation method thereof

ActiveCN110759686ALow thermal conductivityImprove thermal insulationFeeding arrangmentsInsulation layerMicro bubble

The invention discloses a modified vitrified micro bubble thermal insulation composite board and a preparation method thereof. The composite board sequentially comprises a surface layer, a thermal insulation layer and a bottom layer from top to bottom, the surface layer, the thermal insulation layer and the bottom layer are manufactured through a mold pressing integrated forming process, the surface layer is composed of interface mortar, the thermal insulation layer is composed of a modified vitrified micro bubble composite material, and the bottom layer is composed of bottom mortar. The modified vitrified micro bubble thermal insulation composite board has the advantages that the thermal insulation layer is composed of the modified vitrified micro bubble composite material, so that not only is excellent thermal insulation performance provided, but also the strength is good; the composite board adopts a three-time material distribution and mould pressing integrated forming process, sothat the strength of the formed board body is improved, and the formed modified vitrified micro bubble heat preservation layer still has excellent heat preservation and heat insulation performance.

Owner:湖南斯多孚节能科技有限公司

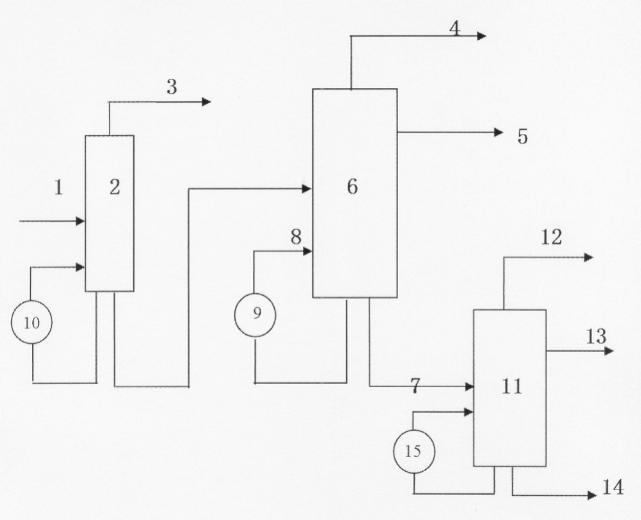

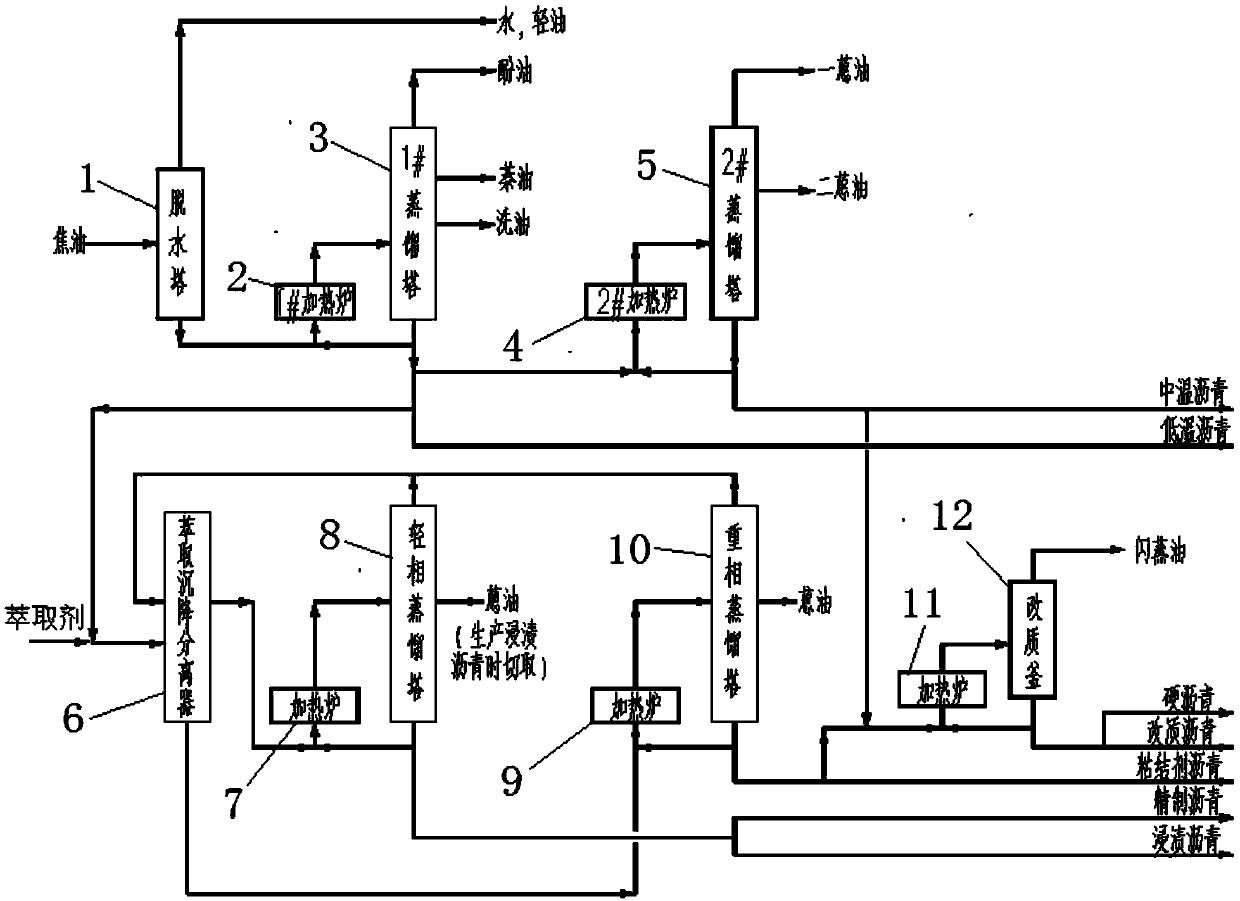

Process and device for producing various asphalt products by combining distillation and extraction

PendingCN109517614AMeet needsSolve the problem of low single added valueWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionDistillationTar

The invention relates to a process and a device for producing various asphalt products by combining distillation and extraction. The device comprises a dehydration tower, a distillation system, an extraction system and an asphalt modification system. Coal tar is used as a raw material to produce low-temperature asphalt, medium-temperature asphalt, modified asphalt, low-quinoline insoluble refinedasphalt, impregnated asphalt, hard asphalt, binder asphalt and other products by using a combined production process of distillation, extraction and asphalt modification. A variety of high value-addedasphalt products can be produced simultaneously with a set of production device, the utilization of the device is maximized, and the process and the device are adaptive to the needs of large-scale tar processing.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

