Automobile skeleton, automobile roof skeleton and automobile sidewall skeleton

A skeleton and automobile technology, which is applied in the field of automobile side frame and automobile skeleton, can solve the problems of weak structural strength of a single connector, inconvenient bonding of interior parts, and uneven surface of the joint, so as to improve market adaptability, Improved reliability and safety, simplified structure and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

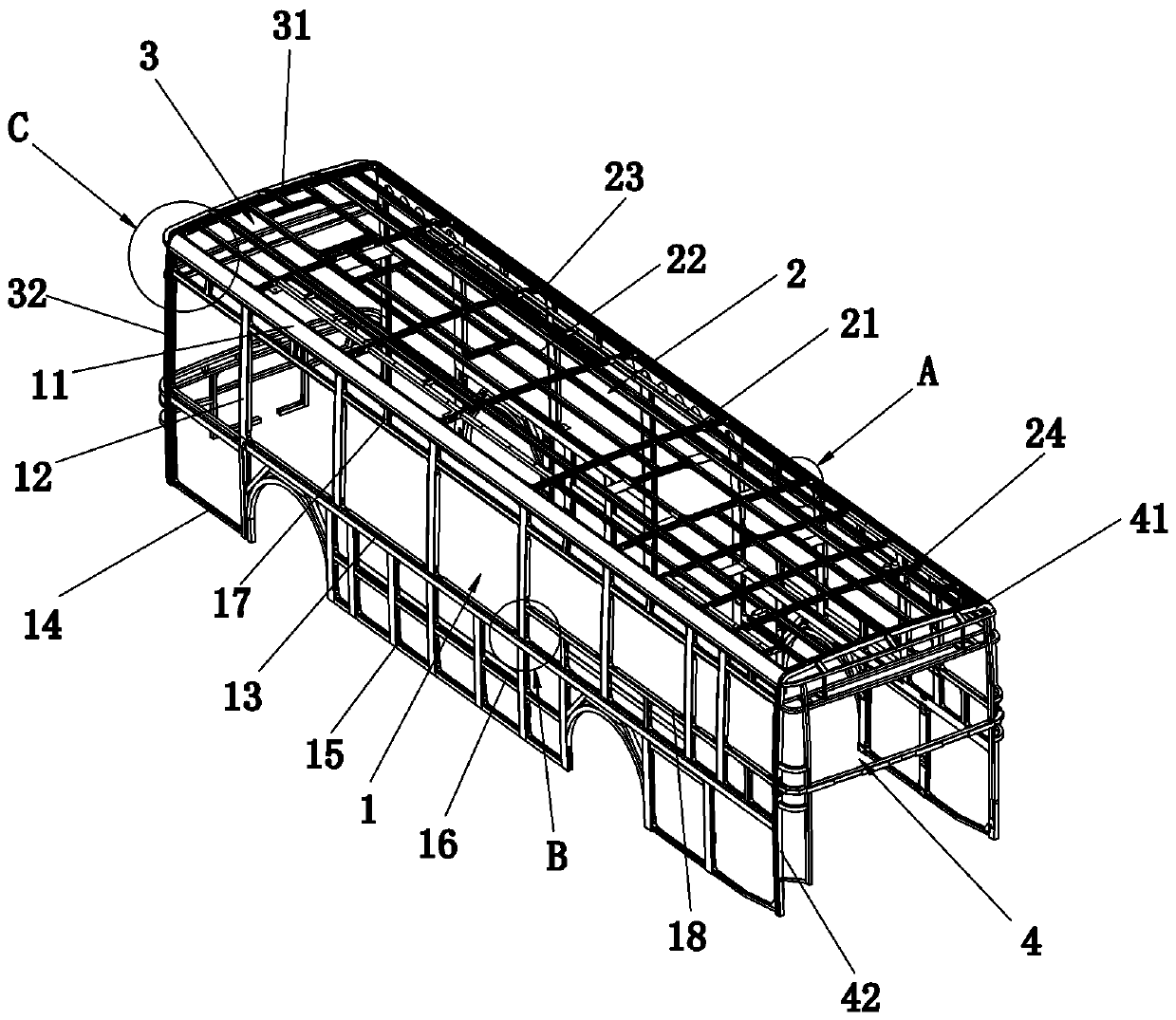

