Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Important Environmental Benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength polypropylene fiber polymer cement mortar and preparation method thereof

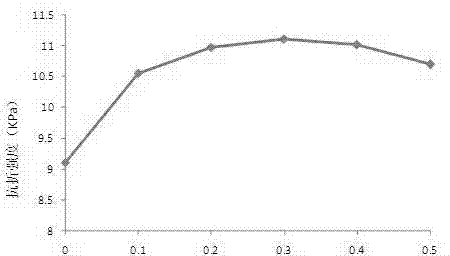

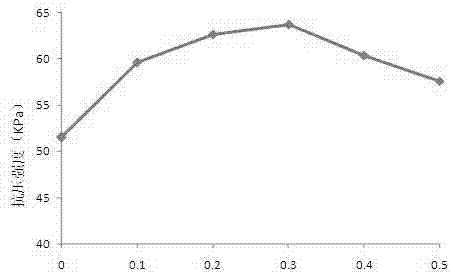

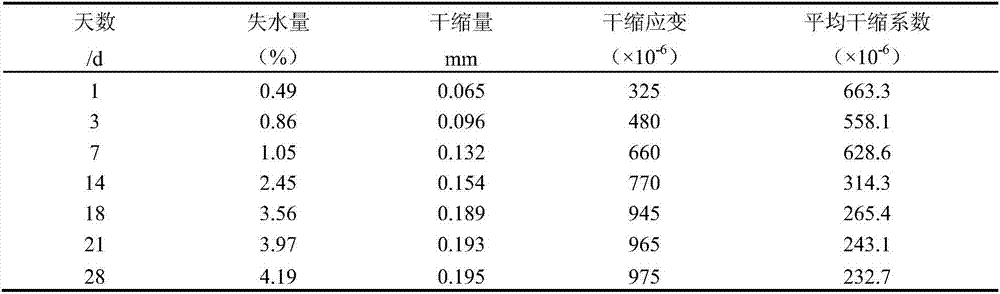

The invention discloses a high-strength polypropylene fiber polymer cement mortar and a preparation method thereof. The mortar is composed of the following components in parts by mass: 0.28-0.3 part of silica fume, 0.68-0.7 part of cement and 1.97-2 part of sand. The SiO3 content in the silica fume is higher than 95%; the water-cement ratio is 0.31; the volume content of the polypropylene fiber is 0.9 kg / m<3>; the water reducer:cementing material ratio is 0.9-1%; the defoaming agent:cementing material ratio is 0.5-0.55%; the coupling agent and diluter:cementing material ratio is 0.3%; the polymer modifier:cementing material ratio is 10-11%; and the reducer:cementing material mass ratio is 3-3.5%. By combining the excellent physical and chemical characteristics of the silica fume, when the silica fume is substituted for cement, the consumption of the cement clinker is saved, and the industrial waste is reutilized, thereby greatly enhancing the pressure resistance and bending resistance of the modified cement mortar.

Owner:ZHENGZHOU UNIV

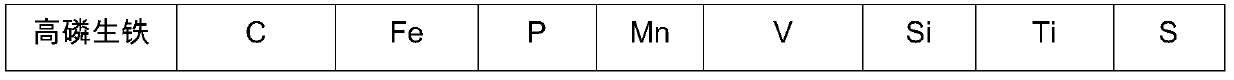

Method for smelting vanadium-rich pig iron from vanadium-containing steel slag

The invention discloses a method for smelting vanadium-rich pig iron from vanadium-containing steel slag, which comprises the following steps: adding 63-67 parts of vanadium-containing steel slag, 14-18 parts of iron powder, 8-12 parts of silica, 4-6 parts of carbon powder and 3-4 parts of aluminum shot into a smelting furnace, and heating to melt the mixture; and after the reaction is finished, separating furnace slag from molten iron, and cooling the molten iron to obtain the vanadium-rich pig iron, wherein the vanadium-containing steel slag is slag left after smelting vanadium-containing molten iron in a converter. The method can enrich 85% of vanadium in the vanadium-containing steel slag into pig iron to obtain the vanadium-rich pig iron, well utilizes the steel slag, has the advantages of simple production technique, strong operability and low production cost, and is convenient for development in industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Recycling treatment system and treatment method of high-salinity high-organic-matter chemical wastewater

ActiveCN106495396ARealize resourcesReduce SS contentWater contaminantsTreatment with aerobic and anaerobic processesElectricityUltrafiltration

The invention discloses a recycling treatment system of high-salinity high-organic-matter chemical wastewater. The recycling treatment system comprises an electrocatalytic oxidation device, a halotolerant bacteria biochemical system, an MBR aerobic device, an electroosmosis unit, an ultrafilter and an RO unit, the halotolerant bacteria biochemical system comprises a halotolerant bacteria anaerobic device, a halotolerant bacteria aerobic device and a halotolerant biological aerated filter. The invention further discloses a treatment method of the high-salinity high-organic-matter chemical wastewater. By the recycling treatment system and the treatment method, the problem of recycling treatment of the high-salinity high-organic-matter chemical wastewater is solved effectively, recycling rate of water and salt is high, no wastewater is discharged basically, no solid waste is generated, generated water is high in quality, generated salt is high in purity, and water resources and salt in the high-salinity high-organic-matter chemical wastewater are recycled to greatest extent; zero discharging of wastewater in the process of enterprise production is realized, and the recycling treatment system and the treatment method have important environment benefit.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