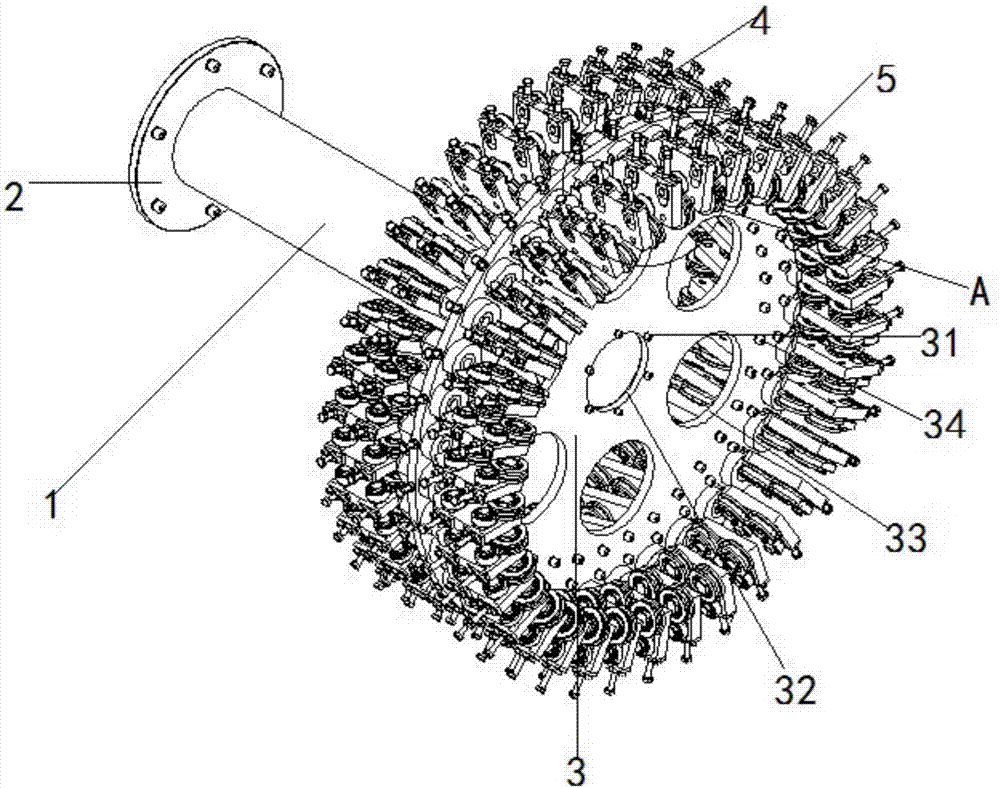

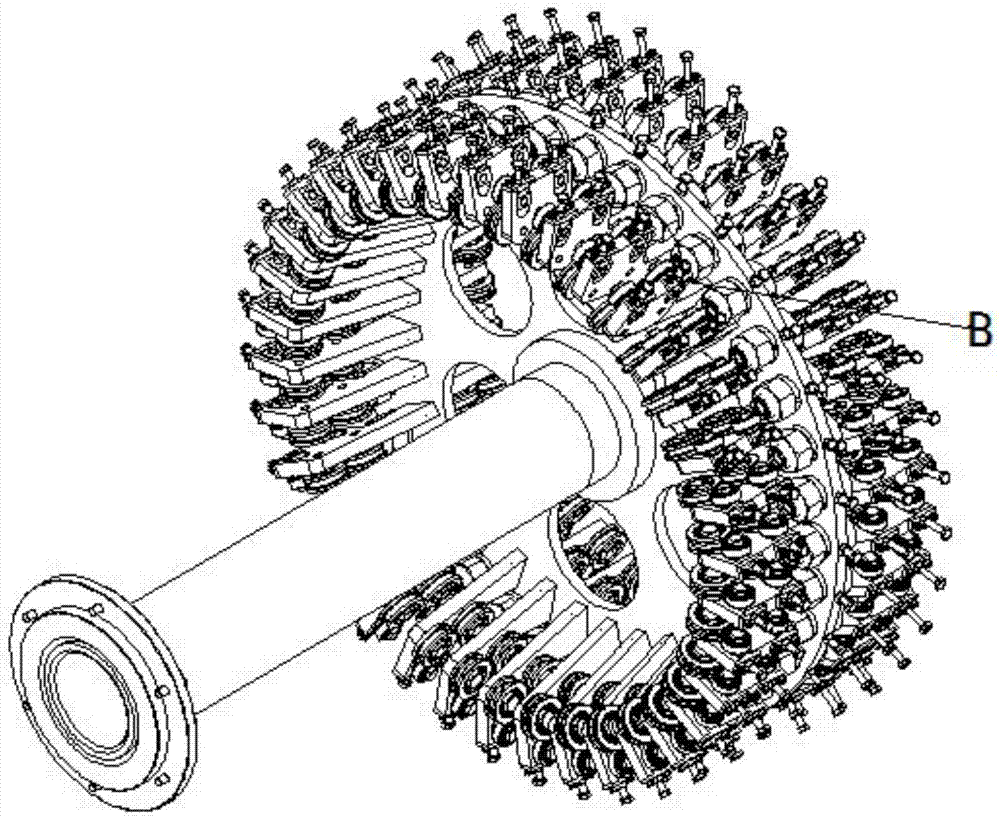

Profile line forming device of frame type strander

ActiveCN107123488AMeet individual needsMeet workmanship standardsCable/conductor manufactureStructural engineeringCopper-wiring

The invention discloses a profile line forming device of a frame type strander. The profile line forming device comprises a center shaft, wherein a positioning disc is arranged at the input end of the center shaft, and a distribution disc is mounted at the output end of the center shaft; a plurality of entry sheave devices are uniformly arranged on the input end side of the distribution disc in the peripheral direction, and a plurality of exit sheave devices are uniformly arranged on the output end side of the distribution disc in the peripheral direction. By means of the design, large-section foreign-shaped single copper strands are pre-twisted for a certain angle before entering a forming compression mold, and the single strands are not overturned or scratched; more convenience and probabilities are provided for a production technology of large-section foreign-shaped round compressed single copper strands, personalized requirements of users are met, and the market adaptability of the device is improved; phenomena of looseness and edge turnup are avoided, and technological standard of the users are met.

