High-strength self-waterproof phosphogypsum roadbed material and preparation method thereof

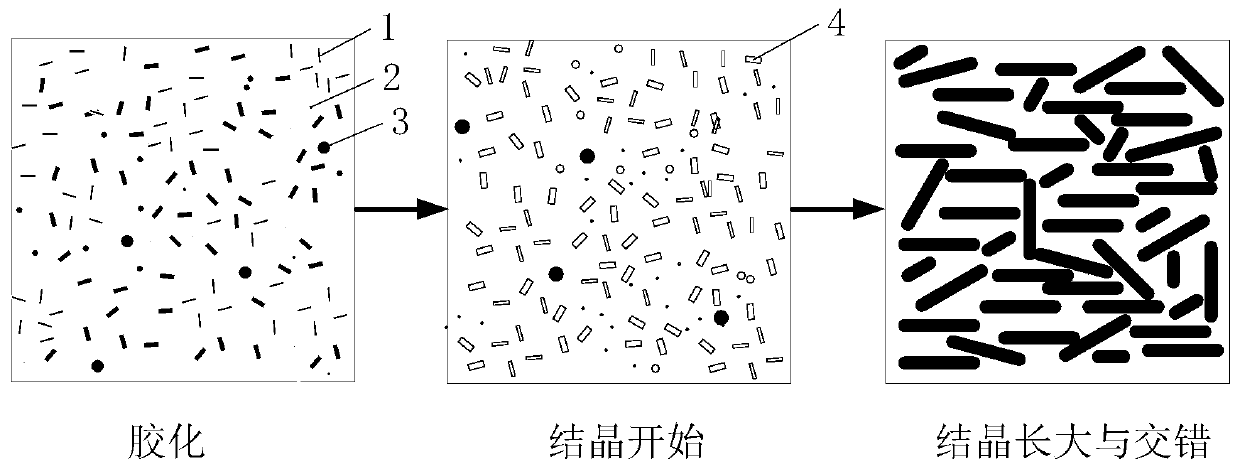

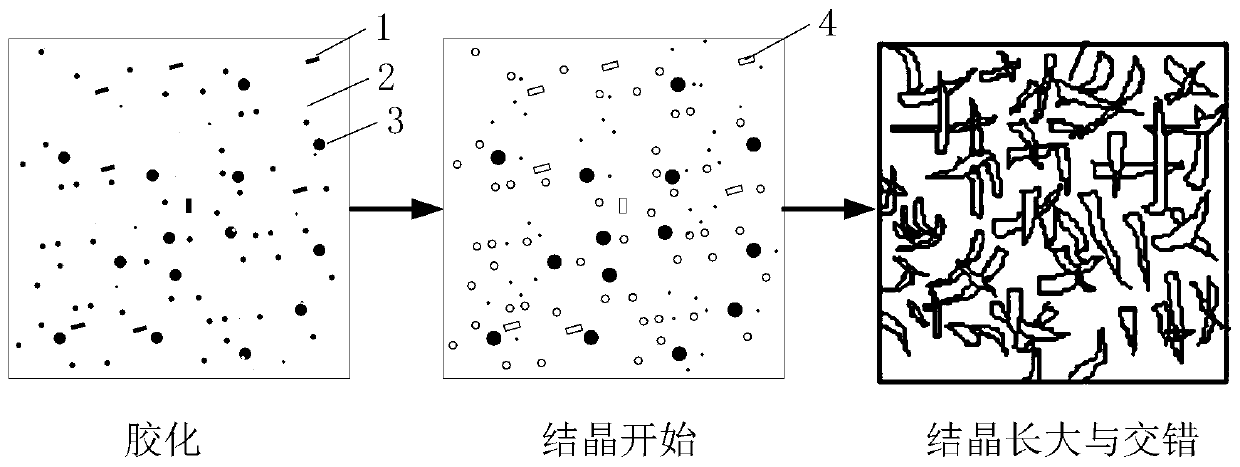

A roadbed material and phosphogypsum technology, which is applied in the field of building materials, can solve the problems of further improvement of cost and construction process control, insufficient compressive strength of phosphogypsum roadbed filler, and inability to meet the strength requirements of high-grade pavement, so as to meet the requirements of on-site construction Requirements, excellent mechanical properties and waterproof performance, the effect of high crystallization strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