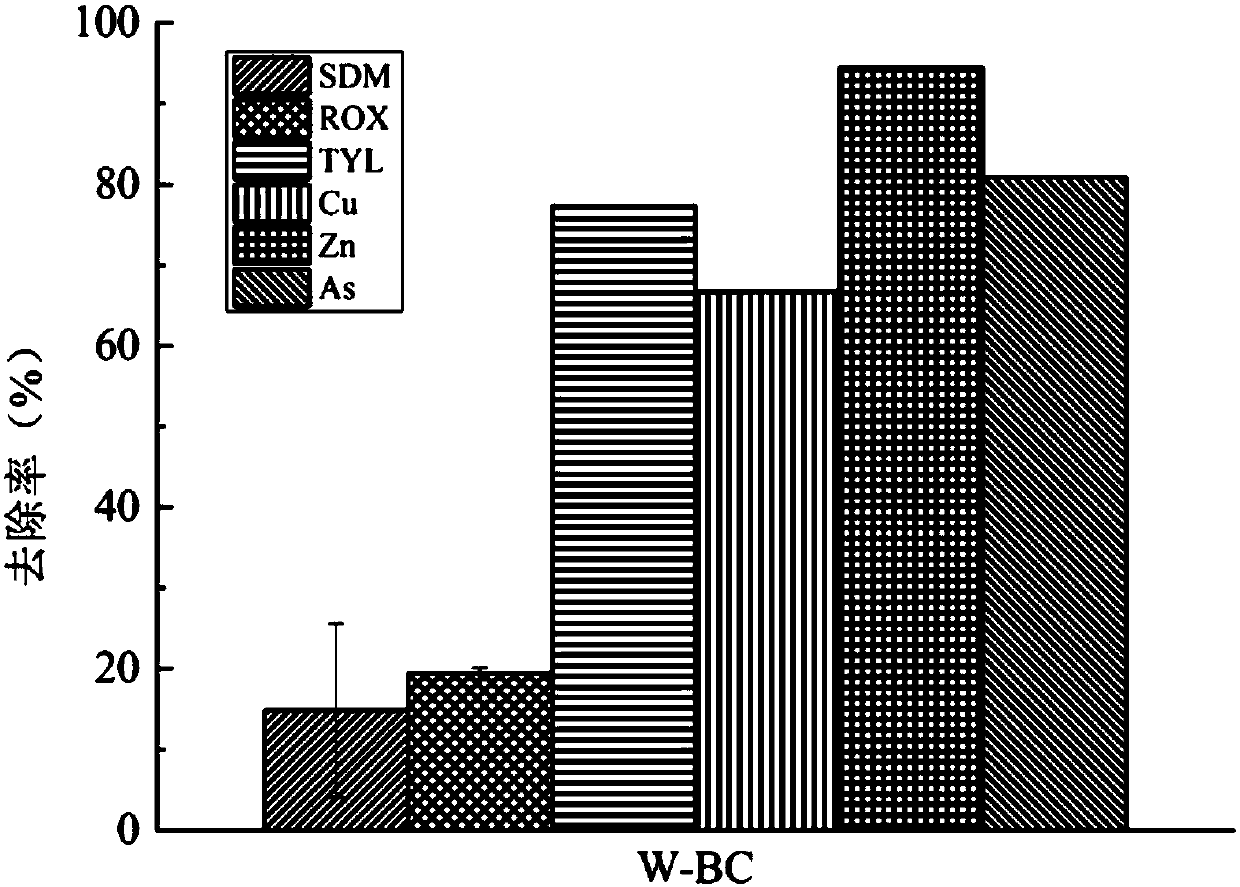

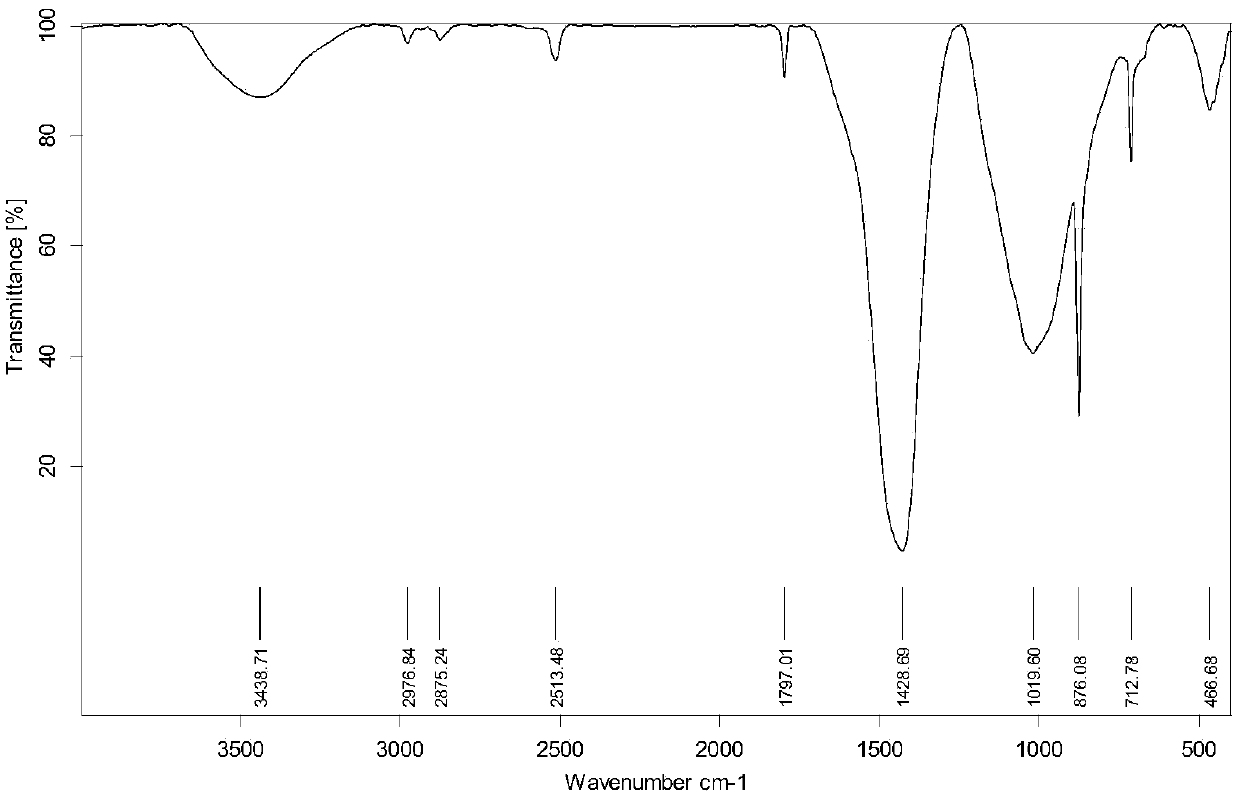

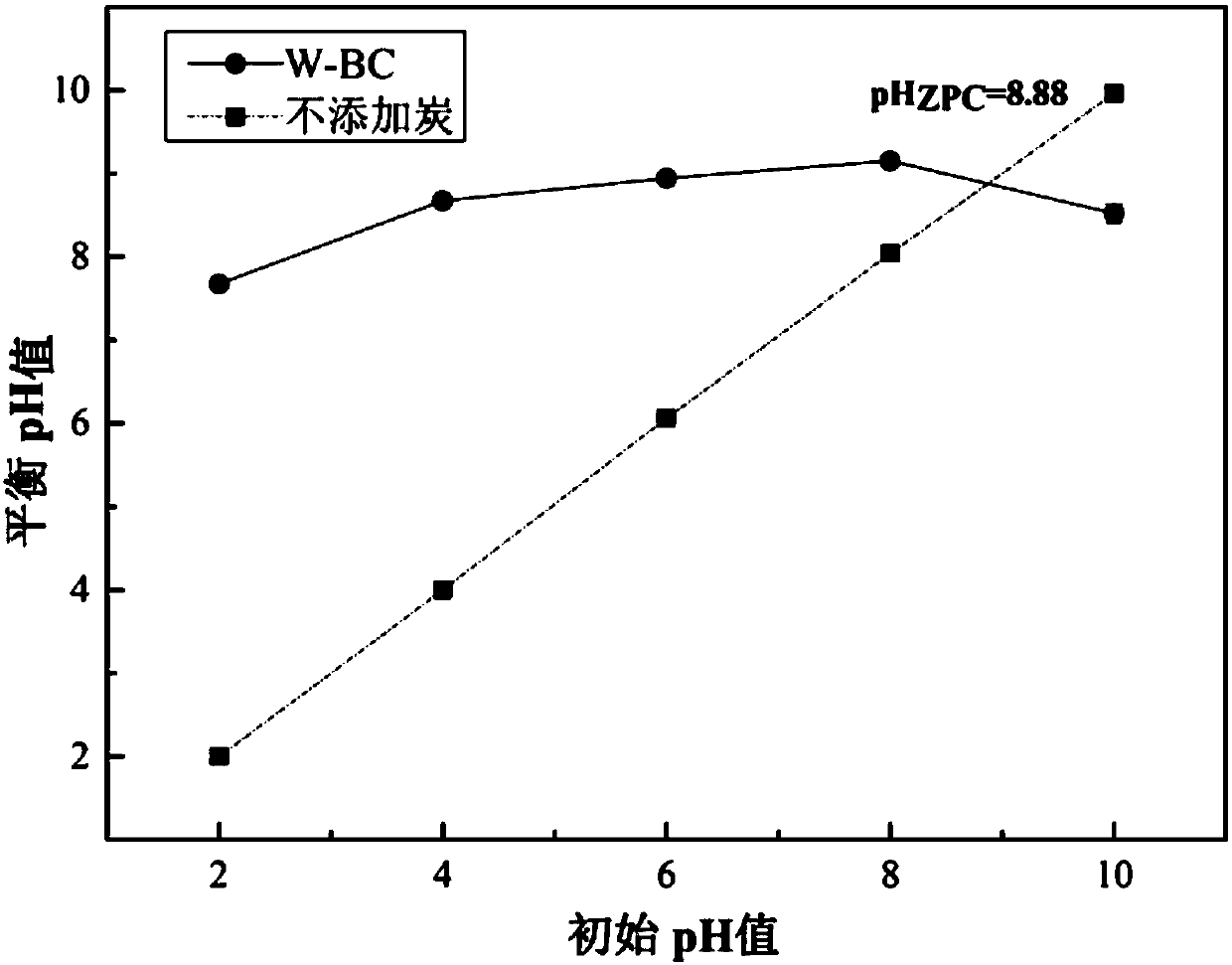

Application of papermaking sludge based biological carbon in removal of antibiotics or heavy metals and antibiotics from water body

InactiveCN107686142ASolve pollutionImportant environmental benefitsWater contaminantsWaste water treatment from animal husbandryRoxithromycinAntibiotic Y

The invention discloses application of papermaking sludge based biological carbon in removal of antibiotics or heavy metals and the antibiotics from a water body and belongs to the technical field ofbiomass treatment and water treatment. The papermaking sludge based biological carbon has larger specific area and a larger pore size and can efficiently remove combined pollution of copper, zinc, arsenic, sulfadimidine, tylosin and roxithromycin. The biological carbon is simple in preparation technology, significant and stable in effect, environment-friendly and free from secondary pollution, andhas a wide application value in a heavy metal / antibiotic pollution repair aspect in the water body. Paper mill sludge difficult to treat is recycled; the environmental pollution problems of wastewater containing the heavy metals and the antibiotics are solved; and therefore, the application has important environmental and economic benefits. The biological carbon has a huge market and an application potential in waste recycling and sewage treatment.

Owner:SOUTH CHINA AGRI UNIV

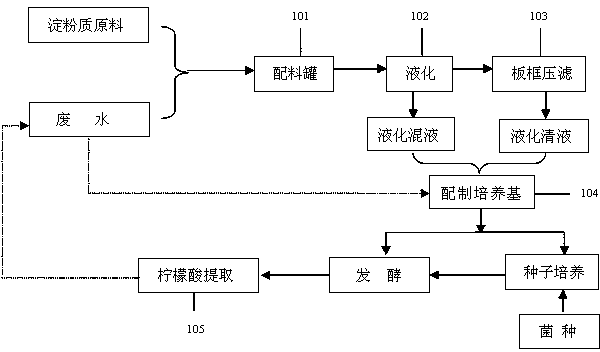

Method for producing citric acid by citric acid wastewater reflux fermentation

ActiveCN104109697AReduce or even eliminate biological processesAchieve recyclingMicroorganism based processesFermentationFiltrationNutrient solution

The invention relates to a method for producing citric acid by citric acid wastewater reflux fermentation. The method comprises the following steps: uniformly mixing a starchy raw material with citric acid wastewater, and adding high-temperature alpha-amylase (2) carrying out injection on the mixed solution twice, and carrying iodine test to obtain a qualified liquefied mixed solution; carrying out plate-frame pressure filtration on the liquefied mixed solution to obtain a liquefied clear solution; (3) mixing the liquefied clear solution with the liquefied mixed solution, adding the citric acid wastewater for water replenishing to obtain a seed culture medium, and carrying out strain seed culture; (4) mixing the liquefied clear solution with the liquefied mixed solution, adding citric acid wastewater for water replenishing to obtain a fermentation nutrient solution, and carrying out fermentation culture; and (5) after the fermentation is finished, carrying out solid-liquid separation to remove the thallus, and extracting by a hydrogen calcium process or chromatography to obtain the citric acid, wherein the generated wastewater returns to the steps (1), (3) and (4), and the cycle repeats. The method has the advantages high fermentation stability and equivalent level with the original technique, saves the consumption of process water and vapor, saves the sewage treatment cost, and has important environmental benefit and economic benefit.

Owner:JIANGNAN UNIV +1

Method for preparing silicon-steel-grade magnesium oxide from magnesium sulfate waste liquor

The invention provides a method for preparing silicon-steel-grade magnesium oxide from magnesium sulfate waste liquor, which comprises the following steps: mixing magnesium sulfate waste liquor and oxydol, regulating the pH value of the mixed liquor, stirring, aging, and filtering, wherein the filtrate is magnesium sulfate purified liquor; adding a precipitant ammonium carbonate solution into the magnesium sulfate purified liquor, stirring, aging, filtering, and drying the filter cake to obtain basic magnesium carbonate; calcining the basic magnesium carbonate, and washing with water at normal temperature to obtain magnesium oxide; and grinding and screening to obtain the silicon-steel-grade magnesium oxide. In the invention, the magnesium sulfate waste liquor generated in the lateritic nickel ore wet-method smelting process is used as the raw material to prepare high-added-value silicon-steel-grade magnesium oxide; the production technique is simple; and the produced silicon-steel-grade magnesium oxide product has the characteristics of high chemical purity, low impurity content and small average particle size. The purity of the silicon-steel-grade magnesium oxide is greater than 98%, the hydration rate is less than 5%, and the average particle size is smaller 5 mu m.

Owner:KUNMING UNIV OF SCI & TECH

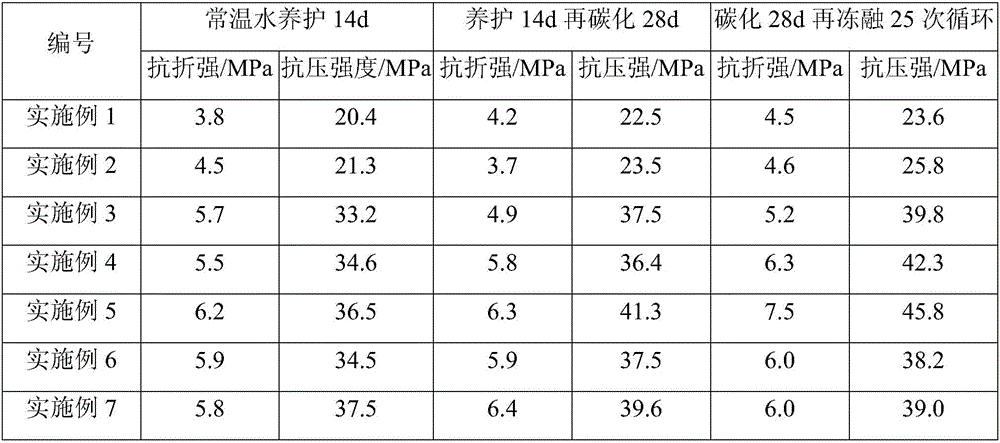

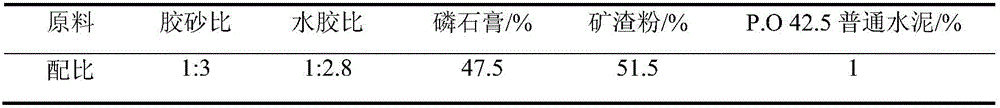

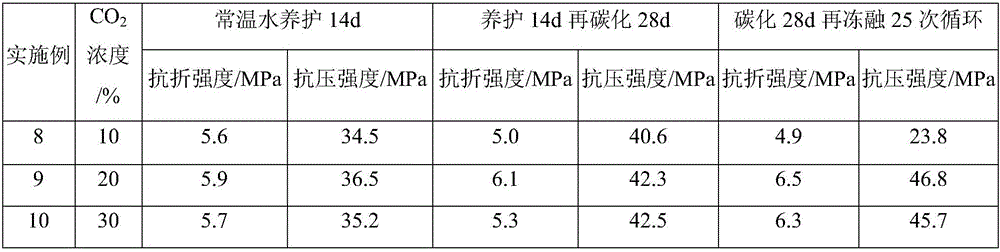

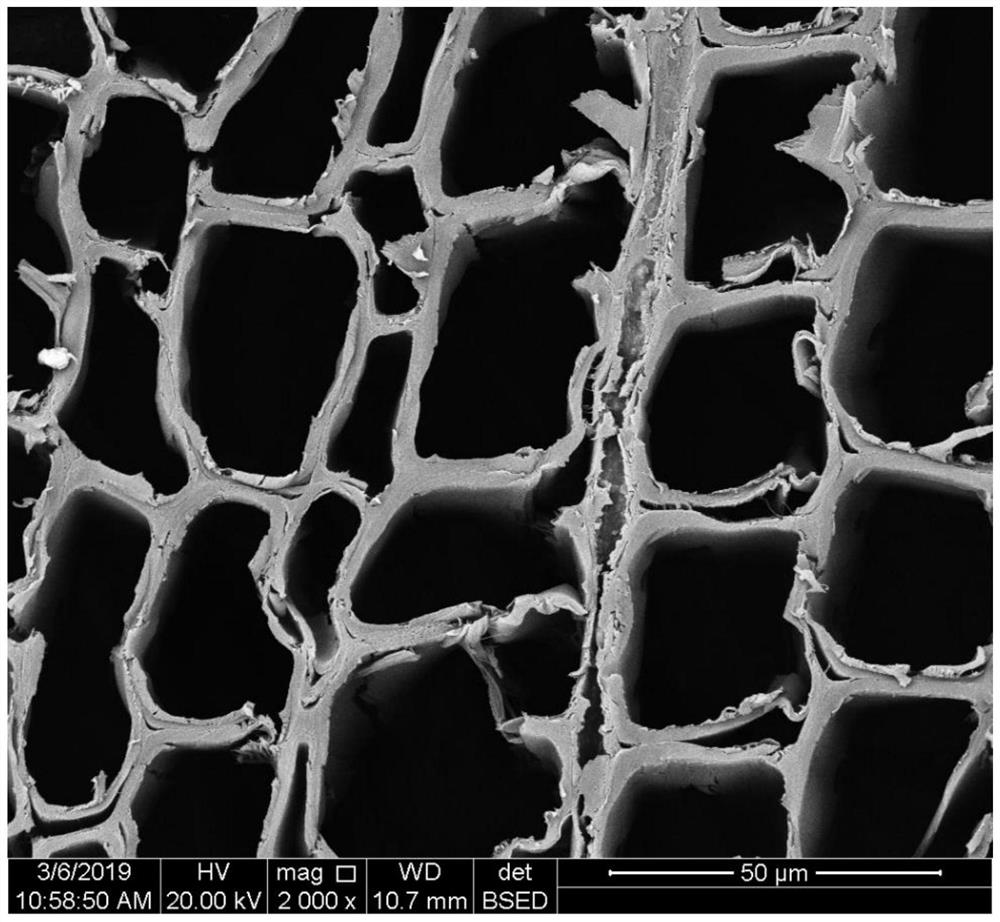

Method for improving frost resistance of excess-sulfate phosphogypsum slag cement product

The invention belongs to the field of building materials and particularly relates to a method for improving frost resistance of an excess-sulfate phosphogypsum slag cement product. The excess-sulfate phosphogypsum slag cement product is prepared from phosphogypsum, cement clinker powder, slag powder, sand and water. A sulfur-phosphorus gypsum slag cement product is put in an air condition with the concentration of carbon dioxide being 10%-30% to be cured, the internal structure of the product is changed through a carbonization reaction of the sulfur-phosphorus gypsum slag cement product by means of carbon dioxide, a compact structure is obtained, and the frost resistance is improved. The process of the method is simple, high-temperature curing is not required, energy consumption is little, the amount of doped clinker powder is small, the cost is low, secondary pollution cannot be caused, a large quantity of industrial waste slags such as phosphogypsum can be used, and the method has important environmental and economic benefits.