Owner:HEFEI SMARTER TECH GROUP CORP

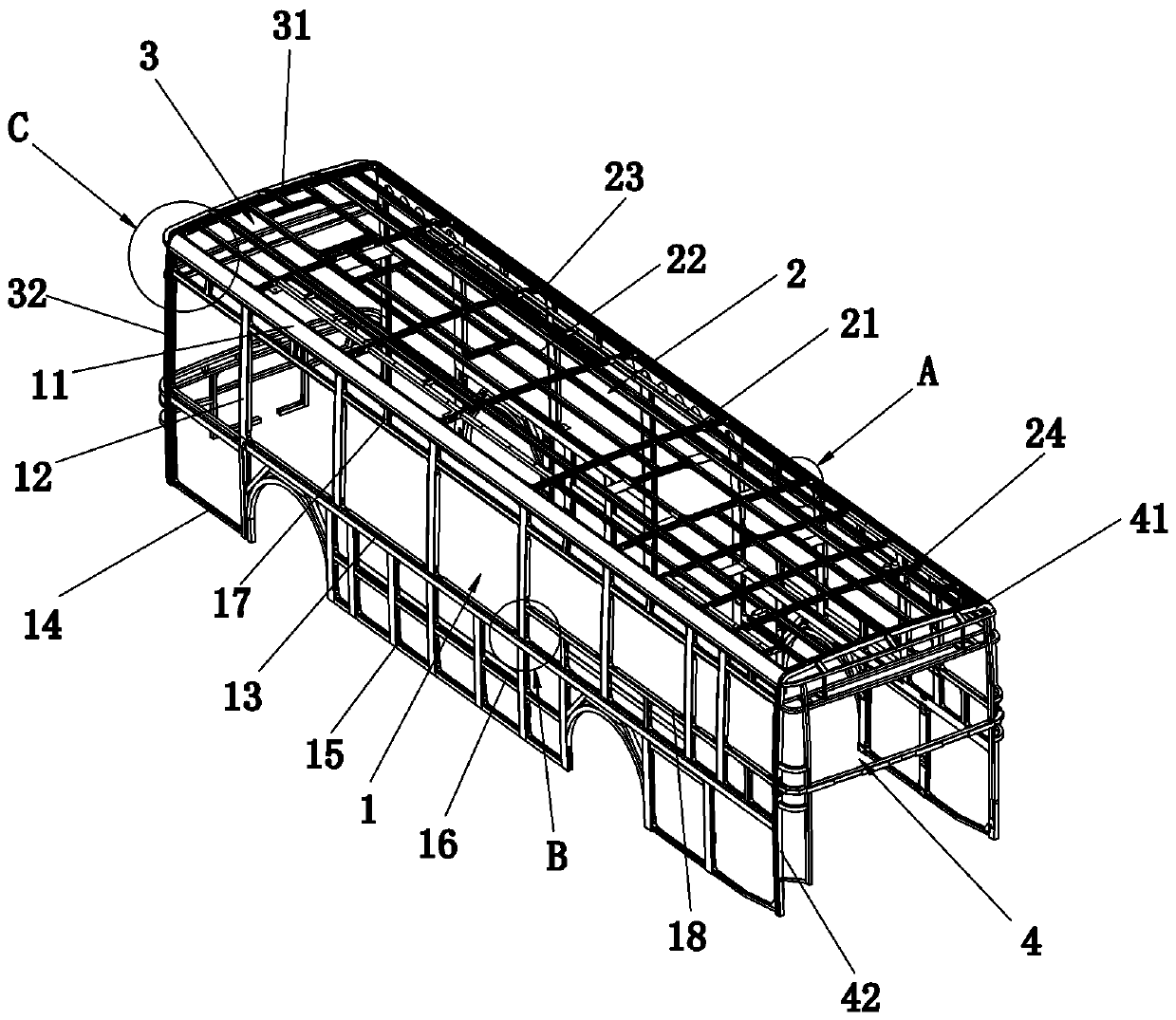

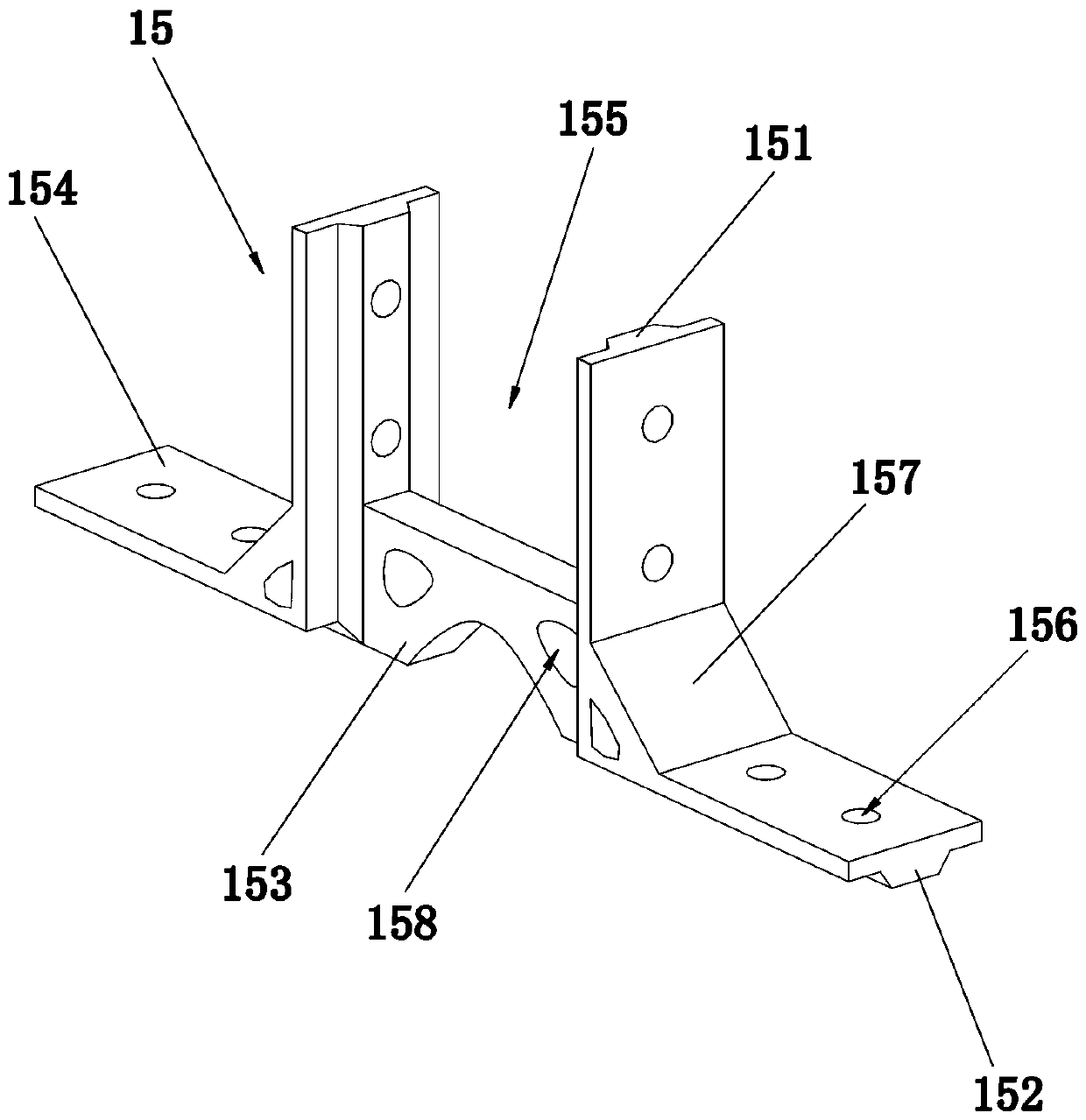

Automobile skeleton, automobile roof skeleton and automobile sidewall skeleton

PendingCN109969272AWill not cause interferenceQuick removable installationSuperstructure subunitsPassenger vehicle superstructuresStructural stabilityAutomotive engineering

The invention discloses an automobile skeleton, an automobile roof skeleton and an automobile sidewall skeleton, and relates to the technical field of automobiles. The automobile skeleton includes a plurality of connecting points formed by plural vehicle beams being vertically connected with each other, the multiple connecting points include first connecting points, and the first connecting pointsare formed by connecting a first vehicle beam and a second vehicle beam through first connecting pieces; the first connecting pieces include a connecting plate and two L-shaped guard plates, the twoL-shaped guard plates with internal corners outwards are oppositely arranged at the two ends of the connecting plate, so that a U-shaped installation part is formed on one sides of the first connecting pieces, and an installation surface is formed on the other sides of the first connecting pieces; and one end of the first vehicle beam is connected to the installation part in an inserted mode, andthe side wall of the second vehicle beam is fixedly arranged on the installation surface. The automobile skeleton, the automobile roof skeleton and the automobile sidewall skeleton have the beneficialeffects that the defects in the prior art are overcome, the skeletons are suitable for the large-scale design and manufacture of bus body skeletons, and have the advantages of being high in lightweight level, high in material utilization rate, high in structural stability, good in technical condition adaptability, and the like.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