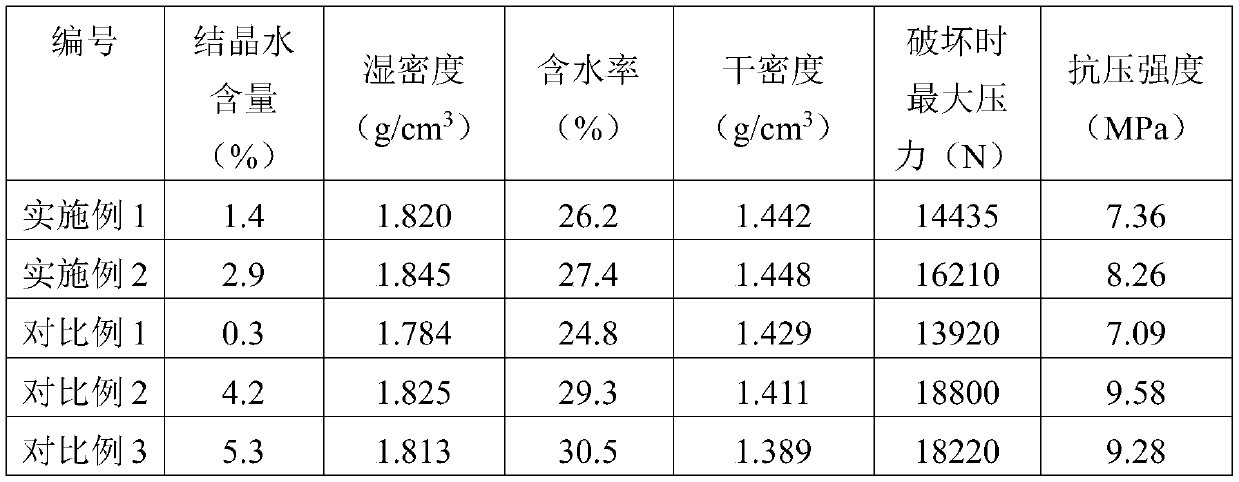

[0034] A high-strength self-waterproof phosphogypsum roadbed material and its preparation method, exploring the influence of different contents of crystal water modified phosphogypsum powder on the performance of roadbed materials, specifically including the following steps:

[0035] 1) The natural moisture content of phosphogypsum raw materials is determined to be 25.8% according to JTG E40-2007 of "Highway Geotechnical Test Regulations";

[0036] 2) Add the phosphogypsum raw material into the closed sintering equipment, and control the ratio of the mass (g) of phosphogypsum in the closed sintering equipment to the volume (L) of the equipment to be 240:1; and the phosphogypsum in the closed sintering equipment needs to be layered and placed in separate plates , not concentratedly stacked; then under the temperature condition of 160°C, calcined for 6, 7, 8, 9, 10h respectively (when the calcining time is 7h, 8h, corresponding to Examples 1 and 2, when the calcining time is 6, 9...

Embodiment 3~4

[0042] A high-strength self-waterproof phosphogypsum roadbed material and its preparation method, exploring the influence of different retarder content on the performance of roadbed materials, specifically including the following steps:

[0043] 1) The natural moisture content of phosphogypsum raw materials is determined to be 26.5% according to JTG E40-2007 of "Highway Geotechnical Test Regulations";

[0044] 2) Add the phosphogypsum raw material into the airtight sintering equipment, and control the ratio of the mass (g) of phosphogypsum in the airtight sintering equipment to the volume (L) of the equipment to be 260:1; and the phosphogypsum in the airtight sintering equipment needs to be layered and placed in separate trays , not stacked together; then calcined at 160°C for 8 hours, cooled, and crushed with a high-speed rotary pulverizer (rotating speed 20000-25000r / min, crushing time 5-8s), to obtain an improved crystal water content of 2.8%. Non-toxic phosphogypsum powder...

Embodiment 5~6

[0050] A high-strength self-waterproof phosphogypsum roadbed material and its preparation method, exploring the influence of different stewing materials and different time lengths on the performance of roadbed materials, specifically including the following steps:

[0051] 1) The natural moisture content of the phosphogypsum raw material is determined to be 24.6% according to JTG E40-2007 of "Highway Geotechnical Test Regulations";

[0052] 2) Add the phosphogypsum raw material into the closed sintering equipment, and control the ratio of the mass (g) of phosphogypsum in the closed sintering equipment to the volume (L) of the equipment to 200:1; and the phosphogypsum in the closed sintering equipment needs to be layered and placed in separate plates , not stacked together; then calcined at 160°C for 8 hours, cooled, and crushed with a high-speed rotary pulverizer (rotating speed 20000-25000r / min, crushing time 5-8s), to obtain an improved crystal water content of 2.8%. Non-tox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com