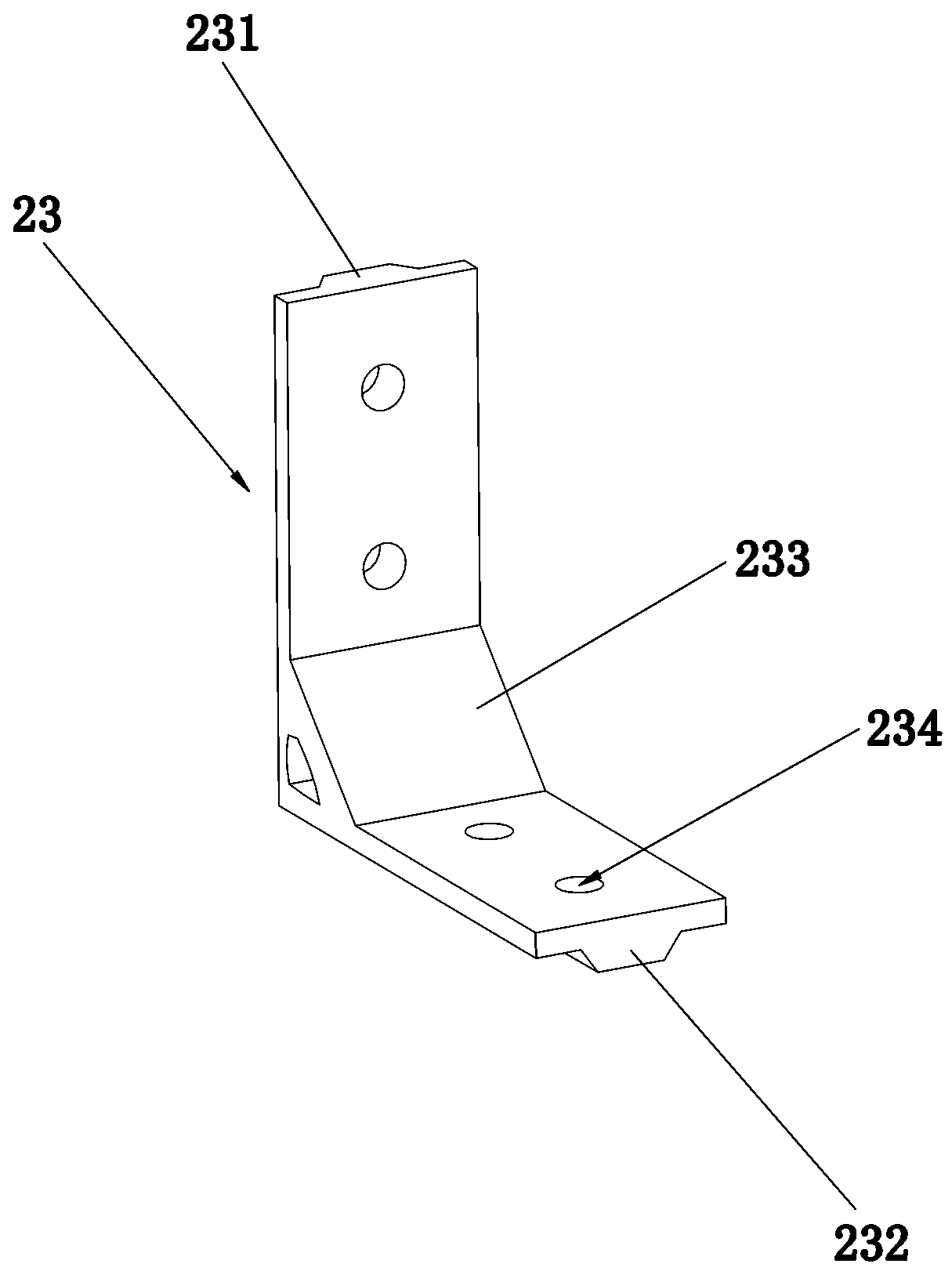

[0040] refer to figure 1 , figure 2 and image 3 , a kind of car frame includes several connection points formed by the vertical connection of a plurality of car beams, and several of the connection points include a first connection point and a second connection point, and the first connection point is composed of the first car beam and the second car beam The second connection point is formed by connecting the third vehicle beam and the fourth vehicle beam through the second connecting piece 23 .