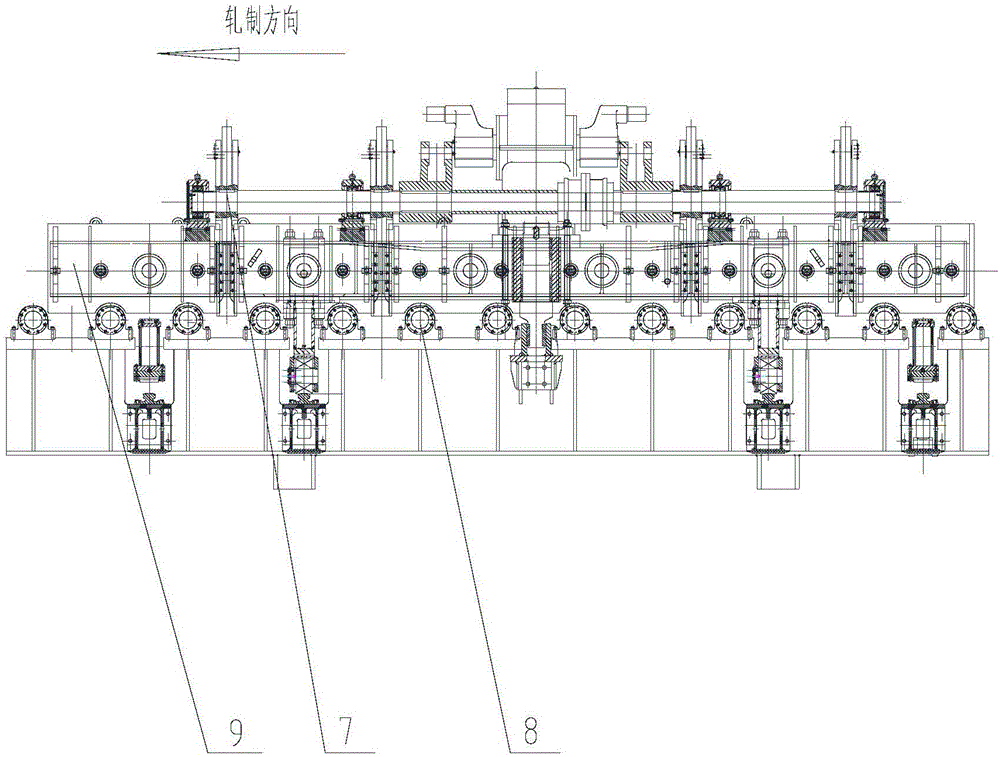

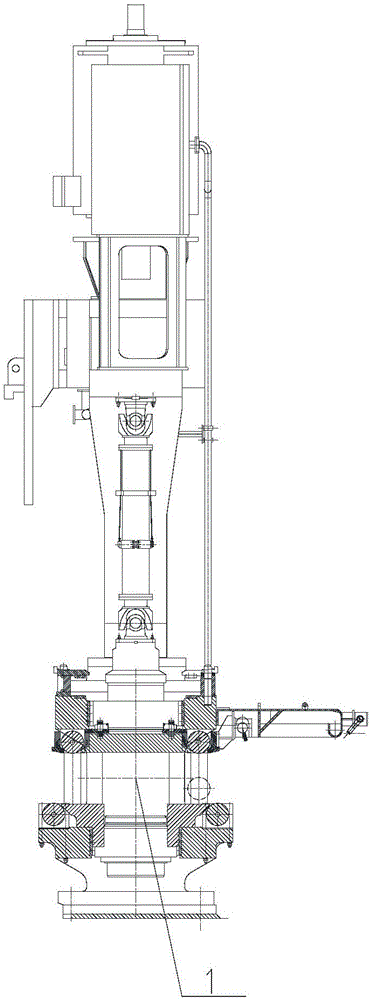

Mould flat steel continuous reversible rolling machine unit and mould flat steel rolling method

ActiveCN106513435AFlexible organizationSatisfy product quality precisionRoll force/gap control deviceTemperature control deviceProduction lineStrip mill

