Method for smelting vanadium-rich pig iron by using high-calcium vanadium-containing steel slag

A steel slag and high-calcium technology, which is applied in the field of smelting vanadium-rich pig iron with high-calcium vanadium-containing steel slag, can solve the problems of high cost, high technical difficulty, and ineffective use of converter steel slag and vanadium, and achieve low production cost and strong operability , The effect of continuous operation production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

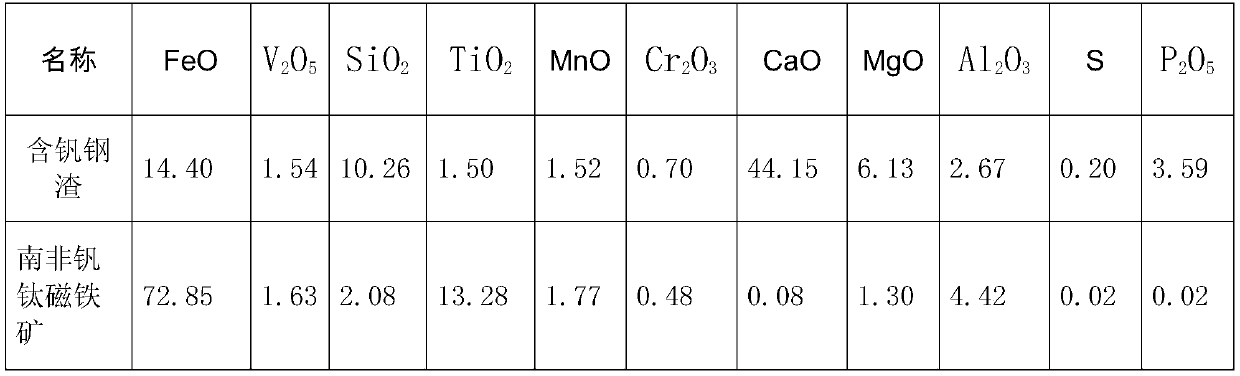

[0026] The mass fractions of selected smelting raw materials are as follows

[0027]

[0028] The selected reducing agent and solvent composition mass parts are as follows

[0029]

[0030] First add 2000kg of bottom coke to the empty furnace of 1800KVA electric furnace; according to the ratio of South African vanadium-titanium magnetite and vanadium-containing steel slag as 3:7, the carbon content is 12.38% (wherein the particle size is 5mm ~ 15mm is 7.425%, The particle size is 30mm ~ 60mm (4.95%) oil shale ash residue is used as a solvent and the dosage is 31.6%. After fully stirring evenly, add it into the furnace; adjust the secondary output voltage of the electric furnace transformer (power is 1800kVA) to the lowest gear 73V; The primary current is slowly increased from 10A to 120A, and the furnace is released after 6 hours; the slag and iron after the furnace are separated to obtain slag and vanadium-containing pig iron.

[0031] The obtained high phosphorus pig ...

Embodiment 2

[0035] According to the following material batch ratio, stir well and add it into the furnace; adjust the secondary output voltage of the electric furnace transformer (power 1800kVA) to the lowest level of 73V; after electrification, the primary current is slowly increased from 10A to 120A, and it will be released after 6 hours; The final slag and iron are separated to obtain vanadium-rich pig iron.

[0036]

[0037] The obtained product composition is as follows

[0038] V Ti C S Fe Si P power consumption 1.89 0.9 3.98 0.045 0.45 1.469 11820

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com