Owner:WUHAN UNIV OF TECH

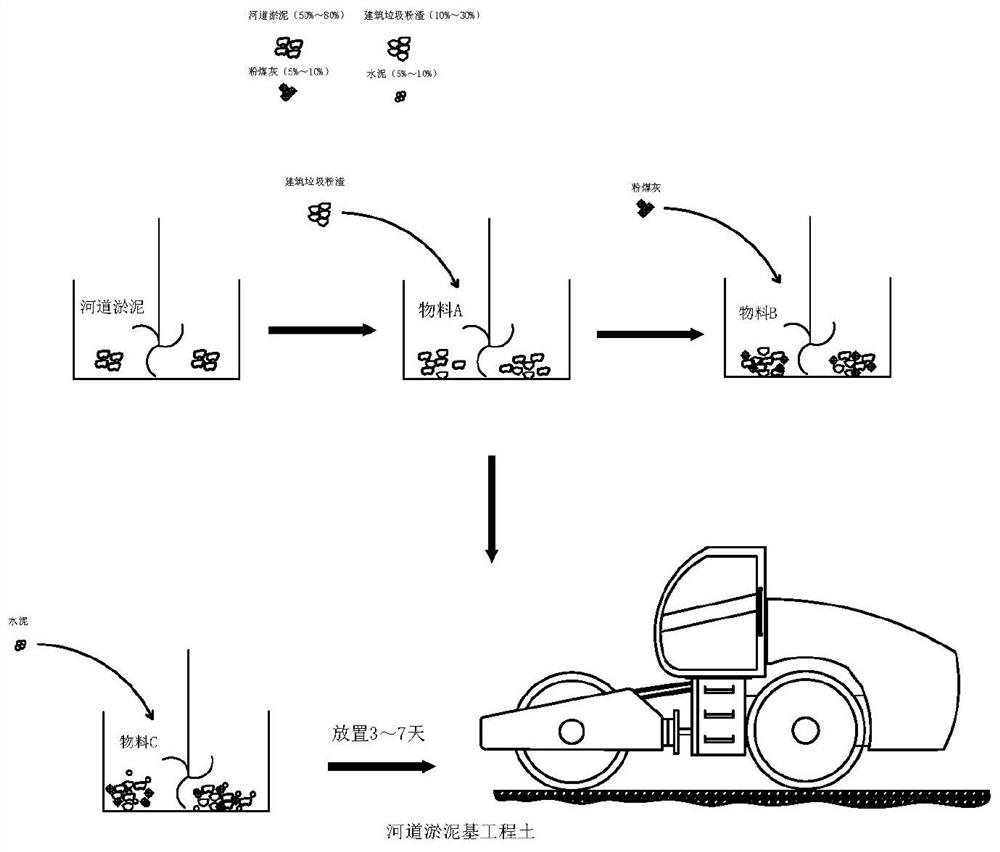

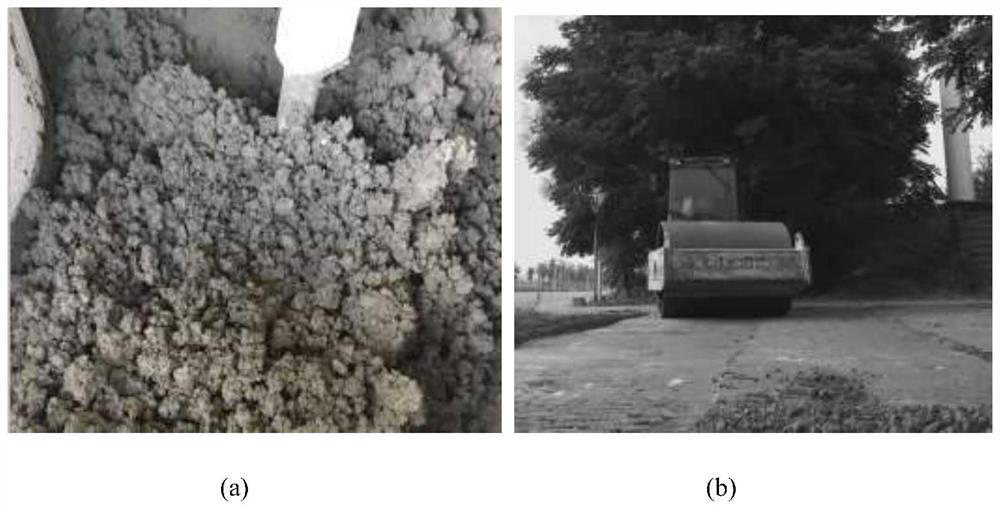

Riverway sludge-based engineering soil and preparation method thereof

The invention discloses riverway sludge-based engineering soil, which is prepared from the following components in percentage by weight: 53-83% of riverway sludge, 10-30% of construction waste powderslag, 5-10% of fly ash and 2-7% of cement, wherein the water cement ratio is controlled to be 0.1-0.5. According to the invention, riverway dredging silt is used as a main raw material, construction waste powder slag is used as fine aggregate, and a small amount of cementing materials such as fly ash and cement are used as auxiliary materials, so that the mechanical property and the stability of an obtained consolidation system can be effectively ensured so as to form riverway silt-based engineering soil meeting the requirements of soil for road filling, bulk disposal and resource utilizationof river dredging silt can be achieved, land is saved, pollution to the environment is avoided, and important economic and environmental benefits are achieved.

Owner:CHINA CONSTR THIRD BUREAU GREEN IND INVESTMENT CO LTD

Method for preparing wood/MOF functional composite material

InactiveCN113183264AExpand the scope of resource utilizationLow costOther chemical processesWood treatment detailsNanoparticleMetal-organic framework

The invention provides a method for preparing a wood / MOF (Metal Organic Framework) functional composite material, which comprises the following steps: adding a precursor solution for synthesizing an MOF material into wood, and carrying out hydrothermal reaction or a physical filling method to prepare the wood / MOF functional composite material. The nano MOF particles are grown in situ or filling wood pores with the nano MOF particles to obtain the wood / MOF functional composite material. The method is easy to operate and low in cost. The defects that powder nano MOF is not easy to recycle and poor in machinability and operability are overcome, and the wood / MOF functional composite material has wide application prospects in the fields of flame retardance, adsorption, catalysis and the like. According to the preparation method, the organic ligand, the metal salt solution and the wood are taken as main raw materials, the synthesized MOF uniformly grows on the wood through a one-step hydrothermal reaction or a physical filling method, the effective load of the MOF active component on the wood can be realized, and the prepared wood / MOF functional composite material has excellent performances of catalysis, flame retardance, adsorption and the like. The raw materials are wide in source, and the preparation method is simple.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Sodium chloride-containing pesticide production wastewater resource treatment system and method

InactiveCN108128968AMaintain microbial biomassIncrease concentrationGeneral water supply conservationWater contaminantsReverse osmosisWater quality

The invention discloses a sodium chloride-containing pesticide production wastewater resource treatment system and method, and belongs to the field of a sewage treatment method. The system comprises asalt-tolerant bacterium biochemical system, a nanofiltration membrane device, an electrodialysis device and an electrocatalytic oxidation device, wherein the salt-tolerant bacterium biochemical system comprises a first salt-tolerant bacterium aerobic device, a salt-tolerant bacterium anaerobic device and a second salt-tolerant bacterium aerobic device; the second salt-tolerant bacterium aerobic device comprises a salt-tolerant bacterium MBR device; the treatment system also comprises a reverse osmosis device. The invention also discloses a wastewater treatment method. The flow process of themethod of the salt-tolerant bacterium biochemical treatment, MBR treatment, nanofiltration membrane treatment, electrodialysis treatment and electrocatalytic treatment is used; after the pesticide production wastewater is subjected to treatment, the water quality of produced water is high; when the system and the method are applied to enterprise production, water resources in the waste water are recovered; the general organic carbon content in the obtained sodium chloride salt wastewater is low; the system and the method can be used for chlor-alkali production; sodium chloride salt in the wastewater is recovered.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

