Bismuth-oxide-based black pigment used for glass digital inkjet printing and preparation method of bismuth-oxide-based black pigment

A technology of digital inkjet and black coloring material, which is applied in applications, household utensils, ink, etc., can solve the problems that restrict product development, and achieve the effects of strong market adaptability, simple and efficient preparation method, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

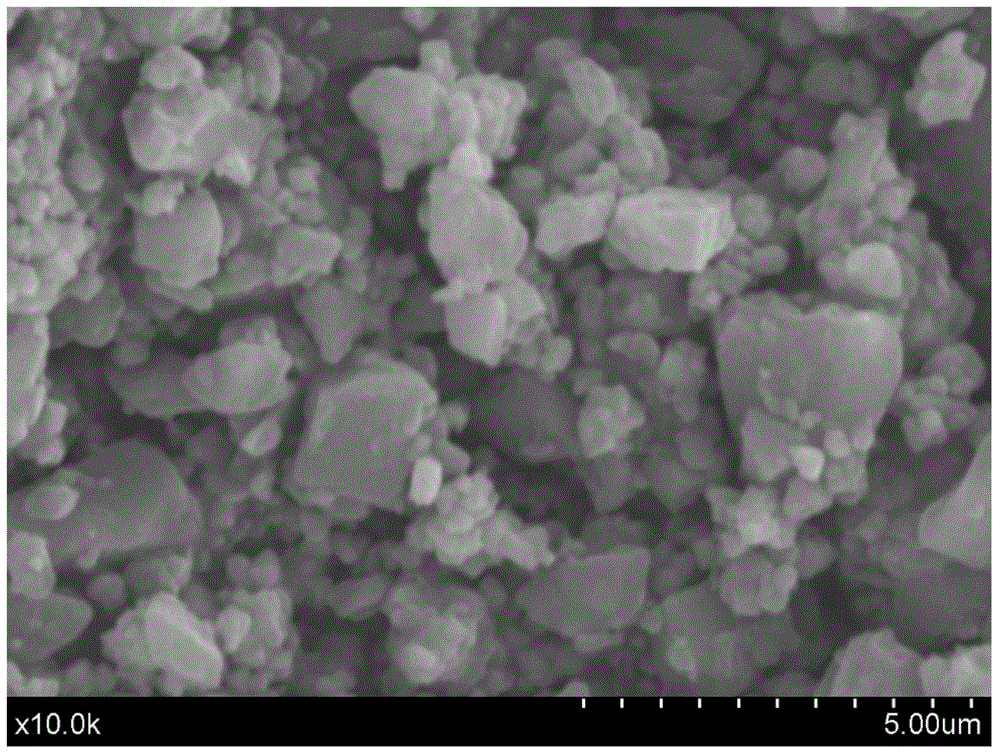

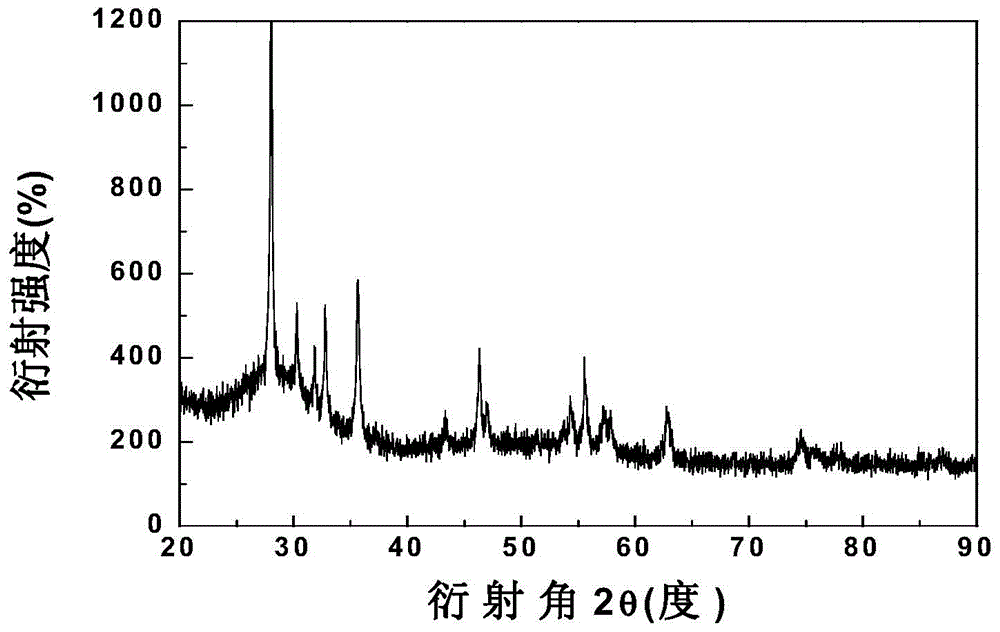

[0029] A bismuth oxide-based black colorant for glass digital inkjet printing, the preparation method of which is as follows:

[0030] First of all, for a 500ml ball mill tank, it is suitable to grind 25g of black pigment at a time, according to bismuth oxide (α-type Bi 2 o 3 ) 37.95%, amorphous silicon oxide (SiO 2 ) 15%, boron oxide (B 2 o 3 )6.8%, lithium oxide (Li 2 O) 4.3%, alumina (Al 2 o 3 )2.75%, zirconia (ZrO 2 ) 1.2%, copper chrome black 32% mass percent, calculate each raw material quality that ball milling 25g black pigment needs, bismuth oxide (alpha-type Bi 2 o 3 ) 9.49 g, amorphous silicon oxide (SiO 2 ) 3.75 grams, boron oxide (B 2 o 3 ) 1.7 g, lithium oxide (Li 2 O) 1.08 grams, aluminum oxide (Al 2 o 3 ) 0.68 g, zirconia (ZrO 2 ) 0.3 grams, copper chrome black 8 grams, then weighed according to the calculation results;

[0031] Secondly, put the weighed raw materials in a beaker, stir evenly, and then weigh 196g of agate balls according to the ...

Embodiment 2