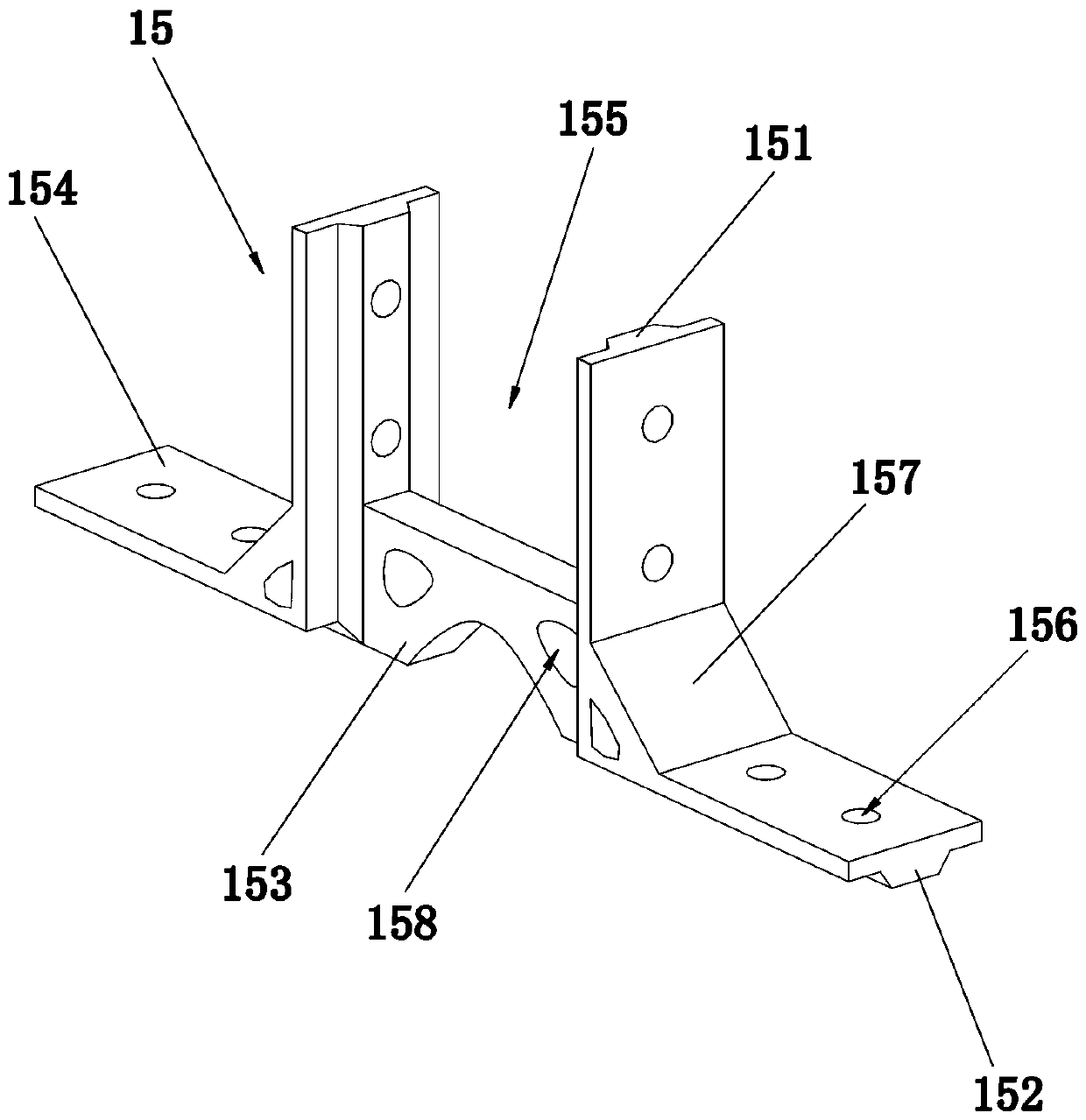

[0041] refer to figure 1 and figure 2The connecting piece 15 includes a connecting plate 153 and an L-shaped guard plate 154, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com