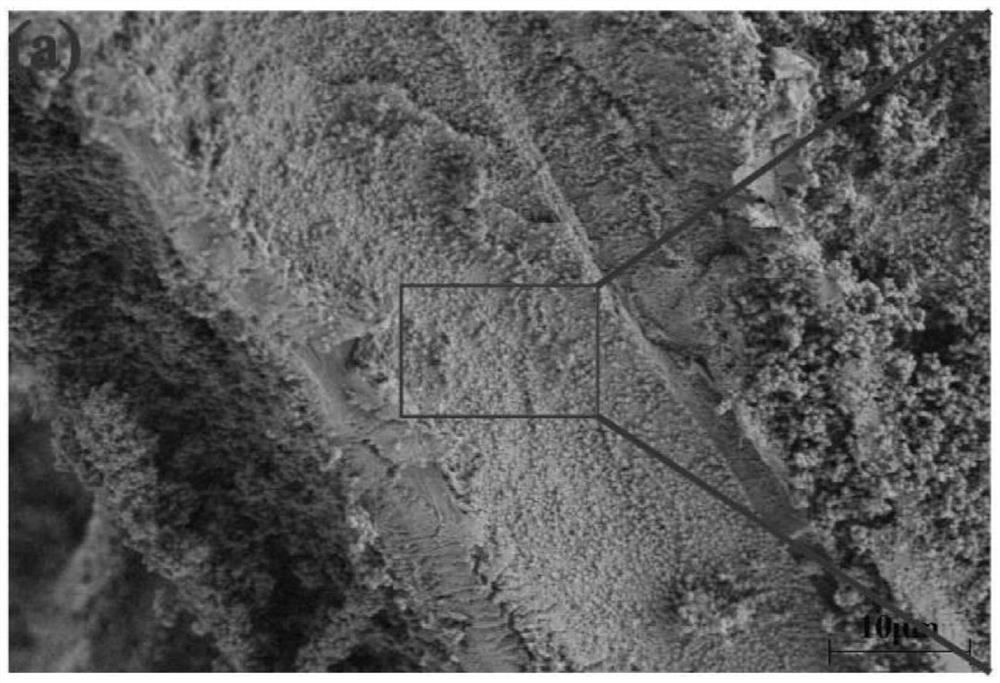

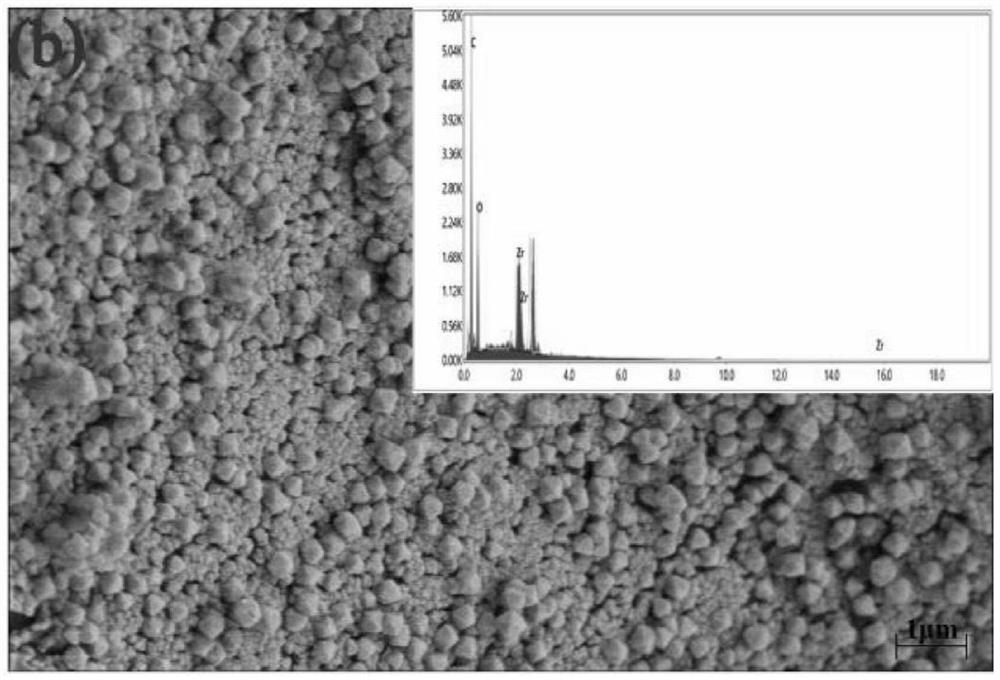

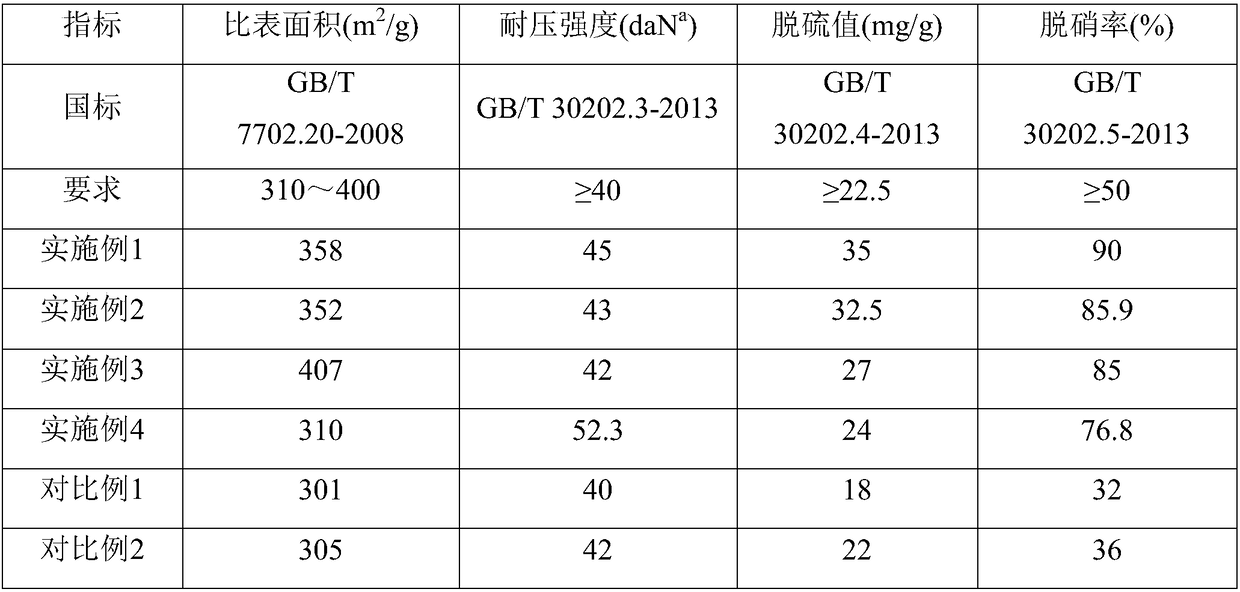

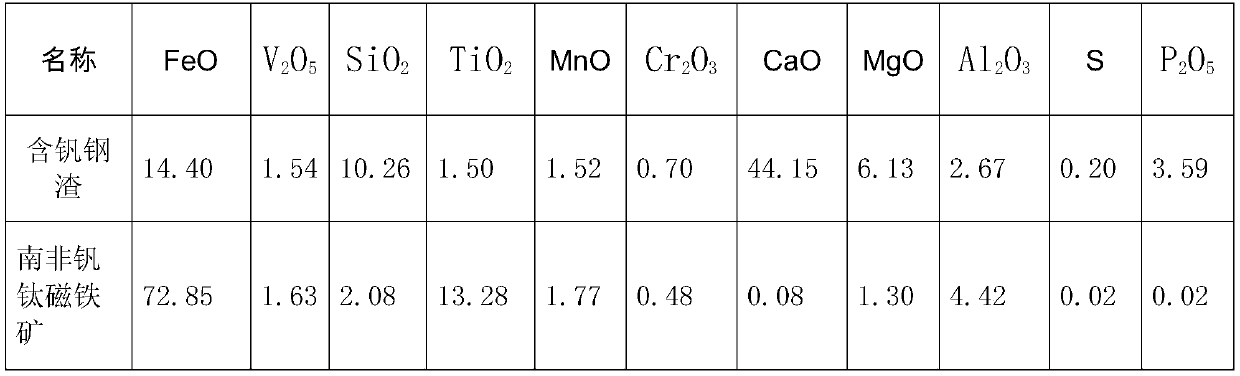

Metallurgical solid waste based pressed active carbon for desulfurization and denitrification of flue gas and preparation method of pressed active carbon

ActiveCN108745282AIncrease the secondary added value of comprehensive utilizationImprove mechanical propertiesNitrous oxide captureGas treatmentActivated carbonFlue gas

The invention discloses a metallurgical solid waste based pressed active carbon for desulfurization and denitrification of flue gas, the pressed active carbon comprises the following various components by mass percent: 65-80% of powdered activated carbon and 20-35% of forming agent, wherein the forming agent is compounded from a steel slag, a mineral waste residue and desulfurized fly ash. A gelatinizer prepared on the basis of the metallurgical waste residues like the steel slag is used to form and adsorb saturated granular active carbon or powdered activated carbon, the steel slag, the mineral waste residue and the desulfurized fly ash are compounded, the combining property of the forming agent and the powdered activated carbon is good, the mechanical property, the desulfurization and denitrification performances and the like of the obtained activated carbon are effectively improved, the problems like low specific surface of the inorganic forming activated carbon is effectively solved, meanwhile, the additional value of the comprehensive utilization of the metallurgical waste residue is improved, and the activated carbon has important economic and environmental benefits.

Owner:武汉钢铁有限公司

Method for smelting vanadium-rich pig iron by using high-calcium vanadium-containing steel slag

The invention discloses a method for smelting vanadium-rich pig iron by using high-calcium vanadium-containing steel slag, and belongs to the technical field of application of metallurgical slag. According to the method, the vanadium-containing steel slag and magnetite (or vanadium-containing magnetite) are used as raw materials, a proper amount of solvent is added, and submerged arc smelting is carried out in a short furnace body submerged arc furnace. The method can utilize a low-grade carbonaceous reducing agent, wherein the carbonaceous reducing agent with the particle size of less than 20mm is used as a reducing agent, the carbonaceous reducing agent with the particle size of 20mm-80mm is used for forming a residual carbon layer in an arc combustion region. According to the electric furnace capacity, timing iron discharge and slag discharge, the furnace slag and molten iron are separated, and after the molten iron is cooled to obtain the vanadium-rich pig iron. The high-calcium vanadium-containing steel slag is residual slag of vanadium -containing molten iron after smelting by a converter. According to the method, 90% of vanadium in the vanadium-containing steel slag can be enriched in the pig iron to obtain the vanadium-enriched pig iron, the steel slag is well recycled, the production process is simple, the operability is high, the production cost is low, and the methodcan be conveniently expanded in industrial production.