The invention discloses a mould flat steel continuous reversible rolling machine unit and a mould flat steel rolling method. The mould flat steel continuous reversible rolling machine unit comprises vertical rolling mills and horizontal rolling mills, wherein the vertical rolling mills comprise a vertical rolling mill I and a vertical rolling mill II; the horizontal rolling mills comprise a horizontal rolling mill I and a horizontal rolling mill II; and the vertical rolling mill I, the horizontal rolling mill I, the vertical rolling mill II and the horizontal rolling mill II are arranged on a horizontal working surface sequentially according to a rolling direction. According to the mould flat steel continuous reversible rolling machine unit and the mould flat steel rolling method, which are provided by the invention, production of multi-size large-size mould flat steel and square steel with the thickness being 6 to 300 mm and the width being 100 to 1000 mm is realized by one production line, the quality precision of products is met, energy consumption is reduced, and the size and the range of the products are enlarged. Therefore, high market adaptive capability is achieved, and enterprises can organize production flexibly according to the market requirements and create more economic benefits.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Production method of polyolefin white oil

ActiveCN104232159ALow viscosityGuaranteed hydrogenation effectTreatment with hydrotreatment processesPolyolefinFixed bed

The invention discloses a production method of polyolefin white oil. The production method comprises the following steps: (1) by taking paraffin and naphthene based lubricating base oil as raw material oil, blending the paraffin and naphthene based lubricating base oil, and dehydrating; (2) inputting the processed raw material oil into two tandem fixed bed reactors with noble metal catalysts, and performing two-section high-pressure hydrogenation treatment in the presence of a hydrorefining catalyst; and (3) dehydrating and refining to obtain the high-viscosity food-grade polyolefin white oil. The production method has the beneficial effects that the reaction temperature can be reduced, the degradation of the raw material viscosity during hydrorefining can be reduced, and the hydrogenation effect of the high-viscosity white oil can be ensured; the change of pour points and flash points can be reduced; the requirements of saturated aromatic hydrocarbons can be met; the strict requirements of the polyolefin white oil on the water content can be met; a process is flexible to perform and the polyolefin white oil is strong in market adaptability.

