Process and device for producing various asphalt products by combining distillation and extraction

A technology for asphalt products and process equipment, which is applied in the processing of tar by distillation, processing tar pitch/petroleum pitch/natural pitch by distillation, and processing tar pitch/petroleum pitch/natural pitch by selective extraction, etc. High, few kinds of asphalt products, can not meet the needs of various asphalt products and other problems, to achieve the effect of environmental protection, avoid high temperature coking, shorten the conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

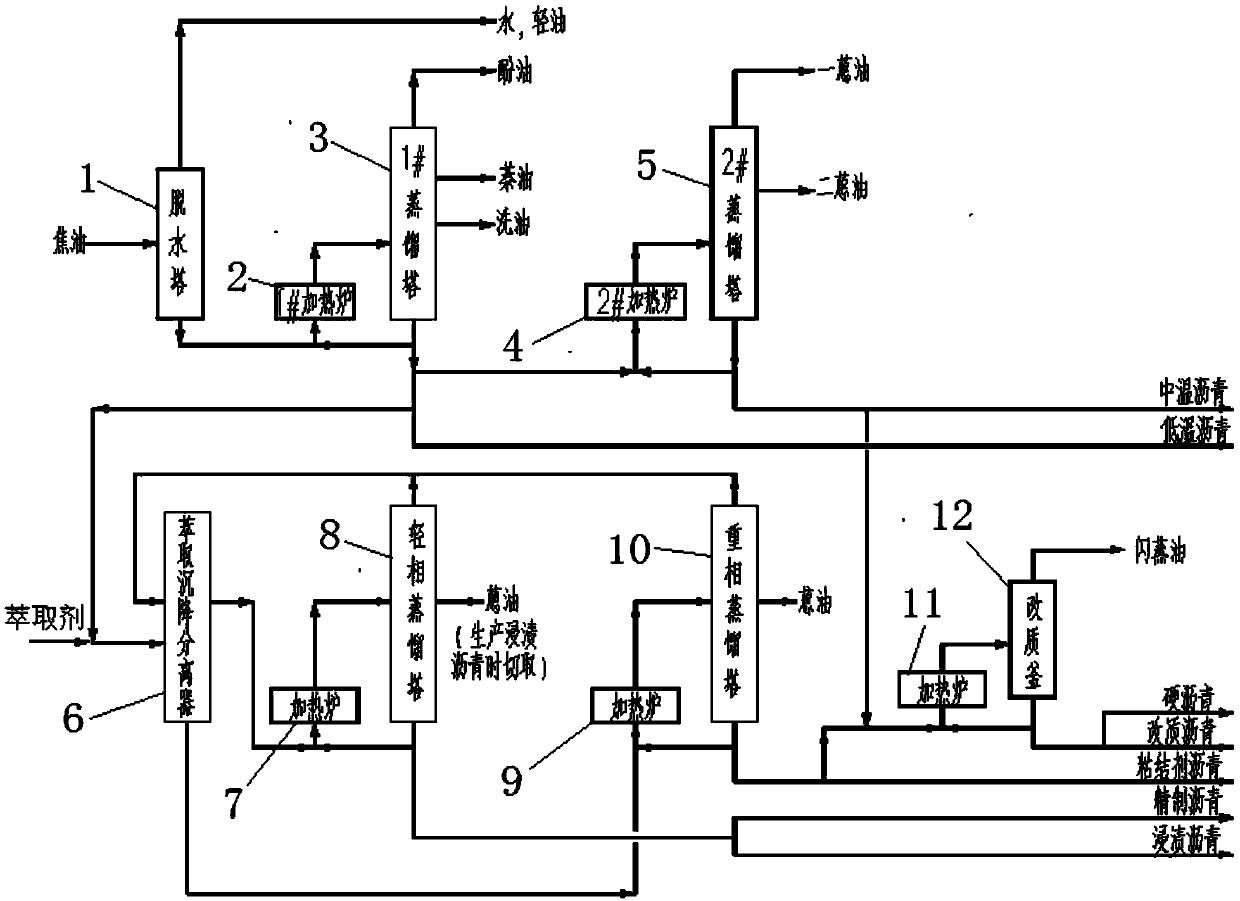

[0048] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0049] See figure 1 As shown, the present invention relates to a combination of distillation and extraction to produce a variety of asphalt products, including a dehydration tower 1, a distillation system, an extraction system and an asphalt modification system, wherein the dehydration tower 1 is provided with a tar Inlet, water / light oil production outlet, dehydrated tar production outlet;

[0050] The distillation system consists of 1 # Heating furnace 2, 1 # Distillation tower 3, 2 # Heating furnace 4, 2 # Composed of 5 distillation towers, of which 1 # Distillation column 2 and 1 # The heating furnace is connected to 3, the top of the tower is equipped with a phenol oil extraction outlet, the side line is equipped with a naphthalene oil extraction outlet and a washing oil extraction outlet, and the bottom of the tower is equipped with fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com