Owner:吉林省金源科技有限公司

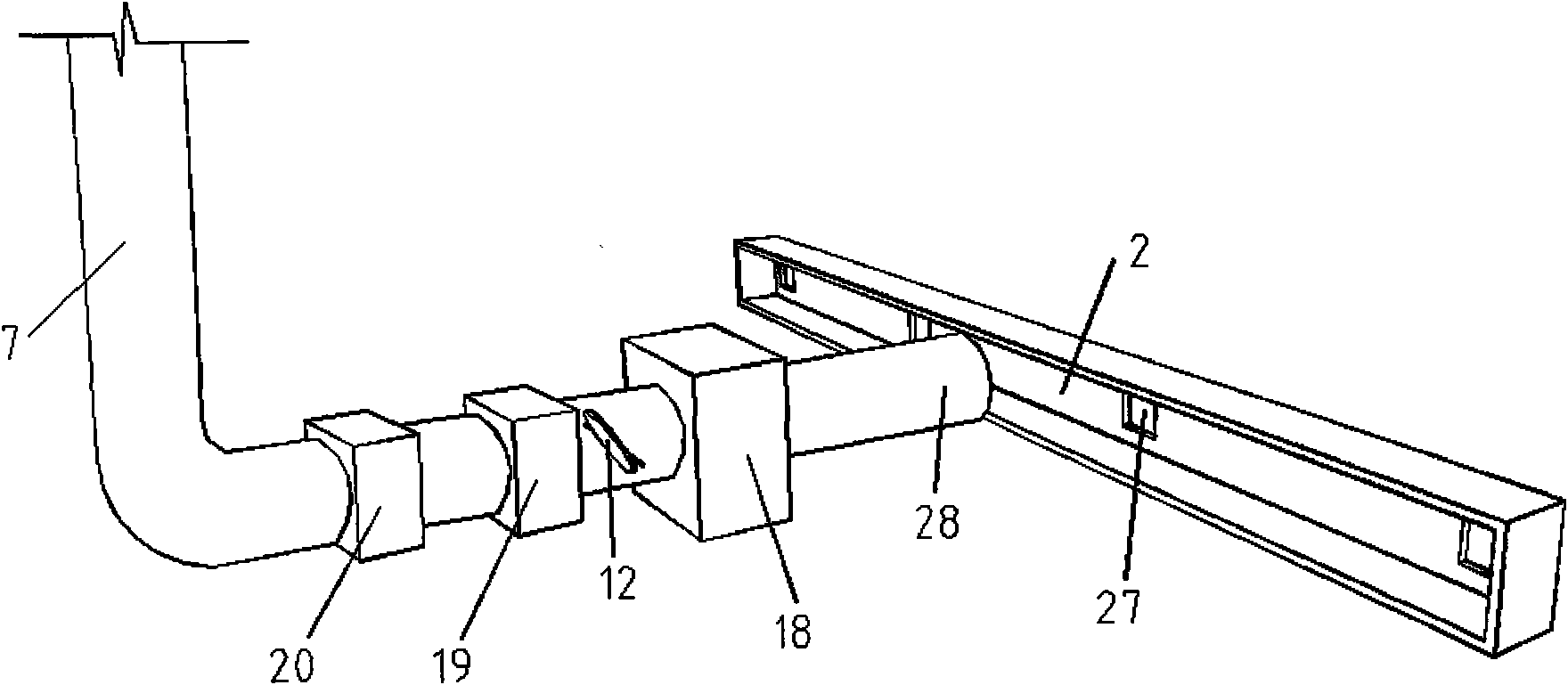

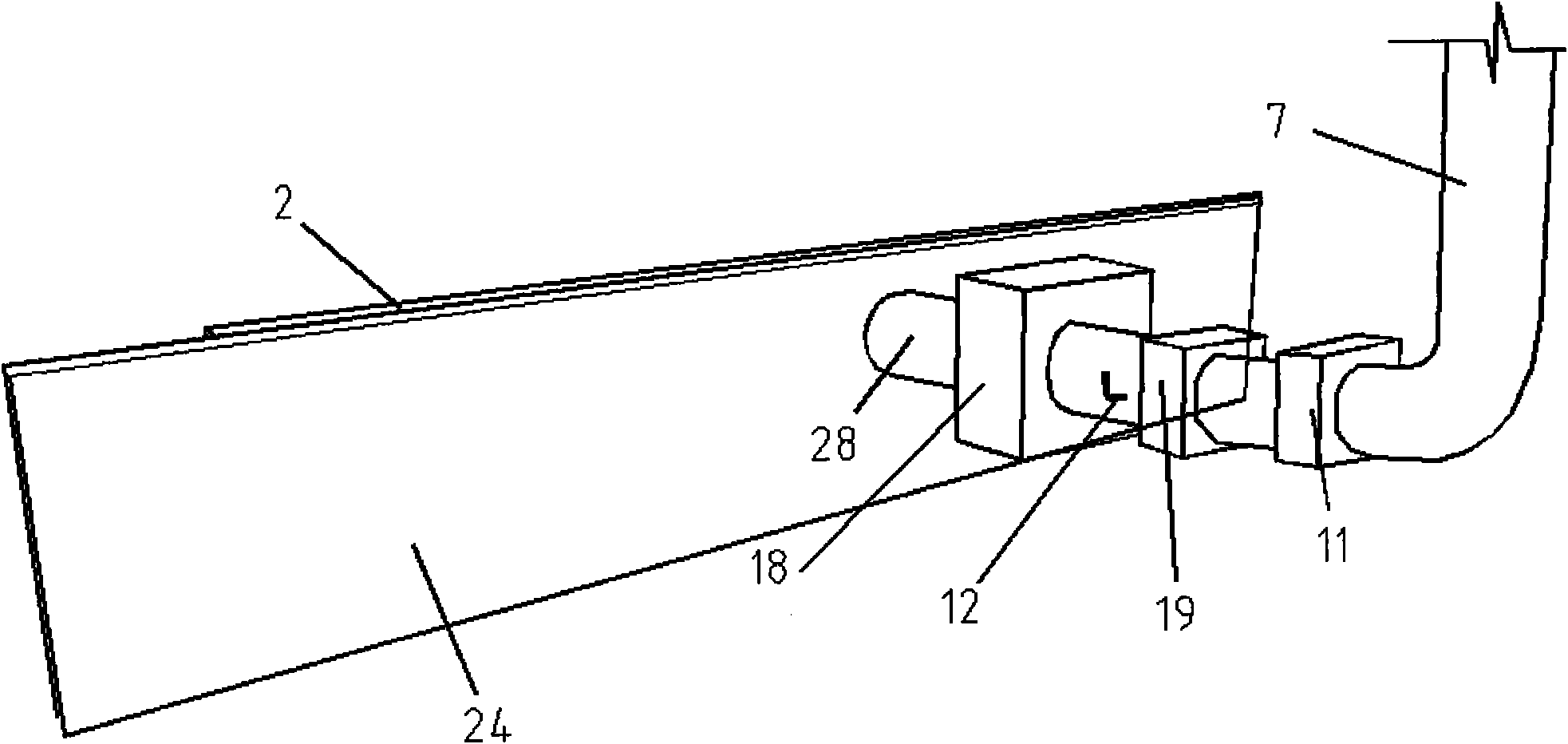

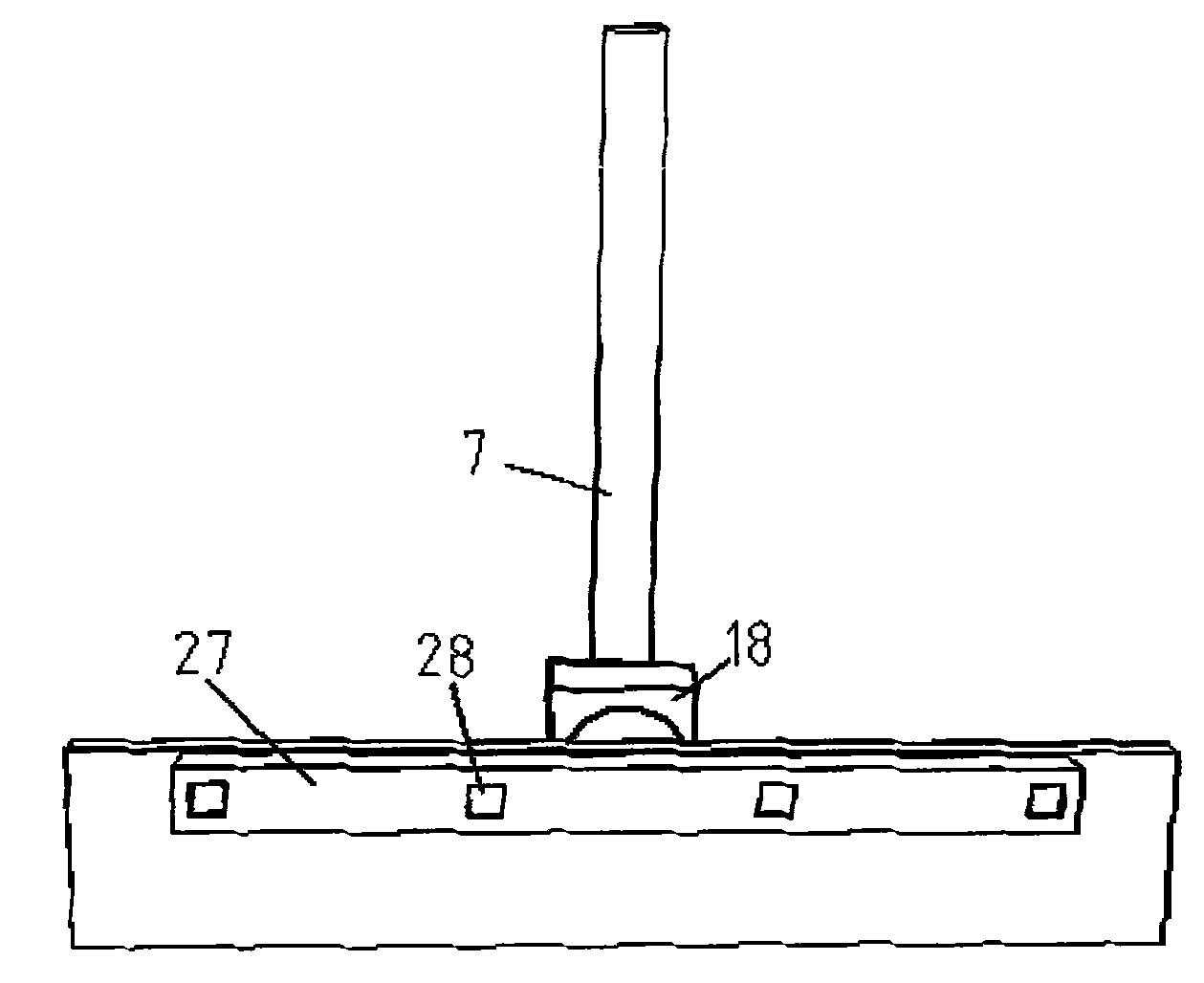

Combustion pool smoke discharging heat recovery and purification system

InactiveCN102183036ASolve the problem of waste heat utilizationSolve the purificationWater heatersChimneysDesorptionEngineering

The invention relates to a combustion pool smoke discharging heat recovery and purification system, belonging to the technical field of recycle of resources and building energy conservation. The system is characterized by mainly consisting of a horizontal flue, flue ports, a vertical chimney, a smoke control valve, a smoke residual heat recovery device, a smoke dust collection device and a smoke purification device; the horizontal flue is provided with a plurality of the flue ports to collect smoke; and the smoke is sequentially subjected to smoke residual heat recycle, smoke particle desorption, and removal of harmful gases such as sulfur oxide, nitrogen oxide in the smoke through the smoke residual heat recovery device, the smoke dust collection device and the smoke purification device, and finally the smoke is discharged through the vertical chimney. The system provided by the invention has the beneficial effects of smoke purification, low carbon discharging, efficient heating, outdoor environmental improvement and the like, can be used in dwelling houses in villages and small towns and industrial factory buildings without central heating, and has very important promotional value and obvious environmental and economic benefits.

Owner:DALIAN UNIV OF TECH

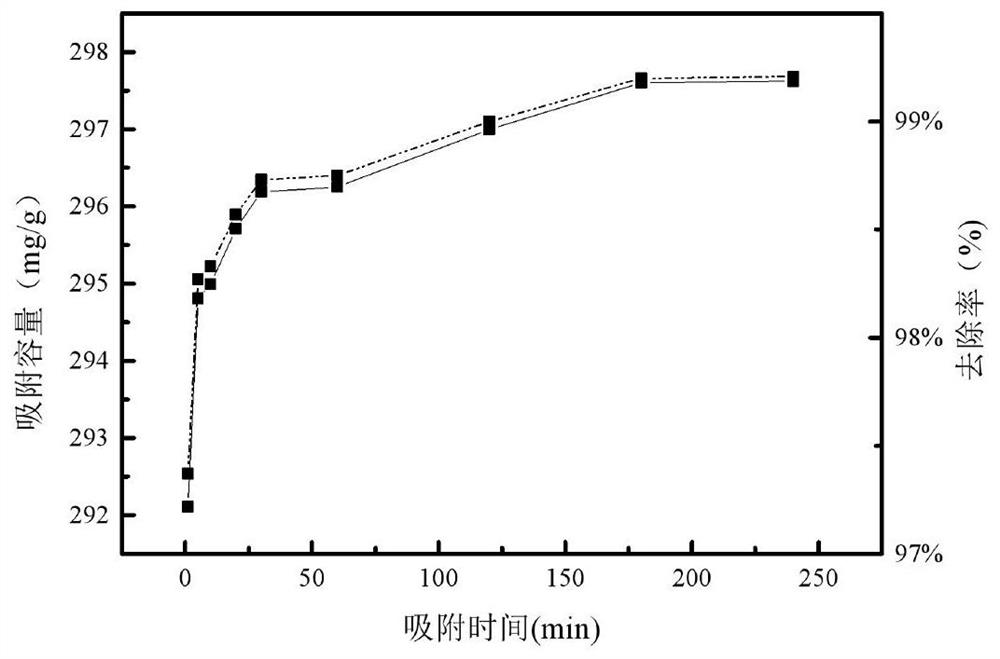

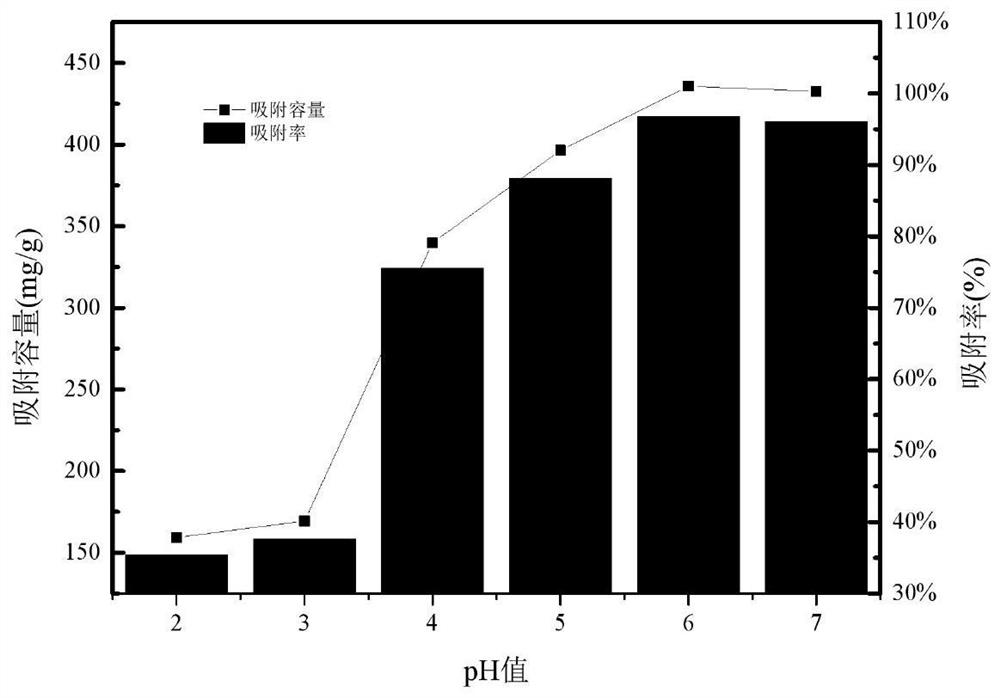

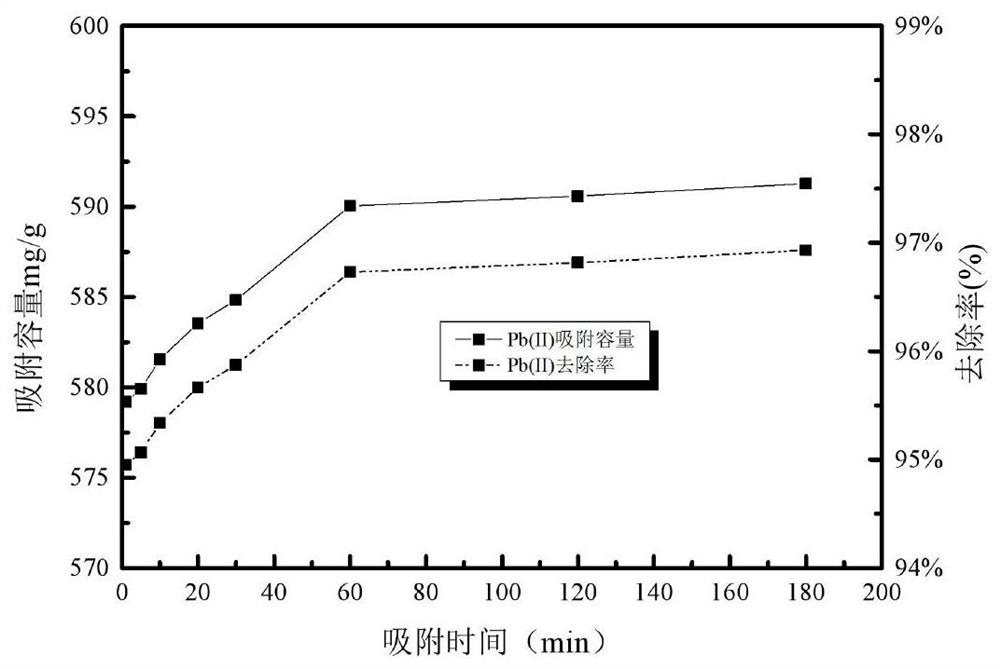

Preparation method and application of adsorbent for efficiently removing heavy metal ions in wastewater based on electrolytic manganese residues

InactiveCN111939868AEasy to prepareEasy to operateOther chemical processesWater contaminantsSorbentWastewater

The invention relates to the technical field of environmental heavy metal removal, and particularly discloses a preparation method and application of an adsorbent for efficiently removing heavy metalions Cd (II) and Pb (II) in wastewater by utilizing electrolytic manganese residues. According to the method, the electrolytic manganese residues are used as a basic material, and are mixed with ore (at least one of calcite, serpentine and wollastonite); through modification, heavy metal ions in the wastewater are adsorbed by carbonate and silicate components of the mixture, the heavy metal ions in the wastewater are rapidly removed, and finally, efficient and rapid removal of Cd (II) and Pb (II) in the wastewater is achieved (in a prepared heavy metal solution, the removal rate of Cd (II) andPb (II) can reach 95%). The adsorbent has important environmental benefits and social value. The preparation method of the adsorbent is simple, convenient to operate, free of secondary pollution, good in adsorption effect and low in cost.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

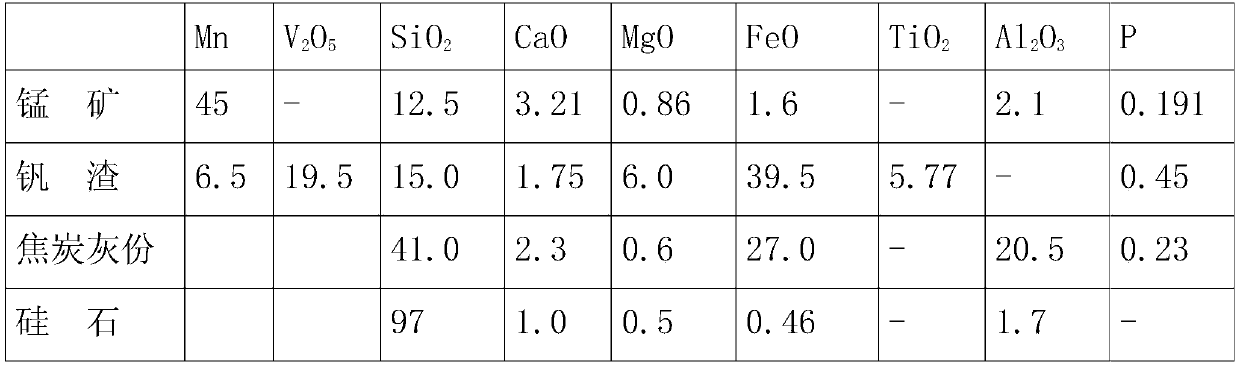

Production method of silicon-manganese-vanadium composite alloy

InactiveCN111235331ARealize continuous operationIncrease productivityRecycling and recovery technologiesShaft furnaceSlagManganese

The invention relates to a production method of a silicon-manganese-vanadium composite alloy, and belongs to the technical field of metal smelting. According to the method, vanadium-containing steel slag, manganese ore and silica are taken as raw materials, a proper amount of solvent is added, and submerged-arc smelting is carried out in a submerged arc furnace with a short furnace body. 90% of vanadium in the vanadium-containing steel slag can be enriched in the alloy to obtain the silicon-manganese-vanadium composite alloy, and the vanadium-containing steel slag is well utilized; and the production process is simple, the operability is high, the production cost is low, and the production method is conveniently carried out in industrial production.