[0037] The experimental method of this embodiment is similar to that of the first embodiment, except that the mass percentages of the raw materials are different. According to bismuth oxide (α-type Bi 2 o 3 ) 32.95%, amorphous silicon oxide (SiO 2 ) 13%, boron oxide (B 2 o 3 )4.8%, lithium oxide (Li 2 O) 3.3%, alumina (Al 2 o 3 ) 2.25%, zirconia (ZrO 2 ) 1%, the mass percentage of copper chromium black 42.7%, calculate the required raw material quality of ball milling 25g black ink powder color material, bismuth oxide (α-type Bi 2 o 3 ) 8.2 g, amorphous silicon oxide (SiO 2 ) 3.25 grams, boron oxide (B 2 o 3 ) 1.2 g, lithium oxide (Li 2 O) 0.83 g, alumina (Al 2 o 3 ) 0.56 g, zirconia (ZrO 2 ) 0.25 gram, copper chrome black 10.71 gram, weigh according to calculation result then, following steps are completely consistent with embodiment 1.

[0038] The black pigment that present embodiment obtains, and figure 1 Similar, compared with Example 1, the finished blac...

Embodiment 3

[0040] The experimental method of this embodiment is similar to that of the first embodiment, except that the mass percentages of the raw materials are different. According to bismuth oxide (α-type Bi 2 o 3 ) 42.95%, amorphous silicon oxide (SiO 2 ) 17%, boron oxide (B 2 o 3 )8.8%, lithium oxide (Li 2 O) 5.3%, alumina (Al 2 o 3 )3.25%, zirconia (ZrO 2 ) 1.4%, copper chromium black 21.3% mass percent, calculate the required each raw material quality of ball milling 25g black ink powder color material, bismuth oxide (α-type Bi 2 o 3 ) 10.7 g, amorphous silicon oxide (SiO 2 ) 4.25 grams, boron oxide (B 2 o 3 ) 2.2 g, lithium oxide (Li 2 O) 1.33 grams, aluminum oxide (Al 2 o 3 ) 0.81 g, zirconia (ZrO 2 ) 0.35 gram, copper chrome black 5.36 gram, weigh according to calculation result then, following steps are completely consistent with embodiment 1.

[0041] The black pigment that present embodiment obtains, and figure 1 Similar, compared with Example 1, the finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com