Owner:BEIJING YOUGONG SCI & TECH

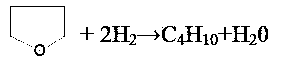

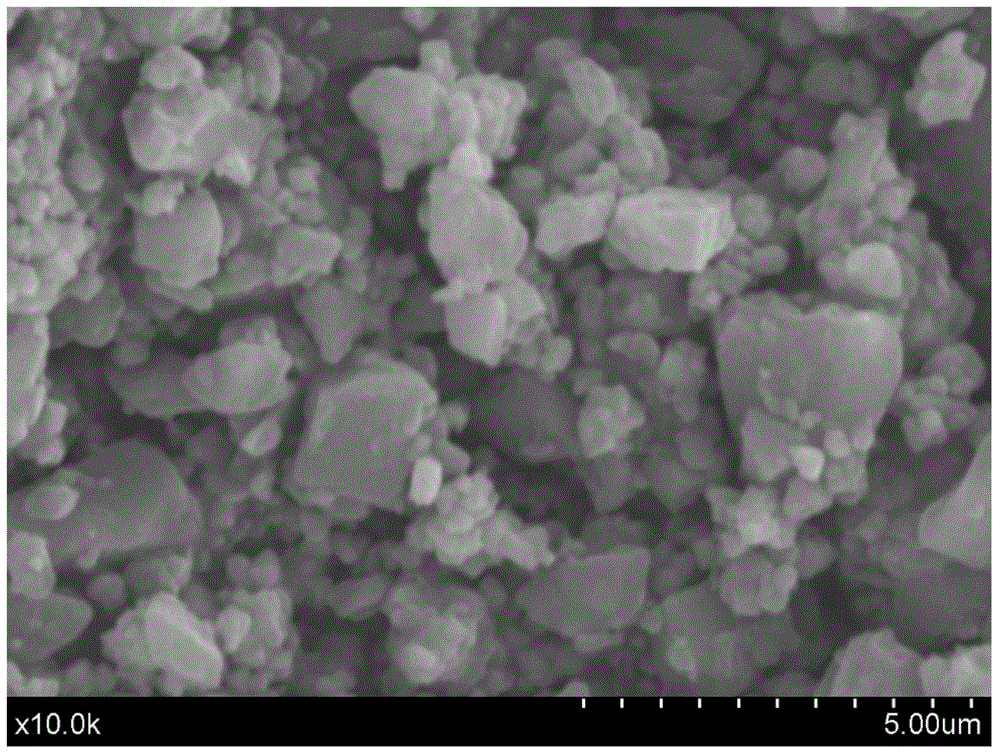

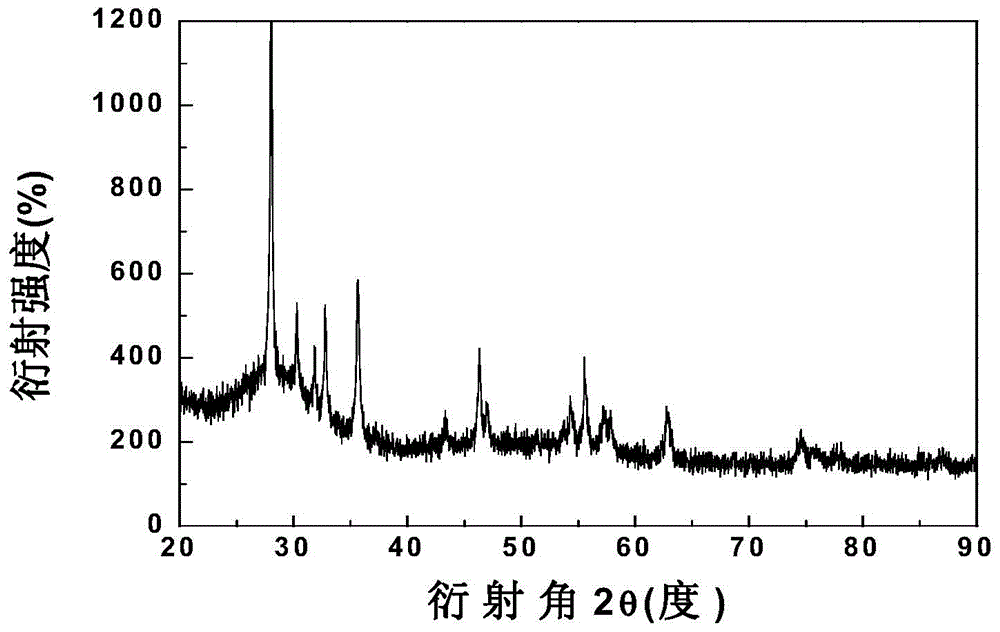

Bismuth-oxide-based black pigment used for glass digital inkjet printing and preparation method of bismuth-oxide-based black pigment

InactiveCN105062198AReduces inkjet head cloggingGood inkjet printing performanceInksLithium oxideSilicon oxide

The invention provides bismuth-oxide-based black pigment used for glass digital inkjet printing and a preparation method of the bismuth-oxide-based black pigment. The bismuth-oxide-based black pigment is characterized in that preparation raw materials of the bismuth-oxide-based black pigment include bismuth oxide (alpha type Bi2O3), amorphous state silicon oxide (SiO2), boron oxide (B2O3), lithium oxide (LiO2), aluminum oxide (Al2O3), zirconium oxide (ZrO2) and copper chromite black (common industrial coloring materials); the preparation method includes the steps of evenly mixing bismuth oxide (alpha type Bi2O3), amorphous state silicon oxide (SiO2), boron oxide (B2O3), lithium oxide (LiO2), aluminum oxide (Al2O3) and zirconium oxide (ZrO2), conducting high energy ball milling to make the mixture sufficiently and mechanically alloyed, and mixing the powder obtained through ball milling with copper chromite black in a ball milling mode. The maximum particle size of the bismuth-oxide-based black pigment is smaller than 2 micrometers, the sintering temperature on glass is between 600 DEG C and 700 DEG C, the bonding strength between the bismuth-oxide-based black pigment and the glass is high, and the bismuth-oxide-based black pigment has wide application prospects in the field of digital inkjet printing.

Owner:JIANGSU UNIV

Constant voltage dimming power supply device compatible with multiple dimming modes

PendingCN108650748AOvercome the problem of being compatible with multiple dimming methods at the same timeCost-effectiveElectrical apparatusElectroluminescent light sourcesPower switchingDimmer

The invention discloses a constant voltage dimming power supply device compatible with multiple dimming modes. The device comprises a rectifying and current maintaining module,a conduction angle detecting module,a power switching module,a conduction angle signal transmission network module and an output voltage adjusting module,the conduction angle detecting module is connected with the rectifyingand current maintaining module,the power switching module and the conduction angle signal transmission network module,one end of the output voltage adjusting module is connected with the conduction angle signal transmission network module,the other end of the output voltage adjusting module is connected with the power switching module,and the rectifying and current maintaining module is externally connected with a dimmer. According to the device,the device is compatible with multiple dimming manners to achieve the adjustment of outputting constant voltage,the cost performance of an LED adjustable dimming light source is improved,and the market adaptability of the LED adjustable dimming light source is enhanced.

Owner:ADPOWER TECH WUXI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com