Owner:吉林省金源科技有限公司

Method for modifying dry de-sliming tail mud, and application thereof

ActiveCN106746827AImprove stacking effectGuaranteed water retentionRoadwaysSolid waste managementLower gradeEngineering

The invention aims at the potential problems of dry de-sliming tail mud serving as a roadbed material and discloses a method for modifying dry de-sliming tail mud. The method comprises the following steps: 1) mixing a catalyst and dry de-sliming tail mud uniformly to obtain mixed tail mud; 2) mixing an acidifying agent into water to form a wetting solution, spraying the wetting solution into the mixed tail mud, and mixing uniformly to obtain wetted tail mud; 3) performing covering treatment on the wetted tail mud by using plastic cloth; and 4) removing the plastic cloth and continuously performing ageing treatment to obtain the modified de-sliming tail mud. The invention provides a method for wetting and catalytically modifying the dry de-sliming tail mud and further provides a processing method of taking the modified de-sliming tail mud as the roadbed material; the technical indexes meet the requirements of low-grade roads; and the method has important economic and environment benefits and is suitable for popularization and application.

Owner:武汉钢铁有限公司

Method for stabilized solidification of mercury-containing waste salt slag by using petrochemical waste alkali slag

The invention relates to the technical field of hazardous waste disposal, and particularly relates to a method for stabilized solidification of mercury-containing waste salt slag by using petrochemical waste alkali slag. The method comprises the following steps that the mercury-containing waste salt slag and the petrochemical waste alkali slag are subjected to first-stage mixing and ball milling,and then an auxiliary stabilizer is added into a material obtained after first-stage mixing and ball milling, the mixture is subjected to second-stage mixing and ball milling; and 2) the material obtained in the step 1) is mixed with a solidifying material, and stirred to obtain a uniform bulk granular solidified material. By the adoption of the method, waste can be treated with waste, important economic, social and environmental benefits are achieved, and a novel method is provided for terminal harmless treatment of mercury-containing waste salt.

Owner:扬州杰嘉工业固废处置有限公司

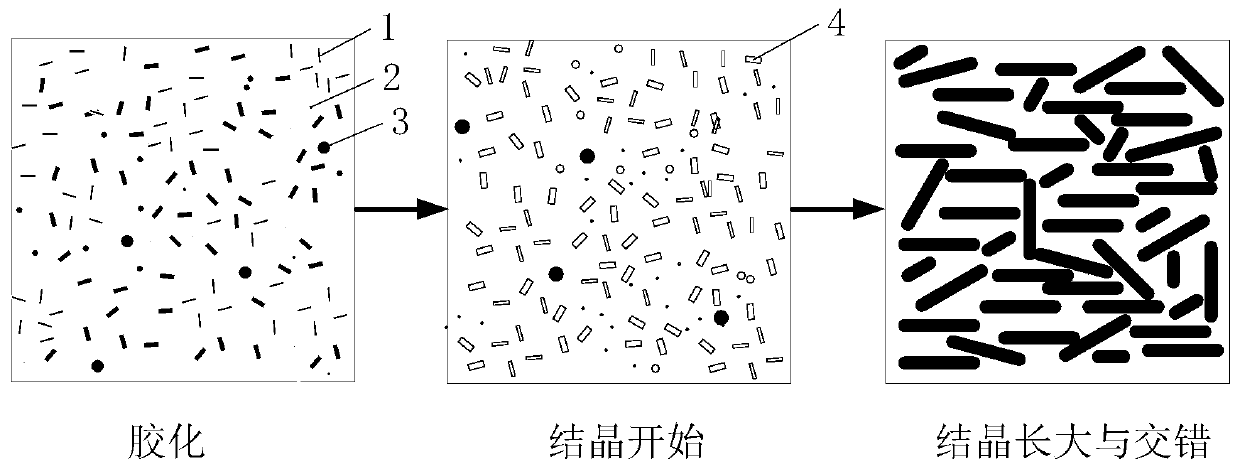

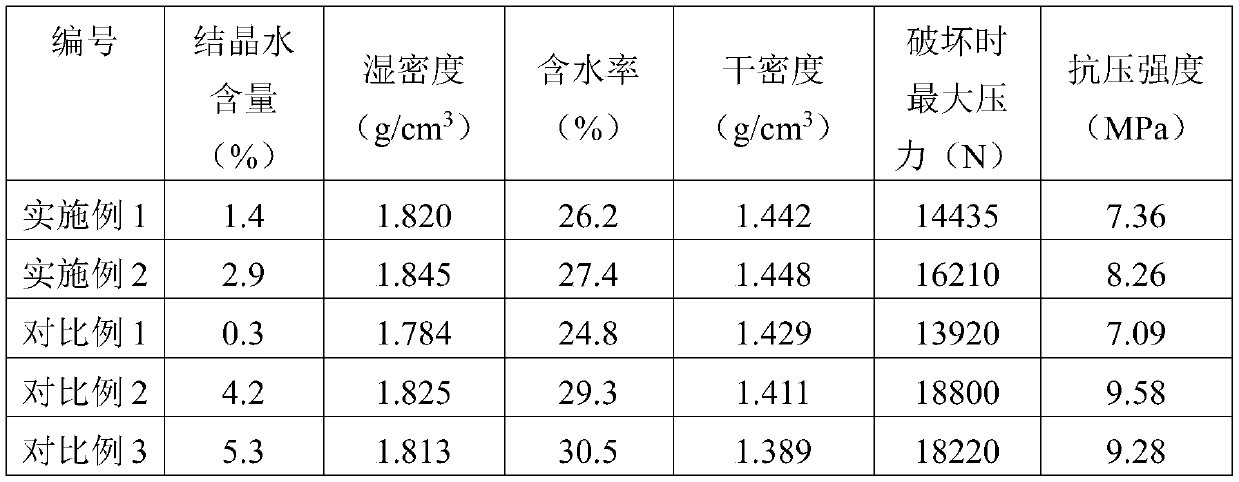

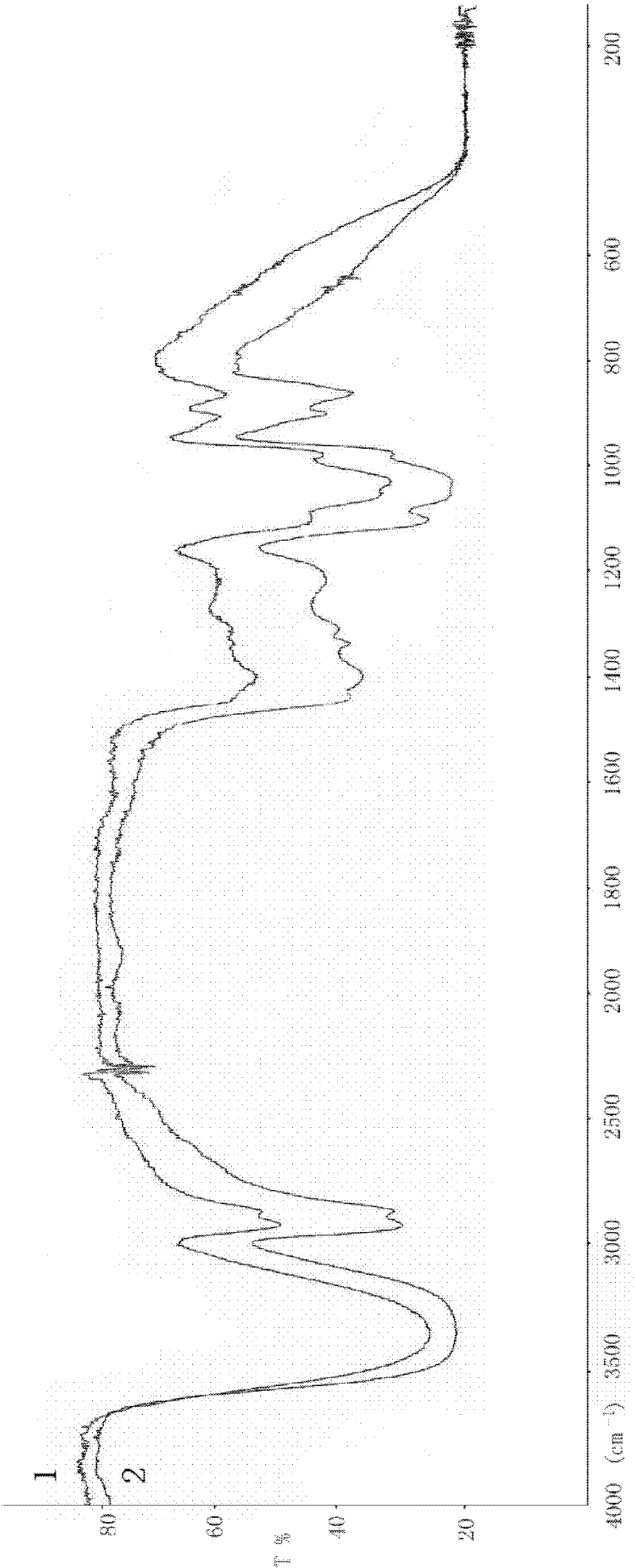

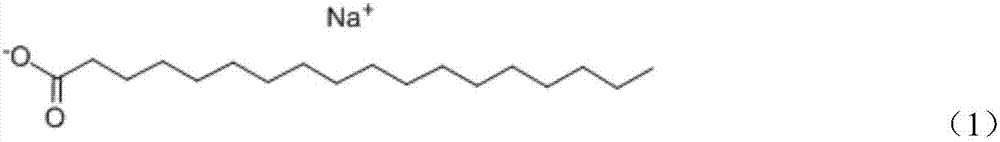

High-strength self-waterproof phosphogypsum roadbed material and preparation method thereof

ActiveCN111320446AHigh strengthImprove waterproof performanceSolid waste managementPhysical chemistryEnvironmental engineering

The invention discloses a high-strength self-waterproof phosphogypsum roadbed material. The ardealite raw material is calcined to obtain modified ardealite powder for preparing an ardealite roadbed material. In the process of converting calcium sulfate dihydrate into hemihydrate gypsum through dehydration, generation of alpha-hemihydrate gypsum is effectively promoted by further regulating and controlling the water content and the input amount of the ardealite raw material in a closed calcining environment, so that the mechanical property and the waterproof property of the obtained ardealite roadbed material are remarkably improved. The modification method provided by the invention is extremely simple and convenient to operate, can realize 100% recycling of phosphogypsum waste, has important economic and environmental benefits, and is suitable for popularization and application.

Owner:HUBEI PROVINCIAL CENT FOR QUALITY SUPERVISION AD TEST OF CONSTR ENG

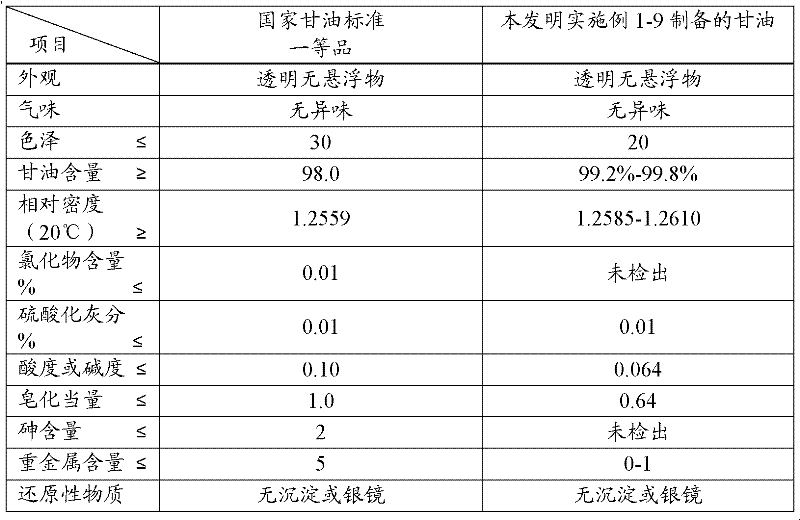

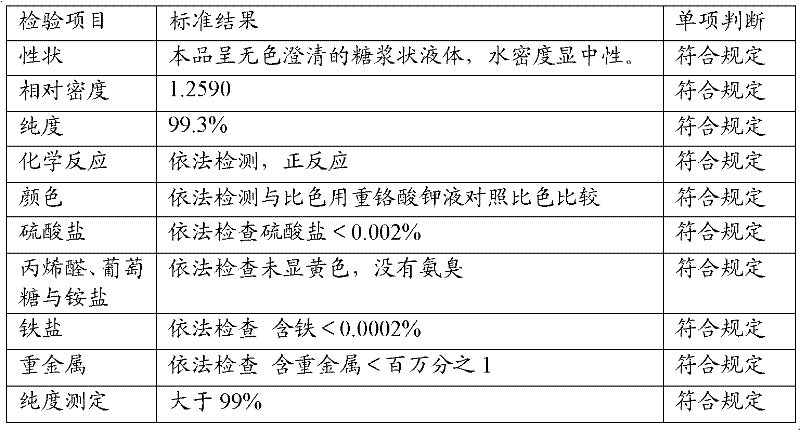

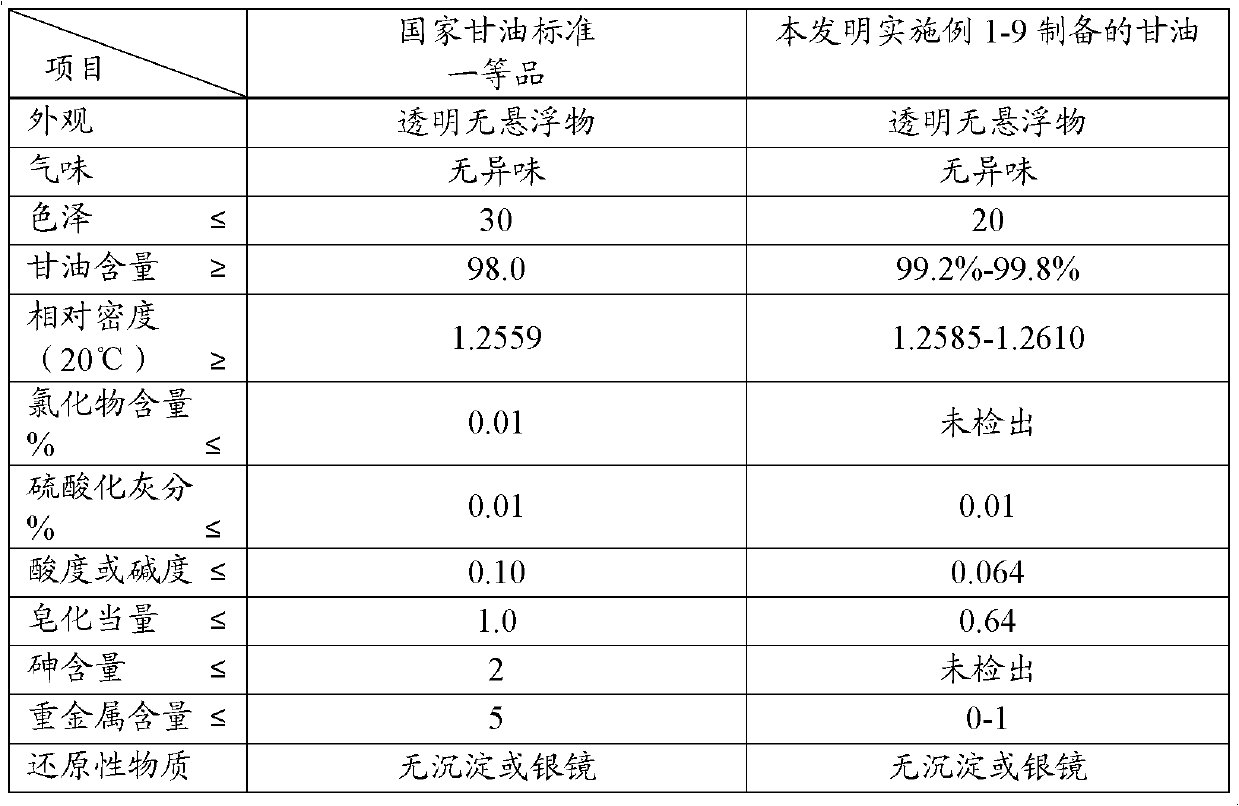

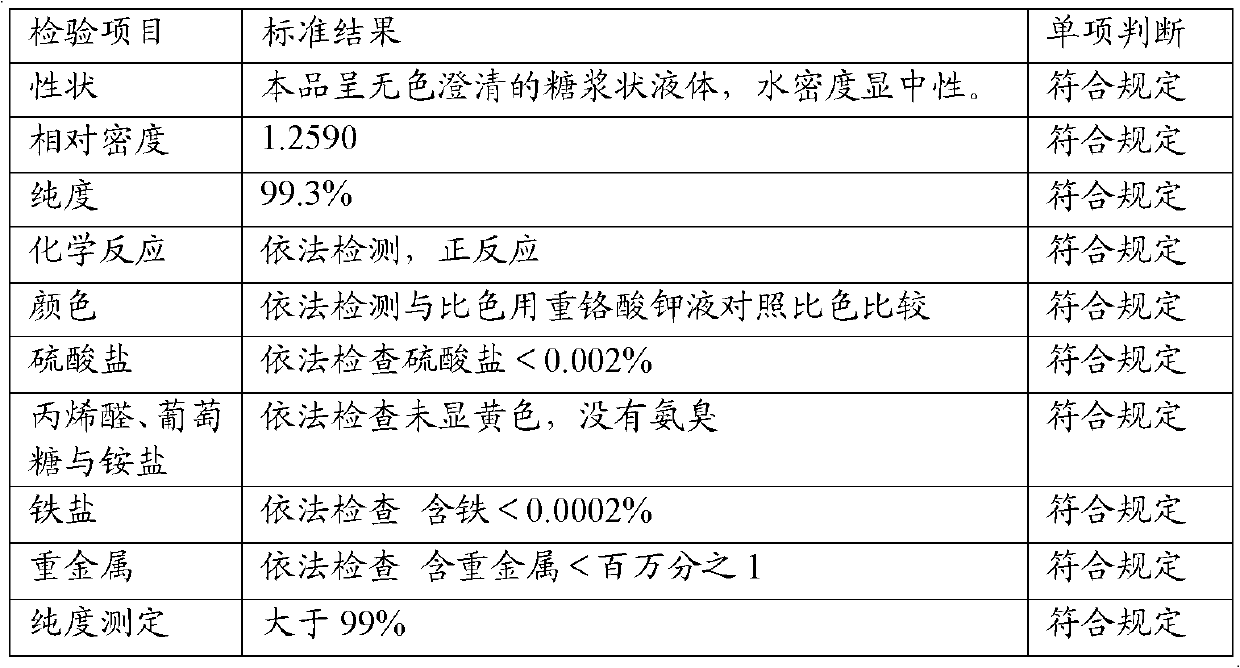

Environment-friendly glycerol and preparation method thereof

InactiveCN102219643AImportant Environmental BenefitsMake up for the shortageOrganic compound preparationHydroxy compound preparationSucroseAlcohol

The invention discloses an environment-friendly glycerol and a preparation method and application thereof. In the invention, saturated sugar solution prepared by sucrose and produced by adopting quantitative carbonization technology reacts with sorbierite, then a certain quantity of dihydric alcohol is added into the reaction solution to be stirred for reaction, and then a proper amount of antiseptic and decolorizing agents are added, and the procedures of filtering, decolorization, thickening and the like are conducted to obtain the finished product, the glycerol. The method is easy in material obtaining and simple in technology; and the prepared environment-friendly glycerol has low cost, and can be widely applied to the fields of medicine, domestic chemistry engineering and the like.

Owner:刘景全 +2

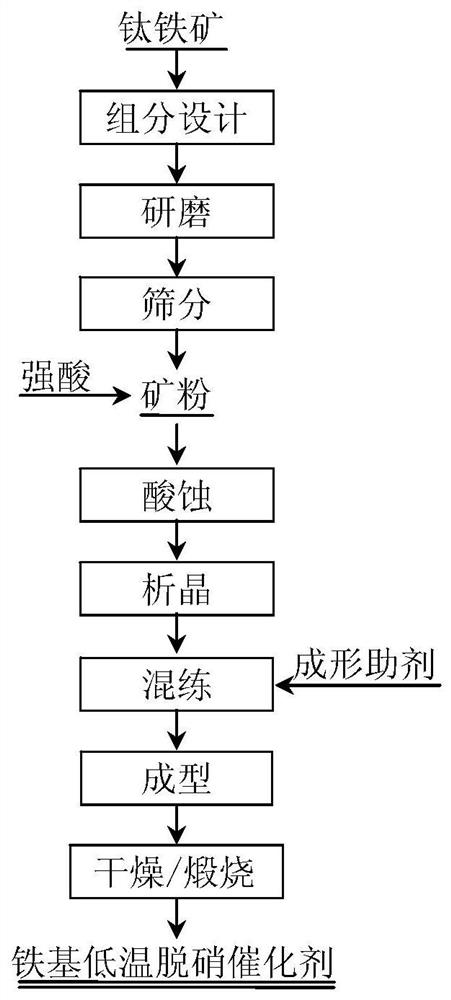

Method for preparing iron-based low-temperature denitration catalyst from ilmenite

ActiveCN111992210ARealize high-value utilizationReduce manufacturing costGas treatmentDispersed particle separationAcid etchingPtru catalyst

The invention belongs to the field of industrial flue gas denitration, and relates to a method for preparing an iron-based low-temperature denitration catalyst from ilmenite. The method sequentially comprises the steps of component design, grinding, screening, acid etching, crystallization, mulling, forming, drying and roasting. The iron-based low-temperature denitration catalyst is obtained by mixing ilmenite of different grades for component design, grinding and screening the ilmenite mixed after component design, eroding the surfaces of minerals through strong acid, controlling crystallization, then adding a forming aid for mixing and forming, and finally performing drying and roasting. According to the method, high-value utilization of the ilmenite is achieved, the production cost of the denitration catalyst is reduced. The method has important economic value and environmental benefits.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

Processing method for enhancing powdery paint through modified red mud

ActiveCN110117451AImprove performanceIncrease filling volumePowdery paintsEpoxy resin coatingsEpoxyRed mud

The invention discloses a processing method for enhancing powdery paint through modified red mud. The method includes the following steps of firstly, preparing modified red mud powder, epoxy resin E-12, polyester resin, a flatting agent GLP588, benzoin, a polyoxyethylene polypropanolamine ether defoaming agent, fumed silica, lead chromate yellow PY-34, a dispersing agent NC and a sensitizer LD-608according to mass percentages, adding the materials into a mixer, and conducting pre-smashing and then mixing to prepare an evenly-mixed raw material; secondly, putting the evenly-mixed raw materialinto an extruder, conducting melt extrusion, tabletting and cooling, and then conducting smashing to form sheets; thirdly, putting the sheets obtained through smashing into a pulverizer to be pulverized, and conducting cyclone separating and screening to prepare the indoor powdery paint. The defects of utilizing existing red mud in paint are overcome, the aims of turning waste into wealth and realizing comprehensive utilization are realized, the new approach for preparing the indoor paint is provided, and important economic and environmental benefits are realized.

Owner:广西福宝信科技有限公司

Unfired building block taking chrysotile mine stripped waste rock as aggregate and preparation method of unfired building block

The invention provides an unfired building block taking chrysotile mine stripped waste rock as aggregate and a preparation method of the unfired building block. The method comprises the following steps: carrying out attribute crushing, shaping and screening on chrysotile mine stripped waste rock raw materials to obtain rough machine-made sand aggregate; scrubbing, washing with water to remove dust and filtering water to obtain refined machine-made sand aggregate; uniformly mixing the refined machine-made sand aggregate with cement, an auxiliary agent and water to obtain a plastic mixture; demoulding after compression molding to obtain an unfired building block green body; and after setting, curing the green body to obtain the unfired building block. The unfired building block is prepared by taking chrysotile mine stripped waste rocks as aggregates, so that the material range of unfired bricks can be expanded, and the source and range of building block materials can be expanded; and besides the performance of a concrete block, the prepared unfired building block also has good fire resistance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

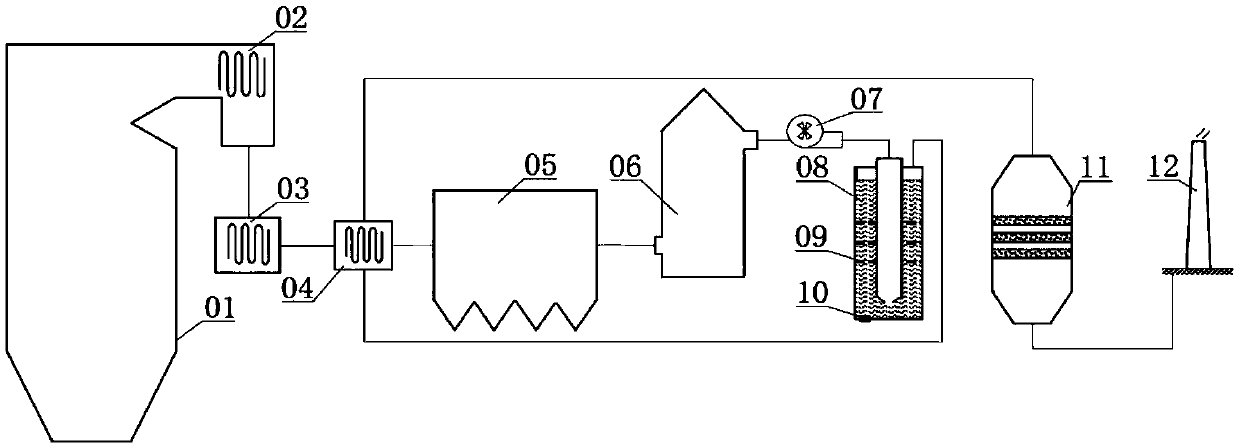

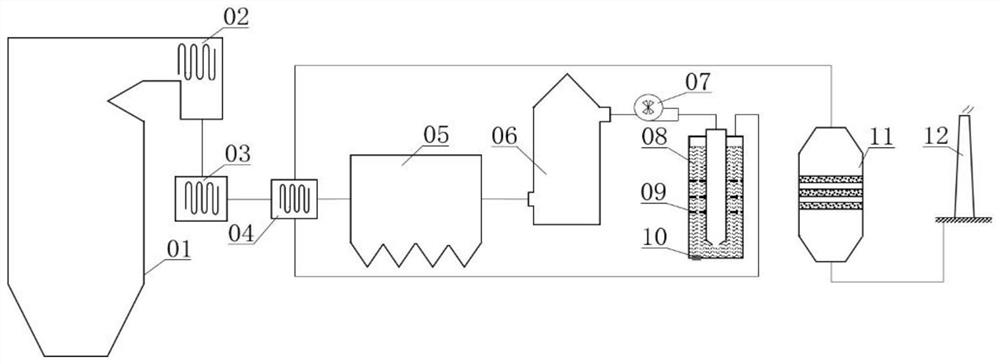

System and method for ultralow discharge of boiler flue gas

ActiveCN109621661AAchieve emissionsImportant environmental benefitsCombination devicesGas treatmentAir preheaterFlue gas

The invention belongs to the technical field of atmosphere contaminant control, and particularly relates to a system and method for ultralow discharge of boiler flue gas. The system comprises a hearth, a coal economizer, an air preheater, a heat exchanger, a dust remover, a desulfurizing tower, an induced draft fan, a cleaning device, a denigration reactor and a chimney. The method comprises the steps that boiler flus gas enters the dust remover through the coal economizer, the air preheater and the heat exchanger, after dust removal is performed, the flue gas enters a desulfurizing tower, after desulfurization, the flue gas is fed into the cleaning device through the induced draft fan, after the flue gas is cleaned, the flue gas is heated through the heat exchanger and then enters the denigration reactor, and finally, the flue gas is exhausted through the chimney. According to the system and method for ultralow discharge of boiler flue gas, the ultralow discharge requirements that thesmoke concentration is not larger than 5 mg / Nm<3>, the SO2 concentration is not larger than 35 mg / Nm<3>, and the NOx concentration is not larger than 50 mg / Nm<3> are met.

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

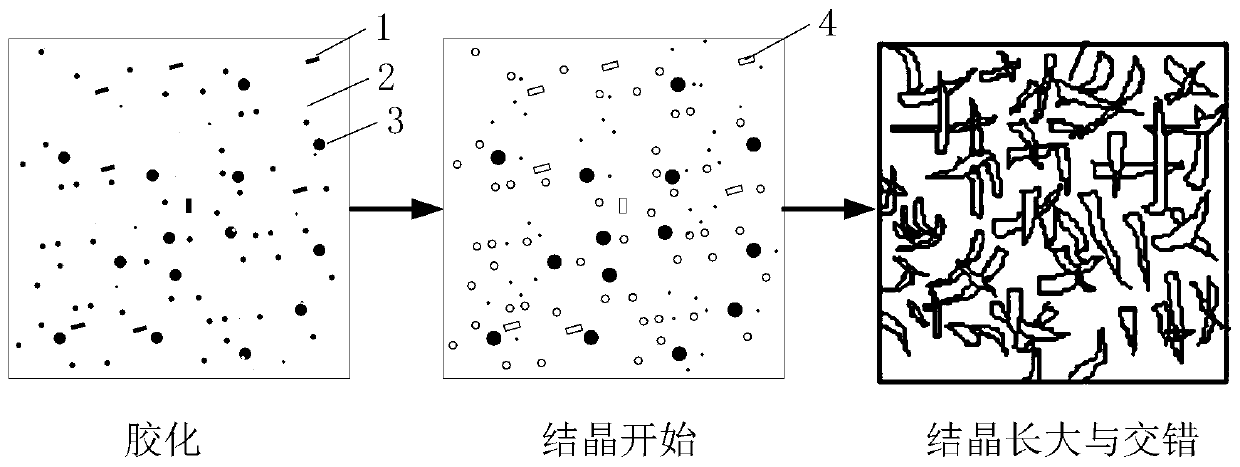

Light high-strength fabricated board based on waste gypsum board and preparation method thereof

ActiveCN111732398AImprove induction abilityHigh strengthEnvironmental engineeringEnvironmental protection

The invention discloses a light-weight high-strength fabricated board based on a waste gypsum board. The light-weight high-strength fabricated board comprises the following components in parts by weight: 100 parts of regenerated alpha-type semi-hydrated gypsum powder, 20-30 parts of fly ash, 5-10 parts of cement, 8-15 parts of EPS light aggregate and 50-55 parts of water. The regenerated alpha-type semi-hydrated gypsum powder is formed by performing activation pretreatment and secondary crystal form conversion treatment on waste gypsum boards. The regenerated alpha-type semi-hydrated gypsum powder obtained by the invention has the characteristics of low standard thickening water demand and high strength, and can be matched with fly ash and cement to further improve the later strength of ahardened body, so as to prepare an assembled plate which can effectively consider the advantages of light weight, high strength and low cost; and the related preparation method is simple, can realizehigh-added-value utilization of the waste gypsum board, and has important economic and environmental benefits.

Owner:CHINA CONSTR TECH WUHAN CO LTD

A method for preparing a denitration catalyst from a secondary resource of neodymium iron boron

ActiveCN108295864BSolve the problem of toxic pollutionImportant environmental benefitsGas treatmentHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

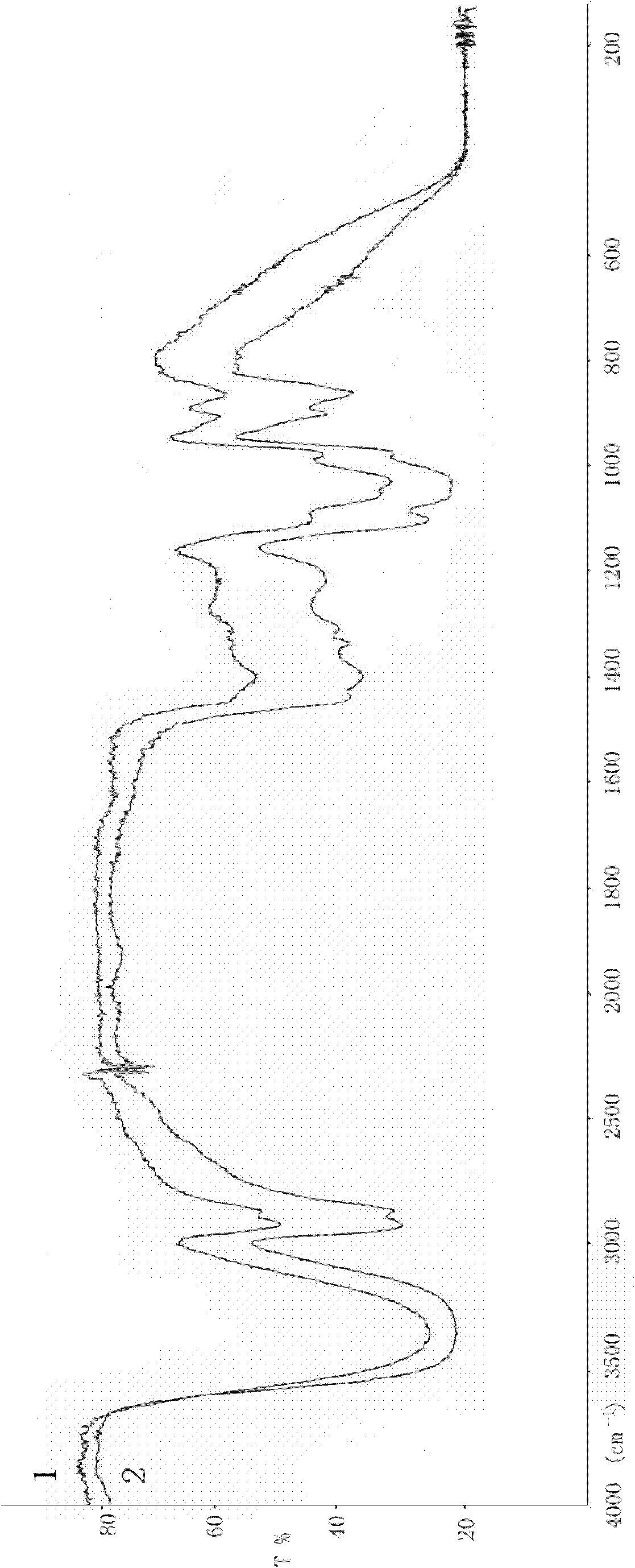

Nitrate-free environment-friendly steel plate enamel low-temperature titanium dioxide cover glaze and preparation method thereof

The invention discloses a nitrate-free environment-friendly steel plate enamel low-temperature titanium dioxide cover glaze and a preparation method thereof. The invention belongs to the technical field of enamel. The formula comprises the following components in parts by mass: 38-40 parts of quartz, 33-35 parts of borax anhydrous, 0.01-0.02 part of cobalt oxide, 14-16 parts of titanium dioxide, 1.8-2.5 parts of magnesium carbonate, 2-4 parts of sodium tripolyphosphate, 6-8 parts of sodium fluosilicate, 4-6 parts of potassium carbonate and 1.5-2 parts of aluminum oxide. The raw materials are uniformly mixed according to the proportion and are molten under the condition of pure oxygen at 1230 + / -10 DEG C, and the firing temperature of the finished product is 760-790 DEG C. The formula of the low-temperature titanium white cover glaze does not contain nitrate, and the major technical problem that in the production process of existing steel plate enamel low-temperature titanium white cover glaze, nitrogen oxide (NOx) gas is generated and discharged to pollute the environment is fundamentally solved.

Owner:SINOPIGMENT & ENAMEL CHEM

System and method for ultra-low emission of boiler flue gas

ActiveCN109621661BAchieve emissionsImportant environmental benefitsCombination devicesGas treatmentAir preheaterFlue gas

Owner:JIANGSU LONGKING COALOGIX CATALYST REGENERATION CO LTD

A resource treatment system and treatment method for high-salt and high-organic chemical wastewater

ActiveCN106495396BEasy to operateReduce dosageWater contaminantsTreatment with aerobic and anaerobic processesElectricityUltrafiltration

The invention discloses a recycling treatment system of high-salinity high-organic-matter chemical wastewater. The recycling treatment system comprises an electrocatalytic oxidation device, a halotolerant bacteria biochemical system, an MBR aerobic device, an electroosmosis unit, an ultrafilter and an RO unit, the halotolerant bacteria biochemical system comprises a halotolerant bacteria anaerobic device, a halotolerant bacteria aerobic device and a halotolerant biological aerated filter. The invention further discloses a treatment method of the high-salinity high-organic-matter chemical wastewater. By the recycling treatment system and the treatment method, the problem of recycling treatment of the high-salinity high-organic-matter chemical wastewater is solved effectively, recycling rate of water and salt is high, no wastewater is discharged basically, no solid waste is generated, generated water is high in quality, generated salt is high in purity, and water resources and salt in the high-salinity high-organic-matter chemical wastewater are recycled to greatest extent; zero discharging of wastewater in the process of enterprise production is realized, and the recycling treatment system and the treatment method have important environment benefit.

Owner:JIANGSU LASON CHEM ENVIRONMENTAL PROTECTION

Environment-friendly glycerol and preparation method thereof

InactiveCN102219643BImportant Environmental BenefitsMake up for the shortageOrganic compound preparationHydroxy compound preparationSucroseAlcohol

The invention discloses an environment-friendly glycerol and a preparation method and application thereof. In the invention, saturated sugar solution prepared by sucrose and produced by adopting quantitative carbonization technology reacts with sorbierite, then a certain quantity of dihydric alcohol is added into the reaction solution to be stirred for reaction, and then a proper amount of antiseptic and decolorizing agents are added, and the procedures of filtering, decolorization, thickening and the like are conducted to obtain the finished product, the glycerol. The method is easy in material obtaining and simple in technology; and the prepared environment-friendly glycerol has low cost, and can be widely applied to the fields of medicine, domestic chemistry engineering and the like.

Owner:刘景全 +2

A high-strength and low-shrinkage anti-crack pavement base material

ActiveCN105948639BHigh cracking early strengthHigh Strength Low ShrinkageSolid waste managementShrinkage crackingCrack resistance

The invention discloses a high-strength low-shrinkage crack-resistant pavement base material and belongs to the field of building materials. The high-strength low-shrinkage crack-resistant pavement base material is prepared through compounding cement, steel slag sand, fine-grained soil and an admixture which are in the mass ratio of 6: (10 to 40): (49 to 83): (1 to 5). According to the base material disclosed by the invention, the steel slag sand and the fine-grained soil serve as raw materials and replace gravels, and a certain volume of the cement and a certain amount of the admixture are adopted to carry out stabilizing treatment on the steel slag sand and the fine-grained soil, so that the problems that road-building resources are short and the shrinkage cracking is high when cement stabilized fine-grained soil serves as a base layer are solved, and the construction cost of a base of a road can be effectively reduced. The base material has the characteristics of high strength, small coefficient of shrinkage, good water stability and the like and meets technical requirements; and the crack resistance of the base material can be improved, cracking is prevented, the road performance and durability of the base material are improved, and the effect of guaranteeing structural stability is achieved, so that the base material can be extensively applied to engineering practice.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com